Page 1

ProMinent® dulco®flex

DF2a

Assembly and operating instructions

A1666

A1666

EN

Original instructions (2006/42/EC)Part number 984881 BA DX 016 11/14 EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Page 2

General non-discriminatory approach

In order to make it easier to read, this

document uses the male form in

grammatical structures but with an

implied neutral sense. It is aimed

equally at both men and women. We

kindly ask female readers for their

understanding in this simplification of

the text.

Supplementary information

Read the following supplementary

information in its entirety!

The following are highlighted sepa‐

rately in the document:

n Enumerated lists

Instructions

ð

Results of the instructions

Information

This provides important informa‐

tion relating to the correct opera‐

tion of the system or is intended to

make your work easier.

Safety information

Safety information are provided with

detailed descriptions of the endan‐

gering situation, see

Ä Chapter 2.1

‘Explanation of the safety information’

on page 7

Supplemental instructions

2

Page 3

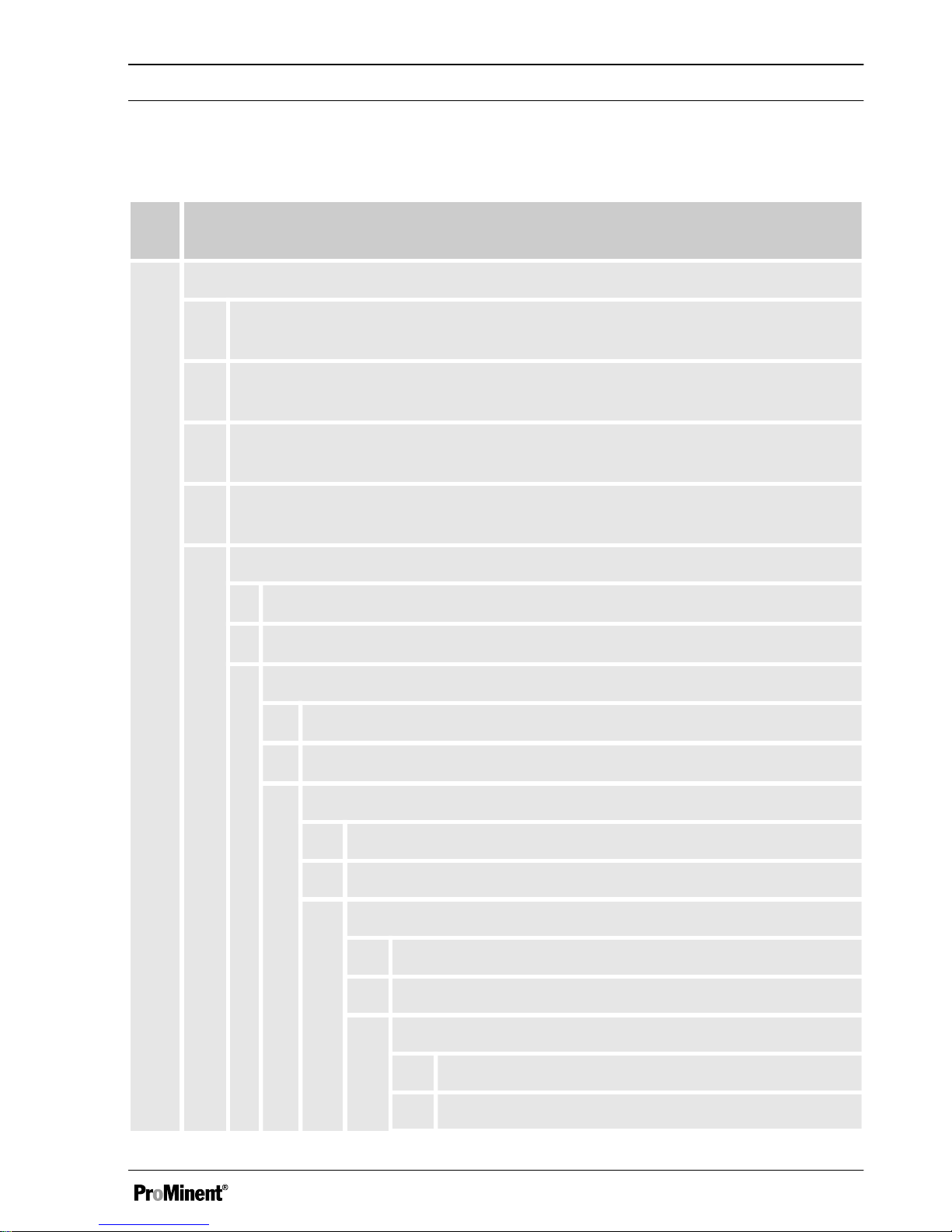

Table of contents

1 About this pump......................................................................................... 4

2 Safety and responsibility............................................................................ 7

2.1 Explanation of the safety information................................................. 7

2.2 Safety notes....................................................................................... 8

2.3 Intended use.................................................................................... 10

2.4 Users' qualifications......................................................................... 11

3 Storage and Transport............................................................................. 13

4 Overview of equipment / Functional description...................................... 14

5 Assembly and Installation........................................................................ 15

5.1 Assembling the peristaltic pump...................................................... 15

5.2 Installing hose lines......................................................................... 17

5.3 Electrical installation of the peristaltic pump.................................... 18

6 Start up.................................................................................................... 21

7 Maintenance, repair and faults ............................................................... 22

7.1 Maintenance.................................................................................... 22

7.2 Repair.............................................................................................. 23

7.3 Troubleshooting............................................................................... 24

8 Decommissioning and disposal............................................................... 25

8.1 Disposal of used parts..................................................................... 25

9 Technical data......................................................................................... 27

9.1 Accessories..................................................................................... 31

9.2 Dimension sheet.............................................................................. 31

10 EC Declaration of Conformity for Machinery........................................... 32

11 Index........................................................................................................ 34

Table of contents

3

Page 4

1 About this pump

ProMinent® dulco®flex peristaltic

pumps are designed for use in private

swimming pools and hotel swimming

pools.

About this pump

4

Page 5

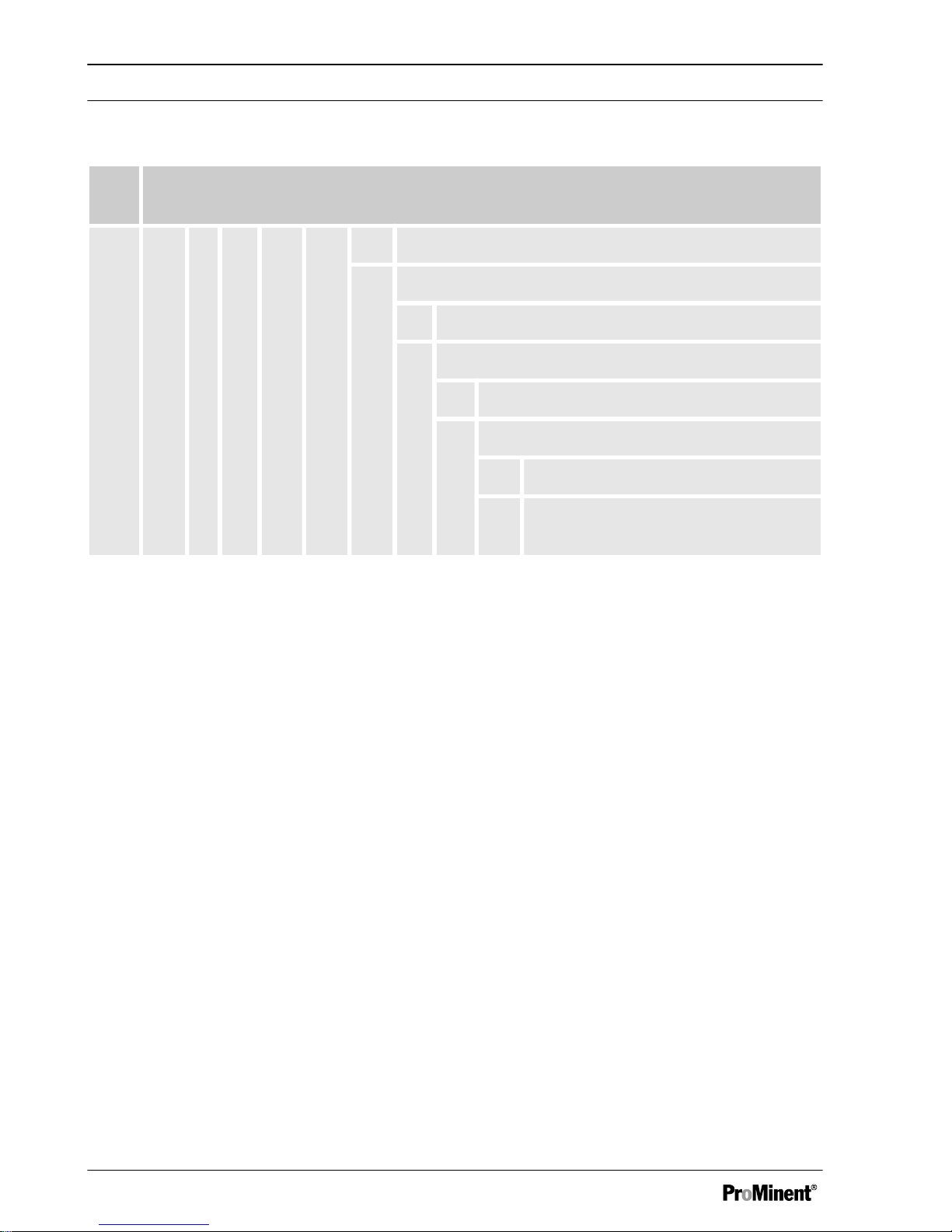

Identity code

DF2adulco®flex, version a

Pump type:

02041.5 bar; 0.4 litres

02081.5 bar; 0.8 litres

02161.5 bar; 1.6 litres

02241.5 bar; 2.4 litres

Hose material:

P

PharMed

®

T

Tygon

®

Design:

0

With ProMinent® logo

1

Without ProMinent® logo

Hydraulic connector:

0 Standard

9 Special connector 10 x 4, discharge side

Electrical connection:

A 230 V, 50/60 Hz

B 115 V, 50/60 Hz

Cable and plug:

0 without cable

1 with cable 2.0 m; open end

About this pump

5

Page 6

DF2adulco®flex, version a

4 with cable 0.8 m; open end

Control:

0 Mains power supply ON/OFF

Mounting type:

W Wall mounting

Accessories:

0 No accessories

1 Metering valve and foot valve;

suction and discharge line

About this pump

6

Page 7

2 Safety and responsibility

2.1 Explanation of the safety

information

Introduction

These operating instructions provide

information on the technical data and

functions of the product. These oper‐

ating instructions provide detailed

safety information and are provided

as clear step-by-step instructions.

The safety information and notes are

categorised according to the following

scheme. A number of different sym‐

bols are used to denote different sit‐

uations. The symbols shown here

serve only as examples.

DANGER!

Nature and source of the danger

Consequence: Fatal or very

serious injuries.

Measure to be taken to avoid this

danger

Danger!

– Denotes an immediate threat‐

ening danger. If this is disre‐

garded, it will result in fatal or

very serious injuries.

WARNING!

Nature and source of the danger

Possible consequence: Fatal or

very serious injuries.

Measure to be taken to avoid this

danger

Warning!

– Denotes a possibly hazardous

situation. If this is disregarded,

it could result in fatal or very

serious injuries.

CAUTION!

Nature and source of the danger

Possible consequence: Slight or

minor injuries, material damage.

Measure to be taken to avoid this

danger

Caution!

– Denotes a possibly hazardous

situation. If this is disregarded,

it could result in slight or minor

injuries. May also be used as

a warning about material

damage.

Safety and responsibility

7

Page 8

NOTICE!

Nature and source of the danger

Damage to the product or its sur‐

roundings

Measure to be taken to avoid this

danger

Note!

– Denotes a possibly damaging

situation. If this is disregarded,

the product or an object in its

vicinity could be damaged.

Type of information

Hints on use and additional infor‐

mation

Source of the information, addi‐

tional measures

Information!

–

Denotes hints on use and

other useful information. It

does not indicate a hazardous

or damaging situation.

2.2 Safety notes

WARNING!

Danger from hazardous sub‐

stances!

Possible consequence: Fatal or

very serious injuries.

Please ensure when handling

hazardous substances that you

have read the latest safety data

sheets provided by the manufac‐

ture of the hazardous substance.

The actions required are

described in the safety data sheet.

Check the safety data sheet regu‐

larly and replace, if necessary, as

the hazard potential of a sub‐

stance can be re-evaluated at any

time based on new findings.

The system operator is respon‐

sible for ensuring that these safety

data sheets are available and that

they are kept up to date, as well

as for producing an associated

hazard assessment for the work‐

stations affected.

Safety and responsibility

8

Page 9

WARNING!

Danger of electric shock

Mains voltage may be present

inside the pump housing.

Immediately disconnect the pump

from the mains power supply if the

pump housing has been dam‐

aged. Only return the pump to

service after an authorised repair.

CAUTION!

Warning of feed chemical

spraying around

The metering pump can generate

a multiple of its rated pressure.

Hydraulic parts may burst if a dis‐

charge line is blocked. -

Correctly install a relief valve in

the discharge line downstream of

the metering pump.

CAUTION!

Warning of backflow

Metering pumps are not abso‐

lutely leak-tight shut-off devices.

Use a shut-off valve, a solenoid

valve or a vacuum breaker for this

purpose.

CAUTION!

Personnel injury and material

damage

The pump can start to pump, as

soon as it is connected to mains

voltage.

Install an emergency cut-off

switch in the pump power supply

line or integrate the pump in the

emergency cut-off management of

the system.

CAUTION!

Device starts immediately

The unit does not have an On/Of

switch and begins to work as soon

as it is connected to the mains

voltage.

Only connect the device to the

mains voltage when all installation

work has been completed and the

pumped chemicals can no longer

escape in an uncontrolled

manner.

CAUTION!

Contact with chemicals

De-pressurise, drain and rinse the

hydraulic part of the unit before

working on it.

Safety and responsibility

9

Page 10

Protective equipment

The transparent cover on the

liquid end serves to prevent direct

contact with the rotor and

escaping chemicals in the event

of a ruptured hose.

Information in the event of an emer‐

gency

In the event of an electrical accident,

disconnect the mains cable from the

mains power supply or press the

emergency cut-off switch fitted on the

side of the system. If feed chemical is

escaping, switch off the pump by

pressing

[Stop/Start]

. If necessary

ensure that the hydraulic system

around the pump is at atmospheric

pressure. Adhere to the safety data

sheet for the feed chemical.

2.3 Intended use

n Only use the unit to meter liquid

media.

n Only use the unit in accordance

with the technical data and speci‐

fications outlined in the operating

instructions.

n Any other uses or modifications to

the system are prohibited

n Do not use the unit to meter gas‐

eous media or solids.

n Do not use the unit to meter flam‐

mable media.

n Only use the unit with further pro‐

tection (exterior housing, weather‐

proof roof) for external use. The

housing can be affected by direct

sunlight

n Only allow adequately qualified

and technically expert personnel

to operate the unit

n Observe the general limitations

with regard to viscosity limits,

chemical resistance and density refer also to the ProMinent®

Resistance List in the Product

Catalogue or at www.promi‐

nent.com!

n The pump is not intended for ope‐

ration in areas at risk from explo‐

sion.

All other uses or modifications are

prohibited.

Safety and responsibility

10

Page 11

2.4 Users' qualifications

WARNING!

Danger of injury with inadequately qualified personnel!

The operator of the plant / device is responsible for ensuring that the qualifi‐

cations are fulfilled.

If inadequately qualified personnel work on the unit or loiter in the hazard

zone of the unit, this could result in dangers that could cause serious injuries

and material damage.

– All work on the unit should therefore only be conducted by qualified per‐

sonnel.

– Unqualified personnel should be kept away from the hazard zone

Training Definition

Instructed per‐

sonnel

An instructed person is deemed to be a person who has

been instructed and, if required, trained in the tasks

assigned to him/her and possible dangers that could

result from improper behaviour, as well as having been

instructed in the required protective equipment and pro‐

tective measures.

Trained user A trained user is a person who fulfils the requirements

made of an instructed person and who has also received

additional training specific to the system from ProMinent

or another authorised distribution partner.

Trained qualified

personnel

A qualified employee is deemed to be a person who is

able to assess the tasks assigned to him and recognize

possible hazards based on his/her training, knowledge

and experience, as well as knowledge of pertinent regu‐

lations. The assessment of a person's technical training

can also be based on several years of work in the rele‐

vant field.

Safety and responsibility

11

Page 12

Training Definition

Electrician Electricians are deemed to be people, who are able to

complete work on electrical systems and recognize and

avoid possible hazards independently based on his/her

technical training and experience, as well as knowledge

of pertinent standards and regulations.

Electricians should be specifically trained for the working

environment in which the are employed and know the

relevant standards and regulations.

Electricians must comply with the provisions of the appli‐

cable statutory directives on accident prevention.

Customer Service

department

Customer Service department refers to service techni‐

cians, who have received proven training and have been

authorised by ProMinent to work on the system.

Note for the system operator

The pertinent accident prevention regulations, as well as all other generally

acknowledged safety regulations, must be adhered to!

Safety and responsibility

12

Page 13

3 Storage and Transport

Store and transport the unit in its orig‐

inal packaging.

Protect the unit against moisture and

the effects of chemicals, even while

still packaged.

Ambient conditions for storage and

transport

Permissible ambient temperature:

-10 ... 45 °C

Permissible storage temperature:

-10 ... 55 °C

Permissible medium temperature:

-10 ... 45 °C

Humidity: None. Rain and condensa‐

tion not permitted.

Other: No dust, no direct sunlight.

Storage and Transport

13

Page 14

4 Overview of equipment / Functional description

Overview of equipment

2

11

1

A

B

3

12

5

2

108

4

7

9

6

A1630

Fig. 1: Overview of equipment

1. Rollers with tensioning springs

2. Dosing head

3. Rotor

4. Pump hose

5. Hose connector, suction side

6. Leakage fitting

7. Hose connector, discharge side

8. Threaded connector

9. Wall bracket

10. Rear section of housing, power

end

11. Upper section of housing, power

end

12. Transparent cover

A. Drive unit

B. Liquid end

Functional description

An electric motor drives a rotor.

Spring-mounted rollers are fitted to

the ends of the rotors, which press

the pump hose against the inner cur‐

vature of the dosing head.

The peristaltic pump operates by the

rollers driving the feed chemical

through the pump hose. The feet

chemical is primed by the pump hose

returning to its initial position.

Overview of equipment / Functional description

14

Page 15

5 Assembly and Installation

n User qualification, mechanical

installation: trained qualified per‐

sonnel, see

Ä Chapter 2.4 ‘Users'

qualifications’ on page 11

n User qualification, electrical instal‐

lation: Electrical technician, see

Ä Chapter 2.4 ‘Users' qualifica‐

tions’ on page 11

General information on

installation and assembly

The unit is resistant to normal

atmospheres in plant rooms.

Permissible ambient temperature:

-10 ... 45 °C

Permissible medium temperature:

-10 ... 45 °C

Humidity: None. Rain and con‐

densation not permitted.

Other: No dust, no direct sunlight.

Please observe the applicable

national regulations and guide‐

lines during installation!

5.1 Assembling the peristaltic

pump

Wall mounting

2

1

A0273

Fig. 2: Removing the wall/tube

retaining bracket

1. Remove the wall/tube retaining

bracket. Pull the two snaphooks (1) outwards and push

upwards

2. Fold out the wall/tube retaining

bracket (2) and pull out in a

downwards direction

3. Mark two drill holes diagonally

to each other, using the wall/

tube retaining bracket as a

drilling template

4. Drill holes: Ø 8 mm, d = 50 mm

Assembly and Installation

15

Page 16

A0274

Fig. 3: Screw the wall/tube retaining

bracket in place using the washers

5. Screw the wall/tube retaining

bracket in place using the

washers

6. Suspend the peristaltic pump at

the top of the wall/tube retaining

bracket and, using light pres‐

sure, press it against the wall/

tube retaining bracket at the

bottom. Then press upwards

until the peristaltic pump audibly

snaps into position.

Pipe assembly

Pipe diameter

Pipe diameter: 25 mm to 60 mm.

2

1

A0273

Fig. 4: Removing the wall/tube

retaining bracket

1. Remove the wall/tube retaining

bracket. Pull the two snaphooks (1) outwards and push

upwards

2. Fold out the wall/tube retaining

bracket (2) and pull out in a

downwards direction

3. Secure the wall/tube retaining

bracket to the pipe with cable

ties (or pipe clamps).

Assembly and Installation

16

Page 17

A0275

3

2

1

Fig. 5: Suspend the peristaltic pump

and fix in place

4. Suspend the peristaltic pump

(1) at the top of the wall/tube

retaining bracket and, using

light pressure, press it against

the wall/tube retaining bracket

at the bottom (2). Then press

upwards (3) until the peristaltic

pump audibly snaps into posi‐

tion.

5.2 Installing hose lines

Only use original hoses with the

specified hose dimensions 6 x 4

mm or 10 x 4 mm, otherwise the

durability of the connection cannot

be guaranteed.

Avoid reducing the hose sizes.

The hose lines used must be able

to withstand twice the operating

pressure of the peristaltic pump.

Assembly and Installation

17

Page 18

Assembling the suction and discharge

lines.

4

2

1

3

A1631

Fig. 6: Installation diagram

1. Peristaltic pump

2. Chemical tank

3. Foot valve or suction lance

4. Injection valve

1. Cut the end of the hose at right

angles.

2. Unscrew a union nut and slide

the union nut over the pump

hose.

3. Push the tube end over the

nozzle until it will go not further.

4. Connect the discharge line to

the right hose connector.

5. Connect the suction line to the

left hose connector.

6. Tighten the union nuts.

7. Shorten the free end of the suc‐

tion line so that the foot valve

hangs just above the base of

the tank. With feed chemicals

that can form sediment, ensure

that the foot valve is suspended

a minimum of 50 mm above the

base of the tank.

8. Guide a hose line into the

storage tank from the leakage

fitting.

5.3 Electrical installation of the

peristaltic pump

–

Only carry out the electrical

installation once the mechan‐

ical and hydraulic installations

have been completed.

–

During installation, ensure that

the mains cable is de-ener‐

gised and has been secured

to prevent it from being

switched on again.

–

Fit a short-circuit fuse during

installation.

–

Fit an Off switch for the mains

power supply during installa‐

tion.

Assembly and Installation

18

Page 19

Mains cable

Let the mains cable project from

the housing so that the front sec‐

tion of the housing can be

removed.

Remove around 120 mm from the

outer insulation of the mains

cable.

N

L

gelb/grün

yellow/green

A1632

Fig. 7: Terminal diagram

1. Loosen the four screws and

remove the upper part of the

housing

2. Break out the small bore hole at

the far right on the underside of

the housing

3. Screw the required threaded

connector in and tighten it prop‐

erly (not the clamping screw)

4. Insert the reducing insert into

the threaded connector

depending on the cable crosssection used

5. Guide the mains cable into the

threaded connector

6. Insulate the mains cable and

press on the corresponding

cable end sleeves

7. Connect the mains cable

accordingly, see Fig. 7 (protec‐

tive conductor connection)

Assembly and Installation

19

Page 20

8. Tighten the clamping nut of the

threaded connector so that they

are properly sealed

9. Place the front section of the

housing on the read section of

the housing

10.

Once again check that the

seal is seated properly. Pro‐

tection class IP 65 is only

achieved if it is correctly

assembled.

Manually tighten the four

housing screws

Assembly and Installation

20

Page 21

6 Start up

n User qualification: trained user,

see

Ä Chapter 2.4 ‘Users' qualifi‐

cations’ on page 11

WARNING!

Danger from hazardous sub‐

stances!

Possible consequence: Fatal or

very serious injuries.

Please ensure when handling

hazardous substances that you

have read the latest safety data

sheets provided by the manufac‐

ture of the hazardous substance.

The actions required are

described in the safety data sheet.

Check the safety data sheet regu‐

larly and replace, if necessary, as

the hazard potential of a sub‐

stance can be re-evaluated at any

time based on new findings.

The system operator is respon‐

sible for ensuring that these safety

data sheets are available and that

they are kept up to date, as well

as for producing an associated

hazard assessment for the work‐

stations affected.

Only operate the pump after

proper installation.

Only operate the pump once the

transparent cover has been

screwed on.

1. Disconnect the discharge hose

from the hose connector.

2. Allow the peristaltic pump to run

until the pump hose is filled.

3. Switch off the peristaltic pump

after the pump hose has been

filled

4. Re-connect the discharge hose

to the hose connector.

5. Allow the peristaltic pump to run

for a short time

ð

The peristaltic pump is now

ready for operation.

6. Check the threaded connectors

and pipe system for leak-tight‐

ness

Start up

21

Page 22

7 Maintenance, repair and faults

n User qualification: trained user,

see

Ä Chapter 2.4 ‘Users' qualifi‐

cations’ on page 11

WARNING!

Danger from hazardous sub‐

stances!

Possible consequence: Fatal or

very serious injuries.

Please ensure when handling

hazardous substances that you

have read the latest safety data

sheets provided by the manufac‐

ture of the hazardous substance.

The actions required are

described in the safety data sheet.

Check the safety data sheet regu‐

larly and replace, if necessary, as

the hazard potential of a sub‐

stance can be re-evaluated at any

time based on new findings.

The system operator is respon‐

sible for ensuring that these safety

data sheets are available and that

they are kept up to date, as well

as for producing an associated

hazard assessment for the work‐

stations affected.

7.1 Maintenance

After extended periods of idleness

If the peristaltic pump has not

pumped gaseous or adhesive feed

chemicals for a longer period of time,

checked whether the state of the

hoses permits reliable operation.

Approx. every six months

Checks:

n Visual control of the liquid end

n Check the pump hose for leak-

tightness

n Check the pump connectors for

leak-tightness

Shorter maintenance intervals may be

necessary depending on the feed

chemicals used and operating condi‐

tions.

Approx. annually

Replace the pump hose.

This can lead to a reduction in

pump capacity over time

depending on the operating condi‐

tions. Therefore replace the pump

hose earlier if necessary.

The power end is maintenance-free.

Maintenance, repair and faults

22

Page 23

7.2 Repair

Ensure that the system is at

atmospheric pressure.

Drain the pump hose and thor‐

oughly rinse it with a suitable

medium.

Only turn the rotor in a clockwise

direction.

Changing the pump hose

1. Loosen the suction hose and

the discharge hose from the

hose connectors

2. Loosen the fixing bolt on the

transparent cover and remove

the transparent cover

3. Remove the suction-side hose

connector (left) from its

mounting

4. Carefully pull the pump hose out

under the rollers

5.

When doing so, ensure that

the rounded sides of the

hose connectors are

pointing towards the unit.

Insert the two hose connectors

of the new pump hose into the

two mountings.

6. Briefly switch on the motor. The

pump hose moves into the cor‐

rect position under the rollers

7. Replace the transparent cover

on the housing and screw it into

place

8. Fix the suction hose and the

discharge hose to the hose con‐

nectors

Maintenance, repair and faults

23

Page 24

7.3 Troubleshooting

Fault Cause Remedy

The peristaltic pump no

longer reaches full

pump capacity

The pump hose has

lost its elasticity

Replace the pump hose,

see

Ä Chapter 7.2 ‘Repair’

on page 23

In all other cases, notify your service technician or your ProMinent branch.

Maintenance, repair and faults

24

Page 25

8 Decommissioning and disposal

n User qualification: instructed user,

see

Ä Chapter 2.4 ‘Users' qualifi‐

cations’ on page 11

WARNING!

Danger from hazardous sub‐

stances!

Possible consequence: Fatal or

very serious injuries.

Please ensure when handling

hazardous substances that you

have read the latest safety data

sheets provided by the manufac‐

ture of the hazardous substance.

The actions required are

described in the safety data sheet.

Check the safety data sheet regu‐

larly and replace, if necessary, as

the hazard potential of a sub‐

stance can be re-evaluated at any

time based on new findings.

The system operator is respon‐

sible for ensuring that these safety

data sheets are available and that

they are kept up to date, as well

as for producing an associated

hazard assessment for the work‐

stations affected.

De-energise the mains cable and

ensure that it cannot be switched

on again during decommissioning.

Thoroughly clean the housing and

especially the pump hose of

chemicals and dirt when decom‐

missioning the pump!

1. Disconnect the unit from the

mains power supply

2. Drain the pump hose and thor‐

oughly rinse it with a suitable

medium

Observe storage conditions for tem‐

porary decommissioning.

8.1 Disposal of used parts

n Users' qualification: instructed

persons, see

Ä Chapter 2.4

‘Users' qualifications’ on page 11

NOTICE!

Regulations governing disposal of

used parts

– Note the current national reg‐

ulations and legal standards

which apply in your country

Decommissioning and disposal

25

Page 26

ProMinent Dosiertechnik GmbH, Hei‐

delberg will take back decontami‐

nated used devices providing that

they are covered by adequate

postage.

Decommissioning and disposal

26

Page 27

9 Technical data

Pump

type

Max. pump capacity*

at maximum back pressure

Connector

size

Ø x Ø

Suct

ion

lift**

Pri‐

ming

lift**

Permis‐

sible

priming

pres‐

sure on

the suc‐

tion

side**

bar 50 Hz 60 Hz mm m m bar

l/h l/h

204 1,5 0,4 0,48 6 x 4, 10 x 4 4 2 0,5

208 1,5 0,8 0,96 6 x 4, 10 x 4 4 2 0,5

216 1,5 1,6 1,92 6 x 4, 10 x 4 4 2 0,5

224 1,5 2,4 2,88 6 x 4, 10 x 4 4 2 0,5

*depending on the back pressure.

** The values were determined with water.

Switching-on duration:

100 %

Precision

The starting precision of the pump

capacity is ± 10 %. The pump

capacity can fall during operation due

to damage to the elasticity of the

pump hose.

Technical data

27

Page 28

Materials specifications and resistance

Part Material

Pump hose

PharMed® or Tygon

®

Hose connectors PVC

Dosing head PPE

Transparent cover PC

Housing (power end) PPE-GF

Wall bracket PPE-GF

Housing seal Silicone

Housing screws M4 A2

Cable threaded connectors

Polyamide/Neoprene

®

Design for fragrance metering

Part Material

Pump hose FPM

Hose connectors PVC

Dosing head PA12

Transparent cover PA12

Housing (power end) PP+GF

Wall bracket PA+GF

Housing seal Silicone

Housing screws M4 A2

Cable threaded connectors

Polyamide/Neoprene

®

Technical data

28

Page 29

Chemical resistance

The unit is resistant to normal atmos‐

pheres in plant rooms.

Resistance to other chemicals, see

ProMinent Resistance List (home‐

page or Product Catalogue).

UV resistance

n Do not use the unit with direct UV

radiation.

Technical data

29

Page 30

No short-circuit fuse is fitted and needs to be taken into consideration in

installation.

Description Data

Dimensions and weights:

Dimensions: 126 x 136 x 105 mm (WxHxD)

PG 9 clamping range Ø 3.5 - Ø 8 mm, spanner

size 19.

Weight: Total weight (including installation material)

approx. 750 g

Total weight (net), approx. 600 g

Electrical data:

Connection voltage: 115 V ±10 % at 50/60 Hz

230 V ±10 % at 50/60 Hz

Power consumption: approx. 5 W

Switching-on duration: 100 %

Degree of protection: Degree of protection 1 - according to DIN EN

60335-1 (protective conductor connection

required)

Protection against accidental

contact and humidity:

IP 65

Temperature data: Permissible ambient temperature: -10 ... 45 °C

Permissible storage temperature: -10 ... 55 °C

Technical data

30

Page 31

Description Data

Permissible medium temperature: -10 ... 45 °C

Sound pressure level: < 30 dB (A) at maximum back pressure (water)

according to DIN EN 12639

9.1 Accessories

Description Order number

Installation material for dulco®flex, com‐

plete

1007297

Mains cable via identity code

Injection valve and foot valve via identity code

Suction lances see Product Catalogue

9.2 Dimension sheet

29

136

126

105

59.5

78

90

A1633

Fig. 8: Dimension sheet for DF2a

Technical data

31

Page 32

10 EC Declaration of Conformity for Machinery

In accordance with DIRECTIVE

2006/42/EC OF THE EUROPEAN

PARLIAMENT AND OF THE

COUNCIL, Appendix I, BASIC

HEALTH AND SAFETY REQUIRE‐

MENTS, section 1.7.4.2. C.

EC Declaration of Conformity for Machinery

32

Page 33

We,

n ProMinent Dosiertechnik GmbH

n Im Schuhmachergewann 5 - 11

n DE - 69123 Heidelberg,

hereby declares that the product specified in the following, complies with the rel‐

evant basic health and safety requirements of the EC Directive, on the basis of

its functional concept and design and in the version distributed by us. This dec‐

laration loses its validity in the event of a modification to the product not agreed

with us.

Designation of the

product:

Peristaltic pump DF2a

Serial number: refer to nameplate on the device

Relevant EC direc‐

tives:

EC Machinery Directive (2006/42/EC)

EC EMC Directive (2004/108/EC)

Compliance with the protection targets of the Low

Voltage Directive (2006/95/EC) according to

Appendix I, No. 1.5.1 of the Machinery Directive

2006/42/EC

Harmonised standards

applied, in particular:

EN 809

EN 60335-1

EN 60335-2-41

EN 61000-6-1

EN 61000-6-3

EN 61000-6-4

Date: 05/03/2012

EC Declaration of Conformity for Machinery

33

Page 34

11 Index

A

Ambient conditions ............13

Ambient temperature ..........13

Applied harmonised standards ...33

C

Changing the pump hose .......23

Components of the device ......14

D

Declaration of Conformity .......33

Designation of the product ......33

F

Fixing materials ...............15

Fragrance metering ............28

Functional description ..........14

G

General information on installation

and assembly ................15

General non-discriminatory

approach .....................2

I

Installation ..................15

M

Maintenance: After extended

periods of idleness ............22

Maintenance: approx. annually ...22

Maintenance: approx. every six

months .....................22

N

non-discriminatory approach ......2

P

Pipe assembly ...............16

Pipe diameter: 25 mm to 60 mm. . 16

Q

Question: Where do I find the

Declaration of Conformity? ......33

Question: Which standards are

complied with? ...............33

R

Relevant EC directives .........33

S

Safety information ..............7

Serial number ................33

Standards complied with ........33

T

Transparent cover .............21

U

Users' qualifications ...........11

W

Wall mounting ................15

Washer .....................15

Index

34

Page 35

35

Page 36

984881, 1, en_GB

© 2014

ProMinent GmbH

Im Schuhmachergewann 5 - 11

69123 Heidelberg

Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

Loading...

Loading...