Page 1

Assembly and operating instructions

A2700

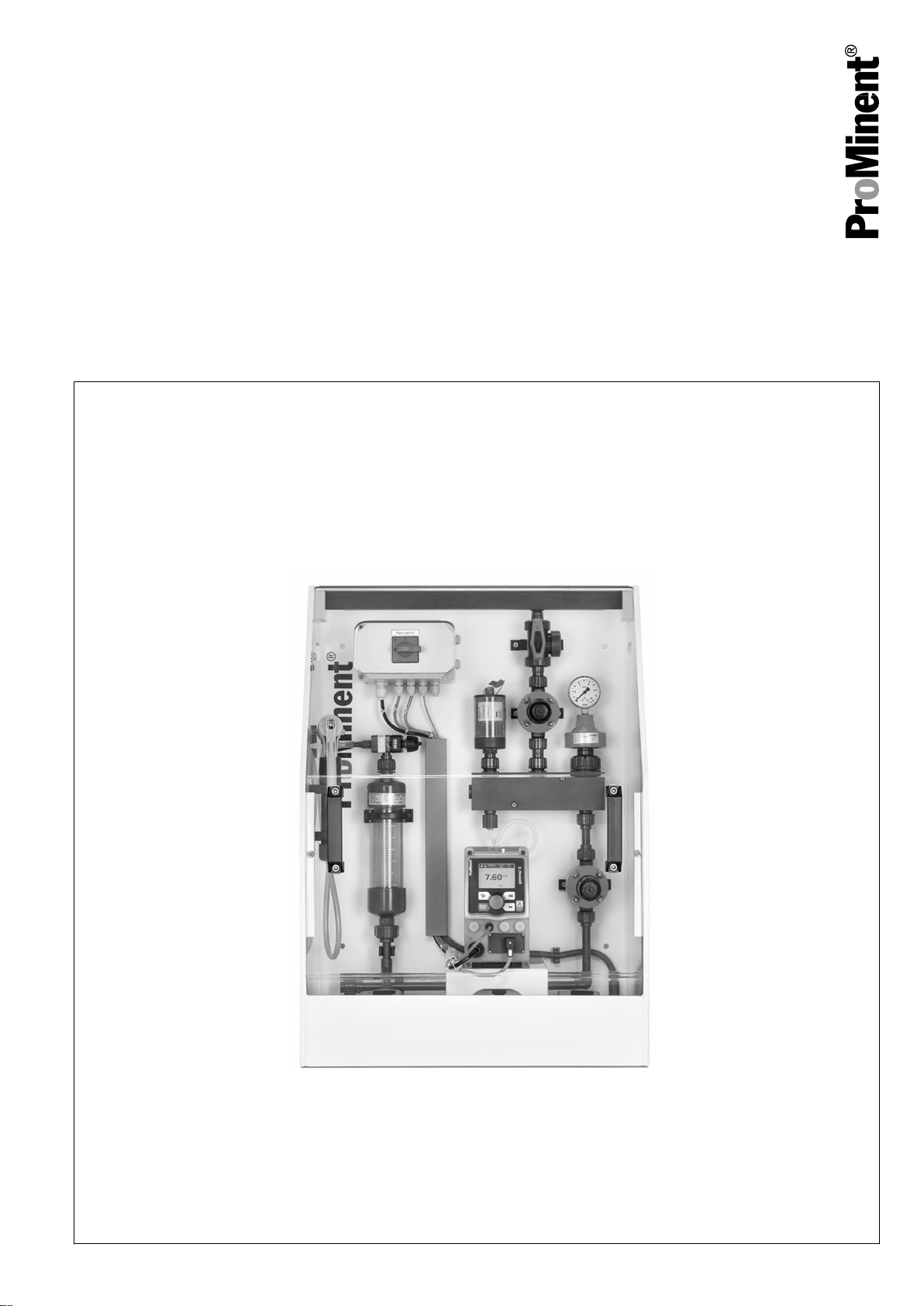

Universal Metering System DSUa Mini

Metering frame complete with all pipework

EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Original operating instructions (2006/42/EC)982011 Version: BA DST 012 02/19 EN

Page 2

Supplemental directives

General non-discriminatory approach

Supplementary information

In order to make it easier to read, this document uses the male

form in grammatical structures but with an implied neutral sense. It

is aimed equally at both men and women. We kindly ask female

readers for their understanding in this simplification of the text.

Please read the supplementary information in its entirety.

Information

This provides important information relating to the

correct operation of the unit or is intended to make

your work easier.

Warning information

Warning information includes detailed descriptions of the haz‐

ardous situation, see

tion’ on page 14

Ä Chapter 2.2 ‘Labelling of Warning Informa‐

.

The following symbols are used to highlight instructions, links, lists,

results and other elements in this document:

Tab. 1: More symbols

Symbol Description

Action, step by step.

⇨ Outcome of an action.

Links to elements or sections of these instructions or other applicable documents.

n

[Button]

List without set order.

Display element (e.g. indicators).

Operating element (e.g. button, switch).

‘Display /GUI’

CODE

Screen elements (e.g. buttons, assignment of function keys).

Presentation of software elements and/or texts.

2

Page 3

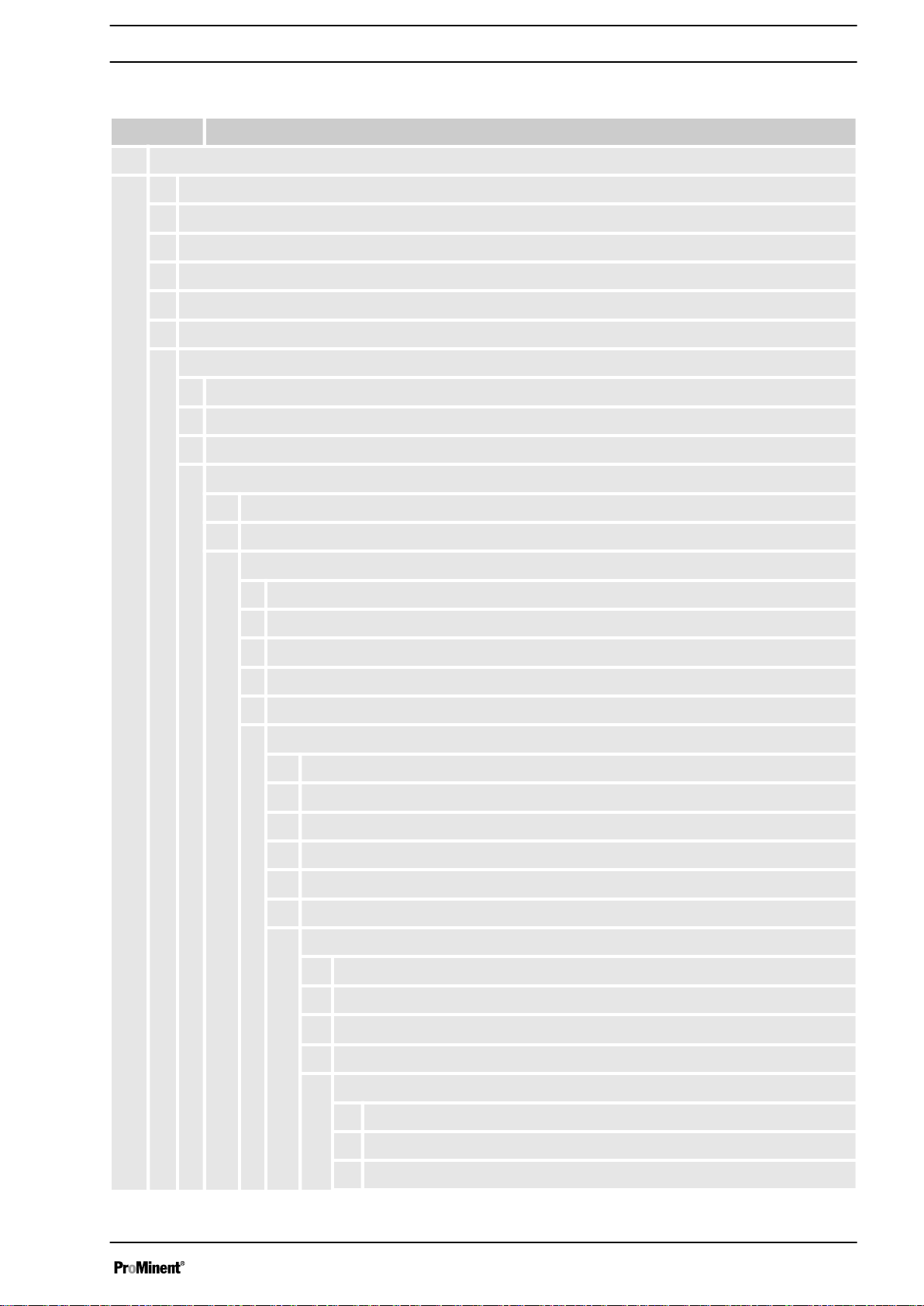

Table of contents

Table of contents

1 About this product................................................................. 4

1.1 Technical details........................................................... 4

1.2 Identity code................................................................. 5

1.3 Metering system, 1 pump, 1 point of injection.............. 9

1.4 Metering system, 2 pumps, 1 point of injection........... 10

1.5 Metering system, 2 pumps, 2 points of injection......... 11

2 Safety and responsibility..................................................... 13

2.1 User qualification........................................................ 13

2.2 Labelling of Warning Information................................ 14

2.3 General safety notes................................................... 15

2.4 Intended Use.............................................................. 18

3 Storage and Transport........................................................ 19

4 Assembly and installation................................................... 20

4.1 General....................................................................... 20

4.2 Installation on the floor................................................ 21

4.3 Installation with stainless steel bracket....................... 22

4.4 Installation on the wall................................................ 22

4.5 Connect the suction lance level gauge....................... 23

5 Commissioning................................................................... 24

5.1 Leaks and Emissions.................................................. 24

5.2 Personal Protective Equipment (PPE)........................ 25

5.3 Commissioning Test Run............................................ 25

5.4 Connecting the Chemical Tank for Commissioning.... 26

6 Operation of the Metering System...................................... 27

7 Maintenance and Troubleshooting...................................... 28

7.1 Maintenance............................................................... 29

7.2 Troubleshooting.......................................................... 31

8 Decommissioning and disposal.......................................... 33

8.1 Disposal of used parts................................................ 34

9 Technical data..................................................................... 35

10 Drawings............................................................................. 37

10.1 Metering system, 1 pump, 1 point of injection.......... 37

10.2 Metering system, 2 pumps, 1 point of injection......... 38

10.3 Metering system, 2 pumps, 2 points of injection....... 39

11 Flow diagram of DSUa mini (PID)....................................... 40

11.1 Legend for flow diagrams......................................... 40

11.2 Flow diagram of DSUa mini 1 (PID).......................... 41

11.3 Flow diagram of DSUa mini 2 (PID).......................... 42

11.4 Flow diagram of DSUa mini 3 (PID).......................... 43

12 Electrical wiring diagram..................................................... 44

12.1 Electrical Wiring Diagram, 1062129, 1 Pump........... 44

12.2 Electrical wiring diagram, 2 pumps........................... 46

13 Declaration of Conformity for Machinery............................. 48

14 Index................................................................................... 49

3

Page 4

A2355

About this product

1 About this product

1.1 Technical details

The metering system DULCODOS® universal combines standard

components with the solenoid-driven metering pump you have

selected. For the reliable metering of liquid chemicals.

Technical details:

n Solenoid-driven metering pumps Beta® 4/5

n delta

®

n gamma/ X

n Dimensions: 850x580x410 mm or 1000x680x410 mm (H x W x

D)

n Material combinations: PP/FKM or PVC/EPDM. Pay attention

to compatibility with the feed chemical.

n Relief valves to protect the pipework

n Manometer

n Collecting pan with leak sensor

n Flushing connectors

n Terminal box with master switch

n The assembly frame is available in 6 standard colours

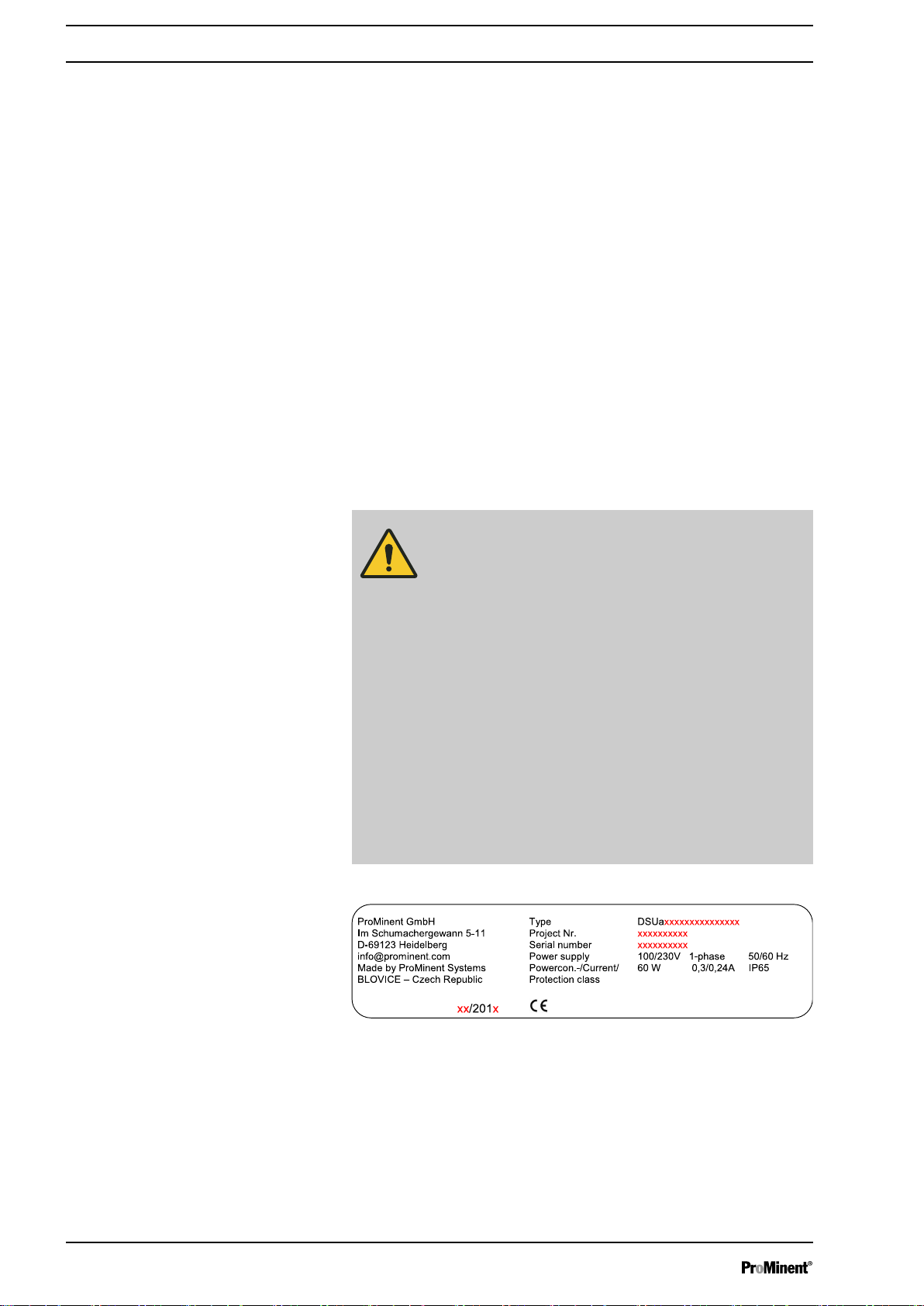

Nameplate

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

Field of application

Fig. 1: Nameplate

Metering of liquid chemicals, e.g.

n Cooling water treatment

n Waste water and process water treatment

n Paper industry

4

Page 5

1.2 Identity code

DSUa DULCODOS universal mini

Pipework / Seal / Function

A PVC, EPDM, for 1 pump and 1 point of injection

B PVC, EPDM, for 2 pumps and 1 point of injection

C PVC, EPDM, for 2 pumps and 2 points of injection

D PP, FKM, for 1 pump and 1 point of injection

E PP, FKM, for 2 pumps and 1 point of injection

F PP, FKM, for 2 pumps and 2 points of injection

Assembly frame

A PP, white, 850x580x410 mm (HxWxD) for (A/D)

B PP, white, 1000x680x410 mm (HxWxD) for (B/E)

C PP, white, 850x880x410 mm (HxWxD) for (C/F)

Design

About this product

00 with ProMinent logo

01 without ProMinent logo

Pulsation damper

0 none

1 1 x pulsation damper PVC/ EPDM

2 1 x pulsation damper PP/FKM

3 2 x pulsation damper PVC/ EPDM

4 2 x pulsation dampers PP/FKM

Hydraulic connectors

0 Insert

1 Hose nipple 6x4

2 Hose nipple 8x5

3 Hose nipple 12x9

4 Pressure hose nozzle DN10

5 Pressure hose nozzle 1/2" NPT

Flushing connectors

0 closed

1 Pressure hose nozzle DN10

2

Gardena

®

3 Pressure hose nozzle 1/2" NPT

Splash guard

0 none

A Splash guard for (A/D)

B Splash guard for (B/E)

5

Page 6

About this product

DSUa DULCODOS universal mini

C Splash guard for (C/F)

Stainless steel bracket

D No stainless steel bracket

A Stainless steel bracket (H= 150 mm) + machine feet for (A/D)

B Stainless steel bracket (H= 150 mm) + machine feet for (B/E)

C Stainless steel bracket (H= 150 mm) + machine feet for (C/F)

Pump 1

00 no pump

Beta® 4

41 10 bar / 0.74 l/h, BT4b 1000 PVT, 6x4

42 16 bar / 2.2 l/h, BT4b 1602 PVT, 6x4

43 16 bar / 3.60 l/h, BT4b 1604 PVT, 6x4

44 7 bar / 7.10 l/h, BT4b 0708 PVT, 8x5

45 4 bar / 12.30 l/h, BT4b 0413 PVT, 8x5

46 2 bar / 19.00 l/h, BT4b 0220 PVT, 12x9

Beta® 5

51 10 bar / 6.80 l/h, BT5b 1008 PVT, 8x5

52 7 bar / 11.0 l/h, BT5b 0713 PVT, 8x5

53 4 bar / 17.10 l/h, BT5b 0420 PVT, 12x9

54 2 bar / 32.00 l/h, BT5b 0232 NPE, 12x9

delta®:

D1 16 bar / 11.3 l/h, DLTa 1612 PVT, 8x5

D2 10 bar / 19.1 l/h, DLTa 1020 PVT, 12x9

D3 7 bar / 29.2 l/h, DLTa 0730 PVT, 12x9

D4 4 bar / 49.0 l/h, DLTa 0450 PVT, DN10

D5 2 bar / 75.0 l/h, DLTa 0280 PVT, DN10

gamma/ X®:

X1 16 bar / 3.6 l/h, GMXa 1604 PVT, 6x4

X2 7 bar / 7.6 l/h, GMXa 0708 PVT, 8x5

X3 10 bar / 9.0 l/h, GMXa 1009 PVT, 8x5

X4 4 bar / 13.5 l/h, GMXa 0414 PVT 8x5

X5 7 bar / 14.5 l/h, GMXa 0715 PVT, 8x5

X6 2 bar / 19.7 l/h, GMXa 0220 PVT, 12x9

X7 4 bar / 24.0 l/h, GMXa 0424 PVT, 12x9

X8 2 bar / 45.0 l/h, GMXa 0245 PVT, 12x9

Pump 2

00 no pump

6

Page 7

DSUa DULCODOS universal mini

About this product

Beta® 4

41 10 bar / 0.74 l/h, BT4b 1000 PVT, 6x4

42 16 bar / 2.2 l/h, BT4b 1602 PVT, 6x4

43 16 bar / 3.60 l/h, BT4b 1604 PVT, 6x4

44 7 bar / 7.10 l/h, BT4b 0708 PVT, 8x5

45 4 bar / 12.30 l/h, BT4b 0413 PVT, 8x5

46 2 bar / 19.00 l/h, BT4b 0220 PVT, 12x9

Beta® 5

51 10 bar / 6.80 l/h, BT5b 1008 PVT, 8x5

52 7 bar / 11.0 l/h, BT5b 0713 PVT, 8x5

53 4 bar / 17.10 l/h, BT5b 0420 PVT, 12x9

54 2 bar / 32.00 l/h, BT5b 0232 NPE, 12x9

delta®:

D1 16 bar / 11.3 l/h, DLTa 1612 PVT, 8x5

D2 10 bar / 19.1 l/h, DLTa 1020 PVT, 12x9

D3 7 bar / 29.2 l/h, DLTa 0730 PVT, 12x9

D4 4 bar / 49.0 l/h, DLTa 0450 PVT, N10

D5 2 bar / 75.0 l/h, DLTa 0280 PVT, DN10

gamma/ X®:

X1 16 bar / 3.6 l/h, GMXa 1604 PVT, 6x4

X2 7 bar / 7.6 l/h, GMXa 0708 PVT, 8x5

X3 10 bar / 9.0 l/h, GMXa 1009 PVT, 8x5

X4 4 bar / 13.5 l/h, GMXa 0414 PVT, 8x5

X5 7 bar / 14.5 l/h, GMXa 0715 PVT, 8x5

X6 2 bar / 19.7 l/h, GMXa 0220 PVT, 12x9

X7 4 bar / 24.0 l/h, GMXa 0424 PVT, 12x9

X8 2 bar / 45.0 l/h, GMXa 0245 PVT, 12x9

Operating instructions

CS Czech

EN German

EN English

ES Spanish

FR French

IT Italian

PT Portuguese

All other languages are available on request.

7

Page 8

About this product

DSUa DULCODOS universal mini

Certification

01 CE certification

8

Page 9

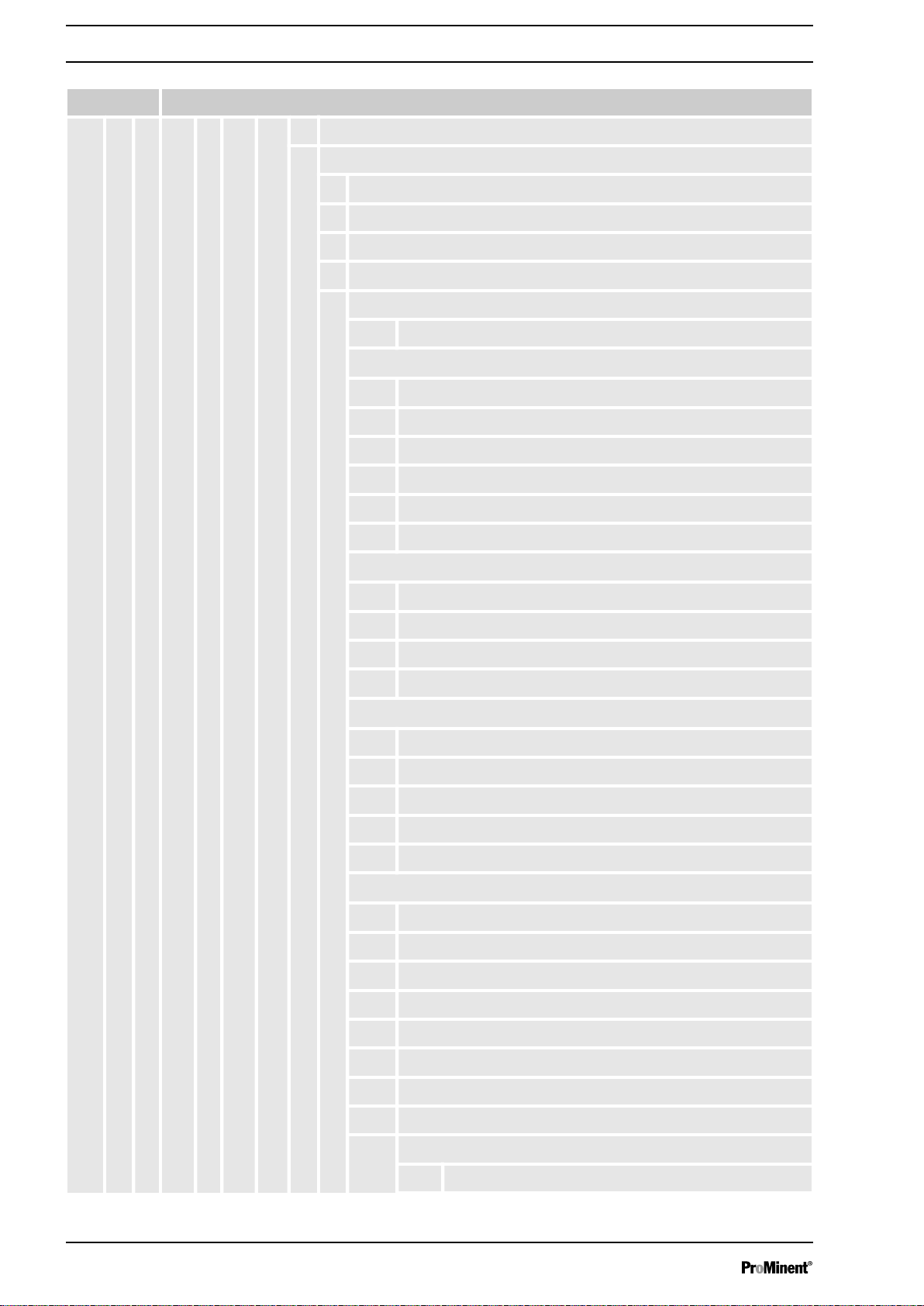

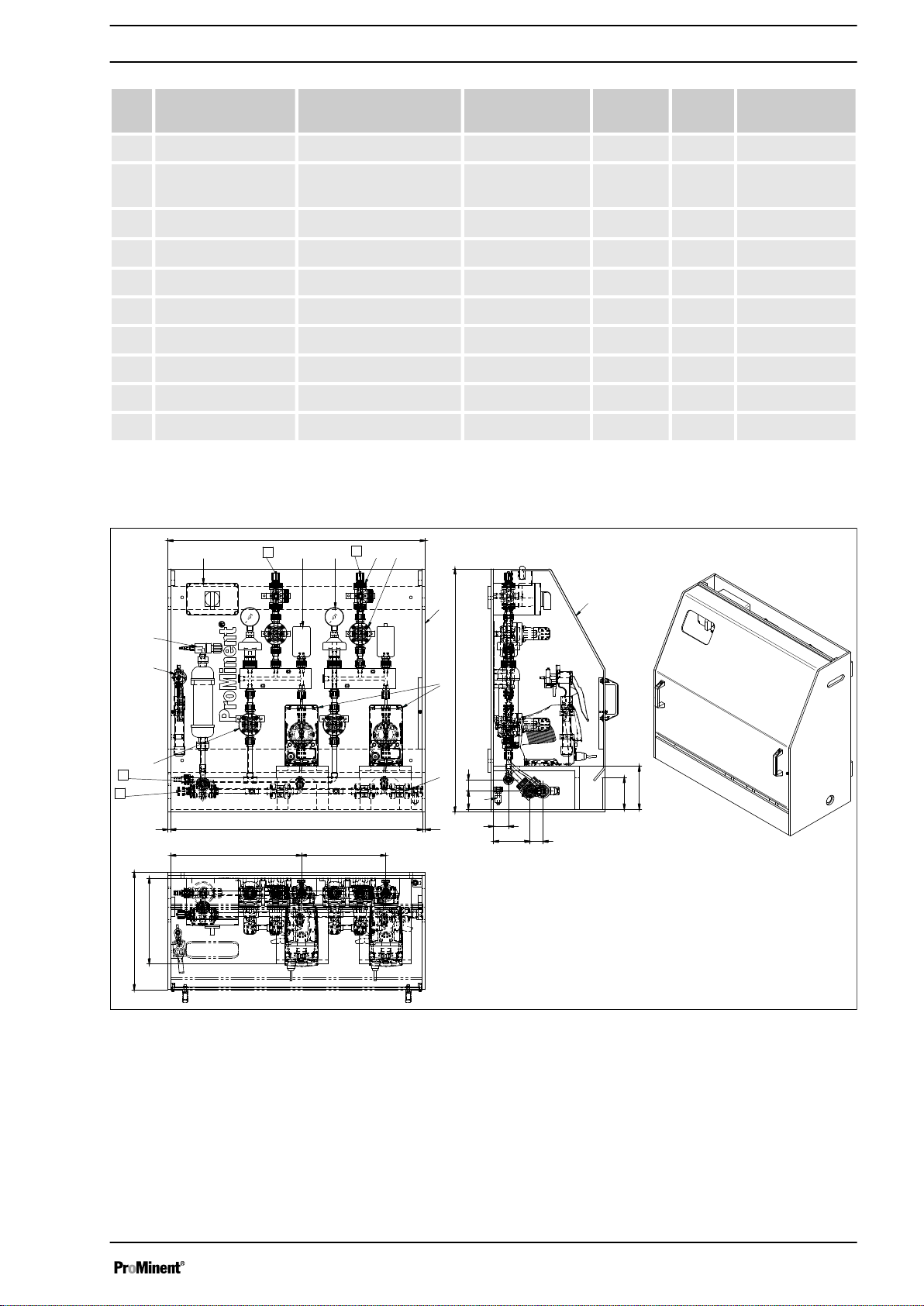

1.3 Metering system, 1 pump, 1 point of injection

600

1

2

13

4

5

6

7

8

13

10

A

C

B

11

410

10

58010

320

300

12

9

63 40

127

52

850

110

150

A2699

About this product

Fig. 2: Metering system, 1 pump, 1 point of injection, all dimensions in mm

A Feed

B Outlet

C Drain

Not shown Connecting parts for flushing pipe DN10,

2 no.

# Name Material/type Dimension Material Quan‐

Part number

tity

1 Assembly frame - 600x850x400 PP 1 -

2 Metering pump To be selected by the

3 Pulsation damper

customer.

Hidracar® U001

- - 1 -

0.09 litres PVC-U 1 1057944

4 Manometer MDM902 d25 / G1/4" PVC-U 1 1030362

5 DHV DHV-U DN10 PVC-U 1 1037765

6 Back pressure

valve

7 Vacuum pump

DHV-U DN10 PVC-U 1 1037765

Hubinont

®

MI8121 - 1 1031565

8 Vacuum cylinder - DN10 PVC-U 1 1025699

9 Ball valve 546 DN10 PVC-U 2 1024538

10 Level switch PP1/PE - - 1 142086

11 Splash guard PVC glass - - 1 -

9

Page 10

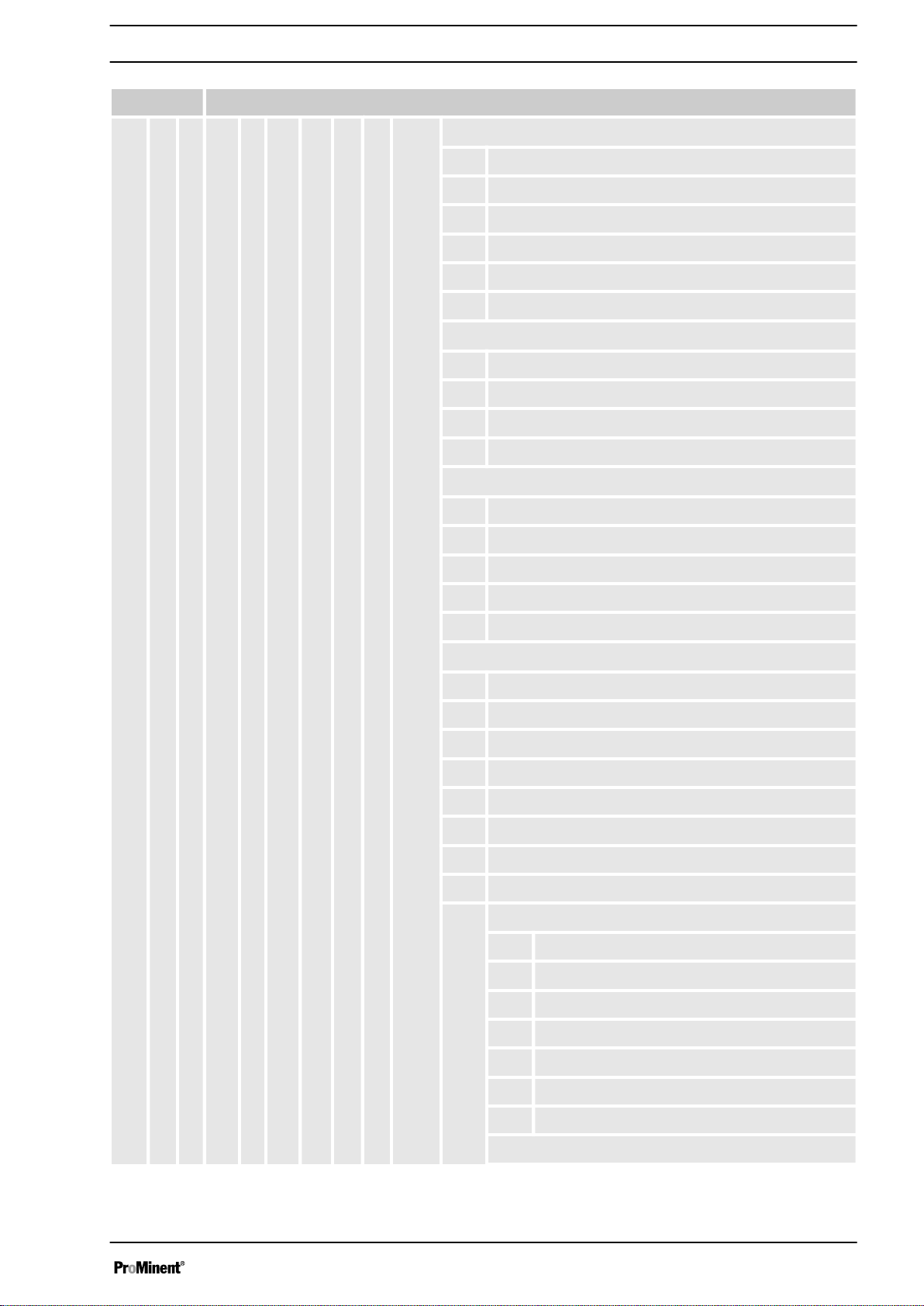

700

10 680

10

1000

63 40

110

150

52

126

410

300

90210

360

410 180

1

2

3

4

5

6

7

8

9

10

11

12 13

14

A

C

B

46

A2701

About this product

# Name Material/type Dimension Material Quan‐

Part number

tity

12 Terminal box - 180x110x90 mm - 1 1036995

13 3-way ball valve 543 DN10 PVC-U 2 1043568

1.4 Metering system, 2 pumps, 1 point of injection

Fig. 3: Metering system, 2 pumps, 1 point of injection

A Feed

B Outlet

C Drain

Not shown Connecting parts for flushing pipe DN10,

# Name Material/type Dimension Material Quan‐

1 Assembly frame - 700x1000x400 PP 1 -

2 Metering pump To be selected by the

3 Pulsation damper

4 Manometer MDM902 d25 / G1/4" PVC-U 1 1030362

2 no.

Part number

tity

customer.

Hidracar® U001

- - 2 -

0.09 litres PVC-U 1 1057944

10

Page 11

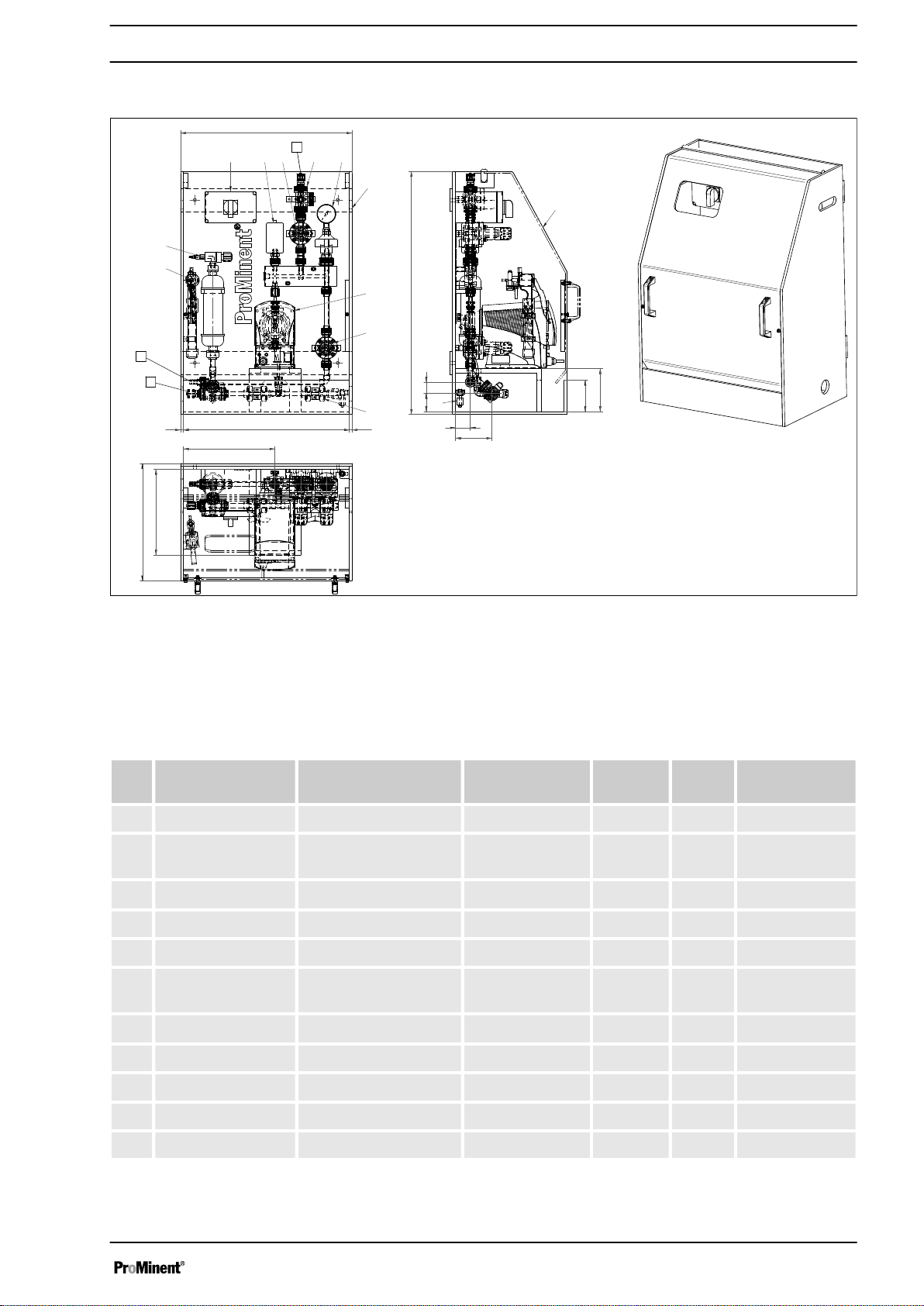

900

880

10

10

850

63

40

52

127

46

110

150

412

300

460 290

A

C

B

B

1

2

3

4

5

6

7

8

9

10

11

12

13

A2702

About this product

# Name Material/type Dimension Material Quan‐

Part number

tity

5 DHV DHV-U DN10 PVC-U 1 1037765

6 Back pressure

DHV-U DN10 PVC-U 1 1037765

valve

7 Vacuum pump

Hubinont

®

MI8121 - 1 1031565

8 Vacuum cylinder - DN10 PVC-U 1 1025699

9 Ball valve 546 DN10 PVC-U 3 1024538

10 Level switch PP1/PE - - 1 142086

11 Splash guard PVC glass - - 1 -

12 Terminal box - 180x110x90 mm - 1 1036995

13 3-way ball valve 543 DN10 PVC-U 2 1043568

14 Non-return valve 360 ND10 PVC-U 2 -

1.5 Metering system, 2 pumps, 2 points of injection

Fig. 4: Metering system, 2 pumps, 2 points of injection

A Feed

B Outlet

C Drain

Not shown Connecting parts for flushing pipe DN10,

2 no.

11

Page 12

About this product

# Name Material/type Dimension Material Quan‐

Part number

tity

1 Assembly frame - 700x1000x400 PP 1 -

2 Metering pump To be selected by the

- - 2 -

customer.

3 Pulsation damper

Hidracar® U001

0.09 litres PVC-U 2 1057944

4 Manometer MDM902 d25 / G1/4" PVC-U 2 1030362

5 DHV DHV-U DN10 PVC-U 2 1037765

6 Back pressure

DHV-U DN10 PVC-U 2 1037765

valve

7 Vacuum pump

Hubinont

®

MI8121 - 1 1031565

8 Vacuum cylinder - DN10 PVC-U 1 1025699

9 Ball valve 546 DN10 PVC-U 3 1024538

10 Level switch PP1/PE - - 1 142086

11 Splash guard PVC glass - - 1 -

12 Terminal box - 180x110x90 mm - 1 1036995

13 3-way ball valve 543 DN10 PVC-U 3 1043568

12

Page 13

2 Safety and responsibility

2.1 User qualification

Safety and responsibility

WARNING!

Danger of injury with inadequately qualified per‐

sonnel

The operator of the system / equipment is respon‐

sible for ensuring that the qualifications are ful‐

filled.

If inadequately qualified personnel work on the unit

or loiter in the hazard zone of the unit, this could

result in dangers that could cause serious injuries

and material damage.

– All work on the unit should therefore only be

conducted by qualified personnel.

– Unqualified personnel should be kept away

from the hazard zone.

The pertinent accident prevention regulations, as

well as all other generally acknowledged safety

regulations, must be adhered to.

Training Definition

Instructed personnel An instructed person is deemed to be a person who has been instructed and,

if required, trained in the tasks assigned to him and possible dangers that

could result from improper behaviour, as well as having been instructed in the

required protective equipment and protective measures.

Trained user A trained user is a person who fulfils the requirements made of an instructed

person and who has also received additional training specific to the system

from the manufacturer or another authorised distribution partner.

Trained, qualified per‐

sonnel

Electrical technician An electrical technician is able to complete work on electrical systems and rec‐

A trained, qualified employee is deemed to be a person who is able to assess

the tasks assigned to him and recognize possible hazards based on his

training, knowledge and experience, as well as knowledge of pertinent regula‐

tions. A trained, qualified employee must be able to perform the tasks

assigned to him independently with the assistance of drawing documentation

and parts lists. The assessment of a person's technical training can also be

based on several years of work in the relevant field.

ognise and avoid possible dangers independently based on his technical

training and experience as well as knowledge of pertinent standards and regu‐

lations. An electrical technician must be able to perform the tasks assigned to

him independently with the assistance of drawing documentation, parts lists,

terminal and circuit diagrams. The electrical technician must be specifically

trained for the working environment in which the electrical technician is

employed and be conversant with the relevant standards and regulations.

Service The Service department refers to service technicians, who have received

proven training and have been authorised by the manufacturer to work on the

system.

13

Page 14

Safety and responsibility

2.2 Labelling of Warning Information

Introduction

These operating instructions provide information on the technical

data and functions of the product. These operating instructions pro‐

vide detailed warning information and are provided as clear stepby-step instructions.

The warning information and notes are categorised according to

the following scheme. A number of different symbols are used to

denote different situations. The symbols shown here serve only as

examples.

DANGER!

Nature and source of the danger

Consequence: Fatal or very serious injuries.

Measure to be taken to avoid this danger.

Description of hazard

– Denotes an immediate threatening danger. If

the situation is disregarded, it will result in fatal

or very serious injuries.

WARNING!

Nature and source of the danger

Possible consequence: Fatal or very serious inju‐

ries.

Measure to be taken to avoid this danger.

– Denotes a possibly hazardous situation. If the

situation is disregarded, it could result in fatal

or very serious injuries.

CAUTION!

Nature and source of the danger

Possible consequence: Slight or minor injuries.

Material damage.

Measure to be taken to avoid this danger.

– Denotes a possibly hazardous situation. If the

situation is disregarded, it could result in slight

or minor injuries. May also be used as a

warning about material damage.

NOTICE!

Nature and source of the danger

Damage to the product or its surroundings.

Measure to be taken to avoid this danger.

– Denotes a possibly damaging situation. If the

situation is disregarded, the product or an

object in its vicinity could be damaged.

14

Page 15

2.3 General safety notes

Safety and responsibility

Type of information

Hints on use and additional information.

Source of the information. Additional measures.

–

Denotes hints on use and other useful informa‐

tion. It does not indicate a hazardous or dam‐

aging situation.

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

WARNING!

Live parts

Possible consequence: Fatal or very serious inju‐

ries

– Measure: Disconnect the mains plug prior to

opening the housing

– De-energise damaged, defective or manipu‐

lated units by disconnecting the mains plug

Immediately disconnect the pump from the

mains/power supply if the pump housing has

been damaged. Only start up the pump again

after it has been repaired by authorised per‐

sonnel.

15

Page 16

Safety and responsibility

WARNING!

Operating error / Unauthorised access

Possible consequence: Fatal or very serious inju‐

ries.

– Measure: Ensure that there can be no unau‐

thorised access to the device

– Ensure that the device is only operated by ade‐

quately qualified and technically expert per‐

sonnel

– Please also observe the operating instructions

for controllers and fittings and any other units,

such as sensors, sample water pumps ...

– The operator is responsible for ensuring that

personnel are qualified

WARNING!

Use of the unit in areas at risk from explosion

Possible consequence: Fatal or very serious inju‐

ries.

Operating the unit in areas at risk from explosion.

The unit is not approved to pump media at risk

from explosion.

WARNING!

Pumping flammable media

Possible consequence: Fatal or very serious inju‐

ries.

Take appropriate safety precautions when

pumping flammable media. Observe the safety

data sheet for the medium.

CAUTION!

Securing the unit

Only operate the unit when fixed to a wall or sim‐

ilar.

CAUTION!

Caution: feed chemical spraying around

The metering pump can generate a multiple of its

rated pressure. Hydraulic parts can burst if a dis‐

charge line is blocked.

Fit a relief valve in the discharge line.

16

Page 17

Safety and responsibility

CAUTION!

Caution: backflow

Metering pumps are not absolutely leak-tight shut-

off devices.

Use a shut-off valve, a solenoid valve or a vacuum

breaker as an absolutely leak-tight shut-off device.

CAUTION!

Personnel injury and material damage / Unit starts

immediately

The pump can start to pump as soon as it is con‐

nected to mains voltage.

Only connect the device to the mains voltage when

all installation work has been completed and the

pumped chemicals can no longer escape in an

uncontrolled manner.

Install an emergency cut-off switch in the pump

power supply line or integrate the pump in the

emergency cut-off management of the system.

Information in the event of an emer‐

gency

CAUTION!

Contact with chemicals

De-pressurise, drain and rinse the hydraulic part of

the unit before working on it.

Flushing connections

Both flushing connections can always remain

closed in normal mode.

In the event of an electrical accident, disconnect the mains cable

from the mains/power supply or press the emergency cut-off switch

fitted on the side of the system. If feed chemical is escaping, switch

off the pump by pressing

[Stop/Start]

. If necessary ensure that the

hydraulic system around the pump is at atmospheric pressure.

Adhere to the safety data sheet for the feed chemical.

17

Page 18

Safety and responsibility

2.4 Intended Use

Intended Use

Only use the metering system to meter liquid feed

chemicals into hydraulic systems.

The metering system is not intended for the

metering of gaseous or solid media.

Only use the metering system in accordance with

the technical data and specifications provided in

these operating instructions and in the operating

instructions for the individual components (such as

sensors, fittings, calibration devices, metering

pumps etc.).

The metering system is designed for installation

indoors. Operation outdoors is not permitted.

Do not operate the metering system under condi‐

tions other than those described in the technical

data.

Only allow technically expert personnel to operate

the metering system.

All other uses or modifications are prohibited.

18

Page 19

3 Storage and Transport

Storage and Transport

n User qualification: instructed user, see

qualification’ on page 13

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

Hazardous feed chemicals (hazardous sub‐

stances)

Prior to storage or transportation, make sure that

the metering system is free from hazardous feed

chemicals.

Ä Chapter 2.1 ‘User

Immediately check the goods on receipt of delivery. Identify any

damage caused by transportation as well as missing parts or incor‐

rect delivery. Immediately notify us of defects in writing upon

receipt of the goods.

Only transport the metering system standing and secured with ten‐

sioning straps.

Only transport the metering system on a pallet.

The metering system cannot be stacked.

Suitable hoisting and lifting equipment must be used for loading

and unloading packed machine components. Make sure that the

lifting equipment and means of transportation have sufficient loadbearing capacity.

When using forklifts, the forks must be sufficiently long to reach

beyond the overall depth of the packaging and the spacing

between the forks must also be sufficient.

Store and transport the metering system in an environment free

from dust.

Do not expose the metering system to direct sunlight of UV radia‐

tion.

Storage and transport temperature of the metering system: -5 °C ...

+50 °C

Maximum air humidity *: 92 % relative air humidity

19

Page 20

Assembly and installation

4 Assembly and installation

4.1 General

n User qualification, mechanical installation: trained and qualified

personnel

n User qualification, electrical installation: electrical technician

Ä Chapter 2.1 ‘User qualification’ on page 13

Installation work:

Ä Chapter 2.1 ‘User qualification’ on page 13

Intended use

The metering system is designed for installation

indoors. Operation outdoors is not permitted.

Do not operate the metering system under condi‐

tions other than those described in the technical

data.

Only allow adequately qualified and technically

expert personnel to operate the metering system.

All other uses or modifications are prohibited.

Hydraulic installation:

1. Only fix the metering system on the feet intended for this pur‐

pose or as a wall panel on the wall.

2. Ensure that the fixing surface is level (e.g. DIN 18202).

3. Tighten all connectors (threaded connectors, flange connec‐

tors ...).

1. When installing the metering system, always make sure that

the connectors on site are connected to the metering system

free of tension.

2. Only use materials that comply with the provisions and speci‐

fications of the ProMinent resistance list.

20

Page 21

A2703

Electrical installation:

Assembly and installation

WARNING!

Live parts

Cause: All work or installation work performed can

lead to danger from electrical current.

Possible consequence: Fatal or very serious inju‐

ries.

Measure: Carry out all work in line with the appli‐

cable national and international statutory regula‐

tions, laws and standards. The system operator is

responsible for compliance and implementation.

We fundamentally recommend the use of appro‐

priate residual current circuit breakers (RCCB) or

other residual current devices (RCD) providing

they can be installed sensibly and professionally

within the electrical installation. Please adhere to

all national standards and regulations.

1. The transition point for the electrical system is a terminal box

attached on the wall mounting plate with a master switch, to

which all signals and the power supply to the pumps and the

power supply to the controller are connected.

2. Connect the metering system in accordance with the terminal

diagram supplied to the on-site electrical installation.

4.2 Installation on the floor

Fig. 5: Installation on the floor. No special fixing is required.

21

Page 22

A2353

A2704

Assembly and installation

4.3 Installation with stainless steel bracket

4 x M8 machine feet with fixing hole Ø15 mm

n 1 x stainless steel bracket 1190x600x100 mm (LxHxW)

n 4 x M8 fixing bolts (bracket – mounting frame)

Fig. 6: Installation with stainless steel bracket

4.4 Installation on the wall

Fig. 7: Installation on the wall

n 4 x M8 bolts

22

Page 23

4.5 Connect the suction lance level gauge

Model: 1 pump, 1 point of injection

n Connect the level switch to the pump.

Model: 2 pumps, 1 point of injection

n Connect the level switch to the active pump.

Model: 2 pumps, 2 points of injection

n Connect the level switch to the terminal box.

n Empty signal prompt by a higher-level control (by the cus‐

tomer).

n The pumps are switched off possibly by the Pause input (by

the customer).

Assembly and installation

23

Page 24

Commissioning

5 Commissioning

5.1 Leaks and Emissions

n User qualification: trained user, see

fication’ on page 13

Prerequisite for commissioning:

All installation and assembly work has been per‐

formed by qualified personnel.

The system operator has produced system-specific

operating guidelines and has trained the operating

personnel on the basis of these operating guide‐

lines.

If necessary, the metering system has been

checked, handed over and approved for operation

in line with national standards and regulations.

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

Ä Chapter 2.1 ‘User quali‐

The continuous sound pressure level emitted by the metering

system is max. 70 ±5 dB(A) in accordance with DIN EN ISO

3743-1.

24

Page 25

5.2 Personal Protective Equipment (PPE)

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

Always wear the necessary personal protective equipment

(PPE) in accordance with the material safety data sheet for

the feed chemical and the internal procedural instructions

issued by the operator of the metering system.

Commissioning

5.3 Commissioning Test Run

Test run of the metering pump

Faults during the test run

Should you identify a fault during the test run, first

remedy this fault. Only approve the metering

system after a further test run with distilled water

providing this test run is fault-free.

Details on the set up of the individual components

can be found in the corresponding operating

instructions for the respective components.

Start-up the respective metering pump with a

100% stroke. The stroke length settings are not

pre-set.

1. Make sure that all fittings are in the operating position and

the overflow connector on the multifunctional valve/back

pressure valve is connected and the overflow connector is

led back into a tank.

2. First, fill the two tanks provided on site with water for the test

run.

3. Guide the suction lance correctly into the tank filled with

water and check the discharge side connector to the injection

point.

4. Start the test run of the metering pump (left line) and check

all fittings and connections have the correct operating setting.

5. Counting the pump strokes enables you to identify the quan‐

tity removed.

25

Page 26

Commissioning

6. Run the metering pump for a few minutes to allow all air bub‐

bles to escape from the metering system. Set the pump to

the required metering volume. You can adjust the pump

output by changing the stroke rate and stroke length.

If the discharge line is routed into a collecting tank, you

ð

can measure the metered volume to determine a

metering volume. Switch off the metering pump again

afterwards.

Draining the metering system

7. Drain the metering system and fully remove water and con‐

taminants from the metering system. The metering system

can be drained by blowing compressed air through the lines.

Do not allow the air pressure to exceed the metering sys‐

tem's permissible operating pressure.

5.4 Connecting the Chemical Tank for Commissioning

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

Pay attention to the information in the operating

instructions for the respective metering pumps.

The metering pumps are self-priming and prime

the feed chemical into the metering line on the dis‐

charge side.

Fully bleed the metering line for trouble-free

metering and fill with feed chemical.

Following a successful test run with distilled water, reinstall

all connectors as they need to be for normal operation. Fully

remove any temporary installations, if any are fitted. Set up

the installations for proper operation.

26

Page 27

6 Operation of the Metering System

Operation of the Metering System

n User qualification: instructed user, see

Ä Chapter 2.1 ‘User

qualification’ on page 13

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

During operation, perform daily checks to ensure the proper condi‐

tion of the metering system. Information on this can be found in the

operator's maintenance schedule and in the operating instructions

for the components.

Keep all shut-off valves in the

flushing connectors.

‘Open’

operating positions. Close all

27

Page 28

Maintenance and Troubleshooting

7 Maintenance and Troubleshooting

n User qualification: trained user, see

fication’ on page 13

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

WARNING!

Live parts

Cause: Incorrectly performed installation work can

lead to danger from electrical power.

Possible consequence: Fatal or very serious inju‐

ries.

Measure: Make sure that the mains power supply

is disconnected during all maintenance and repair

work. Regularly check the continuity of the earth

line by taking measurements. Carry out all work in

line with the applicable national and international

statutory regulations, laws and standards. The

system operator is responsible for ensuring compli‐

ance and implementation.

Ä Chapter 2.1 ‘User quali‐

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic com‐

ponents if they are manipulated or opened due to

pressure in the liquid end and adjacent parts of the

system.

– Disconnect the pump from the mains power

supply and ensure that it cannot be switched

on again by unauthorised persons.

– Depressurise the system before commencing

any work on hydraulic parts.

1. Drain and flush dosing heads, pulsation dampers, valves and

pipework.

2. Keep key spare parts near the metering system, including

spare parts and wear parts sets for the pumps and spare

parts for other system parts.

28

Page 29

7.1 Maintenance

Maintenance and Troubleshooting

Maintenance intervals

Maintenance intervals strongly depend on the feed

chemical, the hydraulic conditions and the effective

run-time of the components. No general statement

on maintenance intervals can therefore be pro‐

vided. The maintenance intervals recommended

and specified in the operating instructions are

based on many years of experience. However, the

maintenance intervals may alter due to the pre‐

vailing operating conditions.

Carry out regular checks on the metering system. Pay attention to

the operating instructions for the components:

n Tightness, visible damage and signs of corrosion

n Check the tightness of the seat of all components of the

metering system

n Remove deposits of dust and soiling

n Check the capacities

n Check the charging pressure of the pulsation damper (bladder

damper) – pay particular attention to the filling medium.

n Check the settings of the back pressure and relief valves,

especially when changing the capacity

n Check and maintain the metering pumps in line with the corre‐

sponding operating instructions

n Check any flow meter equipment and flow displays fitted

Regularly replace wear parts, especially in the pump heads. If the

wear parts are not regularly replaced, it can lead to damage or

excessive noise emission levels.

Annually check all fittings for correct function and leak-tightness.

Replace the seals, O-rings, diaphragms or all fittings etc., if

required.

Following any maintenance work, check the functionality and leaktightness of the metering system.

29

Page 30

Maintenance and Troubleshooting

Tab. 2: "Maintenance" schedule for the metering system.

What? Where? Where described?

Metering pumps

Functional test Daily inspection Pump operating instruc‐

Inspection of the electrical connec‐

tions, mechanical intactness, secure

fixing and corrosion damage

Quarterly inspection

tions

Metering system operating

instructions

Check the starting torques of the

fixing bolts on the dosing head

24 hours after initial commissioning,

then quarterly or when the diaphragm

is replaced

Check and, if required, replace suc‐

tion and discharge valves

After 5,000 hours and/or as per the

information in the operating instruc‐

tions for the pump

Check and, if required, replace the

metering diaphragm

After 10,000 hours and/or as per the

information in the operating instruc‐

tions for the pump

Back pressure / relief valves

Functional test & diaphragm

replacement

Annually or in the event of a fault Metering system operating

instructions

Multifunctional valve oper‐

ating instructions

Functional test Weekly inspection Metering system operating

instructions

Drip tray

Visual inspection for leak-tightness

and damage

Weekly inspection Metering system operating

instructions

Leakage sensor (drip tray level switch)

Functional test Annually and/or in line with the specifi‐

cations of the competent authority

Threaded connectors and hose connectors

Check for secure fixing and leak-

Monthly inspection Metering system operating

tightness, tighten if required

Pipework and hose lines

Visual inspection for leak-tightness

Monthly inspection Metering system operating

and damage / brittleness

Metering system operating

instructions

instructions

instructions

30

Page 31

Maintenance and Troubleshooting

7.2 Troubleshooting

Fault Possible cause Remedy

Suction line contains gas

bubbles

Metering pump is not

pumping or indicates

decreased capacity

Priming lift too high, operating condi‐

tions too close to the vapour pressure

Reduce priming lift, use automatic

gas release, reduce temperature

of the medium

Suction line leaks and is drawing air Check negative pressure tightness

and connections, bleed line

Medium tends to be gaseous Automatic gas release at the highest

point and in the dosing head, always

lay suction lines at a continuous

incline, avoid higher temperatures

and UV radiation, flush suction con‐

nector

Suction line contains gas bubbles See separate fault indication

Suction line is blocked Remove blockage / dirt

Suction pressure required is too high Modify suction line, use a wider

cross-section and/or use a priming

pulsation damper

Suction line contains gas bubbles Bleed at the highest point, lay suction

line with a continuous incline

Flushing or drain open on the suction

side

Shut-off valve on the evacuation tank

not closed

Close flushing or drain tap on the

suction side

Close fitting and, if required, re-evac‐

uate the suction line

Tank and/or priming lift too high Use priming aid

Empty alert and/or low flow contact trig‐

gered

Top up chemicals into the storage

tank: make sure that the level sensor

is immersed in the medium

Ball jammed/stuck in the metering

pump suction or discharge valve

Ball dissolved in the suction or dis‐

Dismantle, clean and, if required,

replace valve

Replace valve and check resistance

charge valve

Diaphragm tear / diaphragm rupture

Replace diaphragm and sealing set

sensor activated

Opening pressure of the relief valve /

Correctly set the opening pressure

safety valve too low

Open flushing and drainage connection

on the discharge side

Close flushing and drainage connec‐

tion

Air in the discharge line Bleed metering line at the highest

points

Metering line ruptured Correctly repair the metering line

Shut-off valve closed (discharge side) Open shut-off valve

Metering line blocked Rectify blockage, check opening

pressure of the relief valve and/or

safety valve

The table does not claim to be complete.

Further reasons for failure and detailed information on the causes of faults can be found in the operating

instructions for the individual components.

31

Page 32

Maintenance and Troubleshooting

Fault Possible cause Remedy

Display on the pressure

manometer pulsates

Back pressure too high at the injection

point

Reduce back pressure or replace

pump with a higher capacity

Injection point blocked Clean injection point

Voltage drop or failure Reconnect the power supply

Cable for power supply is not correctly

connected

Ensure correct power supply through

measurement

Control failure, no control signal Ensure correct control signal through

measurement

Cable for control is loose or incorrectly

connected

Check connector and, if required,

rewire the signal cable

Stroke rate or stroke length set to "0" Set the stroke rate / stroke length to

the desired value

Pump is set to standby mode or pause Check the control or pause signal

Faulty operation of the pump/metering

Train operating staff

system

Electrical connection malfunctioning Check the contacts for corrosion and

secure fixing

Pulsation damper pre-load is incorrect Check the setting of the pulsation

damper

Retrofit pulsation damper if neces‐

sary

Discharge line displays

strong vibrations or starts

"pulsating'

Pressure peaks too high Check the setting of the pulsation

damper

Retrofit pulsation damper if neces‐

sary

Suction line displays

strong vibrations or starts

"pulsating'

Pressure peaks too high Check the setting of the pulsation

damper

Retrofit pulsation damper if neces‐

sary

Fluid is leaking from the

backplate of the metering

pump

Liquid end not tight Tighten the screws on the dosing

head crosswise to the correct tight‐

ening torque

Replace diaphragm/sealing set

The table does not claim to be complete.

Further reasons for failure and detailed information on the causes of faults can be found in the operating

instructions for the individual components.

32

Page 33

8 Decommissioning and disposal

Decommissioning and disposal

n User qualification: instructed user, see

qualification’ on page 13

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

During decommissioning, de-energise the mains

cable and ensure that it cannot be switched on

again.

Thoroughly clean the metering system of chemi‐

cals and dirt when decommissioning it.

Ä Chapter 2.1 ‘User

If the metering system is idle for a long period of time, thoroughly

rinse, clean and then drain all pipework, fittings, metering pump

and all other wetted parts. If possible, dry/flush the pipework with

compressed air. Compressed air can pressurise residue out of the

lines. When doing so, pay attention to the maximum permissible

pressure of the metering system.

Secure the metering system against unauthorised intervention.

Ensure that suitable barriers, such as flexible protective grating or

barrier tape, are in place.

1. Disconnect the metering system from the mains power

supply.

2. Depressurise all components of the metering system.

3. Drain the metering system and thoroughly rinse it with a suit‐

able medium.

4.

Also read the operating instructions for the

individual components used.

Comply with the storage conditions for temporary decommis‐

sioning.

33

Page 34

Decommissioning and disposal

8.1 Disposal of used parts

Sign indicating EU collection system

n User qualification: instructed user, see

Ä Chapter 2.1 ‘User

qualification’ on page 13

NOTICE!

Regulations governing the disposal of used parts

– Note the national regulations and legal stand‐

ards that currently apply in your country

The manufacturer will take back decontaminated used devices pro‐

viding they are covered by adequate postage.

Decontaminate the device before returning it for repair. To do so,

remove all traces of hazardous substances. Refer to the Material

Safety Data Sheet for your feed chemical.

A current Declaration of Decontamination is available to download

on the ProMinent website.

In accordance with the European Directive 2012/19/EU on waste

electrical and electronic equipment, this device features the symbol

showing a waste bin with a line through it. The device must not be

disposed of along with domestic waste. To return the device, use

the return and collection systems available and observe the local

legal requirements.

34

Page 35

Technical data

9 Technical data

DSUa: 1 pump, 1 point of injection 2 pumps, 1 point of injection

Dimensions HxWxD (mm) 850x600x410 1000x700x410

Weight without pump(s) 30 kg 45 kg

Weight with pump(s) 45 kg 65 kg

Storage and transport temperature 0 °C ... +50 °C 0 °C ... +50°C

Operation temperature 0 °C ... +40 °C 0 °C ... +40°C

Installation site Indoors Indoors

Maximum relative air humidity < 92%, non-condensing < 92%, non-condensing

Sound pressure level < 70 dB (A) < 70 dB (A)

Max. operating pressure (25 °C) 10 bar 10 bar

Max. operating pressure (40 °C) 6 bar 6 bar

Pulsation damper Inline, 50 ml Inline, 50 ml

Volume of vacuum cylinder 0.5 l 0.5 l

Metering pump 1 BT4a, BT5a, DLTa, GMXa BT4a, BT5a, DLTa, GMXa

Metering pump 2 - BT4a, BT5a, DLTa, GMXa

Maximum capacity 75 l/h, 2 bar 75 l/h, 2 bar

Nominal width of pipework DN 10 DN 10

Nominal width of flushing connector DN 10 DN 10

Nominal width of return line DN 10 DN 10

Output 6x4, 8x5, 12x9, DN10 nozzle 6x4, 8x5, 12x9, DN10 nozzle

Input 6x4, 8x5, 12x9, DN10 nozzle 6x4, 8x5, 12x9, DN10 nozzle

35

Page 36

Technical data

DSUa: 2 pumps, 2 points of injection

Dimensions HxWxD (mm) 850x900x410

Weight without pumps 50 kg

Weight with pumps 70 kg

Storage and transport temperature 0 °C ... +50 °C

Operation temperature 0 °C ... +40 °C

Installation site Indoors

Maximum relative air humidity < 92%, non-condensing

Sound pressure level < 70 dB (A)

Max. operating pressure (25 °C) 10 bar

Max. operating pressure (40 °C) 6 bar

Pulsation damper Inline, 50 ml

Volume of vacuum cylinder 0.5 l

Metering pump 1 BT4a, BT5a, DLTa, GMXa

Metering pump 2 BT4a, BT5a, DLTa, GMXa

Maximum capacity 2 x 75 l/h, 2 bar

Nominal width of pipework DN 10

Nominal width of flushing connector DN 10

Nominal width of return line DN 10

Output 6x4, 8x5, 12x9, DN10 nozzle

Input 6x4, 8x5, 12x9, DN10 nozzle

36

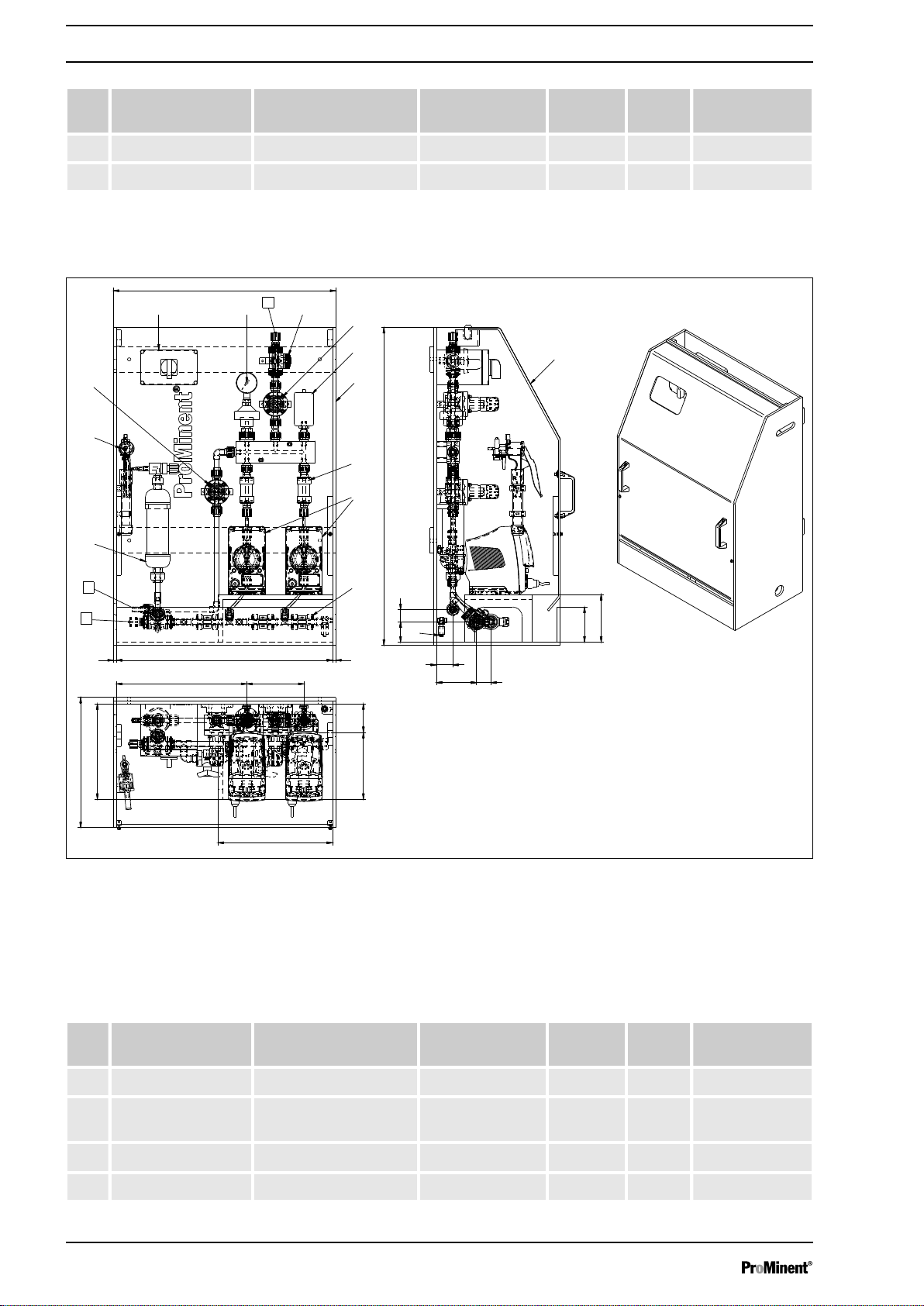

Page 37

10 Drawings

600

1

2

13

4

5

6

7

8

13

10

11

410

10

58010

320

300

12

9

63 40

127

52

850

110

150

A2708

10.1 Metering system, 1 pump, 1 point of injection

Drawings

Fig. 8: Metering system, 1 pump, 1 point of injection

37

Page 38

700

10 680

10

1000

63 40

110

150

52

126

410

300

90210

360

410 180

1

2

3

4

5

6

7

8

9

10

11

12 13

14

46

A2709

Drawings

10.2 Metering system, 2 pumps, 1 point of injection

Fig. 9: Metering system, 2 pumps, 1 point of injection

38

Page 39

10.3 Metering system, 2 pumps, 2 points of injection

Drawings

Fig. 10: Metering system, 2 pumps, 2 points of injection

39

Page 40

Symbols Process line symbols

Ball valve

Main process line

Back pressure valve

Pulsation damper

Calibration pot

Pressure display

Metering pump

A2428

Test valve

Flow diagram of DSUa mini (PID)

11 Flow diagram of DSUa mini (PID)

11.1 Legend for flow diagrams

Fig. 11: Legend for flow diagrams

40

Page 41

11.2 Flow diagram of DSUa mini 1 (PID)

A2705

Flow diagram of DSUa mini (PID)

Fig. 12: Flow diagram of DSUa mini 1 (PID)

41

Page 42

A2706

Flow diagram of DSUa mini (PID)

11.3 Flow diagram of DSUa mini 2 (PID)

Fig. 13: Flow diagram of DSUa mini 2 (PID)

42

Page 43

11.4 Flow diagram of DSUa mini 3 (PID)

A2707

Flow diagram of DSUa mini (PID)

Fig. 14: Flow diagram of DSUa mini 3 (PID)

43

Page 44

A2443

Electrical wiring diagram

12 Electrical wiring diagram

12.1 Electrical Wiring Diagram, 1062129, 1 Pump

Fig. 15: BT4b, BT5b

44

Page 45

A2444

Electrical wiring diagram

Fig. 16: DLTa, GMXa

45

Page 46

A2711

Electrical wiring diagram

12.2 Electrical wiring diagram, 2 pumps

Fig. 17: Electrical wiring diagram, 2 pumps

46

Page 47

A2712

Electrical wiring diagram

Fig. 18: Electrical wiring diagram, 2 pumps

47

Page 48

Declaration of Conformity for Machinery

13 Declaration of Conformity for Machinery

In accordance with DIRECTIVE 2006/42/EC OF THE EUROPEAN

PARLIAMENT AND OF THE COUNCIL, Appendix I, BASIC

HEALTH AND SAFETY REQUIREMENTS, section 1.7.4.2. C.

We,

n ProMinent Systems s.r.o.

n Fügnerova ul. 567

n CZ- 336 01 Blovice, Czech Republic

n IČ: 48363448

hereby declare that the product specified in the following, complies

with the relevant basic health and safety requirements of the EU

Directive, on the basis of its functional concept and design and in

the version distributed by us. Any modification to the product not

approved by us will invalidate this declaration.

Tab. 3: Extract from the Declaration of Conformity

Designation of the product: Panel-mounted metering system DULCODOS universal

Product type: DSUa

Serial number: see nameplate on the device

Relevant EC directives: EC Machinery Directive (2006/42/EC)

EMC Directive (2014/30/EU)

Compliance with the protection targets of the Low Voltage Directive

2006/95/EC according to Appendix I, No. 1.5.1 of the Machinery Direc‐

tive 2014/35/EU.

Harmonised standards applied,

in particular:

Place/Date: Blovice, 09.02.2017

ČSN EN ISO 12100:2011

ČSN EN 60204-1, 2:2007

ČSN EN 60439-1, 2:2010

ČSN EN 61140, 2:2003

ČSN EN 61000-2-4, 2:2003

ČSN EN 61000-6-2, 3:2006

ČSN EN 60529 + A2:2014

The Declaration of Conformity is available to download on our

homepage.

48

Page 49

14 Index

Index

A

Action, step by step ........................2

Applied harmonised standards .............. 48

C

Causes of faults ......................... 32

CE ................................... 48

Collecting pan ............................ 4

Continuous sound pressure level ............ 24

D

Declaration of Conformity .................. 48

Designation of the product ................. 48

E

Electrical installation ...................... 21

F

Faults during the test run ...................25

Field of application ........................ 4

P

Personal protective equipment (PPE) ......... 25

Prerequisite for commissioning .............. 24

Pumping flammable media ................. 16

Q

Question: How should I dispose of the device? .. 33

Question: Is the unit approved for areas at risk

from explosion? ..........................16

Question: Where do I find the safety informa‐

tion? .................................. 15

R

Relevant EU directives .................... 48

S

Securing the unit ......................... 16

Serial number ........................... 48

System-specific operating guidelines ......... 24

T

G

General non-discriminatory approach .......... 2

H

Hydraulic installation ...................... 20

I

Information in the event of an emergency ...... 17

Installation work ......................... 20

L

Leak sensor ............................. 4

Links to elements or sections of these instruc‐

tions or other applicable documents ........... 2

Live parts .............................. 15

M

More symbols ............................ 2

N

Nameplate .............................. 4

Noise level ............................. 24

Non-discriminatory approach ................ 2

Troubleshooting ......................... 31

U

Use of the unit in areas at risk from explosion ... 16

User qualification .........................13

W

Wall mounting plate ........................4

Warning information ...................... 14

O

Operating error / Unauthorised access ........ 16

49

Page 50

50

Page 51

51

Page 52

ProMinent GmbH

Im Schuhmachergewann 5 - 11

69123 Heidelberg, Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

982011, 1, en_GB

© 2019

Loading...

Loading...