Page 1

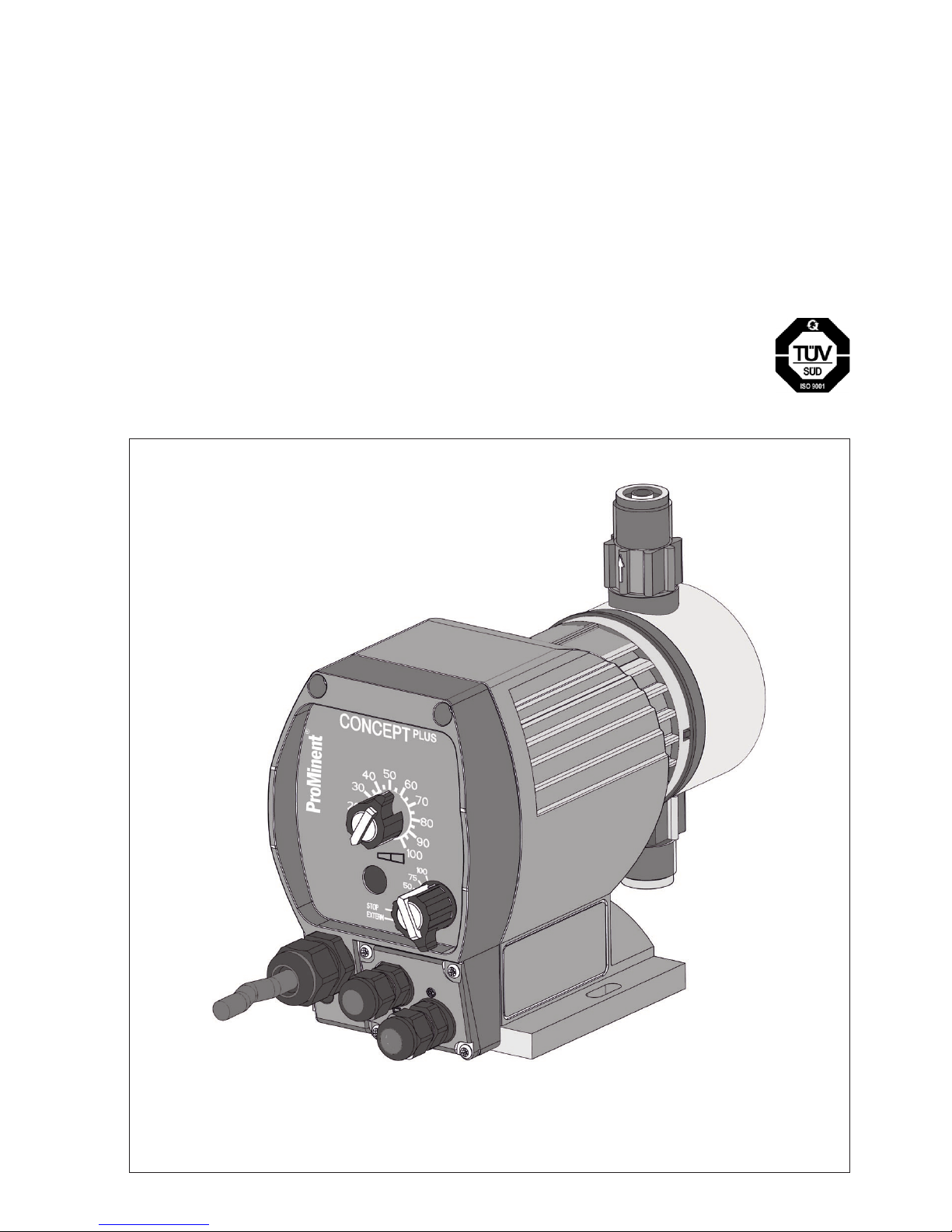

ProMinent

®

Betriebsanleitung

Operating Instructions

Mode d’emploi

Instrucciones de servicio

ProMinent® CONCEPT

PLUS

Part No. 987033 ProMinent Dosiertechnik GmbH · 69123 Heidelberg · Germany BA CO 015 02/05 G/GB/F/E

Page 2

2

ProMinent

®

Betriebsanleitung in Deutsch von Seite 3 bis 13

Operating Instructions in English from page 15 to page 25

Mode d’emploi en francais de la page 27 à la page 37

Instrucciones de servicio en español de página 39 hasta página 49

D

GB

F

E

Page 3

15

ProMinent

®

Please read the opertaing instructions through completely before

commissioning this equipment!

Do not discard!

Any part which has been subject to misuse is excluded from the

warranty!

Page

General user instructions 16

1 Equipment overview .................................................................. 17

2 Type overview/material details ................................................. 18

3 Safety........................................................................................... 18

4 Storage and transport ............................................................... 19

5 Assembly and installation ......................................................... 19

6 Commissioning .......................................................................... 20

7 Maintenance

...............................................................................

20

8 Repair

..........................................................................................

21

9 Troubleshooting ......................................................................... 21

10 Decommissioning and disposal ............................................... 22

11 Technical data ............................................................................ 22

12 Accessories ................................................................................ 23

Declaration of Conformity 25

Table of Contents

Page 4

16

ProMinent

®

General user instructions

Please read through the following user instructions carefully! They will

help you get the best use out of the operating instruction manual.

The following are highlighted in the text:

• Enumerated points

Instructions

Safety guidelines:

WARNING

Describes a potentialy dangerous situation. If not avoided, could

cause fatal or serous injury.

IMPORTANT

Describes a potentialy dangerous situation. If not avoided, could

cause damage to property.

This operating instructions manual is aimed at experts in metering

pumps and their operation.

If you require detailed installation instructions please order ”General Operating Instructions Manual, ProMinent

®

Solenoid Metering

Pumps” (Order No. 987057).

General user instructions

▲

Page 5

17

ProMinent

®

Equipment overview

1 Equipment overview

1 Stroke length adjustment knob

2 Error/operating indicator (error - red / operation - green)

3 Multifunction switch (stroke rates (in % of 180 strokes/min), stop,

operating mode ”external” (Retrofit kit))

4 Power cable

5 “External actuation” socket (actuation via contact signal in ”external”

operating mode; Retrofit kit)

6 “Float switch” socket (for 1-stage float switch; Retrofit kit)

7 Suction valve

8 Discharge valve

The leakage bore is between the suction valve and the drive housing.

7

4

6

8

5

2

1

3

Page 6

18

ProMinent

®

2 Type overview/material details

Order No. CONCEPT

PLUS

, CNPa, 115 V versions

Pump type liquid end material

PP (with EPDM*) NP** (with Viton

®

*)

1000 1022480 1022484

1601 1022481 1022485

1002 1022482 1022486

0704 1022483 1022487

Order No. CONCEPT

PLUS

, CNPa, 230 V versions

Pump type liquid end material

PP (with EPDM*) NP** (with Viton

®

*)

1000 1022452 1022476

1601 1022453 1022477

1002 1022474 1022478

0704 1022475 1022479

* Seal material

** Valve body material is PVC

The valve balls are made of ceramics.

3 Safety

• The pump may be used only for metering liquid media!

• All other uses or modifications are prohibited!

• The pump is not suitable for metering gaseous media or solids!

• The pump must be operated by appropriately trained and authorised

personnel!

The personnel must be familiar with metering pumps and their operation!

WARNING

• The pump may start to operate as soon as it connected to the mains

power supply!

Ensure that no hazardous metering chemical can leak out!

If you have not done so, set the multifunction switch to STOP or

disconnect the pump from the mains immediately.

• The pump cannot be switched off! In the case of an electrical failure,

disconnect the mains cable from the power supply.

• Disconnect the power cable from the mains before working on

the pump.

Type overview/material details / Safety

Correct use of

equipment

Page 7

19

ProMinent

®

Safety / Storage and transport / Assembly and installation

• Risk of electric shock - This pump is supplied with a grounding

conductor and grounding-type attachment plug. To reduce the risk of

electric shock, be certain that it is connected only to a properly

grounding-type receptacle.

• Always depressurise liquid end before working on the pump.

• Always empty and rinse the liquid end before working on the pump

if used with hazardous or unknown feed chemicals.

• Wear safety equipment appropriate to the metering chemical when

working on the liquid end.

• Never let the pump work against a significantly increased operat

ing pressure or a closed stop tap on the discharge-side. This can

cause lines to burst.

• Avoid overfeed due to positive pressure difference between in take

and discharge sides. E.g. use a ball check valve with at least 1.5

bar opening pressure with an atmospheric pressure outlet (not 0213).

• Assembly and installation of ProMinent

®

metering pumps with nonoriginal parts, which have not been checked and recommended by

ProMinent is not allowed and can lead to harm to persons or

property for which no liability can be accepted.

• Note all national directives which apply to the installation.

The sound pressure level is < 70 dB (A) at a distance of 1 m in accordance

with EN 23741 or EN 23742 at maximum stroke, maximum stroke rate, maximum back pressure (water)

4 Storage and transport

Ambient conditions for storage and transport:

Storage and transport temperature: -10 to +50 °C

Humidity: < 92 % rel. humidity,

non-condensing

5 Assembly and installation

IMPORTANT

• The pump must not vibrate when installed.

• Solenoid metering pumps tend to overfeed if the back pressure

is too low. In this case fit a ball check valve, a multifunction valve

or a discharge valve with 1.5 bar opening pressure downstream

from the pump (not 0213).

Sound pressure level

Page 8

20

ProMinent

®

Assembly and installation / Commissioning / Maintenance

• Use only original hoses with the specified diameter and wall

thickness! It is not otherwise possible to ensure the durability of

the connection to the pump valves!

• For tips on hydraulic installation, order the ”General Operating

Instructions Manual, ProMinent

®

Solenoid Metering Pumps”

(Order No. 987057).

• Check that the mains power supply and frequency match the

values specified on the rating plate!

• Note all national directives which apply to the installation!

Mount metering pump on a tank or bracket using screws and

washers (Ø 6 mm).

Keep suction height and length of suction hose as short as possible.

Install suction hose in an ascending position.

Cut the suction and pressure pipe to the required length.

Push union nut and clamping ring onto the hose.

Push the cut hose onto the grommet up to the stop.

Press on hose and tighten the union nut.

Mount the foot-actuated valve.

For this purpose, cut the free suction hose end such that the footactuated valve is suspended close above the tank bottom.

In case of metering solutions with contaminations or residues, cut

the free suction hose end such that the foot-actuated valve is

suspended at least 50 mm above the tank bottom.

6 Commissioning

Precision metering is possible only within a stroke length range of

30-100 %.

7 Maintenance

Quarterly at normal load (approx. 30 % continuous operation)

Check the pump diaphragm for damage

Check that the discharge and suction valves and the discharge lines

are seated firmly

Check the overall tightness of the liquid end (in particular leakage

opening between suction value and drive housing)

Check liquid end screws are tight

Tightening torque for liquid end screws: 4.5 to 5 Nm

▲▲▲

(section)

Hose

Union nut

clamping

ring

grommet

O-Ring

intake

connector

▲

▲▲▲ ▲ ▲▲

▲

Service interval

▲

Page 9

21

ProMinent

®

Repair / Troubleshooting

8 Repair

Repairs which may be carried out by qualified persons (according to

safety instructions):

• Cleaning a valve

• Replacing the diaphragm (installation instructions included with

replacement diaphragm)

For all other repairs consult your ProMinent® Subsidiary.

9 Troubleshooting

The pump does not prime despite full stroke action and venting

Cause: Crystalline deposits on the ball seat due to valves drying out.

Remedy: Remove suction hose from the supply tank and rise liquid

end thoroughly.

If unsuccessful, dismantle valves and clean.

Fluid is leaking from the head washer

Cause: The liquid end is leaking at the pump diaphragm.

Remedy: Screw in the liquid end anti-clockwise (torque: 4.5 to 5 Nm)

If unsuccessful, replace the diaphragm (installation instructions

included with the diaphragm).

Error/operating indicator not lit

Cause: No or incorrect mains voltage.

Remedy: Use mains voltage as specified on the rating plate.

Error/operating indicator lit red

Cause: Liquid level in the supply tank has reached “low liquid level”.

Remedy: Top up supply tank.

Cause: Electronic failure.

Remedy: Send pump away for repair.

Page 10

22

ProMinent

®

* Suction lift with filled suction line and liquid end

** Priming lifts with clean and wetted valves, metering fluid, water

(20 °C), at 100 % stroke length, 180 strokes/min, atmospheric

pressure outlet and/or open venting valve and correctly installed lines.

Materials

Liquid end material specification: see type code

Housing: PPE, glass fibre reinforced

Electrical data

Mains frequency: 50 Hz / 60 Hz

* Fuses must have approvals according to VDE, UL and CSA.

Decommissioning and disposal / Technical data

10 Decommissioning and disposal

IMPORTANT

• When decommissioning a pump, clean all traces of chemicals

and dirt from the housing and particularly the liquid end.

• Observe all relevant disposal directives for your area

(particularly with regard to electronic waste)

11 Technical data

Performance table 230 V version

115 V/AC version CNPa

Wattage: 11 W

Current I eff: 0.26 A

Peak current 1.2 A

Switch-on peak current < 3 A for < 0.1 ms

Fuse*: 0.315 AT

230 V/AC version CNPa

Wattage: 10 W

Current I eff: 0.12 A

Peak current 0.5 A

Switch-on peak current < 4 A for < 0.1 ms

Fuse*: 0.16 AT

10

16

10

7

0.6

1.0

2.0

3.9

0.07

0.10

0.18

0.39

5

8

5

3.5

0.8

1.4

2.6

4.5

0,08

0.13

0.24

0.42

180

180

180

180

6x4

6x4

6x4

6x4

6

6

5

4

1.8

2.0

2.5

3.0

8

8

5.5

3

1000

1601

1002

0704

Pump

type

Minimum delivery rate

at maximum

back pressure

Minimum feed rate

at medium

back pressure

Max.

stroke

rate

Connection

size

ext. Ø x int. Ø

Priming

lift

*

Priming

lift

**

Admissible

priming pressure

Intake

bar l/h

ml/

stroke

bar l/h

strokes/

min mm m Wc m Wc bar

ml/

stroke

3

1.5

8.0

13.5

0.74

1.42

1.5

1.0

10.8

15.5

1.00

1.4

180

180

8x5

8x5

2

1.5

2.0

1.5

1

0.5

0308

0213

Page 11

23

ProMinent

®

Technical data / Accessories

Temperature details

Storage and transport temperature: -10 °C...+50 °C

Function at ambient temperature: -10 °C...+45 °C

Admissible feed chemical temperature: -10 °C...+35 °C

NP

Material

feed unit

Long term at max. back

pressure

max. 15 min.

at max. 2 bar

PP

50 °C

45 °C

100 °C

60 °C

Climate

Admissible relative air humidity: 92 %, non condensing.

Load in wet and alternating climate: FW 24 in accordance with DIN 50016.

Enclosure rating and safety class

Contact and moisture protection: IP 65 in accordance with IEC 529,

EN 60529, DIN VDE 0470 Part 1 Safety class 1 - electric mains with earth

Sound pressure level

Sound pressure level: < 70 dB(A) at a distance of 1 m in accordance

with EN 23741 or EN 23742 at maximum stoke, maximum stroke rate,

maximum back pressure (water)

Shipping weight

Shipping weight: 1.8 kg

12 Accessories

Suction lance for 200 l drum, tank opening 2“ DIN 570, PPE 1022511

Suction lance for 200 l drum, tank opening 2“ DIN 570, PCB 1022512

Suction lance for tank 5-50 l drum, tank opening d50, PPE 1022645

Suction lance for tank 5-50 l drum, tank opening d50, PCB 1022644

Adjustable suction lance with single-stage level switch, closing in the

event of lack of chemicals.

The delivery scope also includes the parts required for connecting the

pump.

Retrofit kit External + level CNP 1022099

Retrofit kit level switch CNP* 1022115

*connecting parts given suction lances and tanks provided by the

customer

Suction lances

Retrofit kits

Page 12

24

ProMinent

®

Technical data

CONCEPT

PLUS

(dimensions in mm)

M20 x1.5

33.9

76

10.5

56.1

105.3

85

158.7

132.5

84.7

18.3

80

92.5

6

70 (90*)

140 (156*)

98 (110*)

* dimensions for pump type 0308, 0213

Page 13

25

ProMinent

®

Conformity declaration

Loading...

Loading...