ProMinent alpha ALPc 1001, alpha ALPc 1002, alpha ALPc 1007, alpha ALPc 0707, alpha ALPc 1004 Operating Instructions Manual

...Page 1

Motor-driven Metering Pump

alpha ALPc

Operating instructions

EN

Original operating instructions (2006/42/EC)Part no. 986353 BA ALP 015 08/18 EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Page 2

Supplementary information

Fig. 1: Please read!

Read the following supplementary information

in its entirety! You will benefit more from using

the operating instructions should you already

know this information.

The following are highlighted separately in the

document:

n Enumerated lists

Instructions

ð

Outcome of the instructions

Ä ‘State the identity code and serial number’

on page 2

: Links to points in this chapter

- refer to ... : References to points in this docu‐

ment or another document

[Keys]

Information

This provides important information

relating to the correct operation of the

unit or is intended to make your work

easier.

Safety Information

Safety information is identified by pictograms see Safety Chapter.

Validity

These operating instructions conform to current

EU regulations applicable at the time of publi‐

cation.

State the identity code and serial number

Please state identity code and serial number,

which you can find on the nameplate when you

contact us or order spare parts. This enables

us to clearly identify the unit type and material

versions.

Supplemental directives

2

Page 3

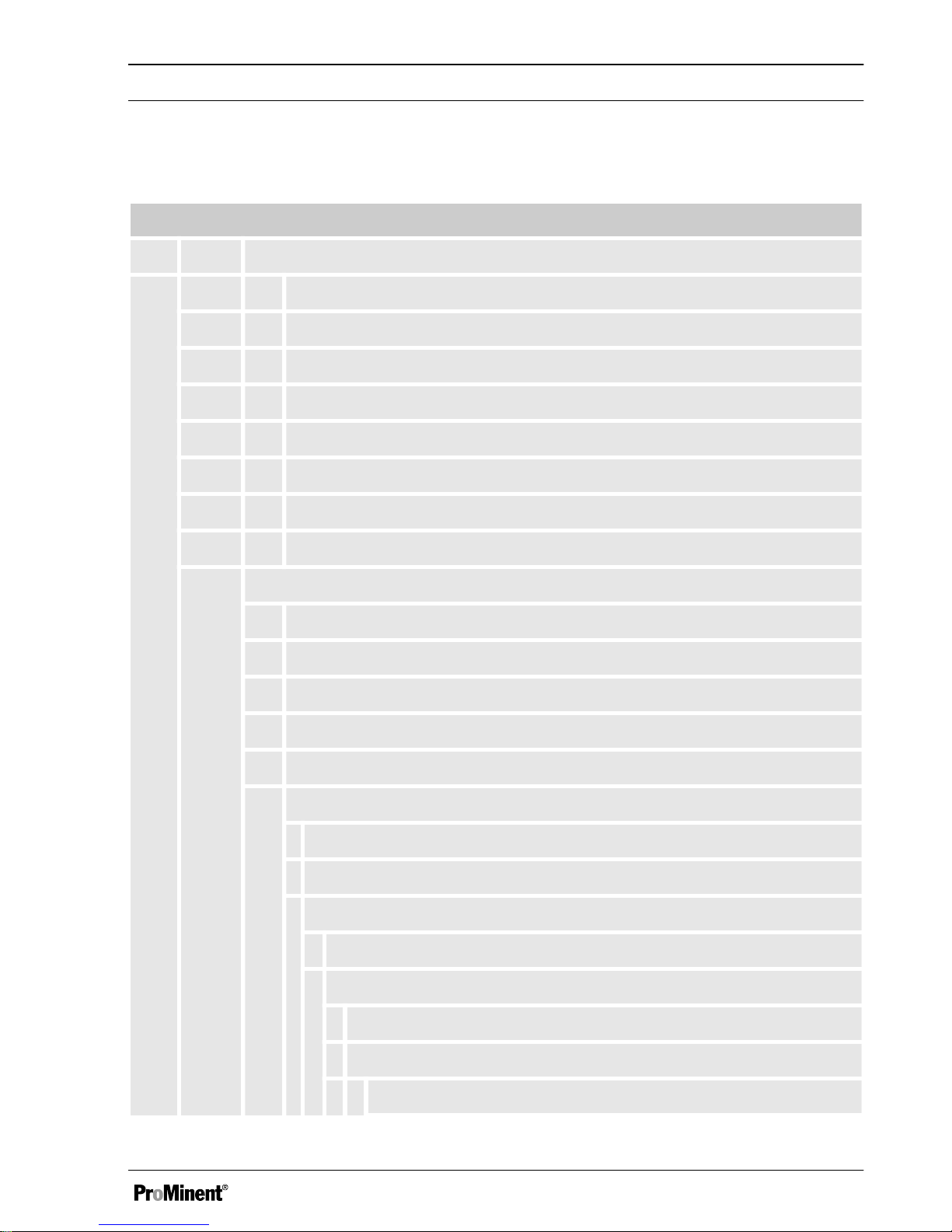

Table of contents

1 Identity code............................................................................................................................ 5

2 Safety chapter......................................................................................................................... 7

3 Storage, Transport and Unpacking....................................................................................... 12

4 Overview of equipment......................................................................................................... 13

5 Functional description........................................................................................................... 14

5.1 Power end.................................................................................................................... 14

5.2 Liquid End.................................................................................................................... 14

6 Assembly............................................................................................................................... 15

7

Installation, hydraulic............................................................................................................. 16

7.1 Installing hose lines...................................................................................................... 17

7.1.1 Installation of the suction and discharge line............................................................ 17

7.1.2 Installation of metering pumps with bleed valve........................................................ 20

7.1.3 Basic installation notes.............................................................................................. 20

8 Electrical installation.............................................................................................................. 23

9 Start up.................................................................................................................................. 24

10 Maintenance.......................................................................................................................... 28

11 Repairs.................................................................................................................................. 31

11.1 Cleaning valves.......................................................................................................... 31

11.2 Replacing the diaphragm........................................................................................... 32

11.3 Replacing the complete dosing head......................................................................... 36

12 Troubleshooting.................................................................................................................... 37

12.1 Faults and troubleshooting......................................................................................... 38

12.2 All other faults............................................................................................................. 39

13 Decommissioning and disposal............................................................................................. 40

13.1 Decommissioning....................................................................................................... 40

13.2 Disposal...................................................................................................................... 41

14 Technical data....................................................................................................................... 42

15 Design Documents................................................................................................................ 46

16 Dimensional drawings........................................................................................................... 47

17 Further order information ..................................................................................................... 48

Table of contents

3

Page 4

18 Declaration of Conformity for Machinery............................................................................... 49

Table of contents

4

Page 5

1 Identity code

alpha product range, version c

ALPc Type Capacity

bar l/h (at 50 Hz)

1001 10 0.9

1002 10 1.8

1004 10 3.5

1008 10 7.7

0707 7 6.9

0417 4 17.0

0230 2 29.7

Dosing head material

PPE PP/PP/EPDM

PPB PP/PP/FPM-B

NPE Clear acrylic/PVC//EPDM

NPB Clear acrylic/PVC/FPM

PVT PVDF/PVDF/PTFE

Seal material

2 Without valve spring, with bleed valve

3 with 2 valve springs (approx. 0.1 bar, material 1.4571), with bleed valve

Hydraulic connector

0 Standard connection in line with technical data

Design

0 with ProMinent logo

M modified

Electrical connection

Identity code

5

Page 6

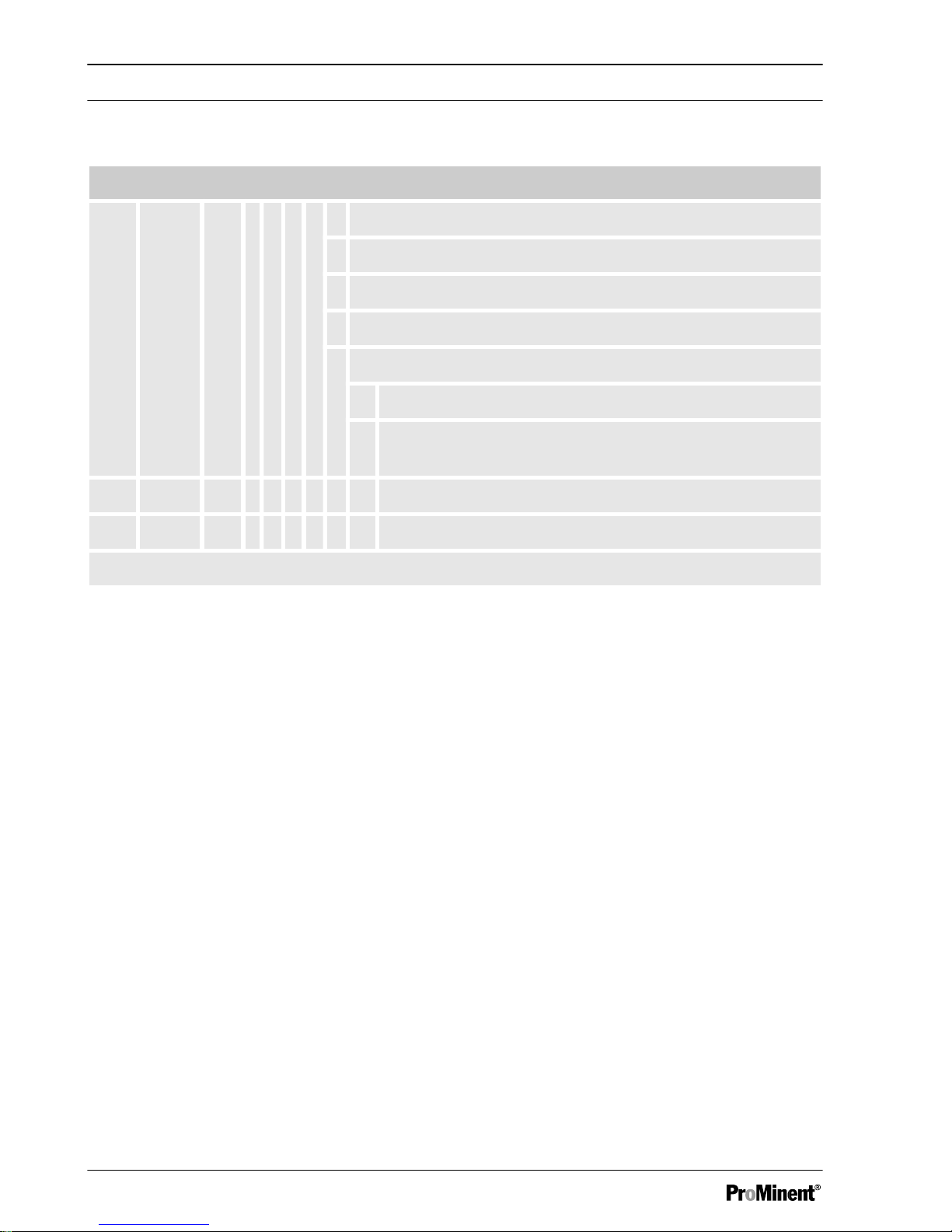

alpha product range, version c

A 230 V , 50/60 Hz, 2 m European

B 230 V, 50/60 Hz, 2 m Swiss

C 230 V, 50/60 Hz, 2 m Australian

D 115 V , 50/60 Hz, 2 m USA

Accessories

0 no accessories

1 with foot and injection valve, 2 m PVC suction line, 5 m

metering line

Identity code

6

Page 7

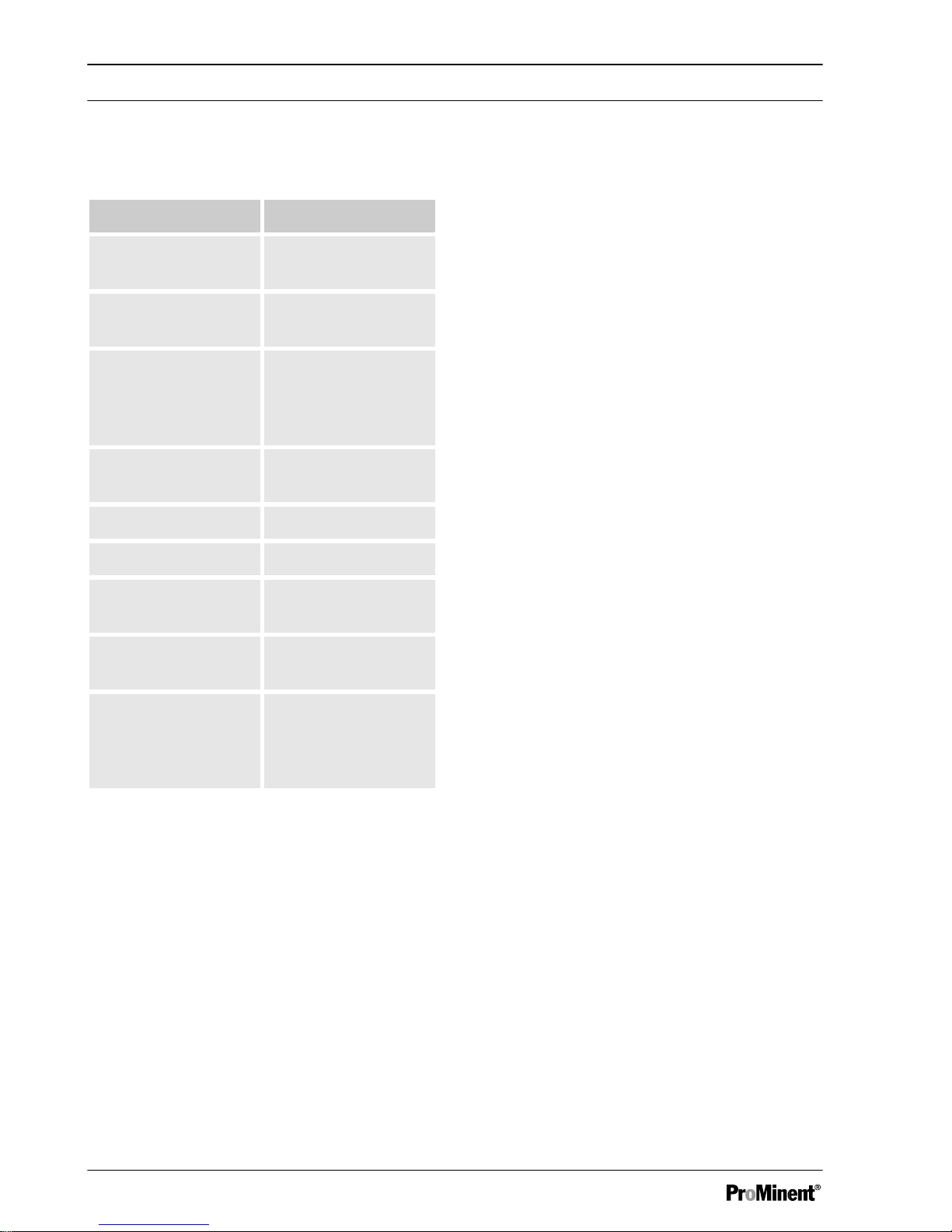

2 Safety chapter

Identification of safety notes

The following signal words are used in these

operating instructions to denote different severi‐

ties of danger:

Signal word Meaning

WARNING Denotes a possibly

dangerous situation.

If this is disregarded,

you are in a lifethreatening situation

and this can result in

serious injuries.

CAUTION Denotes a possibly

dangerous situation.

If this is disregarded,

it could result in slight

or minor injuries or

material damage.

Warning signs denoting different types of

danger

The following warning signs are used in these

operating instructions to denote different types

of danger:

Warning signs Type of danger

Warning – automatic

start-up.

Warning – hand inju‐

ries.

Warning – highvoltage.

Warning signs Type of danger

Warning – danger

zone.

Intended use

n Only use the pump to meter liquid feed

chemicals.

n Only use the pump after it has been cor‐

rectly installed and started up in accord‐

ance with the technical data and specifica‐

tions contained in the operating

instructions.

n Observe the general limitations with regard

to viscosity limits, chemical resistance and

density - see also ProMinent® Resistance

List in the Product Catalogue or at

www.prominent.com!

n All other uses or modifications are pro‐

hibited.

n The pump is not intended for the metering

of gaseous media and solids.

n The pump is not intended to meter flam‐

mable media.

n The pump is not intended for the metering

of explosive media.

n The pump is not intended for operation in

areas at risk from explosion.

n The pump is not intended for exterior

applications without the implementation of

suitable protective measures.

n The pump should only be operated by

trained and authorised personnel, see the

following "Qualifications" table.

n You have a responsibility to adhere to the

information contained in the operating

instructions at the different phases of the

unit's service life.

Safety chapter

7

Page 8

Qualification of personnel

Action Qualification

Storage, transport,

unpacking

Instructed person

Assembly Technical personnel,

service

Planning hydraulic

installation

Qualified personnel

who have a thorough

knowledge of

metering pumps.

Hydraulic installation Technical personnel,

service

Installation, electrical Electrical technician

Operation Instructed person

Maintenance, repair Technical personnel,

service

Decommissioning,

disposal

Technical personnel,

service

Troubleshooting Technical personnel,

electrical technician,

instructed person,

service

Explanation of the terms:

Technical personnel

A qualified employee is deemed to be a person

who is able to assess the tasks assigned to him

and recognise possible dangers based on

his/her technical training, knowledge and expe‐

rience, as well as knowledge of pertinent regu‐

lations.

Note:

A qualification of equal validity to a technical

qualification can also be gained by several

years employment in the relevant work area.

Electrical technician

Electrical technicians are deemed to be people,

who are able to complete work on electrical

systems and recognise and avoid possible dan‐

gers independently based on their technical

training and experience, as well as knowledge

of pertinent standards and regulations.

Electrical technicians should be specifically

trained for the working environment in which

they are employed and know the relevant

standards and regulations.

Electrical technicians must comply with the pro‐

visions of the applicable statutory directives on

accident prevention.

Instructed person

An instructed person is deemed to be a person

who has been instructed and, if required,

trained in the tasks assigned to him/her and

possible dangers that could result from

improper behaviour, as well as having been

instructed in the required protective equipment

and protective measures.

Service

Customer Service department refers to service

technicians, who have received proven training

and have been authorised by ProMinent or Pro‐

Maqua to work on the system.

Safety chapter

8

Page 9

Safety information

WARNING!

Warning about personal and material

damage

The pump can start to pump, as soon

as it is connected to the mains voltage.

– Install an emergency cut-off switch

in the pump power supply line or

integrate the pump in the emer‐

gency cut-off management of the

system.

WARNING!

Danger of electric shock

A mains voltage may exist inside the

pump housing.

– If the pump housing has been

damaged, you must disconnect it

from the mains immediately. It

may only be returned to service

after an authorised repair.

WARNING!

Warning of hazardous feed chemical

Should a dangerous feed chemical be

used: it may escape from the hydraulic

components when working on the

pump, material failure or incorrect han‐

dling of the pump.

– Take appropriate protective meas‐

ures before working on the pump

(e.g. safety glasses, safety

gloves, ...). Adhere to the material

safety data sheet for the feed

chemical.

–

Drain and flush the liquid end

before working on the pump.

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very

serious injuries.

Please ensure when handling haz‐

ardous substances that you have read

the latest safety data sheets provided

by the manufacture of the hazardous

substance. The actions required are

described in the safety data sheet.

Check the safety data sheet regularly

and replace, if necessary, as the

hazard potential of a substance can be

re-evaluated at any time based on new

findings.

The system operator is responsible for

ensuring that these safety data sheets

are available and that they are kept up

to date, as well as for producing an

associated hazard assessment for the

workstations affected.

Safety chapter

9

Page 10

CAUTION!

Warning of feed chemical spraying

around

Feed chemical can spray out of the

hydraulic components if they are

manipulated or opened due to pressure

in the liquid end and adjacent parts of

the system.

– Disconnect the pump from the

mains power supply and ensure

that it cannot be switched on again

by unauthorised persons.

–

Depressurise the system before

commencing any work on

hydraulic parts.

CAUTION!

Warning of feed chemical spraying

around

An unsuitable feed chemical can

damage the parts of the pump that

come into contact with the chemical.

– Take into account the resistance

of the wetted materials and the

ProMinent Resistance List when

selecting the feed chemical - see

the ProMinent Product Catalogue

or visit ProMinent.

CAUTION!

Warning of feed chemical spraying

around

The metering pump can generate a

multiple of its rated pressure. Hydraulic

parts can rupture if a discharge line is

blocked.

– Correctly install a relief valve in the

discharge line downstream of the

metering pump.

CAUTION!

Danger of personnel injury and material

damage

The use of untested third party parts

can result in personnel injuries and

material damage.

– Only fit parts to metering pumps,

which have been tested and rec‐

ommended by ProMinent.

CAUTION!

Danger from incorrectly operated or

inadequately maintained pumps

Danger can arise from a poorly acces‐

sible pump due to incorrect operation

and poor maintenance.

– Ensure that the pump is acces‐

sible at all times.

–

Adhere to the maintenance inter‐

vals.

Safety chapter

10

Page 11

CAUTION!

Warning against illegal operation

Observe the regulations that apply

where the device is installed.

Fixed separating protective equipment

n Cover

n Dosing head

n Housing

The customer may only remove the cover to

adjust the stroke length.

Customer should only remove the dosing head

in accordance with the "Repair" chapter.

Only the ProMinent Service department are

authorised to remove the housing.

Ensure that all protective equipment is properly

fitted before the pump is operated.

Other safety equipment

Vor Deckelabnahme

Pumpe abschalten

Switch off pump

before opening

Arrêtez la pompe

avant de l‘ouvrir

P_ALP_0010_SW

Fig. 2

Ensure that the warning label is always fitted

and legible.

Circuit breaker

The driver motor is fitted with a circuit breaker,

which automatically switches off the motor

when it overheats to more than 106 °C.

The circuit breaker switches the pump on again

once the motor has cooled down.

Information in the event of an emergency

In an emergency, either pull out the mains plug

or press the emergency-off switch, installed by

the customer, or disconnect the pump in line

with the emergency-shut-down guidelines for

your system!

If feed chemical escapes, also ensure that the

pump's hydraulic environment is at atmospheric

pressure. Adhere to the material safety data

sheet for the feed chemical.

Sound pressure level

Sound pressure level LpA < 70 dB according to

EN ISO 20361

at maximum stroke length, maximum stroke

rate, maximum back pressure (water)

Safety chapter

11

Page 12

3 Storage, Transport and Unpacking

Safety Information

WARNING!

Only return metering pumps for repair

in a cleaned state and with a flushed

liquid end - refer to "Decommissioning!

Only return metering pumps with a

completed Decontamination Declara‐

tion form. The Decontamination Decla‐

ration constitutes an integral part of an

inspection / repair order. A unit can only

be inspected or repaired when a Decla‐

ration of Decontamination Form is sub‐

mitted that has been completed cor‐

rectly and in full by an authorised and

qualified person on behalf of the pump

operator.

The "Decontamination Declaration

Form" can be found on our homepage.

CAUTION!

Danger of material damage

The device can be damaged by incor‐

rect or improper storage or transporta‐

tion!

– The unit should only be stored or

transported in a well packaged

state - preferably in its original

packaging.

–

The packaged unit should also

only be stored or transported in

accordance with the stipulated

storage conditions.

– The packaged unit should be pro‐

tected from moisture and the

ingress of chemicals.

Ambient conditions

Ambient conditions - refer to "Technical Data"

chapter.

Scope of delivery

Compare the delivery note with the scope of

delivery:

n Metering pump with mains cable

n Connector kit for hose/pipe connection

n Product-specific operating instructions with

Declaration of Conformity

Storage, Transport and Unpacking

12

Page 13

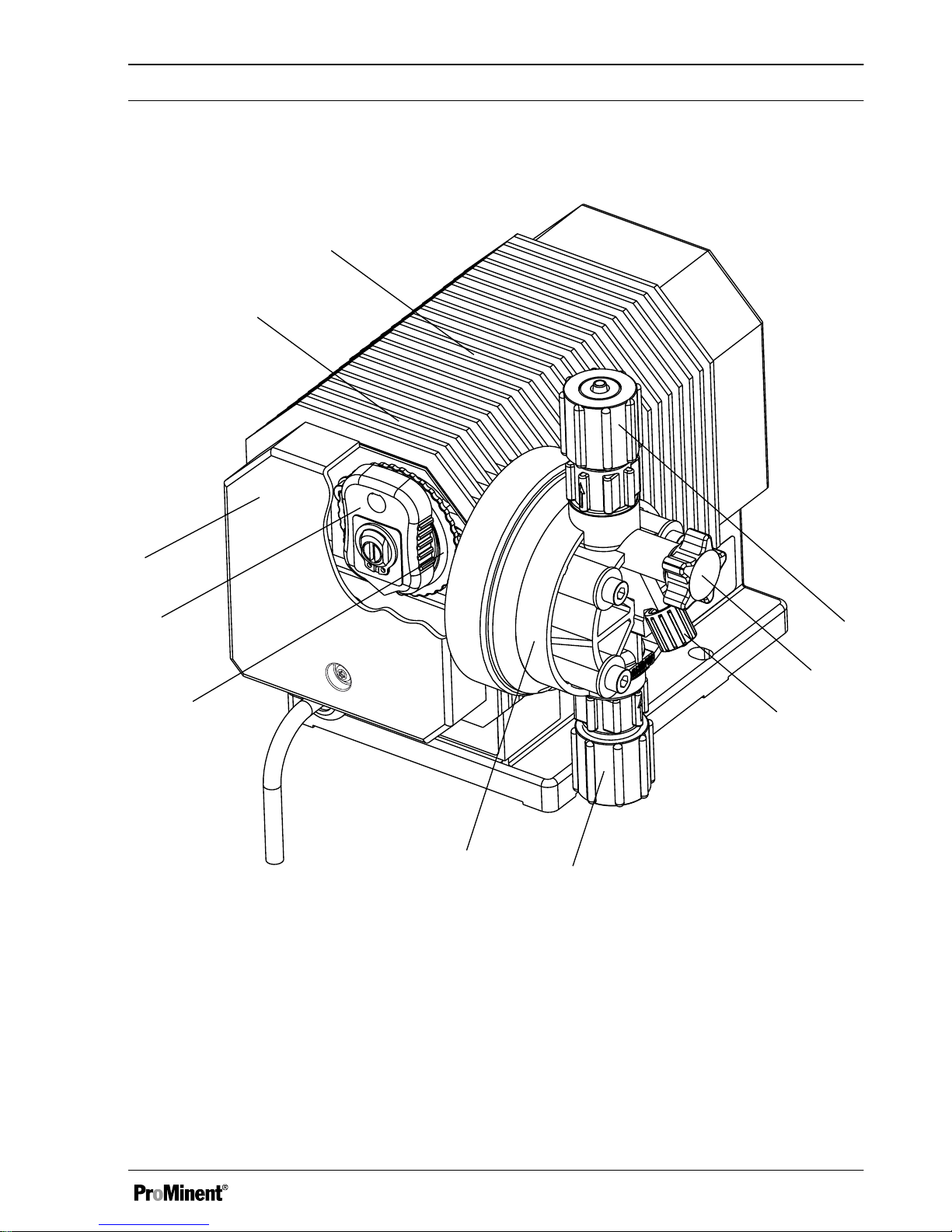

4 Overview of equipment

1

2

3

10

9

8

7

6

5

4

P_ALP_0007_SW

Fig. 3

1 Cover

2 Motor mounting

3 Housing

4 Pressure connector

5 Bleed valve

6 Bypass hose nozzle

7 Suction connector

8 Dosing head

9 Eccentric disc with scale

10 Latched slide

Overview of equipment

13

Page 14

5 Functional description

5.1 Power end

The cam for the stroke movement is guided in

an eccentric disc. Pumps of this size do not

therefore require conventional return springs –

the suction and pressure stroke are positively

driven.

The stroke length can be adjusted by a latched

slide (9) from 100% to 0 in increments of 10%.

The diaphragm is always deflected from the

neutral centre position, producing a smooth

sinusoidal stroke motion.

5.2

Liquid End

The dosing process is performed as follows:

The diaphragm is pressed into the dosing head;

the pressure in the dosing head closes the suc‐

tion valve and the feed chemical flows through

the discharge valve out of the dosing head. The

diaphragm is now drawn out of the dosing

head; the discharge valve closes due to the

negative pressure in the dosing head and fresh

feed chemical flows through the suction valve

into the dosing head. One cycle is completed.

Functional description

14

Page 15

6 Assembly

WARNING!

The IP 23 protection against moisture

and accidental contact only applies to

horizontal pump bases with vertically

installed pumps.

CAUTION!

When assembling the pump, ensure

that there is sufficient room around the

pump for operation, maintenance,

repairs and quick disconnection of the

mains plug.

Capacity too low

Vibrations can disturb the liquid end

valves.

–

Secure the metering pump to

ensure that no vibrations can

occur.

Capacity too low

If the liquid end valves are not upright,

they cannot close correctly.

–

Ensure that the discharge valve is

upright.

Assemble the metering pump on a

storage tank or a bracket using screws

and U-washers (Ø 5 mm).

Assembly

15

Page 16

7 Installation, hydraulic

Safety notes

CAUTION!

Warning of feed chemical spraying

around

An unsuitable feed chemical can

damage the parts of the pump con‐

tacted by the chemical.

– Take into account the resistance

of the materials which will come

into contact with the chemical

when selecting the feed chemical see the ProMinent Product Cata‐

logue or visit www.prominent.com.

CAUTION!

Warning of feed chemical spraying

around

Pumps which are not fully installed

hydraulically can pump feed chemical

from the outlet opening of the discharge

valve as soon as they are connected to

the mains power supply.

– First install the pump hydraulically,

then electrically.

–

In the event that you have failed to

do so, press the On/Off switch (on

site) or the Emergency Stop

switch.

CAUTION!

Warning of feed chemical spraying

around

Feed chemical can spray out of the

hydraulic components if they are

manipulated or opened due to pressure

in the liquid end and adjacent parts of

the system.

– Disconnect the pump from the

mains power supply and ensure

that it cannot be switched on again

by unauthorised persons.

–

Depressurise the system before

commencing any work on

hydraulic parts.

CAUTION!

Danger from rupturing hydraulic com‐

ponents

Peak loads during the dosing stroke

can cause the maximum permissible

operating pressure of the system and

pump to be exceeded.

– The discharge lines are to be

properly designed.

Installation, hydraulic

16

Page 17

CAUTION!

Danger of personnel injury and material

damage

The use of untested third party parts

can result in personnel injuries and

material damage.

– Only fit parts to metering pumps,

which have been tested and rec‐

ommended by ProMinent.

7.1 Installing hose lines

7.1.1

Installation of the suction and

discharge line

Safety notes

CAUTION!

Warning of feed chemical spraying

around

If the pipes are not installed correctly,

they can come lose or burst.

– Route all hose lines so they are

free from mechanical stresses and

kinks.

–

Only use original hoses with the

specified hose dimensions and

wall thicknesses.

– Only use clamp rings and hose

nozzles that are intended for the

hose diameter in question to

ensure the long service life of the

connections.

CAUTION!

Danger resulting from rupturing

hydraulic components

Hydraulic components can rupture if

the maximum permissible operating

pressure is exceeded.

– Always adhere to the maximum

permissible operating pressure of

all hydraulic components - please

refer to the product-specific oper‐

ating instructions and system doc‐

umentation.

–

Never allow the metering pump to

run against a closed shut-off

device.

– Install a relief valve.

CAUTION!

Hazardous feed chemicals can escape

Hazardous or extremely aggressive

feed chemicals can leak out when

using conventional bleeding procedures

with metering pumps.

– Install a bleed line with return into

the storage tank.

Installation, hydraulic

17

Page 18

CAUTION!

Hazardous feed chemicals can escape

Hazardous or extremely aggressive

feed chemicals can leak out in the

event that the metering pump is

removed from the installation.

– Install a shut-off valve on the

metering pump's pressure and dis‐

charge sides.

CAUTION!

Uncontrolled flow of feed chemical

Feed chemicals can leak through a

stopped metering pump if there is back

pressure.

– Use an injection valve or a

vacuum breaker.

CAUTION!

Uncontrolled flow of feed chemical

Feed chemicals can leak through the

metering pump in an uncontrolled

manner in the event of excessive pri‐

ming pressure.

– Do not exceed the maximum per‐

missible priming pressure for the

metering pump.

Align the pipes so that the metering

pump and the liquid end can be

removed from the side if necessary.

Installation, hydraulic

18

Page 19

Installing hose lines

1. Cut off the ends of the hoses at right

angles.

2. Pull the union nut (20) and clamp ring

(21) over the hose (24) - see figure

Ä ‘Installing hose lines’ on page 18

.

3. Push the hose end (24) up to the stop

over the nozzle (4) and widen, if neces‐

sary.

Ensure that the O-ring and the

flat seal (23) is sitting properly.

Never re-use used PTFE seals.

An installation sealed in this way

is not watertight.

This type of seal is permanently

distorted when subjected to

pressure.

4. Place the hose (24) with the nozzle (22)

onto the valve.

5. Clamp the hose connector: Tighten the

union nut (20) while simultaneously

pressing on the hose (24).

6. Re-tighten the hose connector: Pull on

the hose (24) briefly, which is fastened

to the dosing head and then tighten the

union nut (20) once more.

P_ALP_0009_SW

A

20

21

22

23

24

Fig. 4

A Pressure connector

20 Union nut

21 Clamp ring

22 Nozzle

23 O-ring or flat seal

24 Hose

Installation, hydraulic

19

Page 20

7.1.2 Installation of metering

pumps with bleed valve

Safety notes

CAUTION!

– All the installation and safety notes

for metering pumps without bleed

valves also apply.

Installation of the return line

A return line is additionally connected to the

suction and discharge line.

1. Fasten the tube line to the return hose

nozzle or to the liquid end bleed valve.

PVC hose, soft, 6x4 mm is recom‐

mended.

2. Feed the free end of the return line back

to the storage tank.

3. Shorten the return line so that it does

not dip into the feed chemical in the

storage tank.

7.1.3 Basic installation notes

Safety notes

CAUTION!

Danger from rupturing hydraulic com‐

ponents

Hydraulic components can rupture if

the maximum permissible operating

pressure is exceeded.

– Never allow the metering pump to

run against a closed shut-off

device.

–

With metering pumps without inte‐

gral relief valve Install a relief

valve in the discharge line.

CAUTION!

Hazardous feed chemicals can escape

With hazardous feed chemicals Haz‐

ardous feed chemicals can leak out

when using conventional bleeding pro‐

cedures with metering pumps.

– Install a bleed line with return into

the storage tank.

Shorten the return line so that it cannot

dip into the feed chemical in the storage

tank.

Installation, hydraulic

20

Page 21

P_MAZ_0001_SW

2

1

Fig. 5: Standard installation

1 Main line

2 Storage tank

Installation, hydraulic

21

Page 22

Legend for hydraulic diagram

Symbol Explanation Symbol Explanation

Metering pump Foot valve with mesh

Injection valve Level switch

Multifunctional valve Manometer

Installation, hydraulic

22

Page 23

8 Electrical installation

WARNING!

Danger of an electric shock

Only trained and authorised personnel

may install the pump.

WARNING!

Danger of electric shock

This pump is supplied with a protective

earth conductor and a plug with a pro‐

tective contact.

– Ensure that it is only connected to

a socket with a correctly con‐

nected protective contact to

reduce the risk of electric shock.

WARNING!

Danger of electric shock

In the event of an electrical accident,

quickly disconnect the pump from the

mains power supply.

– Install an emergency cut-off switch

in the pump power supply line or

–

Integrate the pump into the emer‐

gency cut-off guidelines for the

system and inform personnel of

electrical isolating options.

WARNING!

Danger of electric shock

Mains voltage may be present inside

the pump housing.

– If the pump housing has been

damaged, disconnect it from the

mains immediately. Only return the

pump to service after it has been

repaired by authorised personnel.

CAUTION!

If the pump is integrated into a system:

Design the system so that potential

hazardous situations are avoided by

pumps starting up automatically subse‐

quent to unintended power interrup‐

tions.

CAUTION!

There should be a normal possibility of

disconnecting the pump from the mains

power supply to switch it off. Install an

On/Off switch as an option.

Connect the pump to the mains/power

supply using the mains cable.

Electrical installation

23

Page 24

9 Start up

WARNING!

Dangerous reactions are possible due

to contact of feed chemical with water

The feed chemical can mix and react in

the liquid end with water remaining

after testing in the factory.

– Read the safety data sheet on the

feed chemical.

–

Blast the liquid end with com‐

pressed air.

– Flush the liquid end with a suitable

medium through the suction con‐

nector.

WARNING!

Risk of fingers being crushed

– Only adjust the stroke length when

the pump is switched off.

–

Only operate the metering pump

with the cover (1) closed and the

safety screw tightly screwed in.

CAUTION!

Danger with dangerous feed chemicals

Contact with the feed chemical is pos‐

sible provided the following handling

instructions are adhered to.

– If the feed chemical is dangerous,

take appropriate safety precau‐

tions when carrying out the fol‐

lowing handling instructions.

–

Adhere to the feed chemical safety

data sheet.

CAUTION!

Warning of feed chemical spraying

around

An unsuitable feed chemical can

damage the parts of the pump that

come into contact with the chemical.

– Take into account the resistance

of the materials that come into

contact with the medium when

selecting the feed chemical - refer

to the ProMinent®

Resistance List

in the Product Catalogue or at

www.prominent.com.de/

downloads

.

Start up

24

Page 25

–

Reliable metering cannot be guar‐

anteed after the metering pump

has been idle for some time, as

the feed chemical can crystallise in

the valves and on the diaphragm.

Regularly check the valves and

diaphragm.

–

The metering pump should prime

at 100% stroke length, as the pri‐

ming lift depends on the stroke

volume when the liquid end is

empty. If the metering pump has to

prime at a smaller stroke length

and is not priming, reduce the pri‐

ming lift (i.e. briefly lift up the

storage tank with the feed chem‐

ical).

Draining the liquid end

With feed chemicals that should not come into

contact with water.

1. Turn the pump so that the pressure con‐

nector is facing downwards.

2. Allow water to flow out of the liquid end.

3. Flush the suction connector from above

with a suitable medium or blast with

compressed air.

Starting up the metering pump

1.

Fill the liquid end -

Ä ‘Filling the liquid

end’ on page 26

.

2. Check the pump connectors and con‐

nections for leak-tightness.

3. Check the suction valve and discharge

valve for leak-tightness and tighten if

necessary.

4. Check the liquid end for leak-tightness

and tighten the screws on the dosing

head if necessary - see below for

starting torque.

5. Only with bleed valve: Check whether

the bleed valve is closed.

Start up

25

Page 26

Filling the liquid end

With liquid ends without bleed valve:

1. Connect the suction line to the liquid

end but not yet to the discharge line.

2. If fitted: Close the shut-off valve on the

discharge side.

3. Connect a short, transparent section of

hose to the discharge valve.

4. Remove the cover (1) and check

whether the stroke length is set to

100%.

5. If not, set the stroke length to 100% refer to "Adjusting stroke length".

6. Switch on the metering pump and allow

to work at maximum stroke length and

stroke rate until some feed chemical

becomes visible in the short section of

hose.

ð

The liquid end has been filled com‐

pletely without bubbles.

7. Switch off the metering pump.

8. Connect the discharge line to the liquid

end.

Continue as described under "Concluding start

up".

With liquid ends with bleed valve:

1. Connect the suction and discharge line

to the liquid end.

2. Connect the return line.

3. Open the bleed valve by turning the

star-shaped handle in a counter-clock‐

wise direction.

ð

You can now use the return line to

bleed the pump.

4. Remove the cover (1) and check

whether the stroke length is set to

100%.

5. If not, set the stroke length to 100% refer to "Adjusting stroke length".

6. Switch on the metering pump and allow

to work at maximum stroke length and

stroke rate until some feed chemical

becomes visible in the return or dis‐

charge line.

ð

The liquid end has been filled com‐

pletely without bubbles.

7. Switch off the metering pump.

8. Close the bleed valve.

Continue as described under "Concluding start

up".

Concluding start up.

1. Start up the relief valve in the system in

line with its operating instructions.

2. Start up the system.

3. After 24 hours of operation: Tighten the

screws on the dosing head - see below

for tightening torque.

Start up

26

Page 27

Tightening torque

Data Value Unit

Tightening torque for screws: 4.5 ... 5.0 Nm

Adjusting the stroke length

1. Remove the cover (1).

2. Replace the latched slide (9) onto the

eccentric disc.

3. Set the eccentric disc (10) to 100 %.

4. Lock the latched slide in place.

5. Replace the cover (1) and secure with

the safety screw.

A

BB

9

10

1

0

0

8

0

6

0

4

0

2

0

3

0

5

0

7

0

9

0

P_ALP_0008_SW

Fig. 6

Start up

27

Page 28

10 Maintenance

WARNING!

It is mandatory that you read the safety

information and specifications in the

"Storage, Transport and Unpacking"

chapter prior to shipping the pump.

CAUTION!

Warning of feed chemical spraying

around

Feed chemical can spray out of the

hydraulic components if they are

manipulated or opened due to pressure

in the liquid end and adjacent parts of

the system.

– Disconnect the pump from the

mains power supply and ensure

that it cannot be switched on again

by unauthorised persons.

–

Depressurise the system before

commencing any work on

hydraulic parts.

Maintenance

28

Page 29

Standard liquid ends:

Interval Maintenance work Personnel

Quarterly*

n Check the metering diaphragm for damage** - refer to

"Repair".

n Check that the hydraulic lines are fixed firmly to the

liquid end.

n Check that the suction valve and discharge valve are

fitted tightly.

n Check the tightness of the entire liquid end - particularly

around the leakage hole - refer to

Ä ‘Standard liquid

ends:’ on page 29

!

n Check that the flow is correct: Allow the pump to prime

briefly - turn the multifunctional switch briefly to "Test"

n Check that the electrical connections are intact.

n Check the integrity of the housing.

n Check that the dosing head screws are tight.

Technical personnel

* Under normal loading (approx. 30 % of continuous operation)

Under heavy loading (e.g. continuous operation): Shorter intervals.

** Check the diaphragm frequently with feed chemicals that put particular pressure on the dia‐

phragm, e.g. those containing abrasive additives.

P_ALP_0011_SW

Fig. 7: Leakage hole

Maintenance

29

Page 30

Liquid ends with bleed valve:

Interval Maintenance work Personnel

Quarterly* In addition:

n Check that the bypass line is fixed firmly to the liquid

end

n Check that the bleed valve is tight.

n Check the discharge and bypass line for kinks

n Check that the bleed valve is operating correctly.

Technical personnel

* Under normal loading (approx. 30 % of continuous operation)

Under heavy loading (e.g. continuous operation): Shorter intervals.

Tightening torque

Data Value Unit

Tightening torque for screws: 4.5 ... 5.0 Nm

Maintenance

30

Page 31

11 Repairs

Safety notes

WARNING!

Danger of an electric shock

Unauthorised repairs inside the pump

can result in an electric shock.

For this reason repairs inside the pump

should only be carried out by a ProMi‐

nent branch office or representative, in

particular the following:

– Replacement of damaged mains

connection lines

–

Replacement of fuses

WARNING!

It is mandatory that you read the safety

information and specifications in the

"Storage, Transport and Unpacking"

chapter prior to shipping the pump.

WARNING!

Contact with the feed chemical

Parts that come into contact with the

feed chemical are exposed and

touched during repair work.

– Protect yourself against the feed

chemical in case it is hazardous.

Read the safety data sheet on the

feed chemical.

CAUTION!

Warning of feed chemical spraying

around

Feed chemical can spray out of the

hydraulic components if they are

manipulated or opened due to pressure

in the liquid end and adjacent parts of

the system.

– Disconnect the pump from the

mains power supply and ensure

that it cannot be switched on again

by unauthorised persons.

–

Depressurise the system before

commencing any work on

hydraulic parts.

Repairs that may be carried out by qualified

technical personnel, in accordance with the

operating instructions:

n Cleaning valves

n Replacing the diaphragm

All other repairs: Contact the responsible ProM‐

inent branch!

11.1

Cleaning valves

Personnel:

n

Technical personnel

Warning of faulty operation

Refer to the exploded views on the CD

when working on the unit.

Repairs

31

Page 32

11.2 Replacing the diaphragm

n If necessary take protective measures.

n Adhere to the safety data sheet for the

feed chemical.

n Ensure that the system is at atmospheric

pressure.

1. Disconnect the pump from the mains

power supply.

2. Empty the liquid end (turn the liquid end

upside down and allow the feed chem‐

ical to run out; flush out with a suitable

medium; flush the liquid end thoroughly

when using hazardous feed chemicals!)

P_ALP_0012_SW

A

BB

9

10

1

0

0

8

0

6

0

4

0

2

0

3

0

5

0

7

0

9

0

Fig. 8

3. Set the eccentric disc (10) to "0".

The latched slide (9) cannot lock

in this position.

ð

The drive axle is then difficult to

turn.

4. Switch off the pump.

5. Unscrew the hydraulic connectors on

the discharge and suction side.

6. With PP types with bleed valve: Firstly

remove the bleed valve (grip), then lift

off the cover of the liquid end with a

screw driver.

7. Remove the screws (6a).

8. Fully remove the dosing head (6) from

the motor mount (2).

5a

6a

6

P_ALP_0013_SW

Fig. 9

Repairs

32

Page 33

Pump types 1001, 1002, 1004, 1008, 0707,

0417: (Diaphragm WITHOUT holes, threaded

rod without hexagonal nut)

14

16

15

P_ALP_0014_SW

Fig. 10

1. Loosen the diaphragm (15) by turning to

the left - use pliers if necessary.

2. If the threaded rod (16) has come loose

together with the diaphragm, unscrew

the diaphragm from the threaded rod

(turning to the left) - using pliers if nec‐

essary.

3. Screw the threaded rod into the con‐

necting rod thread and use a flat wrench

(SW9) to tighten securely at the width

across flats.

4. Position the backplate (14) on the pump

housing.

5. Screw the diaphragm onto the threaded

rod and tighten manually. Ensure that

the backplate no longer moves from

side to side, although it should still be

able to turn slightly.

6. Place the dosing head (2) with the

screws (1) onto the diaphragm (3) and

the backplate (4) - ensure that the suc‐

tion connector points downwards in the

pump's subsequent fitting position.

7. Gently tighten the screws (6a) and then

tighten cross-wise.

Repairs

33

Page 34

Pump type 0230: (Diaphragm WITH holes,

threaded rod with hexagonal nut)

P_ALP_0015_SW

Fig. 11

1. Use a flat wrench (SW 8) to loosen the

hexagonal nut (arrow) in front of the

connecting rod by about one turn.

2. Loosen the diaphragm (15) with the

backplate (14) and the threaded rod (16)

from the motor mount (2) by turning it to

the left.

14

16

15

P_ALP_0014_SW

Fig. 12

3. Unscrew the threaded rod (16) from the

diaphragm (15) (possibly holding the

threaded rod with pliers and loosening

the diaphragm by turning it to the left).

4. Insert the threaded rod (16) into a new

diaphragm and, using pliers, screw it in

until it is lying tightly against the dia‐

phragm.

Repairs

34

Page 35

CAUTION!

There should be no gap visible

between the diaphragm and the

contact surface of the threaded

rod.

5. Screw the hexagonal nut (17) onto the

threaded rod (16) until it will go no fur‐

ther.

6. Insert the diaphragm with the threaded

rod into the backplate (14) and screw

the entire unit onto the connecting rod

(18) until it will go no further. (The stroke

length should still be 0 here.)

7. Turn the diaphragm back until the 4

holes in the diaphragm and backplate

are precisely aligned.

8. Ensure that the suction connector is

pointing downwards and then using the

screws (6a) to place it onto the dia‐

phragm and the backplate - the suction

connector should be pointing down‐

wards in the pump's subsequent fitting

position.

9. Gently tighten the screws (6a) and then

tighten cross-wise.

Concluding the work

1. With PP types with bleed valve: Allow

the cover of the liquid end to rest in the

dosing head, then press the grip on the

bleed valve into the dosing head.

2. Turn the hexagonal nut (17) against the

connecting rod (18) and gently tighten.

3. Set the stroke length required and lock

the latched slide (9) into place.

4. Replace the cover (1) and secure with

the safety screw.

5. Bleed the pump - refer to the "Start up"

chapter.

CAUTION!

Leakage possible

– Check the tightening torque of the

screws after 24 hours of operation!

–

With PP and PV dosing heads,

check the tightening torque again

after three months!

Repairs

35

Page 36

Tightening torque

Data Value Unit

Tightening torque for screws: 4.5 ... 5.0 Nm

11.3 Replacing the complete

dosing head

–

The bleed valve is open on

delivery.

–

Re-tighten the bleed valve (5) after

priming and bleeding.

–

Check that the suction and dis‐

charge valves are tightened.

Repairs

36

Page 37

12 Troubleshooting

Safety notes

WARNING!

Warning of dangerous or unknown feed

chemical

Should a dangerous or unknown feed

chemical be used: It may escape from

the hydraulic components when

working on the pump.

– Take appropriate protective meas‐

ures before working on the pump

(e.g. safety glasses, safety

gloves, ...). Observe the safety

data sheet for the feed chemical.

–

Drain and flush the liquid end

before working on the pump.

CAUTION!

Warning of feed chemical spraying

around

Feed chemical can spray out of the

hydraulic components if they are

manipulated or opened due to pressure

in the liquid end and adjacent parts of

the system.

– Disconnect the pump from the

mains power supply and ensure

that it cannot be switched on again

by unauthorised persons.

–

Depressurise the system before

commencing any work on

hydraulic parts.

WARNING!

Risk of fingers being crushed

– Only adjust the stroke length when

the pump is switched off.

–

Only operate the metering pump

with the cover (1) closed and the

safety screw tightly screwed in.

Troubleshooting

37

Page 38

12.1 Faults and troubleshooting

Fault description Cause Remedy Personnel

Pump does not

prime in spite of

full stroke motion

and bleeding.

Minor crystalline

deposits on the ball

seat due to the valves

drying out

Take suction hose out of the

storage tank and thoroughly flush

out the liquid end

Technical

personnel

Major crystalline

deposits on the ball

seat due to the valves

drying out

Dismantle and clean the valves. Technical

personnel

Fluid is escaping

from the backplate.

The screws in the

dosing head are too

loose

Tighten the screws in the dosing

head crosswise - refer to "Repair"

for tightening torque.

Instructed

personnel

The diaphragm is dam‐

aged.

Replace the diaphragm - refer to

"Repair".

Technical

personnel

The pump auto‐

matically switches

off during

metering.

The circuit breaker has

switched off the over‐

heated motor as the

back pressure is too

high.

Disconnect the pump from the

mains power supply.

Check whether a shut-off device is

closed or there is a blockage on

the discharge side or reduce the

back pressure.

Re-connect the metering pump to

the mains voltage. The circuit

breaker switches the pump on

again once the motor has cooled

down.

Instructed

personnel

The circuit breaker has

switched off the motor

due to the motor over‐

heating, as the intake

or drain openings for

the motor cooling air

are blocked.

Disconnect the pump from the

mains power supply.

Examine and clean the intake and

drain opening for the motor

cooling air to the bottom of the

pump.

Re-connect the metering pump to

the mains voltage. The circuit

breaker switches the pump on

again once the motor has cooled

down.

Technical

personnel

Troubleshooting

38

Page 39

Fault description Cause Remedy Personnel

The pump is not

working despite

being connected to

the mains voltage.

The pending back pres‐

sure is greater than the

permissible operating

or starting pressure.

Check whether a shut-off device is

closed or there is a blockage on

the discharge side or reduce the

back pressure.

Instructed

personnel

12.2 All other faults

Please contact the responsible ProMinent

branch or representative!

Troubleshooting

39

Page 40

13 Decommissioning and disposal

13.1 Decommissioning

Decommissioning

WARNING!

Danger from chemical residue

There is normally chemical residue in

the liquid end and on the housing after

operation. This chemical residue could

be hazardous to people.

– It is mandatory that the safety

information in the "Storage, trans‐

port and unpacking" chapter are

read before shipping or transport.

–

Thoroughly clean the liquid end

and the housing of chemicals and

dirt. Adhere to the material safety

data sheet for the feed chemical.

WARNING!

Warning of hazardous feed chemical

Should a dangerous feed chemical be

used: it may escape from the hydraulic

components when working on the

pump, material failure or incorrect han‐

dling of the pump.

– Take appropriate protective meas‐

ures before working on the pump

(e.g. safety glasses, safety

gloves, ...). Adhere to the material

safety data sheet for the feed

chemical.

–

Drain and flush the liquid end

before working on the pump.

CAUTION!

Warning of feed chemical spraying

around

Feed chemical can spray out of the

hydraulic components if they are

manipulated or opened due to pressure

in the liquid end and adjacent parts of

the system.

– Disconnect the pump from the

mains power supply and ensure

that it cannot be switched on again

by unauthorised persons.

–

Depressurise the system before

commencing any work on

hydraulic parts.

Danger of damage to the device

Take into account the information in the

"Storage, transport and unpacking"

chapter if the system is decommis‐

sioned for a temporary period.

1. Disconnect the pump from the mains/

power supply.

2. De-pressurise the discharge line.

3. Drain the liquid end by turning the pump

upside down and allowing the feed

chemical to run out.

4. Flush the liquid end with a suitable

medium; flush the dosing head thor‐

oughly when using hazardous feed

chemicals!

Decommissioning and disposal

40

Page 41

13.2 Disposal

CAUTION!

Environmental hazard due to incorrect

disposal

There are components in the pump,

which can have a toxic effect on the

environment.

– Note the pertinent regulations cur‐

rently applicable in your country!

Sign indicating EU collection system

In accordance with the European Directive

2012/19/EU on waste electrical and electronic

equipment, this device features the symbol

showing a waste bin with a line through it. The

device must not be disposed of along with

domestic waste. To return the device, use the

return and collection systems available and

observe the local legal requirements.

Decommissioning and disposal

41

Page 42

14 Technical data

Performance data for alpha, version c

Type Minimum

pump capacity

at maximum

back pressure

Minimum

pump capacity

at medium

back pressure

Stroke

rate

Con‐

nector

size

out‐

side Æ

x

inside

Æ

Suction

lift*

Pri‐

ming

lift**

Max‐

imum

per‐

mis‐

sible

starting

pres‐

sure

Max.

permis‐

sible

priming

pres‐

sure on

the

suction

side

bar l/h bar l/h Stroke

s / min

mm m WS m WS bar bar

50 Hz design

1001 10 0.9 5.0 1.0 30 6x4 5.0 2.6 10 5.0

1002 10 1.8 5.0 2.1 58 6x4 5.0 3.6 10 5.0

1004 10 3.5 5.0 3.9 58 8x5 5.0 3.6 10 5.0

1008 10 7.7 5.0 8.6 128 8x5 5.0 3.6 10 5.0

0707 7 6.9 3.0 7.7 58 8x5 4.0 4.1 7 3.5

0417 4 17.0 2.0 18.3 128 8x5 4.0 4.1 4 2.0

0230 2 29.7 1.0 32.7 128 12x9 3.0 3.1 2 1.0

60 Hz design

1001 10 1.1 5.0 1.3 36 6x4 5.0 2.6 10 5.0

1002 10 2.2 5.0 2.6 69 6x4 5.0 3.6 10 5.0

1004 10 4.1 5.0 4.7 69 8x5 5.0 3.6 10 5.0

1008 10 8.9 5.0 10.4 154 8x5 5.0 3.6 7 5.0

0707 7 8.3 3.0 9.2 69 8x5 4.0 4.1 7 3.5

0417 4 20.6 2.0 21.9 154 8x5 4.0 4.1 2.5 2.0

0230 2 34.4 1.0 39.2 154 12x9 3.0 3.1 1.5 1.0

*) Suction lift with unfilled dosing head, valves wetted.

Technical data

42

Page 43

Pump capacity was calculated using water and a metering pump warmed to operating temperature.

With types 1001, 1002 and 1004, the pump capacity can fall to zero at 20% stroke length

and back pressure of > 4 bar.

Precision

Data Value Unit

Capacity range of the product range -10 ... +10 % *

Reproducibility ±2 % **

* - with max. stroke length and max. operating pressure for all material versions

** - with constant conditions, minimum back pressure of 1 bar, min. 40 % stroke length, water as

the feed chemical and over short time intervals (5 min)

Viscosity

The liquid ends are suitable for the following viscosity ranges:

Design Range Unit

Standard 0 ... 200 mPas

With valve springs 200 ... 500 mPas

Technical data

43

Page 44

Material specifications

Design Dosing head Suction/pressure

connector

Seals Valve balls

PPE Polypropylene Polypropylene EPDM Ceramic

PPB Polypropylene Polypropylene FPM-B Ceramic

NPE Clear acrylic PVC EPDM Ceramic

NPB Clear acrylic PVC FPM-B Ceramic

PVT PVDF PVDF PTFE Ceramic

Diaphragm with a PTFE coating.

FPM = fluorine rubber.

Electrical data

Tab. 1: El. connector "A", "B", "C", 230 VAC

(220 ... 240V)

50 Hz 60 Hz

Capacity 50 W 45 W

Power con‐

sumption

0.4 A 0.35 A

Tab. 2: Elec. connector "D" 115 VAC (108 ...

134V)

50 Hz 60 Hz

Capacity 60 W 50 W

Power con‐

sumption

0.9 A 1.1 A

Circuit breaker

The drive motor is fitted with a circuit breaker,

which automatically switches off the motor

when it overheats to more than 106 °C; the cir‐

cuit breaker switches the pump on again once

the motor has cooled down.

Technical data

44

Page 45

Pump temperature, compl.

Data Value Unit

Storage and transport temperature -20 ... +60 °C

Ambient temperature in operation (drive and control): -10 ... +45 °C

Liquid end temperature, long-term*

Data Value Unit

Liquid end temperature -10 ... +35 °C

* long term at max. operating pressure, dependent on the ambient temperature and the feed chem‐

ical temperature

Degree of protection

Protection against accidental contact and

humidity:

IP 23 according to DIN EN 0470 Part 1

with horizontal pump foot with an upright pump

Sound pressure level

Sound pressure level LpA < 70 dB according to

EN ISO 20361

at maximum stroke length, maximum stroke

rate, maximum back pressure (water)

Shipping weight

Shipping weight 3 kg

Technical data

45

Page 46

15 Design Documents

Design documents, such as dimen‐

sional drawings, ordering data

(exploded drawings), performance dia‐

grams ... are available in the relevant

online version of these operating

instructions on our website.

When searching on the website, please

use simply the 6-digit order number for

these operating instructions - this can

be found at the bottom left corner of the

cover page. You can find an older ver‐

sion – if the website provides the print

number – using the print number (say

"BA G 059 04/15 EN" – which can be

found at the bottom right of the cover

page).

Design Documents

46

Page 47

16 Dimensional drawings

Dimensional drawing of alpha ALPc

P_ALP_0006_SW

184

Ø 50

12

142.5

Ø 70

4252 46 44

8.8

6.8

8.8

7.2

8.8

100

77.6

6.8

177.6

100

35.9

41.7

21.9

78.1

164.2

Fig. 13: Dimension drawing of ALPc - dimensions in mm

Dimensional drawings

47

Page 48

17 Further order information

Spare parts kits for alpha c

Type PPE PPB NPE NPB PVT

1001, 1002,

1004, 1008

1001647 1001655 1001716 1001724 1023110

0707, 0417 1001649 1001657 1001718 1001726 1023112

0230 1001650 1001658 1001719 1001727 1023113

Replacement diaphragms for alpha c

Type Part no.

1001, 1002, 1004, 1008 1000247

0707, 0417 1000249

0230 1000250

Further sources of information

Further information on spare parts, accessories

and options can be found in:

n the identity code

n the ProMinent® Product Catalogue

n at www.prominent.com

Further order information

48

Page 49

18 Declaration of Conformity for Machinery

In accordance with DIRECTIVE 2006/42/EC OF THE EUROPEAN PARLIAMENT AND OF THE

COUNCIL, Appendix I, BASIC HEALTH AND SAFETY REQUIREMENTS, section 1.7.4.2. C.

We,

n ProMinent GmbH

n Im Schuhmachergewann 5 - 11

n DE - 69123 Heidelberg,

hereby declare that the product specified in the following, complies with the relevant basic health

and safety requirements of the EC Directive, on the basis of its functional concept and design and in

the version distributed by us.

Any modification to the product not approved by us will invalidate this declaration.

Tab. 3: Extract from the Declaration of Conformity

Designation of the product: Metering pump, alpha product range

Product type: ALPc ...

Serial number: see nameplate on the device

Relevant EC directives: Machinery Directive (2006/42/EC)

Compliance with the protection targets of the Low Voltage Direc‐

tive according to Appendix I, No. 1.5.1 of the Machinery Directive

(2006/42/EC)

EMC Directive (2014/30/EU)

Harmonised standards

applied, in particular:

EN ISO 12100:2010

EN 809:1998 + A1:2009 + AC:2010

EN 61010-1:2010

EN 61000-6-2:2005 + AC:2005

EN 61000-6-3:2007 + A1:2011 + AC:2012

Date: 20/04/2016

You can download the Declaration of Conformity at www.prominent.com.

Declaration of Conformity for Machinery

49

Page 50

50

Page 51

51

Page 52

986353, 3, en_GB

© 2013

ProMinent GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg

Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

Loading...

Loading...