Page 1

DULCODOS® Pool

DSPa, R01, C01, V01, B01

Assembly and operating instructions

A1114

Original Operating Instructions (2006/42/EC)Part number 985541 BA DD 020 05/12 EN

Please carefully read these operating instructions before use! · Do not discard!

The operator shall be liable for any damage caused by installation or operating errors!

Technical changes reserved.

Page 2

985541, 1, en_GB

© 2012

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5 - 11

69123 Heidelberg

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

email: info@prominent.de

Internet: www.prominent.com

2

Page 3

In order to make it easier to read, this document uses the male

form in grammatical structures but with an implied neutral sense. It

is aimed equally at both men and women. We kindly ask female

readers for their understanding in this simplification of the text.

Read the following supplementary information in its entirety!

The following are highlighted separately in the document:

n Enumerated lists

Instructions

ð

Results of the instructions

Information

This provides important information relating to the cor‐

rect operation of the system or is intended to make

your work easier.

Safety information

Safety information are provided with detailed descriptions of the

endangering situation, see

Ä Chapter 3.2 ‘Explanation of the

safety information’ on page 10

General non-discriminatory approach

Supplementary information

Supplemental instructions

3

Page 4

Table of contents

1

Identity code.......................................................................... 5

2 About this product................................................................. 7

2.1 Overview of equipment................................................. 7

3 Safety and responsibility....................................................... 9

3.1 Users' qualifications...................................................... 9

3.2 Explanation of the safety information.......................... 10

3.3 General Safety Information......................................... 11

3.4 Correct and proper use............................................... 12

4 Storage and transport......................................................... 14

5

Assembly............................................................................ 15

5.1 Wall mounting............................................................. 15

5.2 Fit the antikink device for the bleed line...................... 16

5.3 Hydraulic installation................................................... 17

5.3.1 Metering system...................................................... 18

5.3.2 Sensors.................................................................... 20

5.4 Electrical installation................................................... 21

6 Start up............................................................................... 22

6.1 Priming and bleeding.................................................. 23

6.2 Adjust the flow sensor switching point........................ 23

6.3 Calibration................................................................... 23

7 Maintenance....................................................................... 29

7.1 Maintenance work....................................................... 29

7.2 Troubleshooting.......................................................... 31

7.3 Disposal of used parts................................................ 31

8 Technical data..................................................................... 32

9 Systems.............................................................................. 34

9.1 Spare parts and accessories...................................... 34

9.2 EC Declaration of Conformity..................................... 35

10 Index................................................................................... 37

Table of contents

4

Page 5

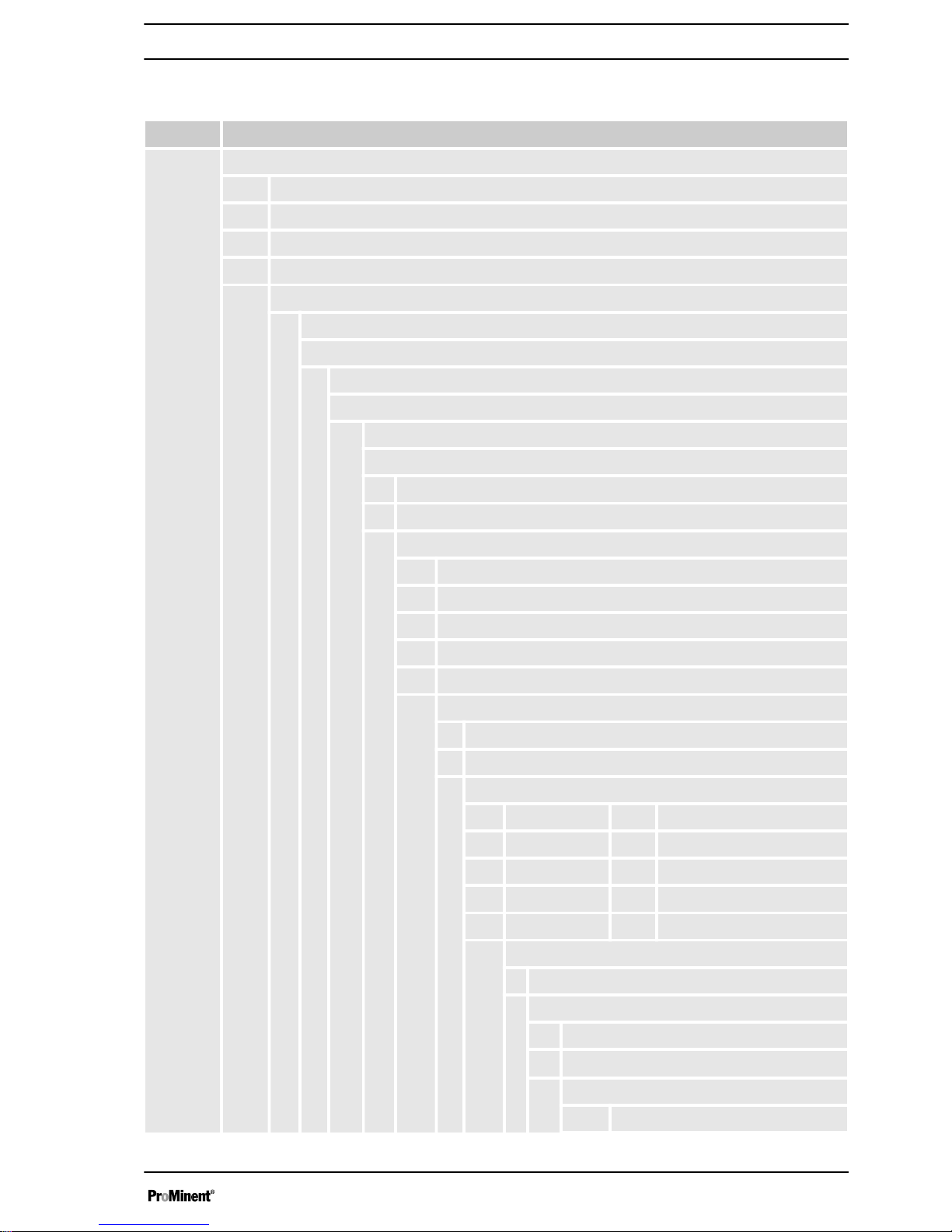

1

Identity code

DSPa

DULCODOS® Pool

Measured variable:

R01 Redox (D1C)

C01 Free chlorine (D1C)

V01 Total chlorine (D1C)

B01 Bromine (D1C)

Hardware auxiliary functions:

0 Standard

Software auxiliary functions:

0 none

Communication interfaces:

0 none

Electrical connection:

A 230 V, 50/60 Hz, European standard plug

B 230 V, 50/60 Hz, Swiss plug

Sensor equipment:

0 with sensors

2 Measured variable R01 without sensors

3 Measured variable C01 without sensors

4 Measured variable V01 without sensors

5 Measured variable B01 without sensors

Version:

0 with logo

1 without logo

Language**:

A Swedish H Swiss

D German I Italian

E English N Dutch

F French P Polish

G Czech S Spanish

Metering pumps for acid / alkali:

0 without metering pumps

Multifunctional valve for acid/alkali pump:

0 none

1

with MFV (only for Beta®)

Metering pumps for disinfection:

0 without metering pumps

Identity code

5

Page 6

DSPa

DULCODOS® Pool

1

0.8 l/h DULCO®flex for up to 45/10

m3/h circulation HB/FB*

2

1.6 l/h DULCO®flex for up to

100/20 m3/h circulation HB/FB*

3

2.4 l/h DULCO®flex for up to

140/30 m3/h circulation HB/FB*

4

1.8 l/h alpha for up to 100/20 m3/h

circulation HB/FB*

5

3.5 l/h alpha for up to 200/40 m3/h

circulation HB/FB*

6

0.9 l/h Beta®flex for up to 50/10

m3/h circulation HB/FB*

7

2.1 l/h Beta®flex for up to 125/25

m3/h circulation HB/FB*

8

3.9 l/h Beta®flex for up to 225/45

m3/h circulation HB/FB*

Multifunctional valve for disinfec‐

tion pump

0 none

1

with MFV (only for Beta® and

alpha)

Assembly

0 supplied loose without

assembly plate

1 assembled on a base plate

Certification

0 with CE mark

* Calculated for 12 % sodium-calcium hypochlorite:

n HB = Indoor swimming pool

n FB = Outdoor swimming pool

** Other languages upon request

Identity code

6

Page 7

2

About this product

DULCODOS®

Pool metering systems are specifically designed for

the treatment of swimming pool water. Ready mounted, fully-wired

and ready for use, they provide disinfection using chlorine or bro‐

mine.

DULCODOS® Pool metering systems are equipped with all neces‐

sary components mounted on a plate.

n Sensors

n Controller

n Metering pumps

2.1

Overview of equipment

A1115

13.

12.

11.

10.

9.

8.

7.

6.

5.

4.

3.

2.

1.

Fig. 1: Overview of equipment based on the example DULCODOS® Pool metering system R01 (with all

options and metering pump Beta® or DF2a)

1. Redox controller

2. Flow sensor

3. Redox sensor*

4. Flow module with flow sensor

5. Ball valve, inlet side

6. Disinfectant injection valve

7. Sampling tap

8.

Metering pump Beta® disinfectant

9 Cable disinfectant level switch (only

with metering pump )

10. Suction assembly disinfectant

11. Metering pump DF2a disinfectant

12. Dirt filter

13. Ball valve, outlet side

Not shown

in figure

Disinfectant multifunctional valve

* To be fitted by the customer. These

components are ready for subsequent

installation, but are supplied sepa‐

rately to avoid damage in transit.

Components P01

About this product

7

Page 8

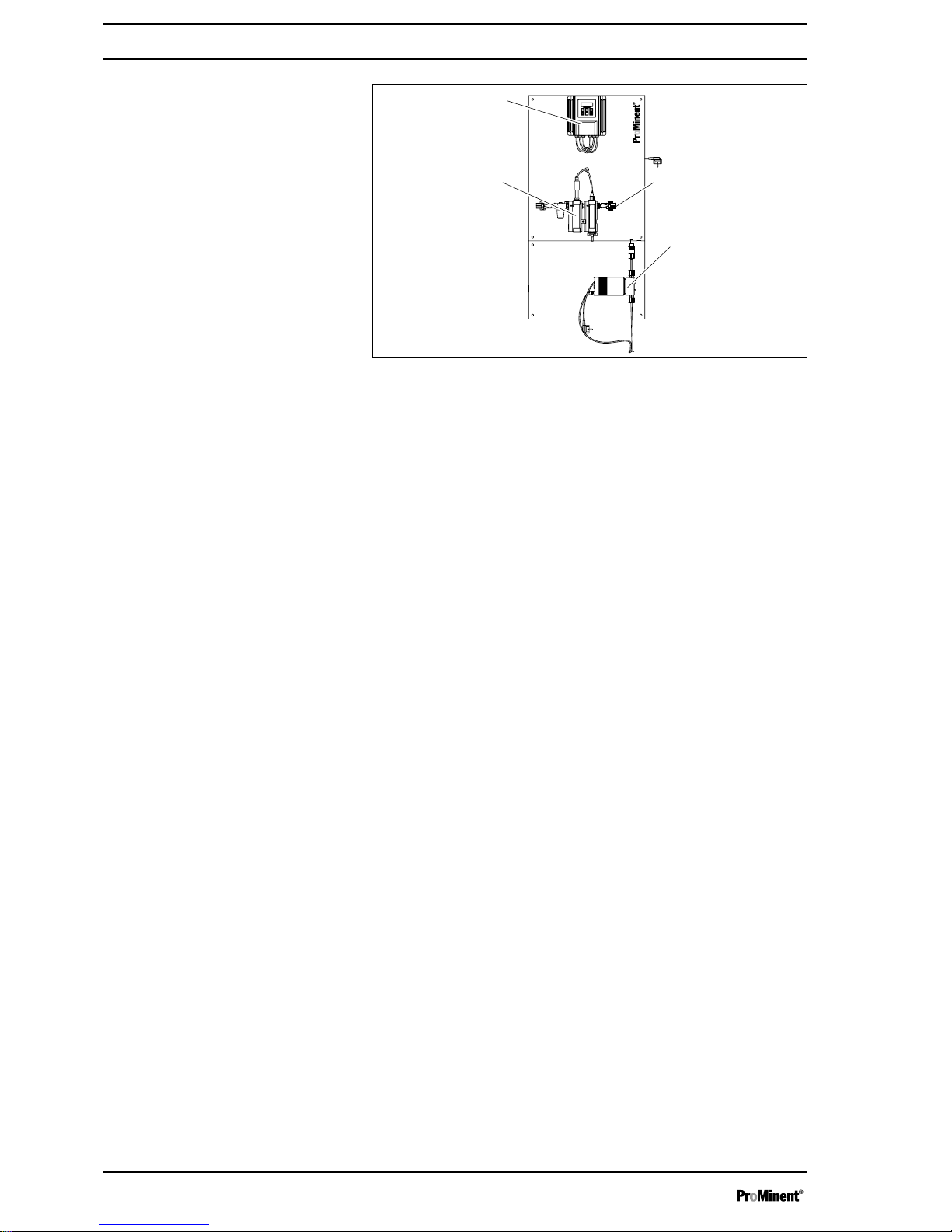

2.

1.

4.

A1116

3.

Fig. 2: Control elements for the example DULCODOS® Pool

metering system R01 (with all options and metering pumps Beta®)

The following are used as control elements:

1. Controller keys and display

2. Flow meter (by scale)

3 Stroke adjustment dial of the metering pump (con‐

cealed with the alpha pump)

4. Ball valve, in-line probe housing, inlet side

(Not shown in

figure)

Multifunctional valve

Control elements e.g. R01

About this product

8

Page 9

3

Safety and responsibility

3.1

Users' qualifications

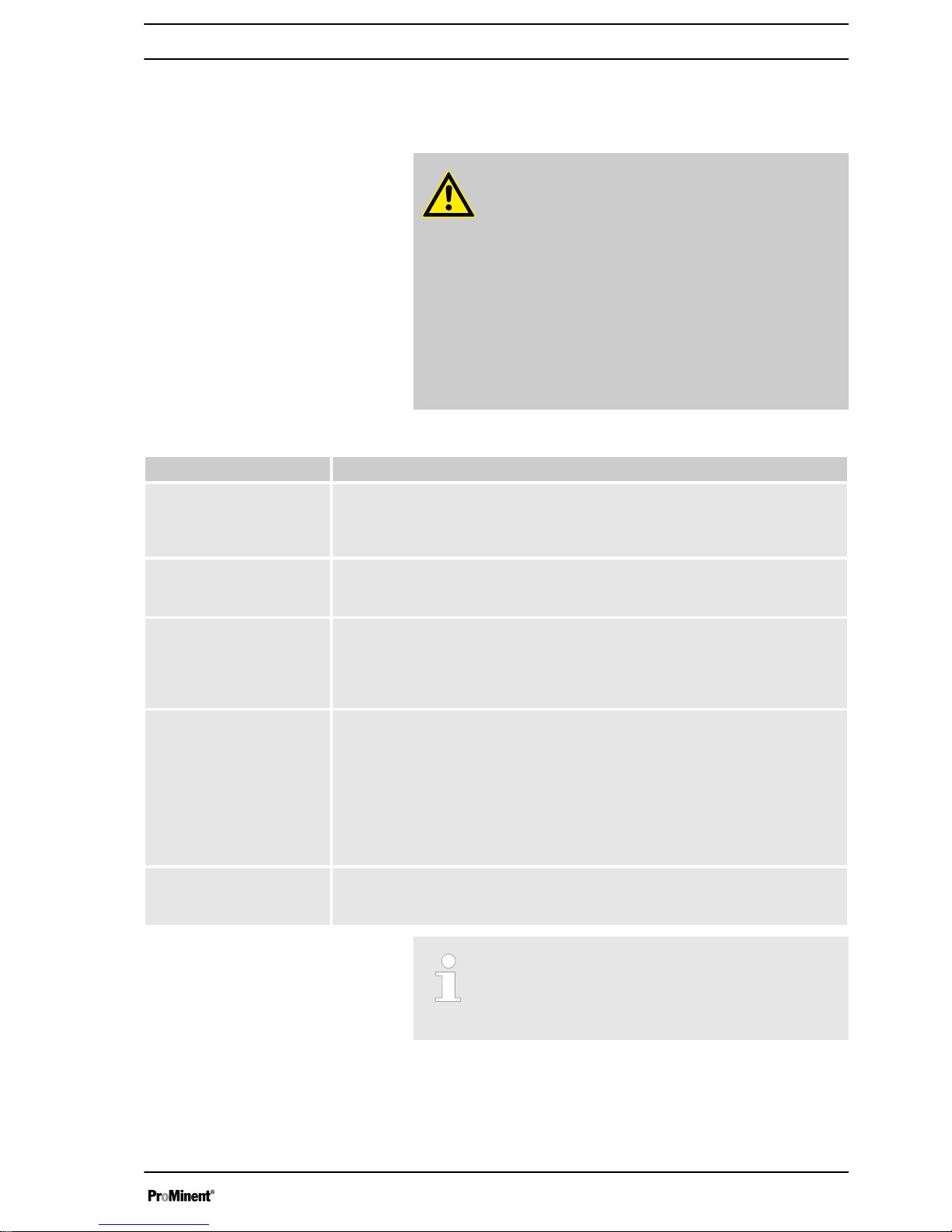

WARNING!

Danger of injury with inadequately qualified personnel!

The operator of the plant / device is responsible for

ensuring that the qualifications are fulfilled.

If inadequately qualified personnel work on the unit or

loiter in the hazard zone of the unit, this could result in

dangers that could cause serious injuries and material

damage.

– All work on the unit should therefore only be con‐

ducted by qualified personnel.

–

Unqualified personnel should be kept away from

the hazard zone

Training Definition

Instructed personnel An instructed person is deemed to be a person who has been instructed and,

if required, trained in the tasks assigned to him/her and possible dangers that

could result from improper behaviour, as well as having been instructed in the

required protective equipment and protective measures.

Trained user A trained user is a person who fulfils the requirements made of an instructed

person and who has also received additional training specific to the system

from ProMinent or another authorised distribution partner.

Trained qualified per‐

sonnel

A qualified employee is deemed to be a person who is able to assess the

tasks assigned to him and recognize possible hazards based on his/her

training, knowledge and experience, as well as knowledge of pertinent regula‐

tions. The assessment of a person's technical training can also be based on

several years of work in the relevant field.

Electrician Electricians are deemed to be people, who are able to complete work on elec‐

trical systems and recognize and avoid possible hazards independently based

on his/her technical training and experience, as well as knowledge of pertinent

standards and regulations.

Electricians should be specifically trained for the working environment in

which the are employed and know the relevant standards and regulations.

Electricians must comply with the provisions of the applicable statutory direc‐

tives on accident prevention.

Customer Service depart‐

ment

Customer Service department refers to service technicians, who have

received proven training and have been authorised by ProMinent to work on

the system.

Note for the system operator

The pertinent accident prevention regulations, as well

as all other generally acknowledged safety regulations,

must be adhered to!

Safety and responsibility

9

Page 10

3.2

Explanation of the safety information

These operating instructions provide information on the technical

data and functions of the product. These operating instructions pro‐

vide detailed safety information and are provided as clear step-bystep instructions.

The safety information and notes are categorised according to the

following scheme. A number of different symbols are used to

denote different situations. The symbols shown here serve only as

examples.

DANGER!

Nature and source of the danger

Consequence: Fatal or very serious injuries.

Measure to be taken to avoid this danger

Danger!

–

Denotes an immediate threatening danger. If this is

disregarded, it will result in fatal or very serious

injuries.

WARNING!

Nature and source of the danger

Possible consequence: Fatal or very serious injuries.

Measure to be taken to avoid this danger

Warning!

–

Denotes a possibly hazardous situation. If this is

disregarded, it could result in fatal or very serious

injuries.

CAUTION!

Nature and source of the danger

Possible consequence: Slight or minor injuries, mate‐

rial damage.

Measure to be taken to avoid this danger

Caution!

–

Denotes a possibly hazardous situation. If this is

disregarded, it could result in slight or minor inju‐

ries. May also be used as a warning about material

damage.

NOTICE!

Nature and source of the danger

Damage to the product or its surroundings

Measure to be taken to avoid this danger

Note!

–

Denotes a possibly damaging situation. If this is

disregarded, the product or an object in its vicinity

could be damaged.

Introduction

Safety and responsibility

10

Page 11

Type of information

Hints on use and additional information

Source of the information, additional measures

Information!

–

Denotes hints on use and other useful information.

It does not indicate a hazardous or damaging sit‐

uation.

3.3

General Safety Information

WARNING!

Live parts!

Possible consequence: Fatal or very serious injuries

– Measure: Disconnect the mains power supply prior

to opening the housing

–

De-energise damaged, defective or manipulated

units by disconnecting the mains plug

WARNING!

Unauthorised access!

Possible consequence: Fatal or very serious injuries

– Measure: Ensure that there can be no unauthor‐

ised access to the unit

WARNING!

Operating errors!

Possible consequence: Fatal or very serious injuries

– The unit should only be operated by adequately

qualified and technically expert personnel

–

Please also observe the operating instructions for

controllers and fittings and any other component

groups, such as sensors, measuring water

pumps ...

– The operator is responsible for ensuring that per‐

sonnel are qualified

CAUTION!

Electronic malfunctions

Possible consequence: Material damage to destruction

of the unit

– The mains connection cable and data cable should

not be laid together with cables that are prone to

interference

–

Measure: Take appropriate interference suppres‐

sion measures

Safety and responsibility

11

Page 12

NOTICE!

Correct and proper use

Damage to the product or its surroundings

– The unit is not intended to measure or regulate

gaseous or solid media

–

The unit may only be used in accordance with the

technical details and specifications provided in

these operating instructions and in the operating

instructions for the individual components

NOTICE!

Correct sensor operation / Run-in time

Damage to the product or its surroundings

– Correct measuring and dosing is only possible if

the sensor is working perfectly

– It is imperative that the run-in times of the sensors

are adhered to

– The run-in times should be allowed for when plan‐

ning initial operation

– It may take a whole working day to run-in the

sensor

– Please read the operating instructions for the

sensor

NOTICE!

Correct sensor operation

Damage to the product or its surroundings

– Correct measuring and dosing is only possible if

the sensor is working perfectly

–

Check and calibrate the sensor regularly

NOTICE!

Compensation of control deviations

Damage to the product or its surroundings

– This controller cannot be used in control circuits

which require rapid compensation (< 30 s)

3.4

Correct and proper use

NOTICE!

Compensation for control deviations

Damage to the product or its surroundings

– The controller can be used in processes, which

require compensation of > 30 seconds

Safety and responsibility

12

Page 13

NOTICE!

Correct and proper use

The unit is intended to measure and regulate liquid

media. The marking of the measured variables is

located on the controller and is absolutely binding.

The unit may only be used in accordance with the

technical details and specifications provided in this

operating manual and in the operating manuals for the

individual components (such as, for example, sensors,

fittings, calibration devices, metering pumps etc.).

Any other uses or modifications are prohibited.

Safety and responsibility

13

Page 14

4

Storage and transport

CAUTION!

– Prior to storage or transport, the

DULCODOS® Pool metering systems

must be free

from feed chemicals and water

– Rinse out the media carrying parts, including the

tubes using clean, pure water

– Transport and store the DULCODOS® Pool

metering systems in their original packaging

– Also protect the packaged DULCODOS® Pool

metering systems against damp, exposure to

chemicals and mechanical effects

– Please also observe the operating instructions for

controllers and fittings and other units, such as

sensors, filters, metering pumps ...

Storage temperature: 0 ... 50 °C

Air humidity: < 95% relative air humidity, non-condensing

NOTICE!

If the DULCODOS® Pool metering systems are stored

as an assembly with the sensors, then the storage and

transport conditions must be appropriate for the com‐

ponent with the least resistance to external influences.

Ambient conditions for storage and

transport without sensors

Storage and transport

14

Page 15

5

Assembly

Cleaning the injection valve

Localised increases in pH can occur through the

metering of chlorine into the swimming pool water.

This can result in limescale forming in the injection

valve.

Regularly check, clean and descale the injection valve.

The frequency of this work depends on the usage and

ambient parameters of your system and must be deter‐

mined during operation.

To avoid bursting of the metering hose, with metering

pumps of type alpha and Beta®, a multifunctional

valve, identity code characteristic "Multifunctional valve

disinfection pump", must be fitted in the metering line.

5.1

Wall mounting

Secure the metering system perpendicular and upright

on a wall or a stable mounting system.

The metering system should be freely accessible.

Select the mounting height you require so that:

n The controller's display can be easily read

n the controller lid can still be parked in the

[Park position]

(150

mm)

n There is still space for maintenance work beneath the in-line

probe housing (100 mm)

n There is still room for the chemical storage tank (600 mm)

n The fluid level of the full chemical storage tanks is below the

metering pumps

n The maximum priming lift of the metering pumps is not

exceeded.

Assembly

15

Page 16

10 mm

A0924

1

2

3

4

Fig. 3: Hanger bolt

1 Rawlplug (type dependent on substrate and according to stipu‐

lations of the rawlplug manufacturer)

2 Hanger bolt

3 U-washer

4 Hexagon nut

5.2

Fit the antikink device for the bleed line

A0965

4.

3.

2.

1.

Fig. 4: Fit the antikink device for the bleed line (only SEK liquid

end)

1. Bleed valve for the return line in the storage tank, 6/4 mm

2. Red sleeve

3. Discharge valve for discharge line to injection point, 6/4 - 12/9

mm

4. Suction valve for suction line in storage tank, 6/4 - 12/9 mm

1. Fit the antikink device for the bleed line on the upper valve

(red sleeve)

2. route the bleed hose in the gutter of the antikink device

3. Pull the bleed hose downwards

ð

The bleed hose engages in the antikink device.

Only SEK liquid end (metering pump

Beta® for disinfection, right side):

Assembly

16

Page 17

5.3

Hydraulic installation

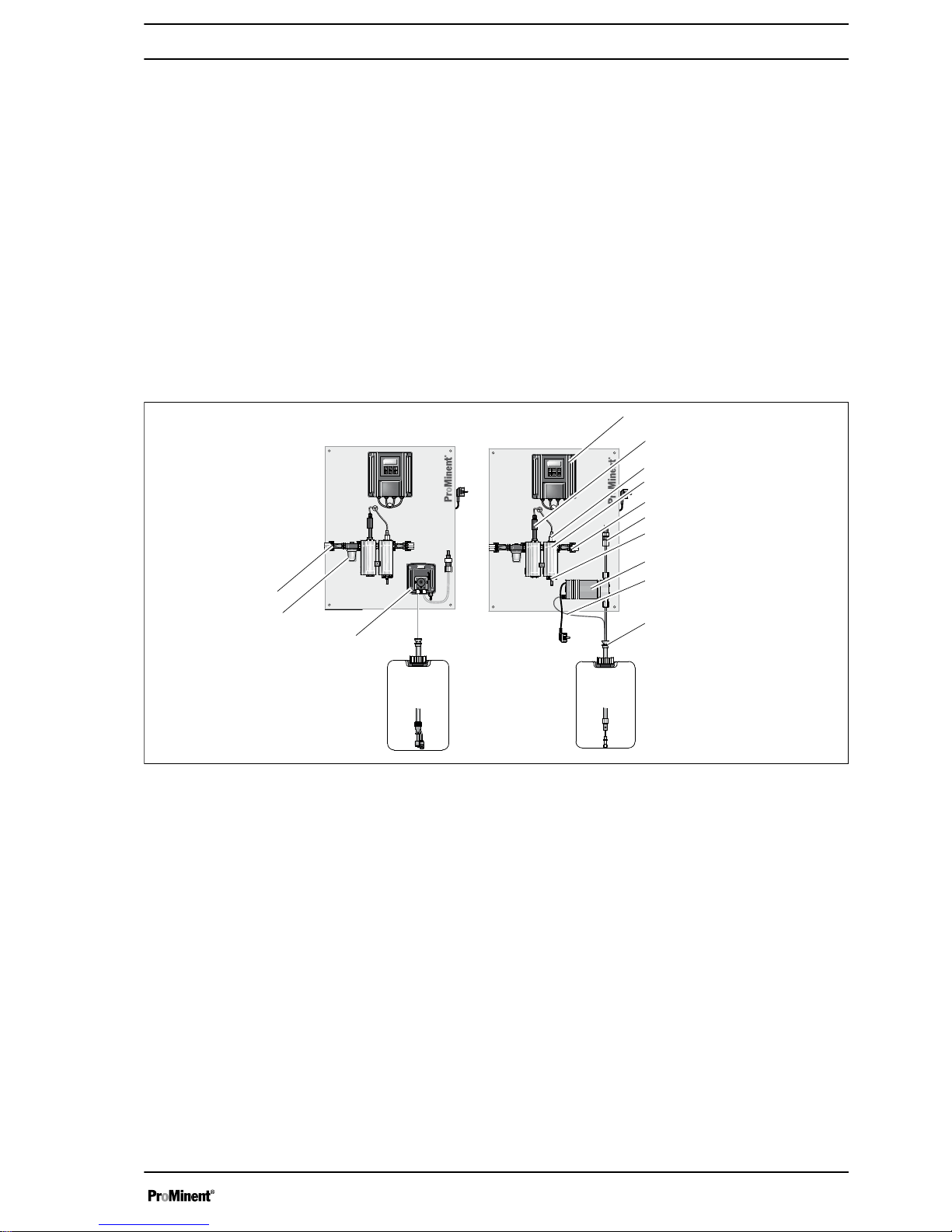

A1117

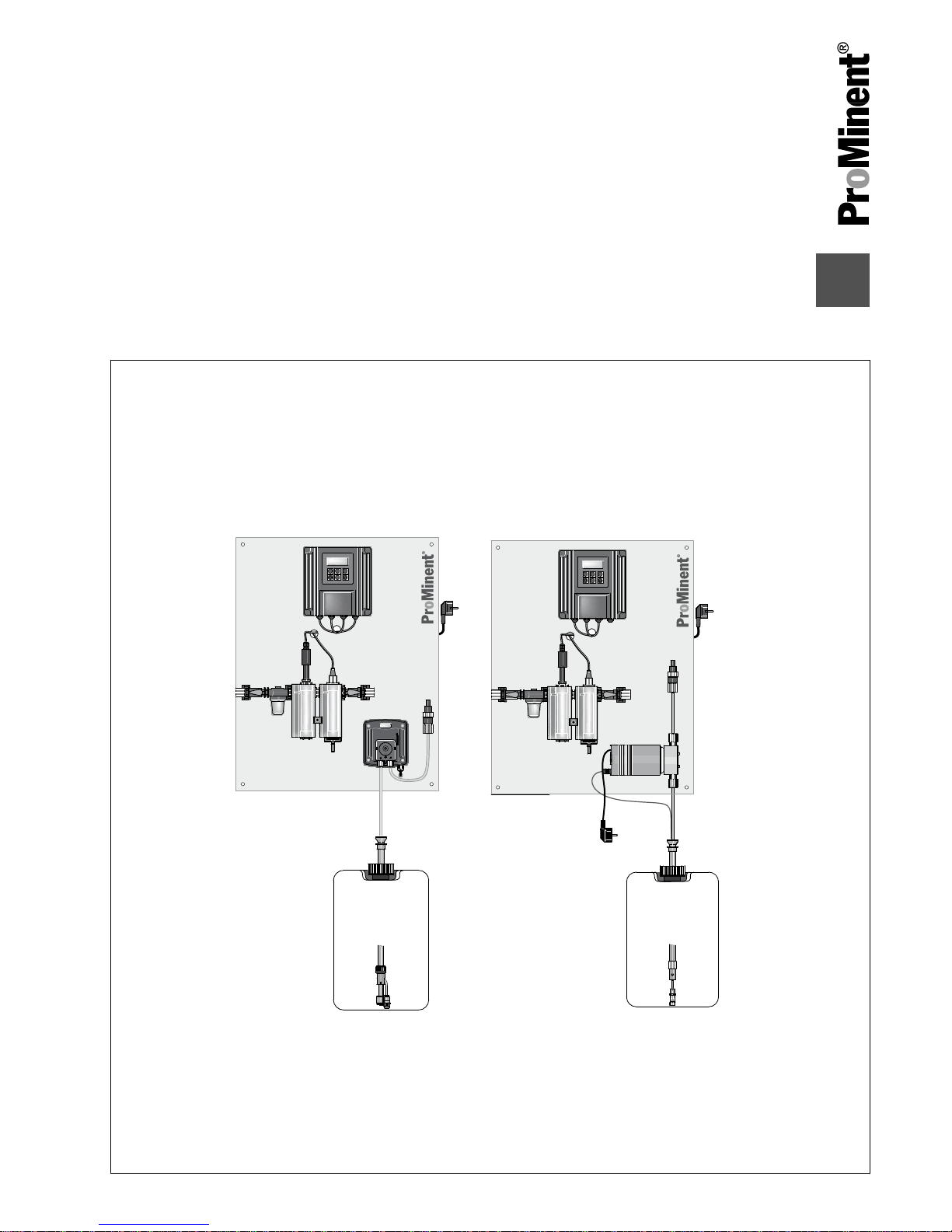

Fig. 5: Indoor swimming pool: hydraulic connection of the swimming pool metering system to the swimming

pool installation

Advantage: "Direct" measured values without depletion

Disadvantage: In-line probe housing can become dirty

Assembly

17

Page 18

A1118

Fig. 6: Outdoor swimming pool: hydraulic connection of the swimming pool metering system to the swimming

pool installation

Advantage: In-line probe housing cannot become dirty

Disadvantage: Measured values with depletion

5.3.1

Metering system

NOTICE!

Maximum permissible operating pressure of in-line

probe housing

Limit the pressure to a maximum of 2 bar (at 30 °C)

directly at the sample water extraction point using a

pressure reducer, otherwise the maximum permissible

operating pressure of the in-line probe housing will be

exceeded.

Do not allow a back pressure of more than 2 bar

(at 30 °C) to build up at the outlet, otherwise the max‐

imum permissible operating pressure of the in-line

probe housing will be exceeded.

1. With flow sensor: Push the flow sensor into the in-line probe

housing and tighten the reducing nipple and the mounting

clip

2. Route the sample water feed via a ball valve from the filter

circuit to the in-line probe housing, see figures above

3. Route the sample water feed via a ball valve from the filtra‐

tion circuit to the in-line probe housing, see figures above

4. Install a 1/2" straight union on the filtration circuit pipe for

each injection valve

Assembly

18

Page 19

5. Screw the injection valves into a straight union of the filtration

circuit pipe

1

2

3

4

5

6

A0929

Fig. 7: Connect the tube using the connector kit

1. Valve

2. O-ring

3. Nozzle

4. Clamp ring

5. Union nut

6. Hose

6. Connect the suction hose of the suction assembly to the con‐

nector kit on the liquid end

7. Connect the pressure hose to the pressure connector using

the connector kit

8. Connect the pressure hose to the injection valve using the

connector kit

To ensure reliable measuring and control, the sample

water must be free from air bubbles.

1. Set a flow of 20 ... 60 l/h using the stopcock (read-off at the

top edge of the float).

2. Check the hydraulic leak-tightness of the system (escaping

liquid, continuous air bubbles in the in-line probe housing, ...)

ð

Tighten the threaded connectors if necessary.

1.

Have a collecting vessel at the ready

Open the sampling tap

Testing the hydraulic installation of

the metering system:

Check the system for negative pres‐

sure

Assembly

19

Page 20

2. If water flows out of the sampling tap, the system is not under

negative pressure and is working correctly

If air is drawn in, this means that there is nega‐

tive pressure in the system. In this case, throttle

the valve at the point at which the sample water

pipe enters the filtration circuit - the pressure

should not exceed 2 bar.

3. Use the stopcock on the sample water drain to finely adjust

the system

5.3.2

Sensors

Observe the operating instructions for the sensors.

1. Close the shut-off valves upstream and downstream of the

in-line probe housing

2. Remove the transparent protective cap from the ball-shaped

end of the redox sensor

3. Manually screw the redox sensors into separate threaded

holes on the in-line probe housing. Then carefully tighten

using an SW 17 open-ended spanner until the threaded con‐

nector is tight

4. Testing the sensors' hydraulic installation: Adjust the flow

using the shut-off valve to 20... 60 l/h

ð

Check whether the threaded connectors on the in-line

probe housing are tight.

Redox sensor installation

Assembly

20

Page 21

If there is already sample water in the in-line probe

housing

Slowly lower the sensor into the in-line probe housing.

Otherwise the diaphragm of the sensor is over‐

stretched and the sensor delivers incorrect values.

1. Remove the securing bolt (1) using a 35 mm ring spanner

2. Fit the sensor with electrolyte as described in the sensor

operating instructions

3. Push the O-ring (4), then the assembly washer (5) onto the

sensor (3) from below

ð

The components must lie against the clamp disc (2)

4. Then push the securing bolt (1) from above onto the sensor

(3)

5. Carefully push the sensor (3) into the module (6) of the in-line

probe housing

6. Tighten the securing bolt (1) using a 35 mm ring spanner

7. Testing the sensors' hydraulic installation: Adjust the flow

using the shut-off valve to 20... 60 l/h

ð

Check whether the threaded connectors on the in-line

probe housing are tight.

5.4

Electrical installation

If power sockets are provided on the metering system,

then the socket on the side of the metering pump

should always be used. The power socket is controlled

so that it switches the pump which is installed on the

same side as it.

1. Screw the orange-coloured SN6 plugs onto the sensors

2. With level switch: Plug the plug of the level sensor cable into

the

[level]

socket of the metering pump

Installing a chlorine or bromine sen‐

sors

A0968

1.

2.

3.

4.

5.

6.

Fig. 8: Assembling the sensor

Assembly

21

Page 22

6

Start up

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets pro‐

vided by the manufacture of the hazardous substance.

The actions required are described in the safety data

sheet. Check the safety data sheet regularly and

replace, if necessary, as the hazard potential of a sub‐

stance can be re-evaluated at any time based on new

findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they

are kept up to date, as well as for producing an associ‐

ated hazard assessment for the workstations affected.

CAUTION!

Wear suitable protective equipment (gloves, protective

goggles,...) when commissioning.

Refer to the latest safety data sheets on the feed

chemicals.

NOTICE!

The sampling tap must be closed otherwise sample

water will escape.

The service technician is responsible for instructing the

operating and maintenance personnel during commis‐

sioning.

If power sockets are provided on the metering system,

then the socket on the side of the metering pump

should always be used. The power socket is controlled

so that it switches the pump which is installed on the

same side as it.

Maximum permissible operating pressure:

In the sample water line:

–

2 bar at 30 °C (sample water)

1. Tighten all threaded connectors prior to initial commissioning

2. Open the shut-off valves downstream of the metering pumps,

in the sample water line and also the shut-off valves in your

system

3. Insert the suction lances into the relevant chemical storage

tanks for disinfectant

Preparation:

Start up

22

Page 23

4. Plug the mains plug into the socket and switch on the mains

voltage

6.1

Priming and bleeding

Start the control process, if correctly installed, the lines bleed them‐

selves.

6.2

Adjust the flow sensor switching point

Sample water may escape.

1. Adjust the flow to 50 l/h using the ball valve

2. Hold the flow sensor in place and loosen the mounting clip a

little

3. Press the float to 40 l/h using the flow sensor

ð

The error message should disappear.

4. Hold the flow sensor in this position and tighten the mounting

clip

5. Then re-adjust the flow required using the ball valve

6. Acknowledge any error message that occurs

7. Reset any possible consequences of this in the overall instal‐

lation

8. Check the threaded connector for leak-tightness

6.3

Calibration

You have to regularly calibrate the sensor during ope‐

ration. That means: 24 hours after initial calibration

and then weekly thereafter.

Please take into account any differing national regula‐

tions.

The flow sensor should switch when

the flow falls (flow sensor is con‐

nected as an NC).

Start up

23

Page 24

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets pro‐

vided by the manufacture of the hazardous substance.

The actions required are described in the safety data

sheet. Check the safety data sheet regularly and

replace, if necessary, as the hazard potential of a sub‐

stance can be re-evaluated at any time based on new

findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they

are kept up to date, as well as for producing an associ‐

ated hazard assessment for the workstations affected.

There must be a chlorine or bromine concentration of approx.

0.5 ... 0.8 mg/l in the pool to be able to calibrate the sensors.

Example (without depletion losses): A swimming pool contains 60

m3, by way of example. To obtain a chlorine concentration of 0.5 ...

0.8 mg/l in this swimming pool, requires 0.20 ... 0.32 litres of 12 %

sodium-calcium hypochlorite (density (

ρ) 1.22 ± 0.02).

Meter in the required quantity of sodium-calcium hypochlorite

into the filtration circuit, either using the chlorine metering

pump or evenly distribute the quantity of sodium-calcium

hypochlorite needed into the swimming pool using a meas‐

uring cup.

ð

An even concentration can be expected once the reac‐

tion time has elapsed:

reaction time [h] = cup contents [m3] / circulation capacity

[m3/h]

Preparing the filtration circuit

Start up

24

Page 25

calibration

zero p.:

take over value?

4.00 mA

calibration

DPD-value

1.55 ppm

calibration

zero p.: 4.00 mA

slope

6.50 mA/ppm

calibration

zero p.: 4.00 mA

slope

6.50 mA/ppm

calibration

Zeropoint

4.00 mA

calibration

DPD-value

01.55 ppm

A0018_GB

14.00 mA

Fig. 9: Calibration of All Amperometric Measured Variables

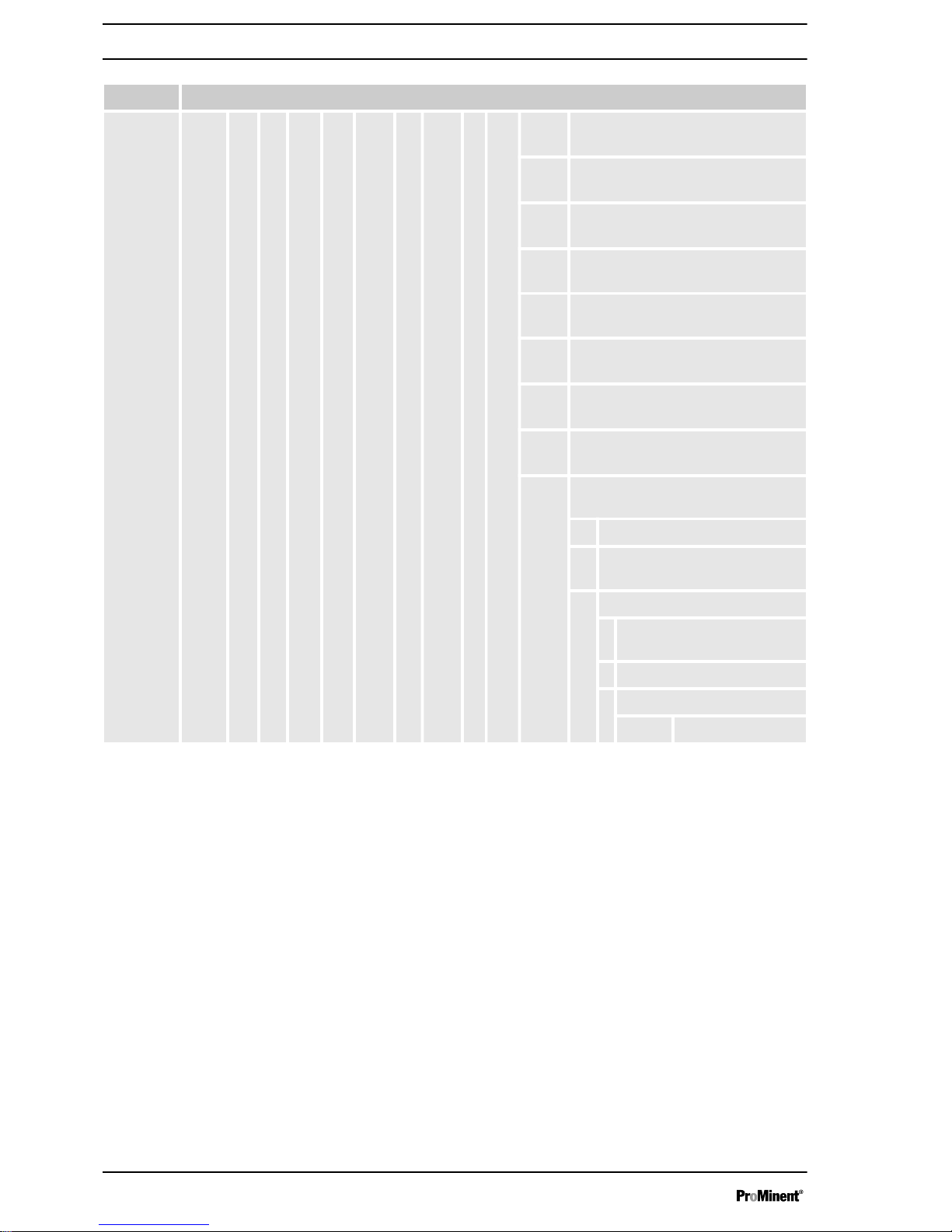

Fault message Condition Remarks *

Calibration not possible!

Slope too low

Slope too low

(< 20 % of standard slope)

Repeat calibration

Calibration not possible!

Slope too high

Slope too high

(> 300 % of standard slope)

Repeat calibration

DPD value too low

DPD > x.xx ppm

DPD < 2 % of measuring range Repeat calibration after addition of

metering medium or fit sensor

suitable for the process

Calibration not possible!

Zero point low

< 3 mA

(only with 4 - 20 mA sensors)

Check sensor/cable

Repeat calibration in water without

metering medium

Calibration not possible!

Zero point high

> 5 mA

> 6 mA for 0.5 ppm chlorite

Check sensor/cable

Repeat calibration in water without

metering medium

* Please also note the operation manual for the respective sensor

Only the slope can be calibrated in the restricted operating menu of

the DULCOMETER®

D1Cb / D1Cc.

Both the zero point and the slope can be calibrated in the complete

operating menu of the DULCOMETER® D1Cb / D1Cc.

CAUTION!

Correct sensor operation / Run-in time

Damage to the product or its surroundings

– Correct measuring and dosing is only possible if

the sensor is working perfectly

–

Please read the operating manual for the sensor

– Please also read the operating manuals for the fit‐

tings and other components used

– It is imperative that the run in periods of the sen‐

sors are adhered to

– The run in periods should be allowed for when

planning commissioning

– It may take a whole working day to run-in the

sensor

Testing the sensor

Start up

25

Page 26

Necessity of calibrating the zero point

Calibration of the zero point is not generally necessary.

Calibration of the zero point is only necessary if the

sensor is operated at the lower limit of the measuring

range or if the 0.5 ppm sensor version is used.

During the calibration, the DULCOMETER® D1Cb / D1Cc sets the

control outputs to "0". Exception: a basic load or a manual control

value has been set, this remains active. The mA standard signal

outputs are frozen. The measured value frozen at the start of cali‐

bration is suggested as a DPD value. The DPD value can be set

using the arrow keys. Calibration is only possible if the DPD value

is ≥ 2 % of the measuring range of the sensor.

NOTICE!

Prerequisites for correct calibration of the sensor slope

– The DPD method required by the feed chemical

employed will be used

–

The run in period for the sensor has been adhered

to

– There is permitted and constant flow at the in-line

probe housing

– There is temperature equalisation between the

sensor and the sample water

– There is a constant pH value in the permitted

range

The sensor is fitted, flushed with sample water and connected

electrically to the DULCOMETER® D1Cb / D1Cc and run-in.

There has to be adequate feed chemical in the sample water for

calibration (> 2% of the measuring range of the sensor).

Remove sample water directly at the measuring point and deter‐

mine the content of metering medium in the sample water in "ppm"

using an appropriate reference method (e.g. DPD, titration etc.).

Enter this value as follows at the DULCOMETER® D1Cb / D1Cc:

1.

Select Calibration menu. Then press

ð

The current measured value will now be frozen.

2. Take a sample of water and perform a reference measure‐

ment within 15 minutes

3.

Select "DPD value" of unit to be calibrated using the key

4.

Continue with

5. If necessary, match the flashing ppm value to the value

determined with the measurement using the keys,

, and

ð

The mA value of the sensor shown in this display now

corresponds to the measured value in "ppm".

6.

Then press the following key twice

ð

The display now shows the value determined for the zero

point and slope. Refer to the Error Message table should

an error be displayed.

Calibration of amperometric sensors:

slope (in the reduced and complete

operating menu)

Start up

26

Page 27

Necessity of calibrating the zero point

Calibration of the zero point is not generally necessary.

Calibration of the zero point is only necessary if the

sensor is operated at the lower limit of the measuring

range or if the 0.5 ppm sensor version is used.

A container with water, which is free of additives that could falsify

the measured result, is needed for calibration. Immerse the dis‐

mounted, but still electrically connected to the

DULCOMETER® D1Cb / D1Cc, sensor in this water. Use the

sensor to stir the water for approx. 5 minutes until the measured

value displayed at the DULCOMETER® D1Cb / D1Cc is steady

and close to "0".

1.

Select Calibration menu. Then press

2.

Select "Zero point" of unit to be calibrated using the key

3.

Continue with

ð

A prompt is shown in the display

4.

Confirm prompt with the key

5.

Continue with

6. Apply the "zero point" displayed during calibration using the

key

7.

Then press

ð

Display shows the values determined.

8.

Then press

ð

Refer to the Error Message table should an error be dis‐

played.

NOTICE!

Then definitively calibrate the slope with a suitable ref‐

erence method (e.g. DPD. titration etc.).

Calibration of amperometric sensors:

Zero point (only in the complete oper‐

ating menu)

Start up

27

Page 28

NOTICE!

Testing the ORP Sensor

With ORP measured variables, the sensor is not cali‐

brated but tested according to its design

– Observe any notification of abnormal behaviour

when testing the ORP sensor

–

Should the test not be successful, replace the ORP

sensor

= automatic timing

check sensor

ORP

check sensor

ORP

sensor in buffer r

460 mV

check sensor

measuremactive

please wait!

check sensor

ORP

mea. val

buffer

460 mV

465 mV

permanent display 1

A0064_GB

460 m

V

Fig. 10: Testing ORP sensors

A container with a ORP buffer solution (e.g. 465 mV) is needed for

testing.

1.

Select the Test menu

2. Immerse ORP sensor in the ORP buffer solution containing

test container (e.g. 465 mV)

3.

Start test with

ð

Test is running.

A buffer value is suggested once the waiting time has

expired.

4.

Using keys , and adjust the displayed "buffer"

(flashing) value to the mV value of the ORP buffer solution in

the test container. Confirm the value with

.

ð

The D1Cb displays the status message of the ORP

sensor in plain text. If the ORP sensor is functioning cor‐

rectly, continuous display 1 will be displayed directly

5. If the ORP sensor is unclean or defective, the ORP sensor

should be cleaned, as described in the ORP sensor oper‐

ating instructions, or alternatively replaced

Should the result of the calibration lie outside of the specified error

limits, an error message will appear, see

Testing the ORP Sensor

Description of the Testing of ORP

Sensors

Start up

28

Page 29

7

Maintenance

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets pro‐

vided by the manufacture of the hazardous substance.

The actions required are described in the safety data

sheet. Check the safety data sheet regularly and

replace, if necessary, as the hazard potential of a sub‐

stance can be re-evaluated at any time based on new

findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they

are kept up to date, as well as for producing an associ‐

ated hazard assessment for the workstations affected.

Observe the operating instructions for the metering

pump (option), the in-line probe housing, the sensors,

dirt filter and multifunctional valve (optional).

Thoroughly flush the metering system with water

before carrying out maintenance.

You must now calibrate the sensors regularly. That

means: 24 hours after initial calibration and then

weekly thereafter. Take into account any differing

national regulations.

7.1

Maintenance work

An overview of maintenance work

Maintenance interval Maintenance task

daily Check swimming pool water values

weekly Visual inspection of metering system (flow meter)

Only with metering pump Beta®

Metering pump LEDs

Check storage tank liquid/powder levels

Check sensors

6 months Clean valves

Maintenance

29

Page 30

You must check the actual swimming pool water

values daily to guarantee the safe operation of your

swimming pool system.

1. Check the chlorine concentration using the DPD test (refer to

the operating instructions for the test kit)

2. Check the pH value using the phenol red test (refer to the

operating instructions for the test kit)

ð

If the swimming pool water values lie outside the toler‐

ance limits, then conduct additional tests, as described in

Ä ‘An overview of maintenance work’ Table on page 29

.

1. Regularly conduct a visual inspection of the metering system,

specifically the sensors and the flow meter with flow sensor

for:

n Air bubbles in the sample water

n The state of the sensors

n Leakages

n Correct flow values

n To ascertain whether the flow sensor is fastened correctly

onto the flow meter

n To ascertain whether the float is moving easily within the

flow meter: To do so, note down the flow value and then

change the flow value - the float should change position

ð

Call Customer service if one of these points is not cor‐

rect.

2.

Only with metering pump Beta®

Check the LEDs at the

metering pumps. Call service if:

n the red LED illuminates

n the yellow LED illuminates

n the green LED does not illuminate and the circulating

pump is running

3. Check the liquid/powder levels in the storage tanks

ð

Pour in feed chemical if the liquid/powder level has fallen

below 10 cm.

4. Check the sensors by calibrating them

1. Close the stopcocks upstream and downstream of the in-line

probe housing

2. Unscrew the filter bowl

3. Remove the filter insert and clean it without detergent

4. Insert the filter insert into the housing

5. Check the sealing ring and the sealing surfaces for cleanli‐

ness, and clean if necessary

6. Screw the filter bowl until tight

7. Open the stopcocks on the in-line probe housing

Maintenance interval:daily

Maintenance interval: weekly

Maintenance interval: 6 months

Clean dirt filter regularly:

Maintenance

30

Page 31

7.2

Troubleshooting

Use the operating instructions for controllers, sensors, in-line probe

housings, metering pumps and multifunctional valves (optional) to

eliminate functional faults or call Customer service.

7.3

Disposal of used parts

n Users' qualification: instructed persons, see

Ä Chapter 3.1

‘Users' qualifications’ on page 9

NOTICE!

Regulations governing disposal of used parts

– Note the current national regulations and legal

standards which apply in your country

ProMinent Dosiertechnik GmbH, Heidelberg will take back decon‐

taminated used devices providing that they are covered by ade‐

quate postage.

Maintenance

31

Page 32

8

Technical data

Refer to the product-specific operating instructions for

technical data on the controller, sensors, in-line probe

housing, metering pump and multifunctional valve.

Cleaning the injection valve

Localised increases in pH can occur through the

metering of chlorine into the swimming pool water.

This can result in limescale forming in the injection

valve.

Regularly check, clean and descale the injection valve.

The frequency of this work depends on the usage and

ambient parameters of your system and must be deter‐

mined during operation.

To avoid bursting of the metering hose, with metering

pumps of type alpha and Beta®, a multifunctional

valve, identity code characteristic "Multifunctional valve

disinfection pump", must be fitted in the metering line.

Maximum permissible operating pressure

n In the sample water line:

– without chlorine or bromine sensor: 2 bar at 30 °C (sample

water)

– with chlorine or bromine sensor: 1 bar at 30 °C (sample

water)

Sample water line connector

n 8x5 mm PE tube

Sample water filter element

n 300 µm

Weights

n with pumps: approx. 10 kg

n without pumps: approx. 5 kg

Materials

n Plate material: PP

n Materials, wetted: The wetted materials are resistant to the

media commonly used in swimming pools. Consult the oper‐

ating instructions for the individual components with other

media.

n Sample water filter: polypropylene, nylon, nitrile rubber, stain‐

less steel

Dimensions sheet

Technical data

32

Page 33

745

595

min. 150

min. 600

400

A1119

Fig. 11: Dimensions sheet. All dimensions in mm. Depth 150 mm

Technical data

33

Page 34

9

Systems

9.1

Spare parts and accessories

Spare parts

Spare parts Part no.

Chlorine sensor CLE 3-mA-2 ppm (for free chlorine) 792920

Spare diaphragm cap for CLE 3 815073

Electrolyte solution for chlorine sensor for CLE, 100ml506270

Chlorine sensor CLE 2-mA-2ppm (for organically

bound chlorine)

792843

Spare diaphragm cap for CGE 2 792862

Electrolyte solution for chlorine sensor for CGE, 50ml792892

Redox sensor RHES-Pt-SE 150703

Buffer solution 465 mV, 50 ml 506240

Chlorine metering pump spare parts kit (clear

acrylic):

BT4a 0401 NPB .... 1001666

BT4a 0402 NPB .... 1001667

BT4a 0404 NPB .... 1035334

Chlorine metering pump spare parts kit (clear

acrylic):

ALPc 1002 NPB ... 1001724

ALPc 1004 NPB ... 1001724

Spare tube, complete, PharMed® for DULCO® flex

1009480

Filter element 300 µm, stainless steel 1038867

Spare parts kits for metering pumps Beta® comprising:

n 1 x metering diaphragm

n 1 x suction valve, complete

n 1 x discharge valve, complete

n 2 x valve balls

n 1 x set of seals

n 1 x connector kit

Accessories

Accessories Part no.

Photometer: To detect chlorine and bromine 1039315

Systems

34

Page 35

9.2

EC Declaration of Conformity

We,

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5 - 11

D - 69123 Heidelberg

hereby declare that the product identifiedbelowconformstothe basichealthand

safety

requirementsof the ECDirective,by virtue of its design and construction, and inthe configuration

placed on the market by us.

This declaration isno longer applicableifchangesare made tothe product without our authorisation.

Product description:

DULCODOS POOL swimming pool dosing system

Product type:

DSPa _ _ _ _ _ _ _ _ _ _ 0 _ 0 _ 1_

i.e. for installed systems without factory-fitted dosing pumps

Serialno.:

see type plate on the unit

Applicable

EC Low Voltage Directive (2006/95/EC)

EC Directives:

EC EMC Directive (2004/108/EC)

Applied harmonised standards,

EN 61010 - 1, EN 60335 -1,

especially:

EN 61000 -6 -1/2/3/4

Date/ Manufacturersignature:

09.03.2012

Name/ positionof the signatory:

Joachim Schall, Manager Innovation and Technology

EC Declaration of Conformity for Machinery

Fig. 12: EC Declaration of Conformity

Systems

35

Page 36

- Original -

We,

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5 - 11

D - 69123 Heidelberg

hereby declare that the product identified below conforms to the basic health and safety

requirements of the EC Directive, by virtue of its design and construction,and in the configuration

placed on the market by us.

This declaration is no longer applicable if changes are made to the product without our authorisation.

Product description:

DULCODOS POOL swimming pool dosing system

Product type:

DSPa _ _ _ _ _ _ _ _ _ _ X _ X _ 1_

and X >

0

i.e. for installed systems with factory-fitted dosing pump

s

Serial no.:

see type plate on the unit

Applicable

EC Machinery Directive (2006/42/EC)

EC Directives:

EC EMC Directive (2004/108/EC)

The safety objectives of the Low Voltage Directive 2006/95/E

C

were complied with in accordance with Appendix 1, No. 1.5.

1

of the Machinery Directive 2006/42/E

C

Applied harmonised standards,

EN ISO 12100, EN 809

especially:

EN 61010 - 1, EN 60335 -1,

EN 61000 -6 -1/2/3/

4

Technical documentation was

Dr. Johannes Hartfiel

compiled by the authorised

Im Schuhmachergewann 5-11

representative for documentation:

D - 69123 Heidelberg

Date / Manufacturer signature:

09.03.2012

Name / position of the signatory:

Joachim Schall, Manager Innovation and Technology

EC Declaration of Conformity for Machinery

Fig. 13: EC Declaration of Conformity

Systems

36

Page 37

10

Index

A

Actuating outputs................................................. 26

Ambient conditions............................................... 14

C

Calibration............................................................ 25

Cleaning the injection valve................................. 32

D

Descaling the injection valve................................ 32

G

General non-discriminatory approach.................... 3

N

non-discriminatory approach.................................. 3

Q

Question: Can the injection valve become

blocked?............................................................... 32

Question: How and why must I calibrate the

product?............................................................... 23

Question: How can I store and transport the

product?............................................................... 14

Question: How do I calibrate the ORP sensor?... 28

Question: How do I calibrate the sensor?............ 25

Question: How do I eliminate functional faults?... 31

Question: How is the product hydraulically

connected and what connection versions are

available?............................................................. 17

Question: What ambient conditions need to

be taken into consideration?................................ 14

Question: What components does the product

include?.................................................................. 7

Question: What do I need to consider when

operating the product for the first time?............... 22

Question: What is the purpose of this product?..... 7

Question: What should I consider when

mounting the product on the wall?....................... 15

Question: What type of buffer solutions do I

need?................................................................... 28

R

Run-in times......................................................... 26

S

Safety information................................................ 10

Sensor function.................................................... 26

Standard signal outputs....................................... 26

Storage.................................................................

14

T

Transport.............................................................. 14

U

Users' qualifications............................................... 9

Z

Zero point calibration............................................ 26

Index

37

Loading...

Loading...