ProMinent DCM 2 Series Installation Manual

Installation Guide

DCM 2 series

Aquatic Water Quality Controller

ProMinent Fluid Controls 136 Industry DrivePittsburgh, PA, USA 15275-1014 DCM 2 Installation Guide 12/9/16

p/n 7500612

DCM 2 Installation

This page intentionally left blank

Page 2

DCM 2 Installation

1. Overview

2. Installation-Commissioning

2.1. Safety

2.2. Mounting

2.2.1. Sample Connections

2.2.2. Sensor Installation

2.3. Wiring

2.3.1. 120VAC Line Power and Feeder Wiring

2.3.2. Pulse Controlled Pumps

2.3.3. Flow switches, Contact Sets, and Water Meters

2.3.4. Sensors

3. Calibrations

3.1. Single Point Calibrations, 1 point or Standardization

3.2. Two Point Calibration

4. Password Security

4.1. Overview

4.2. Password Level Activ ities

4.3. Browser Passwords & Lockout

4.4. LCD Keypad Passwords

4.5. Passwords Reset

5. Application Notes

5.1. Sensor Inputs & Control Outputs

5.2. Communications

5.2.1. Ethernet

5.2.2. USB Services

5.2.3. Data Logging

5.3. Control Configuration

5.3.1. Control Method

5.3.2. Frequency Cont r olled Pump Cont ac t s 4 & 5

5.3.3. Special Cont r ol Responses

6. Sensors

6.1. Compensation

6.2. Digital Input Sensor F

6.3. Contact Sets, Flow Switch F

6.4. Frequency Controlled Pumps

6.5. Technical: Pump Frequency-Stroke Controls

6.6. Relay & Frequency Controls C omparison

6.6.1. ON/OFF Controls

6.6.2. Frequency Controls

6.7. System Alarms & Indicating LEDs

Contents

Page 3

DCM 2 Installation

6.8. Units for Volumes & Temperatures

6.8.1. Metric – US Units Selection

6.8.2. Water Meter Volumes

6.8.3. Rate-to-Volume

6.8.4. Copy Volume to

6.8.5. Pump Volu m es

6.8.6. mL/Pulse Met ers

6.8.7. Temperatures

6.8.8. User Assigned Units

7. Spare Parts

Contents

Page 4

DCM 2 Installation

Read this installation manual completely

before attempting the installation of your

and pool users.

1. Overview

1.1. All ProMinent DCM2 controll ers have an integral web server with an RJ-45 Ether net connection,

ready to co m m unicate wit h any internet ready computer, regardless of operating system. This

makes the ProMinent DCM2 one of the easiest aquatic controllers to remotely monitor and

control your pool or spa.

1.2. DCM2 controllers are optimi zed for aquatic water disinfection control applications. These

controllers use sensors to measure wat er quality and then control chemical feeders, UV systems,

recirculation pumps, he aters and more t o maintain a safe and comfort able aquatic environment.

1.3. AC powered pumps and solenoi ds for ON-OFF, Time Modulated, and PID control may also be

used wit h pulse frequency controlled pumps.

2. Installation-Commissioning

2.1. Safety

Before we talk about any installation or configuration, we need to talk about safety for you and your

co-workers, customers and swimmers. Please read and follow the caution and warning statements

below to familiarize yourself with the hazards associated with installation and operation of the

equipment covered in this manual.

General Precautions

ProMinent controller.

Follow all CAUTIONS, WARNINGS and

DANGER notices for the safety of installers

Electrical Shock Hazards

A 120VAC plug and receptacle socket cables are usually provided with controllers installed in North

America. All must be grounded to the ground lug provided. For personal safety, and moisture

corrosion contamination prevention, the enclosure cover should always be installed and secured with

all 4 screws when the DCM2-CL is in operation.

Opening the controller enclosure with the

controller power turned on or plugged in, may

expose the user to AC line voltages on the

controller circuit boards.

Ground the controller AC power ground (earth)

conductors to the groun d lug provided.

Page 5

DCM 2 Installation

NEVER OVERRIDE A FLOW SWITCH

Flow switches should NEVER be bypassed, even temporarily.

Fully understand the implications of the control setpoints,

Aquatic Water

and toxic chemicals.

Configuration Hazards

interlocks and alarms that you select.

Treatment Con t rollers

operate chemical

feeders and other

devices that may pump

hazardous, corrosive

Flow Switch Function

Uncontr oll ed fee din g of concentrated chemicals can result in personal injury

or death. Sample and recirculation flow switches are critical safety devices

which prevent uncontrolled chemical feed. Follow Instructions Carefully.

Flow switches are provided with all ProMinent pool controllers and are an

integral safety device to prevent the uncontrolled feed of chemicals, which

could cause personal injury or death. This critical safety device must always

be available to protect the swimmers and others near the pool.

Injury or damage to equipment may result from improper

configuration.

Unplug or turn OFF the AC power to the controller if you

have any concerns regarding safety or incorrect controller

operation, an d notify supervisory staff.

The above precaution pertains to Input ‘F’ lockouts as well as the integral sample flow switch on input ‘E’.

If disabled or bypassed, the sensor would not be able to sense a hazardous situation and turn of the

chemical feed pumps to prevent uncontrolled chemical feed.

Test Flow Switch Functi on

Test Flow Switches Weekly

Stop the flow of sample water to the

sensor housing to verify interlocks

are functioning.

If flow switch ‘float’ does not drop to the bottom and remain there d uring no-flow, backwash, or very low

flow conditions, the controller cannot prevent the uncontrolled feed of chemicals, which could cause

personal injury or death.

Testing of the flow switch periodically is essential to verify that low sample water flow will disable the feed

of chemicals. When flow to sens or hous ing is int errupt ed or, sl owed be low 10 g allons/ho ur, the controller

blue OK LED will start to flash and the LED status for each feeder will show “OFF:Interlocked E” within 2

Page 6

DCM 2 Installation

ELECTRICAL SURGES CA N DAMAGE YOUR

NEVER CONNEC T FEEDERS DIRECTLY TO POWER SOURCE

If the chemical feeders are connected to a wall outlet, the safety devices

will be bypassed. It is very important that the chemical feeders be

when the flow of water to the pool stops due to filter backwash, the

circulation pump losing prime or other causes, potentially hazardous

ALWAYS USE ANTI-SYPHON DEVICES

device is installed on the chemical feeders, potentially hazardous

seconds. If not, plumbing corrections or the installation of additional safeguards will be necessary to avoid

dangerous uncontrolled chemical feed.

Chemical Feeders

Electrical Surges

ProMinent controllers, like all modern electronic devices can be damaged by severe electrical spikes and

surges, like lightning. Every effort has been made to harden your controller against such surges, but no

precautions are 100% effective. Additional surge protection can be installed at time of installation, but

even that is not a guarantee that surge damage will not occur. If surge damage occurs, chemicals could

be fed to your pool or spa, continuously with no safety controls. If you inspect your ProMinent controller

after a possibly damaging power surge (thunderstorm or power outage) and suspect the controller is not

operating properly, disconnect the chemical feeders at once, and contact your ProMinent dealer for

service.

integral to your ProMinent controller, and to the safe feeding of chemicals,

connected to the controller and never directly to a wall outlet. If the

chemical feeders are connected to a wall outlet and feeding continuously,

concentrations of chemicals can be fed into a pool or spa. Follow

Instructions carefully to insure safe operation.

Uncontrolled feeding of chemicals can result in injury or death.

Anti-Syphon devices must be installed on chem ical feeders to preven t

uncontrolled feed of concentrated chemicals.

If a vacuum is created in the water circulation line and no anti-siphon

concentrations of chemicals can be drawn into pool or spa. Always use

injection check valves and anti-siphon valves in the chemical feed lines to

prevent this situation from occurring.

CONTROLLER

Uncontrolled feeding of chemicals can result i n injury or death.

A damaged controller could feed chemicals in an uncontrolled

manner.

If you suspect your ProMinent controller is not operating properly,

disconnect it from t he chemical feeders until the problem has been

corrected.

Page 7

DCM 2 Installation

Water disinfection

these chemic als.

DO NOT INSTALL YOUR

WARNING!

2.2 System Mou nting

Fully Assembled System on Acrylic Backpanel

• Locate an area on a flat wall large enough to accommodate the full size of the

18 x 30” acrylic system panel with enough extra r oom to

accommodate flexible sample tubing connections.

• NOTE: Location of the system should not be in the direct

sunlight if mounted outside, as this ma y cause false

temperature readings and can cause tem p eratures insi de the

enclosure t o exceed maximum temperature ratings of 120°F.

• The controller is shipped with a 3 f t. power cord already installed,

for easy con nection to a close indoor wall receptacle.

Alternatively, you may choose, or be required by local electrical

code, to install conduit into the bottom of the controller enclosur e.

Refer to the wiring section of thi s manu al for enclosure opening

sizes and locations.

• Refer to dimensional drawings for location and spa cing of predrilled mounting holes, measure and mar k these locations on the

wall.

• Approximate weight of the assembled system with water flowing,

may be in excess of 30 lbs., so t ake care to choose adequately

sized mount ing hardware.

• NOTE: Spacers on the back of the acrylic panel, if present, are

not secure d and can be easily removed from their groove, if

desired.

control involves

irritating, corrosive,

caustic, and potentially

toxic chemicals. Use

extreme caution and

comply with all nat iona l,

state and lo cal

regulations and

recommendat ions for the

handling and storage of

CONTROLLE R I N ARE AS

ACCESSIBLE TO THE PUBLIC

Page 8

DCM 2 Installation

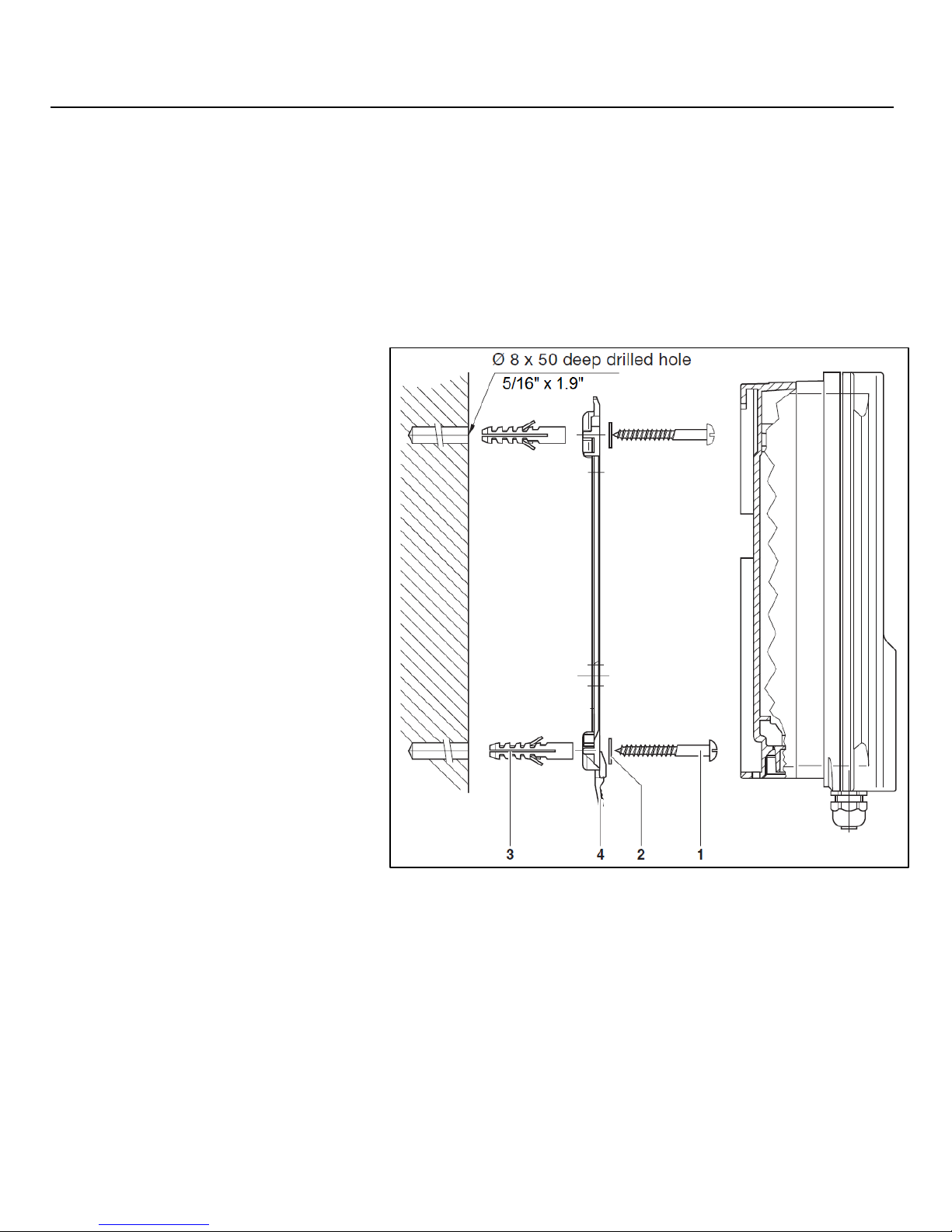

Individual C omponents

DCM2 Control ler Enclosure M ounting

• Locate an area on a vertical wall where the controller can me mounted at approximately eye level and

have enough clearance to allow the DGMa modular sensor housing to be installed near an d below the

controller. Avoid outdoor installations, especially in direct sunlight. The location of the DGMa sensor

housing must have about 18” of clearance above it to all ow removal of the sens ors, and about 12

inches below to access water sample petcock and a sampl e cup.

NOTE: a common mistake made at installation, is not allowing enough space above the sensor housing

to accommodate routine sensor maintenance.

• Individual DCM2 controllers

are shipped with mounting

bracket (4) and mounting

screws (1) to assist with wall

mount installation.

• Disconnect the bracket from

the back of the enclosure by

pressing the black plastic

release clip (4) at the

bottom, and slide the

enclosure down towards t he

clip, then tip the bracket off

the back of the enclosure.

The wall mounting bracket

can then b e used as a

drilling template as shown.

• Mount the bracket on a

vertical wall at approximately

eye level, within 30 in. of the

nearest 120VAC pow er

outlet. Alternativel y, mount

near a power disconnect,

and wir e the power directly

to the controller through

electrical conduit. Conduit

adaptor fittings are available

from ProMinent. Refer to local and national electrical codes for wet locations.

• Fasten enclosure securely to the bracket as shown, by hanging enclosure on the bracket, pushing

the encl osure against wall and lifting until the enclosure snaps securely to the bracket.

• After controller is mounted, time is best used mounting the DGMa mo dular sensor housing to

allow sens ors to equilibrate whil e the r em ainder of the installation, wiring and configuration is

performed.

Page 9

DCM 2 Installation

2.2.1. Sample Connections

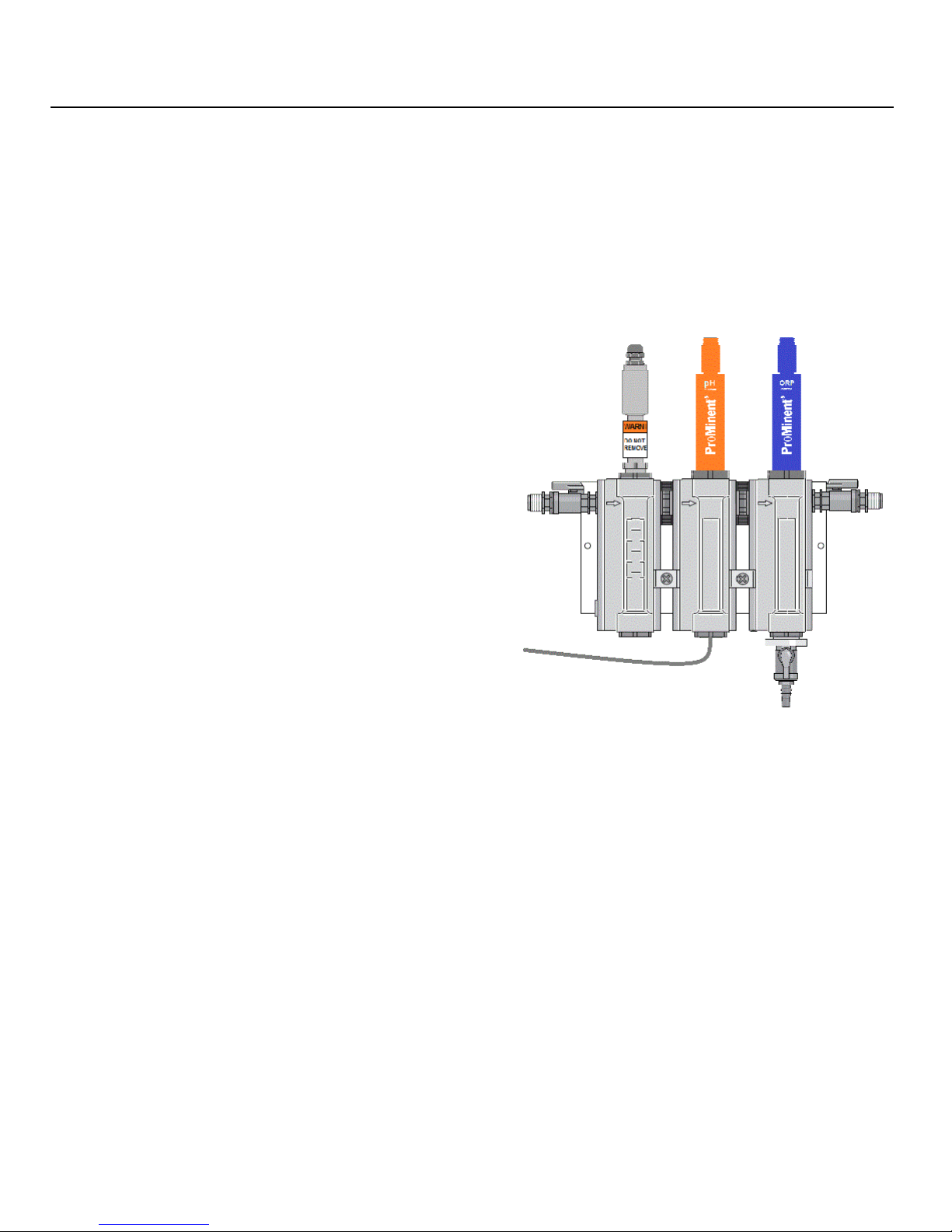

Modular Sens or Housing (DGM a)

• When shipped separatel y, the DGMa Sensor housing is mounted to a small white acrylic

backpanel.

• Mount pl ate within 60” of the DCM2 controller, and allow at least 18” clearance above the t op of

the mounting plate. Do not mount in direct sunlight as this will pr omote algae growth and create

temperature swings not representative of the pool or spa under control.

• Using the typical installation drawings on the following pages, connect sampl e tubing to the DGMa

modular sen sor housing a nd the main recirculation lines, using the fittings supplied.

NOTE: The default mounting of the modular

housing is to flow from left to right (note the flow

direction molded into each module).

• If preferred, the modular housing is

reversible by removing t he assembled

modules fr om the black upper snap cli ps.

• First disconnect the spa cer standoff

brackets a nd pull the module assembly to

unsnap it from the upper clips.

• Once it is loose, simply flip the assembled

modules so t hat the molded arr ows on the

modules are pointing right to left,

• Then reconnect it to the standoff brackets

and remount onto the backpanel.

Adjustment of the standof f brackets

mounting screws may be needed.

• Next, use the typical installation drawing

below as a guide, and connect the sample

supply and return tubi ng using the selection

of fittings supplied.

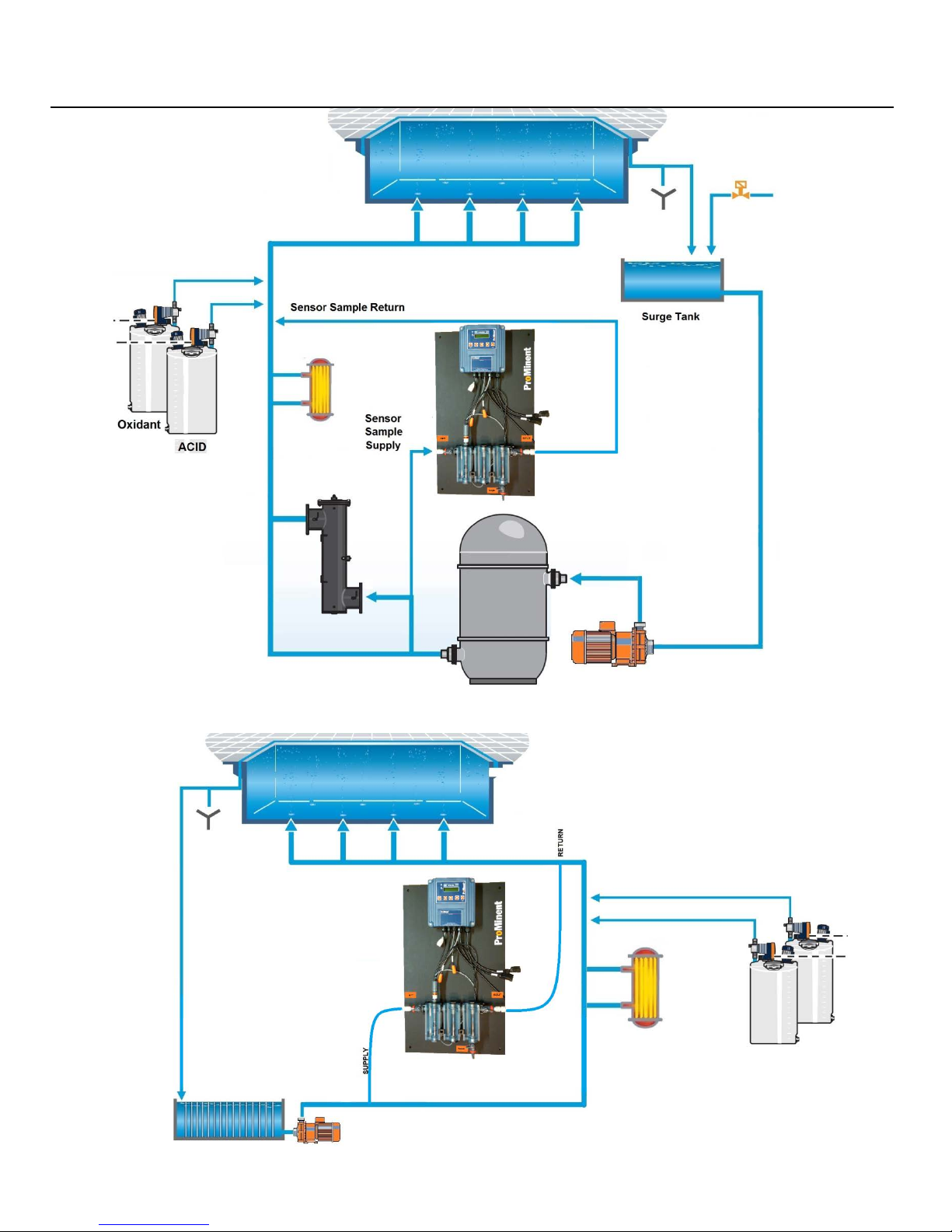

NOTE: Keep in mi nd that a very smal l sample volume (11-12 GPH) is needed for ProMinent

controllers. That is only (0.18 GPM) com pared to other aquatic controllers requiring 1-3 GPM .

Sensor sample should always be taken from downstream of the filter, but up stream of UV or

Ozone treatment system, heater and any chemical inj ection. Discharge sample into the line

returning t o the pool or spa as close to the pool as pos sible to get the maximum pressure

differential. Using the pressure drop created by other devices like heaters or the UV system works

best.

CAUTIO N: Never take the senso r sample from u nfiltered water as this may introduce hair or o t her debris into t he

flow switch and sample cell. Never return sample to the suction side of the recirculatio n pump as this will cause a

negative p ressure enviro nment (vacuum) for the sensors, which will cause non-warranty dam age to the sensors,

and more importantly, w i ll cause erroneous readings and poor water quality control.

Page 10

DCM 2 Installation

Proper Vacuum Filter Arrangement

Proper Pressure Filter Arrangem ent

Page 11

DCM 2 Installation

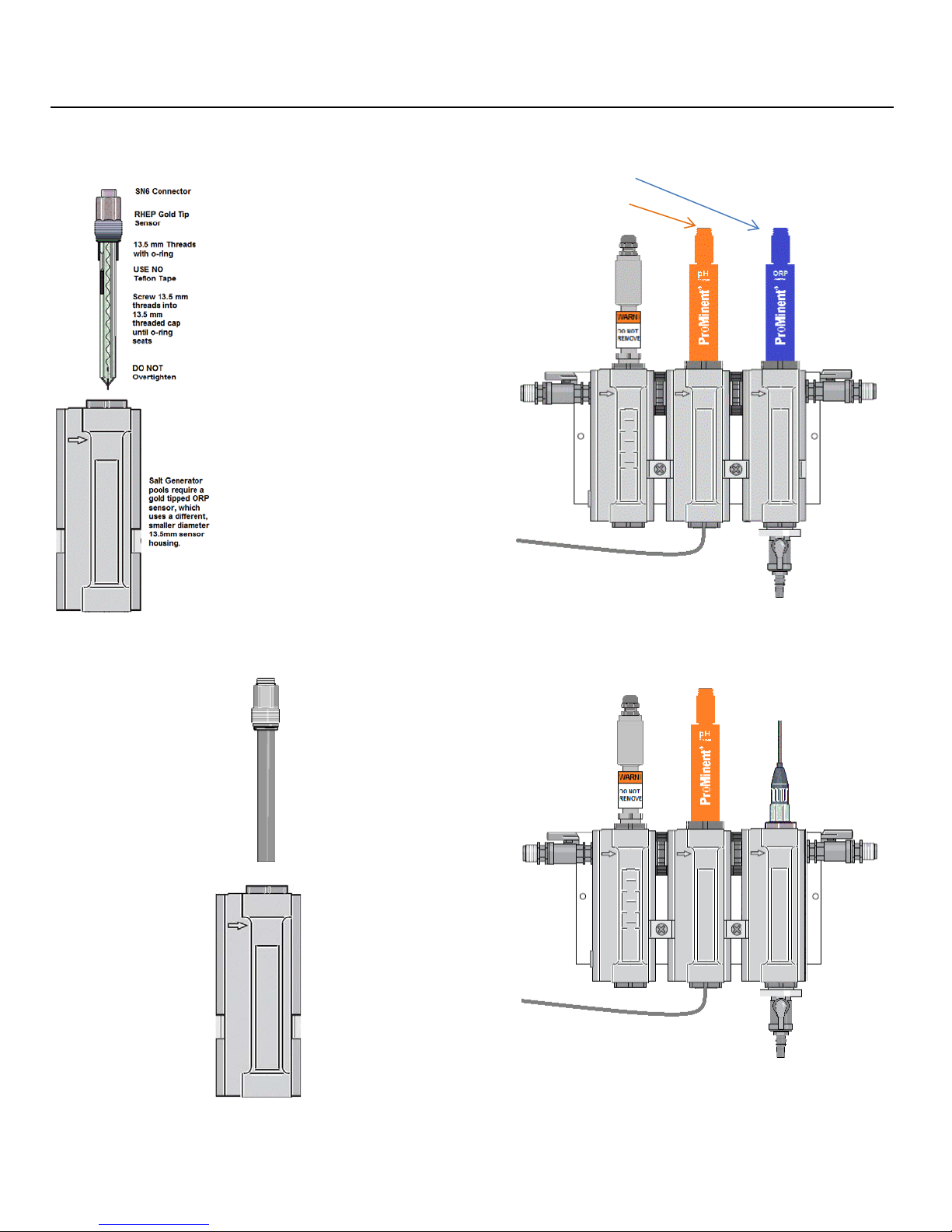

ORP sensor

Permanently

DCM200 Sensor Arrangement

DCM2-Cl Sensor Arrangement

CLB3 Sensor

2.2.2. Sensor Installation

pH sensor

connected cable

CLB3 Free

Chlorine sensor

Unique 13.5 mm

Swivel cap with

o-ring

USE NO Teflon

tape

Screw 13.5 mm

threads into

threaded cap

until o-ring

seats. Hand

tight should be

enough

DO NOT over

tighten

DCM2-Cl

versions of the

controll er are

supplied with a

CLB3 free

chlorine sensor,

instead of an

ORP sensor. The

CLb3 sensor

also uses the

13.5mm cell.

Page 12

Loading...

Loading...