Page 1

Operating instructions

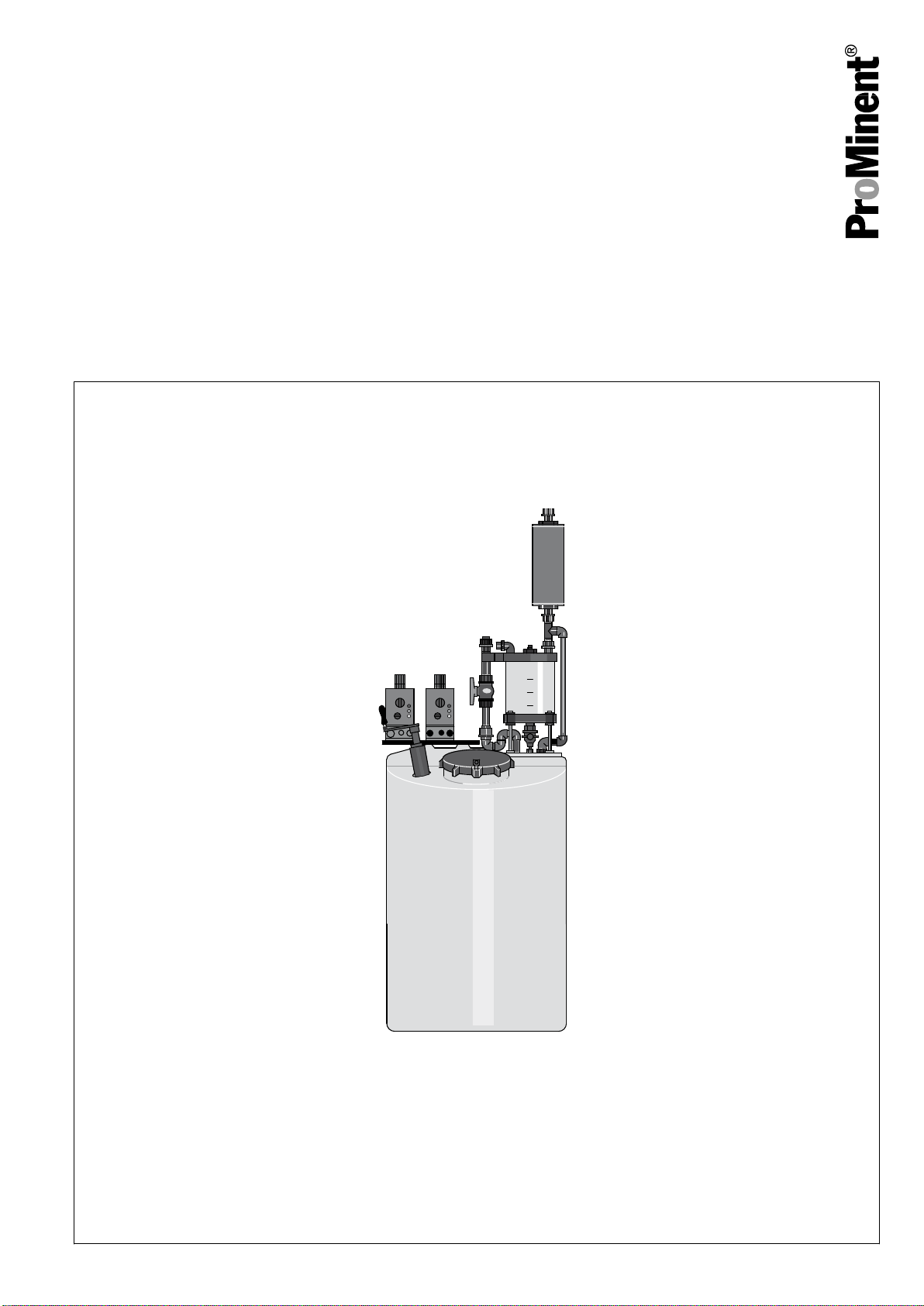

P_HYD_0001_SW

Hydrazine metering systems

DULCODOS® Hydrazin

EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Original operating instructions (2006/42/EC)Part no. 986548 BA DD 036 08/18 EN

Page 2

Supplemental directives

Supplementary information

Fig. 1: Please read!

Read the following supplementary information in its entirety! You will ben‐

efit more from using the operating instructions should you already know

this information.

The following are highlighted separately in the document:

n Enumerated lists

Instructions

Information

This provides important information relating to the cor‐

rect operation of the unit or is intended to make your

work easier.

Safety information

Safety information is identified by pictograms - see "Safety Chapter".

Notes for the system operator

This document includes notes and quotes from German guidelines relating

to the system operator's scope of responsibility. This information does not

discharge the operator from his responsibility as an operator and is

intended only to remind him or make him aware of specific problem areas.

This information does not lay claim to being complete, nor applicable to

every country and every type of application, nor to being unconditionally

up-to-date.

2

Page 3

Table of contents

Table of contents

List of other applicable documents.................................................. 4

1

2 Type list with performance data....................................................... 5

3 About the product............................................................................ 6

4 Safety chapter................................................................................. 7

5 Storage, transport, unpacking....................................................... 11

6 Overview of equipment and control elements............................... 12

7 Functional description.................................................................... 13

8 Assembly....................................................................................... 14

9 Installation..................................................................................... 15

9.1 Installation, hydraulic............................................................. 15

9.2 Installation, electrical............................................................. 17

10 Adjustment..................................................................................... 18

Start up.......................................................................................... 19

11

12 Operation....................................................................................... 23

13 Maintenance.................................................................................. 25

14 Repair and troubleshooting........................................................... 27

15 Decommissioning and disposal..................................................... 28

16 Technical data............................................................................... 30

16.1 Technical data for the complete system.............................. 30

16.2 Materials and properties of the components....................... 31

17 Spare parts and accessories......................................................... 33

17.1 Spare parts.......................................................................... 33

17.2 Accessories......................................................................... 34

18 Appendix........................................................................................ 35

18.1 Dimension sheets................................................................ 35

18.2 EC Declaration of Conformity.............................................. 36

18.3 Declaration of Decontamination.......................................... 36

18.4 Acceptance test certificate.................................................. 37

18.5 Technical data for hydrazine / levoxine 15%....................... 38

3

Page 4

List of other applicable documents

1 List of other applicable documents

Dependent on your order, you will find the

following applicable documents in the

appendix to these operating instructions:

Title

Operating Instructions Beta® b BT4b and BT5b Solenoid Metering Pump

4

Page 5

2 Type list with performance data

Hydrazine metering systems DUL‐

CODOS® Hydrazin

Pump data

Type list with performance data

Dosing tank volume Metering pump

capacity

l l / h bar l / h

140 7.1 7.0 approx. 17 913018

250 11.0 7.0 approx. 32 913019

Back pressure, max. Transfer pump capacity Order no.

5

Page 6

About the product

3 About the product

The Hydrazine metering systems DULCODOS® Hydrazin are used for the

manual batching and automatic metering of diluted hydrazine solution.

They are closed hydrazine systems. Hydrazine is used as an oxygen

binding agent to prevent corrosion in hot water and steam generators.

6

Page 7

4 Safety chapter

Safety chapter

Labelling of safety information

Signal word Meaning

WARNING Denotes a possibly hazardous situation. If this is disre‐

CAUTION Denotes a possibly hazardous situation. If this is disre‐

Warning symbols denoting different types

of danger

The following signal words are used in these operating instructions to

denote different levels of danger:

garded, your life is at risk or you are at risk of severe inju‐

ries.

garded, it could result in slight or minor injuries or material

damage.

The following warning symbols are used in these operating instructions to

denote different types of danger:

Warning signs Type of danger

Warning – toxic substances.

Warning – danger zone.

Intended use

Qualification of personnel

Task Qualification

Storage, transport, unpacking Technical personnel

Assembly, installation of the hydraulic system Technical personnel

n The systems are only intended for the batching of hydrazine-water

solutions and for metering as corrosion inhibitors in water-steam cir‐

cuits or steam and condensate systems.

n The systems may only be started up after correct installation and com‐

missioning - in accordance with the technical data and specifications

detailed in these operating instructions and the operating instructions

for the individual components.

n All other uses or a modification of the system are only permitted with

the written authorisation of ProMinent, Heidelberg.

n The systems are not intended for operation in areas at risk from explo‐

sion.

n The systems are not intended for the metering of gaseous or solid

media or other liquid media.

n The systems are not intended for use outdoors.

n You are obliged to observe the information contained in the operating

instructions at the different phases of the unit’s service life (such as

assembly, installation etc.).

n Make sure that the metering systems are only operated by trained and

authorised personnel, see table.

Electrical installation Technical personnel, electrical technician recommended

Start up Technical experts or authorised technical personnel

Operation Instructed person

Maintenance Technical personnel and instructed personnel, depending

on task

7

Page 8

Safety chapter

Task Qualification

Repair Technical personnel

Troubleshooting Technical personnel

Decommissioning / Disposal Technical personnel

Technical personnel

A qualified employee is deemed to be a person who is able to assess the

tasks assigned to him and recognise possible dangers based on his/her

technical training, knowledge and experience, as well as knowledge of

pertinent regulations.

Technical expert

A technical expert is deemed to be a person who is able to assess the

tasks assigned to him and recognise possible dangers based on his/her

technical training and experience, as well as knowledge of applicable reg‐

ulations.

Instructed person

An instructed person is deemed to be a person who has been instructed

and, if required, trained in the tasks assigned to him/her and possible dan‐

gers that could result from improper behaviour, as well as having been

instructed in the required protective equipment and protective measures.

Sound pressure level

Safety information

Electrical technician

An electrical technician is able to complete work on electrical systems and

recognise and avoid possible dangers independently based on his tech‐

nical training and experience as well as knowledge of pertinent standards

and regulations.

The electrical technician must be specifically trained for the working envi‐

ronment in which he is employed and be conversant with the relevant

standards and regulations.

The electrical technician must comply with the provisions of the applicable

statutory directives on accident prevention.

The sound pressure level is < 70 dB (A)

According to DIN EN ISO 3743-1

Operator’s obligations!

The operator of the system has a duty to operate the

system in such a way that there is no risk from the

system. It is the responsibility of the operator to provide

appropriate personnel and ensure the correct qualifica‐

tion of personnel.

8

Page 9

Safety chapter

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets provided

by the manufacture of the hazardous substance. The

actions required are described in the safety data sheet.

Check the safety data sheet regularly and replace, if

necessary, as the hazard potential of a substance can

be re-evaluated at any time based on new findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they are

kept up to date, as well as for producing an associated

hazard assessment for the workstations affected.

CAUTION!

Danger due to insufficient information

Disregarding the operating instructions for the metering

pump and other possible units can lead to potentially

hazardous situations.

Please observe the operating instructions for the

metering pumps and any other units which may be fitted.

Safety equipment

Information in the event of an emergency

Personal protective equipment

Health hazards

First aid instructions

NOTICE!

Warning of illegal operation

Observe the regulations that apply where the device is

installed.

The safety equipment available and instructions for testing are contained

in the "Start up" chapter.

Disconnect the system from the mains/power supply in the event of an

electrical emergency or if the solution leaks from the system during

pumping.

Refer to the material safety data sheet for hydrazine / levoxine in the event

of any accidents with hydrazine / levoxine.

Refer to the safety data sheet for hydrazine / levoxine.

- refer to the material safety data sheet for hydrazine / levoxine.

Note for the system operator

Keywords when searching for the necessary regulations:

n Hydrazine systems

n Hydrazine

n Storage

n Hazardous substances

n Personal protective equipment

n Water protection

n Air protection

9

Page 10

Safety chapter

Labelling

The operator must classify and label all storage tanks according to the

concentration of hydrazine contained in them.

10

Page 11

5 Storage, transport, unpacking

Safety information for hydrazine

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets provided

by the manufacture of the hazardous substance. The

actions required are described in the safety data sheet.

Check the safety data sheet regularly and replace, if

necessary, as the hazard potential of a substance can

be re-evaluated at any time based on new findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they are

kept up to date, as well as for producing an associated

hazard assessment for the workstations affected.

WARNING!

Only return metering pumps for repair in a cleaned state

and with a flushed liquid end - refer to "Decommis‐

sioning!

Only return metering pumps with a completed Decon‐

tamination Declaration form. The Decontamination Dec‐

laration constitutes an integral part of an inspection /

repair order. A unit can only be inspected or repaired

when a Declaration of Decontamination Form is sub‐

mitted that has been completed correctly and in full by

an authorised and qualified person on behalf of the

pump operator.

The "Decontamination Declaration Form" can be found

on our homepage.

Storage, transport, unpacking

NOTICE!

Danger of material damage

The device can be damaged by incorrect or improper

storage or transportation!

– The device should only be stored or transported in a

well packaged state - preferably in its original pack‐

aging.

–

The packaged unit should also only be stored or

transported in accordance with the stipulated

storage conditions.

– The packaged unit should be protected from mois‐

ture and the ingress of chemicals.

Ambient conditions

n Storage and transport temperature +5 ... +50 °C.

n Air humidity, max. 92% relative humidity, non-condensing.

11

Page 12

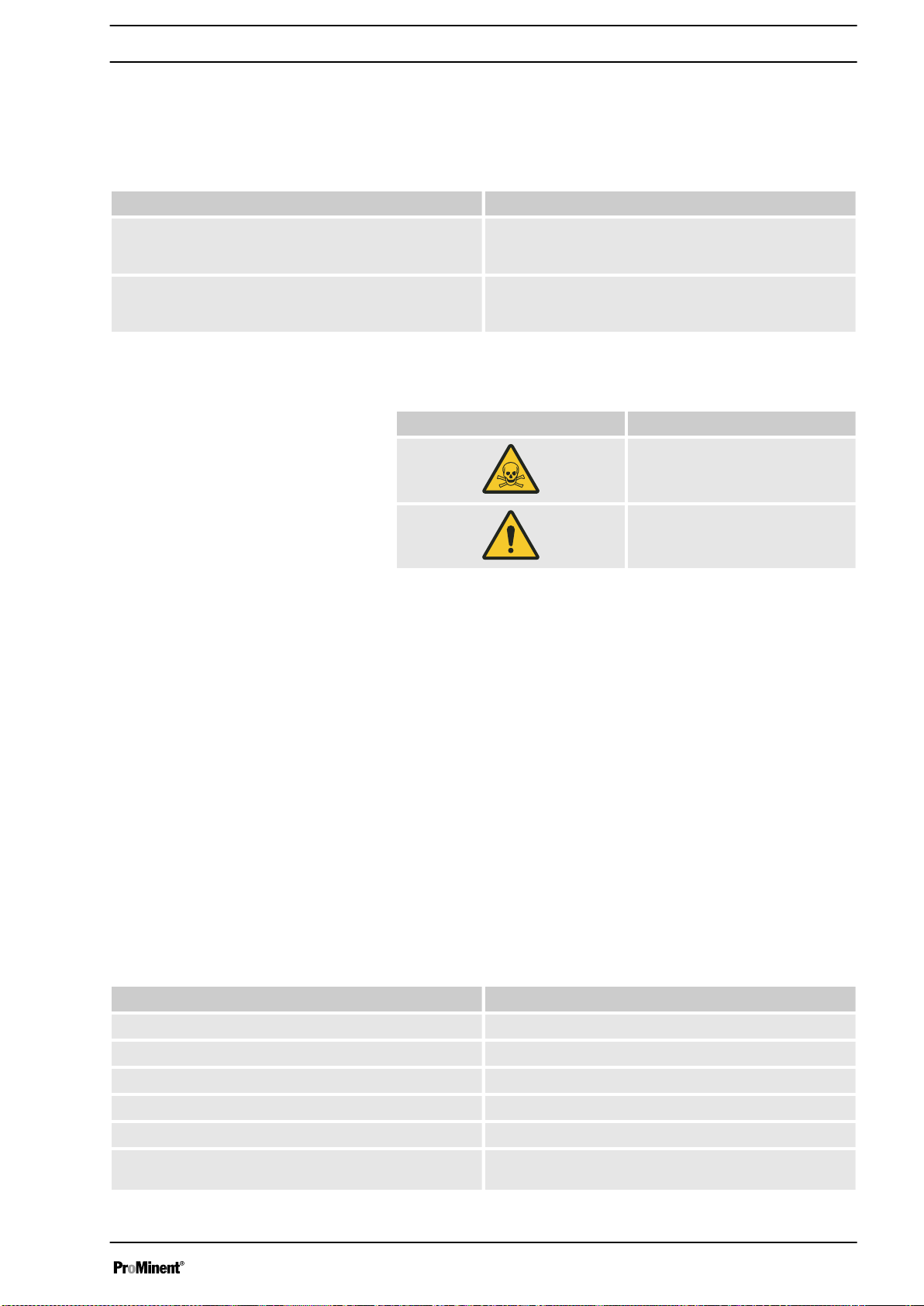

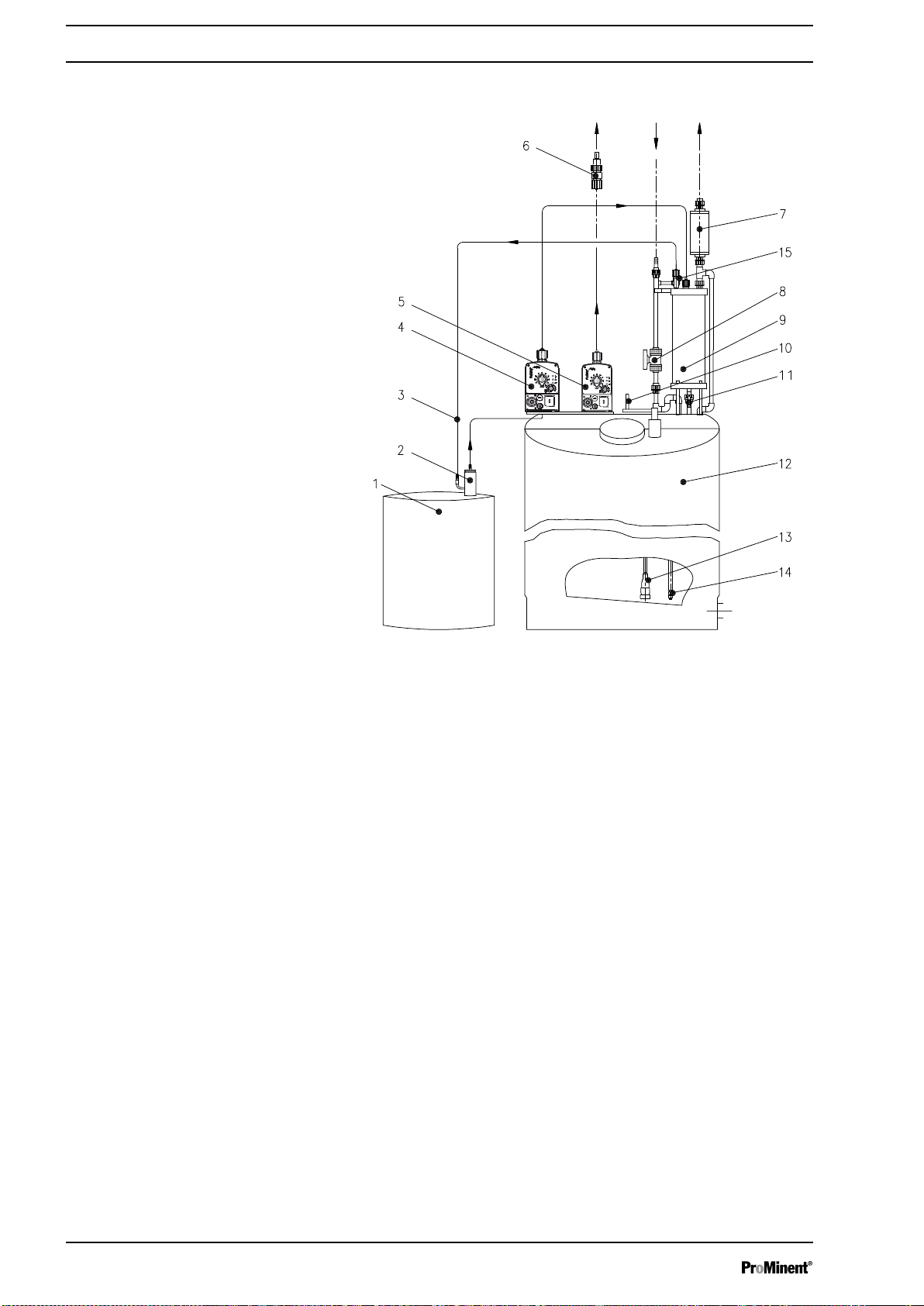

P_HYD_0020_SW

Overview of equipment and control elements

6 Overview of equipment and control elements

Fig. 2: Overview of equipment metering system DULCODOS® Hydrazin

1 Storage tank with connector for coupling (accessories)

2 Coupling (accessories)

3 Vapour recovery line

4 Decanting pump (with control elements)

5 Metering pump for metering (with control elements

6 Injection valve

7 Vent filter

8 Stopcock 1 (for diluting water)

9 Metering container with level switch

10 Manual stirrer

11 Stopcock 2 (for hydrazine in metering container)

12 Chemical feed container with sprinkler

13 Suction assembly

14 Chemical feed container level switch

Not shown in

figure

Not shown in

figure

Collecting pan

Flushing equipment (accessories. connector for cou‐

pling)

12

Page 13

7 Functional description

The hydrazine solution is batched semi-automatically. The operating per‐

sonnel use the manual stirrer to create a homogeneous solution.

The metering pump meters the hydrazine solution via the injection valve

into the desired pipework. Metering can be precisely controlled via the

external control of the metering pump.

The vapour recovery line permits transfer within a closed system. The dis‐

charge air filter breaks down escaping hydrazine into ammonia. A bleed

line transports the ammonia out of the building.

The operator of the system must use a collecting pan or other suitable

measure to prevent hydrazine from discharging into the environment in the

event of a leak. The operator of the system may wish to attach a leak

probe etc. to the collecting pan to trigger an alarm.

Functional description

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets provided

by the manufacture of the hazardous substance. The

actions required are described in the safety data sheet.

Check the safety data sheet regularly and replace, if

necessary, as the hazard potential of a substance can

be re-evaluated at any time based on new findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they are

kept up to date, as well as for producing an associated

hazard assessment for the workstations affected.

13

Page 14

Assembly

8 Assembly

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets provided

by the manufacture of the hazardous substance. The

actions required are described in the safety data sheet.

Check the safety data sheet regularly and replace, if

necessary, as the hazard potential of a substance can

be re-evaluated at any time based on new findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they are

kept up to date, as well as for producing an associated

hazard assessment for the workstations affected.

Requirements for the installation site

The operator must provide the following at the installation site:

1 - Water connection with eye bath

1 - Water connection for deionised water (diluting water and rinsing

water)

2 - Mains power sockets for both metering pumps

1 - Leak-tight pan provided by the customer around the installation loca‐

tion and suitable for hydrazine or a collecting pan - see "Accessories"

chapter.

The following parameters serve as a guideline for the operator, although

other or supplementary measures may be needed depending on the

installation site:

n The installation location must be in a closed room with good ventila‐

tion.

n The site of the hydrazine system must be protected against sun, frost-

proof and well ventilated.

n The exhaust air must be able to rise upwards and outside or into a

bleed line.

n It must be possible to fit the flushing adapter.

n A horizontal, smooth and stable surface must be available for the

installation.

n It must be possible to fasten the system to prevent if from toppling

over.

n The operator must ensure that the system cannot be damaged

mechanically from internal traffic

plate.

n The operator must ensure that the system cannot be flooded at the

installation site.

etc. If necessary, mount a guard

14

Page 15

9 Installation

P_HYD_0021_SW

A B

Installation, hydraulic

9.1

Installation

Fig. 3: A. Screw parts together, B. make the internal piping connections

1. Assemble the supplied parts of the hydrazine dosing system and

screw together with the connectors of the chemical feed container to

form a tight fit - see

1. - Decanting pump

2. - Metering pump.

3. - Diluting water feed

4. - Activate carbon filter. Also secure using the metal angle!

5. - Hand crank

2. Make the internal piping connections - see

1. - Decanting pump suction line for the storage tank. Use hose

clips as necessary!

2. - Vapour recovery line from the dosing tank for the storage tank.

Use hose clips as necessary!

3. - Decanting line from the decanting pump to the metering con‐

tainer

4. - Suction line of the metering pump

Fig. 3 A.

Fig. 3 B.

15

Page 16

P_HYD_0022_SW

Installation

Fig. 4: Make external piping connections

3. Make the external piping connections - see

WARNING!

Warning of toxic hydrazine

The system can overflow in the event of backflow

from the main line.

– Install an injection valve or vacuum breaker.

WARNING!

Warning of toxic hydrazine vapour

Hydrazine vapour can escape in the event of a

problem with the active carbon filter at the installa‐

tion site.

– Lay an exhaust line leading outdoors from the

active carbon filter.

–

The exit point of the exhaust air line is to be

aligned so that it is not directly accessible and

so that foreign bodies cannot penetrate

inside.

– The exhaust air line must be subsequently

accessible for inspection.

Fig. 4.

1. - Metering line from the metering pump to the installed injection

valve

2. - Diluting water line of the diluting water supply to the water line

3. - Exhaust line leading outdoors from the active carbon filter

4. - Flushing water line for the flushing adapter to the water supply

(not illustrated)

16

Page 17

9.2 Installation, electrical

P_HYD_0026_SW

4 3 4 1 2

A B

Installation

4. Install the flushing adapter.

n Mount the flushing adapter to the wall.

n Connect the flushing adapter to the diluting water stopcock.

Fig. 5: Undertake the electrical installation for (A) the transfer pump and (B) metering pump

Make the electrical cabling connections - see Fig. 5.

1. - Insert the plug of the suction lance level switch (chemical feed

container) in the "Level switch connector" at the metering

pump.

2. - Plug the signal cable from a control into the "External oper‐

ating modes connection" at the metering pump.

3. - Insert the plug of the decanting vessel level switch in the

"Level switch connector" at the decanting pump.

4. - Only for collecting pan with leakage probe: Undertake the

electrical installation for the leakage probe so that an alarm is

triggered in the event of a leak.

5. - Install an emergency cut-off switch for both pumps.

6. - Connect both mains cables to the mains outlets.

17

Page 18

1

2

P_HYD_0027_SW

Adjustment

10 Adjustment

1. Set the transfer pump to 100% stroke length - while it is running and to 100% stroke rate (multifunctional switch).

2. Adapt the “metering pump” using the stroke length and the stroke

rate (multifunctional switch) to the conditions of your process - see

also "Operating instructions for metering pumps Beta BT4 and BT5".

Fig. 6: Pump adjustment

1 Stroke length adjustment button

2 Multifunctional switch

18

Page 19

11 Start up

Safety information

Start up

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets provided

by the manufacture of the hazardous substance. The

actions required are described in the safety data sheet.

Check the safety data sheet regularly and replace, if

necessary, as the hazard potential of a substance can

be re-evaluated at any time based on new findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they are

kept up to date, as well as for producing an associated

hazard assessment for the workstations affected.

WARNING!

Hydrazine can escape

Hydrazine can escape if the system is not handled cor‐

rectly.

– Only allow technical experts or authorised technical

personnel to start up the system!

– The accepting technical expert or authorised tech‐

nical personnel must verify acceptance of the hydra‐

zine metering system for the operator by means of

the "Acceptance test certificate" - see appendix for

copy.

List of safety equipment

Safety equipment test

The following parameters serve as a guideline for the operator, although

other or supplementary measures may be needed depending on the

installation site:

n Coupling for storage tank (e.g. Micro-Matic coupling) and flushing

adapter

n Vapour recovery line

n Active carbon filter with exhaust air line to be provided on site

n Tank cover with seal

n Labels on tank cover

n Injection valve or vacuum breaker (the latter to be provided on site)

n Collecting pan (to be provided on site), leak sensor recommended

n Guard plate (optional, to be provided on site)

n Emergency stop switch (to be provided on site)

Flush the system before undertaking the test.

Most of the safety equipment is tested in

on page 19

n Tank cover seal

n Labels on tank cover

n Active carbon filter

and

Ä Chapter 11 ‘Start up’ on page 19

Test: Is the seal intact and firmly screwed to the storage tank lid?

Test: Is the label still attached, up-to-date and easily legible?

Test: Not possible. Replace every 6 months.

Ä Chapter 11 ‘Start up’

. In addition:

19

Page 20

Start up

Checking for cleanliness

n Injection valve or vacuum breaker

Test: Loosen the discharge line on the metering pump and observe if

liquid is forced back.

n Collecting pan (to be provided on site)

Test: Fill with water and check for water tightness. Then remove the

water again.

n Guard plate (optional)

Test: Check to ensure it is still sufficiently sturdy.

n Emergency stop switch (to be provided on site)

Test: Press the emergency stop switch while the pump is in operation.

The pump must come to a standstill.

CAUTION!

Warning catalytic decomposition

Dirt can trigger catalytic decomposition with hydrazine.

– Check that the system is free of dirt and contamina‐

tion.

Check that the system is free of dirt and contamination.

Perform initial commissioning

Checking for leak-tightness

The following parameters serve as a

guideline for the operator, although other

or supplementary measures may be

needed depending on the installation site:

Initial commissioning together with the acceptance test is under‐

taken in Germany in accordance with the principles set out in

"Admission of closed decanting and metering systems for aqueous

solutions of hydrazine", according to BBG-907/1999.

1. If hydrazine has already been present in the system, flush it out see chapter "Decommissioning".

2. Carefully meter the resulting solution into the application.

3. Close the active carbon filter with a blanking cap.

4. Close the screw lid on the dosing tank.

5. Open the stopcock on the metering vessel.

6. Close the stopcock for diluting water.

7. Remove the threaded connector on the diluting water connection.

8. Screw the T-piece with manometer and compressed air connector

on to the diluting water connector of the hydrazine metering system.

9. Adjust the pressure reduction valve of the compressed air supply to

a test pressure of 80 mbar.

10. Open the diluting water stopcock and fill the complete hydrazine

metering system with compressed air until the manometer displays

a constant 80 mbar. Close the stopcock on the testing fitting. The

test duration is 5 minutes.

11. Check the closed screw lid of the storage tank of the hydrazine

metering system as well as the stirrer and its storage tank opening

for leaks (leak spray).

12. Check the fastening points for the foot valve support pipe and the

level switch as well as the openings for the suction lines and the

level switch cable for leaks.

13. Check the flange of the storage tank flange for the metering vessel,

the fixing bolts, all openings for the diluting water lines, the aerating

and bleed lines and the filling line (with stopcock) for leak-tightness.

14. Check the complete top part of the storage tank and the fastening

points of the fastening plate of the metering and transfer pumps for

leak-tightness.

20

Page 21

Start up

15. Check the storage tank and storage tank base for cracks or other

damage and leak-tightness.

16. Check all adhesion points for leak-tightness, all pipework, threaded

connectors and pipe connections on the metering vessel.

17. Check all threaded connectors for leak-tightness:

n on the stopcocks

n on the stopcock

n on the diluting water line

n on the active carbon filter

n on the metering vessel, as well as the float plugs of the level

switches

18. Check the housing of the active carbon filter for leak-tightness.

19. Check the vapour recovery line for leak-tightness at the connectors,

the metering tank and the suction line of the transfer pump as well

as the test tank connection.

20. The pressure must not have fallen by more than

duration of 5 minutes has expired.

21. Remove the blind cap on the active carbon filter and hook up the

exhaust air line again.

10 mbar after a test

Operational test using diluting water

The following parameters serve as a

guideline for the operator, although other

or supplementary measures may be

needed depending on the installation site:

1. Close the bottom stopcock on the metering vessel and connect the

diluting water line.

2. Fill the dosing tank through the diluting water line up to the max‐

imum level (140 l or 250 l marking) depending on the size of the

tank.

3. Close the stopcock on the diluting water line.

4. Completely fill the test tank (empty hydrazine storage tank) with

rinsing water, e.g. condensate or deionised water.

5. Check the operation of the transfer pump and also check that the

transfer pump is switched off by the level switch in the metering

vessel:

Switch on the transfer pump and fill the metering vessel until the

level switch is triggered and the transfer pump stops. Simultane‐

ously check the parts, such as the transfer pump, suction line, the

line to the metering vessel and the metering vessel itself for leaktightness. Finally close the stopcock once more.

6. Functional test of the metering pump for metering: Switch on the

metering pump and bleed the liquid end (see "Operating instructions

for solenoid metering pump Beta® BT4 and BT5"). While doing this,

check the metering pump, metering line and the injection valve and

its fastening point for leaks. Finally switch off the metering pump.

7. Replace the test tank with a storage tank, once the Micro-Matic cou‐

pling has been removed. When doing so and prior to placing the

coupling on the storage tank, ensure that the suction line and the

vapour recovery line are fastened to the coupling with hose clips.

Ensure the line connectors are securely seated and check for leaks.

8. After commissioning the hydrazine metering system, carry out one

more complete visual inspection to ensure ultimate safety.

Acceptance test certificate

The accepting personnel (technical expert or authorised technical

personnel) must verify acceptance of the hydrazine metering system

for the operator by means of the "Acceptance test certificate" (see

appendix for "Acceptance test certificate" template).

21

Page 22

Start up

The hydrazine metering system can be released for operation if all of the

points detailed in the acceptance test are fulfilled during initial commis‐

sioning.

22

Page 23

12 Operation

Batching hydrazine solution

Operation

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets provided

by the manufacture of the hazardous substance. The

actions required are described in the safety data sheet.

Check the safety data sheet regularly and replace, if

necessary, as the hazard potential of a substance can

be re-evaluated at any time based on new findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they are

kept up to date, as well as for producing an associated

hazard assessment for the workstations affected.

WARNING!

Hydrazine solution can escape

If hydrazine solution is batched without supervision,

hydrazine solution can be forced out of the system under

pressure.

– As batching is done in manual mode, it must be

monitored from start to finish.

WARNING!

Hydrazine vapours can escape

Hydrazine vapours will escape if the lid of the dosing

tank is open.

– The lid of the dosing tank must not and may not be

opened.

1. Open the stopcock 1 (2) for diluting water and initially fill the dosing

tank a third full.

2. Using the multifunctional switch (1), switch the transfer pump from

"stop" to "100", so that hydrazine is pumped from the storage tank

into the metering vessel (3). When the maximum liquid level is

reached, the level switch turns the transfer pump off.

3. Using the multifunctional switch (2), switch the transfer pump from

"100" to "stop" so that the transfer pump does not meter unwanted

hydrazine as soon as the level switch drops when emptying the

metering vessel (3).

4. Simultaneously open the stopcock 2 (5) at the bottom of the

metering storage tank and stopcock 1 (2) for diluting water – hydra‐

zine flows into the dosing tank and, at the same time, a mist of

diluting water condenses evaporated hydrazine.

5. Close both stopcocks as soon as the maximum filling level has been

reached (marking 140 l or 250 l depending on the size of tank).

6. Use the manual stirrer (4) to stir for approximately 15 seconds to

ensure a homogeneous solution.

The metering pump can now meter the hydrazine solution into

ð

the application.

Adjusting the capacity

The capacity can be adjusted using both the stroke rate (multifunctional

switch) and the stroke length (see the attached "Operating instructions for

solenoid metering pump Beta®

23

BT4 and BT5").

Page 24

Operation

Replacing the storage tank

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets provided

by the manufacture of the hazardous substance. The

actions required are described in the safety data sheet.

Check the safety data sheet regularly and replace, if

necessary, as the hazard potential of a substance can

be re-evaluated at any time based on new findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they are

kept up to date, as well as for producing an associated

hazard assessment for the workstations affected.

WARNING!

Droplets of hydrazine could be released

When replacing the storage tank, it is possible that drop‐

lets of hydrazine are spilt.

– Wear tightly fitting safety glasses and suitable safety

gloves when working on the system!

WARNING!

Hydrazine can escape

Hydrazine can escape if the storage tank is not handled

correctly.

– Return any empty re-usable containers to the sup‐

plier.

–

Dispose of any unrinsed single-use drums correctly.

As soon as the storage tank is empty, replace it with a full storage tank.

Replacement of the storage tank is described for a Micro-Matic coupling:

1. Unscrew the protective cap from the new storage tank.

2. Push up the release handle on the Micro-Matic coupling on the old

storage tank.

3. Unscrew the Micro-Matic coupling in an anticlockwise direction from

the valve on the connecting piece.

4. Place the Micro-Matic coupling with the 3 cams on the valve on the

connecting piece and turn clockwise until it engages and stops.

5. Press the handle of the Micro-Matic coupling downwards so that the

spring steel bracket on the coupling engages. The valve is now

opened.

6. Seal the suction connection on the empty storage tank with the pro‐

tective cap.

7. Return the empty storage tank to the supplier or a waste manage‐

ment firm.

24

Page 25

13 Maintenance

Safety information

Maintenance

WARNING!

It is mandatory that you read the safety information and

specifications in the "Storage, Transport and Unpacking"

chapter prior to shipping the pump.

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets provided

by the manufacture of the hazardous substance. The

actions required are described in the safety data sheet.

Check the safety data sheet regularly and replace, if

necessary, as the hazard potential of a substance can

be re-evaluated at any time based on new findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they are

kept up to date, as well as for producing an associated

hazard assessment for the workstations affected.

WARNING!

Hydrazine can escape

Hydrazine may escape when carrying out the work listed

below.

– Wear tightly fitting safety glasses and suitable safety

gloves when working on the system!

WARNING!

Hydrazine vapours can escape

Hydrazine vapours will escape if the dosing tank or the

storage tank needs to be opened.

– Refer to the material safety data sheet provided by

the chemical supplier.

Maintenance work

Interval Maintenance work Personnel

annually Check the hydrazine metering system to ensure it is in good working order. Technical personnel

Check the hydrazine metering system for leak-tightness - see chapter

"Start up".

Technical personnel

Replace the diaphragms of the metering and transfer pumps. Technical personnel

Perform an acceptance test for the hydrazine metering system. This must

be verified by the "Acceptance test certificate" - see "Appendix".

daily Check the hydrazine metering system to ensure that it is in good working

order (visual inspection).

Check the hydrazine metering system for leaks (visual inspection). Instructed personnel

25

Technical personnel

Instructed personnel

Page 26

Maintenance

Interval Maintenance work Personnel

every 6 months Replace the active carbon filter - see section "Maintenance of active

carbon filter" below.

every two years Replace the relief valve diaphragm - see operating instructions for the relief

valve.

Maintenance of the active carbon filter

WARNING!

Hydrazine can escape

Hydrazine may escape when carrying out the work listed

below.

– Therefore always flush the system - see chapter

"Decommissioning and disposal"!

Refit the new active carbon filter to the metal bracket

–

so that it cannot break off!

– Properly dispose of the active carbon filter!

1. Flush the hydrazine metering system - see chapter "Decommis‐

sioning and disposal".

2. Dismantle the used active carbon filter.

3. Fit the new active carbon filter.

4. Refit the new active carbon filter to the metal bracket so that it

cannot break off.

5. Re-connect the exhaust air line to the active carbon filter

6. Properly dispose of the used active carbon filter.

Technical personnel

Technical personnel

26

Page 27

14 Repair and troubleshooting

WARNING!

It is mandatory that you read the safety information and

specifications in the "Storage, Transport and Unpacking"

chapter prior to shipping the pump.

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets provided

by the manufacture of the hazardous substance. The

actions required are described in the safety data sheet.

Check the safety data sheet regularly and replace, if

necessary, as the hazard potential of a substance can

be re-evaluated at any time based on new findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they are

kept up to date, as well as for producing an associated

hazard assessment for the workstations affected.

Repair and troubleshooting

WARNING!

Hydrazine / levoxine can escape

Hydrazine / levoxine may escape when carrying out the

work listed below.

– Therefore always flush the system - see chapter

"Decommissioning and disposal"!

–

Take the safety measures recommended in the

material safety data sheets when working on the

system.

– Refer to the material safety data sheet provided by

the chemical supplier if the dosing tank or the

storage tank needs to be opened.

– Only use the correct spare parts.

– On completion of the work, check the system for

leak-tightness and record the results.

If necessary refer to the operating instructions for the metering pumps and

the relief valve when troubleshooting.

27

Page 28

Decommissioning and disposal

15 Decommissioning and disposal

Decommissioning

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets provided

by the manufacture of the hazardous substance. The

actions required are described in the safety data sheet.

Check the safety data sheet regularly and replace, if

necessary, as the hazard potential of a substance can

be re-evaluated at any time based on new findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they are

kept up to date, as well as for producing an associated

hazard assessment for the workstations affected.

WARNING!

Toxic hydrazine / levoxine can escape

The hydrazine metering system still contains residue of

hydrazine / levoxine.

– Flush the system with diluting water - see "Flushing

the system".

– Take appropriate protective measures, referring to

the material safety data sheet provided by the chem‐

ical supplier.

Flushing the system

Fig. 7: Flushing the system

1 Stopcock (rinsing water)

2 Pressure reducer (max. 2 bar)

3 Flushing adapter

4 Micro-Matic coupling

5 Hydrazine system

1. First remove the Micro-Matic coupling from the vessel and place it

on the flushing adapter.

2. Completely fill the metering vessel with water at least twice and

drain into the dosing tank through the ball valve.

3. Carefully meter the resulting solution into the process.

The transfer pump could be removed after

28

this.

Page 29

Disposal

Decommissioning and disposal

WARNING!

Hydrazine / levoxine can escape

The hydrazine metering system contains at the very

least the residue of hydrazine / levoxine.

– Flush the system with diluting water - see

Ä ‘Decommissioning’ on page 28

– Correctly dispose of the diluting water.

– Wear protective equipment, as outlined in the mate‐

rial safety data sheet provided by the chemical sup‐

plier.

– Refer to the material safety data sheet provided by

the chemical supplier if the dosing tank or the

storage tank needs to be opened.

CAUTION!

Warning about non-compliance with disposal regulations

– Note the pertinent regulations currently applicable in

your country.

–

Also refer to the operating instructions for the

metering pumps and relief valves.

.

29

Page 30

Technical data

16 Technical data

Safety information

CAUTION!

Warning about operation with insufficient technical data

Incomplete technical data could result in problems

occurring during operation of the hydrazine metering

system!

– Also observe the operating instructions for "Solenoid

metering pumps Beta® BT4 and BT5".

16.1 Technical data for the complete system

Dimensions and weights, metering system

with 140 l

Data Value Unit

Width 520 mm

Height 1,650 mm

Depth 600 mm

Dimensions and weights, metering system

with 250 l

Ambient conditions

Net weight, approx. 23 kg

Gross weight, approx. 160 kg

Diluting water connector, hose nozzle DN10

Max. operating pressure of diluting water 3 bar

Data Value Unit

Width: 650 mm

Height: 2,120 mm

Depth 650 mm

Net weight, approx.: 35 kg

Gross weight, approx.: 280 kg

Diluting water connector, hose nozzle: DN10

Max. operating pressure of diluting water: 3 bar

Data Value Unit

Storage and transport temperature: +5 ... +50 °C

Pump data

Ambient temperature during operation: +5 ... +40 °C

Feed chemical temperature: +5 ... +35 °C

Maximum air humidity*: 92 % relative

humidity

* non-condensing

30

Page 31

Technical data

Dosing tank volume Metering pump

l l / h bar l / h

140 7.1 7.0 approx. 17 913018

250 11.0 7.0 approx. 32 913019

Degree of protection

Sound pressure level

16.2

Hydrazine metering system, 140 l

Materials and properties of the components

capacity

Back pressure, max. Transfer pump capacity Order no.

Protection against contact and moisture:

IP 65 in accordance with IEC 529, EN 60529, DIN VDE 0470 Part 1

The sound pressure level is < 70 dB (A)

According to DIN EN ISO 3743-1

1 - Metering pump Beta®

at max. back pressure 7.0 bar. You can find more detailed information

in your operating instructions.

1 - Metering pump Beta® BT5b0420NPE0000UA004100, used as a

transfer pump, pump capacity 17.1 l/h

You can find more detailed information in your operating instructions.

1 - PE dosing tank, volume 140 l, with litre scale and closable screw lid,

"gas-tight version"

1 - Complete PVC suction assembly, "gas-tight version" (installed in the

dosing tank)

1 - Electrical level switch with support pipe (installed in the dosing tank)

1 - PVC manual stirrer, "gas-tight version"

1 - Fastening plate for mounting the metering pumps on the storage tank

1 - Metering vessel, transparent PVC, volume 2 l, with electrical level

switch for switching off the transfer pump on reaching a high level, as

well as the necessary hoses

1 - Active carbon filter

1 - PVC ball valve, d16, NW10 with pipework

1 - 1.4571 stainless steel injection valve , connector 8 mm-1/2“

1 - Metering line PTFE , 11 bar, 12 x 9 mm

1 - Micro-Matic coupling with flushing adapter (optional)

1 - Suction line PVC 12 x 9 mm, 1.5 m

1 - Vapour recovery line PVC 8 x 5 mm, 1.5 m

BT4b0708NPE0000UA004100, capacity 7.1 l/h

at max. back pressure 4 bar.

31

Page 32

Technical data

Hydrazine metering system, 250 l

1 - Metering pump Beta® BT5b0713NPE0000UA004100, capacity

11.0 l/h at max. back pressure 7.0 bar. You can find more detailed

information in your operating instructions.

1 - Metering pump Beta®

BT5b0232NPE0000UA004100, used as a

transfer pump, pump capacity 32.0 l/h at max. back pressure 2 bar.

You can find more detailed information in your operating instructions.

1 - PE dosing tank, volume 250 l, with litre scale and closable screw lid,

"gas-tight version"

1 - Complete PVC suction assembly, "gas-tight version" (installed in the

dosing tank)

1 - Electrical level switch with support pipe (installed in the dosing tank)

1 - PVC manual stirrer, "gas-tight version"

1 - Fastening plate for mounting the metering pumps on the storage tank

1 - Metering vessel, transparent PVC, volume 5 l, with electrical level

switch for switching off the transfer pump on reaching a high level, as

well as the necessary hoses

1 - Active carbon filter

1 - PVC ball valve, d16, NW10 with pipework

1 - 1.4571 stainless steel injection valve , connector 12 mm-1/2“

1 - Metering line PTFE, 11 bar 8x5 mm, 5 m

1 - Micro-Matic coupling with flushing adapter (optional)

1 - Suction line PVC 12 x 9 mm, 1.5 m

1 - Vapour recovery line PVC 8 x 5 mm, 1.5 m

Dosing tank, complete

Injection valve

Coupling for the storage tank (e.g. MicroMatic)

PE dosing tank, gas-tight screw lid, gas-tight PVC manual stirrer, trans‐

parent PVC metering vessel with drain tap, connectors for filling line,

vapour recovery line, aeration and bleeding, with active carbon filter 1.0 l,

diluting water line with stopcock, all connectors PVC gas-tight, water line

connector R 1/2".

1.4571 stainless steel injection valve, with support insert for connection to

a stainless steel line:

n 8 mm - for

140 l system

n 12 mm - for 250 l system

The injection valve is equipped with a 1/2" nipple for fixing to the point of

injection.

The coupling has hose nozzles for the transfer pump and the vapour

recovery line.

32

Page 33

17 Spare parts and accessories

Spare parts and accessories

17.1

Metering system 140 l (part no. 913018)

Tab. 1: For metering pump Beta® BT4b0708NPT0000UA004100:

Description Order no.

Beta® BT4b0708NPT0000UA004100 without bleed valve

Dosing head with suction/pressure connectors, without diaphragm, without connector kit 1034458

Connector kit 8x5 1035641

Diaphragms 46.0x21.5 1000248

Discharge valve, complete 9.2-2 PCE 1021690

Suction valve, complete 9.2-2 PCE 1021677

Tab. 2: For transfer pump Beta® BT5b0420NPT0000UA004100:

Description Order no.

Beta® BT5b0420NPT0000UA004100 without bleed valve

Dosing head with suction/pressure connectors, without diaphragm, without connector kit 1034460

Connector kit 12x9 1035642

Metering diaphragm 70.0x33.5 1000250

Spare parts

1036869

1036868

Discharge valve, complete 9.2-2 PCE 1021690

Suction valve, complete 9.2-2 PCE 1021677

Tab. 3: Miscellaneous parts:

Description Order no.

Active carbon filter (including 500202) 809819

Metering vessel, 2 l 809860

Manual stirrer, 140 l 809803

Micro-Matic coupling 1003964

33

Page 34

Spare parts and accessories

Metering system 250 l (part no. 913019)

Tab. 4: For metering pump Beta® BT5b0713NPT0000UA004100:

Description Order no.

Beta® BT5b0713NPT0000UA004100 without bleed valve

Dosing head with suction/pressure connectors, without diaphragm, without connector kit 1034461

Connector kit 8x5 1035642

Metering diaphragm 55.0x26.0 1000249

Discharge valve, complete 9.2-2 PCE 1021690

Suction valve, complete 9.2-2 PCE 1021677

1037109

Tab. 5: For transfer pump Beta® BT5b0232NPT0000UA004100:

Description Order no.

Beta® BT5b0232NPT0000UA004100 without bleed valve

Dosing head with suction/pressure connectors, without diaphragm, without connector kit 1034461

Connector kit 12x9 1035642

Metering diaphragm 91.0x46.0 1000251

Discharge valve, complete 9.2-2 PCE 1021690

Suction valve, complete 9.2-2 PCE 1021677

1037108

Tab. 6: Miscellaneous parts:

Description Order no.

Active carbon filter (including 500202) 809819

Metering vessel, 5 l 809861

Manual stirrer, 250 l 809813

Micro-Matic coupling 1003964

17.2 Accessories

Tab. 7: For all metering systems

Description Order no.

Stainless steel extraction kit 1003964

Collecting pan 200 l with design certification and galvanised grid on request

Collecting pan 1000 l with design certification and galvanized grid on request

34

Page 35

18 Appendix

P_HYD_0023_SW

P_HYD_0024_SW

Appendix

18.1

DULCODOS® Hydrazin 140 l

Dimension sheets

DULCODOS® Hydrazin 250 l

Fig. 8: Dimensional drawing Hydrazin 140 l (dimensions in mm)

Fig. 9: Dimensional drawing Hydrazin 250 l (dimensions in mm)

35

Page 36

Appendix

18.2 EC Declaration of Conformity

In accordance with DIRECTIVE 2006/42/EC OF THE EUROPEAN PAR‐

LIAMENT AND OF THE COUNCIL, Appendix II 1.A.

We,

n ProMinent GmbH

n Im Schuhmachergewann 5 - 11

n D - 69123 Heidelberg, Germany,

hereby declare that the product specified in the following complies with the

relevant basic health and safety rules of the EC Directive, on the basis of

its functional concept and design and in the version marketed by us.

Tab. 8: Excerpt from the Declaration of Conformity

Designation of the product:

Product type: Hydrazine metering system

Material numbers: 913018

Serial number: see nameplate on the unit

DULCODOS® Hydrazin

913019

Relevant EC directives: EC Machinery Directive (2006/42/EC)

EC EMC Directive (2014/30/EC)

Compliance with the protection targets of the Low Voltage Directive 2014/35/EU

according to Appendix I, No. 1.5.1 of the Machinery Directive 2006/42/EC

Harmonised standards applied, in

particular:

Date: 09.04.2018

EN ISO 12100:2010

EN 60204-1:2006/A1:2009

EN 809:1998+-a1:2009+AC:2010

EN 14123-1:2015

You can download the Declaration of Conformity at www.prominent.com.

18.3 Declaration of Decontamination

You will find the current Declaration of Decontamination to download on

the manufacturer's homepage.

36

Page 37

18.4 Acceptance test certificate

DULCODOS® Hydrazin

ACCEPTANCE TEST CERTIFICATE

Serial number

Project number / customer order

Custom

(Tick where applicable)

Initial commissioning in accordance with BBG-907, updated version 1999

Cyclic testing in accordance with BBG-907, updated version 1999

Layout and installation of the hydrazine metering system corresponds to BBG-907 /1999?

yes

no

Does the installation of the hydrazine metering system correspond to the current state of the art?

yes

no

Does the labelling of the hydrazine metering system correspond to BGI-567 and M 011?

yes

no

Does the function of the hydrazine metering system correspond to BGI-907 /1999?

yes

no Does the leak test for the hydrazine metering system correspond to BGI-907 /1999?

yes

no

Is the operator of the hydrazine metering system in possession of a set of operating instructions?

yes

no

Can the hydrazine metering system be started?

yes

no

Can the hydrazine metering system remain in normal operation?

yes

no

Remarks:

Operator:

Date:

Plac

Signature operator:

Signature technical expert:

Original for operator / carbon copy for ProMinent Dosiertechnik GmbH

Notice: 10068/001 created:

Bannas

tested:

Bannas

changed: Page 1 of 1

Document: 82 05-401 00 07-TB A 1D-01 (AbnahmeDrkoll deu Hvdrazin) Date: 2010-06-02 Time: 10:24

ProMinent Dosiertechnik GmbH, P.O. Box 10 17 60, D-69007 Heidel berg - Germany

Appendix

37

Page 38

Appendix

18.5 Technical data for hydrazine / levoxine 15%

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets provided

by the manufacture of the hazardous substance. The

actions required are described in the safety data sheet.

Check the safety data sheet regularly and replace, if

necessary, as the hazard potential of a substance can

be re-evaluated at any time based on new findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they are

kept up to date, as well as for producing an associated

hazard assessment for the workstations affected.

38

Page 39

39

Page 40

ProMinent GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg

Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

986548, 2, en_GB

© 2007

Loading...

Loading...