Page 1

Maxprep™ Liquid Handler

Operating Manual

Instructions for use of AS9100, AS9101, AS9200 and AS9201

TM509 | Revised 1/19

Page 2

Page 3

Table of Contents

1 Introduction ........................................................................................5

1.1 Maxprep™ Liquid Handler ........................................................................5

1.2 Product Use .............................................................................................6

1.3 Product Use Limitations ............................................................................6

1.4 Maxprep™ Liquid Handler Features ..........................................................6

1.5 Maxprep™ Liquid Handler Specifications ..................................................7

1.6 Product Components ...............................................................................9

1.7 Precautions ............................................................................................10

1.8 Safety Symbols and Marking ..................................................................11

1.9 Environmental Requirements (Operating, Shipping and

Storage Conditions) ...............................................................................13

2 Hardware Overview ..........................................................................15

2.1 Hardware Features .................................................................................16

2.2 UV Light (optional)...................................................................................17

2.3 Labware Carriers ....................................................................................18

3 Setting Up the Maxprep™ Liquid Handler .........................................23

3.1 Installing the Maxprep™ Liquid Handler ..................................................23

3.2 Switching On the Maxprep™ Liquid Handler ...........................................24

3.3 Shutting Down the Maxprep™ Liquid Handler ........................................24

3.4 Configuring the PC .................................................................................24

1 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 4

Table of Contents

4 Maxprep™ Software .........................................................................25

4.1 ‘Home’ Screen .......................................................................................25

4.2 Software Settings ...................................................................................28

4.3 Administrator Settings .............................................................................31

5 Operating the Maxprep™ Liquid Handler ........................................... 53

5.1 Maintenance ...........................................................................................53

5.2 Methods .................................................................................................55

5.3 Starting a Method ...................................................................................56

5.4 Error Recovery ........................................................................................64

5.5 Reports ..................................................................................................67

5.6 Accessing Reports..................................................................................70

6 Cleaning the Maxprep™ Liquid Handler ............................................73

6.1 Weekly Cleaning .....................................................................................73

6.2 Dealing with Spills ..................................................................................75

7 Troubleshooting ................................................................................ 77

7.1 Errors and Warnings ...............................................................................78

7.2 Using a USB Flash Drive .........................................................................79

8 Instrument Service ............................................................................81

8.1 Service ...................................................................................................81

8.2 Maxprep™ Liquid Handler Service ..........................................................81

8.3 Instrument Disposal ................................................................................81

2 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 5

Table of Contents

9 Warranties, Service Agreements and Related Products ....................83

9.1 Warranty .................................................................................................83

9.2 Warranty and Service Agreement Options ...............................................83

9.3 Related Products ....................................................................................86

10 Certificate of Decontamination ......................................................... 87

11 Appendix: Configuring the PC .........................................................89

11.1 Maxprep™ Liquid Handler and PC .......................................................89

11.2 Glossary ...............................................................................................90

11.3 Adjusting Volume Settings ....................................................................92

11.4 Configuring Date and Time Settings ......................................................92

11.5 Managing Local Windows® User Accounts ...........................................92

11.6 Managing Maxprep™ Access Levels for a Windows® User Account ...102

11.7 Managing the Current Active Account .................................................110

11.8 Shutting Down and Restarting ............................................................111

11.9 Connecting to a Network ....................................................................112

11.10 Adding a Network Printer ..................................................................113

3 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 6

Table of Contents

4 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 7

Introduction

1

1.1 Maxprep™ Liquid Handler

The Maxprep™ Liquid Handler provides automated methods for preprocessing of samples

prior to nucleic acid purification on the Maxwell® RSC and Maxwell® RSC 48 Instruments for a

range of research sample types. In addition, the Maxprep™ Liquid Handler provides a variety

of post-processing automated methods for handling and analysis of eluted nucleic acids. The

Maxprep™ Liquid Handler is designed for use by laboratory professionals. Up to 48 samples

can be prepared in a single preprocessing run.

The instrument is controlled through a graphical user interface running on a PC. The Maxprep™

Liquid Handler has the ability to record and report sample tracking and method run data. The

included automated and manual bar code readers can be used with the Maxprep™ Liquid

Handler to capture bar code information for samples and reagents. The Maxprep™ Liquid

Handler provides reports of the data gathered for instrument operations; reports can be printed

and exported to a storage location or a USB drive for transfer to a separate computer. Sample

tracking and run-specific information can also be tracked in the Promega Portal software to

facilitate information transfer between the Maxprep™ Liquid Handler and the Maxwell® RSC

and Maxwell® RSC 48 Instruments. Reports of information contained within the Promega Portal

software can be generated using the separate Portal Access reporting software (see Technical

Manual #TM549).

To start a run, select the appropriate method and follow the instrument setup instructions

displayed by the user interface including scanning or entering sample bar code information.

For preprocessing methods, the Maxprep™ Liquid Handler prepares the samples for addition

to Maxwell® RSC cartridges, adds samples to the cartridges, adds elution buffer to the elution

tubes, and transfers plungers to the Maxwell® deck trays. The deck trays containing prepared

cartridges are manually transferred to the appropriate Maxwell® instrument(s) for the purification

run where sample tracking information that was entered can be retrieved from the Promega

Portal software. For post-processing methods, the Maxprep™ Liquid Handler can start with

samples in Maxwell® deck trays or other labware options for a variety of handling and analysis

methods. Training on the use of the Maxprep™ Liquid Handler is provided during installation

(see Section 9.2, Warranty and Service Agreement Options).

5 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 8

1.2 Product Use

The Maxprep™ Liquid Handler is exclusively designed to be used with Maxwell® RSC reagent

kits to perform automated preprocessing of samples prior to isolation of nucleic acids with the

Maxwell® RSC and Maxwell® RSC 48 Instruments. A variety of post-processing methods are

available with the Maxprep™ Liquid Handler that are compatible with reagents from a variety of

vendors.

The Maxprep™ Liquid Handler is for research use only.

1.3 Product Use Limitations

The Maxprep™ Liquid Handler is not intended for use with purification kits other than Maxwell®

RSC nucleic acid purification kits or with samples other than those defined within the product

limitations of the specific Maxwell® RSC kit being used. Post-processing methods provided with

the Maxprep™ Liquid Handler are tested for use with Promega reagents. It is the responsibility

of the end-users to internally verify/validate that these methods perform to their needs with

reagents from other vendors.

Introduction

1.4 Maxprep™ Liquid Handler Features

• Easy-to-use system

• Standardized sample preparation workflow

• Ability to create administrator-defined method variants

• Comprehensive technical support

• System controlled via PC and touch-screen monitor

• Run-specific and sample-specific reporting functionality

• Preprogrammed methods for preprocessing and post-processing of samples

• Included bar code reader and manual bar code scanner

6 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 9

Introduction

1.5 Maxprep™ Liquid Handler Specifications

Instrument Specifications

Desktop PC

Communication

Weight

Dimensions (W × D × H)

Power Requirements

Operating

Temperature

Relative Humidity

Altitude

Storage

Temperature

Relative Humidity

UV Bulb (optional)

Regulatory

Compliance

CE Compliance

Windows® 10 Operating System with Ethernet connection to

instrument, wired connectivity to local network

Ethernet

Approximately 220lb (98.6kg)

42.1 × 27.8 × 33 inches (106.9 × 70.6 × 83.3cm)

height with door open: 48.4 inches (123cm)

Input: 100–240VAC, 50/60Hz, 5A

Output: 42VDC ± 5%, 600W max

250VAC, 5A, low breaking capacity, time-lag fuse (AC250V,

T5AL, 5 × 20mm)

15–35°C (59–95°F)

30% to 85% non-condensing

0–2,000m above sea level

–20° to 70°C

10% to 90% non-condensing

Average lifetime approximately 10,000 hours, length 9.2in

(233mm base face to face, diameter 15mm, 11W, 0.43A

current, 25.6V, UV-C, UV output 32W at 1 meter)

For Research Use Only. Not for use in Diagnostic Procedures.

Pollution degree 2.

Installation category II.

Indoor use only.

Main supply voltage fluctuations are not to exceed >10% of the

nominal supply voltage.

This instrument complies with the requirements of the EU

Directives for electromagnetic compatibility (EMC Directive)

and for electrical safety (LVD). Compliance with the relevant

directives was demonstrated by third-party testing to the

appropriate EN and IEC standards. The product bears the

CE mark on its label as evidence of compliance, and an EU

Declaration of Conformity for the product is available from

Promega on request.

7 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 10

Introduction

1.5 Maxprep™ Liquid Handler Specifications (continued)

Pipetting Specifications

Liquid Level Detection

Independent Channels

Shaking

Pipetting

Specifications for

Channels

Gantry Bar Code Scanner Supported Symbologies.

1D Bar Codes

2D Bar Codes

UPC/EAN/JAN, Codabar, Interleaved 2 of 5, Code 39, Code 128,

Code 93

QR Codes

Capacitive Liquid Level Detection

Pressure Liquid Level Detection

3mm Orbit

Up to 2500rpm

Temperature range ambient to 105°C

Disposable

Tips Size Volume

50µl 1µl 5.0% 5.0%

300µl 10µl 5.0% 2.5%

1000µl 10µl 7.5% 3.5%

Accuracy

(%)

5µl 2.5% 2.0%

50µl 2.0% 1.0%

50µl 2.0% 1.0%

300µl 1.0% 1.0%

100µl 2.0% 1.0%

1000µl 1.0% 1.0%

Precision

(%CV)

8 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 11

1.6 Product Components

PRODUCT CAT.#

Maxprep™ Liquid Handler, RSC Carriers AS9100

Maxprep™ Liquid Handler, RSC Carriers w/ UV Light AS9101

Maxprep™ Liquid Handler, RSC 48 Carriers AS9200

Maxprep™ Liquid Handler, RSC 48 Carriers w/UV Light AS9201

Cat.# AS9100 and AS9101 are provided with Maxwell® RSC-compatible 16-position deck tray carriers.

Cat.# AS9200 and AS9201 are provided with Maxwell® RSC 48-compatible 24-position front and back deck tray carriers.

Cat.# AS9101 and AS9201 are provided with an optional UV light in the Maxprep™ Liquid Handler.

Includes:

• 1 Maxprep™ Liquid Handler

• 3 10mm Sample Tube Carriers

• 3 12–13mm Sample Tube Carriers

• 3 15–17mm Sample Tube Carriers

• 1 Box of Maxprep™ 50µl Conductive Disposable Tips, Filtered (5 × 96)

• 1 Box of Maxprep™ 300µl Conductive Disposable Tips, Filtered (5 × 96)

• 1 Box of Maxprep™ 1000µl Conductive Disposable Tips, Filtered (5 × 96)

• 1 Box of Maxprep™ Reagent Reservoirs, 50ml (28 reservoirs)

• 2 Maxwell® Deck Tray Carriers

• 3 Reagent Reservoir Carriers

• 1 Utility Carrier (for Heater Shaker, tools and plates)

• 1 Tip and Plate Carrier

• 1 Heater Shaker

• 4 Plunger Tools

• 2 Gripper Paddles

• 1 Maxprep™ Accessory Kit

• 1 PC preloaded with Maxprep™ Software

• 1 Ethernet cable for connection of Maxprep™ Liquid Handler to PC

• 1 Power Cable for Maxprep™ Liquid Handler

• 1 Power Cord for PC

• 1 Power Cord for PC Monitor

• 1 Manual Bar Code Reader

• 2 Maxprep™ Plunger Holders

• 4 Maxprep™ 3-Position Reagent Tube Holders

Introduction

9 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 12

1.7 Precautions

Important Safety Instructions. Save these instructions.

• Changes or modifications to this unit not expressly approved by the party responsible for

• This equipment has been designed and tested to CISPR 11 Class A. It may cause radio

• Do not use this device in proximity to sources of strong electromagnetic radiation (e.g.,

• Do not use this instrument for anything other than its designed purpose.

• Always disconnect the power to the instrument and the PC before cleaning or performing

• Do not disassemble unit.

• Ensure that any deck setup instructions are faithfully followed. Failure to do so may result in

Introduction

compliance could void the user’s authority to operate the equipment.

interference, in which case you may need to take measures to mitigate the interference.

unshielded intentional RF sources), as these may interfere with the proper operation.

routine maintenance.

damage to the instrument.

• Use only Promega Maxwell® RSC branded and supplied cartridges, plungers and elution

tubes. Use only Promega-supplied consumables (tips, troughs, preprocessing plates).

• Do not reuse cartridges, plungers or elution tubes.

• If the equipment is used in a manner other than that specified by Promega, the protection

provided by the equipment may be impaired.

• During some processing methods, the heated shaker at the back left corner of the instrument

becomes very hot. Do not touch.

• Do not attempt to lift or move the Maxprep™ Liquid Handler. The Maxprep™ Liquid Handler

should only be moved by a trained Promega representative.

• Equipment can be hazardous due to the use of chemical and biohazardous substances.

• Do not override the door sensor.

• This instrument can be used with potentially biohazardous materials. Use appropriate

personal protective equipment (e.g., gloves, safety goggles, lab coat, etc.) for handling and

disposing of biohazardous materials.

• Loading nonessential software programs on the PC supplied with Maxprep™ Liquid Handler

is not recommended. Promega cannot guarantee compatibility of the Maxprep™ Liquid

Handler software with other third-party software programs. Additional programs may also

cause the application to slow down.

• Do not use any software other than the Maxprep™ software to control the Maxprep™ Liquid

Handler.

10 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 13

1.8 Safety Symbols and Marking

6422MA

Important Safety Instructions. Save these instructions.

Safety Symbols and Markings

Warning. Risk of personal injury to the operator or a

safety hazard to the instrument or surrounding area.

Warning. Hot surface. Burn hazard.

Warning. Biohazard.

Introduction

Warning. UV light hazard. Do not look directly at the

UV light.

11 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 14

Introduction

AS4000

123456789

Maxwell

®

CSC

Promega BioSystems Sunnyvale, Inc.

645 N Mary Ave.

Sunnyvale, CA 94085 USA

Made in

USA

6006TA

14840TA

1.8 Safety Symbols and Marking (continued)

Symbols Explanation

Catalog Number

Serial Number

Manufacturer

Consult your local Promega Representative regarding

instrument disposal WEEE Directive (European Community

directive 2002/96/EC on Waste Electrical and Electronic

Equipment)

Test Certification

CE Compliance Marked

Representative in the European Community

Device is China RoHS-compliant

Important Information

12 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 15

Introduction

1.9 Environmental Requirements (Operating, Shipping and

Storage Conditions)

Power

Requirements

Temperature

Humidity

Operating Altitude

The Maxprep™ Liquid Handler is intended for indoor use only. Wipe up spills immediately. To

avoid shortening the expected lifespan of the instrument, install in a location that meets the

following criteria:

• Locate on a sturdy, level surface capable of stably supporting 350lb.

• Avoid dusty areas.

• Choose a location that has good air circulation and is not exposed to direct sunlight.

• Avoid electrically noisy power sources (e.g., power generators).

• Do not install in a location where there is large temperature variability or high humidity.

• Do not position the instrument so that it is difficult to unplug from the power source.

• Do not place next to heat sources.

• Do not use near flammable gases or liquids.

100–240VAC, 50/60Hz, 5A

–20 to 70°C (shipping/storage), 15–35°C (operation)

30–85% relative humidity, non-condensing (operation)

10–90% non-condensing (storage)

<2000 meters

• Allow at least 6 inches (15.25cm) clearance on all sides of the Maxprep™ Liquid Handler.

• Do not place near other electrically sensitive instruments. Allow at least 6 inches (15.25cm)

on all sides of the Maxprep™ Liquid Handler.

• Connect the Maxprep™ Liquid Handler and PC to a power outlet. Promega recommends

that you plug the instrument and PC into an uninterruptible power supply.

13 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 16

Introduction

Notes

14 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 17

2Hardware Overview

The Maxprep™ Liquid Handler (Figure 1) is a fully enclosed four-channel pipetting system

designed to automate sample preprocessing and deck tray preparation for a variety of Maxwell®

RSC chemistries and post-processes for storage, normalization, and analysis of nucleic acid

eluates. The front of the instrument has a large door for access to the inside of the system. To

open the door, grip the handle, pull toward you, and then slide the door upwards. To close the

door, grip the handle, pull toward you, slide the door downwards, and then push the door

inwards at the bottom of its vertical motion. When the instrument is in operation, door locks

prevent access to the inside of the instrument. In the lower front corner of the instrument is the

power button. Press the power button to turn the instrument on/off.

Figure 1. Front of the Maxprep™ Liquid Handler.

15 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 18

2.1 Hardware Features

14833T

The gantry system on the Maxprep™ Liquid Handler has four independently controlled pipetting

channels, which can support a 1µl to 1ml volume range using 50, 300 and 1000µl disposable

tips (Figure 2). These channels are capable of both pressure and capacitive liquid level sensing.

The pipetting channels of the instrument can retrieve tools to perform other tasks including

transferring Maxwell® RSC plungers to Maxwell® cartridges and moving plates within the

instrument. Included on the front arm of the gantry is a 1D/2D bar code reader that can

automate the process of reading tube bar codes that are loaded on the system in tube carriers.

Pipetting Channels

Hardware Overview

1D/2D Bar code reader

A

Figure 2. Gantry system on the Maxprep™ Liquid Handler. The gantry system on the

Maxprep™ Liquid Handler houses the four pipetting channels on the system. On the front

arm of the gantry is the 1D/2D bar code reader.

In the back left corner of the instrument are the heater shaker and the tool rack that houses the

gripper paddles and plunger tools (Figure 3). When placing the gripper paddles in the tool rack,

make sure the magnet and pins on each paddle are facing toward the center of the tool rack.

16 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 19

Hardware Overview

A. B.

Figure 3. Heater shaker and tool rack. Panel A. The heater shaker is in the back left

corner of the Maxprep™ Liquid Handler. In front of the heater shaker is the tool rack that

houses the plunger tools and gripper paddles. Panel B. Plunger tools are shown at the top

of the image and gripper paddles at the bottom of the image. When placing gripper paddles

in the tool rack make sure the magnet and pins on each paddle are facing toward the center

of the tool rack.

2.2 UV Light (optional)

Maxprep™ Liquid Handler Cat.# AS9101 and AS9201 are provided with a UV light system. UV

lights are present on the top left and top right side of the instrument enclosure. The UV lights,

in addition to regular cleaning of the instrument, can be used for sanitization. A Sanitization

maintenance method is included in the Maxprep™ software to perform UV treatment of the

system for an administrator-defined time period. UV sanitization can only be performed with

the instrument door closed. If necessary, always replace the UV lights on the system with

Maxprep™ UV Lamp bulbs from Promega (Cat.# AS9310).

17 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 20

Hardware Overview

2.3 Labware Carriers

Provided with the Maxprep™ Liquid Handler are a variety of carriers that hold the labware

needed to perform preprocessing and post-processing methods (Figure 4). The configuration

of the carriers on the instrument is designed to be consistent amongst Maxprep™ Liquid

Handler methods. The instrument platform is divided into 30 tracks. On the metallic plate at the

front of the instrument you can see the individual tracks with tracks 1, 5, 10, 15, 20, 25, and

30 indicated. The tracks are used as reference positions when placing carriers on the system.

To remove carriers from the instrument, grasp the handle on the carrier and pull it straight out

toward you, supporting the bottom of the carrier as you remove it from the system. When

adding carriers to the instrument, support the bottom of the carrier and place the back edge

of the carrier on the track positions at the front of the instrument; then slide the carrier straight

back until it touches the backstop of the instrument. Below is a table indicating the carriers

provided with the system and their track positions and functions.

Track

Carrier Type Number Provided

Utility Carrier 1 1–6 Static carrier (cannot be removed from system)

Maxwell® Deck

2 7–12

Tray Carriers (2)

[either 16-position

or 24-position deck

trays depending

on catalog number

purchased]

Positions Function

with heater shaker and tool rack at the back two

sites and two plate positions at the front two

sites.

Removable carriers that hold Maxwell® deck

14–19

trays. There are two types of Maxwell® Deck

Tray Carriers available: the Maxprep™ Carrier,

Maxwell® RSC, that is used for Maxwell® RSC

(16-position) Deck Trays, and the Maxprep™

Carrier, Maxwell® RSC 48 Front and Back, that

are used for Maxwell® RSC 48 (24-position)

Deck Trays. On the left top side of the carrier is

a removable magnet that interfaces with elution

tubes on the Maxwell® deck tray to help remove

residual resin from eluates when pipetting from

these positions. Underneath the deck tray are

two plate positions. For some methods, it may be

necessary to remove the magnet from the carrier

in order to use the plate positions.

A reagent carrier is placed between the Maxwell®

deck tray carriers to provide appropriate spacing

on the instrument.

Maxwell® RSC 48 deck tray carriers are keyed to

accept either the Maxwell® RSC Front deck tray

or Maxwell® RSC Back deck tray.

18 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 21

Carrier Type Number Provided

Maxprep™

3 13, 20, 21 Removable reagent reservoir carriers hold

Reagent Carriers

Maxprep™

Carriers, Sample

Tubes

9

• Maxprep™ Carrier,

15–17mm Sample

Tubes (3)

• Maxprep™ Carrier,

12–13mm Sample

Tubes (3)

• Maxprep™ Carrier,

10mm Sample

Tubes (3)

Hardware Overview

Track

Positions Function

reagents required for each method run. These

carriers have four sites and each site can hold

either a Maxprep™ Reagent Reservoir, 50ml, or

Maxprep™ 3-Position Reagent Tube Holders.

22, 23, 24 Removable tube racks can hold primary sample

tubes and elution storage tubes. Provided with

the system are three types of tube carriers that

can accommodate a variety of tube types: large

diameter 15–17mm tubes (16), small diameter

12–13mm tubes (16), 1.5ml flip-cap tubes or

2.0ml screw-cap tubes (16).

Maxprep™ Carrier,

Tips and Plate

1 25–30 The tip carrier has a plate position at the back

site of the carrier and three tip rack positions

at the front three sites of the carrier. The types

of tips (50, 300, or 1000µl) are determined by

the method being run and are detailed in the

technical manuals for the chemistry methods.

19 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 22

2.3 Labware Carriers (continued)

Hardware Overview

14835TA

Utility Carrier

Deck Tray Carrier

®

Maxwell

Reagent Carrier

™

®

Maxprep

Deck Tray Carrier

Maxwell

Reagent Carriers

™

Carriers, Sample Tubes

™

Maxprep

Maxprep

Carrier, Tips and Plate

™

Maxprep

Figure 4. Internal components of the Maxprep™ Liquid Handler. The hardware

components inside the Maxprep™ Liquid Handler. Carriers on the instrument can hold

primary sample tubes (10mm diameter, 12–13mm diameter or 15–17mm diameter),

Maxwell® deck trays (Maxwell® RSC 16-position deck trays [2], or Front and Back Maxwell®

RSC 48 24-position deck trays), processing plates, tips and Maxwell® RSC plunger racks.

The heater shaker device is capable of shaking incubation of samples in Nunc 2.0ml Deep

Well Plates as required by any individual processing method.

On the right side of the instrument, past track 30 is a waste position with a black removable tip

eject bar at the back and a calibration block at the front (Figure 5). Remove the tip eject bar from

the system for cleaning and as instructed during maintenance procedures. Underneath the tip

eject bar are two probes that are used for maintenance procedures. During these procedures,

the system will prompt the user to remove the tip eject bar to expose these probes. When

running preprocessing and post-processing methods on the instrument, the tip eject bar should

always be in place; make sure the tip eject bar is returned to the system in the orientation shown

in Figure 5. The pin on the waste position should fit in the small hole at the front of the tip eject

20 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 23

Used tips should

be disposed of

appropriately

according to

your institution’s

procedures for

hazardous and

biohazardous

waste.

Hardware Overview

bar, the large cut out should be at the back of the instrument and the angled side of the tip eject

bar should be on the right side and facing downward toward the waste bin.

To the right of the waste position is a black removable plastic waste bin that is for disposal of

used tips. Waste bags are provided with the system to line the plastic waste bin and collect

used tips. Reorder Maxprep™ Waste Bags, Clear, from Promega (Cat.# AS9305). When

removing the waste bin, lift it out toward the right while angling up the right side of the bin to

avoid hitting the tip eject bar. Return the waste bin to the system by angling it under the tip eject

bar and placing the bin in position.

Tip Eject Bar

Calibration Block

Waste Basket

Figure 5. Waste position and plastic waste bin. To the right of the carriers is a waste

position that has a removable black tip eject bar as well as a calibration block. On the far

right side of the instrument is a removable black plastic waste bin that is used for disposal of

used tips.

21 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 24

Hardware Overview

Notes

22 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 25

Setting Up the Maxprep™ Liquid Handler

3.1 Installing the Maxprep™ Liquid Handler

The Maxprep™ Liquid Handler will be installed by a trained Promega representative. Prior

to installation, identify a location for the instrument that conforms to the environmental

requirements in Section 1.9 and the Maxprep™ Site Preparation Document sent by Promega.

We recommend connecting the Maxprep™ Liquid Handler, PC and Monitor to an uninterruptible

power supply. In order to use the Portal sample tracking functionality, it will be necessary to

connect the PC to your internal network. Prior to installation of the Maxprep™ Liquid Handler,

consult with your IT department to evaluate any concerns or limitations with connecting the

Maxprep™ Liquid Handler PC and any Maxwell® Tablet PCs to your network.

Recommended Domain policy settings when the Maxprep™ Liquid Handler PC is

connected to your internal network

Ensure that domain policies for the PC adhere to the following:

3

• Disable automatic Windows® updates.

• Virus scanning programs can interfere with the operation of the instrument. Please disable

virus scanning programs, manually perform virus scans, or schedule virus scanning outside

of working hours. When placed on a site domain, contact your IT department to ensure that

domain policies are amended such that the Maxprep™ software is excluded from virus

scanning software.

• Disable automatic power off, sleep or hibernation settings.

• Disable “Fast Startup”. Set the power button to Shut Down, not Sleep.

• Disable any other automatically or manually started software that would consume PC

resources during operation.

23 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 26

Setting Up the Maxprep™ Liquid Handler

3.2 Switching On the Maxprep™ Liquid Handler

The Maxprep™ Liquid Handler has two power switches: a rocker switch that is located next to

the power cable connection behind the right access hatch, and a power button located on the

right front side of the instrument. After installation, the rocker switch behind the right access

hatch should be left in the on position.

Press the power button on the right front side of the Maxprep™ Liquid Handler to turn the

instrument “ON” (Figure 6). After turning the instrument on, wait at least one minute after the

green light on the gantry bar code scanner is illuminated before starting the Maxprep™

Application Software or any methods. Press the PC power button to turn the PC “ON”. Start the

Maxprep™ Application Software by double-clicking the icon on the PC desktop.

Figure 6. On/Off Switch.

3.3 Shutting Down the Maxprep™ Liquid Handler

1. Shut down the Maxprep™ Software by pressing the X in the upper right corner of the user

interface.

2. Turn the Maxprep™ Liquid Handler “OFF” by pressing the power button on the right front

side of the instrument.

3. Shut down the PC using the Windows® 10 shut down procedure: touch the Windows®

Start button in the lower left corner of the screen, select the power icon from the left side of

the Start menu, and select Shut Down.

4. When not in use for a prolonged period of time, the PC should be unplugged.

3.4 Configuring the PC

Your Maxprep™ Liquid Handler is controlled by Maxprep™ software running on a PC with a

touch-screen monitor. The PC should be configured to meet the needs of your site, including

adding users, specifying access-levels for users, connecting to a network and adding network

printers. Instructions for configuring the PC can be found in the Appendix of this user manual.

24 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 27

Maxprep™ Software

4.1 ‘Home’ Screen

The ‘Home’ screen is the main launching pad for interaction with the functionalities built into the

Maxprep™ User Interface. The ‘Home’ screen (Figure 7) contains four buttons:

4

Start

Results

Maintenance

Pressing the Start button on the ‘Home’

screen will begin the process of preparing

a method run on the Maxprep™ Liquid

Handler (see Section 5.3, Starting a

Method).

The Results button opens the ‘Results’

Screen, where it is possible to review,

print and export any of the run reports

from previous chemistry and maintenance

processes that have been performed

on this instrument module (see Section

5.5, Reports, and Section 5.6, Accessing

Reports).

Pressing the Maintenance button opens

the ‘Maintenance’ screen. From this

screen you can perform Daily and Weekly

Maintenance tasks or a UV sanitization

of the system (if the system has been

purchased with the UV light option; see

Section 5.1, Maintenance).

25 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 28

4.1 ‘Home’ Screen (continued)

Maxprep™ Software

Settings

The Settings button opens the ‘Settings’

screen, which includes functions to view

Instrument Info, Export Logs and set

administrator-specific instrument settings

with Administrator (only available to

users with Administrator-level access to

the Maxprep™ software; see Section

4.2, Software Settings, and Section 4.3,

Administrator Settings).

Figure 7. Maxprep™ software ‘Home’ screen. On the Maxprep™ ‘Home’ screen are

buttons to Start a method, view Results, run Maintenance methods, and adjust software

Settings.

26 Promega Spectrum CE System

14675CA

26 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 29

Maxprep™ Software

The instrument name appears in the title bar of the user interface. The following navigation

buttons are displayed across the top of the user interface screen:

Home

From any screen other than the ‘Home’ screen,

touch this icon to return to the ‘Home’ screen.

Back

Portal

Portal Error

Minimize

Resize

Help

When active, pressing the Back button will return

the interface to the screen accessed prior to the

current screen.

When visible, the Portal icon indicates that the

Maxprep™ software is connected to the Portal

software.

When visible, the Portal icon with a red circle

containing an exclamation point indicates that the

connection to Portal software has been lost. Results

from the last run will be exported to Portal software

when the connection is restored. Disable Portal

sample tracking to run methods until connection is

returned, and then reactivate Portal sample tracking.

This button will minimize the Maxprep™ software to

an icon in the Windows® task bar. Select the task

bar icon to restore the Maxprep™ software screen.

The Resize button toggles between displaying the

Maxprep™ software maximized on the screen or

resized.

Access context-sensitive help by pressing this

button.

Exit

When active, pressing the Exit button will close

the Maxprep™ software and return users to the

Windows® Operating System.

27 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 30

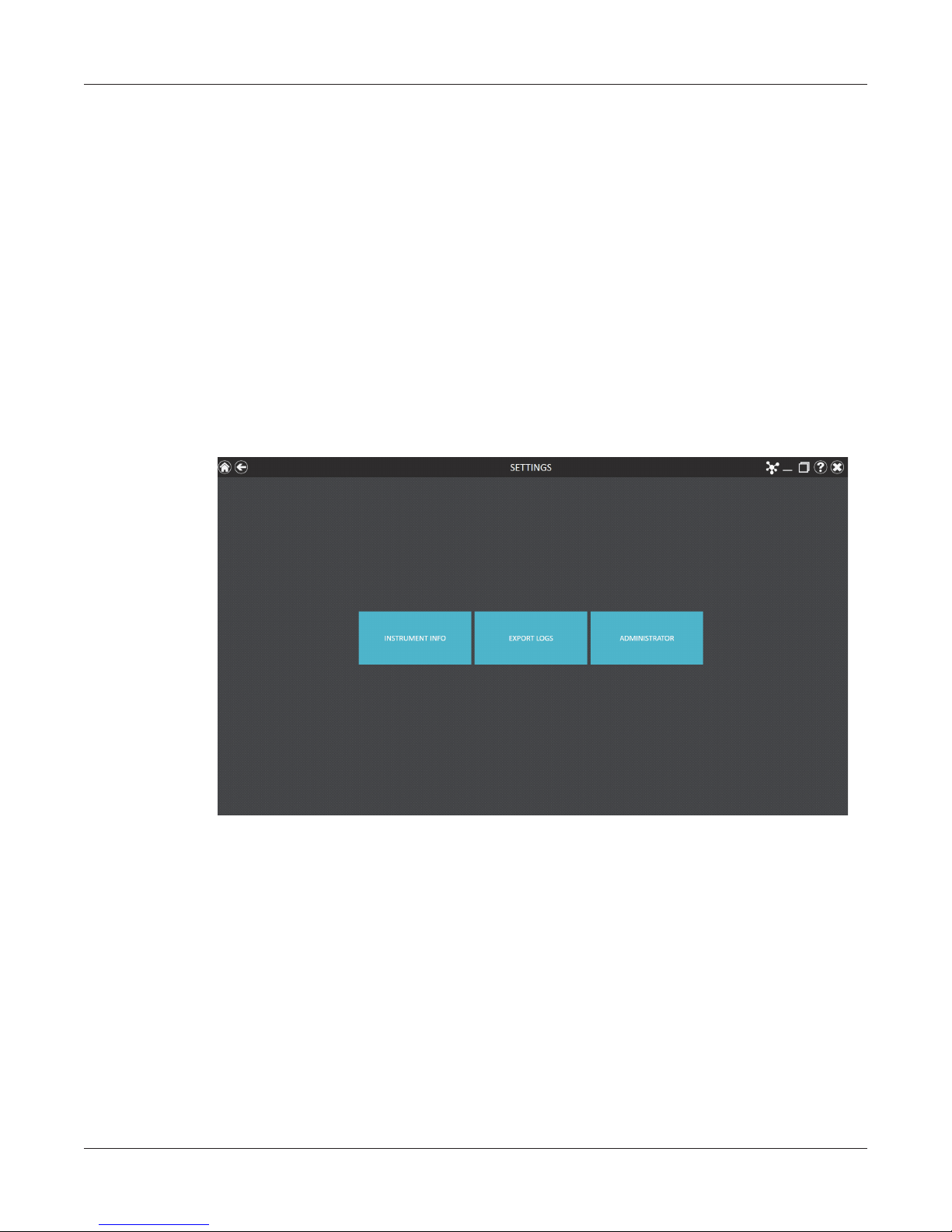

4.2 Software Settings

14644T

Within the Maxprep™ software it is possible for all users to access instrument-specific

information and export log files. In addition, users with Administrator-level access to the

Maxprep™ software can modify software options to tailor the behavior of the software to the

needs of their laboratory. Below are sections that describe the functionalities that are accessible

from the Settings button on the ‘Home’ screen of the Maxprep™ software.

The appearance of the ‘Settings’ screen (Figure 8) is tailored to the Maxprep™ software access

level assigned to the Windows® user account (see Appendix). A Windows® user account with

user-level access to the Maxprep™ software will see the buttons Instrument Info and Export

Logs. A Windows® user account with administrator-level access to the Maxprep™ software will

additionally see an Administrator button. From this screen the operator can access the

instrument functionalities described below.

Maxprep™ Software

Figure 8. Maxprep™ ‘Settings’ screen. From this screen various instrument-specific

functions can be accessed. The Administrator button will be displayed only for Windows®

user accounts with administrator-level access to the Maxprep™ software.

A

28 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 31

Maxprep™ Software

Instrument Info

Touch the Instrument Info button to display software and instrument-specific information for

this Maxprep™ instrument on an ‘About Maxprep™’ screen (Figure 9). The information shown

on this screen includes:

• Maxprep™ Software Version: the Maxprep™ software version installed on the PC

• Maxprep™ Software Revision: the Maxprep™ software revision number of the software

version installed on the PC

• Instrument Software Version: the instrument control software version installed on the PC

• Maxprep™ Name: the name that an administrator has assigned to this instrument

• Maxprep™ Serial Number: the serial number of the Maxprep™ Liquid Handler

14645TA

Figure 9. ‘About Maxprep™’ screen. Instrument- and software-specific information are

displayed on the ‘About Maxprep™’ screen.

29 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 32

4.2 Software Settings (continued)

Export Logs

The Export Logs button will export instrument logs for troubleshooting purposes. If in the

course of troubleshooting an instrument problem you are directed to export logs to send to

Promega Technical Services, press this button to generate instrument-specific log files.

1. Press the Export Logs button to display the ‘Export Logs’ screen (Figure 10, Panel A).

Select the path to which instrument logs should be exported.

2. Using the Yellow and Red rectangle buttons you can select the folder location where the

instrument logs will be saved. The current path is indicated by the yellow rectangles at the

top of the ‘Export Logs’ screen. Any folders present within the selected directory are

displayed as red rectangles in the main portion of the screen. Press the Drive\ button to

navigate to the drive location of the desired folder. Select the red folder buttons to navigate

to the desired folder location.

3. Once a path has been defined, press the OK button to export logs to the specified path, or

press Cancel to return to the ‘Settings’ screen without exporting logs.

Maxprep™ Software

4. After pressing OK, the ‘Export’ screen is displayed, indicating that the log files were

successfully exported to the specified path (Figure 10, Panel B). Press Open on the ‘Export’

screen to open the folder location containing the exported logs.

5. Press Done to close the ‘Export’ screen and return to the ‘Settings’ screen.

Instrument logs will be exported as a zip file to the path that was specified by the operator. The

zip file of the logs should be retrieved from the specified location and sent to a Promega

Technical Services representative for further troubleshooting.

A.

B.

14646TA

Figure 10. Export Logs. Panel A. The ‘Export Logs’ screen is displayed after pressing the

Export Logs button. Specify a path to which the instrument log files should be exported.

Press OK to export instrument logs to the specified location or Cancel to return to the

‘Settings’ screen without exporting logs. Panel B. After instrument log files are exported,

the ‘Export’ screen is displayed, indicating that logs have been saved to the specified path.

Press Open to view the folder location of the exported instrument log files. Press Done to

exit the ‘Export’ screen and return to the ‘Settings’ screen.

30 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 33

4.3 Administrator Settings

Software settings for the Maxprep™ software can be accessed by Windows® user accounts

with administrator-level access to the Maxprep™ software using the Administrator button on

the ‘Settings’ screen. From the ‘Settings’ screen press the Administrator button to open the

‘Administrator’ screen.

The functions available from the ‘Administrator’ screen allow users with administrator-level

access to the Maxprep™ software to customize the behavior of the Maxprep™ software to

the needs of their laboratory. Buttons on the ‘Administrator’ screen allow the administrator to:

manage Methods installed in the software, import or delete Labware, Manage Kits installed in

the software, configure Preferences for the Maxprep™ software, define an Instrument Name

for this Maxprep™ Liquid Handler and view user-readable Audit Records. The behavior of each

button on the ‘Administrator’ screen is detailed below. Follow the instructions below to adapt

the behavior of the Maxprep™ software to the needs of the laboratory, or refer to any individual

subsection to address a specific setting.

1. To return to the ‘Home’ screen from any other screen, press the Home button in the upper

left corner of the screen. From the ‘Home’ screen of the Maxprep™ software (Figure 11)

press the Settings button.

Maxprep™ Software

Figure 11. Maxprep™ ‘Home’ screen. Selecting Settings opens the Maxprep™ ‘Settings’

screen.

31 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 34

Maxprep™ Software

14644T

14568TA

4.3 Administrator Settings (continued)

2. If the current operator logged into the PC has administrator access rights within the

Note: If the

Administrator

button is not

visible, log out

of the Windows®

operating system

as this user and

log back in with

user credentials

that have

administrator

access rights

within the

Maxprep™

software.

Maxprep™ software, the ‘Settings’ screen (Figure 12) displays an Administrator button.

On the ‘Settings’ screen select the Administrator button to proceed to the ‘Administrator’

screen (Figure 13).

A

Figure 12. Maxprep™ ‘Settings’ screen. The Administrator button will only be visible if the

currently logged-in operator has administrator-level rights within the Maxprep™ software.

Figure 13. Maxprep™ ‘Administrator’ screen. The ‘Administrator’ screen is only visible

to operators with administrator-level rights to the Maxprep™ software and gives access to

customize the behavior of several aspects of the Maxprep™ system.

32 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 35

Maxprep™ Software

Methods

View the methods currently installed in the Maxprep™ software on the ‘Methods’ screen

(Figure 14) by touching the Methods button from the ‘Administrator’ screen (Figure 13).

A

Figure 14. ‘Methods’ screen. This screen displays a list of the methods installed in the

Maxprep™ software. For entries with a folder icon, select the entry to view variant methods.

Use the filter check boxes on the left side of the screen to display only certain types of methods.

You can filter by:

• Method Type: Preprocessing or post-processing methods.

• Sample Type: DNA, RNA or Universal (total nucleic acid) sample types.

• Favorites: Only methods where the Favorites star icon to the left of the method is

highlighted.

• Keyword: Type in a word or word fragment to only show methods that contain that word in

the Name, Description or CatalogID field.

33 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 36

Maxprep™ Software

4.3 Administrator Settings (continued)

For each method on the “Methods’ screen (Figure 14), the following are displayed:

Mark this method as a favorite for filtering purposes. Favorites are

displayed at the top of the list of methods.

When the folder icon appears in an entry it indicates that variant

methods have been created for this entry. Touch the entry to view

the existing variant methods.

Name

Description

Type

Sample Type

Catalog Number

Version Number

The name of the method

A description of the method

Indicates whether this is a preprocessing or post-processing

method

Indicates the target nucleic acid to which this method applies:

DNA, RNA or Universal (total nucleic acid) samples

The catalog number for the kit (if any) associated with the method

The version number of the method

Icon for creation of a new variant method based on the settings for

an existing method

Icon for editing an existing variant method

Icon for deletion of a method or variant method

Importing Methods

Only Administrators can add new methods, update, or delete existing methods. Administrators

can download new or updated methods from the Promega web site

(www.promega.com/resources/software-firmware/maxprep-liquid-handler-methods/)

Methods are provided as files with a .package extension. Follow the instructions below to import

a method into the Maxprep™ software.

1. Save the method (.package) file on the PC attached to the Maxprep™ Liquid Handler.

2. If not already running, start the Maxprep™ software by double-clicking the software icon on

the desktop.

3. Navigate to the ‘Methods’ screen (‘Home’ -> ‘Settings’ -> ‘Administrator’ -> ‘Methods’)

4. Press the Import... button on the top left side of the screen to open the ‘Methods’ file

browser screen (Figure 15).

34 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 37

Maxprep™ Software

14648T

A

Figure 15. Method import file selection. Use the ‘Methods’ file browser to navigate to the

location of a method (.package) file. Valid import files are shown on the right side of the file

browser as blue rectangles (yellow when selected).

5. Within the ‘Methods’ screen, navigate to the location at which you saved the method

(.package) file. The current path will be shown in yellow boxes along the top of the window.

Select any aspect of the path to navigate to the desired folder. Press the Drive\ button to

select the drive in which to search. Folders within the current path are shown as red

rectangles on the left side of the screen. Valid method (.package) files will be shown as blue

rectangles (yellow when selected) on the right side of the screen.

6. Select the blue rectangle(s) corresponding to the desired (.package) file(s) to highlight, and

then press the OK button to import the selected methods.

Note: When importing the same version of an existing method, the imported method will

overwrite the existing method and all existing variants will be deleted. A warning is

displayed, indicating that the existing method and variants will be deleted. The warning will

ask whether you wish to proceed with import; press Yes to delete the existing method and

variants or No to cancel the import. New versions of methods will not overwrite existing

methods. To remove a previous version, delete the desired method by touching the X on the

right side of the method entry.

7. A screen will indicate successful import of the method(s) into the software. If import was

successful, the new method file(s) will appear in the list of method files on the ‘Methods’

screen.

35 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 38

Maxprep™ Software

A

.B.

4.3 Administrator Settings (continued)

Variant Methods

Each of the methods on the Maxprep™ Liquid Handler can be customized by the administrator

to meet the processing needs of the laboratory. The administrator can create variants of

the default method that specify new default values, set minimum and maximum ranges and

determine whether values can be changed by users at run time for a variety of processing

options.

Creating a Variant Method

1. To create a new variant method, select the icon on an existing method entry to open the

‘Save-As Variant’ screen (Figure 16, Panel A). The new variant method will initially be

populated with the values from the original method or variant method. Changes made to the

method will be saved as a new variant method.

To edit an existing variant method, select the icon on an existing variant method entry

to open the ‘Edit Variant’ screen (Figure 16, Panel B). Changes made to the variant method

will modify the existing variant method.

Figure 16. Creating a variant method. Panel A. The ‘Save-As Variant’ screen allows the

administrator to create a new variant method based on the settings for an existing default or

variant method loaded in the Maxprep™ software. Panel B. The ‘Edit Variant’ screen allows the

administrator to edit the settings of an existing variant method.

2. Enter a name and description to identify the variant method in the Name: and Description:

fields.

14649TA

36 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 39

Maxprep™ Software

3. Below the Description: field are groups of variables whose values can be modified by the

administrator. Touch the +/– icon to the left of the group to expand/hide any individual group

of accessible variables.

4. For each variable type, the following are listed:

a. Name: A description of the variable that is being set.

b. Value: The default value for this variable. If the default value falls outside of the allowable

range for the variable, the value will default to the nearest allowable value within the

range.

c. Min/Max: The range of values that are acceptable for this variable. Each method will

have an absolute Min/Max range that is set by Promega. The administrator can narrow

this range if desired to meet laboratory needs. The software will check that the entries

conform to the following conditions:

i. The minimum value is less than or equal to the maximum value.

ii. The minimum and maximum values are within the absolute range set by Promega.

iii. The default value is within the specified range.

If there is an issue with any of these conditions, the software will automatically reset the

offending value to the nearest allowable value within the range.

d. User Modifiable: A check box to indicate whether users can change the default value

during a run.

Note: Not all variables that can be specified in a variant method are available for users

to modify during a method run.

Information regarding the variables that can be set for method types or specific methods,

and the impact of these settings, can be found in Technical Manuals specific to

preprocessing or post-processing methods.

i. Preprocessing Methods for the Maxprep™ Liquid Handler Technical Manual #TM529.

ii. QuantiFluor® Dye Quantitation Methods for the Maxprep™ Liquid Handler Technical

Manual #TM531.

iii. Amplification Setup Methods for the Maxprep™ Liquid Handler Technical Manual

#TM526.

iv. Normalization, Dilution and Transfer Methods for the Maxprep™ Liquid Handler

Technical Manual #TM530.

5. The administrator can modify any of the accessible variables to meet the needs of the

laboratory workflow.

37 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 40

Maxprep™ Software

4.3 Administrator Settings (continued)

6. Once all changes have been applied, touch the OK button to save the variant method. New

variant methods will be added to the list of variant methods in the folder (Figure 17).

15317TA

Figure 17. Appearance of variant methods. Administrator ‘Methods’ screen showing an

expanded method folder with a variant method.

In the list of methods, variant methods have the following information present:

Mark this method as a favorite so it is always sorted to the top of the

variant methods list.

Name

Description

The name of the method

A description of the method

Icon for creation of a new variant method based on the values set for

the specified variant method. Saves the resulting variant method as a

new entry.

Icon that allows editing of the values in an existing variant method.

Replaces the existing variant method with the newly entered values.

Icon for deletion of a variant method.

Once variant methods have been created by the administrator, they will be available for users to

run on the system (see Section 5.3, Starting a Method).

38 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 41

Deleting Methods

Maxprep™ Software

Note: When

deleting a default

method from

the Maxprep™

software, a

warning will be

displayed to

confirm that you

wish to delete the

default method

and all variants of

that method.

To delete a method or variant method from the Maxprep™ software, press the X on the right

side of the method list entry to delete it. A ‘Warning’ screen will be shown asking whether the file

should be permanently deleted. Select Delete to permanently remove the file from the

Maxprep™ software or Cancel to return to the ‘Methods’ screen without deleting the method.

Labware

View the labware currently installed in the Maxprep™ software on the ‘Labware’ screen

(Figure 16) by touching the Labware button from the ‘Administrator’ screen (Figure 13).

Figure 18. ‘Labware’ screen. This screen displays a list of the labware installed in the

Maxprep™ software.

For each labware listed on the “Labware’ screen (Figure 16), the following are displayed:

Name

Description

Type

The name of the labware

Description of the labware

The type of labware (Plate, Tube, Maxwell® RSC deck tray, Maxwell® RSC 48 deck tray)

Icon for deletion of a labware

39 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 42

Maxprep™ Software

4.3 Administrator Settings (continued)

Importing Labware

Only Administrators can import new labware into the Maxprep™ software. Administrators can

request new labware from Promega Technical Services (techserv@promega.com). Labware

definitions are provided in files with a .labware extension. Follow the instructions below to import

a labware import file into the Maxprep™ software.

1. Save the labware (.labware) file on the PC attached to the Maxprep™ Liquid Handler.

2. If not already running, start the Maxprep™ software by double-clicking the software icon on

the desktop.

3. Navigate to the ‘Labware’ screen (‘Home’ -> ‘Settings’ -> ‘Administrator’ -> ‘Labware’)

4. Press the Import... button on the top left side of the screen to open the ‘Labware Import’

file browser screen (Figure 19).

Figure 19. Labware import file selection. Use the ‘Labware Import’ file browser to navigate

to the location of a labware (.labware) file. Valid import files are shown on the right side of the

file browser as blue rectangles (yellow when selected).

40 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 43

Maxprep™ Software

5. Within the ‘Labware Import’ file selection screen, navigate to the location at which you

saved the labware (.labware) file. The current path will be shown in yellow boxes along the

top of the window. Select any aspect of the path to navigate to the desired folder. Press the

Drive\ button to select the drive in which to search. Folders within the current path are

shown as red rectangles on the left side of the screen. Valid labware (.labware) files will be

shown as blue rectangles (yellow when selected) on the right side of the screen.

6. Select the blue rectangle(s) corresponding to the desired (.labware) file(s) to highlight, and

then press the OK button to import the selected labware.

Note: When importing the same or a new version of an existing labware, the imported

labware will overwrite the existing labware. During import a warning is displayed, indicating

that the existing labware will be deleted. The warning will ask whether you wish to proceed

with import; press Yes to delete the existing labware or No to cancel the import.

7. A ‘Labware Import’ selection screen is displayed (Figure 20) that enables the administrator

to determine which labware will be imported from the selected (.labware) file. This screen

displays the name of each labware type present in the (.labware) import file and check

boxes for whether the labware will be imported, the RCK file will be overwritten, and the

CTR file will be overwritten. If any labware within the file already exists in the Maxprep™

software, a red triangle with a white exclamation point is displayed to the left of the labware

type. When importing labware, unless instructed otherwise, it is recommended to leave the

check boxes for Import, RCK file and CTR file checked. To complete labware import press

the OK button, or to cancel import press the Cancel button.

Note: Separate instructions will be sent with the labware import file that describe how to

use the Maxprep™ Labware Management utility to determine the methods for which the

new labware will be available.

41 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 44

Maxprep™ Software

4.3 Administrator Settings (continued)

Figure 20. ‘Labware Import’ Selection Screen. Use the check boxes on this screen to

determine which items will be imported and which labware files will be overwritten on import.

A red triangle with white exclamation point indicates that the specified labware already

exists in the Maxprep™ software.

Deleting Labware

To delete a labware from the Maxprep™ software, press the X on the right side of the labware

list entry. A ‘Warning’ screen will be shown asking whether the labware should be permanently

deleted. Select Delete to permanently remove the labware from the Maxprep™ software or

Cancel to return to the ‘Labware’ screen without deleting the labware.

Manage Kits

The ‘Manage Kits’ screen provides a forward-looking functionality for managing kit files that

work in concert with future Maxprep™ methods. Currently no methods exist that use this

functionality. When implemented, instructions will be provided for managing kits.

42 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 45

Maxprep™ Software

Preferences

Administrators can view additional preferences available in the Maxprep™ software by pressing

the Preferences button on the ‘Administrator’ screen. The ‘Preferences’ screen displays a set

of four tabs that can be used by the administrator to adapt the functionality of the software to

the needs of the laboratory. Below are descriptions of the options that can be set on each of

these tabs.

‘Common Settings’ Tab

The ‘Common Settings’ tab on the ‘Preferences’ screen (Figure 21) provides administrators the

ability to specify the following options:

• Allow expired Maxwell kits: Checking this box allows users to run methods with kits that

have passed their expiration date. When this box is unchecked the software will not allow

expired kits to be used for any preprocessing runs.

• Require Maxwell Kit Lot Number: Checking this box will require users to enter a valid

Maxwell kit lot number for each preprocessing method.

• Allow deletion of results: When checked, this box will allow administrators to delete

extraction report files from the local database of run reports.

• Save aborted runs: When this box is checked, the software will save local run reports for

aborted runs of all instrument functions regardless of why they were aborted. If left

unchecked, any instrument functions that have been aborted will not generate a local run

report

• Export to PDF: Checking this box will create a PDF version of exported results in addition

to the tab-delimited text file version of the results.

• Export to Excel®: Checking this box will create an Excel® version of exported results in

addition to the tab-delimited text file version of the results.

• Auto Export: Report files can be automatically exported to an administrator-defined location

at the end of each method. Check the Auto Export box to enable this function, and then

select the text box below this option to specify the path to which exported results files

should be saved. An ‘Export Folder’ screen will open with the current path specified in

yellow rectangles. Select any aspect of the path to navigate to the desired folder. Press the

Drive\ button to select the drive in which to search. Folders within the current path will be

shown as red rectangles in the main area of the screen. Results will be exported as tabdelimited text files. If the options for Export to PDF or Export to Excel® have been enabled,

reports will also be exported in the selected format(s) to the specified drive location.

• Sanitize: Checking this box will display the UV Sanitization method in the list of

maintenance methods and allow the administrator to specify the time period for UV

sanitization when running the Sanitization maintenance method. After checking the box,

select the text box to specify the sanitization time (in minutes).

• Enforce Maintenance: Checking this box will require that users perform Daily or Weekly

maintenance before being able to run any methods on the Maxprep™ instrument.

43 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 46

Maxprep™ Software

4.3 Administrator Settings (continued)

A prompt to save or discard changes made to the preferences is displayed when you navigate

away from the ‘Preferences’ screen.

A

Figure 21 ‘Common Settings’ tab on the ‘Preferences’ screen. From the ‘Common

Settings’ tab the administrator can allow use of expired kits, require entry of Maxwell® kit lot

information, allow deletion of results, specify whether reports from aborted runs should be

saved, specify the file format(s) for exported reports, specify whether and to where reports

will be automatically exported after a run, and set the visibility and sanitization duration

(optional, if UV light is installed) for the Sanitize maintenance method.

44 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 47

Maxprep™ Software

‘Alarm Settings’ Tab

The ‘Alarm Settings’ tab on the ‘Preferences’ screen (Figure 22) provides administrators the

ability to specify whether the software will provide audible alarms for completed method runs

and error states. Available options are:

• Play sound when extraction is completed: Check this box to have the PC generate a

sound when a method run is completed.

• Play sound on error: Check this box to have the PC generate a sound if an error occurs

during a method run on the instrument.

A prompt to save or discard changes made to preferences is displayed when you navigate away

from the ‘Preferences’ screen.

A

Figure 22. ‘Alarm Settings’ tab on the ‘Preferences’ screen. From the ‘Alarm Settings’ tab

the administrator can specify whether audible alarms should be played on completion of a

method run or on error during a method run.

45 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 48

Maxprep™ Software

4.3 Administrator Settings (continued)

‘E-mail Settings’ tab

The ‘E-mail Settings’ tab on the ‘Preferences’ screen (Figure 23) is where e-mail server details

are specified and administrators can determine when and to whom e-mail notifications will be

sent. It is necessary to fill out the user and server information on the ‘E-mail Settings’ tab in

order to use e-mail notifications. Required e-mail server information on the left side of the screen

includes:

• Username: The name of the user for the e-mail account that will send e-mail notifications.

• E-mail: The e-mail account that will send e-mail notifications.

Note: Contact

your IT

department

to provide the

information

required to

complete e-mail

settings.

• Password: The password for the e-mail account that will send e-mail notifications.

• SMTP Server: The SMTP server address for the e-mail account.

• Port: The port that should be used for the SMTP server.

• SSL Encrypted Connection: Check box indicating whether the e-mail account uses an

SSL Encrypted connection.

On the right side of the screen, the administrator can specify under what conditions and to

whom e-mail notifications will be sent. Options include:

• Send mail when method is completed: Check this box to have e-mails automatically sent

to the specified e-mail addresses when a method run has been completed.

• Send mail on error: Check this box to have e-mails automatically sent to the specified

e-mail addresses if an error state occurs during a method run.

• E-mail Recipients: Enter the e-mail address(es) separated by a space that will act as the

distribution list for e-mail notifications under the conditions that have been selected.

Upon completing the entries for e-mail settings you can test the validity of the settings by

pressing the Test Connection button. Pressing this button will attempt to send a test e-mail to

the e-mail account and e-mail recipients designated by the settings on this tab.

A prompt to save or discard changes made to preferences is displayed when you navigate away

from the ‘Preferences’ screen.

46 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 49

Maxprep™ Software

14653TA

Figure 23. ‘E-mail Settings’ tab on the ‘Preferences’ screen. From the ‘E-mail Settings’

tab the administrator can specify e-mail server settings, under what conditions e-mail

notifications should be sent, and the distribution list to which e-mails should be sent. Use

the Test Connection button to check the settings entered on this screen.

47 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 50

Maxprep™ Software

14654TA

4.3 Administrator Settings (continued)

‘Portal’ tab

The ‘Portal’ tab (Figure 24) presents settings for use of the Portal software to connect multiple

instrument modules for the purposes of sample tracking and data sharing. Information on this

tab will determine whether your system communicates with the Portal software and define the

server information necessary to connect to the Portal software.

Figure 24. ‘Portal’ tab on the ‘Preferences’ screen. The information entered on the ‘Portal’

tab determines whether Portal Sample Tracking is enabled on your system and allows entry

of the communications settings necessary to connect to the Portal software.

If you wish to share sample tracking and other method-specific data between multiple

modules, check the Enable Portal Sample Tracking check box on this tab. By default the Portal

software is installed on the PC connected to the Maxprep™ Liquid Handler (Cat.# AS9100,

AS9101, AS9200, AS9201). During installation of the Maxprep™ Liquid Hander the connection

information for the Portal software will be configured. In order for your system to communicate

with the Portal software, the following information is required:

• Server Name: Name of the server hosting the Portal software [Default = Maxprep-HP\

PromegaPortal]

• Database: Name of the SQL database containing Portal information [Default = Portal]

• Username: User name necessary to access the Portal software [Default = PortalLogin]

• Password: Password necessary to access the Portal software [Default = PortalLogin]

• Use Windows Authentication: Checkbox to indicate whether Windows authentication

should be used when accessing the Portal Software [Default = Unchecked]

48 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 51

Maxprep™ Software

Once the Portal software information has been entered, press the Test Connection button

to determine whether the Maxprep™ software can successfully connect to Portal using

the information supplied. A message is displayed, indicating whether the connection was

successful. If unsuccessful, confirm that the connection information was correctly entered and

try again.

If communication to Portal is lost at any time during a method run, the resulting data will be

queued up for export to Portal when communication is re-established. If there are continuing

problems with export of a data set to Portal, press the Clear Pending Export button to clear

the data from the export process. This may help resolve persistent communication problems

with Portal that are caused by issues with the data. Data that has been cleared from export will

not be sent to the Portal software and will only exist in local reports.

A prompt to save or discard changes made to preferences is displayed when you navigate away

from the ‘Preferences’ screen.

Instrument Name

It is possible to define a unique identifying name for the Maxprep™ Liquid Handler. This name is

shown on the title bar of the Maxprep™ software ‘Home’ screen and is recorded in method run

reports.

1. From the ‘Administrator’ screen press the Instrument Name button to open the

‘Instrument Name’ screen.

2. On the ‘Instrument Name’ screen select the text box and enter the desired name for this

instrument (Figure 25). The instrument name should be entered following the procedures

and rules at your site.

3. Press the OK button to save the instrument name you have entered. An informational

message is displayed, indicating that the name of the instrument has been successfully

changed.

49 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 52

Maxprep™ Software

14650T

4.3 Administrator Settings (continued)

4. If you do not wish to save any changes to the instrument name, press the Cancel button to

return to the ‘Administrator’ screen.

A

Figure 25. ‘Instrument Name’ screen. Use this screen to enter a name for this Maxprep™

Liquid Handler.

Audit Records

The Maxprep™ software contains a user-readable audit trail of all functions that have been

performed in the Maxprep™ software. Administrators have access to view and export the audit

records from the instrument through the Audit Records button on the ‘Administrator’ screen.

The ‘Audit Records’ screen displays a listing of all of the functions that have been performed

on the instrument (Figure 26). You can filter the audit records by pressing the buttons on the left

side to view records for functions performed today, this week, this month, the past 6 months,

this year or all functions performed over the life of the instrument. Press the column headers to

sort the records based on column contents. Press the desired row to see the audit message

from that particular record. Administrators can export all audit records for the selected date

range by pressing the Export button at the bottom left corner of the screen. The administrator is

required to specify a location to which the exported information should be saved.

1. Press the Export button on the ‘Audit Records’ screen.

2. Using the Yellow and Red rectangle buttons you can select the folder location (Figure 27)

where the method run reports will be saved.

The current path is indicated by the yellow rectangles at the top of the ‘Export Folder’

screen. Any folders present within the selected directory are displayed as red rectangles in

the white portion of the screen. Press the Drive\ button to navigate to the drive location of

the desired folder. Select red folder buttons to navigate to the specified folder location.

50 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 53

Maxprep™ Software

3. Once the desired file path has been specified, press the OK button to export audit records

or press the Cancel button to cancel any changes. After pressing either OK or Cancel you

will be returned to the ‘Administrator’ screen.

Figure 26. ‘Audit Records’ screen. A user-readable record of events that have occurred in

the Maxprep™ software can be viewed by the administrator and exported to a specified

drive location from the ‘Audit Records’ screen.

Figure 27. ‘Export Folder’ screen. From the ‘Export Folder’ screen you can set the folder

location to which all displayed audit records will be exported.

51 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 54

Maxprep™ Software

Notes

52 Maxprep™ Liquid Handler | TM509 | Revised 1/19

Page 55

Operating the Maxprep™ Liquid Handler

5.1 Maintenance

Maintenance is critical to ensuring performance of the Maxprep™ Liquid Handler over the life of

the instrument. Press the Maintenance button on the ‘Home’ screen (Figure 28) of the

Maxprep™ software to access the ‘Maintenance’ screen (Figure 29). Listed on the

‘Maintenance’ screen are methods designed to ensure your instrument is in working order. The