Page 1

ADDENDUM: Aegis II Communication Driver Card

Industrial Communication Driver Card

“Com Module”

Aegis II

Communication Driver Card Part Number: 734593

This document contains general information regarding the implementation of the ProMinent Industrial

Communication Card, “Com Module” into the Aegis II Controllers.

Revision D Part Number 1079218

Page 1 of 30

Page 2

1. Description

2. Layman’s Glossary of terms

3. Multiple Protocols

4. Com Module Installation

5. Pyxis Sensor

6. The RTU Slave Connection

7. Gateway Settings

8. The Inputs and Outputs

9. Gateway Enclosure kits

10. Replacement Parts

1 Description

The ProMinent Industrial Communication Driver card (Com Module) provides the Aegis II with the ability to

interface with most industrial communication protocols thus providing the customer with live I/O values.

The Com Module includes:

o Two 4-20mA outputs, assigned as I/O points I and J

o One Modbus RTU (RS-485 serial) Master port for a Modbus Pyxis Fluorometer which will be assigned

point M. Any previous use of M will be removed. See section 5.

o Modbus RTU (RS-485 serial) Slave communication ports for use with a Modbus RTU network or any

Modbus RTU gateway.

o Can be ordered separately or with a power supply and terminal strip mounted in an enclosure. See

section 9.

Optionally, a dual 4-20mA input driver card can be added to this module. Currently, this is the only driver that can

be added. These inputs are assigned letters K and L in the controller program. If K and L were previously in use,

those programs are removed.

The Modbus connection is Read only. This connection will not allow any user to edit or modify any part of the

program. Only live I/O data is available. See a complete list of the controller I/O in section 8.

The Slave port can be directly connected to any Modbus RTU Master. RTU Masters includes various SCADA

systems as well as Gateways which convert the data to other Protocols.

Once the Com Module Slave port is connected to a Master, the second Com Module Slave port can be used to

‘Daisy Chain’ other Modbus RTU Slave devices to the same Master. See Daisy Chain example on page 10.

Note: A Master port can monitor multiple Slave devices. A Slave device must obey one and only one Master.

ProMinent has optional Gateway devices to convert this serial connection to Modbus TCP-IP (Ethernet), BACnet

MS/TP (RS 485-Serial) and BACnet IP (Ethernet). Each gateway can be chosen with or without UL certification.

Page 2 of 30

Page 3

2 Layman’s Glossary of terms

PFC

Part #

Description

Link to Gateway manual

1092940

Modbus TCP Slave / Modbus Master – Converter UL Certified (RTA brand)

http://www.rtaautomation.com/userguides/BFR3000-NNA1_Userguide.pdf

1092941

Modbus TCP Slave / Modbus Master – Converter (ADFweb brand)

http://www.adfweb.com/download/filefold/modbus_TCP_Server_RTU_Master_MN67507_ENG.pdf

1092942

BACnet IP Slave / Modbus Master – Converter UL Certified (RTA brand)

http://www.rtaautomation.com/userguides/460MMBS-NNA1_Userguide.pdf

1092943

BACnet IP Slave / Modbus Master – Converter (ADFweb brand)

http://www.adfweb.com/download/filefold/mn67671_eng.pdf

1092964

BACnet MSTP Slave / Modbus Master – Converter UL Certified (RTA brand)

http://www.rtaautomation.com/userguides/460MMBMS-NNA4_Userguide.pdf

1092965

BACnet MSTP Slave / Modbus Master – Converter (ADFweb brand)

http://www.adfweb.com/download/filefold/mn67671_eng.pdf

TCP and IP indicate Ethernet type connections. MSTP and RTU indicates a serial connection.

In the chart below, the first gateway has the description “Modbus TCP Slave/Modbus Master”. This describes the

gateway as being a slave to the customers Modbus TCP(Ethernet) and passing through to our driver via the serial

port as a Master to our driver card slave connection. Therefore, in each of these descriptions, ‘Modbus Master’

refers to the serial connection between the Gateway and our communication driver.

3 Multiple Protocols

The following chart list Gateways available through ProMinent. A link is provided in the event you need a Gateway

manual.

Other Gateways are available from electronics vendors. These gateway part numbers do not include complete

kits. See section 9.

Any gateway that can convert from the user’s protocol to Modbus RTU can be used with the Com Module.

RTA gateways are UL certified. ADFweb brands are not.

An example of Gateways from RTA is shown below.

Allen Bradley PCL ASCII BACnet/IP Client

BACnet/IP Server BACnet MS/TP Initiator BACnet MS/TP Responder

DeviceNet Master DeviceNet Slave DF1 Devices

Ethernet/IP Adapter Ethernet/IP Scanner Modbus RTU Slave

Modbus TCP/IP Client Modbus TCP/IP Server Profibus Master

Profinet Controller Ethernet TCP/IP USB

Page 3 of 30

Page 4

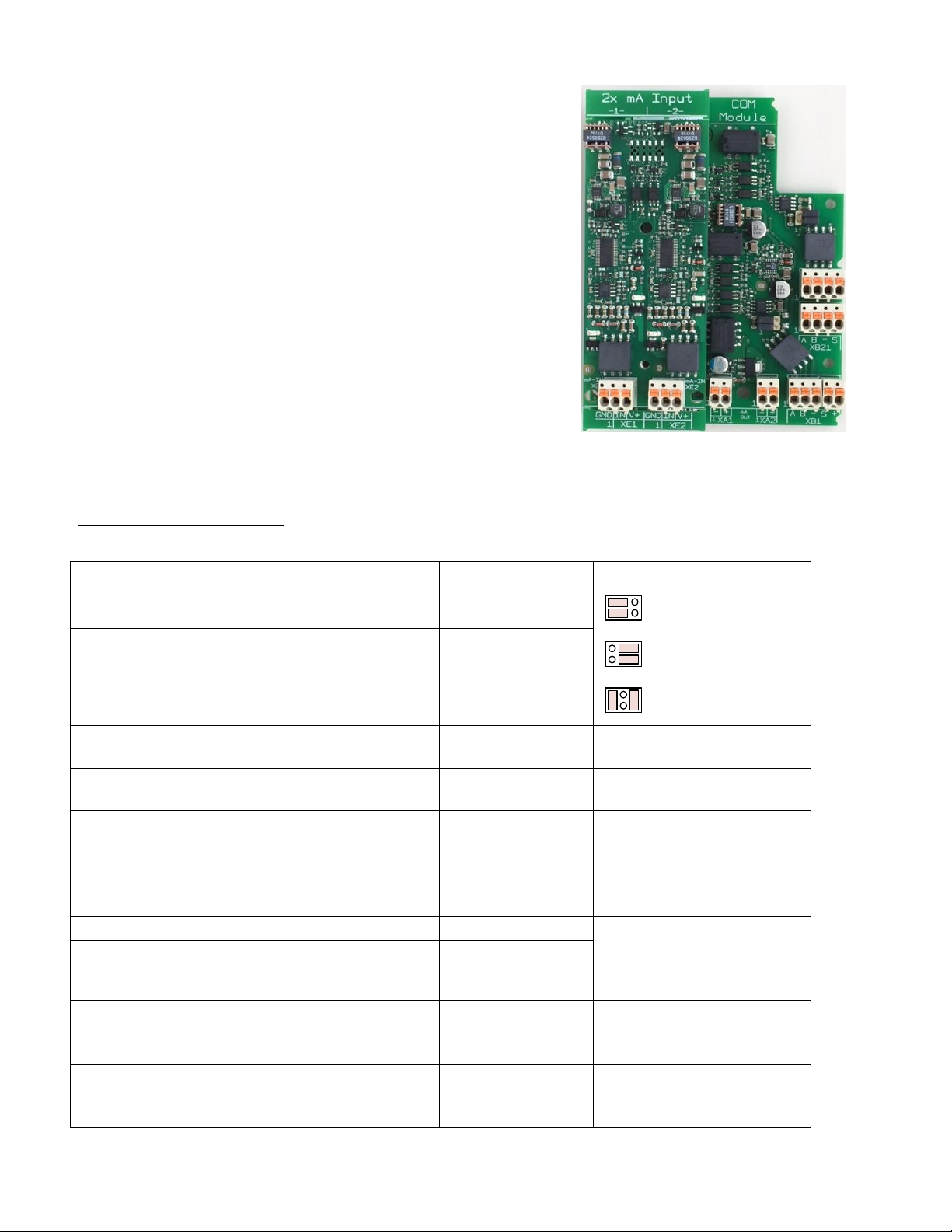

Dual 4-20mA Input

Driver

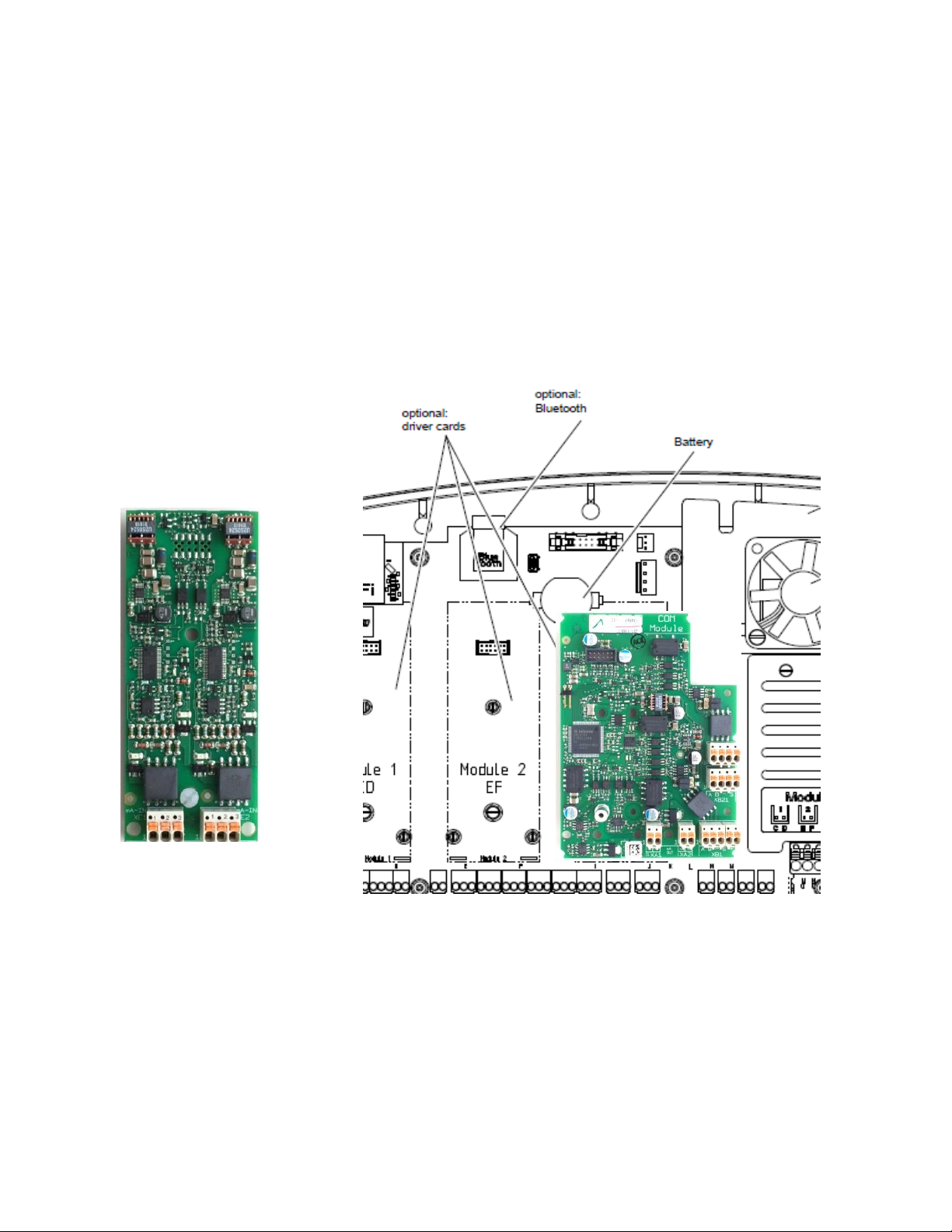

4 Com Module Installation

Com Module installed in expansion slot 3

From the factory, the Com Module will be installed in expansion slot 3. This card will not operate in expansion

slots 1 or 2. A plastic screw secures the card in place. The Com module may or may not have an optional driver

card attached. This optional driver is supplied with a plastic support screw as well. See optional driver card below.

Never install nor remove any driver or Com Module with power applied to the controller.

Instructions for installation, operation and maintenance of the 4-20mA input driver are in the controller operation

manuals.

The dual 4-20mA input driver can be installed in any expansion slot, Module 1, Module 2, Module 3 or in the feed

through slot on the communication driver card. See next page.

Page 4 of 30

Page 5

Driver card installed on Com module

Component

Function

Description

Connection

XT1

Modbus RTU Master to ext. Slave

(For Pyxis)

resistor jumpers

Def: Failsafe

1 3 5

2 4 6

1 3 5

2 4 6

1 3 5

2 4 6

Failsafe termination

Standard termination

or SW control

No termination

(park position)

XT2

Modbus RTU Slave to ext. Master

For Gateways and direct connection

resistor jumpers

Default: Standard?

XA1

mA output Channel 1

Pin 1 = (-)

Pin 2 = (+)

XA2

mA output Channel 2

Pin 1 = (-)

Pin 2 = (+)

XB11

Modbus RTU Master to ext. Slave

Pin 1 = (A)

Pin 2 = (B)

Pin 3 = (GND)

XB12

Modbus RTU Master to ext. Slave

Pin 1 = (shield)

Pin 2 = (+24)

XB21

Modbus RTU Slave to ext. Master

Pin 1 = (A)

Pin 2 = (B)

Pin 3 = (GND)

Pin 4 = (shield)

XB22

Modbus RTU Slave to ext. Master

For Daisy chain

XE1

mA input Channel 1

(optional driver)

Pin 1 = (GND)

Pin 2 = (mA input)

Pin 3 = (+23)

XE2

mA input Channel 2

(optional driver)

Pin 1 = (GND)

Pin 2 = (mA input)

Pin 3 = (+23)

When a Com Module is added to expansion slot #3, the dual 4-20mA

outputs acquire the identification letters I and J. These are the letter

assignments for any card installed in this slot.

If the dual 4-20mA input driver is installed onto the Com Module, it is

represented by the letters K and L.

The Dual 4-20mA input driver card is the only card that can be added

to the Com Module.

The Wiring Terminal Table shows all connections to the Com Module

Wiring Terminal Table:

Page 5 of 30

Page 6

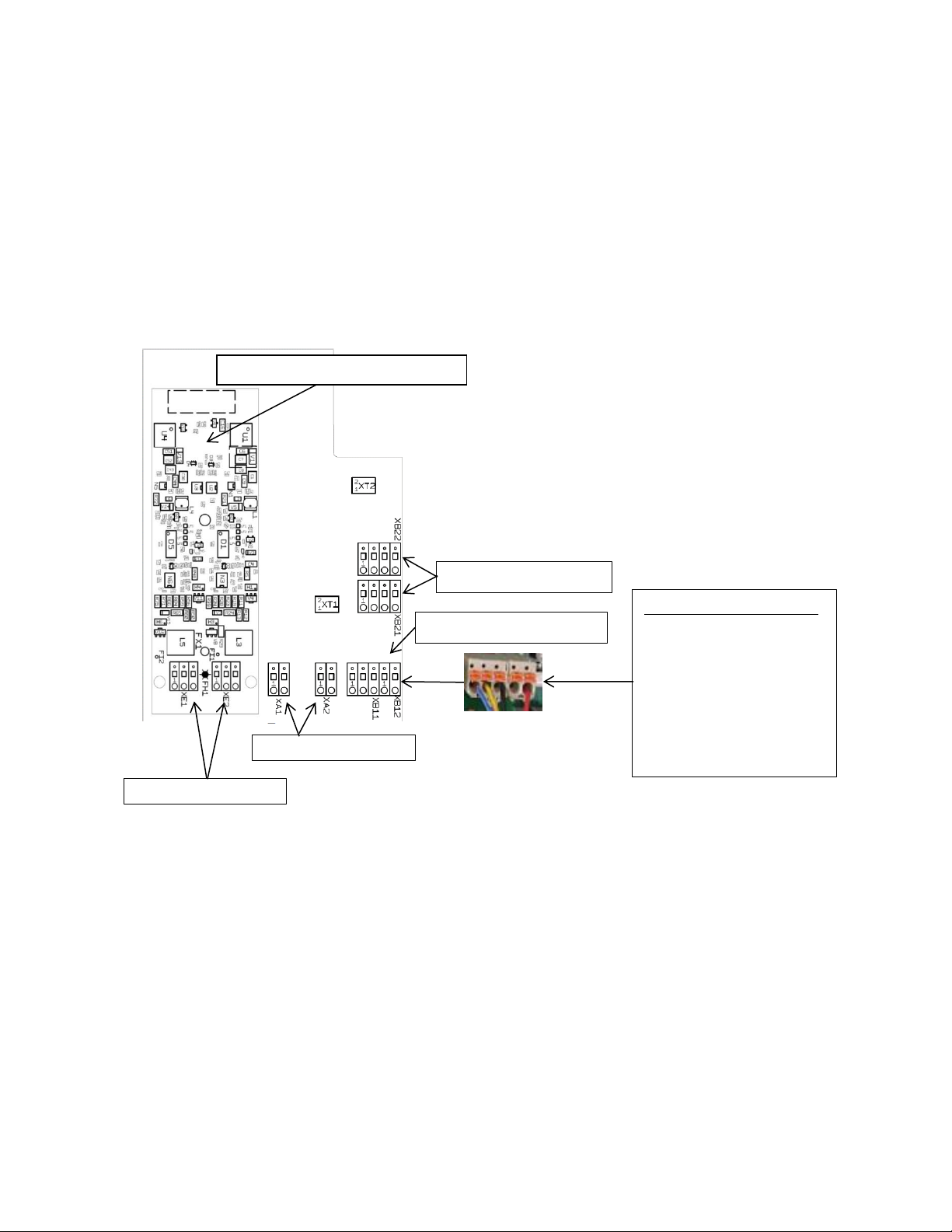

5 Pyxis Sensor

Optional plug in 4-20mA input Module

Com Module

Pyxis sensor connection:

- XB11:01 -> Blue

- XB11:02 -> Yellow

Modbus RTU RS-485 Slave

Pyxis connection to Modbus Master RTU

Modbus RTU RS-485 Master

The Com card was constructed to accept a Modbus RTU version Pyxis Fluorometer. Connect the sensor as shown

below. This is currently the only input to the Master Modbus RTU terminals.

The fluorometer on input M can be monitored, used for control, show diagnostics and be calibrated through the

keypad or via a network connection using the Ethernet port or WiFi.

Consult the Aegis II and Pyxis manuals for programming instructions.

The Modbus RTU slave connections allow other entities to monitor this controller. The users can see the I/O

values but cannot edit them.

6 The RTU Slave Connection

Connect up to 120 communication driver card slaves to one master. The master can be the plant Modbus RTU

network or any number of Gateways. Currently, ProMinent has six gateways in stock that provide conversion to 3

protocols; Modbus TCP (Ethernet), BACnet IP (Ethernet) and BACnet MSTP (Serial). These gateways are available

with or without UL approval. The RTA brands are UL approved. The ADFweb brands are not UL approved and are

therefore available at a lesser price. See also section 9 for complete enclosure kits.

- XB11:03 -> Black

- XB12:01 (Blank)

- XB12:02 -> Red

Page 6 of 30

Page 7

Gateway devices require a separate DC power supply. See instructions accompanying the Gateway.

Controller Modbus RTU Comm Module

Gateway Slave to

TCP Master

External Power

Max 24V

V DC: Min 12V

Max 5V

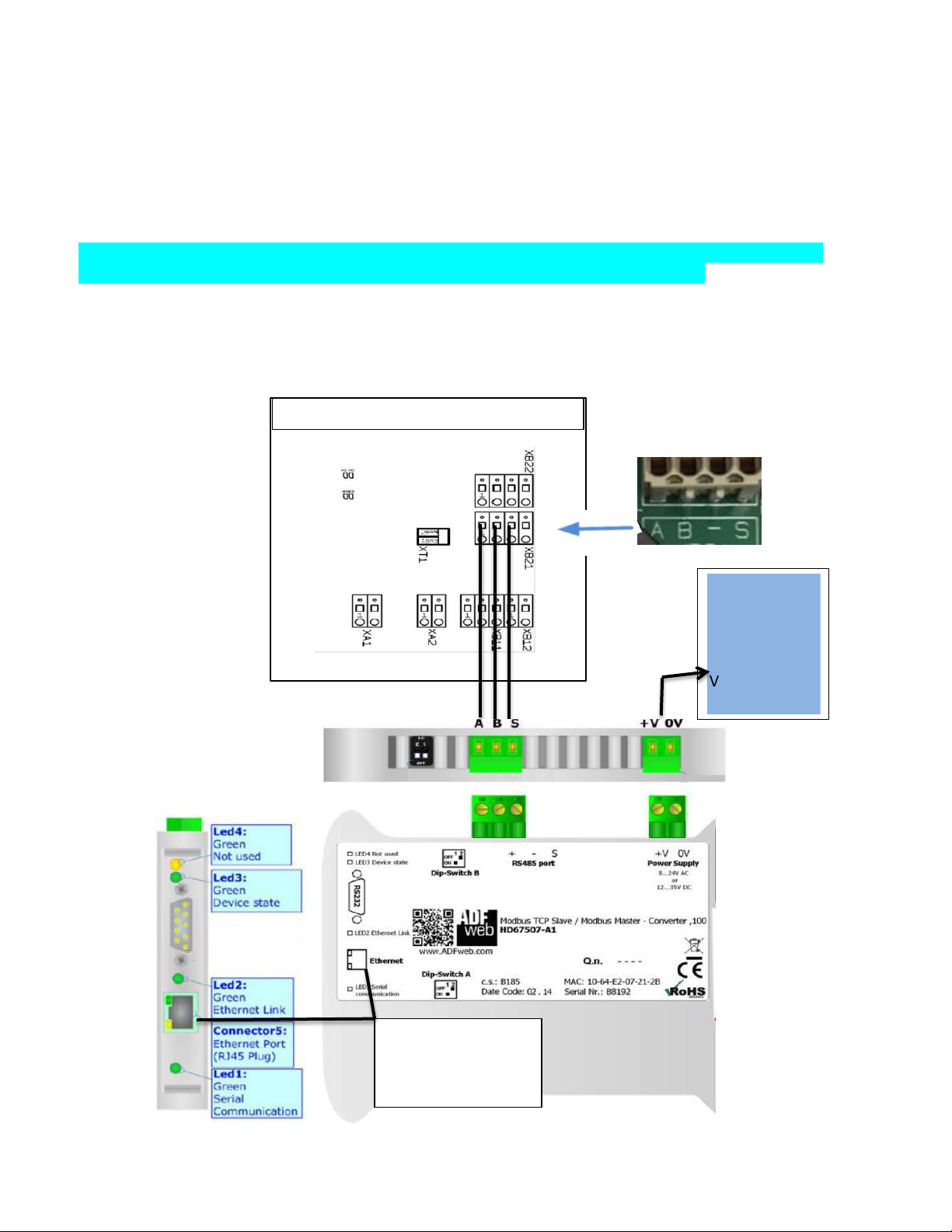

The next few illustrations depict ADFweb brand, non-UL approved gateways which convert the Com Module

Modbus RTU Slave to another Protocol. The connection to the Com card is via the Modbus Master serial port on

the Gateway. The Gateway Slave port connects to the plant network Master. This port can be serial or Ethernet as

you choose.

ADFweb Modbus TCP (Ethernet) Slave to Modbus Master. Not UL approved.

(Description explanation: ‘Modbus TCP Slave’ is the Gateway’s connection to the plant master via Ethernet.

‘Modbus Master’ describes the Gateway’s serial master to the communication card slave.)

Wiring the gateway terminal to Com card:

A+ to XB21 pin 1 (A), B - to pin 2 (B), Common (S) to pin 3 (Shown as a dash).

To load Configuration please refers to manufacture instruction manual MN67507_ENG section “UPDATE VIA

UDP:”

Gateway Part number:

1092941

Complete Kit part number:

1094286

See page 22 for kit

information.

Supply

V AC: Min 8V;

Customer Modbus-

Page 7 of 30

Page 8

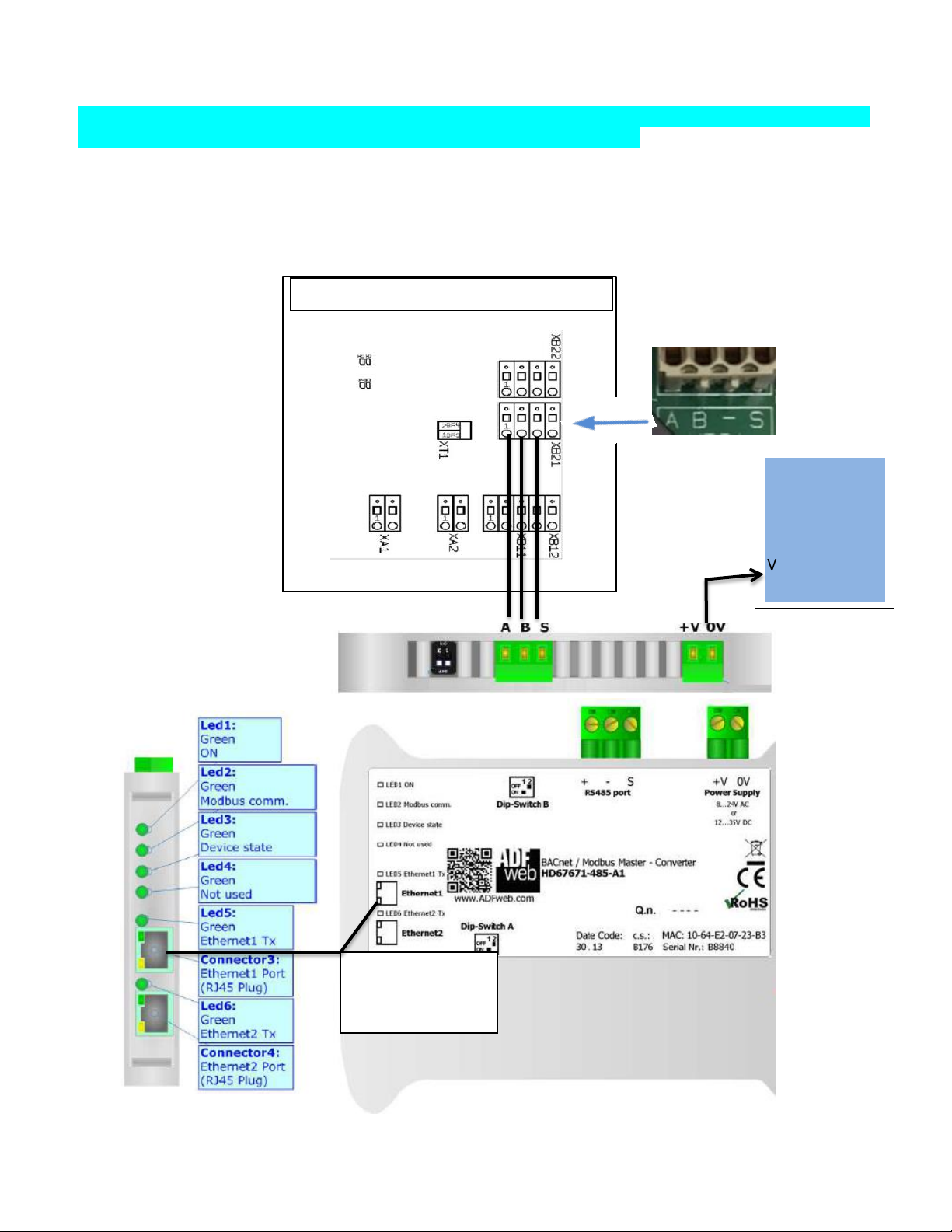

ADFweb BACnet IP (Ethernet) Slave to Modbus Master. Not UL approved.

Gateway Slave to

IP Master

External Power

Max 35V

Controller Modbus RTU Comm Module

(Description explanation: ‘BACnet IP Slave’ is the Gateway’s connection to the plant master via Ethernet. ‘Modbus

Master’ describes the Gateway’s serial master to the communication card slave.)

Gateway terminal to Com card: A+ to XB21 pin 1 (A), B - to pin 2 (B), Common (S) to pin 3 (Shown as a dash).

To load Configuration please refers to manufacture instruction manual MN67671_ENG section

“UPDATE DEVICE:”

Gateway Part number:

1092943

Complete kit part number:

1094287

See page 23 for kit

information.

Supply

V AC: Min 8V;

Max 24V

V DC: Min 12V

Customer BACnet

Page 8 of 30

Page 9

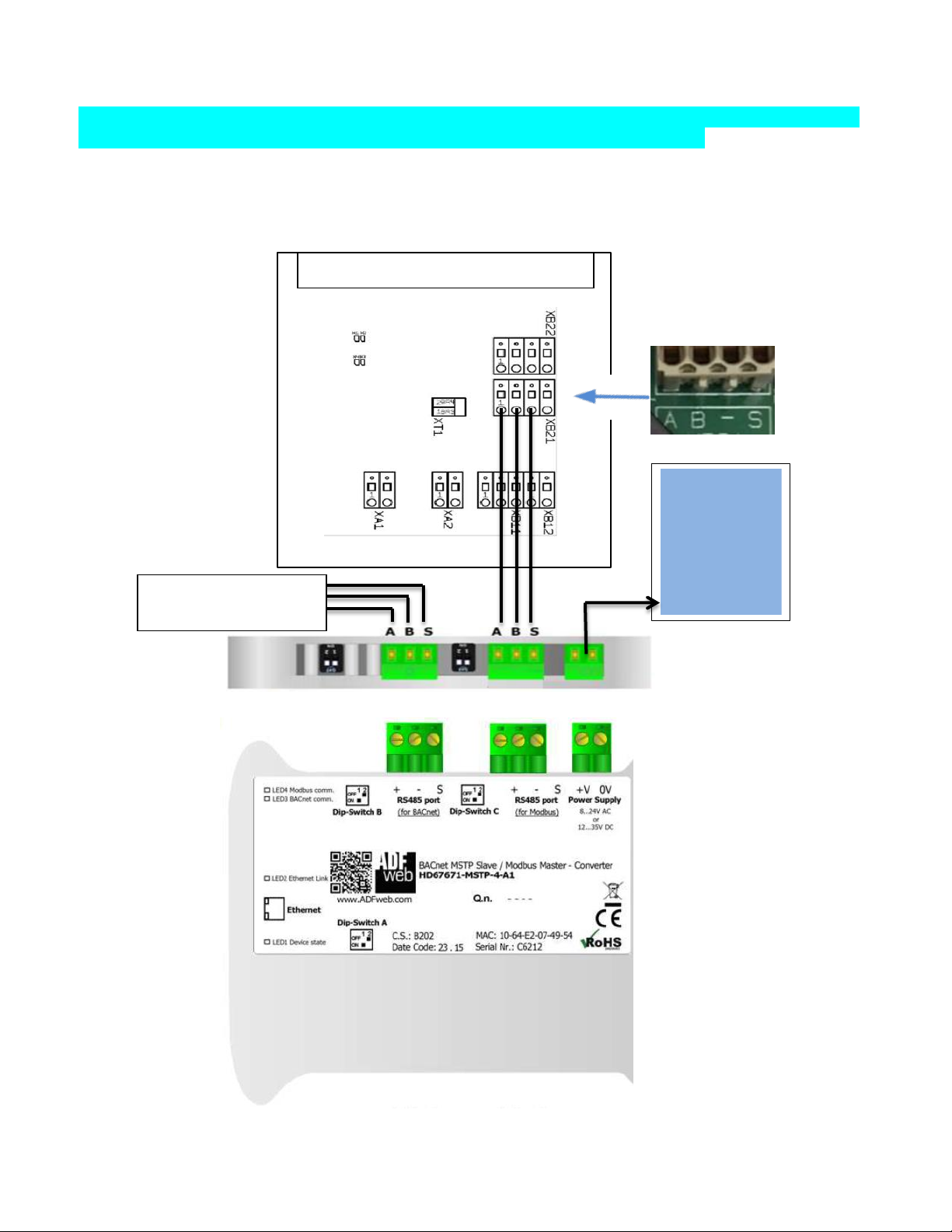

ADFweb BACnet MSTP (Serial) Slave to Modbus Master. Not UL approved.

External Power

Max 35V

To Customer BACnet

MSTP Master

Controller Modbus RTU Comm Module

(Description explanation: ‘BACnet MSTP Slave’ is the Gateway’s connection to the plant master via Serial wiring.

‘Modbus Master’ describes the Gateway’s serial master to the communication card slave.)

Gateway terminal to Com card: A+ to XB21 pin 1 (A), B - to pin 2 (B), Common (S) to pin 3 (Shown as a dash).

To load Configuration please refers to manufacture instruction manual MN67671_ENG section

“UPDATE DEVICE:”

Gateway Part number:

1092945

Complete Kit part number:

1094290

See page 21 for kit

information.

Supply

V AC: Min 8V;

Max 24V

V DC: Min 12V

Page 9 of 30

Page 10

Second controller with Comm

Controller Modbus RTU Comm Module

To Customer

Modbus-TCP

Master

Daisy Chain Example:

Page 10 of 30

Page 11

Controller Modbus RTU Comm Module

The RTA brand, UL approved models are shown here. Refer to manufacturer instructions for more detail.

External Power Supply

12-24VDC, 175 mA at

12VDC

To Customer

Modbus-TCP

Master

RTA Modbus TCP (Ethernet) Slave to Modbus Master. UL approved.

(Description explanation: ‘Modbus TCP Slave’ is the Gateway’s connection to the plant master via Ethernet.

‘Modbus Master’ describes the Gateway’s serial master to the communication card slave.)

Wiring the gateway terminal to Com card: +Tx to XB21 pin 1 (A), -Tx to pin 2 (B), Com to pin 3 (Shown as a dash).

To load a configuration, please refer to the manufacture’s instruction manual BFR3000NNA1_Userguide.

Gateway Part number:

1092940

Complete Kit part

Number: 1094288

See page 22 for kit

information.

Page 11 of 30

Page 12

Controller Modbus RTU Comm Module

RTA BACnet IP (Ethernet) Slave to Modbus Master. UL approved.

External Power Supply

12-24VDC, 175 mA at

12VDC

To Customer

BACnet IP Master

(Description explanation: ‘BACnet IP Slave’ is the Gateway’s connection to the plant master via Ethernet.

‘Modbus Master’ describes the Gateway’s serial master to the communication card slave.)

Wiring the gateway terminal to Com card: +Tx to XB21 pin 1 (A), -Tx to pin 2 (B), Com to pin 3 (Shown as a dash).

To load Configuration please refers to manufacture instruction manual 460MMBS-NNA1_Userguide.

Gateway Part number:

1092942

Complete kit part number:

1094289

See page 23 for kit

information.

Page 12 of 30

Page 13

Controller Modbus RTU Comm Module

RTA BACnet MSTP (Serial) to Modbus Master. UL approved.

External Power Supply

12-24VDC, 175 mA at

12VDC

To Customer

BACnet-MSTP

(Description explanation: ‘BACnet MSTP Slave’ is the Gateway’s connection to the plant master via Serial wiring.

‘Modbus Master’ describes the Gateway’s serial master to the communication card slave.)

Wiring the gateway terminal to Com card: +Tx to XB21 pin 1 (A), -Tx to pin 2 (B), Com to pin 3 (Shown as a dash).

To load Configuration please refers to manufacture instruction manual 460MMBMS-NNA4_Userguide.

Gateway Part number:

1092946

Complete Kit part number:

1094291

See page 21 for kit

information.

Page 13 of 30

Page 14

7 Gateway Settings

Parameter

Standard Value

Serial Mode

RS-485 differential

Termination

Disabled

Serial Format

8 data bits

Odd parity

1 stop bit

Baud rate

19200

Slave Address

10

The implementation of the Modbus interface is based on the following standards:

http://www.modbus.org/docs/Modbus_over_serial_line_V1_02.pdf. More information about Modbus can be

found at www.modbus.org.

The ProMinent Aegis II Modbus interface supports RS-485 interface standard

- Half-duplex, 2-wire technology

- twisted pair cable [twisted pair]

- Differential voltage level ± 5 V

- Cable length up to 1200 m

The device can be connected as an endpoint slave (either with one of the connections) or

as [Daisy-Chain-Slave] (with both connections).

Default-Connection-Settings:

This is the default configuration for Aegis II controller Modbus interface; this configuration can be modified in

System -> Communication Menu

Supported Modbus commands:

Function Code: Read-Holding-Register 0x03 (3)

Note: In order for your customer to have access to all Modbus registers in the Aegis II controller, you will need to

have a Modbus driver card with firmware version 1.0.23.0 or newer and Aegis II controller firmware 18.04.14.00

(2018/April/14) or newer.

Page 14 of 30

Page 15

8 The Inputs and Outputs

Register Address

(Starting from 0)

Register Number

(Starting from 1)

Parameter

Format (Type)

Access Level

R= Read

W = Write

Byte order

info

500

501

Actual Measure

Value on ‘A’ input

FLOAT32

R

BADC

502

503

Actual Measure

Value on ‘B’ input

FLOAT32

R

BADC

504

505

Actual Measure

Value on ‘C’ input

FLOAT32

R

BADC

506

507

Actual Measure

Value on ‘D’ input

FLOAT32

R

BADC

508

509

Actual Measure

Value on ‘E’ input

FLOAT32

R

BADC

510

511

Actual Measure

Value on ‘F’ input

FLOAT32

R

BADC

512

513

Actual Measure

Value on ‘G’ input

FLOAT32

R

BADC

514

515

Actual Measure

Value on ‘H’ input

FLOAT32

R

BADC

516

517

Actual Measure

Value on ‘I’ input

FLOAT32

R

BADC

Assigned to

4-20mA output 1

(Comm Module)

518

519

Actual Measure

Value on ‘J’ input

FLOAT32

R

BADC

Assigned to

4-20mA output 2

(Comm Module)

520

521

Actual Measure

Value on ‘K’ input

FLOAT32

R

BADC

Assigned to

4-20mA input 1

(Comm Module)

522

523

Actual Measure

Value on ‘L’ input

FLOAT32

R

BADC

Assigned to

4-20mA input 2

(Comm Module)

524

525

Actual Measure

Value on ‘M’ input

FLOAT32

R

BADC

Modbus Pyxis

Sensor

526

527

Actual Measure

Value on ‘N’ input

FLOAT32

R

BADC

Register Address

(Starting from 0)

Register Number

(Starting from 1)

Parameter

Format

(Type)

Access Level

R= Read

Byte order

info

552

553

Output ‘Relay 1’

FLOAT32

R

BADC

ON/OFF: ON=1, OFF =0

554

555

Output ‘Relay 2’

FLOAT32

R

BADC

ON/OFF: ON=1, OFF =0

556

557

Output ‘Relay 3’

FLOAT32

R

BADC

ON/OFF: ON=1, OFF =0

558

559

Output ‘Relay 4’

FLOAT32

R

BADC

ON/OFF: ON=1, OFF =0

560

561

Output ‘Relay 5’

FLOAT32

R

BADC

ON/OFF: ON=1, OFF =0

562

563

Output ‘P6’

FLOAT32

R

BADC

ON/OFF: ON=1, OFF =0

Pulse: 0-100 %

564

565

Output ‘P7’

FLOAT32

R

BADC

ON/OFF: ON=1, OFF =0

Pulse: 0-100 %

566

567

Output ‘P8’

FLOAT32

R

BADC

ON/OFF: ON=1, OFF =0

Pulse: 0-100 %

568

569

Output ‘P9’

FLOAT32

R

BADC

ON/OFF: ON=1, OFF =0

Pulse: 0-100 %

Analog Inputs/Outputs:

Digital Outputs:

Page 15 of 30

Page 16

Register Address

(Starting from 0)

Register Number

(Starting from 1)

Parameter

Format (Type)

Access Level

R= Read

Byte order

info

528

529

Input ‘O’

FLOAT32

R

BADC

Contact: Closed=1,

Opened=0

Water meter/turbine:

Volume

530

531

Input ‘P’

FLOAT32

R

BADC

Contact: Closed=1,

Opened=0

Water meter/turbine:

Volume

532

533

Input ‘Q’

FLOAT32

R

BADC

Contact: Closed=1,

Opened=0

Water meter/turbine:

Volume

534

535

Input ‘R’

FLOAT32

R

BADC

Contact: Closed=1,

Opened=0

Water meter/turbine:

Volume

536

537

Input ‘S’

FLOAT32

R

BADC

Contact: Closed=1,

Opened=0

Water meter/turbine:

Volume

538

539

Input ‘T’

FLOAT32

R

BADC

Contact: Closed=1,

Opened=0

Water meter/turbine:

Volume

540

541

Input ‘U’

FLOAT32

R

BADC

Contact: Closed=1,

Opened=0

Water meter/turbine:

Volume

542

543

Input ‘V’

FLOAT32

R

BADC

Contact: Closed=1,

Opened=0

Water meter/turbine:

Volume

544

545

Input ‘W’

FLOAT32

R

BADC

Contact: Closed=1,

Opened=0

Water meter/turbine:

Volume

546

547

Input ‘X’

FLOAT32

R

BADC

Contact: Closed=1,

Opened=0

Water meter/turbine:

Volume

548

549

Input ‘Y’

FLOAT32

R

BADC

Contact: Closed=1,

Opened=0

Water meter/turbine:

Volume

550

551

Input ‘Z’

FLOAT32

R

BADC

Contact: Closed=1,

Opened=0

Water meter/turbine:

Volume

Digital Inputs:

Page 16 of 30

Page 17

Register Address

(Starting from 0)

Register Number

(Starting from 1)

Parameter

Format (Type)

Access Level

R= Read

Byte order

info

570

571

Input ‘A’, High Alarm

FLOAT32

R

BADC

572

573

Input ‘A’, Low Alarm

FLOAT32

R

BADC

574

575

Input ‘B’, High Alarm

FLOAT32

R

BADC

576

577

Input ‘B’, Low Alarm

FLOAT32

R

BADC

578

579

Input ‘C’, High Alarm

FLOAT32

R

BADC

580

581

Input ‘C’, Low Alarm

FLOAT32

R

BADC

582

583

Input ‘D’, High Alarm

FLOAT32

R

BADC

584

585

Input ‘D’, Low Alarm

FLOAT32

R

BADC

586

587

Input ‘E’, High Alarm

FLOAT32

R

BADC

588

589

Input ‘E’, Low Alarm

FLOAT32

R

BADC

590

591

Input ‘F’, High Alarm

FLOAT32

R

BADC

592

593

Input ‘F’, Low Alarm

FLOAT32

R

BADC

594

595

Input ‘G’, High Alarm

FLOAT32

R

BADC

596

597

Input ‘G’, Low Alarm

FLOAT32

R

BADC

598

599

Input ‘H’, High Alarm

FLOAT32

R

BADC

600

601

Input ‘H’, Low Alarm

FLOAT32

R

BADC

602

603

Input ‘I’, High Alarm

FLOAT32

R

BADC

604

605

Input ‘I’, Low Alarm

FLOAT32

R

BADC

606

607

Input ‘J’, High Alarm

FLOAT32

R

BADC

608

609

Input ‘J’, Low Alarm

FLOAT32

R

BADC

610

611

Input ‘K’, High Alarm

FLOAT32

R

BADC

612

613

Input ‘K’, Low Alarm

FLOAT32

R

BADC

614

615

Input ‘L’, High Alarm

FLOAT32

R

BADC

616

617

Input ‘L’, Low Alarm

FLOAT32

R

BADC

618

619

Input ‘M’, High Alarm

FLOAT32

R

BADC

620

621

Input ‘M’, Low Alarm

FLOAT32

R

BADC

622

623

Input ‘N’, High Alarm

FLOAT32

R

BADC

624

625

Input ‘N’, Low Alarm

FLOAT32

R

BADC

Register Address

(Starting from 0)

Register Number

(Starting from 1)

Parameter

Format

(Type)

Access Level

R= Read

Byte order

info

626

627

Input ‘O’, Total Counter

FLOAT32

R

BADC

628

629

Input ‘P’, Total Counter

FLOAT32

R

BADC

630

631

Input ‘Q’, Total Counter

FLOAT32

R

BADC

632

633

Input ‘R’, Total Counter

FLOAT32

R

BADC

634

635

Input ‘S’, Total Counter

FLOAT32

R

BADC

636

637

Input ‘T’, Total Counter

FLOAT32

R

BADC

638

639

Input ‘U’, Total Counter

FLOAT32

R

BADC

640

641

Input ‘V’, Total Counter

FLOAT32

R

BADC

Alarms:

Total Counter ( if these inputs are configurated as Daily counter):

If not configurated as daily counter the register value will be NULL

Page 17 of 30

Page 18

Setpoints:

Register Address

(Starting from 0)

Register Number

(Starting from 1)

Parameter

Format (Type)

Access Level

R= Read

Byte order

info

642

643

R 1 - high set point

FLOAT32

R

BADC

644

645

R 1 - low set point

FLOAT32

R

BADC

646

647

R 2 - high set point

FLOAT32

R

BADC

648

649

R 2 - low set point

FLOAT32

R

BADC

650

651

R 3 - high set point

FLOAT32

R

BADC

652

653

R 3 - low set point

FLOAT32

R

BADC

654

655

R 4 - high set point

FLOAT32

R

BADC

656

657

R 4 - low set point

FLOAT32

R

BADC

658

659

R 5 - high set point

FLOAT32

R

BADC

660

661

R 5 - low set point

FLOAT32

R

BADC

662

663

P 6 - high set point

FLOAT32

R

BADC

664

665

P 6 - low set point

FLOAT32

R

BADC

666

667

P 7 - high set point

FLOAT32

R

BADC

668

669

P 7 - low set point

FLOAT32

R

BADC

670

671

P 8 - high set point

FLOAT32

R

BADC

672

673

P 8 - low set point

FLOAT32

R

BADC

674

675

P 9 - high set point

FLOAT32

R

BADC

676

677

P 9 - low set point

FLOAT32

R

BADC

Register Address

(Starting from 0)

Register Number

(Starting from 1)

Parameter

Format (Type)

Access Level

R= Read

Byte order

info

678

679

Input ‘A’

UINT16

R

BADC

679

680

Input ‘B’

UINT16

R

BADC

680

681

Input ‘C’

UINT16

R

BADC

681

682

Input ‘D’

UINT16

R

BADC

682

683

Input ‘E’

UINT16

R

BADC

683

684

Input ‘F’

UINT16

R

BADC

684

685

Input ‘G’

UINT16

R

BADC

685

686

Input ‘H’

UINT16

R

BADC

686

687

Input ‘I’

UINT16

R

BADC

687

688

Input ‘J’

UINT16

R

BADC

688

689

Input ‘K’

UINT16

R

BADC

689

690

Input ‘L’

UINT16

R

BADC

690

691

Input ‘M’

UINT16

R

BADC

691

692

Input ‘N’

UINT16

R

BADC

692

693

Input ‘O’

UINT16

R

BADC

693

694

Input ‘P’

UINT16

R

BADC

694

695

Input ‘Q’

UINT16

R

BADC

695

696

Input ‘R’

UINT16

R

BADC

696

697

Input ‘S’

UINT16

R

BADC

697

698

Input ‘T’

UINT16

R

BADC

698

699

Input ‘U’

UINT16

R

BADC

699

700

Input ‘V’

UINT16

R

BADC

700

701

Input ‘W’

UINT16

R

BADC

701

702

Input ‘X’

UINT16

R

BADC

702

703

Input ‘Y’

UINT16

R

BADC

SETPOINTS ONLY WORK IF “SET FEED MODE” IS SELECTED AS

Setpoints only work if “SET FEED MODE” is selected as a “SENSOR CONTROL” OR “WATER METER”

Error Message:

Page 18 of 30

Page 19

703

704

Input ‘Z’

UINT16

R

BADC

704

705

Output ‘R1’

UINT32

R

BADC

706

707

Output ‘R2’

UINT32

R

BADC

708

709

Output ‘R3’

UINT32

R

BADC

710

711

Output ‘R4’

UINT32

R

BADC

712

713

Output ‘R5’

UINT32

R

BADC

714

715

Output ‘P6’

UINT32

R

BADC

716

717

Output ‘P7’

UINT32

R

BADC

718

719

Output ‘P8’

UINT32

R

BADC

720

721

Output ‘P9’

UINT32

R

BADC

722

723

System

UINT32

R

BADC

Input A-Z States:

S_enabled 0x0001 disabled parameters are not logged, do not display, cannot be used in commands

S_alarmed 0x0002 execute alarm action bit(s)

S_events 0x0004 timed events exist for this relay

S_arelay 0x0008 trip alarm relay on alarm // if Alarm Relay is set to Yes in Alarm setting

S_off 0x0010 Actively Turned OFF by Interlock, Lockout, Alarmed (reference output states for cause)

S_stopped 0x0020 HOA set to STOP // not applicable to Aegis II

S_manual 0x0040 HOA set to MANUAL // not applicable to Aegis II

S_disconn 0x0080 Serial sensor or Modbus Driver not responding

Output R1-R5 and P6-P9 States:

Some of the bits reflect configuration (C_offonalarm), some reflect control state (C_rlocked)

Here is the example how to use these bitwise masking: If mask for bit 0 you will get ON/OFF state.

Note: in order to extract a subset of the bits in the value do Bitwise ANDing

Mask: 0x00000001b (C_on)

Value: 0x01010101b (R1 register 704 value)

Result: 0x00000001b (the result shows the relay is ON)

C_on 0x00000001 current state of Relay ON|OFF or Pulse Drive, also Prime ON/OFF

C_ilocked 0x00000002 interlocked on contact set (U to Z)

C_tlocked 0x00000004 lockout on time

C_vary 0x00000008 varying cycle controls, adjusts setpoints (unused for PID)

C_do 0x00000010 Control Field Frequency output is set as Digital Output and also for Analog Outputs

C_offonalarm 0x00000020 turned OFF on alarm

C_rlocked 0x00000040 interlocked by another relay

Page 19 of 30

Page 20

C_meters 0x00000080 control by Volume & Time

C_special 0x00000100 control by special control

C_sequence 0x00000200 2nd phase of an Q:P sequential volume control; ON for 'P'

C_forcedon 0x00000400 prebleed has turned relay ON

C_owed 0x00000800 time owed, count down if not blocked

C_blocking 0x00002000 Output R1 to R5, P6 to P9 is blocking another relay

C_oxidant 0x00004000 one of assist, pH lockout or alt. control events is active // not applicable to Aegis II

C_delayed 0x00008000 User set delay on flow switch // not applicable to Aegis II

C_drvfault 0x00010000 Driver card communication timeout (implies no card, card fault)

C_prebleed 0x00020000 ON because prebleed active on time or uS

C_ontrip 0x00100000 Set when ON setpoint exceeded, stays On until OFF setpoint exceeded

C_eventsp 0x00200000 Set when Oxidant Event Setpoints override control setpoints

C_latched 0x00800000 Contact Set controls, retains state during deadtime

System State:

SYS_USB 0x00000400 USB host port active (USB thumb drive plugged in), file uploading, Pumps OFF, A/D blocked

SYS_LOCKED 0x00004000 LOCKOUT_LIMIT password fails, reset @ 7:00AM or power cycle

SYS_NOUSD 0x08000000 File System faults, no USD

Page 20 of 30

Page 21

9 Gateway Enclosure Kits

Kits include the gateway, a 24VDC power supply, serial terminations mounted in a Nema 4X enclosure.

BACnet MSTP Converter Terminal Box

Kit part number 1094290 includes the ADFweb (not UL approved) BACnet MSTP Slave to Modbus

Master gateway, part number 1092945. See page 9 for gateway information.

Kit part number 1094291 includes the RTA (UL approved) BACnet MSTP Slave to Modbus Master

gateway, part number 1092946. See page 13 for gateway information.

Dimensions: 10.88 x 7.38 x 9.06 Construction: Fibox NEMA 4X Polycarbonate

Page 21 of 30

Page 22

MODBUS TCP Converter Terminal Box

Kit part number 1094286 includes the ADFweb (not UL approved) Modbus TCP Slave to Modbus

Master gateway, part number 1092941. See page 7 for gateway information.

Kit part number 1094288 includes the RTA (UL approved) Modbus TCP to Modbus Master

gateway, part number 1092940. See page 11 for gateway information.

Dimensions: 10.88 x 7.38 x 9.06 Construction: Fibox NEMA 4X Polycarbonate

Page 22 of 30

Page 23

BACnet IP Converter Terminal Box

Kit part number 1094287 includes the ADFweb (not UL approved) BACnet IP Slave to Modbus

Master gateway, part number 1092943. See page 8 for gateway information.

Kit part number 1094289 includes the RTA (UL approved) BACnet IP Slave to Modbus Master

gateway, part number 1092942. See page 12 for gateway information.

Dimensions: 10.88 x 7.38 x 9.06 Construction: Fibox NEMA 4X Polycarbonate

Page 23 of 30

Page 24

10 Replacement Parts

PFC Part #

Description

1092940

Modbus TCP Slave / Modbus Master – Converter UL Certified (RTA brand)

1092941

Modbus TCP Slave / Modbus Master – Converter (ADFweb brand)

1092942

BACnet IP Slave / Modbus Master – Converter UL Certified (RTA brand)

1092943

BACnet IP Slave / Modbus Master – Converter (ADFweb brand)

1092964

BACnet MSTP Slave / Modbus Master – Converter UL Certified (RTA brand)

1092965

BACnet MSTP Slave / Modbus Master – Converter (ADFweb brand)

The following list includes all parts necessary to build a complete enclosure, including the power supply, but does

not include the gateway. Gateway part numbers below.

ProMinent Gateway part numbers

Page 24 of 30

Page 25

11 Technical Support

If the communication link is not working, refer to this checklist.

Try to swap the serial connection

Are the wires connected to the correct terminals?

Do the default settings listed on page 14 agree with the controller’s System Configure page?

Do these settings agree with the Gateway or other Master settings?

Addresses must not be the same

If using a gateway, did you load a configuration into the gateway according to the manufacturer’s instruction?

Can you test the Master line with another Slave?

Test the Com Module using the instructions in section 12: Communication Module Register Test

Page 25 of 30

Page 26

12 Communication Module Register Test

Converter Module

Printer style USB cable

Test the Modbus registers via the Com Module on an Aegis II using a TTL/RS485 USB dual function dual

protection USB turn 485 module FT232 chip module.

You will need the converter module, a Printer USB cable and Fenix or similar software.

You can purchase this converter module from NewEgg.com. Use the link below.

You will also need a Printer style USB cable. (Note the USB port on the card).

https://www.newegg.com/Product/Product.aspx?Item=9SIAAZM4RC0009&ignorebbr=1&nm_mc=KNCGoogleMKP-PC&cm_mmc=KNC-GoogleMKP-PC-_-pla-_-EC+-+Test+%26+Measurement-_9SIAAZM4RC0009&gclid=EAIaIQobChMIxvql-5yP2gIVgj2BCh0xwQ6IEAkYDiABEgILKvD_BwE&gclsrc=aw.ds

Page 26 of 30

Page 27

Download Fenix Software. Use this link:

https://sourceforge.net/projects/fenixmodbus/?source=typ_redirect

Press the Green Download button.

You may need IT permission to install the Fenix program on your company laptop. Check with your company IT

department!

Connect as shown.

Use the Printer style USB cable to connect the

converter to your PC.

Open the Fenix software on the PC.

Create a new project.

Page 27 of 30

Page 28

Fill in the project page. Press Save.

Create a directory to store your project. Ex: C:\Users\peters\Documents\Controllers\Software\Fenix

3.0.8\Projects and supply a name.

Page 28 of 30

Page 29

Select Add Connection. Provide a name, choose Modbus Master RTU for driver name, and all settings as below.

The COM port will depend on how your PC chooses this device. Use your Device Manager to look at the USB

connections when you plug in the cable. Press OK. (Hint: Type ‘device manager’ in your search box)

Right click on the Connection you created and select Add Device.

Name the device based on where the Com Module is located. Use the controller System Communication

properties to find the Device Address and enter it here.

Add all pertinent I/O points using Add Tag from the Device menu.

Page 29 of 30

Page 30

The starting address is 501 (which stands for 500 and 501). Consult section # 8 Inputs and Outputs for a list of I/O

points.

Input A is 501, B is 503, C is 505 etc.

Select the Table View icon to view the I/O

Highlight the Connection (Office in my example) and use the start and stop icons to run/stop the data acquisition.

Save your Project at this point. If you forget, all will be lost.

Next session, select Open rather than New.

ProMinent Fluid Controls, Inc.

136 Industry Drive

Pittsburgh, PA 15275-1014

412.787.2484

www.proMinent.us

Page 30 of 30

Loading...

Loading...