Page 1

Supplementary instructions: PROFINET

A2666

®

DULCOMETER

®

Multi-parameter Controller diaLog DACb

EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Target group: trained electronics technicians982194 Version: BA DM 228 08/18 EN

Page 2

Supplemental directives

General non-discriminatory approach

Supplementary information

In order to make it easier to read, this document uses the male

form in grammatical structures but with an implied neutral sense. It

is aimed equally at both men and women. We kindly ask female

readers for their understanding in this simplification of the text.

Please read the supplementary information in its entirety.

Information

This provides important information relating to the

correct operation of the unit or is intended to make

your work easier.

Warning information

Warning information include detailed descriptions of the hazardous

situation.

The following symbols are used to highlight instructions, links, lists,

results and other elements in this document:

Tab. 1: More symbols

Symbol Description

Action, step by step.

⇨ Outcome of an action.

Links to elements or sections of these instructions or other applicable documents.

n

[Button]

List without set order.

Display element (e.g. indicators).

Operating element (e.g. button, switch).

‘Display /GUI’

CODE

Screen elements (e.g. buttons, assignment of function keys).

Presentation of software elements and/or texts.

2

Page 3

Table of contents

Table of contents

1

Supplementary Instructions for PROFINET®........................ 4

1.1 Prerequisites................................................................. 4

1.2 Terminal diagram for the DAC communication unit...... 4

1.3 Adjusting the Controller................................................ 4

1.3.1 General...................................................................... 4

1.3.2

1.4

1.4.1 General...................................................................... 6

1.4.2 Display....................................................................... 6

1.4.3

1.5 Installation..................................................................... 7

1.6 Operation...................................................................... 7

1.6.1 General...................................................................... 7

1.6.2 GSDML file................................................................ 7

1.6.3 Description of the DACa data objects........................ 8

1.7 Bit field definitions....................................................... 14

1.7.1 Status of the channel............................................... 14

1.7.2 Error of the channel................................................. 16

1.7.3 Warning of the channel............................................ 17

1.7.4 Potential-free relay................................................... 18

1.7.5 Settings of the channel configuration....................... 19

1.8 Diagnostic messages.................................................. 20

1.9 PLC Programmable Logic Controller error message

Configuring PROFINET®........................................... 4

Special Features in Active PROFINET® Mode............. 6

LEDs on the PROFINET® DP module....................... 6

and controller behaviour............................................. 20

3

Page 4

A1173

Communication

Communication

external connector

Socket M12x1 female

4-pin (D-coded)

green (A)

red (B)

green (A)

red (B)

external

communication

Plug M8x1

ext. connector

2x socket M12x1

Female 4-pin

(D-coded)

Switch

alternative

ext. WLAN router

e.g. TP link

TL-WR702N

Communication

2 x plugs

M8x1 (male)

Supplementary Instructions for PROFINET

1

Supplementary Instructions for PROFINET

1.1 Prerequisites

Personnel must be familiar with the contents of the "Assembly and

Operating Instructions for DULCOMETER® Multi-parameter Con‐

troller diaLog DACa".

The controller must have a PROFINET® module.

®

®

Validity of the supplementary instruc‐

tions

These supplementary instructions are only valid when used in con‐

junction with the operating instructions for the Multi-parameter

Controller diaLog DACb.

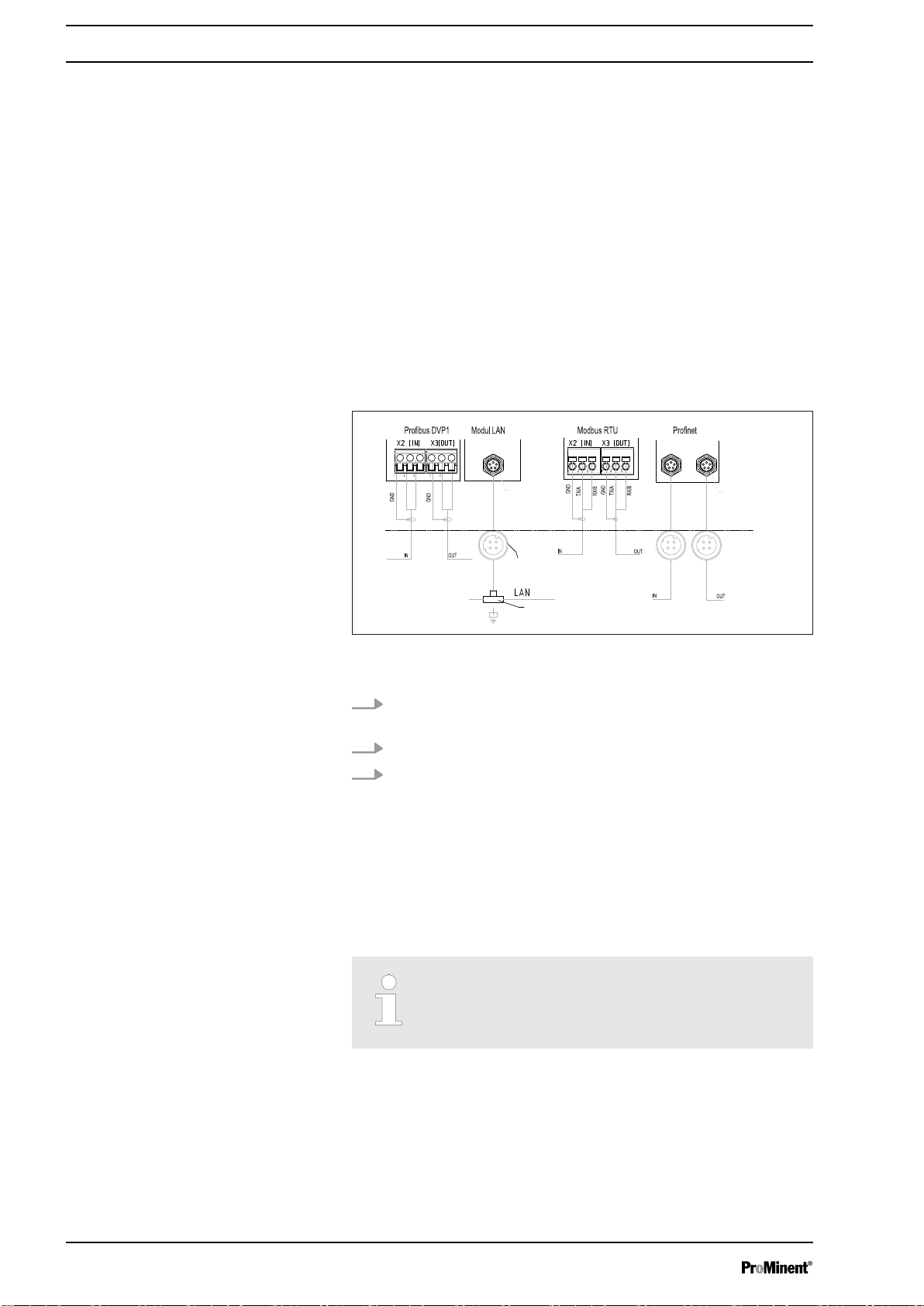

1.2 Terminal diagram for the DAC communication unit

Fig. 1: Terminal diagram for the DAC communication unit (module

B, optional)

1.

Connect the PROFINET® to the DAC communication unit,

Fig. 1.

2. Slot 1 is the left-hand

3. Slot 2 is the right-hand

[IN]

connector.

[OUT]

connector.

1.3 Adjusting the Controller

1.3.1 General

1.3.2

Configuring PROFINET

The controller with PROFINET® functionality is adjusted in the

same way as the standard controller, with the addition of the bus

functionality.

Adjustment process cancelled

The adjustment process is cancelled in the event

of a pause longer than 60 seconds.

®

Remote configuration needs to be enabled to be able to configure

and control the controller via the PROFINET®. The PROFINET® is

always enabled but it does not accept external commands if

remote configuration has not been enabled.

4

Page 5

Supplementary Instructions for PROFINET

All external inputs also work while the PROFINET® is enabled. The

external inputs lead to the expected reactions, as in the case of a

controller without PROFINET® functionality (see controller oper‐

ating instructions). The controller sends corresponding information

via the PROFINET® to the master (PLC Programmable Logic Con‐

troller, PC etc.).

Even if the remote configuration is set to inactive, the master is

able to read-access the controller data defined in the GSDML file.

If the remote configuration is inactive or switched to inactive, then

the settings for the operating mode selected prior to "inactive"

status are reloaded in the controller.

If the controller is switched to another operating mode, it stops and

can only be restarted using the

1. To access the

2. Use the arrow keys to select the menu item

firm with

The

ð

‘Menu’

[OK]

‘Device setup’

[Stop/Start]

: press the

menu appears.

[Menu]

key.

key

‘Setup’

and con‐

®

3. Use the arrow keys to select the menu item

configuration’

ð

In the

4.

n

n DHCP

n

n

n

n

n

The

‘Configuration’

‘Remote configuration’

– Switch remote configuration on or off.

– Switch DHCP on or off.

‘IP address’

– You can set the IP address here at which the con‐

‘Subnet’

– You can set the address of the subnet here.

‘Gateway’

– You can set the address of the gateway here.

‘DNS’

– You can set the address of the DNS here.

‘Station name’

– You can set the station name as an actual word e.g.

and confirm with

‘Configuration’

troller can be accessed.

"daca" or "daisy", using lower case letters only.

menu appears.

menu, you can:

[OK]

‘Bus

Origin of the designations

The different names and/or addresses represent

user-specific information and are the responsibility

of the system operator.

5

Page 6

Supplementary Instructions for PROFINET

1.4

Special Features in Active PROFINET® Mode

®

1.4.1 General

Setting or programming

In PROFINET® mode, the controller cannot be

manually set or programmed. Switch off remote

configuration to set or program the controller.

1.4.2 Display

1.4.3

LEDs on the PROFINET® DP module

n The settings from the last operating mode without PROFINET

are carried over when switching to PROFINET® mode. By con‐

trast, the settings made via the PROFINET® are not saved.

They only apply as long as the controller is linked to the PRO‐

FINET®.

n The controller stops if it is set to PROFINET® mode. The con‐

troller can be controlled again by pressing the

key. The start command is given via the PROFINET®.

When PROFINET® mode is running there are further identifiers in

the operating indicator.

[Stop/Start]

Common identifiers

The common identifiers are described in the con‐

troller operating instructions.

®

LED 1 (left) - module operating status

Signal Cause

Off The module has no supply voltage or connection.

Green The module and the master are exchanging information.

Green flashing The module has been initialised.

LED 2 (right) - module status

Signal Cause

Off The module has not been initialised.

Green The module has been initialised/normal mode

Green flashing, single flash The module has been initialised and there are diagnostic mes‐

sages.

Green flashing, 1 Hz DCP flash

Red Serious exception error

Red, single flash Configuration error

Red, double flash IP address error

6

Page 7

A1173

Communication

Communication

external connector

Socket M12x1 female

4-pin (D-coded)

green (A)

red (B)

green (A)

red (B)

external

communication

Plug M8x1

ext. connector

2x socket M12x1

Female 4-pin

(D-coded)

Switch

alternative

ext. WLAN router

e.g. TP link

TL-WR702N

Communication

2 x plugs

M8x1 (male)

Supplementary Instructions for PROFINET

Signal Cause

Red, triple flash Station name error

Red, quadruple flash Internal error

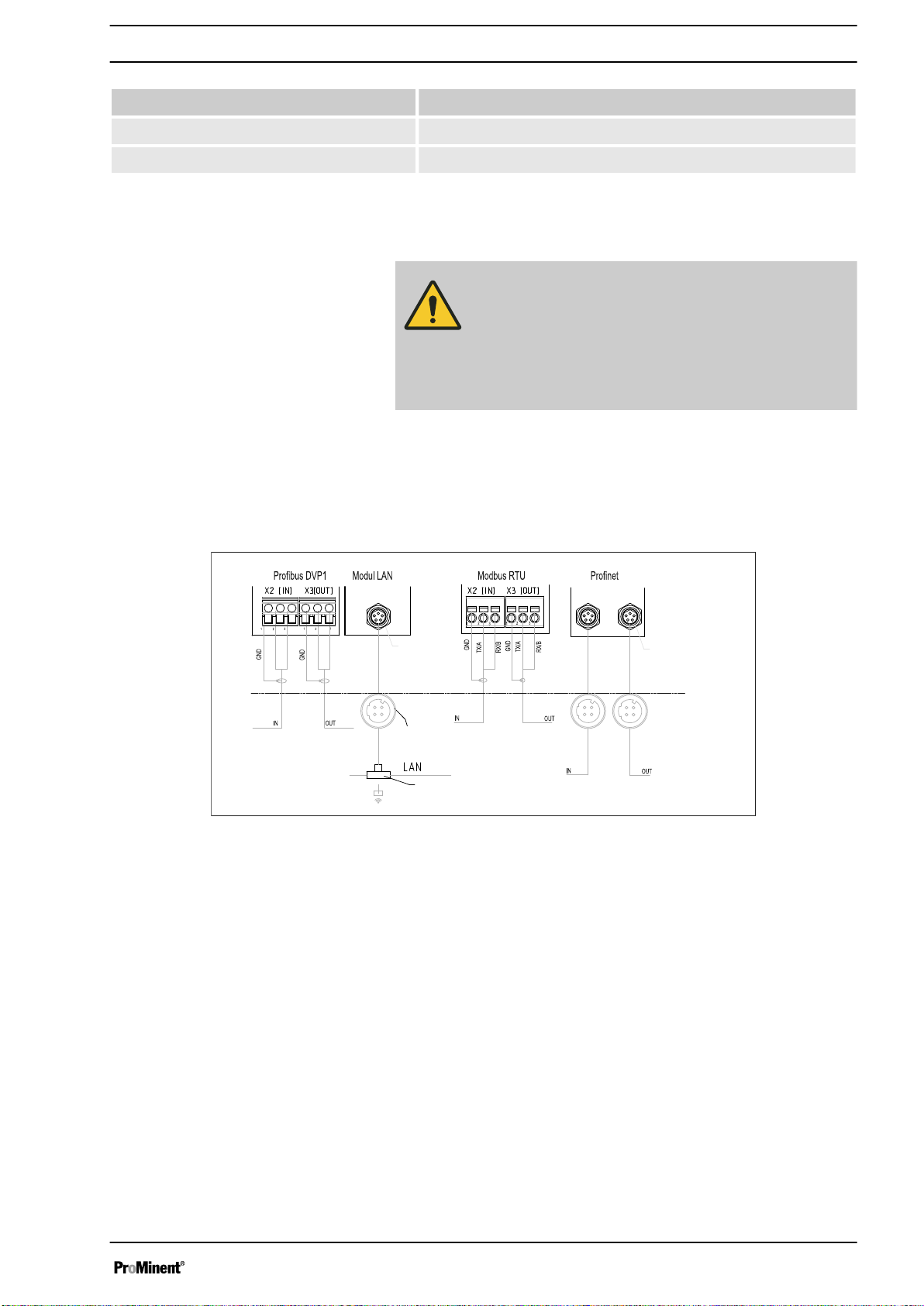

1.5 Installation

Bus installation

CAUTION!

Degree of protection IP 67

– IP 67 degree of protection only applies if the

appropriate assembly accessories (cable pas‐

sages etc.) have been correctly installed (see

controller assembly and operating instructions).

The connection to the existing LAN infrastructure is provided by a

suitable LAN cable, e.g. twisted pair cable (CAT5 or higher) to

comply with IP 67 with a screwed M12x1 plug, 4-pin, D-coded to

IEC 61076-2-101. Complies with IEEE 802.3.

Mains extension:

®

n Copper-based twisted pair cable (TP) maximum 100 metres.

Fig. 2: Terminal diagram of the communication modules

1.6 Operation

1.6.1 General

When the

PROFINET® represents a subscriber with slave functionality.

PROFINET®

module is connected, the controller in the

1.6.2 GSDML file

Use the GSDML file to configure the master. The GSDML file

describes all the features of the controller in PROFINET® mode

(keywords, diagnosis, modules, sub-modules). The GSDML file

can be downloaded from the PROFINET® website and from the

ProMinent website. The file name is clearly indicated: GSDMLV2.32-Prominent-DACa-PRT2P-20150721.xml .

7

Page 8

Supplementary Instructions for PROFINET

®

1.6.3 Description of the DACa data objects

Tab. 2: Output data

Slot Index Name Module name Data type Byte

count

Output data

Total:

Channel 1

1 2 Measured

1 3 Controller

1 4 Temperature INT16 2 0.1 °C

1 5 Setpoint FLOAT 4

1 6 Channel

‘Channel 1’

FLOAT 4

value

INT16 2

control vari‐

able

UINT16 2

status

Ä Chapter 1.7.1

‘Status of the

channel’

on page 14

1 7 Warnings UINT16 2

Ä Chapter 1.7.3

‘Warning of the

channel’

on page 17

Channel 2

2 2 Measured

‘Channel 2’

FLOAT 4

value

2 3 Controller

control vari‐

able

2 4 Temperature INT16 2 0.1 °C

2 5 Setpoint FLOAT 4

2 6 Channel

status

INT16 2

UINT16 2

Ä Chapter 1.7.1

‘Status of the

channel’

on page 14

2 7 Warnings UINT16 2

Ä Chapter 1.7.3

‘Warning of the

channel’

on page 17

Channel 3

3 2 Measured

3 3 Controller

‘Channel 3’

FLOAT 4

value

INT16 2

control vari‐

able

8

Page 9

Supplementary Instructions for PROFINET

®

Slot Index Name Module name Data type Byte

count

3 4 Temperature INT16 2 0.1 °C

3 5 Setpoint FLOAT 4

3 6 Channel

status

UINT16 2

Total:

Ä Chapter 1.7.1

‘Status of the

channel’

on page 14

3 7 Warnings UINT16 2

Ä Chapter 1.7.3

‘Warning of the

channel’

on page 17

Channel 4

(differential

channel)

4 1 Measured

4 2 Channel

‘Channel 4’

FLOAT 4

value

UINT16 2

status

Ä Chapter 1.7.1

‘Status of the

channel’

on page 14

4 3 Warnings UINT16 2

Ä Chapter 1.7.3

‘Warning of the

channel’

on page 17

Digital out‐

puts

5 1 Relay UINT16 2

‘digital output’

Ä Chapter 1.7.4

‘Potential-free

relay’

on page 18

5 2 MosFET 1 UINT16 2 Frequency

5 3 MosFET 2 UINT16 2 Frequency

5 4 MosFET 3 UINT16 2 Frequency

5 5 MosFET 4 UINT16 2 Frequency

Error

‘errors’

9

Page 10

Supplementary Instructions for PROFINET

®

Slot Index Name Module name Data type Byte

count

6 1 Error

channel 1

6 2 Error

channel 2

6 3 Error

channel 3

6 4 Error

channel 4

UINT32 4

UINT32 4

UINT32 4

UINT16 2

Total:

Ä Chapter 1.7.2

‘Error of the

channel’

on page 16

Ä Chapter 1.7.2

‘Error of the

channel’

on page 16

Ä Chapter 1.7.2

‘Error of the

channel’

on page 16

Ä Chapter 1.7.2

‘Error of the

channel’

on page 16

10

Page 11

Supplementary Instructions for PROFINET

Tab. 3: Input data

Slot Index Name Module name Data type Byte

count

Input data

®

Total:

Stop / Pause

(belongs to

the

‘Channel1/

Channel2’

module)

1 1

2 1

3 1

Controller

channel 1

‘Channel 1’

Stop / Pause

UINT8 1 Bit 7 = Stop

channel 1

‘Channel 2’

Stop / Pause

UINT8 1 Bit 7 = Stop

channel 2

‘Channel 3’

Stop / Pause

UINT8 1 Bit 7 = Stop

channel 3

‘controller

channel 1’

Bit 1 = Pause/

HOLD

Bit 0 = Pause

Bit 1 = Pause/

HOLD

Bit 0 = Pause

Bit 1 = Pause/

HOLD

Bit 0 = Pause

7 1 Configuration UINT16 2

7 2 Limit value 1

FLOAT 4

value

7 3 Limit value 2

FLOAT 4

value

7 4 Setpoint 1 FLOAT 4

7 5 Xp FLOAT 4

Controller

channel 2

‘controller

channel 2’

Ä Chapter

1.7.5 ‘Settings

of the channel

configuration’

on page 19

(Parameter

via bus,

mode, limit

value direc‐

tion, control

time)

11

Page 12

Supplementary Instructions for PROFINET

®

Slot Index Name Module name Data type Byte

count

8 1 Configuration UINT16 2

8 2 Limit value 1

value

8 3 Limit value 2

value

8 4 Setpoint 1 FLOAT 4

8 5 Xp FLOAT 4

Controller

channel 3

‘controller

channel 3’

FLOAT 4

FLOAT 4

Total:

Ä Chapter

1.7.5 ‘Settings

of the channel

configuration’

on page 19

(Parameter

via bus,

mode, limit

value direc‐

tion, control

time)

9 1 Configuration UINT16 2

9 2 Limit value 1

value

9 3 Limit value 2

value

9 4 Setpoint 1 FLOAT 4

9 5 Xp FLOAT 4

Error confir‐

mation

10 1 Error

‘error

confirmation’

channel 1

FLOAT 4

FLOAT 4

UINT32 4

Ä Chapter

1.7.5 ‘Settings

of the channel

configuration’

on page 19

(Parameter

via bus,

mode, limit

value direc‐

tion, control

time)

0xFFFFFFFF

*

=> all pending

errors have

been con‐

firmed

Ä Chapter

1.7.2 ‘Error of

the channel’

on page 16

12

Page 13

Supplementary Instructions for PROFINET

®

Slot Index Name Module name Data type Byte

count

10 2 Error

channel 2

10 3 Error

channel 3

10 4 Error

channel 4

UINT32 4

UINT32 4

UINT16 2

Total:

0xFFFFFFFF

*

=> all pending

errors have

been con‐

firmed

Ä Chapter

1.7.2 ‘Error of

the channel’

on page 16

0xFFFFFFFF

*

=> all pending

errors have

been con‐

firmed

Ä Chapter

1.7.2 ‘Error of

the channel’

on page 16

0xFFFF *

=> all pending

errors have

been con‐

firmed

Ä Chapter

1.7.2 ‘Error of

the channel’

on page 16

* These errors can also be deleted/acknowledged individually.

Controller

parameter

channel 1

11 1 Additive

11 2 Control vari‐

11 3 Delay after

11 4 Delay after

11 5 Setpoint 2 FLOAT 4 only with neu‐

‘controller

parameter ch1’

INT16 2

basic load

UINT16 2

able limit

UINT16 2

stop

UINT16 2

restart

tral zone con‐

trol

Controller

parameter

channel 2

‘controller

parameter ch2’

13

Page 14

Supplementary Instructions for PROFINET

®

Slot Index Name Module name Data type Byte

Total:

count

12 1 Additive

INT16 2

basic load

12 2 Control vari‐

UINT16 2

able limit

12 3 Delay after

UINT16 2

stop

12 4 Delay after

UINT16 2

restart

12 5 Setpoint 2 FLOAT 4 only with neu‐

tral zone con‐

trol

Controller

parameter

‘controller

parameter ch3’

channel 3

13 1 Additive

INT16 2

basic load

13 2 Control vari‐

UINT16 2

able limit

13 3 Delay after

UINT16 2

stop

13 4 Delay after

UINT16 2

restart

13 5 Setpoint 2 FLOAT 4 only with neu‐

tral zone con‐

trol

1.7 Bit field definitions

1.7.1 Status of the channel

Bit Description

15 1 = channel uses bus control parameters; 0 = channel uses internal parameters

14

13 1 = error exists; 0 = no error

12 1 = warning exists; 0 = no warning

11 1 = SD card full; 0 = SD card not full

10 1 = SD card free < 20%; 0 = SD card free ≧ 20%

9 1 = SD card exists; 0 = no SD card

8 1 = local control rate 2 active; 0 = local control rate 1 active

7

6

5

4

14

Page 15

Supplementary Instructions for PROFINET

Bit Description

3

2

1 1 = local stop active; 0 = no local stop active

0 1 = channel active; 0 = channel inactive (or cannot be connected)

®

15

Page 16

Supplementary Instructions for PROFINET

1.7.2 Error of the channel

Bit Description

®

31 Error 99: There is a system error;

30

29

28

27

26

25

24

23

22

21

20 Error 88: The connection to the extension module is faulty;

[A system error exists]

[The connection to the expansion module is faulty ]

19 Error 34: Incorrect correction variable;

18 Error 19: The liquid level in storage tank 3 is too low;

17 Error 18: The liquid level in storage tank 2 is too low;

[Incorrect correction variable ]

[The level in tank 3 is too low ]

[The level in tank 2 is too low ]

16 Error 17: The liquid level in storage tank 1 is too low;

15 Error 16: The mA input is overloaded;

14 Error 15: The mA input supply is overloaded;

13 Error 14: The status of the controller is pause / hold

[The mA input is overloaded]

[The mA input supply is overloaded]

[The level in tank 1 is too low ]

[PAUSE / HOLD]

;

[The controller is in the state PAUSE / HOLD]

12 Error 13: The status of the controller is pause

11 Error 12: There is a sample water fault e.g. no flow;

10 Error 11: After elapse of the delay period, a limit value error still exists;

[PAUSE]; [The controller is in the state PAUSE]

[Error sample water exists, e. g. no flow]

[After elapsing of the delay time a limit error still exists]

9 Error 10: The mA input current is less than 4 mA;

8 Error 9: The mA input current is greater than 20 mA;

[The mA input current is less than 4 mA ]

[The mA input current is greater than 20 mA ]

7 Error 8: The check time was infringed;

6 Error 7: Check the mechanical condition (glass breakage) of the sensor;

[The checkout time was infringed]

[Check the mechanical status of the sensor Glass break is possible]

5 Error 6: No sensor available;

4 Error 5: Calibration error exists;

3 Error 4: The temperature is too high;

[No sensor is available ]

[A calibration error exists]

[The temperature is too high]

2 Error 3: The temperature is too low;

1 Error 2: The mV input voltage is too high;

0 Error 1: The mV input voltage is too low;

[The temperature is too low ]

[The mV input voltage is too high ]

[The mV input voltage is too low ]

16

Page 17

1.7.3 Warning of the channel

Bit Description

15

14

13

12

11

10

9

8

7

Supplementary Instructions for PROFINET

®

6 Warning 73: The fan has a fault;

5 Warning 72 The time must be checked;

4 Warning 71 The battery needs to be replaced;

[The fan has an error]

[The time must be checked]

[The battery must be replace]

3 Warning 4 The measuring channel is not yet calibrated;

[The measuring channel is not yet calibrated]

2 Warning 3 The wash timer has timed out. Maintenance is required;

[The wash timer has timed out. Maintenance is necessary]

1 Warning 2 The limit value was exceeded;

0 Warning 1 The limit value was not reached;

[The limit was exceeded ]

[The limit was undershot]

17

Page 18

Supplementary Instructions for PROFINET

1.7.4 Potential-free relay

If relay output is active, then according bit is used.

Bit Description

15

14

13

12

11

10

9

8

7

6

®

5

4

3

2 Configuring alarm relay (XR3)

1 Relay 2 (XR2)

0 Relay 1 (XR1)

18

Page 19

Supplementary Instructions for PROFINET

1.7.5 Settings of the channel configuration

Bit Description

15 1 = Channel uses remote control parameters; 0 = Channel uses internal parameters;

[1 = Channel uses remote control parameters; 0 = Channel uses internal parameters]

14 1 = Channel uses internal set 2; 0 = Channel uses internal set 1;

[1 = Use internal parameter set 2; 0 = Use internal parameter set 1]

13

12

11

10

9

8 1 = Limit value 2 configuration on; 0 = limit value 2 configuration off

[1 = limit 2 configuration on; 0 = limit 2 configuration off]

7 1 = Limit value 1 configuration on; 0 = limit value 1 configuration off

[1 = limit 1 configuration on; 0 = limit1 configuration off]

®

6 0 = Control off;

[0 = Control off]

5

3 = P (1 way, decrease);

4

[3 = P (1 way, decrease)]

3

6 = PID (1 way, increase)

[6 = PID (1 way, increase) ]

9 = PID (2 way, dead zone)

1 = manual

[1 = manual]

4 = P (2 way, standard)

[ 4 = P (2 way, standard)]

7 = PID (1 way, decrease);

[7 = PID (1 way, decrease)]

[9 = PID (2 way, deadzone)]

2

1 1 = Limit value 2 configuration high; 0 = limit value 2 configuration low;

[1 = limit 2 configuration high; 0 = limit 2 configuration off]

0 1 = Limit value 1 configuration high; 0 = limit value 1 configuration low;

[1 = limit 1 configuration high; 0 = limit 1 configuration off ]

n Bit 14 is only valid if bit 15 = 0

n Bit 3, 4, 5, 6 are only valid if bit 15 = 1

n Bit 3, 4, 5, 6, 14, 15 only exists on channels 1 and 2

2 = P (1 way, increase)

[2 = P (1 way, increase)]

5 = P (2 way, dead zone)

[5 = P (2 way, deadzone)]

8 = PID (2 way, standard)

[ 8 = PID (2way, standard)]

19

Page 20

Supplementary Instructions for PROFINET

®

1.8 Diagnostic messages

The diagnostic messages are shown in plain text in the PLC Pro‐

grammable Logic Controller.

Error type Diagnostic messages

12755 Limit error when writing

12773 Limit error when reading

13011 Protected value

13029 Protected value

13267 Device not in remote mode

13285 Device not in remote mode

13523 Option not installed

13541 Option not installed

13779 Service not defined

13797 Service not defined

14035 Value cannot be changed

14053 Value cannot be changed

1.9 PLC Programmable Logic Controller error message and controller behaviour

PLC Programmable Logic Controller error message Controller behaviour

IOPS = bad stopped

Disconnected connection stopped

Mains power On stopped

20

Page 21

21

Page 22

22

Page 23

23

Page 24

ProMinent GmbH

Im Schuhmachergewann 5 - 11

69123 Heidelberg

Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

982194, 1, en_GB

© 2018

Loading...

Loading...