Page 1

Assembly and operating instructions

A2543

Universal relief valve

Universelles Überströmventil

DHV-UR

EN/DE

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Target group: trained users983439 Version: BA MOZ 042 03/18 DE

Page 2

Overall Table of Contents

Overall Table of Con‐

tents

EN Universal relief valve DHV-UR..... 4

1 About this product................... 9

1.1 Nameplate.......................... 10

1.2 Versions............................. 11

2 Safety chapter....................... 15

2.1 Labelling of Warning Infor‐

mation................................ 15

2.2 User qualification............... 17

2.3 General safety informa‐

tion..................................... 19

2.4 Intended use...................... 22

3 Storage and transport........... 23

3.1 Storage.............................. 23

3.2 Transport............................ 23

3.3 Packaging material............ 23

4 Assembly.............................. 24

4.1 Assembling the relief

valve................................... 24

4.2 Fitting a manometer

(optional)............................ 29

5 Commissioning..................... 30

5.1 Pressure/temperature dia‐

gram................................... 31

5.2 Initial commissioning.......... 32

5.3 Releasing pressure from

the relief valve.................... 33

5.4 Setting the relief valve........ 34

5.5 Setting the process pres‐

sure.................................... 36

6 Maintenance......................... 37

7 Repair................................... 38

7.1 Dismantling the relief

valve................................... 40

7.2 Inspecting and replacing

the parts............................. 45

7.3 Assembling the relief

valve................................... 47

8 Troubleshooting.................... 49

9 Use Parts Disposal/Declara‐

tion of Decontamination........ 51

10 Technical data..................... 52

10.1 Applied standards............ 59

11 DHV-UR spare parts........... 60

12 Exploded view drawing....... 62

12.1 Exploded view drawing of

DHV-UR PP_, PC_, PV_.. 62

12.2 Exploded view drawing of

DHV-UR SS..................... 63

12.3 Parts list........................... 64

13 Dimensional drawing........... 65

13.1 Dimensional drawing of

DHV-UR PVC, PP,

PVDF............................... 65

13.2 Dimensional drawing of

DHV-UR SS..................... 67

DE Universelles Überströmventil

DHV-UR..................................... 72

1 Über dieses Produkt............. 77

1.1 Typenschild........................ 78

1.2 Ausführungen..................... 79

2 Sicherheitskapitel.................. 83

2.1 Kennzeichnung der Warn‐

hinweise............................. 83

2.2 Benutzer-Qualifikation........ 85

2.3 Allgemeine Sicherheitshin‐

weise.................................. 87

2.4 Bestimmungsgemäße Ver‐

wendung............................ 90

3 Lagern und transportieren .... 91

3.1 Lagern................................ 91

3.2 Transport............................ 91

3.3 Verpackungsmaterial......... 91

4 Montieren.............................. 92

2

Page 3

4.1 Das Überströmventil mon‐

tieren.................................. 92

4.2 Ein Manometer montieren

(Option).............................. 97

5 Inbetriebnahme..................... 98

5.1 Druck-Temperatur-Dia‐

gramm................................ 99

5.2 Erstinbetriebnahme.......... 100

5.3 Druckentlasten des Über‐

strömventils...................... 101

5.4 Überströmventil einstellen 102

5.5 Prozessdruck einstellen... 104

6 Wartung.............................. 105

7 Reparieren.......................... 106

7.1 Überströmventil zerlegen 108

7.2 Teile untersuchen und aus‐

tauschen.......................... 113

7.3 Überströmventil zusam‐

mensetzen....................... 115

8 Funktionsstörungen

beheben.............................. 117

9 Altteileentsorgung/Dekonta‐

minationserklärung.............. 119

10 Technische Daten............. 120

10.1 Angewandte Normen..... 127

11 Ersatzteile DHV-UR.......... 128

12 Explosionszeichnung........ 130

12.1 Explosionszeichnung

DHV-UR PP_, PC_ und

PV_ ............................... 130

12.2 Explosionszeichnung

DHV-UR SS................... 131

12.3 Stückliste........................ 132

13 Maßblatt............................ 133

13.1 Maßblatt DHV-UR PVC-

U, PP, PVDF ................. 133

13.2 Maßblatt DHV-UR SS.... 135

Overall Table of Contents

3

Page 4

Assembly and operating instructions

A2543

Universal relief valve

DHV-UR

EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Target group: trained usersPart number 983439 Version: BA MOZ 042 03/18 EN

Page 5

Supplemental directives

General non-discriminatory approach In order to make it easier to read, this

document uses the male form in grammat‐

ical structures but with an implied neutral

sense. It is aimed equally at both men and

women. We kindly ask female readers for

their understanding in this simplification of

the text.

Supplementary information

Please read the supplementary information in its entirety.

Information

This provides important information relating to the correct operation of the unit or

is intended to make your work easier.

Warning information

Warning information includes detailed descriptions of the hazardous situation, see

Ä Chapter 2.1 ‘Labelling of Warning Information’ on page 15

.

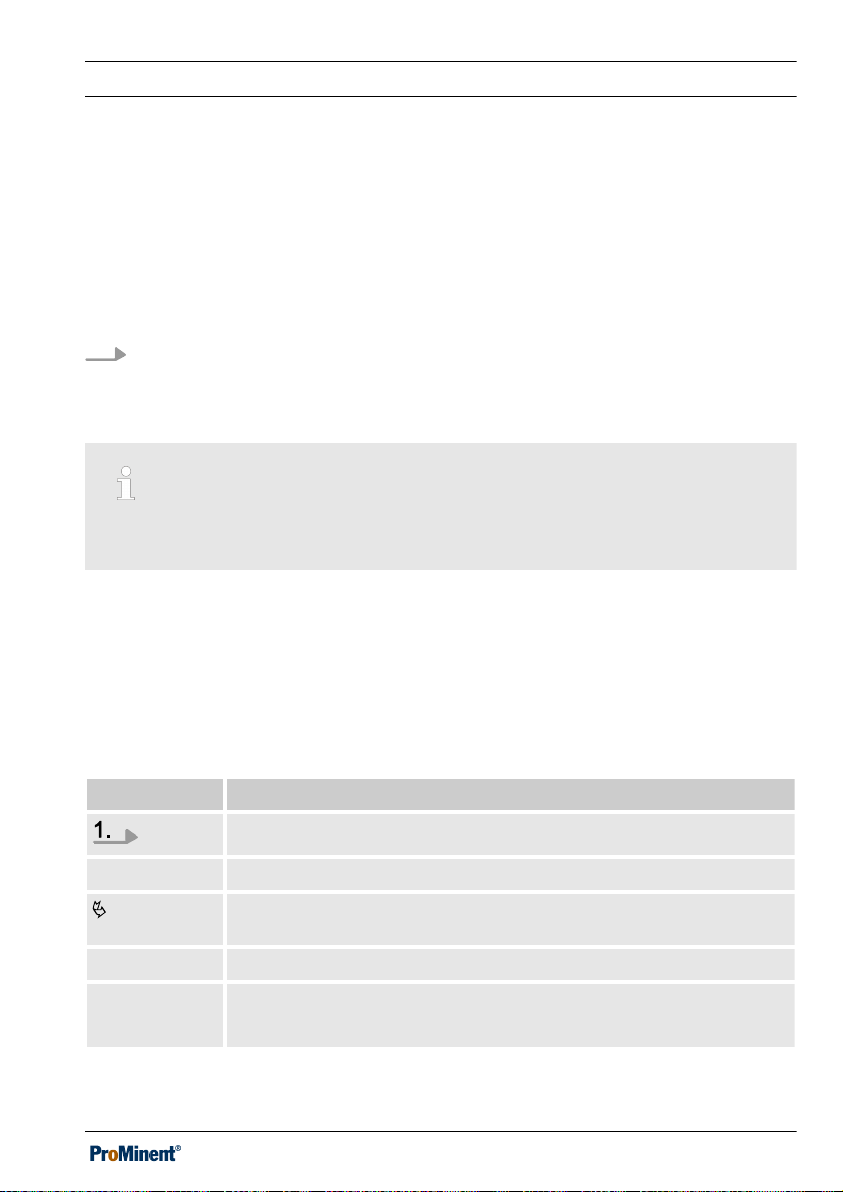

The following symbols are used to highlight instructions, links, lists, results and other ele‐

ments in this document:

Tab. 1: More symbols

Symbol Description

Action, step by step.

⇨ Outcome of an action.

Links to elements or sections of these instructions or other applicable

documents.

n

[Button]

List without set order.

Display element (e.g. indicators).

Operating element (e.g. button, switch).

5

Page 6

Supplemental directives

Symbol Description

‘Display /GUI’

CODE

Screen elements (e.g. buttons, assignment of function keys).

Presentation of software elements and/or texts.

6

Page 7

Table of contents

Table of contents

1 About this product................................................................................................... 9

1.1 Nameplate.................................................................................................... 10

1.2 Versions....................................................................................................... 11

1.2.1 Design of the standard version.................................................................. 11

1.2.2 Design with FDA approval......................................................................... 12

1.2.3 Version configured for manometer............................................................ 13

2 Safety chapter....................................................................................................... 15

2.1 Labelling of Warning Information.................................................................. 15

2.2 User qualification.......................................................................................... 17

2.3 General safety information........................................................................... 19

2.3.1 Information in the event of an emergency................................................. 21

2.4 Intended use................................................................................................. 22

3 Storage and transport........................................................................................... 23

3.1 Storage......................................................................................................... 23

3.2 Transport...................................................................................................... 23

3.3 Packaging material....................................................................................... 23

4 Assembly.............................................................................................................. 24

4.1 Assembling the relief valve........................................................................... 24

4.1.1 Installation examples................................................................................. 28

4.2 Fitting a manometer (optional)..................................................................... 29

5 Commissioning..................................................................................................... 30

Pressure/temperature diagram..................................................................... 31

5.1

5.2 Initial commissioning.................................................................................... 32

5.3 Releasing pressure from the relief valve...................................................... 33

5.4 Setting the relief valve.................................................................................. 34

5.5 Setting the process pressure........................................................................ 36

6 Maintenance......................................................................................................... 37

7 Repair................................................................................................................... 38

Dismantling the relief valve.......................................................................... 40

7.1

7.2 Inspecting and replacing the parts............................................................... 45

7.3 Assembling the relief valve........................................................................... 47

8 Troubleshooting.................................................................................................... 49

7

Page 8

Table of contents

9 Use Parts Disposal/Declaration of Decontamination............................................ 51

10 Technical data...................................................................................................... 52

10.1 Applied standards....................................................................................... 59

11 DHV-UR spare parts............................................................................................. 60

12 Exploded view drawing......................................................................................... 62

12.1 Exploded view drawing of DHV-UR PP_, PC_, PV_................................... 62

12.2 Exploded view drawing of DHV-UR SS...................................................... 63

12.3 Parts list...................................................................................................... 64

13 Dimensional drawing............................................................................................ 65

13.1 Dimensional drawing of DHV-UR PVC, PP, PVDF.................................... 65

13.2 Dimensional drawing of DHV-UR SS......................................................... 67

14 Index..................................................................................................................... 69

8

Page 9

A2538

About this product

1 About this product

The relief valve protects pumps from impermissible overpressure caused by operational

faults or blockages.

The universal relief valve type DHV-UR is a continuously adjustable plunger diaphragm

valve with an internal flow. In the event of impermissible overpressure, the internal

plunger diaphragm opens the second outlet line, the relief outlet. The relief valve can be

installed at any location in the pipework system. There are only very low pressure losses

due to the virtually free pipe cross-section.

Fig. 1: Scope of delivery: relief valve with seals for the connector.

A manometer can also be installed on the “M” version of the relief valve DHV-UR.

The relief valve is also available as an FDA-approved version.

9

Page 10

A2539

About this product

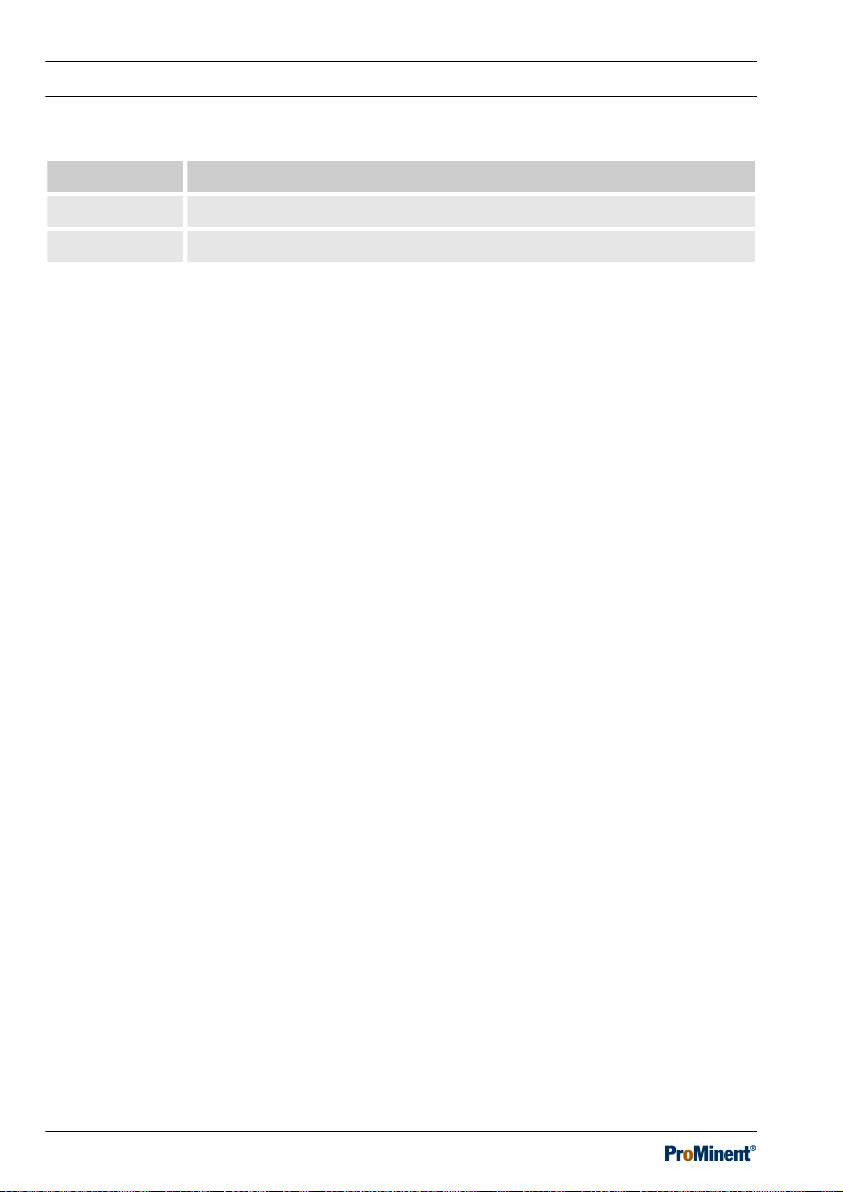

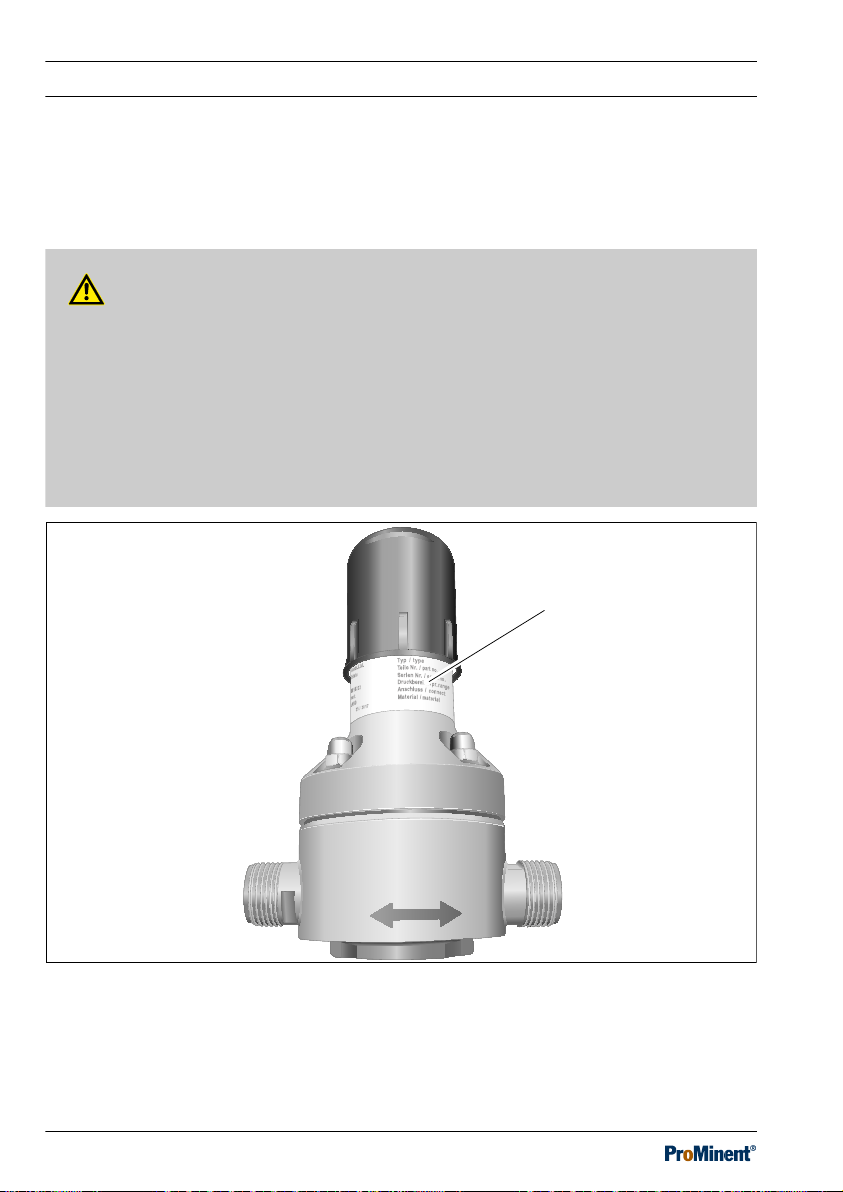

1.1 Nameplate

Fig. 2: Nameplate

The nameplate provides information on:

n Manufacturer with address and phone number

n Place and country of origin,

n Manufacturing data –– week / year

n Type of device with diameter and material version

n Part number

n Serial number

n Pressure range in bar und psi

n Connector size in inches and millimetres

n Material version

[Teile Nr. / part no.]

[Serien Nr. / serial no.]

[Druckbereich / pr. range]

[Material / material]

,

[Anschluss / connect]

.

[Typ / type]

,

,

10

Page 11

About this product

1.2 Versions

1.2.1 Design of the standard version

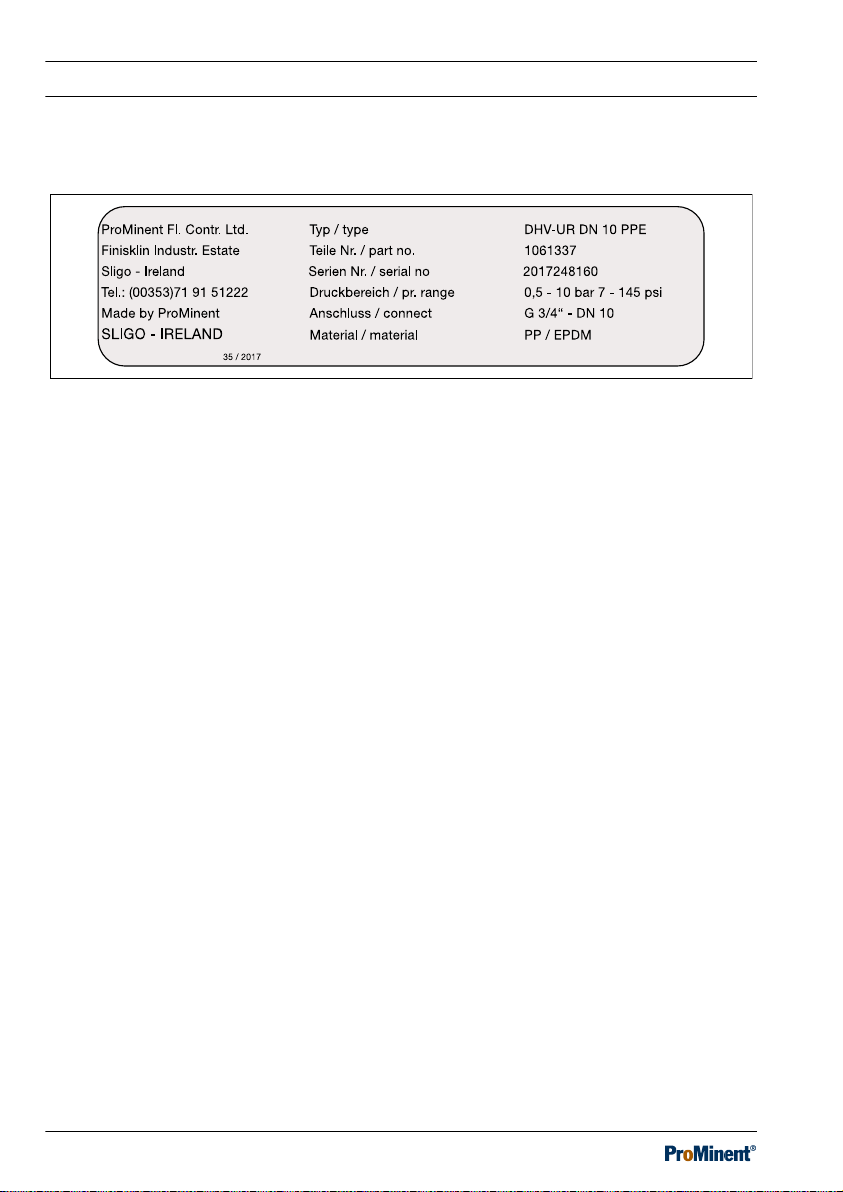

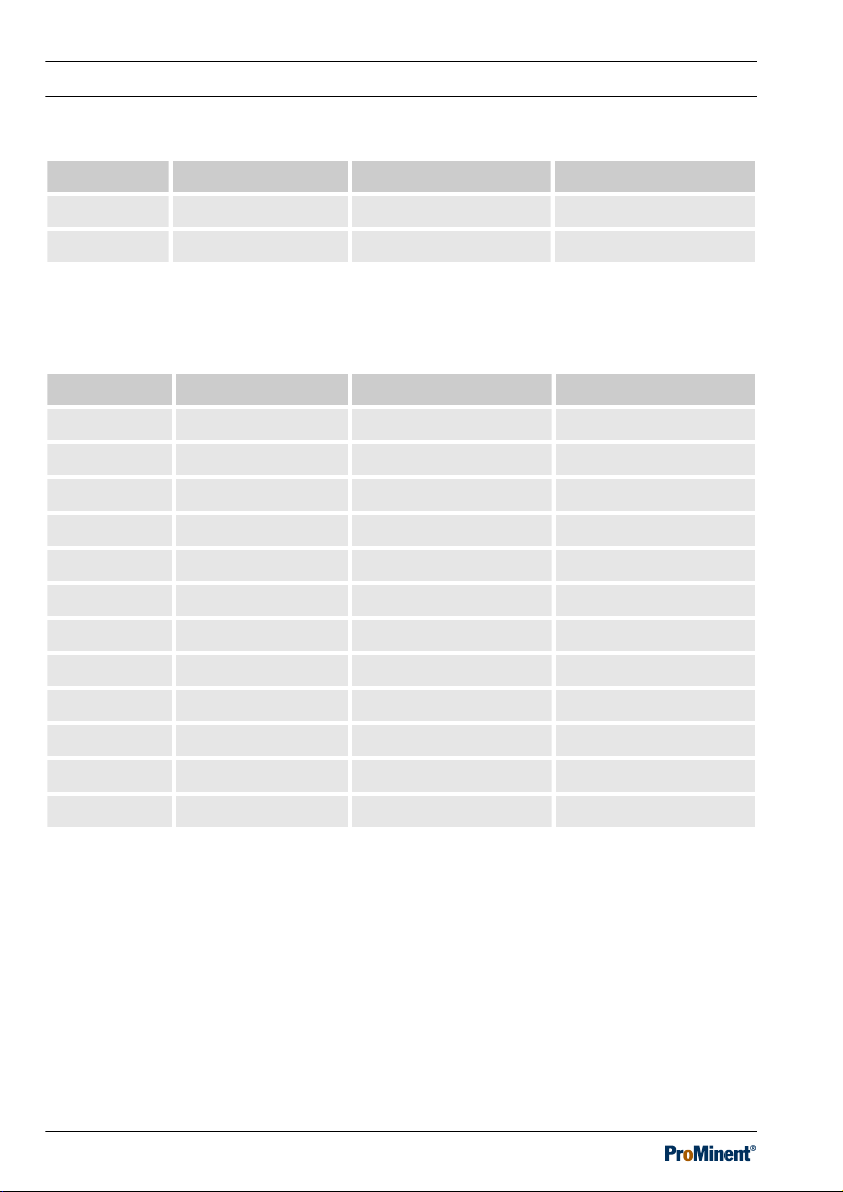

Tab. 2: Design: standard

Design Nominal width Thread in inches Order number

PPE DN 10 3/4 1061337

PPB DN 10 3/4 1061341

PCE DN 10 3/4 1061339

PCB DN 10 3/4 1061343

PVT DN 10 3/4 1061365

SST DN 10 3/4 1061550

PPE DN 15 1 1061336

PPB DN 15 1 1061340

PCE DN 15 1 1061338

PCB DN 15 1 1061342

PVT DN 15 1 1061364

SST DN 15 1 1061551

PPE DN 20 1 1/4 1061367

PPB DN 20 1 1/4 1061371

PCE DN 20 1 1/4 1061369

PCB DN 20 1 1/4 1061373

PVT DN 20 1 1/4 1061375

SST DN 20 1 1/4 1061569

PPE DN 25 1 1/2 1061366

PPB DN 25 1 1/2 1061370

PCE DN 25 1 1/2 1061368

PCB DN 25 1 1/2 1061372

11

Page 12

About this product

Design Nominal width Thread in inches Order number

PVT DN 25 1 1/2 1061374

SST DN 25 1 1/2 1061570

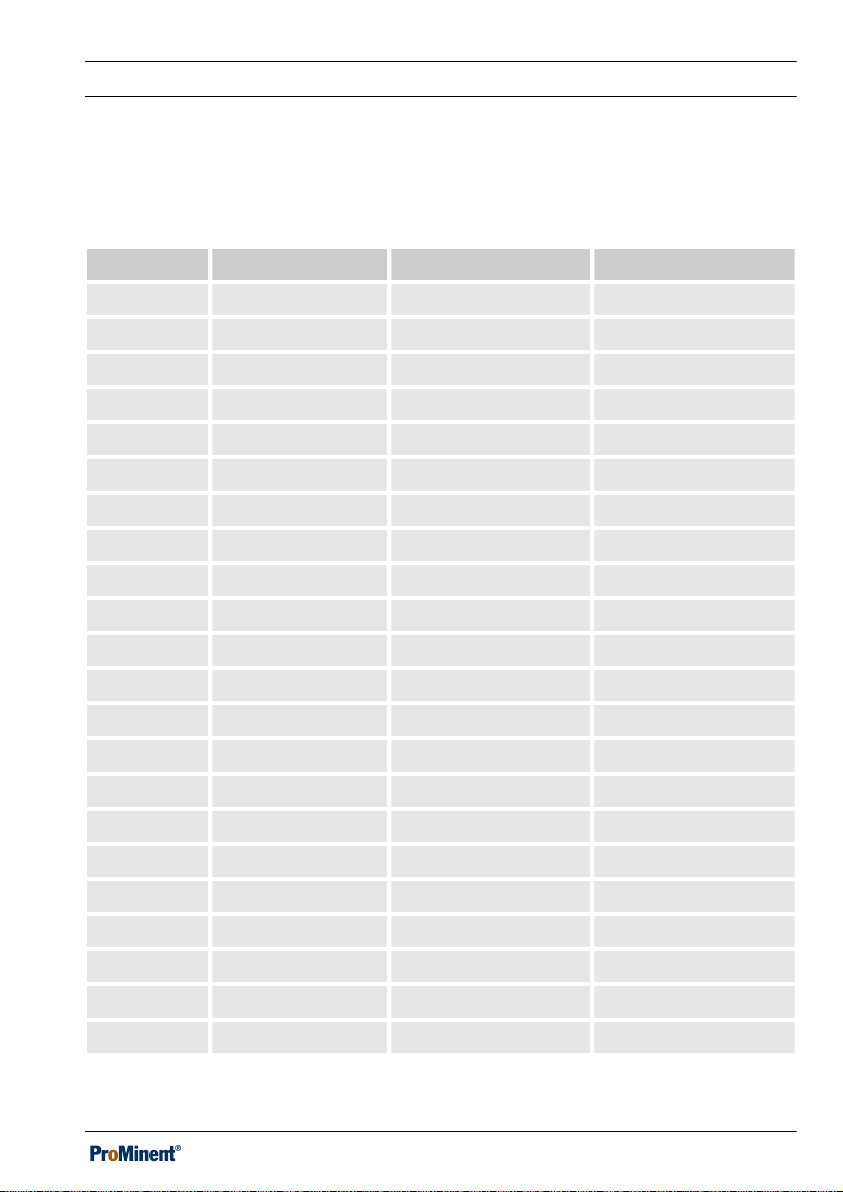

1.2.2 Design with FDA approval

Tab. 3: Design: FDA

Design Nominal width Thread in inches Order number

PPE DN 10 3/4 1075828

PVT DN 10 3/4 1075830

SST DN 10 3/4 1075847

PPE DN 15 1 1075827

PVT DN 15 1 1075829

SST DN 15 1 1075846

PPE DN 20 1 1/4 1075833

PVT DN 20 1 1/4 1075845

SST DN 20 1 1/4 1075849

PPE DN 25 1 1/2 1075832

PVT DN 25 1 1/2 1075844

SST DN 25 1 1/2 1075848

All wetted materials in the "Physiologically safe (FDA) in respect of wetted materials"

design comply with the following FDA guidelines:

FDA guidelines for the materials:

n PTFE: 21CFR177.1510,

n PVDF: 21CFR177.2510,

n PP: 21CFR177.1520,

n EPDM/FKM: 21CFR177.2600.

12

Page 13

About this product

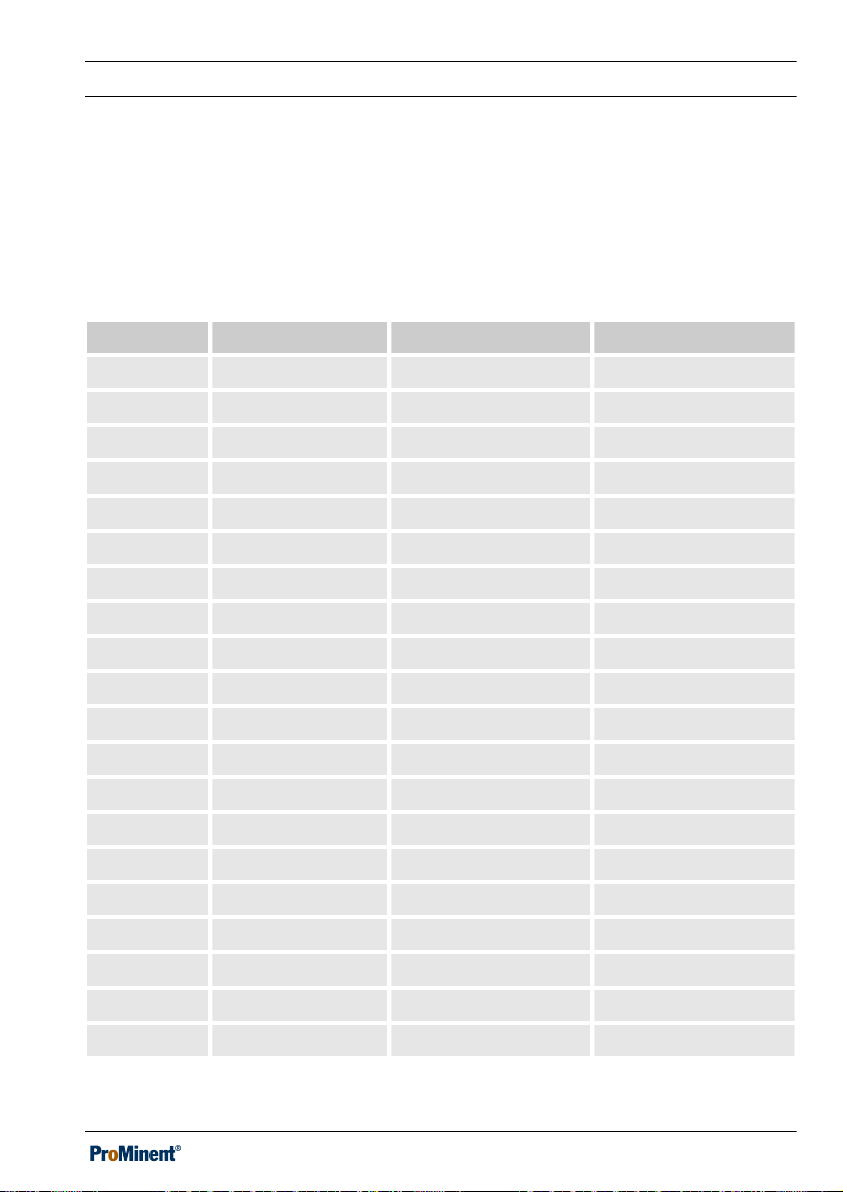

1.2.3 Version configured for manometer

The “M” version of relief valve DHV-UR is configured with an opening in the housing for

installation of a manometer. Manometers with a G 1/4“ (ISO 228) threaded socket can be

fitted directly by the customer.

Tab. 4: Design: relief valve type DHV-UR M configured for manometer

Design Nominal width Thread in inches Order number

PPE DN 10 3/4 1077221

PPB DN 10 3/4 1077259

PCE DN 10 3/4 1077255

PCB DN 10 3/4 1077263

PVT DN 10 3/4 1077267

PPE DN 15 1 1077220

PPB DN 15 1 1077258

PCE DN 15 1 1077254

PCB DN 15 1 1077262

PVT DN 15 1 1077266

PPE DN 20 1 1/4 1077219

PPB DN 20 1 1/4 1077257

PCE DN 20 1 1/4 1077223

PCB DN 20 1 1/4 1077261

PVT DN 20 1 1/4 1077265

PPE DN 25 1 1/2 1077218

PPB DN 25 1 1/2 1077256

PCE DN 25 1 1/2 1077222

PCB DN 25 1 1/2 1077260

PVT DN 25 1 1/2 1077264

13

Page 14

About this product

14

Page 15

2 Safety chapter

A2540

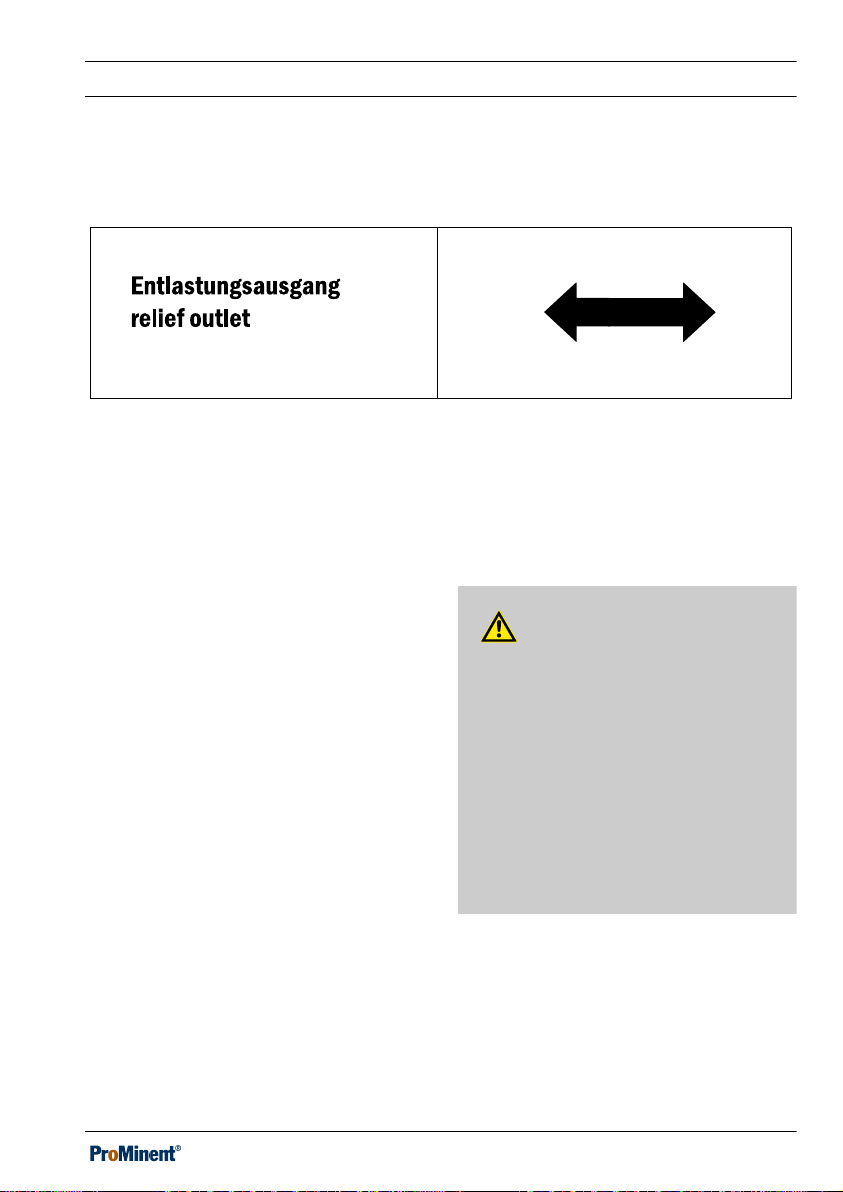

The adhesive labels and signs on the device e.g.:

Fig. 3: Relief outlet [Entlastungsausgang/relief outlet] / Flow direction

n Labels for fluid connectors,

n Direction of flow arrow,

n Nameplate,

must be observed and maintained in a fully legible condition.

2.1 Labelling of Warning Infor‐

mation

Introduction

These operating instructions provide infor‐

mation on the technical data and functions

of the product. These operating instruc‐

tions provide detailed warning information

and are provided as clear step-by-step

instructions.

The warning information and notes are

categorised according to the following

scheme. A number of different symbols

are used to denote different situations.

The symbols shown here serve only as

examples.

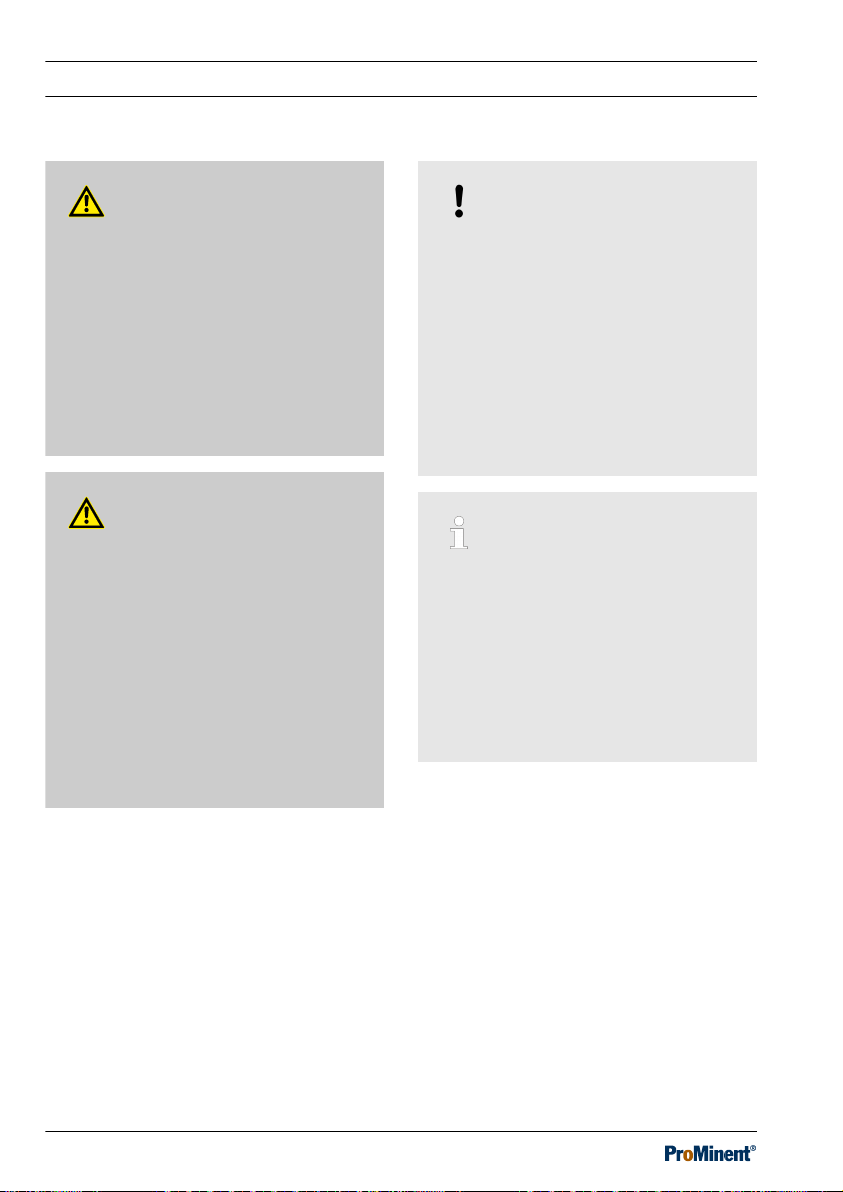

DANGER!

Nature and source of the danger

Consequence: Fatal or very

serious injuries.

Measure to be taken to avoid this

danger.

Description of hazard

– Denotes an immediate threat‐

ening danger. If the situation is

disregarded, it will result in

fatal or very serious injuries.

Safety chapter

15

Page 16

Safety chapter

WARNING!

Nature and source of the danger

Possible consequence: Fatal or

very serious injuries.

Measure to be taken to avoid this

danger.

– Denotes a possibly hazardous

situation. If the situation is dis‐

regarded, it could result in fatal

or very serious injuries.

CAUTION!

Nature and source of the danger

Possible consequence: Slight or

minor injuries. Material damage.

Measure to be taken to avoid this

danger.

– Denotes a possibly hazardous

situation. If the situation is dis‐

regarded, it could result in

slight or minor injuries. May

also be used as a warning

about material damage.

NOTICE!

Nature and source of the danger

Damage to the product or its sur‐

roundings.

Measure to be taken to avoid this

danger.

– Denotes a possibly damaging

situation. If the situation is dis‐

regarded, the product or an

object in its vicinity could be

damaged.

Type of information

Hints on use and additional infor‐

mation.

Source of the information. Addi‐

tional measures.

–

Denotes hints on use and

other useful information. It

does not indicate a hazardous

or damaging situation.

16

Page 17

Safety chapter

2.2 User qualification

WARNING!

Danger of injury with inadequately qualified personnel

The operator of the system / equipment is responsible for ensuring that the qualifi‐

cations are fulfilled.

If inadequately qualified personnel work on the unit or loiter in the hazard zone of

the unit, this could result in dangers that could cause serious injuries and material

damage.

– All work on the unit should therefore only be conducted by qualified per‐

sonnel.

– Unqualified personnel should be kept away from the hazard zone.

The pertinent accident prevention regulations, as well as all other generally

acknowledged safety regulations, must be adhered to.

Training Definition

Instructed personnel An instructed person is deemed to be a person who has been

instructed and, if required, trained in the tasks assigned to him

and possible dangers that could result from improper behav‐

iour, as well as having been instructed in the required protective

equipment and protective measures.

Trained user A trained user is a person who fulfils the requirements made of

an instructed person and who has also received additional

training specific to the system from the manufacturer or another

authorised distribution partner.

Trained, qualified

personnel

A trained, qualified employee is deemed to be a person who is

able to assess the tasks assigned to him and recognize pos‐

sible hazards based on his training, knowledge and experience,

as well as knowledge of pertinent regulations. A trained, quali‐

fied employee must be able to perform the tasks assigned to

him independently with the assistance of drawing documenta‐

tion and parts lists. The assessment of a person's technical

training can also be based on several years of work in the rele‐

vant field.

17

Page 18

Safety chapter

Training Definition

Electrical technician An electrical technician is able to complete work on electrical

systems and recognise and avoid possible dangers independ‐

ently based on his technical training and experience as well as

knowledge of pertinent standards and regulations. An electrical

technician must be able to perform the tasks assigned to him

independently with the assistance of drawing documentation,

parts lists, terminal and circuit diagrams. The electrical techni‐

cian must be specifically trained for the working environment in

which the electrical technician is employed and be conversant

with the relevant standards and regulations.

Service The Service department refers to service technicians, who have

received proven training and have been authorised by the man‐

ufacturer to work on the system.

18

Page 19

2.3 General safety information

WARNING!

Danger from hazardous sub‐

stances!

Possible consequence: Fatal or

very serious injuries.

Please ensure when handling haz‐

ardous substances that you have

read the latest safety data sheets

provided by the manufacture of the

hazardous substance. The actions

required are described in the

safety data sheet. Check the safety

data sheet regularly and replace, if

necessary, as the hazard potential

of a substance can be re-evaluated

at any time based on new findings.

The system operator is responsible

for ensuring that these safety data

sheets are available and that they

are kept up to date, as well as for

producing an associated hazard

assessment for the workstations

affected.

Safety chapter

WARNING!

Feed chemical can escape from

the DHV.

In the event of a diaphragm rupture

or insufficiently tightened housing

screws, feed chemical can escape

from between the housing parts or

through the adjusting screw.

Feed chemical can leak out from

insufficiently tightened sealing

stoppers or manometers.

– Produce an appropriate action

plan, based on these operating

instructions and the material

safety data sheet for your feed

chemical, to be used in the

event of uncontrolled leakage

of feed chemical.

CAUTION!

FDA valves only: problems with

hygiene are possible

The valves and the seals supplied

can become dirty from the pack‐

aging and shipment.

– Thoroughly clean the seals

supplied before use and flush

through the relief valve.

19

Page 20

Safety chapter

n Only the flow volume of the con‐

nected pump can be re-directed with

the DHV-UR.

n Take appropriate precautions on the

system when using as a relief valve

with sticky media, for example with

styrene: rinse the relief valve if it has

possibly reacted.

n Prior to installation, remove water

from the relief valve if it is to be used

together with media that may not

come into contact with water.

n The DHV-UR relief valve is not a

safety valve according to DIN EN ISO

4126-1.

n The DHV-UR relief valve is not

intended for use as a completely leaktight shut-off device.

n The DHV-UR relief valve is not

intended for use with gaseous media

or solids.

n Do not use the DHV-UR relief valve

with abrasive or crystallising media.

n Do not allow the DHV-UR relief valve

to come into contact with liquids,

which corrode the material of the

relief valve. This also applies to

cleaning agents and fats. Refer to the

ProMinent Resistance List in the

product catalogue or at www.promi‐

nent.com in this respect.

n Do not operate the relief valve outside

the ambient and operating conditions

specified in these operating instruc‐

tions.

n Only allow trained and authorised per‐

sonnel to operate the relief valve.

n You have a duty to observe the infor‐

mation contained in the operating

instructions during the different

phases of the system's service life.

20

Page 21

A2544

11

14

13

Safety chapter

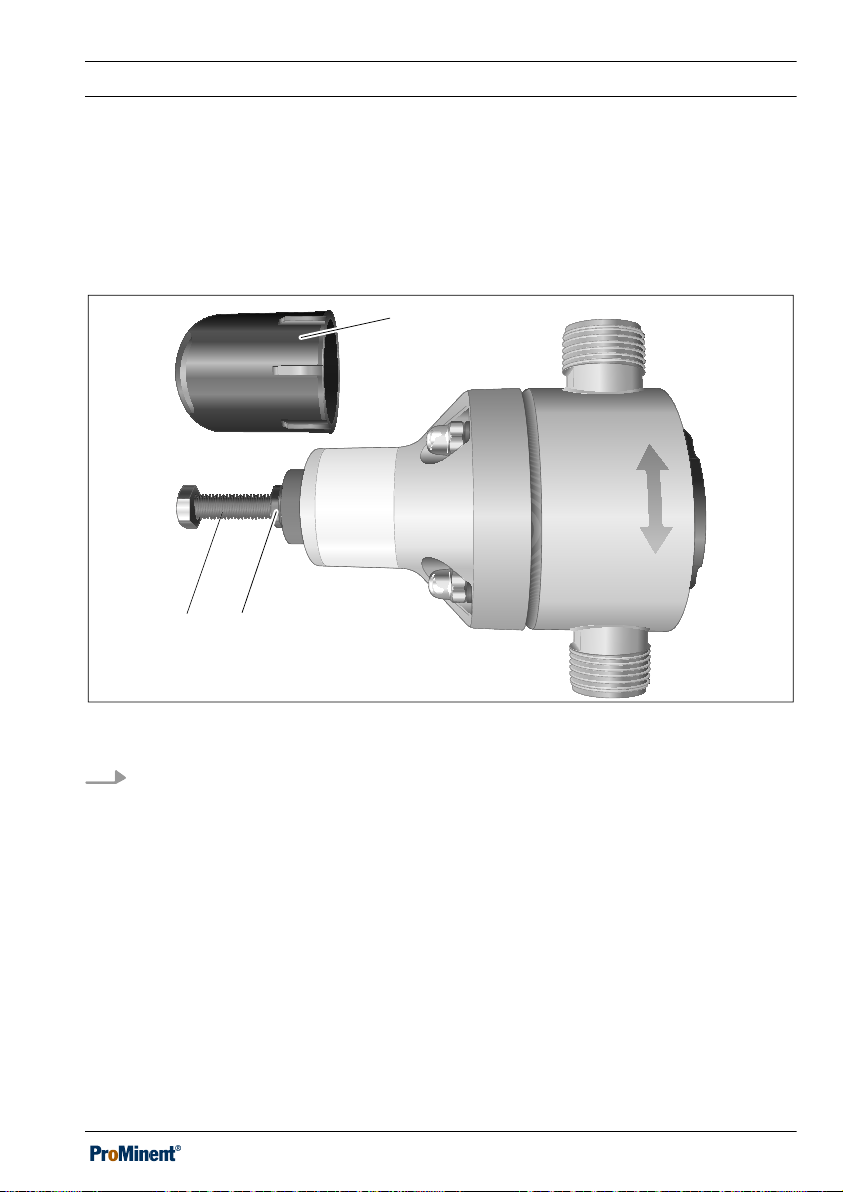

2.3.1 Information in the event of an emergency

In the event that feed chemical escapes from the relief valve, depressurise the hydraulic

surroundings of the relief valve and refer to the material safety data sheet for the feed

chemical.

If you have to depressurise the relief valve in an emergency:

Fig. 4: Relieving pressure

Remove the cap (11). Loosen the locking nut (14) and unscrew the adjusting

screw (13).

The pressure now drops through the relief outlet.

ð

21

Page 22

Safety chapter

2.4 Intended use

n The relief valve DHV-UR is only

intended for use with liquids.

n When used correctly as a relief valve,

the relief valve DHV-UR limits the

operating pressure of the pumps and

protects pumps from overpressure

caused by operational faults or block‐

ages.

n The properties of the relief valve

DHV-UR can only be guaranteed

when used in conjunction with ProMi‐

nent pumps.

n All other uses or modifications are

prohibited.

22

Page 23

3 Storage and transport

User qualification: instructed user,

Ä Chapter 2.2 ‘User qualification’

on page 17

Original packaging

Damage to the product.

–

Transport, ship and store the

device in its original pack‐

aging.

–

Retain the packaging.

–

Please refer to the disposal

instructions should you need

to dispose of the packaging,

Ä Chapter 3.3 ‘Packaging

material’ on page 23

3.1 Storage

Permissible ambient temperature: +5

°C ... +50 °C.

Humidity: maximum 90% relative air

humidity, non-condensing.

Other ambient conditions: No dust, no

direct sunlight.

Storage and transport

3.3 Packaging material

Dispose of packaging material in an envi‐

ronmentally responsible way. All pack‐

aging components carry the corre‐

sponding recycling code

.

3.2 Transport

The sensor should be transported in its

original packaging and in compliance with

the permissible environmental conditions.

No further special conditions have to be

observed in relation to transport.

23

Page 24

Assembly

4 Assembly

4.1 Assembling the relief valve

n User qualification: trained qualified personnel,

on page 17

CAUTION!

Serious damage to the feeder assembly, relief line or pump is possible

The relief pipe for the relief valve must:

– Have an internal diameter greater than or equal to the internal diameter of the

relief outlet on the DHV-UR.

– End in an open or ventilated dosing tank.

– End above the maximum fill level of the dosing tank.

– Uninterruptedly run through the shut-off devices.

The relief valve can be installed in any fitting position.

Ä Chapter 2.2 ‘User qualification’

24

Page 25

A2550

1

Assembly

Fig. 5: The label [Entlastungsausgang/relief outlet] indicates the relief outlet (1).

If the relief line is pointing upwards, you will need to take appropriate measures,

for instance by installing a shut-off valve, to ensure that a filled relief line can be disman‐

tled.

25

Page 26

P_MOZ_0077_SW

Assembly

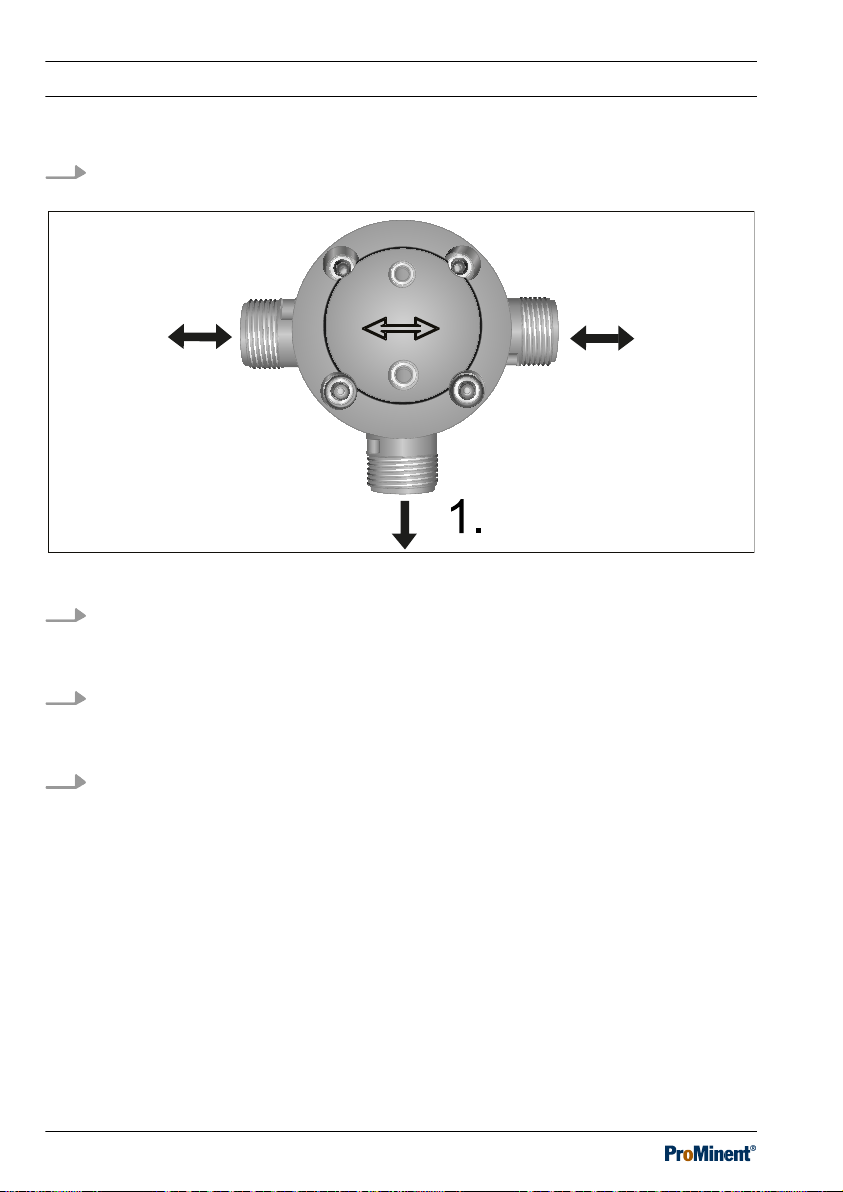

1. Prior to installation, remove water from the relief valve if it is to be used together

with media that may not come into contact with water.

Fig. 6: Directions of flow

2. Insert the relief valve into the pipework so that the directional arrows on the

housing of the relief valve point in the direction of flow.

The label

[Entlastungsausgang/relief outlet]

indicates the relief outlet (1).

3. Fit the relief valve so that it is not under mechanical tension, which could be

caused, among other things, by the pipework system.

Fit pipe compensators if required.

4. Tighten the threaded connectors.

26

Page 27

A2541

Assembly

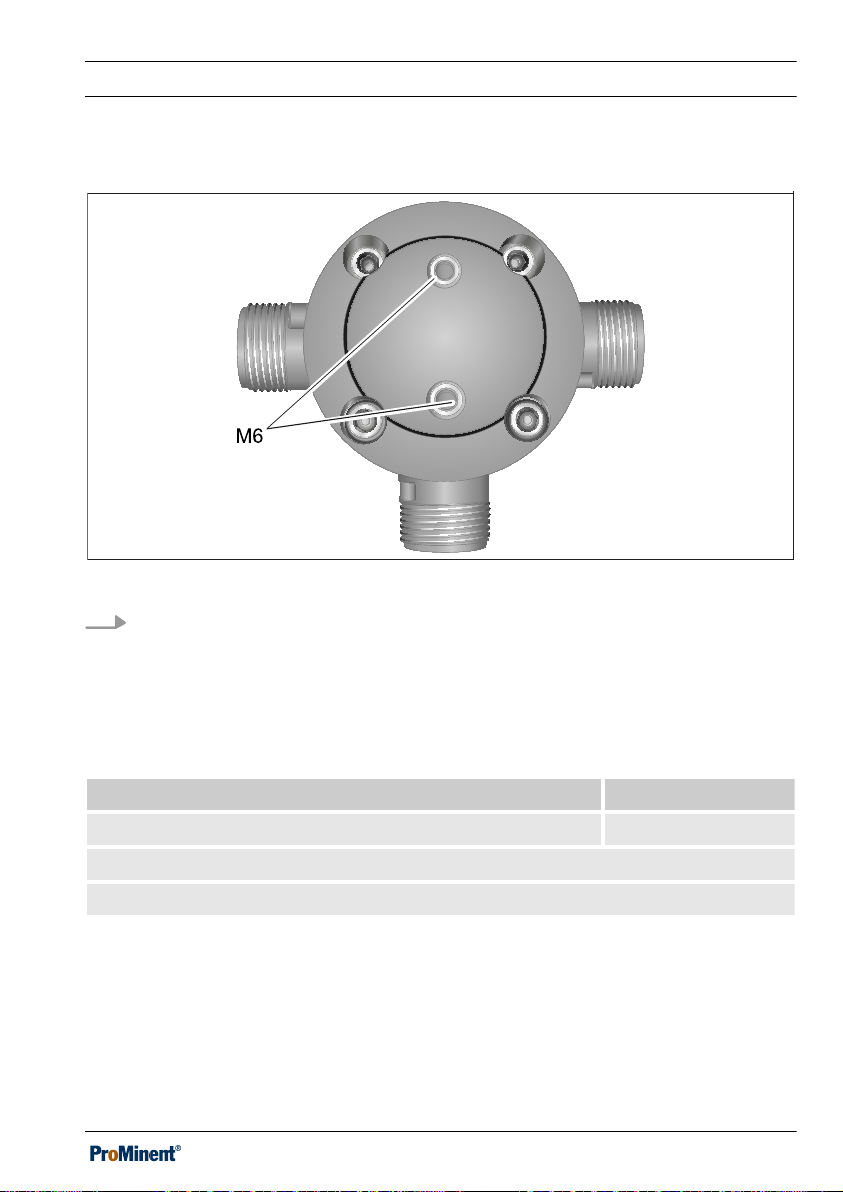

Optional: Installation on a mounting plate

Fig. 7: Holes for fixing bolts

5. 2 holes for M6 fixing bolts are located on the underside of the valve housing for

fixing it to a mounting plate.

Tightening torque for housing screws

Screw connection Value

Housing screws* DN10 / DN15 / DN20 / DN25 6 Nm

* greased

Check the tightening torque of the housing screws after 24 hours of operation.

27

Page 28

PD

P_MOZ_0061_SW

2.

1.

Assembly

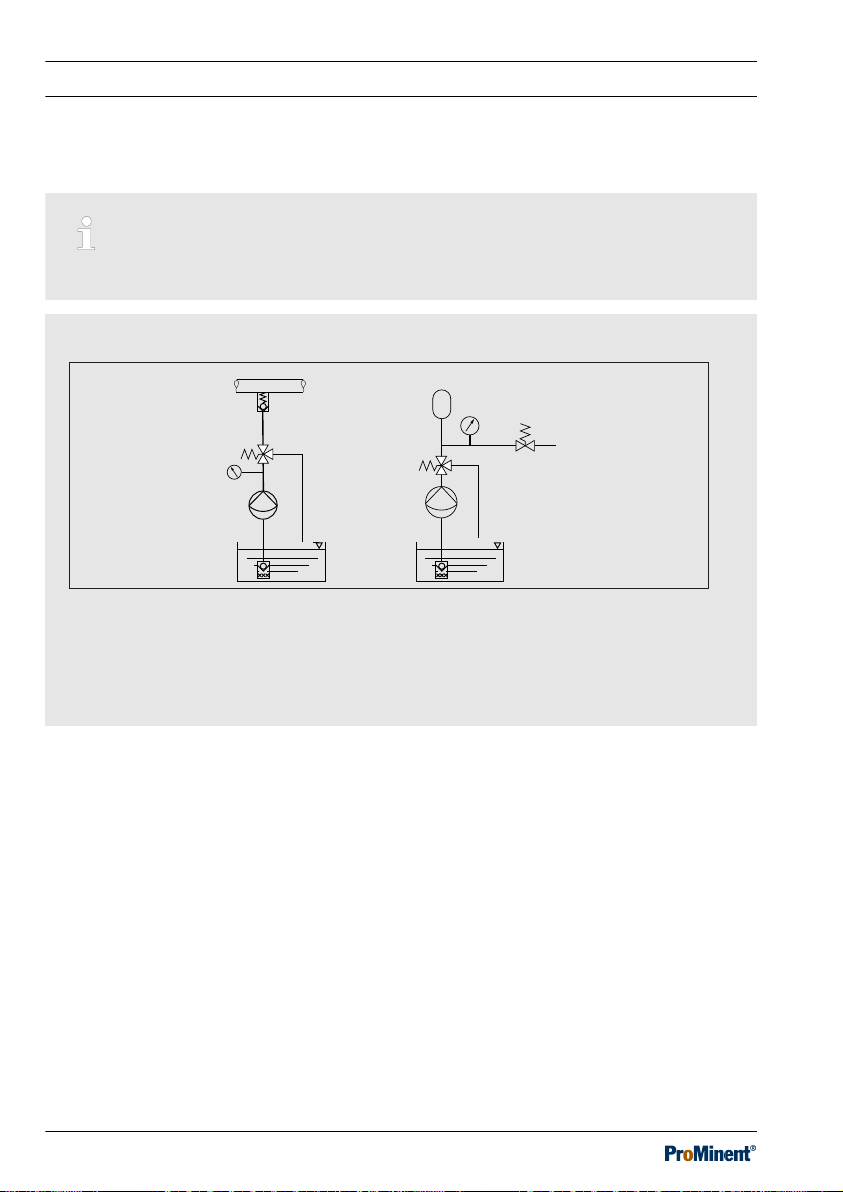

4.1.1 Installation examples

Read the operating instructions for your pump.

Installation examples

Fig. 8: Installation examples

1. - Use as a relief valve in the discharge line to protect the pump from

unauthorised over pressure

2. - Use together with a pulse damper to provide low-pulse metering

28

Page 29

Assembly

4.2 Fitting a manometer (optional)

Only with relief valve DHV-UR M (with manometer connection):

1. Screw the manometer into the hole in the housing of the relief valve using the flat

seal supplied in the packaging of the relief valve.

2. Check, when running, whether the connection between the valve body and the

manometer is tight.

Tab. 5: Maximum tightening torque of the screw connection.

Screw connection Value

Manometer 3 Nm

Plug 3 Nm

Store the plug supplied with its seal. You will need the plug if you dismantle the manom‐

eter.

29

Page 30

A2545

1

Commissioning

5 Commissioning

n User qualification: trained qualified personnel,

on page 17

CAUTION!

As supplied, the relief valve is set to 0 bar.

As the relief valve has not yet been set, there is a risk of hazardous situations

occurring when starting up the system or opening the shut-off devices, as the

relief valve is not yet capable of releasing impermissible overpressure.

– Take the necessary precautions.

– Refer to the material safety data sheet for the feed chemical.

– Please refer to the information on the nameplate (1).

Ä Chapter 2.2 ‘User qualification’

Fig. 9: Information on the nameplate (1).

30

Page 31

5.1 Pressure/temperature diagram

PVC-U

PP

PVDF, SS

10

9

8

7

6

5

4

3

2

1

-50 - 40 0-30 -20 -10 403010 5020 60 70 80 90 100 110

P [bar]

T [°C]

P_MAZ_0038_SW

Commissioning

Fig. 10: Pressure/temperature diagram

P Pressure in bar

T Temperature in °C

The pressure and temperature of your feed chemical must be below the corresponding

curve for the material of your relief valve.

The pressure/temperature diagram provides guideline values for the pressure and tem‐

perature resistance of the different material versions.

31

Page 32

A2544

11

14

13

Commissioning

5.2 Initial commissioning

1. Remove the cap (11).

2. Loosen the locking nut (14) and screw the adjusting screw (13) into the relief valve

as far as the stop.

3. Unscrew the adjusting screw (13) from the relief valve and tighten the locking nut

(14).

The relief valve is now activated.

ð

4. Replace the cap (11).

Fig. 11: Initial commissioning / Pressure relief

32

Page 33

5.3 Releasing pressure from the relief valve

1. Remove the cap (11).

2. Loosen the locking nut (14) and

unscrew the adjusting screw (13)

until the setting screw moves easily.

The pressure now drops

ð

through the relief outlet.

3. Subsequently reset the setting

pressure,

on page 34

Ä Further information

Commissioning

33

Page 34

Commissioning

5.4 Setting the relief valve

Set the relief valve under the same operating conditions as it will be subsequently used.

Never set the relief valve on a test rig and then install it in a system. Consider also the

viscosity of the feed chemical.

System components can burst if the pressure is set too high.

The set pressure PE at the relief valve should always be at least 1 bar lower than the

maximum permissible operating pressure PN of system components, such as the pulsa‐

tion damper, pump and piping system etc.

The set pressure PE at the relief valve must always be greater than the priming

pressure PV plus the differential pressure ΔP caused by mass deceleration.

PE > PV + ΔP

The priming pressure PV caused by the height h is:

PV = h x ρ where

PV is in bar, h in cm and ρ in kg/cm

ΔP is approx. 1.5 bar for standard piping up to approx. 3 m in length.

3

34

Page 35

A2544

11

14

13

Commissioning

Fig. 12: Setting the relief valve

Install a manometer in the discharge line or on the relief valve to set the adjustment pres‐

sure (e.g. 7 bar) more precisely.

1. Remove the cap (11).

2. Loosen the locking nut (14) and unscrew the adjusting screw (13) until the setting

screw moves easily.

3. Open the shut-off devices in the discharge line.

4. Switch on the metering pump.

5. Set the pressure as follows:

a. Fully screw in the adjusting screw (13) of the relief valve slowly.

b. Slowly screw in the adjusting screw of the back pressure valve in your installa‐

tion until the target operating pressure of +10% (e.g. 7.7 bar) is reached – and no

further!

c. Check whether the relief valve is correctly set at this pressure:

The setting is correct if feed chemical starts to drip out of the relief outlet.

n

n If no feed chemical drips out of the relief outlet, slowly open the adjusting

screw (13) until feed chemical starts to drip at the relief outlet – the setting is

then correct.

35

Page 36

Commissioning

n If feed chemical flows out of the relief outlet, slowly close the adjusting screw

(13) until no feed chemical escapes from the relief outlet.

Then check the operating pressure of the system (target operating pressure

+10% e.g 7.7 bar) at the manometer and adjust at the back pressure valve if

necessary.

Slowly open the adjusting screw (13) until feed chemical starts to drip out of

the relief outlet – the setting is then correct.

Please contact the manufacturer of the relief valve if you have unsuccessfully

performed this point in the setting instructions for the second time.

5.5 Setting the process pressure

1. Slowly unscrew the adjusting screw

of the back pressure valve until

normal target operating pressure

(e.g. 7 bar) is reached.

2. Check whether the set target oper‐

ating pressure remains constant

and whether the system’s threaded

connectors remain leak-tight.

3. Check that the relief valve does not

drip out of the relief outlet at normal

target operating pressure.

4. Secure the adjusting screws (13) of

the relief valve and the back pres‐

sure valve by tightening the locking

nuts (14).

5. Replace the cap (11).

6. Only with relief valve DHV-UR M

(with manometer connection):

Check whether the manometer con‐

nection is tightly sealed.

36

Page 37

Maintenance

6 Maintenance

n User qualification: trained user

CAUTION!

Elastomer seals can swell.

Hydrocarbon-based grease and cleaning agents can cause elastomer seals to

swell.

– Do not treat elastomer seals with cleaning agents.

– Only grease elastomer seals using silicone-based greases.

You may need to shorten the required maintenance intervals depending on the feed

chemicals used and operating conditions. Please take this into account when producing

your internal maintenance schedule.

Interval Maintenance work

Ä Chapter 2.2 ‘User qualification’ on page 17

bi-annually Check the interior parts of the relief valve and replace if necessary,

especially the diaphragm and the plunger seal.

To do this dismantle the relief valve – see

Ä Chapter 7 ‘Repair’

on page 38

In the event of a leak, tighten the connections or the manometer

connection, and check the tightening torque of the housing screws.

every 2 years Replace the diaphragm.

Tightening torque for housing screws

Screw connection Value

Housing screws* DN10 / DN15 / DN20 / DN25 6 Nm

* greased

Check the tightening torque of the housing screws after 24 hours of operation.

37

Page 38

Repair

7 Repair

n User qualification: trained user

WARNING!

Only return the unit for repair in a cleaned state and flushed through.

Only send the unit together with a completed Declaration of Decontamination. The

Declaration of Decontamination constitutes an integral part of an inspection /

repair order. We can only inspect or repair a unit if a Declaration of Decontamina‐

tion is submitted that has been completed correctly and in full.

The "Declaration of Decontamination” form can be found at www.prominent.com.

CAUTION!

Elastomer seals can swell.

Hydrocarbon-based grease and cleaning agents can cause elastomer seals to

swell.

– Do not treat elastomer seals with cleaning agents.

– Only grease elastomer seals using silicone-based greases.

Ä Chapter 2.2 ‘User qualification’ on page 17

CAUTION!

Only FDA: Seals can contaminate the feed chemical

Seals made of non-FDA-certified material, which have not been professionally

cleaned, can contaminate the feed chemical.

– Only use the right ProMinent seals.

– Have the seals professionally cleaned before use.

38

Page 39

A2546

11

2

8

5

6

4

12,

17,

18.

7

1

3

10

Fig. 13: Overview of components.

1 Valve body

2 Spring dome

3 Separating disc

4 Thrust washer

5 Diaphragm

6 Pressure plate with steel ball

Repair

7 Spring collar

8 Compression spring

10 Plunger

11 Cap

12, 17, 18 Nuts, screws, washers

39

Page 40

Repair

7.1 Dismantling the relief valve

1. Ensure that the pipework is at atmospheric pressure and drain the pipework.

2. Dismantle the relief valve.

3. Drain the relief valve and use a suitable medium to flush through the relief valve,

referring to the material safety data sheet for your feed chemical.

4. Position the relief valve upright.

5. Remove the cap (11).

6. Loosen the locking nut (14) and the adjusting screw (13) until the pressure on the

compression spring (8) has been fully released.

When the compression spring has been depressurised, the adjusting screw

ð

(13) can be easily turned.

7. Loosen the housing screws (12) and remove them.

8. Remove the spring dome (2).

9. Remove the following from the spring dome (2): the thrust washer (4), spring collar

(7), diaphragm (5), spring (8) and pressure plate (6) with the steel ball (9).

40

Page 41

Dismantling the plunger

A2554

1

10

3

Repair

Fig. 14: Dismantling the plunger

10. Remove the following from the valve body (1): the separating disc (3) and the com‐

plete plunger (10). To do so, lever the separating disc carefully out of the valve

body.

41

Page 42

3990

P_MOZ_0068_SW

1

19

18

20

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

Repair

Fig. 15: Cross-section through the DHV-UR PVC, PP, PVDF

42

Page 43

Replacing the plunger seal (16):

A2555

10.1

16

10.2

Repair

Fig. 16: Dismantling the plunger seal (16)

1. Clamp or fix the plunger to the plunger head (10.1) without damaging it.

2. Unscrew the plunger guide (10.2).

3. Remove the plunger seal (16).

43

Page 44

E

n

t

l

a

s

t

u

n

g

s

a

u

s

g

a

n

g

r

e

l

i

e

f

o

u

t

l

e

t

A2556

10.1 16

10.2

3

1

Repair

Fig. 17: Cleaning and checking all components.

4. Cleaning and checking all components.

5. Insert a new plunger seal (16) into the plunger head (10.1).

6.

Screw in the plunger guide (10.2), tightening torque

plunger guide on the plunger head’ on page 44

Tab. 6: Tightening torque: plunger guide on the plunger head

Screw connection Value

Ä Tab. 6 ‘Tightening torque:

.

Plunger guide on plunger head DN10 / DN15 3 Nm

Plunger guide on plunger head DN20 / DN25 4 Nm

44

Page 45

P_MOZ_0067_SW

3989

1

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

Repair

7.2 Inspecting and replacing the parts

Fig. 18: Cross-section through the DHV-UR SS

45

Page 46

Repair

1. Examine whether the diaphragm (5) and the connector seals (15) have any

obvious changes.

Replace the diaphragm, when required, and always the connection seals.

ð

2. Check the spring (8) for wear.

3. Check the plunger guide hole, plunger seat sealing surface, diaphragm contact

surface and O-ring groove on the valve body (1) for damage, dirt or lime scale.

CAUTION!

The relief valve can fail

Damaged sealing elements can lead to a loss of function and leakage of

the relief valve.

Always replace the sealing elements removed.

46

Page 47

7.3 Assembling the relief valve

1. Assemble the following into the

valve body (1): the complete

plunger (10) and separating disc

(3).

2. Assemble the following into the

spring dome (2): the thrust washer

(4), spring collar (7), spring (8), dia‐

phragm (5) and pressure plate (6)

with the steel ball (9).

3. Place the spring dome (2) onto the

housing.

4. Insert the housing screws (12) and

tighten the housing screws,

Ä ‘Tightening torque for housing

screws’ on page 48

5. Screw in the adjusting screw until

the adjusting screw becomes a little

harder to turn and tighten the

locking nut (14).

6. Replace the cap (11) onto the relief

valve.

7. Refit the relief valve.

Correctly reset the relief valve

ð

after fitting,

tion on page 34

.

Ä Further informa‐

.

Repair

47

Page 48

Repair

Tightening torque for housing screws

Screw connection Value

Housing screws* DN10 / DN15 / DN20 / DN25 6 Nm

* greased

Check the tightening torque of the housing screws after 24 hours of operation.

48

Page 49

Troubleshooting

8 Troubleshooting

n User qualification: trained user

WARNING!

With FDA only: Feed chemical can be physiologically contaminated

Non-FDA-certified parts will also become wetted in the event of a diaphragm rup‐

ture.

– Secure your entire process to prevent dangers with FDA versions.

Ä Chapter 2.2 ‘User qualification’ on page 17

For the position numbers – see Figure

Ä Chapter 7 ‘Repair’ on page 38

Fault description Cause Remedy

Pressure falls below the set

value.

Plunger seal (16) dirty. Clean the plunger seal

(16), see "Repair".

Plunger seal (16)

faulty.

Plunger seat in the

housing is dirty.

Plunger seat in the

Replace the plunger seal

(16), see "Repair".

Clean the plunger seat,

see "Repair".

Contact ProMinent.

housing is faulty.

Diaphragm (5) dirty. Clean the diaphragm (5),

see "Repair".

Diaphragm (5) faulty. Replace the diaphragm

(5), see "Repair".

Set pressure cannot be reached. Relief valve is installed

incorrectly.

Observe the direction

arrows and “Relief outlet”

label.

Pressure rises above the per‐

mitted value but the relief valve

does not properly depressurise.

The plunger guide is

sticking, possibly

because of dirt.

The valve is set to too

high an opening pres‐

Dismantle the valve and

clean, referring to

"Repair".

Set the valve to a lower

opening pressure.

sure.

49

Page 50

Troubleshooting

Fault description Cause Remedy

Pressure rises above the per‐

mitted value but the relief valve

does not properly depressurise.

The plunger guide

sticks due to too high a

media temperature.

Lower the media tem‐

perature in accordance

with the pressure-tem‐

perature diagram.

Leakage at the level of the dia‐

phragm (5).

Leakage at the adjusting screw

(13).

Contact pressure of the

diaphragm tensioner is

too low.

Tighten screws (12).

Tightening torque, see

"Repair".

Diaphragm (5) faulty. Replace the diaphragm

(5), see "Repair".

Loud noises when overflowing. Relief valve too small. Use a larger relief valve.

Type M only: Manometer display

"0" or remains at a constant

value.

Manometer faulty. Replace manometer*.

Manometer holes

Clean manometer holes.

blocked.

* If the manometer is faulty, remove the manometer and temporarily seal the hole with

the blanking plug – see

Ä Chapter 4 ‘Assembly’ on page 24

if operation without a man‐

ometer is permitted.

50

Page 51

Use Parts Disposal/Declaration of Decontamination

9 Use Parts Disposal/Declaration of Decontamination

n User qualification: instructed user,

see

Ä Chapter 2.2 ‘User qualification’

on page 17

WARNING!

Danger from hazardous sub‐

stances!

Possible consequence: Fatal or

very serious injuries.

Please ensure when handling haz‐

ardous substances that you have

read the latest safety data sheets

provided by the manufacture of the

hazardous substance. The actions

required are described in the

safety data sheet. Check the safety

data sheet regularly and replace, if

necessary, as the hazard potential

of a substance can be re-evaluated

at any time based on new findings.

The system operator is responsible

for ensuring that these safety data

sheets are available and that they

are kept up to date, as well as for

producing an associated hazard

assessment for the workstations

affected.

A completed and signed "Declara‐

tion of Decontamination" is

required by law and in order to pro‐

tect our staff, before your order can

be processed.

Ensure that the Declaration of

Decontamination is attached to the

outside of the package. Otherwise

we are unable to accept your

delivery.

NOTICE!

Regulations governing the disposal

of used parts

– Note the national regulations

and legal standards that cur‐

rently apply in your country

when disposing of the product.

ProMinent GmbH, Heidelberg/Germany

will take back clean used parts.

NOTICE!

The used part can only be

accepted with a completed Decla‐

ration of Decontamination

Printed copy also available as a

download at: www.prominent.com

51

Page 52

PVC-U

PP

PVDF, SS

10

9

8

7

6

5

4

3

2

1

-50 - 40 0-30 -20 -10 403010 5020 60 70 80 90 100 110

P [bar]

T [°C]

P_MAZ_0038_SW

Technical data

10 Technical data

The properties given for the relief valve DHV-UR can only be guaranteed when used in

connection with ProMinent® pumps.

Fig. 19: Pressure/temperature diagram

P Pressure in bar

T Temperature in °C

The pressure and temperature of your feed chemical must be below the corresponding

curve for the material of your relief valve.

The pressure-temperature diagram provides guideline values for the pressure and tem‐

perature resistance of the different material versions for feed chemicals to which the relief

valves are resistant.

52

Page 53

Technical data

Temperatures

Specification Value

Storage and transport temperature * -10 ... +50 °C

Ambient temperature in operation * -10 ... +45 °C

* Note the freezing temperature of the feed chemical to reliably prevent the relief valve

from being damaged.

Operating parameters

Parameter Value

Permissible rated pressure PN at +20°C10 bar

Operating pressure Pressure/temperature diagram Fig. 19

Setting range 0.5 ... 10 bar

Working pressure equal to set pressure + pressure loss – see

Ä ‘Diagrams for using the DHV-UR’

on page 55

Minimum opening pressure, approx. 0.5 bar

Approx. difference between opening

0.3 bar

and closing pressure

Maximum flow Q

53

max

Ä ‘Maximum flow Q

’ on page 54

max

Page 54

Technical data

Maximum flow Q

A) The following values are only applicable to Q

max

when using metering pumps with

max

properly dimensioned pulsation dampers or with constant flow velocity:

Valve type DHV-UR Q

for H2O at 20 °C

max

DN 10 500 l/h

DN 15 890 l/h

DN 20 1000 l/h

DN 25 1300 l/h

B) The following applies to the flow Qu when operating metering pumps without a pulsa‐

tion damper:

For solenoid metering pump: Qu = Q

For motor-driven metering pumps: Qu = Q

max

/20

max

/3

54

Page 55

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

0,0 0,2 0,4 0,6 0,8 1,0 1,2 1,4 1,6 1,8 2,0

P [bar]

Q [m3/h]

DN 10

DN 15

DN 20

DN 25

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

0,2 0,4 0,6 0,8 1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6

ΔP [bar]

Q [m3/h]

2,8 3,0 3,2 3,4 3,6

DN 10

DN 15

DN 20

DN 25

Technical data

Diagrams for using the DHV-UR

Fig. 20: Opening pressure curve with overflow for DHV-UR – with water at 20°C and a

constant flow velocity. P: Working pressure / Q: Flow, set to 1 bar

Fig. 21: Pressure drop curves with overflow with fully opened valve for DHV-UR – with

water at 20°C and a constant flow velocity. ΔP: Pressure difference/Q: Flow

55

Page 56

0,0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

1,0

0,5

∆p [bar]

1,0 1,5 2,0 2,5 3,0 3,5 4,0 4,5

Q [m³/h]

DN 10 - 15

DN 20 - 25

Technical data

Fig. 22: Pressure drop curves for the main line (valve closed) without overflow for DHVUR – with water at 20°C and a constant flow velocity. ΔP: Pressure difference/Q: Flow

Tab. 7: Kv values* for the main line without overflow (the relief line is 100% closed):

DHV-UR Kv

DN10 ... 15 4.5 m³/h

DN20 ... 25 13 m³/h

* The Kv values correspond to the water flow through a valve with a pressure difference

of 1 bar

56

Page 57

Technical data

Material specifications

All wetted materials in the "Physiologically safe (FDA) in respect of wetted materials"

design comply with the FDA guidelines in line with the certificate supplied.

For the position numbers - see

Ä Chapter 12 ‘Exploded view drawing’ on page 62

Tab. 8: Material specifications for the PPE, PPB and PCE versions

Pos. Description PPE PPB PCE

1.19 Valve housing PP PVC-U

2 Spring dome PP + 30% GF

3 Separating disc PP PVC-U

4 Thrust washer POM

5 Diaphragm EPDM / PTFE, laminated

6 Pressure plate Steel, nickel plated

7 Spring collar POM

8 Compression spring Steel, galvanised

9 Ball 1.3541

10 Plunger PP* PVC-U*

11 Protective cap PE

15 Seal EPDM FKM EPDM

16 Plunger seal EPDM FKM EPDM

20 O-ring EPDM FKM EPDM

21** Plug PP PP PVC-U

22** Seal for a manometer PTFE, natural

Various Housing screws, nuts, washers V2A

FKM = fluorine rubber

* or high quality PVDF / ** not shown

57

Page 58

Technical data

Tab. 9: Material specifications for the PCB, PVT and SST versions

Pos. Description PCB PVT SST

1.19 Valve housing PVC-U PVDF 1.4404

2 Spring dome PP + 30% GF

3 Separating disc PVC-U PVDF 1.4404

4 Thrust washer POM

5 Diaphragm EPDM / PTFE, laminated

6 Pressure plate Steel, nickel plated

7 Spring collar POM

8 Compression spring Steel, galvanised

9 Ball 1.3541

10 Plunger PVC-U PVDF PTFE, nat‐

ural

11 Protective cap PE

15 Seal FKM PTFE**

16 Plunger seal FKM PTFE*

20 O-ring FKM PTFE, nat‐

ural

21*** Plug PVC-U PVDF -

22*** Seal for a manometer PTFE, natural -

Various Housing screws, nuts, washers V2A

FKM = fluorine rubber

*. PTFE / FKM cover ring

** PTFE / EPDM shaped composite seal

*** not shown

58

Page 59

Technical data

Combination options

The relief valve / metering pump combination options are limited by the maximum flow

Q

of the relief valve.

max

The universal relief valve DHV-UR can essentially be used with metering pumps in the

low pressure range, taking into consideration pressure, feed chemical and flow.

Tab. 10: Assignment of the relief valves to the corresponding ProMinent® pump types

DHV-UR Pump type

DN 10 alpha, Beta, DLTa, GMX_, Pneumados, Vario DN 10, Hydro DN 10,

EXtronic DN10

DN 15 Vario DN15, Sigma DN15, Hydro DN15

DN 20 Sigma DN20, Meta DN20, Makro TZ DN20

DN 25 Sigma DN25/DN32, Hydro DN25/DN32, Meta DN25,

Makro TZ DN 25/DN32

10.1 Applied standards

EN 12266-1:2012

EN ISO 16138:2006

59

Page 60

A2542

DHV-UR spare parts

11 DHV-UR spare parts

Spare parts kits

Ordering address for spare parts and accessories: The current address for ordering

spare parts and accessories can be found on the homepage of the manufacturer ProMi‐

nent.

Fig. 23: Example: Spare parts kit for DHV-U, -UR DN10/15, 1078732

Contents:

n O-ring, external

n Diaphragm

n Plunger seal

n Seal, blanking plug

60

Page 61

DHV-UR spare parts

Spare parts kit Material design Order no.

DHV-U, -UR DN10/15 EPDM 1078732

DHV-U, -UR DN10/15 FKM 1078733

DHV-U, -UR DN10/15 PTFE 1078734

DHV-U, -UR DN20/25 EPDM 1078735

DHV-U, -UR DN20/25 FKM 1078736

DHV-U, -UR DN20/25 PTFE 1078737

DHV-U DN32/40 EPDM 1078784

Plug

The plug is used to seal the manometer connection.

Description Order no.

Plug for PP_ 1077791

Plug for PC_ 1077792

Plug for PV_ 1077793

61

Page 62

P_MOZ_0072_SW

3985_2

1

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

18

10.2

10.1

Exploded view drawing

12 Exploded view drawing

12.1 Exploded view drawing of DHV-UR PP_, PC_, PV_

Fig. 24: Exploded view drawing of DHV-UR PP_, PC_, PV_

62

Page 63

12.2 Exploded view drawing of DHV-UR SS

P_MOZ_0073_SW

3986

1

18

17

16

15

14

13

12

11

10.2

10.1

10

9

8

7

6

5

4

3

2

Exploded view drawing

Fig. 25: Exploded view drawing of DHV-UR SS

63

Page 64

Exploded view drawing

12.3 Parts list

Position Description

1 Valve housing

2 Spring dome

3 Separating disc

4 Thrust washer

5 Diaphragm

6 Pressure plate

7 Spring collar

8 Compression spring

9 Ball

10 (1/2) Plunger

11 Protective cap

12 Housing screws

13 Adjusting screw

14 Locking nut

15 Seal

16 Plunger seal

17 Nuts

18 Washers

64

Page 65

13 Dimensional drawing

63_03-101_00_49-7a

P_MOZ_063_SW

m

G 1/4“

12.5

A

D

A

L

G

d

DN

h

max. H

L/2

B

A

A

13.1 Dimensional drawing of DHV-UR PVC, PP, PVDF

Dimensional drawing

Fig. 26: Dimensional drawing of DHV-UR PVC-U, PP, PVDF - dimensions in mm

* connector for a manometer.

Union nut and insert are not supplied in the scope of delivery.

65

Page 66

Dimensional drawing

DN10 DN15 DN20 DN25

d 16 20 25 32

DN (mm) 10 15 20 25

DN (inches) 3/8 1/2 3/4 1

T G 3/4 G 1 G 1 1/4 G 1 1/2

B 35 35 46 46

D 79 79 99 99

h 24 24 37 37

H 144 144 196 196

L 118 118 150 150

m M6 M6 M6 M6

66

Page 67

13.2 Dimensional drawing of DHV-UR SS

63_03-101_00_52-7a

P_MOZ_064_SW

m

A

A

D

G

d

DN

max. H

L

h

L1

+1,0

L

1

/2

L/2

AA

Dimensional drawing

Fig. 27: Dimensional drawing of DHV-UR SS - dimensions in mm

Union nut and insert are not supplied in the scope of delivery.

67

Page 68

Dimensional drawing

DN10 DN15 DN20 DN25

d 16 20 25 32

DN (mm) 10 15 20 25

DN (inches) 3/8 1/2 3/4 1

T G 3/4 G 1 G 1 1/4 G 1 1/2

B 35 35 46 46

D 79 79 99 99

H 144 144 196 196

h 20 20 30 30

L 116 116 148 148

L1 118 118 150 150

m M6 M6 M6 M6

68

Page 69

14 Index

1, 2, 3 ...

“M” version .................... 9

A

Action, step by step .............. 5

Address, nameplate ............. 10

Adhesive labels ................ 15

Air humidity ................... 23

Ambient temperature in operation ....53

Assembling the relief valve ........ 47

Assigning relief valves ........... 59

C

Combination options .............59

Configuration for manometer ....... 13

D

Date, nameplate ................10

Declaration of Decontamination ..... 38

Decontamination declaration ....... 51

Diagrams for using the DHV-UR .....55

Dimensional drawing ............ 65

Dismantling the plunger .......... 42

Dismantling the relief valve ........ 40

Disposal ..................... 51

E

Error ........................49

F

Faults ....................... 49

FDA guidelines ................ 12

Index

FDA version ................... 9

Fitting position ................. 25

Flow volume of the connected pump ..20

Functional mode ................ 9

G

General non-discriminatory approach .. 5

I

Information in the event of an emer‐

gency ....................... 21

Initial commissioning .............32

Inspecting and replacing the parts ... 45

Installation on a mounting plate ..... 27

Intended use .................. 22

K

Kv values .................... 56

L

Labels for fluid connections ........ 15

Links to elements or sections of these

instructions or other applicable docu‐

ments ........................ 5

M

Manometer .................... 9

Manometer connector ............ 29

Material specifications ............57

Maximum flow Q

More symbols .................. 5

Mounting plate ................. 27

............. 54

max

69

Page 70

Index

N

Nominal width ............ 11, 12, 13

Non-discriminatory approach ........ 5

O

Operating parameters ............ 53

Original packaging .............. 23

Other ambient conditions ..........23

Overview of components ..........39

P

P-T diagram .................. 52

Permissible ambient temperature .... 23

Plug with seal ................. 29

Pressure/temperature diagram ... 31, 52

R

Recycling .................... 23

Regulations governing the disposal of

used parts .................... 51

Releasing pressure from the relief

valve ....................... 33

Relief outlet ................... 15

Relieving pressure .............. 21

Replacing the plunger seal ........ 43

S

Safety information .............. 19

Scope of delivery ................ 9

Setting the process pressure ....... 36

Setting the relief valve ............34

Setting, process pressure ......... 36

Signs ....................... 15

Standards .................... 59

T

Temperatures ................. 53

Thread in inches .......... 11, 12, 13

Tightening torque ............... 44

Tightening torque of the screw con‐

nection ...................... 29

U

User qualification ............... 17

W

Warning information ............. 15

70

Page 71

ProMinent GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg, Germany

Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

983439, 3, en_GB

© 2018

Page 72

Montage- und Betriebsanleitung

A2543

Universelles Überströmventil

DHV-UR

DE

Betriebsanleitung bitte zuerst vollständig durchlesen. · Nicht wegwerfen.

Bei Schäden durch Installations- oder Bedienfehler haftet der Betreiber.

Die neueste Version einer Betriebsanleitung ist auf unserer Homepage verfügbar.

Zielgruppe: geschulter AnwenderTeilenummer 983439 Version: BA MOZ 042 03/18 DE

Page 73

Ergänzende Anweisungen

Allgemeine Gleichbehandlung Dieses Dokument verwendet die nach der

Grammatik männliche Form in einem

neutralen Sinn, um den Text leichter

lesbar zu halten. Es spricht immer Frauen

und Männer in gleicher Weise an. Die

Leserinnen bitten wir um Verständnis für

diese Vereinfachung im Text.

Ergänzende Anweisungen

Lesen Sie bitte die ergänzenden Anweisungen durch.

Infos

Eine Info gibt wichtige Hinweise für das richtige Funktionieren des Geräts oder

soll Ihre Arbeit erleichtern.

Warnhinweise

Warnhinweise sind mit ausführlichen Beschreibungen der Gefährdungssituation ver‐

sehen, siehe

Ä Kapitel 2.1 „Kennzeichnung der Warnhinweise“ auf Seite 83

.

Zur Hervorhebung von Handlungsanweisungen, Verweisen, Auflistungen, Ergebnissen

und anderen Elementen können in diesem Dokument folgende Kennzeichnungen ver‐

wendet werden:

Tab. 1: Weitere Kennzeichnung

Kennzeichen Beschreibung

Handlung Schritt-für-Schritt.

⇨ Ergebnis einer Handlung.

Links auf Elemente bzw. Abschnitte dieser Anleitung oder mitgel‐

tende Dokumente.

n

[Taster]

Auflistung ohne festgelegte Reihenfolge.

Anzeigeelemente (z. B. Signalleuchten).

Bedienelemente (z. B. Taster, Schalter).

73

Page 74

Ergänzende Anweisungen

Kennzeichen Beschreibung

„Anzeige/GUI“

CODE

Bildschirmelemente (z. B. Schaltflächen, Belegung von Funktions‐

tasten).

Darstellung von Softwareelementen bzw. Texten.

74

Page 75

Inhaltsverzeichnis

Inhaltsverzeichnis

1 Über dieses Produkt............................................................................................. 77

1.1 Typenschild.................................................................................................. 78

1.2 Ausführungen............................................................................................... 79

1.2.1 Ausführung der Standardversion............................................................... 79

1.2.2 Ausführung mit FDA-Freigabe................................................................... 80

1.2.3 Ausführung mit Manometervorbereitung................................................... 81

2 Sicherheitskapitel.................................................................................................. 83

2.1 Kennzeichnung der Warnhinweise............................................................... 83

2.2 Benutzer-Qualifikation.................................................................................. 85

2.3 Allgemeine Sicherheitshinweise................................................................... 87

2.3.1 Angaben für den Notfall............................................................................. 89

2.4 Bestimmungsgemäße Verwendung............................................................. 90

3 Lagern und transportieren ................................................................................... 91

3.1 Lagern.......................................................................................................... 91

3.2 Transport...................................................................................................... 91

3.3 Verpackungsmaterial.................................................................................... 91

4 Montieren.............................................................................................................. 92

4.1 Das Überströmventil montieren.................................................................... 92

4.1.1 Installationsbeispiele................................................................................. 96

4.2 Ein Manometer montieren (Option).............................................................. 97

5 Inbetriebnahme..................................................................................................... 98

Druck-Temperatur-Diagramm...................................................................... 99

5.1

5.2 Erstinbetriebnahme.................................................................................... 100

5.3 Druckentlasten des Überströmventils......................................................... 101

5.4 Überströmventil einstellen.......................................................................... 102

5.5 Prozessdruck einstellen............................................................................. 104

6 Wartung.............................................................................................................. 105

7 Reparieren.......................................................................................................... 106

Überströmventil zerlegen .......................................................................... 108

7.1

7.2 Teile untersuchen und austauschen.......................................................... 113

7.3 Überströmventil zusammensetzen............................................................. 115

8 Funktionsstörungen beheben............................................................................. 117

75

Page 76

Inhaltsverzeichnis

9 Altteileentsorgung/Dekontaminationserklärung.................................................. 119

10 Technische Daten............................................................................................... 120

10.1 Angewandte Normen................................................................................ 127

11 Ersatzteile DHV-UR............................................................................................ 128

12 Explosionszeichnung.......................................................................................... 130

12.1 Explosionszeichnung DHV-UR PP_, PC_ und PV_ ................................. 130

12.2 Explosionszeichnung DHV-UR SS........................................................... 131

12.3 Stückliste.................................................................................................. 132

13 Maßblatt.............................................................................................................. 133

13.1 Maßblatt DHV-UR PVC-U, PP, PVDF ..................................................... 133

13.2 Maßblatt DHV-UR SS............................................................................... 135

14 Index................................................................................................................... 137

76

Page 77

A2538

Über dieses Produkt

1 Über dieses Produkt

Das Überströmventil schützt Pumpen vor unzulässigem Überdruck infolge von Betriebs‐

fehlern oder Blockierungen.

Das universelle Überströmventil Typ DHV-UR ist ein stufenlos einstellbares, innen ange‐

strömtes Kolben-Membranventil. Im Falle eines unzulässigen Überdrucks öffnet die

innenliegende Kolben-Membran die zweite Ausgangsleitung, den Entlastungsausgang.

Die Montage des Überströmventils ist an beliebiger Stelle des Rohrleitungssystems mög‐

lich. Aufgrund eines nahezu freien Rohrquerschnitts entsteht nur ein sehr geringer Druck‐

verlust.

Abb. 1: Lieferumfang: Überströmventil mit Dichtringen für den Anschluss.

An das Überströmventil DHV-UR in der Ausführung "M" kann zusätzlich ein Manometer

installiert werden.

Das Überströmventil gibt es auch als FDA-Version.

77

Page 78

A2539

Über dieses Produkt

1.1 Typenschild

Abb. 2: Typenschild

Das Typenschild gibt Ihnen Auskunft über:

n Hersteller mit Adresse und Telefonnummer

n Herstellungsort und -land,

n Herstellungsdatum in Woche / Jahr

n Typ des Gerätes mit Durchmesser und Materialausführung

n Teilenummer

n Seriennummer

n Druckbereich in bar und psi

n Anschlussgewinde in Zoll und Millimeter

n Werkstoffausführung

[Teile Nr. / part no.]

[Serien Nr. / serial no.]

[Druckbereich / pr. range]

[Material / material]

,

[Anschluss / connect]

.

[Typ / type]

,

,

78

Page 79

Über dieses Produkt

1.2 Ausführungen

1.2.1 Ausführung der Standardversion

Tab. 2: Ausführung: Standard

Ausführung Nennweite Gewinde in Zoll Bestell-Nummer

PPE DN 10 3/4 1061337

PPB DN 10 3/4 1061341

PCE DN 10 3/4 1061339

PCB DN 10 3/4 1061343

PVT DN 10 3/4 1061365

SST DN 10 3/4 1061550

PPE DN 15 1 1061336

PPB DN 15 1 1061340

PCE DN 15 1 1061338

PCB DN 15 1 1061342

PVT DN 15 1 1061364

SST DN 15 1 1061551

PPE DN 20 1 1/4 1061367

PPB DN 20 1 1/4 1061371

PCE DN 20 1 1/4 1061369

PCB DN 20 1 1/4 1061373

PVT DN 20 1 1/4 1061375

SST DN 20 1 1/4 1061569

PPE DN 25 1 1/2 1061366

PPB DN 25 1 1/2 1061370

PCE DN 25 1 1/2 1061368

PCB DN 25 1 1/2 1061372

79

Page 80

Über dieses Produkt

Ausführung Nennweite Gewinde in Zoll Bestell-Nummer

PVT DN 25 1 1/2 1061374

SST DN 25 1 1/2 1061570

1.2.2 Ausführung mit FDA-Freigabe

Tab. 3: Ausführung: FDA

Ausführung Nennweite Gewinde in Zoll Bestell-Nummer

PPE DN 10 3/4 1075828

PVT DN 10 3/4 1075830

SST DN 10 3/4 1075847

PPE DN 15 1 1075827

PVT DN 15 1 1075829

SST DN 15 1 1075846

PPE DN 20 1 1/4 1075833

PVT DN 20 1 1/4 1075845

SST DN 20 1 1/4 1075849

PPE DN 25 1 1/2 1075832

PVT DN 25 1 1/2 1075844

SST DN 25 1 1/2 1075848

Alle medienberührten Werkstoffe in der Ausführung „physiologisch unbedenklich (FDA)

bezüglich medienberührtem Werkstoff“ entsprechen den nachfolgenden FDA-Richtlinien:

FDA-Richtlinien für die Werkstoffe:

n PTFE: 21CFR177.1510,

n PVDF: 21CFR177.2510,

n PP: 21CFR177.1520,

n EPDM/FKM: 21CFR177.2600.

80

Page 81

Über dieses Produkt

1.2.3 Ausführung mit Manometervorbereitung

Das Überströmventil DHV-UR in der Ausführung M ist mit einer Gehäusebohrung für den

Manometereinbau vorbereitet. Hier können vom Kunden Manometer mit einem Gewinde‐

stutzen G 1/4“ (ISO 228) direkt montiert werden.

Tab. 4: Ausführung: Überströmventil Typ DHV-UR M mit Manometervorbereitung

Ausführung Nennweite Gewinde in Zoll Bestell-Nummer

PPE DN 10 3/4 1077221

PPB DN 10 3/4 1077259

PCE DN 10 3/4 1077255

PCB DN 10 3/4 1077263

PVT DN 10 3/4 1077267

PPE DN 15 1 1077220

PPB DN 15 1 1077258

PCE DN 15 1 1077254

PCB DN 15 1 1077262

PVT DN 15 1 1077266

PPE DN 20 1 1/4 1077219

PPB DN 20 1 1/4 1077257

PCE DN 20 1 1/4 1077223

PCB DN 20 1 1/4 1077261

PVT DN 20 1 1/4 1077265

PPE DN 25 1 1/2 1077218

PPB DN 25 1 1/2 1077256

PCE DN 25 1 1/2 1077222

PCB DN 25 1 1/2 1077260

PVT DN 25 1 1/2 1077264

81

Page 82

Über dieses Produkt

82

Page 83

A2540

Sicherheitskapitel

2 Sicherheitskapitel

Die an dem Gerät angebrachten Aufkleber und Schilder wie z. B.:

Abb. 3: Entlastungsausgang [Entlastungsausgang/relief outlet] / Durchflussrichtung

n Kennzeichen für Fluidanschlüsse,

n Durchflussrichtungspfeil,

n Typenschild,

müssen von Ihnen beachtet und in vollständig lesbarem Zustand gehalten werden.

2.1 Kennzeichnung der Warn‐

hinweise

Einleitung

Diese Betriebsanleitung beschreibt die

technischen Daten und Funktionen des

Produktes. Die Betriebsanleitung gibt aus‐

führliche Warnhinweise und ist in klare

Handlungsschritte aufgegliedert.

Warnhinweise und Hinweise gliedern sich

nach dem folgenden Schema. Hierbei

kommen verschiedene, der Situation

angepasste, Piktogramme zum Einsatz.

Die hier aufgeführten Piktogramme dienen

nur als Beispiel.

GEFAHR!

Art und Quelle der Gefahr

Folge: Tod oder schwerste Verlet‐

zungen.

Maßnahme, die ergriffen werden

muss, um diese Gefahr zu ver‐

meiden.

Beschriebene Gefahr

– Bezeichnet eine unmittelbar

drohende Gefahr. Wenn die

Situation nicht gemieden wird,

sind Tod oder schwerste Ver‐

letzungen die Folge.

83

Page 84

Sicherheitskapitel

WARNUNG!

Art und Quelle der Gefahr

Mögliche Folge: Tod oder

schwerste Verletzungen.

Maßnahme, die ergriffen werden

muss, um diese Gefahr zu ver‐

meiden.

– Bezeichnet eine möglicher‐

weise gefährliche Situation.

Wenn die Situation nicht

gemieden wird, können Tod

oder schwerste Verletzungen

die Folge sein.

VORSICHT!

Art und Quelle der Gefahr

Mögliche Folge: Leichte oder

geringfügige Verletzungen. Sach‐

beschädigung.

Maßnahme, die ergriffen werden

muss, um diese Gefahr zu ver‐

meiden.

– Bezeichnet eine möglicher‐

weise gefährliche Situation.