Page 1

Operating instructions

Ammonia water dilution and metering system

DULCODOS® Ammonia

EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Original operating instructions (2006/42/EC)981962 BA DD 037 02/19 EN

Page 2

Supplemental directives

Supplementary information

Read the following supplementary information in its entirety! You

will benefit more from using the operating instructions should you

already know this information.

The following are highlighted separately in the document:

Fig. 1: Please read!

Validity

Notes for the system operator

n Enumerated lists

Instructions

Information

This provides important information relating to the

correct operation of the unit or is intended to make

your work easier.

Safety information

Safety information is identified by pictograms - see "Safety

Chapter".

These operating instructions conform to current EU regulations

applicable at the time of publication.

This document includes notes and quotes from German guidelines

relating to the system operator's scope of responsibility. This infor‐

mation does not discharge the operator from his responsibility as

an operator and is intended only to remind him or make him aware

of specific problem areas. This information does not lay claim to

being complete, nor applicable to every country and every type of

application, nor to being unconditionally up-to-date.

2

Page 3

Table of contents

Table of contents

List of other applicable documents....................................... 4

1

2 Type list with performance data............................................ 5

3 About the product.................................................................. 6

4 Safety chapter....................................................................... 7

5 Storage, transport, unpacking............................................. 12

6 Overview of equipment and control elements..................... 14

7 Functional description......................................................... 16

8 Assembly............................................................................ 17

9 Installation........................................................................... 19

9.1 Installation, hydraulic.................................................. 19

9.2 Installation, electrical.................................................. 21

10 Start up............................................................................... 23

10.1 Checking for leak-tightness...................................... 23

10.2 Setting....................................................................... 24

10.3 Functional test with dilution water............................. 25

11 Operation............................................................................ 27

Maintenance....................................................................... 33

12

13 Repair................................................................................. 35

14 Troubleshooting.................................................................. 37

15 Decommissioning and disposal.......................................... 38

15.1 Decommissioning..................................................... 38

15.2 Disposal.................................................................... 38

16 Technical data..................................................................... 40

16.1 Technical data for the complete system................... 40

16.2 Materials and properties of the components............. 42

17 Spare parts and accessories.............................................. 44

17.1 Spare parts............................................................... 44

17.2 Accessories.............................................................. 45

18 Dimensional drawings......................................................... 46

19 Declaration of Conformity for Machinery............................. 48

20 Index................................................................................... 49

3

Page 4

List of other applicable documents

1 List of other applicable documents

Dependent on your order, you will find

the following applicable documents in

the appendix to these operating

instructions:

Title

Operating Instructions for Solenoid Metering Pump Beta® b BT4b

and BT5b

Wiring diagram for the terminal box for ammonia water with up to

25% w/w:

Document no. 82_05-401_00_05-44

4

Page 5

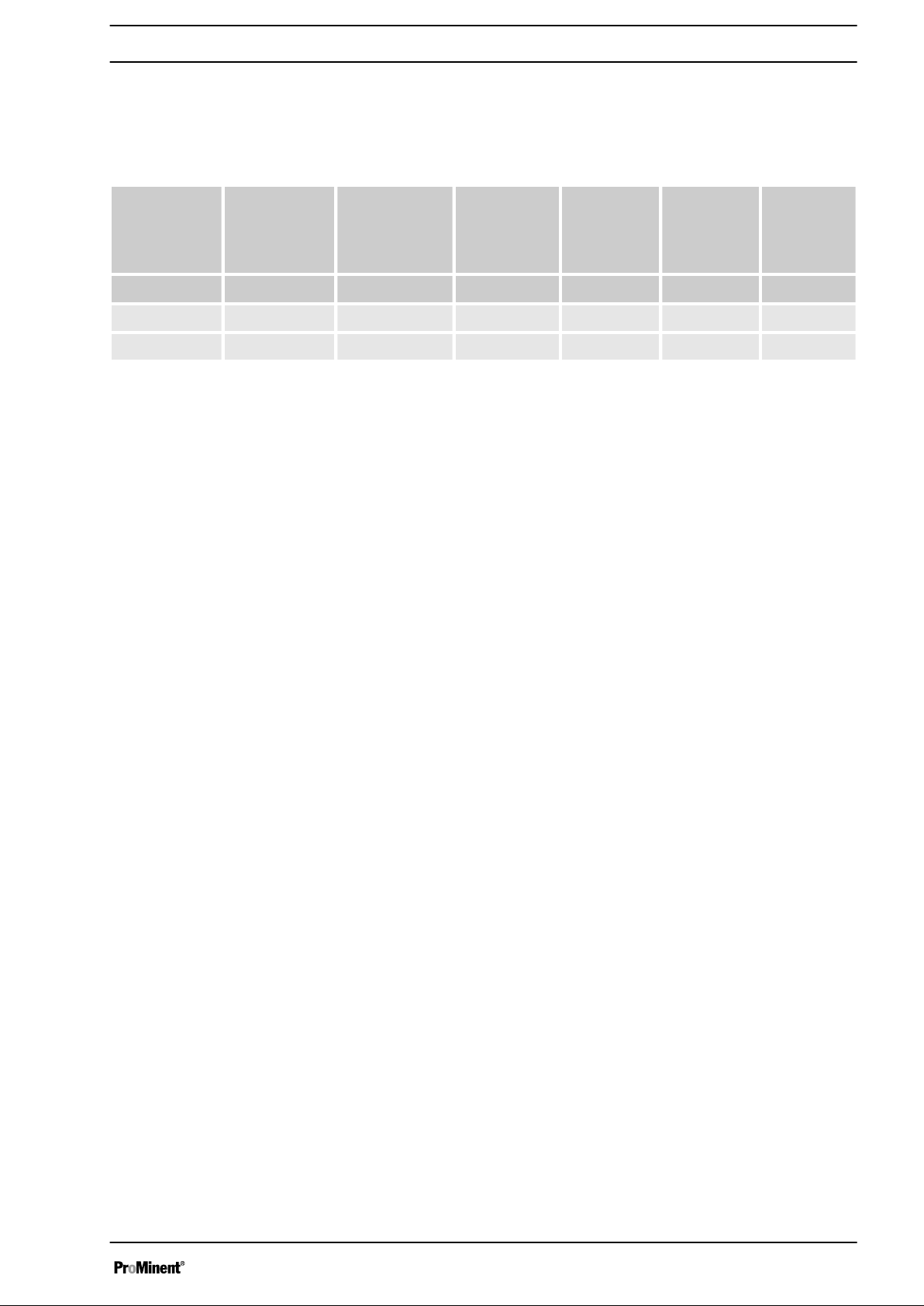

Type list with performance data

2 Type list with performance data

Ammonia water metering systems

DULCODOS® Ammonia

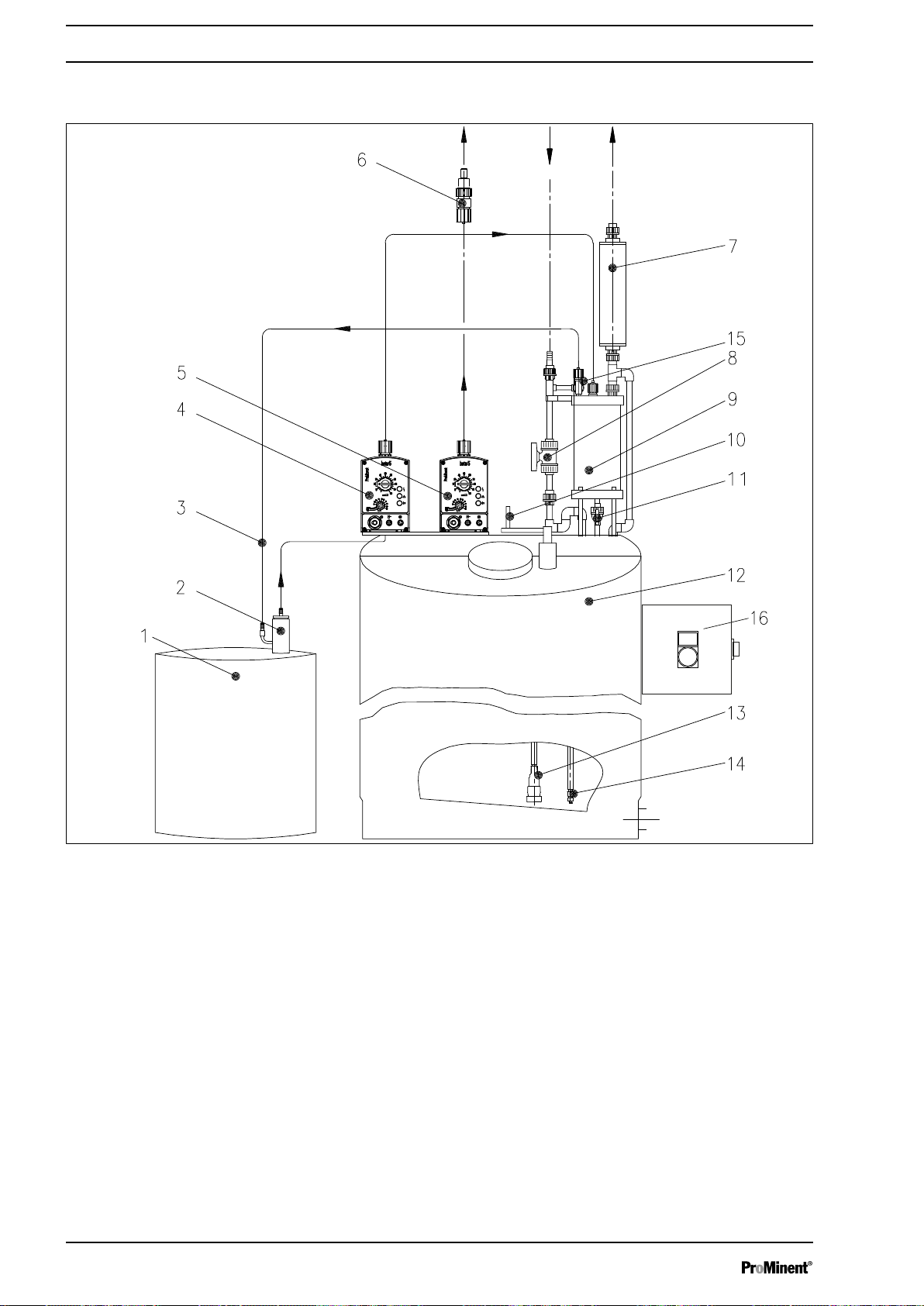

Tab. 1

Dosing tank

volume, nom‐

inal

l l l l / h bar l / h

130 120 2 7 4 approx. 15 1039192

250 250 5 7 2 approx. 36 1039193

Dosing tank

volume,

usable

Metering

vessel, usable

Metering

pump

Capacity

Transfer

pump

Delivery

height

Transfer

pump

Pump

capacity

Order no.

5

Page 6

About the product

3 About the product

The metering system DULCODOS® Ammonia is used for the gastight transfer and dilution of ammonia water to common metering

concentrations and for automatic metering into the feed water.

Ammonia (NH3), or diluted in water: Ammonium hydroxide

(NH4OH) is used for the alkalising and binding of free carbonic acid

in boiler water and condensate.

Common stock solutions: from 5% to 25% NH3 (% w/w) (ammonia

water).

The usual metering concentration is 0.1% ... 2.5% NH3 (% w/w).

6

Page 7

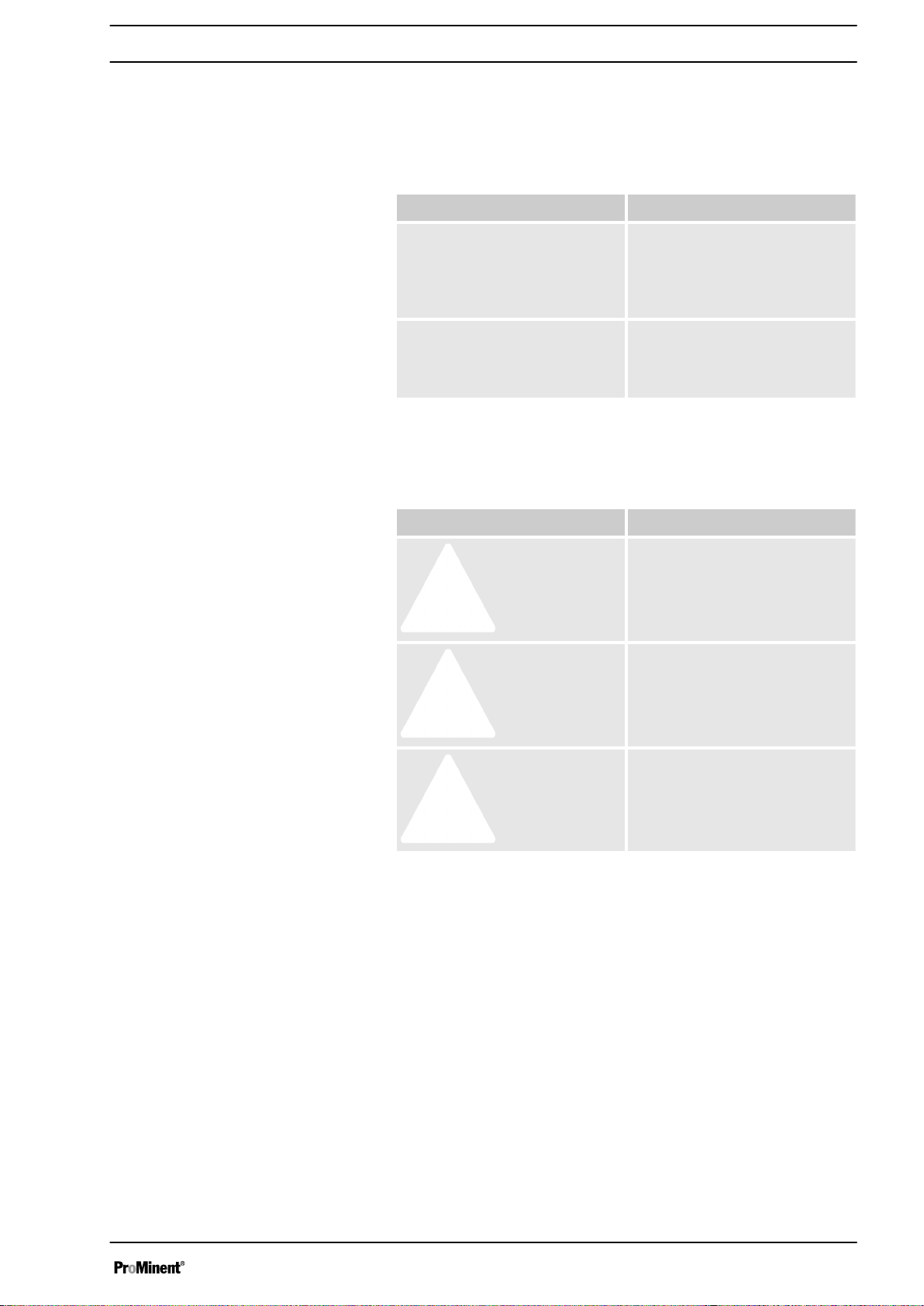

4 Safety chapter

Safety chapter

Labelling of safety information

Warning symbols denoting different

types of danger

The following signal words are used in these operating instructions

to denote different levels of danger:

Signal word Meaning

WARNING Denotes a possibly hazardous

situation. If this is disregarded,

you are in a life-threatening sit‐

uation and this can result in

serious injuries.

CAUTION Denotes a possibly hazardous

situation. If this is disregarded,

it could result in slight or minor

injuries or material damage.

The following warning symbols are used in these operating instruc‐

tions to denote different types of danger:

Warning symbol Type of danger

Warning of a dangerous area.

Intended use

Warning of hazardous electrical

voltage.

Warning of a risk of explosion

n The metering system DULCODOS® Ammonia is only intended

for batching ammonia water in common concentrations of up to

max. 25% into standard solutions of 0.1% to max. 2.5% and

metering this into water-steam circuits or into steam and con‐

densate systems.

n The metering system DULCODOS®

used after correct installation and start up - according to the

technical data and specifications outlined in these operating

instructions and the operating instructions for the individual

components.

n The metering system DULCODOS® Ammonia is not intended

for other uses.

n In the event of a modification, the operator or the contractor he

has appointed becomes the manufacturer of the modified

system in accordance with EC Regulation 2006/42/EC – with

the corresponding obligations.

Ammonia may only be

7

Page 8

Safety chapter

n The metering system DULCODOS® Ammonia is not intended

for metering other chemicals, such as sodium hydroxide solu‐

tion.

n The metering system DULCODOS® Ammonia is not intended

for the metering of gaseous or solid media or other liquid

media.

n You are obliged to observe the information contained in the

operating instructions at the different phases of the unit’s

service life (such as assembly, installation etc.).

n These operating instructions contain a summary of the impor‐

tant functions of each of the components used.

The technical information and operating instructions for the

components used form an integral part of the entire operating

instructions and must be observed.

n Make sure that the metering systems are only operated by

trained and authorised personnel, see table.

Qualification of personnel

Task Qualification

Storage, transport, unpacking Technical personnel

Assembly, installation of the

Technical personnel

hydraulic system

Electrical installation Technical personnel, electrical

technician recommended

Start up Authorised technical personnel

Operation Instructed person

Maintenance Technical personnel

Repair Authorised skilled personnel

proven to have been trained by

ProMinent

Troubleshooting Technical personnel

Decommissioning / Disposal Technical personnel

Electrician

Electricians are deemed to be people, who are able to complete

work on electrical systems and recognise and avoid possible haz‐

ards independently based on his/her technical training and experi‐

ence, as well as knowledge of pertinent standards and regulations.

Electricians should be specifically trained for the working environ‐

ment in which the are employed and know the relevant standards

and regulations.

Electricians must comply with the provisions of the applicable stat‐

utory directives on accident prevention.

Instructed personnel

The instructed personnel have been instructed by the operator in a

training session about the tasks allocated to them and potential

hazards with incorrect and improper conduct.

Technical personnel

Technical personnel are deemed to be people, who are able to

complete the tasks allocated to them and recognise and avoid haz‐

ards independently based on his/her technical training and experi‐

ence, as well as knowledge of pertinent regulations.

8

Page 9

Safety information

Safety chapter

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

WARNING!

Danger of electric shock

Mains voltage may be present inside the pump

housing and the switch cabinet.

– Immediately disconnect the system from the

mains power supply if the pump housing or

switch cabinet has been damaged. Only return

the pump to service after it has been repaired

by authorised personnel.

Potential danger from the system

CAUTION!

Please also observe the operating instructions for

the metering pump and any other units which may

be fitted.

CAUTION!

Do not climb onto the system or parts thereof - the

metering station cannot support the load, could

leak or topple over.

NOTICE!

Warning of illegal operation

Observe the regulations that apply where the

device is installed.

The following dangers could arise if incorrectly operated or mis‐

used:

Water pollution and damage to health

n Water pollution and damage to health due to escaping liquids.

n Damage to health from the inhalation of ammonia vapours.

n Dangerous reactions due to contact with other chemicals.

9

Page 10

Safety chapter

Take special precautions with storage and metering. The specific

potential danger and resulting hazards should be taken from the

current material safety data sheet for the substance used.

Danger of explosion

n Risk of explosion due to trapped ammonia-air mixtures.

A potentially explosive ammonia-air mixture (lower explosion limit

15.4 vol.%, upper explosion limit 33.6 vol.%) can form in the inte‐

rior of the metering vessel and also in the interior of the supply

drum via the liquid phase depending on the temperature and con‐

centration of the commercial ammonia water product.

The built-in level switch in the metering vessel is therefore

designed to be intrinsically safe “i” with an explosion-proof design.

Pay attention to any static charge when connecting or replacing a

supply drum!

Information in the event of an emer‐

gency

Health hazards

First aid instructions

Note for the system operator

Turn the Emergency Stop switch to “0” in the event of an emer‐

gency or if liquid escapes from the system during pumping.

Refer to the material safety data sheet for ammonia water supplied

by the chemical supplier in the event of any accidents with

ammonia water.

If ammonia water escapes, evacuate the room, put on protective

equipment, seal the leak and, if necessary, collect the escaped sol‐

ution and dispose of!

Refer to the material safety data sheet for ammonia water provided

by the chemical supplier.

Refer to the material safety data sheet for ammonia water provided

by the chemical supplier.

Keywords when searching for the necessary regulations:

n Ammonia water systems

n Ammonia water

n Storage

n Hazardous substances

n Personal protective equipment

n Water protection

n Air protection

n ...

The “GESTIS Substance Database” published by the IFA Institute

for Occupational Health and Safety of the German Social Accident

Insurance provides valuable information.

Emissions

Direct contact with ammonia water may occur when changing over

the supply drum and during maintenance work. Observe the

instructions.

Emissions of ammonia gas are not expected due to the gas-tight

design of the storage tanks and the downstream exhaust air

adsorber. This is the case providing the adsorber is regularly

changed.

10

Page 11

Sound pressure level

Safety chapter

Sound pressure level LpA < 70 dB according to EN 3746

Protective equipment

Warning labels

The system is provided with the following protection equipment,

which prevents large quantities of ammonia from escaping, or the

resulting ignition of an ammonia water-air mixture:

n The level switch in the metering vessel prevents overflowing.

n The system is designed so that the transfer from the storage

tank to the metering vessel is via a vapour recovery line.

n The aeration and venting of the system is through an active

carbon filter, which absorbs the escaping ammonia gas.

n The lid of the dosing tank protects the user from ammonia gas.

It needs to be secured by a seal when operating with ammonia.

n The level switches in the metering vessel and in the dosing

tank are designed to be explosion-proof and intrinsically safe “i”

with an appropriate explosion-proof intrinsically safe “i” switch

amplifier.

Further recommendations, the implementation of which is however

outside our area of responsibility:

n Place the dosing tank in a collecting pan.

Affix workplace labels in line with the current regulations.

They might look like this in accordance with the German regula‐

tions governing printing of the operating instructions:

Warning of caustic substances

Use eye protection

Use safety gloves

Ensure that the warning label is always fitted and legible.

11

Page 12

Storage, transport, unpacking

5 Storage, transport, unpacking

Safety information

WARNING!

Warning of hazardous ammonia

Ammonia can escape in the event of damage.

– Make sure that the metering system is free

–

WARNING!

Only return metering pumps for repair in a cleaned

state and with a flushed liquid end - refer to

"Decommissioning!

Only return metering pumps with a completed

Decontamination Declaration form. The Declara‐

tion of Decontamination constitutes an integral part

of an inspection/repair order. A unit can only be

inspected or repaired when a Declaration of

Decontamination Form is submitted that has been

completed correctly and in full by an authorised

and qualified person on behalf of the pump oper‐

ator.

The "Declaration of Decontamination” form can be

found at www.prominent.com.

from ammonia prior to storage or transport.

Carefully protect the metering system against

mechanical damage, so that no one can be

endangered by escaping caustic ammonia

during subsequent operation.

WARNING!

Danger of leakage

The device can be damaged or leak by incorrect or

improper storage or transportation!

– Only store or transport the unit in its original

packaging.

–

The packaged device should also only be

stored or transported in accordance with the

stipulated storage conditions.

– The packaged device should be protected from

moisture and the ingress of chemicals.

CAUTION!

Danger of material damage

The device is top-heavy as long as the dosing tank

is empty.

– Bear this in mind when transporting it.

12

Page 13

Storage, transport, unpacking

Ambient conditions

Parameter Value

Minimum storage and transport temperature: 0 °C

Maximum storage and transport temperature: +50 °C

Minimum ambient temperature during operation: 0 °C

Maximum ambient temperature during operation*

at up to 15% ammonia water:

at up to 20% ammonia water:

at up to 25% ammonia water:

35°C

30°C

25°C

Max. temperature of the dilution water: 20°C

Maximum air humidity**: 92% relative humidity

* The higher the starting concentration, the lower the temperature

needs to be.

** non-condensing

Do not allow to stand in direct sunlight.

13

Page 14

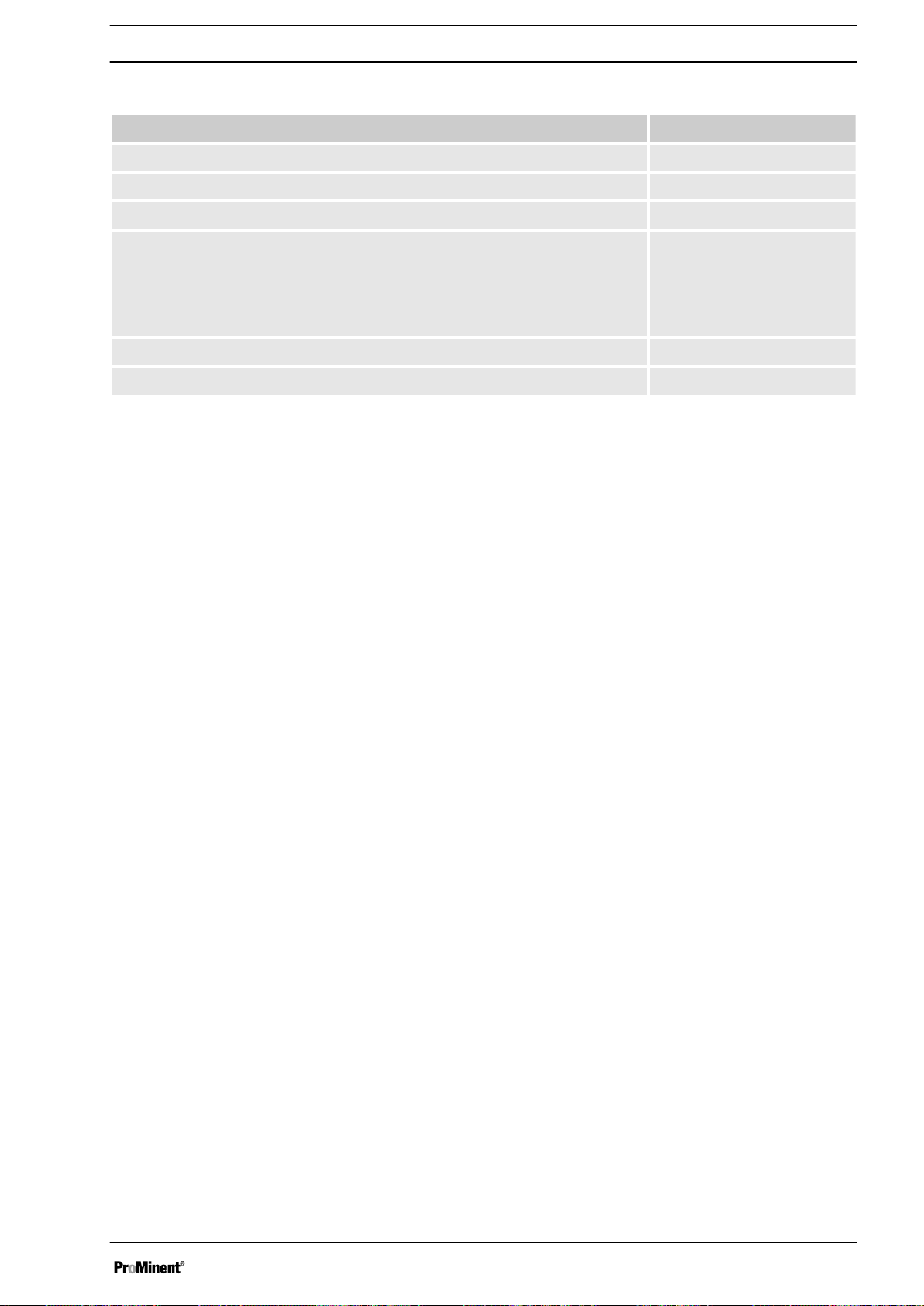

P_HYD_0011_SW.svg

Overview of equipment and control elements

6 Overview of equipment and control elements

Fig. 2: Overview of equipment: metering system DULCODOS® Ammonia

1 Supply drum (not in the scope of

delivery)

2 Suction lance with gas recovery (acces‐

sory)

3 Vapour recovery line

4 Transfer pump (with control elements)

5 Metering pump (for metering; with con‐

trol elements)

6 Injection valve

7 Chemical vapour lock

8 Stopcock (dilution water)

9 Metering vessel with level switch

10 Manual stirrer

11 Stopcock (metering vessel drainage)

12 Dosing tank with sprinkler

13 Suction assembly

14 Dosing tank level switch

15 Stopcock (rinsing water metering vessel)

16 Switch cabinet - see also Fig. 3

Not shown Collecting pan (accessory)

14

Page 15

1

2

P_HYD_0029_SW

Overview of equipment and control elements

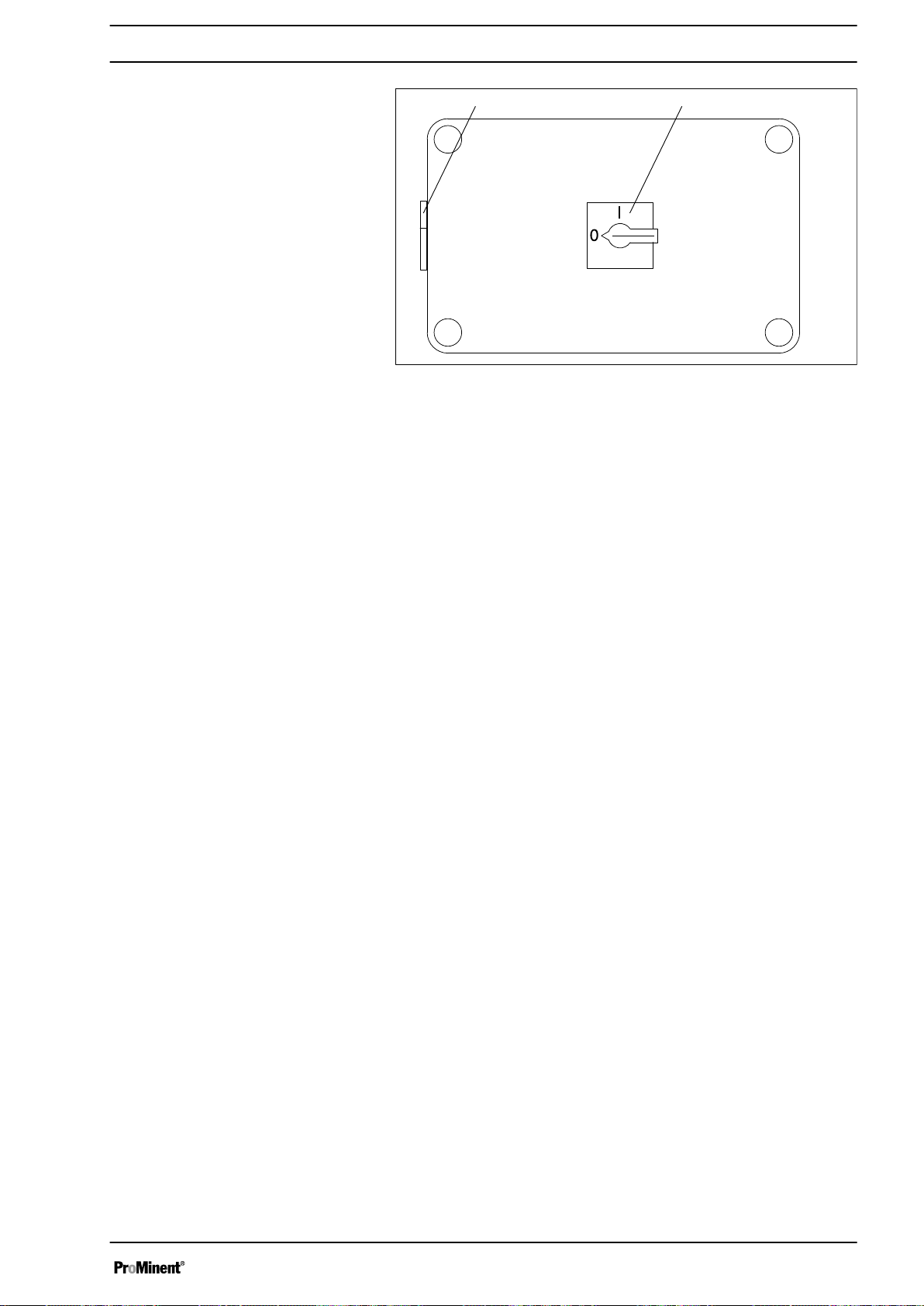

Fig. 3: Switch cabinet control elements(on the side of the system)

1 Main switch with Emergency Stop function

2 “Start filling metering vessel” key

15

Page 16

Functional description

7 Functional description

The DULCODOS® Ammonia system is used for the gas-tight

transfer and dilution to usual metering concentrations and then

automatic metering into the feed water.

The dosing tank (12) needs to be filled with de-ionised water to

batch a diluted usable ammonia water solution. The transfer pump

(4) semi-automatically fills concentrated ammonia water solution

(max. 25%) from the supply drum (1) into a metering vessel (9). An

appropriate amount of this concentrated solution from this metering

vessel needs to be left in the dosing tank to obtain a final concen‐

tration of between 0.1% ... 2.5%.

The manual stirrer (10) mixes the solution until it is homogeneous.

A chemical vapour lock (adsorber) (7) is fitted on the metering

vessel to prevent ammonia vapours from escaping into the envi‐

ronment.

The metering pump (5) meters the ready-to-use ammonia solution

from the dosing tank at the corresponding point of injection (6).

Metering can be provided on-demand using external control of the

metering pump.

Optional fault indicating relays on the pumps can report faults on a

control panel.

16

Page 17

8 Assembly

Safety information

Assembly

WARNING!

Warning of hazardous ammonia

Ammonia can escape if the system is not handled

correctly.

– Store and transport the metering system in its

original packaging. Take special precautions to

ensure that the metering system is protected

against mechanical damage

Select a suitable installation site for the

–

ammonia water metering system.

WARNING!

Danger of severe eye injuries

Immediately rinse the eyes in the event of

ammonia coming into contact with them.

– Provide an eye shower (with water connection)

directly adjacent to the installation site.

Requirements for the installation site

WARNING!

Warning of explosive atmospheres

An explosive air-ammonia mixture can form with

high concentrations of ammonia water – particu‐

larly above 15% w/w – or also at high ambient tem‐

peratures (at over 30 °C above 10% w/w).

– Note the current regulations and technical reg‐

ulations dealing with ammonia and ensure ade‐

quate ventilation.

CAUTION!

Observe the material safety data sheet

Observe the current material safety data sheet for

ammonia water.

The following must be available at the installation site:

n Water connector with eye shower (refer to the material safety

data sheet)

n Water connector for deionised water (dilution water and rinsing

water). Properties - refer to "Technical data" chapter

n Prevent the installation site from unauthorised access.

n Mains connection 230 V / 50 Hz for the system.

n An appropriate exhaust air duct for an exhaust air line from the

chemical vapour lock.

n Recommendation: There needs to be a gas detector fitted

n brick or masonry, leak-tight tray provided on site around the

installation site or a collecting pan with ribs on the inside (on

request).

n A horizontal, level and stable surface must be available for the

installation.

17

Page 18

Assembly

n The system must be secured against possible damage from

people, objects and mobile equipment, such as fork-lifts or

pallet trucks.

n There needs to be 1 metre clearance around the system for

maintenance purposes.

n The installation site must have continuous effective ventilation.

n Depending on the actual conditions on site, the installation site

for the system and supply drum may need to fulfil other

requirements in line with the applicable regulations and tech‐

nical rules!

n Take appropriate measures if any of the following chemicals

are stored at the installation site: phosphorus oxides, acids,

oxygen bottles, hydrogen sulphide (H2S), strong oxidising

agents, hydrogen peroxide (H2O2), zinc, nitric acid, ethylene

oxide, strong alkalis, chlorates, mercury, silver or hydrogen

bromide (HBr).

18

Page 19

9 Installation

P_HYD_0012_SW

1

2

3

Installation, hydraulic

9.1

Installation

WARNING!

Warning of hazardous ammonia solution

Ammonia solution will escape if the metering line

comes off or tears.

– Only fit lines of sufficient strength.

Note the resistance of the line material.

–

– Prevent the metering line from coming off

caused by back pressure or tearing. You may

wish to install a relief valve.

WARNING!

Warning of hazardous ammonia solution

Liquid from the application could press back

through the metering pump.

– Use an injection valve or vacuum breaker.

Personnel:

1.

Technical personnel

n

Screw together the units supplied for the metering system

DULCODOS® Ammonia as shown - see A:

1. - Chemical vapour lock

2. - Fastening bracket. Use it to screw the chemical vapour

lock to the metering vessel.

3. - Hand crank

19

Page 20

P_HYD_0033_SW

2

3

1

5

4

f

d

Installation

2. Make the internal piping connections - see B:

1. - “Transfer pump” (f) suction line to the suction lance for

the storage tank. Use hose clips!

2. - Vapour recovery line from the metering vessel to the

suction lance for the storage tank. Use hose clips!

3. Make the external pipe connections - see

Fig. 4:

1. - “Metering pump” (d) metering line to the installed injec‐

tion valve

2. - De-ionised water feed connector to fill the dosing tank

3. - Chemical vapour lock exhaust air line to the respective

exhaust air duct

20

Page 21

P_HYD_0013_SW_2

f

d

Installation

Fig. 4: External pipe connections

Note for the operator

An explosive atmosphere can form in the supply

drum with concentrations of over 15% w/w and/or

high ambient and media temperatures. If a spark

jumps as the suction lance is approaching the

open opening of the supply drum, it could cause

this atmosphere to explode.

Therefore take appropriate measures, such as the

following:

–

Use an earthing cable to ensure that the suc‐

tion lance and storage tank have the same

potential just before inserting the suction lance

into the storage tank.

–

Use suction lances with a level switch with

explosion protection for Zone 0.

–

Only connect the ammonia water to the system

in its original drum or in an electrically con‐

ducting vessel.

9.2 Installation, electrical

CAUTION!

The pump can start up again after a mains failure

– The operator needs to take appropriate meas‐

ures to rule out hazards that could arise during

this process when integrating the ammonia

metering system into a higher-level system.

21

Page 22

1

2

P_HYD_0029_SW

Installation

Personnel:

Electrician

n

1. Check whether the mains voltage is switched off!

2. Possibly: Connect a fault signalling alarm.

3. A remote demand can be connected to the metering pump

for metering the diluted ammonia solution into your process refer to “Operating instructions for solenoid metering pump

Beta b, BT4b and BT5b" and wiring diagram

"82_05-401_00_05-44".

4. Connect a mains cable from the switch cabinet (terminal strip

X0) to the mains voltage.

Fig. 5: Switch cabinet control elements(on the side of the system)

1 Main switch with Emergency Stop function

2 “Start filling metering vessel” key

22

Page 23

10 Start up

Safety information

10.1 Checking for leak-tightness

Materials required:

n Compressed air generator

n Leak spray

1. Fill the dosing tank using the dilution water tap.

2. Use a blanking cap to close the chemical vapour lock.

3. Open the bottom stopcock on the metering vessel.

4. Close the stopcock for dilution water.

5. Remove the threaded connector on the dilution water con‐

6. Screw the T-piece with manometer and compressed air con‐

7. Adjust the pressure reduction valve of the compressed air

8. Open the dilution water stopcock and fill the complete

9. Check the closed lid of the storage tank of the ammonia

10. Check the fastening points of the foot valve support pipe and

11. Check the tank flange for the metering vessel at the flange

12. Check the complete top part of the storage tank and the fas‐

13. Check the storage tank and storage tank base for cracks or

14. Check all adhesion points for leak-tightness on the complete

Start up

WARNING!

Hazardous ammonia water may escape

Hazardous ammonia water can escape from it if

the system is not operated correctly.

– Only allow authorised technical personnel to

start up the system!

nection.

nector onto the dilution water connector of the ammonia

water metering system.

supply to a test pressure of 80 mbar.

ammonia water metering system with compressed air until

the manometer displays a constant

cock on the test fitting. The test takes 5 minutes.

water metering system and the stirrer and its tank opening for

leaks (leak spray).

the level switch as well as the openings for the suction lines

and the level switch cable for leaks.

and the fixing bolts for leak-tightness as well as the openings

for the dilution water lines, the aerating and vent lines and

the filling line (with stopcock).

tening points of the fastening plate for the metering and

transfer pumps for leak-tightness.

other damage and leak-tightness.

pipework, on the threaded connectors and pipe connections,

on the metering vessel.

80 mbar. Close the stop‐

23

Page 24

A

P_HYD_0016_SW

f

d

Start up

15. Check all threaded connectors for leak-tightness:

n on the stopcocks

n on the dosing tank

n on the stopcock

n on the dilution water line

n on the chemical vapour lock

n on the metering vessel, as well as the float plug of the

level switch

16. Check that the housing of the chemical vapour lock is leaktight.

17. Check the vapour recovery line for leak-tightness at the con‐

nectors, the metering vessel and the suction line of the

transfer pump and on the test tank connection.

18. The pressure should not fall by more than

10 mbar after a

test time of 5 minutes.

19. The system can be started up if these conditions are met:

Remove the blanking cap on the chemical vapour lock again.

Re-connect the chemical vapour lock to the exhaust air duct.

20. Do not operate the system if the pressure falls by more than

10 mbar

!

Call ProMinent Service to rectify the leak.

10.2 Setting

1. Set the master switch on the terminal box to “I”.

2. If there is no voltage: Arrange for an electrical technician to

activate the automatic circuit breakers in the terminal box refer to the wiring diagram.

3. Set the “transfer pump” (f) to 100% stroke rate (multifunc‐

tional switch) and - while it is running - to 100% stroke length.

4. Use the stroke length and the stroke rate (multifunctional

switch) to adapt the “metering pump” (d) to the conditions of

your process - see also "Operating instructions for metering

pumps Beta BT4 and BT5".

Fig. 6: Operating elements

24

Page 25

1

2

P_HYD_0032_SW

Start up

Fig. 7: Adjusting the pump

1 Stroke length adjustment knob

2 Multifunctional switch

10.3 Functional test with dilution water

Note for the operator

An explosive atmosphere can form in the supply

drum with concentrations of over 15% w/w and/or

high ambient and media temperatures. If a spark

jumps as the suction lance is approaching the

open opening of the supply drum, it could cause

this atmosphere to explode.

Therefore take appropriate measures, such as the

following:

–

Use an earthing cable to ensure that the suc‐

tion lance and storage tank have the same

potential just before inserting the suction lance

into the storage tank.

–

Use suction lances with a level switch with

explosion protection for Zone 0.

–

Only connect the ammonia water to the system

in its original drum or in an electrically con‐

ducting vessel.

1. Close the bottom stopcock on the metering vessel and con‐

nect the dilution water line.

2. Fill the dosing tank through the dilution water line up to the

maximum level - 120 l or 250 l marking, dependent on the

tank size.

3. Close the stopcock on the dilution water line.

4. Completely fill the test tank (empty ammonia water supply

drum) with rinsing water, e.g. condensate or deionised water.

25

Page 26

Start up

5. Check the operation of the “transfer pump” and check that it

switches off via the level switch in the metering vessel: Start

up the “transfer pump” using the green key

[Start filling metering vessel]

(is the multifunctional switch

turned to “External”?) and fill the metering vessel until the

level switch is triggered and the “transfer pump” stops. At the

same time, check the parts, such as the “transfer pump”, suc‐

tion line, the line to the metering vessel and the metering

vessel itself for leak-tightness. Finally close the stopcock

once more.

6. Functional test of the “metering pump": Switch on the

“metering pump” at the multifunctional switch and bleed the

liquid end - see "Operating instructions for solenoid metering

pump Beta® BT4b and BT5b". Check the leak-tightness of

the “metering pump”, metering line and injection valve and

their threads. Finally switch off the “metering pump”.

7. Check whether the suction line and the vapour recovery line

are fastened to the suction lance with hose clips. Ensure the

line connectors are securely seated and check for leaks.

8. Only with concentrations above 15% w/w: Take appropriate

measures to prevent a spark jumping to ignite the ammoniaair atmosphere when attaching the suction lance to the

storage tank.

9. Replace the test tank with a storage tank.

10. After commissioning the ammonia water metering system,

carry out one more complete visual inspection to ensure its

final safety.

The ammonia water metering system can now be handed over for

operation.

26

Page 27

11 Operation

Batching ammonia water solution

Operation

WARNING!

Hazardous ammonia water solution may escape

If ammonia water solution is batched without

supervision, ammonia water solution can be

pressed out of the system.

– As batching is done in manual mode, the entire

process must be monitored from start to finish.

WARNING!

Hazardous ammonia vapours may escape.

Ammonia vapours will escape if the lid of the

dosing tank is open.

– The lid of the dosing tank must not and may

not be opened.

– The system must be shut down immediately

should the seal be missing on the lid and the

seal must be replaced by an authorised techni‐

cian.

CAUTION!

Only particle-free commercial ammonia water may

be used for batching.

Note for the operator

An explosive atmosphere can form in the supply

drum with concentrations of over 15% w/w and/or

high ambient and media temperatures. If a spark

jumps as the suction lance is approaching the

open opening of the supply drum, it could cause

this atmosphere to explode.

Therefore take appropriate measures, such as the

following:

–

Use an earthing cable to ensure that the suc‐

tion lance and storage tank have the same

potential just before inserting the suction lance

into the storage tank.

–

Use suction lances with a level switch with

explosion protection for Zone 0.

–

Only connect the ammonia water to the system

in its original drum or in an electrically con‐

ducting vessel.

Personal protective equipment

- always refer to the chemical supplier’s latest hazardous sub‐

stance data sheet and the latest regulations and materials safety

data sheets issued by the statutory accident prevention authorities.

27

Page 28

A

P_HYD_0016_SW

f

d

Operation

Eye protection:

Adequate eye protection must be worn. Wear goggles. Use a protective shield if the face

is also compromised.

Hand protection:

Use safety gloves. The glove material must be sufficiently impermeable and resistant to

the substance used.

Protective clothing:

Depending on the level of risk, wear a sufficiently long apron and boots or an appropriate

protective chemical suit.

Respiratory protection:

Wear respiratory protection in exceptional situations (e.g. in the event of accidental

release of the substance, exceeding of the occupational exposure limit): Gas filter K,

green colour code (Germany). Note the limits on time of wearing!

Use an isolation unit with concentrations above the application limit of filter equipment,

with oxygen contents bellow 17 vol% or in the event of unclear conditions!

Fig. 8: Operating elements

1 Multifunctional switch

2 Stopcock (dilution water)

3 Metering vessel

4 Manual stirrer

5 Stopcock (metering vessel drainage)

A Flushing connector - see next figure

Personnel:

Instructed personnel

n

1. Check whether the “metering pump” (d) is set to “Stop".

2. Check whether the “transfer pump” (f) is set to “100”.

3. Set the main switch to "I".

28

Page 29

6

2

5

P_HYD_0030_SW

Operation

Fig. 9: Detail A: Flushing connector and stopcocks

2 Stopcock (dilution water)

5 Stopcock (metering vessel drainage)

6 Stopcock (rinsing water metering vessel)

4. Open the dilution water stopcock (2) and fill the dosing tank

until half full.

WARNING!

The dosing tank needs to be filled with dilu‐

tion water to at least halfway – due to the

system’s internal explosion protection.

5. Open the bottom stopcock (5) on the metering vessel. Drain

any remains in the metering vessel through this stopcock into

the dosing tank.

The ammonia passes into the dosing tank through a pipe

ð

below the water level.

6. Start the “transfer pump” using the “Start filling metering

vessel” key.

It pumps ammonia water from the supply drum into the

ð

metering vessel (3).

The transfer pump level switch is triggered when the

maximum liquid level is reached**.

29

Page 30

Operation

7. Open the bottom stopcock (5) on the dilution water metering

vessel.

The ammonia passes into the dosing tank through a pipe

ð

below the water level.

Steps 5 and 6 can be repeated several

times if the required final concentration

needs several top-ups of the metering

vessel.

WARNING!

Note the following to ensure that the

ammonia concentration in the dosing

tank remains below the explosion limit:

– With starting solutions of 25% w/w

ammonia in water:

A maximum of 6 top-ups of the

metering vessel can be added to the

“120 l” dosing tank.

A maximum of 5 top-ups of the

metering vessel can be added to the

“250 l” dosing tank.

This ensures that the maximum per‐

mitted metering solution of 2.5% w/w

is not exceeded. Correspondingly

more top-ups are needed with lower

starting solutions.

8. Open the stopcock (6) – briefly flush the metering vessel with

the dilution water and re-close the stopcock (6).

9. Wait until the metering vessel has emptied and then close

the stopcock (5).

10. Open the stopcock (2) for dilution water and allow as much

water to flow into the dosing tank until the required concen‐

tration has been reached.

WARNING!

Hazardous ammonia water solution may

escape

Overfilling can cause hazardous ammonia

water solution to escape.

– Fill the dosing tank at most up to the top

marking (120 l or 250 l marking)

11. Use the manual stirrer (4) to stir for approximately 15 s to

obtain a homogeneous solution.

12. Set the multifunctional switch on the “metering pump” to the

required frequency or to “External”.

The “metering pump” can now meter the diluted ammonia

ð

water into the application.

30

Page 31

Tab. 2: **

Dosing tank

Volume, nominal

Dosing tank

Volume, usable

l l l

130 120 2

250 250 5

Operation

Metering vessel

Volume, usable

Adjusting the capacity

Replacing the storage tank

The capacity can be adjusted using both the stroke rate (multifunc‐

tional switch) and the stroke length - see the attached "Operating

instructions for solenoid metering pump Beta® BT4 and BT5".

WARNING!

Drops of hazardous ammonia water could be

released

Drops of ammonia water can spill when changing

the supply drum.

– Take appropriate protective measures as out‐

lined in the material safety data sheet when

working on the system.

WARNING!

Hazardous ammonia water can escape

Ammonia water can escape if the supply drum is

not handled correctly.

WARNING!

Warning of explosive atmospheres

An explosive air-ammonia mixture can form with

high concentrations of ammonia water – particu‐

larly above 15% w/w – or also at high ambient tem‐

peratures (at over 30 °C above 10% w/w).

– Note the current regulations and technical reg‐

ulations dealing with ammonia and ensure ade‐

quate ventilation.

31

Page 32

Operation

Note for the operator

An explosive atmosphere can form in the supply

drum with concentrations of over 15% w/w and/or

high ambient and media temperatures. If a spark

jumps as the suction lance is approaching the

open opening of the supply drum, it could cause

this atmosphere to explode.

Therefore take appropriate measures, such as the

following:

–

Use an earthing cable to ensure that the suc‐

tion lance and storage tank have the same

potential just before inserting the suction lance

into the storage tank.

–

Use suction lances with a level switch with

explosion protection for Zone 0.

–

Only connect the ammonia water to the system

in its original drum or in an electrically con‐

ducting vessel.

As soon as the supply drum is empty, replace it with a full

original supply drum.

32

Page 33

12 Maintenance

Safety information

Maintenance

WARNING!

It is mandatory that you read the safety information

and specifications in the "Storage, Transport and

Unpacking" chapter prior to shipping the pump.

WARNING!

Warning of explosive atmospheres

An explosive air-ammonia mixture can form with

high concentrations of ammonia water – particu‐

larly above 15% w/w – or also at high ambient tem‐

peratures (at over 30 °C above 10% w/w).

– Note the current regulations and technical reg‐

ulations dealing with ammonia and ensure ade‐

quate ventilation.

WARNING!

Hazardous ammonia vapours or ammonia water

may escape

Hazardous ammonia vapours will escape if the

dosing tank or the supply drum need to be opened.

– Wear suitable personal protective equipment -

see below.

Personal protective equipment

Eye protection:

Adequate eye protection must be worn. Wear goggles. Use a protective shield if the face

is also compromised.

Hand protection:

Use safety gloves. The glove material must be sufficiently impermeable and resistant to

the substance used.

Protective clothing:

Depending on the level of risk, wear a sufficiently long apron and boots or an appropriate

protective chemical suit.

Respiratory protection:

Wear respiratory protection in exceptional situations (e.g. in the event of accidental

release of the substance, exceeding of the occupational exposure limit): Gas filter K,

green colour code (Germany). Note the limits on time of wearing!

- always refer to the chemical supplier’s latest hazardous sub‐

stance data sheet and the latest regulations and materials safety

data sheets issued by the statutory accident prevention authorities.

Use an isolation unit with concentrations above the application limit of filter equipment,

with oxygen contents bellow 17 vol% or in the event of unclear conditions!

33

Page 34

Maintenance

Daily inspections

Inspection point Personnel

Check the surroundings of the system for the smell of ammonia. Technical personnel

Inspect the system for damage. Technical personnel

Check whether the seal on the dosing tank is damaged. Technical personnel

Stop the system and immediately have it repaired if one of these

points applies!

Maintenance work

Interval Maintenance work Personnel

monthly Check the ammonia water metering system to ensure it is in cor‐

rect working order.

Check whether the lines to the ammonia water metering system

and downstream of it are brittle or worn.

Visually check whether the electrical insulation of all cables to

the metering system and the supply lines are intact.

annually Replace the pump diaphragms - see "Operating instructions for

solenoid metering pump Beta BT4 and BT5".

quarterly Check the pump diaphragms for damage and replace if neces‐

sary - see "Operating instructions for solenoid metering pump

Beta BT4 and BT5".

every six months

Replace the chemical vapour lock - refer to

chemical vapour lock’ on page 34

.

Ä ‘Replacing the

Check the ammonia water metering system for leak-tightness

Ä Chapter 10.1 ‘Checking for leak-tightness’ on page 23

see

.

Record the result of the leak tightness test. Technical personnel

Replacing the chemical vapour lock

WARNING!

Hazardous ammonia water may escape

Ammonia water may escape when carrying out the

work listed below.

– Therefore always flush the system first, see

Ä Chapter 15 ‘Decommissioning and disposal’

on page 38

!

– Refit the new chemical vapour lock to the metal

bracket so that it cannot break off!

– Properly dispose of the chemical vapour lock!

Technical personnel

Technical personnel

Electrician

Technical personnel

Technical personnel

Technical personnel

Technical personnel

1.

Flush the ammonia water metering system see

‘Decommissioning and disposal’ on page 38

Ä Chapter 15

.

2. Dismantle the old chemical vapour lock.

3. Fit the new chemical vapour lock.

4. Refit the new chemical vapour lock to the metal bracket so

that it cannot break off!

5. Properly dispose of the chemical vapour lock!

34

Page 35

13 Repair

Repair

WARNING!

It is mandatory that you read the safety information

and specifications in the "Storage, Transport and

Unpacking" chapter prior to shipping the pump.

WARNING!

Hazardous ammonia water may escape

Ammonia water may escape when working on the

system.

– Therefore always flush the system first, see

Ä Further information on page 38

– Wear tightly fitting safety goggles and suitable

safety gloves when working on the system!

– Wear respiratory protection in exceptional sit‐

uations (e.g. in the event of accidental release

of the substance, exceeding of the occupa‐

tional exposure limit): Gas filter K, green colour

code (Germany). Note the limits on time of

wearing!

Use an isolation unit with concentrations above

the application limit of filter equipment, with

oxygen contents bellow 17 vol% or in the event

of unclear conditions!

– Only use the correct, high quality original spare

parts!

– On completion of the work, check the system

for leak-tightness!

!

WARNING!

Warning of explosive atmospheres

An explosive air-ammonia mixture can form with

high concentrations of ammonia water – particu‐

larly above 15% w/w – or also at high ambient tem‐

peratures (at over 30 °C above 10% w/w).

– Note the current regulations and technical reg‐

ulations dealing with ammonia and ensure ade‐

quate ventilation.

WARNING!

Warning of explosive atmospheres

Only allow an electrical technician qualified in

ATEX explosion protection to carry out tests and

repairs on the level switches and switch amplifiers

used here.

35

Page 36

Repair

Flushing the system

WARNING!

Hazardous ammonia water may escape

The ammonia water metering system contains the

remains of ammonia water.

– Wear suitable protective equipment - refer to

the chemical supplier’s material safety data

sheet.

1. Replace an ammonia supply drum with one that is filled with

water.

2. Completely fill the metering vessel with water at least twice

and drain into the dosing tank through the ball valve.

36

Page 37

14 Troubleshooting

Troubleshooting

WARNING!

It is mandatory that you read the safety information

and specifications in the "Storage, Transport and

Unpacking" chapter prior to shipping the pump.

WARNING!

Hazardous ammonia water may escape

Ammonia water may escape when working on the

system.

– Therefore always flush the system first, see

Ä Further information on page 38

– Wear tightly fitting safety goggles and suitable

safety gloves when working on the system!

– Wear respiratory protection in exceptional sit‐

uations (e.g. in the event of accidental release

of the substance, exceeding of the occupa‐

tional exposure limit): Gas filter K, green colour

code (Germany). Note the limits on time of

wearing!

Use an isolation unit with concentrations above

the application limit of filter equipment, with

oxygen contents bellow 17 vol% or in the event

of unclear conditions!

– Only use the correct, high quality original spare

parts!

– On completion of the work, check the system

for leak-tightness!

!

WARNING!

Warning of explosive atmospheres

An explosive air-ammonia mixture can form with

high concentrations of ammonia water – particu‐

larly above 15% w/w – or also at high ambient tem‐

peratures (at over 30 °C above 10% w/w).

– Note the current regulations and technical reg‐

ulations dealing with ammonia and ensure ade‐

quate ventilation.

WARNING!

Warning of explosive atmospheres

Only allow an electrical technician qualified in

ATEX explosion protection to carry out tests and

repairs on the level switches and switch amplifiers

used here.

If necessary, refer to the operating instructions for the

metering pumps when troubleshooting.

37

Page 38

Decommissioning and disposal

15 Decommissioning and disposal

15.1

Flushing the system

15.2

Decommissioning

Disposal

WARNING!

Hazardous ammonia water may escape

The ammonia water metering system contains the

remains of ammonia water.

– Flush the system with dilution water - see

"Flushing the system".

Wear suitable protective equipment - refer to

–

the chemical supplier’s material safety data

sheet.

1. Replace an ammonia supply drum with one that is filled with

water.

2. Completely fill the metering vessel with water at least twice

and drain into the dosing tank through the ball valve.

The “transfer pump”, for instance, could then be removed.

WARNING!

Hazardous ammonia water may escape

The ammonia water metering system contains the

remains of ammonia water.

– Flush the system with dilution water - see

Ä Further information on page 38

– Correctly dispose of the dilution water.

– Wear tightly fitting safety goggles and suitable

safety gloves!

– Wear respiratory protection in exceptional sit‐

uations (e.g. in the event of accidental release

of the substance, exceeding of the occupa‐

tional exposure limit): Gas filter K, green colour

code (Germany). Note the limits on time of

wearing!

Use an isolation unit with concentrations above

the application limit of filter equipment, with

oxygen contents bellow 17 vol% or in the event

of unclear conditions!

CAUTION!

Warning about non-compliance with disposal regu‐

lations

Non-observation of disposal regulations can lead

to environmental damage or problems with the

authorities.

– Note the pertinent regulations currently appli‐

cable in your country!

.

38

Page 39

Decommissioning and disposal

CAUTION!

Warning against incorrect disposal

Incorrect disposal can lead to environmental

damage or problems with the authorities.

– Please also observe the information in the

operating instructions for the metering pumps!

WARNING!

Warning of explosive atmospheres

An explosive air-ammonia mixture can form with

high concentrations of ammonia water – particu‐

larly above 15% w/w – or also at high ambient tem‐

peratures (at over 30 °C above 10% w/w).

– Note the current regulations and technical reg‐

ulations dealing with ammonia and ensure ade‐

quate ventilation.

39

Page 40

Technical data

16 Technical data

CAUTION!

Warning about operation without reference to the

technical data

Failure to observe the technical data could lead to

problems with the ammonia water metering

system!

– Refer to the technical data on the ammonia

water metering system.

Observe the information in the operating

–

instructions for the metering pumps.

16.1 Technical data for the complete system

Ammonia water metering systems

DULCODOS® Ammonia

Tab. 3

Dosing tank

volume, nom‐

inal

Dosing tank

volume,

usable

Metering

vessel, usable

Metering

pump

Capacity

Transfer

pump

Delivery

height

Transfer

pump

Pump

capacity

Order no.

l l l l / h bar l / h

130 120 2 7 4 approx. 15 1039192

250 250 5 7 2 approx. 36 1039193

Dimensions and weights, metering

system with 130 l

Dimensions and weights, metering

system with 250 l

Data Value Unit

Width 520 mm

Height 1,650 mm

Depth 600 mm

Net weight, approx. 23 kg

Gross weight, approx. 160 kg

Diluting water connector, hose nozzle DN10

Max. operating pressure of dilution

water

Filling capacity, max. 1 m³/h

Data Value Unit

Width: 650 mm

3 bar

Height: 2,120 mm

Depth 650 mm

Net weight, approx.: 35 kg

Gross weight, approx.: 280 kg

40

Page 41

Technical data

Data Value Unit

Diluting water connector, hose nozzle: DN10

Max. operating pressure of dilution

3 bar

water:

Filling capacity, max. 2 m³/h

Ambient conditions

Parameter Value

Minimum storage and transport temperature: 0 °C

Maximum storage and transport temperature: +50 °C

Minimum ambient temperature during operation: 0 °C

Maximum ambient temperature during operation*

at up to 15% ammonia water:

at up to 20% ammonia water:

at up to 25% ammonia water:

35°C

30°C

25°C

Max. temperature of the dilution water: 20°C

Maximum air humidity**: 92% relative humidity

* The higher the starting concentration, the lower the temperature

needs to be.

** non-condensing

Do not allow to stand in direct sunlight.

Degree of protection

Sound pressure level

Protection against contact and moisture:

IP 54 according to IEC 60529:1989 + A1:1999 + A2:2013

Sound pressure level LpA < 70 dB according to EN 3746

41

Page 42

Technical data

16.2 Materials and properties of the components

Ammonia water metering system, 130

l

1x - Metering pump Beta® BT4B0708NPE0000UA104H00,

capacity 7.1 l/h at max. back pressure 7.0 bar. Find more

detailed information in your operating instructions.

1x - Metering pump Beta® BT5B0420NPE0000UA104H00, used

as a transfer pump, pump capacity

17.1 l/h at max. back

pressure 4 bar. Find more detailed information in your oper‐

ating instructions.

1x - PE dosing tank, volume 130 l, with litre scale and lockable

screw lid, "gas-tight version"

1x - Complete PVC suction assembly, "gas-tight version"

(installed in the dosing tank)

1x - Electrical level switch with support pipe (installed in the

dosing tank)

1x - PVC manual stirrer, "gas-tight version"

1x - Fastening plate for mounting the metering pumps on the

storage tank

1x - Metering vessel, transparent PVC, volume 2 l, with electrical

level switch for switching off the transfer pump when it rea‐

ches a high level, as well as the necessary hoses

1x - Chemical vapour lock

1x - PVC ball valve, d16, NW10 with pipework

1x - 1.4571 stainless steel injection valve , connector 8 mm-1/2“

1x - Metering line PE 8/5 mm, 5 m

1x - Suction lance with vapour recovery

1x - Suction line PVC 12 x 9 mm, 1.5 m

1x - Vapour recovery line PVC 8 x 5 mm, 1,5 m

1x - Switch amplifier

1x - Metering vessel level switch, intrinsically safe “i”

1x - Dosing tank level switch, intrinsically safe “i”

42

Page 43

Ammonia water metering system, 250

l

Technical data

1x - Metering pump Beta® BT5B0713NPE0300UA104H00,

capacity 11.0 l/h at max. back pressure 7.0 bar. Find more

detailed information in your operating instructions.

1x - Metering pump Beta®

BT5B0232NPE0000UA104H00, used

as a transfer pump, pump capacity 32.0 l/h at max. back

pressure 2 bar. Find more detailed information in your oper‐

ating instructions.

1x - PE dosing tank, volume 250 l, with litre scale and lockable

screw lid, "gas-tight version"

1x - Complete PVC suction assembly, "gas-tight version"

(installed in the dosing tank)

1x - Electrical level switch with support pipe (installed in the

dosing tank)

1x - PVC manual stirrer, "gas-tight version"

1x - Fastening plate for mounting the metering pumps on the

storage tank

1x - Metering vessel, transparent PVC, volume 5 l, with electrical

level switch for switching off the transfer pump when it rea‐

ches a high level, as well as the necessary hoses

1x - Chemical vapour lock

1x - PVC ball valve, d16, NW10 with pipework

1x - 1.4571 stainless steel injection valve , connector 12 mm-1/2“

1x - Metering line PE 12/9 mm, 5 m

1x - Suction lance with vapour recovery (optional)

1x - Suction line PVC 12 x 9 mm, 1.5 m

1x - Vapour recovery line PVC 8 x 5 mm, 1,5 m

1x - Switch amplifier

1x - Metering vessel level switch, intrinsically safe “i”

1x - Dosing tank level switch, intrinsically safe “i”

Dosing tank, assembled

Injection valve

PE dosing tank, gas-tight screw lid, gas-tight PVC manual stirrer,

transparent PVC metering container with drain tap, connectors for

filling line, vapour recovery line, vent and bleed valve, with chem‐

ical vapour lock, dilution water line with stopcock, all connectors

PVC gas-tight, water line connector R 1/2".

1.4571 stainless steel injection valve with support insert for con‐

nection to a plastic line:

n 8 mm - for

130 l system

n 12 mm - for 250 l system

The injection valve is equipped with a 1/2" nipple for fixing to the

point of injection.

43

Page 44

Spare parts and accessories

17 Spare parts and accessories

17.1

Metering system, 130 l

Spare parts

Tab. 4: For “metering pump” Beta® BT4b 0708 NPE0000UA104H00:

Description Order no.

Beta® BT4b 0708 NPE0000UA104H00 without bleed valve

Dosing head with suction/pressure connector, without diaphragm,

without connector kit

Connector kit 8x5 817048

Metering diaphragm 46.0x21.5 1000248

Pressure connector M20x1.5 1000500

Suction connector M20x1.5 1000498

1036869

1000481

Tab. 5: For “transfer pump” Beta® BT4b 0420 NPE0000UA104H00:

Description Order no.

Beta® BT5b 0420 NPE0000UA104H00 without bleed valve

Dosing head with suction/pressure connector, without diaphragm,

without connector kit

1036868

1000483

Connector kit 12x9 817049

Metering diaphragm 70.0x33.5 1000250

Pressure connector M20x1.5 1000500

Suction connector M20x1.5 1000498

Tab. 6: Miscellaneous parts:

Description Order no.

Chemical vapour lock 1039761

Metering vessel, 2 l 809860

Manual stirrer, 130 l 809803

Suction lance with vapour recovery on request

Switch amplifier 1039412

Metering vessel level switch, intrinsically safe “i” 1022183

Dosing tank level switch, intrinsically safe “i” 1040746

44

Page 45

Spare parts and accessories

Metering system, 250 l

Tab. 7: For “metering pump” Beta® BT5b 0713 NPE0300UA104H00:

Description Order no.

Beta® BT5b 0713 NPE0300UA104H00 without bleed valve

Dosing head with suction/pressure connector, without diaphragm, without

1037109

1000482

connector kit

Connector kit 8x5 817048

Metering diaphragm 55.0x26.0 1000249

Pressure connector M20x1.5 1000500

Suction connector M20x1.5 1000498

Tab. 8: For “transfer pump” Beta® BT4b 0232 NPE0000UA104H00:

Description Order no.

Beta® BT5b 0232 NPE0000UA104H00 without bleed valve

Dosing head with suction/pressure connector, without diaphragm, without

1037108

1000484

connector kit

Connector kit 12x9 817049

Metering diaphragm 91.0x46.0 1000251

Pressure connector M20x1.5 1000500

Suction connector M20x1.5 1000498

Tab. 9: Miscellaneous parts:

Description Order no.

Chemical vapour lock 1039761

Metering vessel, 5 l 809861

Manual stirrer, 250 l 809813

Suction lance with vapour recovery on request

Switch amplifier 1039412

Metering vessel level switch, intrinsically safe “i” 1022183

Dosing tank level switch, intrinsically safe “i” 1040746

17.2 Accessories

Description Order no.

Collecting pan 200 l with design certification and grid on request

Collecting pan 1000 l with design certification and grid on request

45

Page 46

P_HYD_0014_SW-2

500

860

Ø 500

520

1650

230

200

Dimensional drawings

18 Dimensional drawings

DULCODOS® Ammonia 130 l

CAUTION!

There needs to be 1 metre clearance around the

system for maintenance purposes.

Fig. 10: Dimensional drawing of DULCODOS® Ammonia 130 l (dimensions in mm)

* Storage tank, to be provided by the customer

46

Page 47

P_HYD_0015_SW-2

750

1100

2120

230

200

Ø 650

DULCODOS® Ammonia 250 l

Dimensional drawings

Fig. 11: Dimensional drawing of DULCODOS® Ammonia 250 l (dimensions in mm)

* Storage tank, to be provided by the customer

47

Page 48

Declaration of Conformity for Machinery

19 Declaration of Conformity for Machinery

In accordance with DIRECTIVE 2006/42/EC OF THE EUROPEAN

PARLIAMENT AND OF THE COUNCIL, Appendix I, BASIC

HEALTH AND SAFETY REQUIREMENTS, section 1.7.4.2. C.

We hereby declare

n ProMinent GmbH

n Im Schuhmachergewann 5 - 11

n D - 69123 Heidelberg, Germany,

hereby declare that the product specified below complies with the

relevant basic health and safety requirements of the EC Directive

on the basis of its functional concept and design and in the version

marketed by us.

Tab. 10: Excerpt from the Declaration of Conformity

Designation of the product:

Product type: Metering system for ammonia water

DULCODOS® Ammonia

Material numbers: 1039192, 1039193

Serial number: see nameplate on the unit

Relevant directives: Machinery Directive (2006/42/EC)

EMC Directive (2014/30/EC)

Compliance with the protection targets of the Low Voltage Directive

2014/35/EU according to Appendix I, No. 1.5.1 of the Machinery Direc‐

tive 2006/42/EC

Applied harmonised standards:

EN ISO 12100:201

EN 60204-1:2006/A1:2009

EN 809:1998 + A1:2009 +

AC:2010

EN ISO 14123-1:2015

Date: 12.06.2018

Safety of machinery - general design principles- risk assessment and risk

minimisation

Safety of machinery - electrical equipment of machines - Part 1: General

requirements (IEC 60204- 1:2005 (modified))

Pumps and pump units for liquids - General safety requirements

Safety of machinery - Reduction of risks to health resulting from haz‐

ardous substances emitted by machinery -- Part 1: Principles and specifi‐

cations for machinery manufacturers

You can download the Declaration of Conformity at www.promi‐

nent.com.

48

Page 49

20 Index

Index

A

About the product ......................... 6

Accessories .............................44

Adjusting the capacity ..................... 31

Ambient conditions .................... 13, 41

Appendix ...............................46

Assembly .............................. 17

B

Batching ............................... 27

Batching ammonia water solution ............ 27

C

Checking for leak-tightness ................. 23

Chemical vapour lock ..................... 14

Collecting pan ........................... 45

Control elements .........................14

D

Declaration of Conformity .................. 48

Declaration of Decontamination ............. 12

Decommissioning ........................ 38

Degree of protection ...................... 41

Dimensional drawings ..................... 46

Dimensions .......................... 40,

Disposal ............................... 38

Dosing tank .......................... 14, 43

Drum adapter ........................... 14

46

E

Emergency ............................. 10

Emergency stop switch .................... 14

Emissions .............................. 10

EU Declaration of Conformity ............... 48

F

Filling the metering vessel ..................14

First Aid ................................10

Flushing the system ...................... 38

Functional description ..................... 16

H

Health hazards .......................... 10

I

Information .............................. 2

Information in the event of an emergency ...... 10

Injection valve ........................ 14, 43

Installation site .......................... 17

Installation, electrical ......................21

Installation, hydraulic ......................19

Instructions .............................. 2

Intended use ............................. 7

IP .................................... 41

L

Labelling of safety information ................7

Leak-tightness ...........................23

Level switch ............................ 14

M

Maintenance ............................ 33

Manual stirrer ........................... 14

Materials and properties ................... 42

Metering pump .......................... 14

Metering vessel ..........................14

N

Notes for the system operator ................ 2

O

On/Off switch ........................... 14

Operation .............................. 27

Overview of equipment .................... 14

P

Performance data ...................... 5, 40

Potential danger from this system ............. 9

Protection against contact and moisture ....... 41

Protective equipment ..................... 11

Q

Qualification of personnel ................... 8

R

Repair ................................. 35

Replacing the storage tank ................. 31

Requirements for the installation site ..........17

Rinsing ................................ 38

S

Safety chapter ............................7

Setting .................................24

Sound pressure level ...................11, 41

49

Page 50

Index

Spare parts ............................. 44

Start filling metering vessel ................. 14

Start up ................................ 23

Stopcock ............................... 14

Storage ................................ 12

Suction assembly ........................ 14

Supplementary information .................. 2

Supply drum ............................ 14

T

Technical data ...........................40

Transport .............................. 12

Troubleshooting ......................... 37

Type list ..............................5

, 40

V

Vapour recovery line ...................... 14

W

Warning symbol .......................... 7

Weight .................................40

50

Page 51

51

Page 52

ProMinent GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg

Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

981962, 2, en_GB

© 2019

Loading...

Loading...