USER GUIDE

BENCH // PB-410 SERIES

Review 09/19

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

CONTENTS

01 INTRODUCTION

01.1 Using this manual 05

01.2 Technical data sheet 06

02 INSTALLATION

02.1 Transport and unpacking 11

02.2 Anchorage points 12

03 OPERATION

03.1 Commands 15

03.2 Elements of the manual system 19

03.3 Loading and unloading operation 21

03.4 Scoop stretcher fastening 22

03.5 Tensors 23

03.6 Loading angle setting 24

04 MOUNTING AND COMPONENTS

04.1 Main exploded view SERIE PB-410 25

04.2 Top platform exploded view PB-410 • PB-410/3 26

04.3 Top platform bill of materials PB-410 • PB-410/3 27

04.4 Top platform exploded view PB-410/4 28

04.5 Top platform bill of materials PB-410/4 29

04.6 Top platform exploded view PB-410/5 30

04.7 Top platform bill of materials PB-410/5 31

04.8 Base platform exploded view SERIE PB-410 32

04.9 Base platform bill of materials SERIE PB-410 33

04.10 Base platform mounting plates exploded view SERIE PB-410 34

04.11 Base platform mounting plates bill of materials SERIE PB-410 35

04.12 Base platform exploded view PB-410 • PB-410/4 • PB-410/5 36

04.13 Base platform bill of materials PB-410 • PB-410/4 • PB-410/5 37

04.14 Base platform exploded view PB-410/3 38

04.15 Base platform bill of materials PB-410/3 39

05 GENERAL MAINTENANCE 40

06 LEGAL NOTICES 41

07 PRODUCT WARRANTY 42

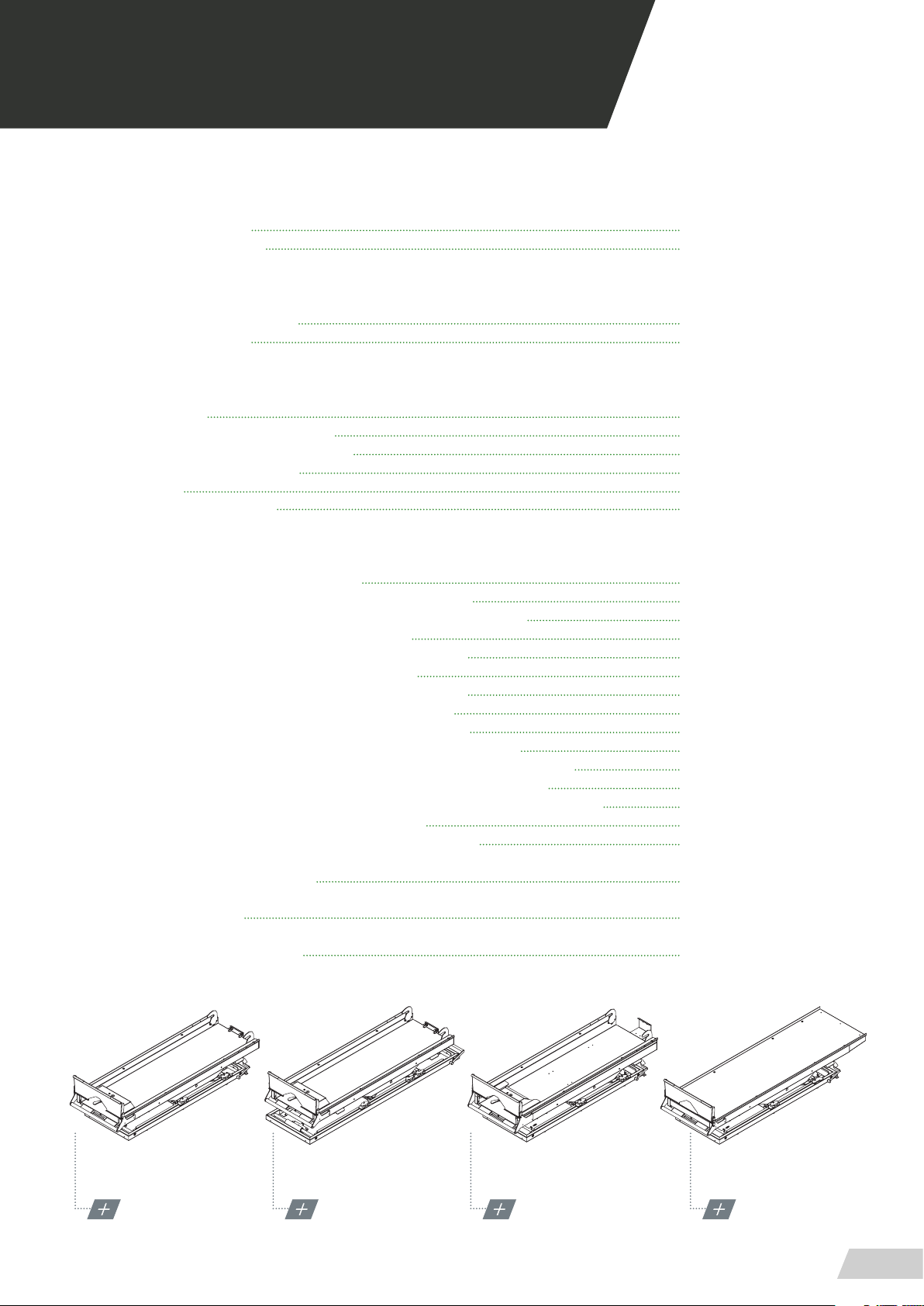

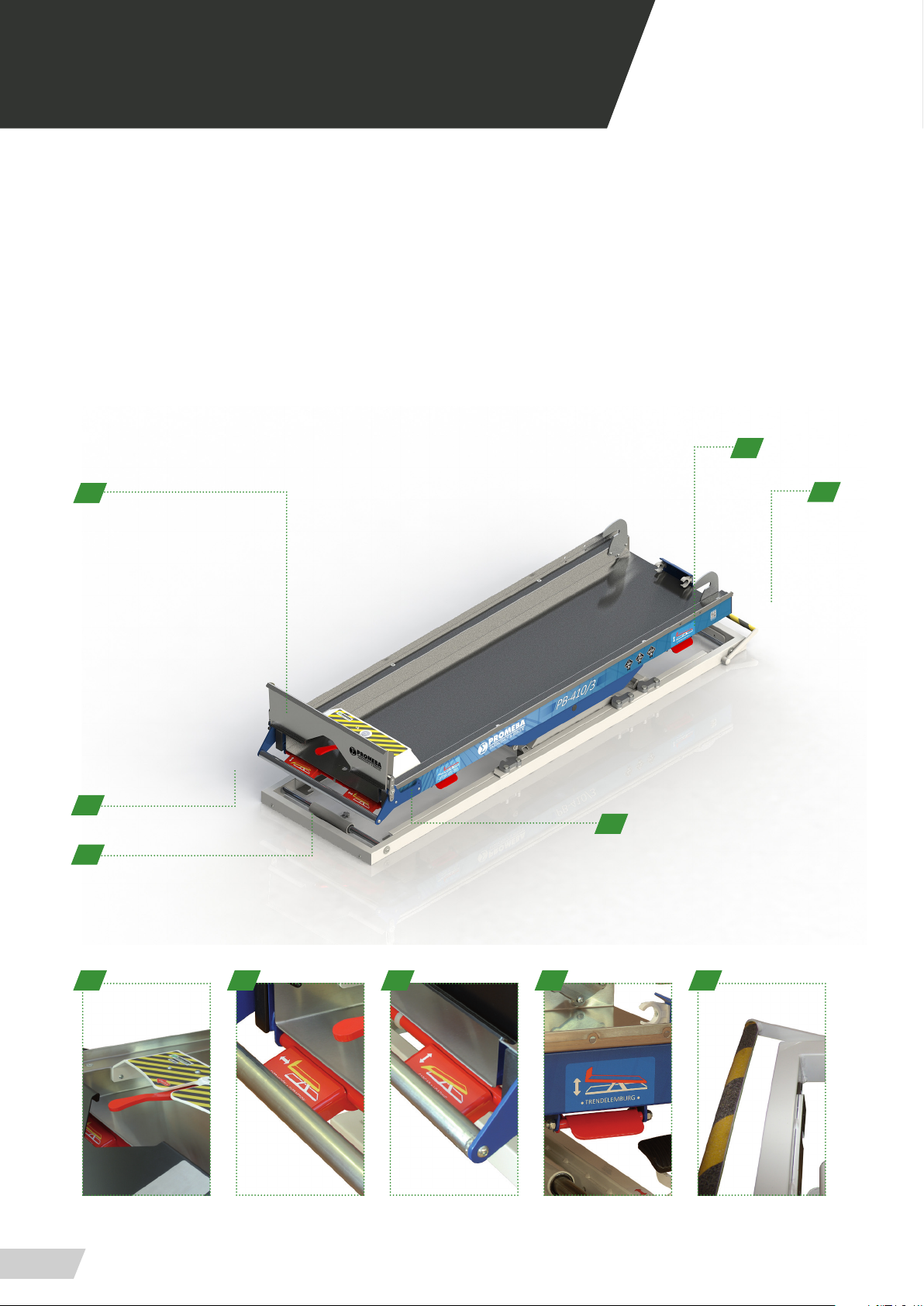

MODEL PB410

WITH CAVITY

FOR SCOOP STRETCHER

MODEL PB410/3

WITH LONGITUDINAL

SLIDING PLATFORM

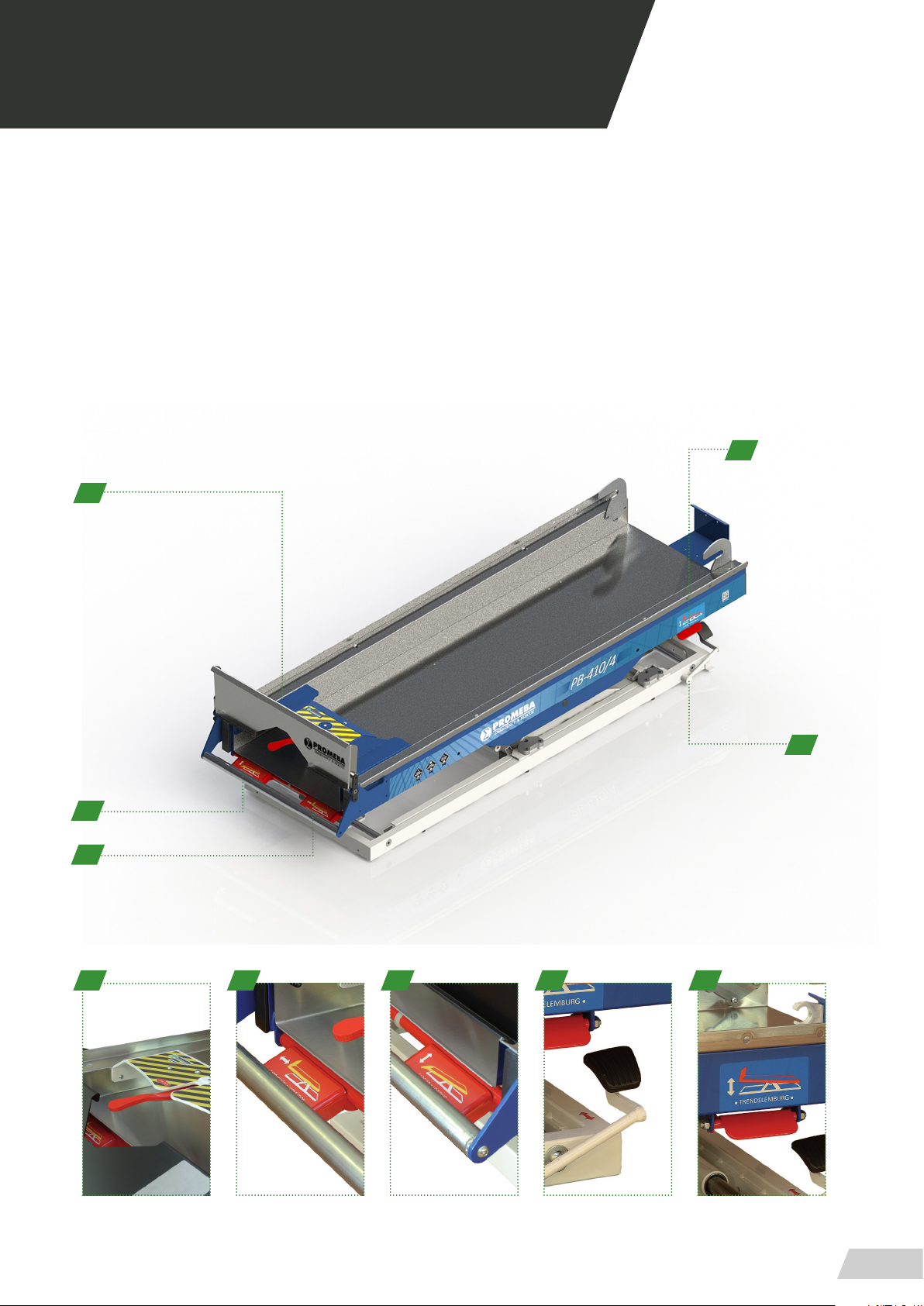

MODEL PB410/4

CAVITY FOR SCOOP STRETCHER

AND SPINE BOARD

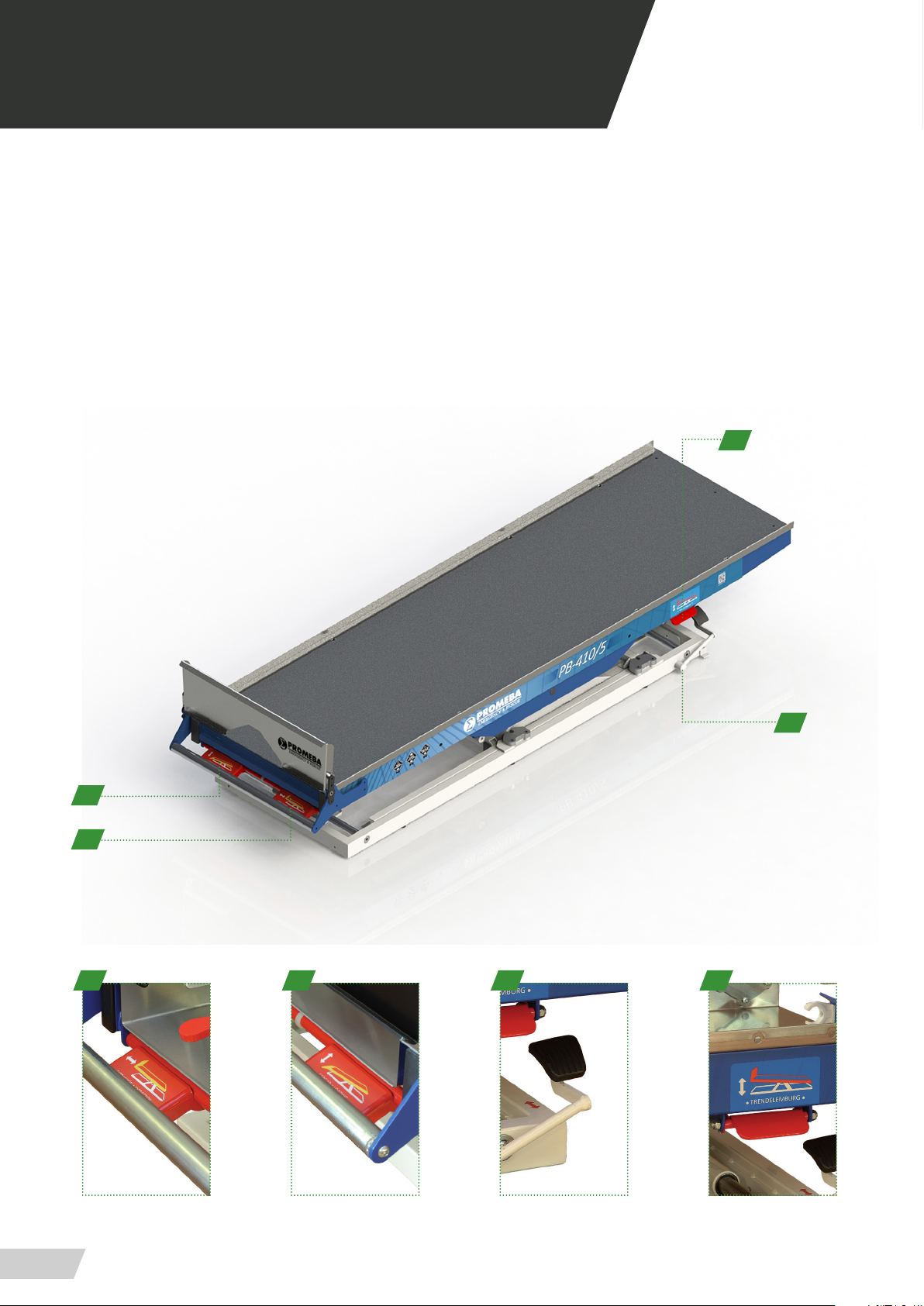

MODEL PB410/5

WITH FLAT UPPER TRAY

3

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

01 INTRODUCTION

01.1 Using this manual

This manual provides using and maintenance instructions of the product, as well as the way of xing minor

faults that could appear.

It is recommended before the operation of the product

to read carefully this manual in order to avoid damages

caused by a misuse.

Do not lose this document, it should be accessible to

any doubt that could appear by medical personnel.

Remember that a good use and maintenance are necessary for the proper operation of the product.

Each product incorporates an identication sticker with

the serial number and the model. Keep these numbers

so that they can be indicated to the dealer if necessary.

5

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

01 INTRODUCTION

01.2 Technical data sheet

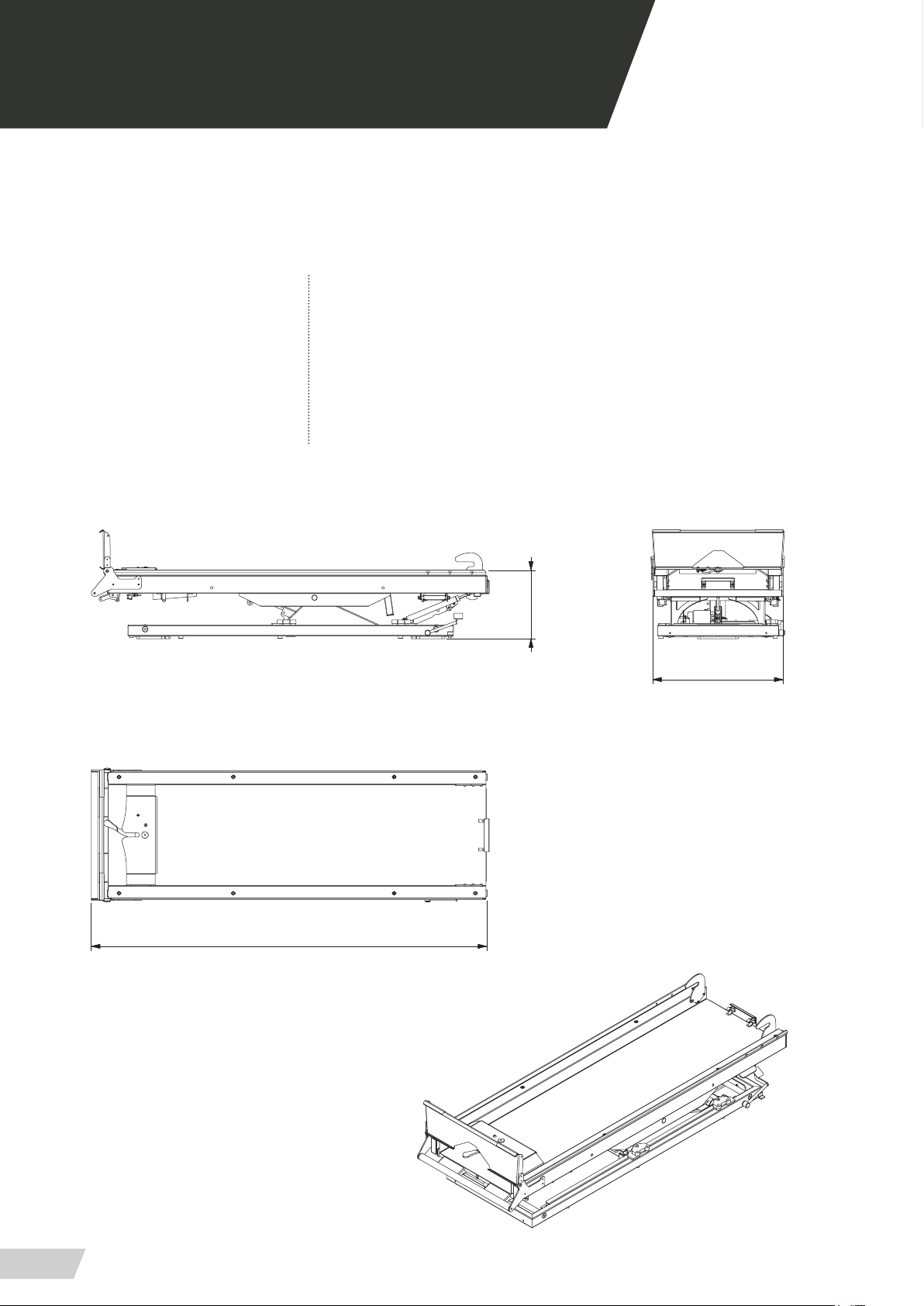

MEASURES AND FEATURES // PB 410

LENGHT 1800 mm TRENDELEMBURG -10º / +10º

WIDTH 595 mm HEIGHT LOADING ± 100 mm

HEIGHT 315 mm SIDE MOVEMENT 300 mm

WEIGHT 83 Kg MAX. LOAD 220 Kg

1800

315

595

6

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

01 INTRODUCTION

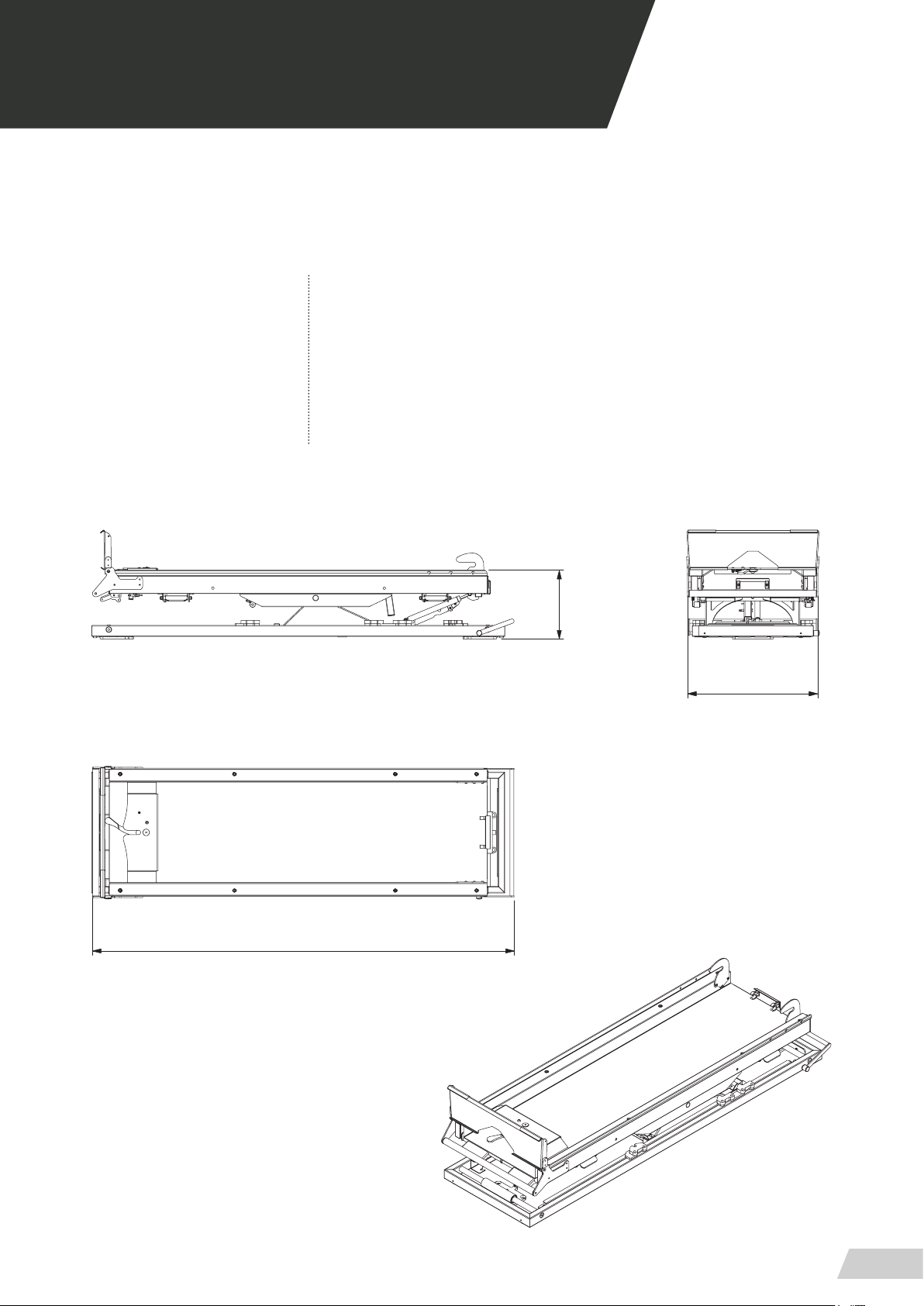

MEASURES AND FEATURES // PB 410/3

LENGHT 1925 mm TRENDELEMBURG -10º / +10º

WIDTH 595 mm HEIGHT LOADING ± 100 mm

HEIGHT 315 mm FRONT / SIDE MOVEMENT 300 mm / 360 mm

WEIGHT 85 Kg MAX. LOAD 220 Kg

1925

315

595

7

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

01 INTRODUCTION

MEASURES AND FEATURES // PB 410/4

LENGHT 1930 mm TRENDELEMBURG -10º / +10º

WIDTH 600 mm HEIGHT LOADING ± 100 mm

HEIGHT 345 mm SIDE MOVEMENT 300 mm

WEIGHT 83 Kg MAX. LOAD 240 Kg

1930

345

600

8

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

01 INTRODUCTION

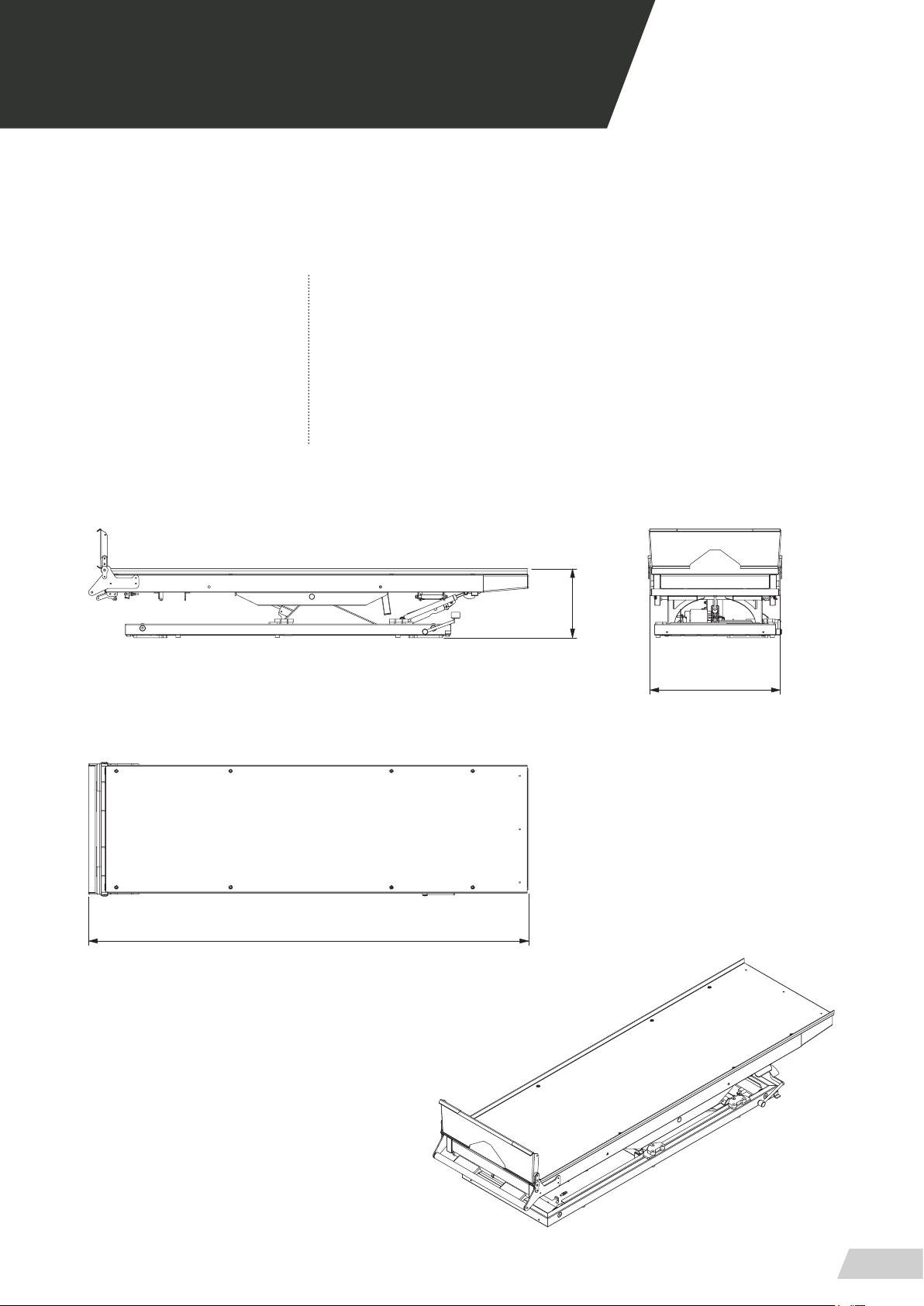

MEASURES AND FEATURES // PB 410/5

LENGHT 2000 mm TRENDELEMBURG -10º / +10º

WIDTH 595 mm HEIGHT LOADING ± 100 mm

HEIGHT 315 mm SIDE MOVEMENT 300 mm

WEIGHT 88 Kg MAX. LOAD 220 Kg

2000

315

595

9

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

02 INSTALLATION

02.1 Transport and unpacking

First carefully remove the packaging to prevent the damage of the outside of the stretcher support.

1. Transport with a crane (high load)

· Thread tapes through the upper platform for its transport (as shown in graphs)

· Transport the load level following all the precepts and

regulations for the transport of suspended loads.

2. Transport with a forklift

· Place a pallet or a at surface under the bench and

transport it transversely.

· Do not load the bench directly on the forklift without

a pallet or a at support surface.

· Do not load the bench longitudinally on the forklift if

a suciently long base is not available.

· Every bench has been thoroughly inspected leaving

the factory. To ensure that it hasn’t been damaged during the transport, it is requested to carefully examine

the interior and exterior, and in case of nding any damage, communicate immediately to the installer.

· The bench should be levelled for an optimum performance.

TRANSPORT WITH A CRANE

FIX THE TAPES TO LEVEL THE LOAD WEIGHT

TRANSPORT WITH A FORKLIFT

USE ALWAYS A FLAT SUPPORT SURFACE

11

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

02 INSTALLATION

02.2 Anchore points

Before putting the bench into operation, ensure that

each and every anchorage points are placed and

clasped.

ANCHORE FOR BENCH PB410

(8 anchorage points)

12,5

ANCHORE FOR BENCH PB410/3

(8 anchorage points)

102

1174

159

102

12,5

159

1574 102 102

12

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

02 INSTALLATION

ANCHORE FOR BENCH PB410/4

(8 anchorage points)

12,5

ANCHORE FOR BENCH PB410/5

(8 anchorage points)

102 1174

159

102

12,5

159

102

102 1174

13

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

03 OPERATION

03.1 Commands PB-410

1. Stretcher rear anchor closure

2. Extraction lever

3. Load lever

4. Lateral shift lever

5. Trendelemburg movement lever

1

5

2

3

1 2 3 4 5

4

15

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

03 OPERATION

03.1 Commands PB-410/3

1. Stretcher rear anchor closure

2. Extraction lever

3. Load lever

4. Trendelemburg movement lever

5. Lateral shift lever

6. Longitudinal shift lever

4

1

2

6

3

5

1 2 3 4 5

16

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

03 OPERATION

03.1 Commands PB-410/4

1. Stretcher rear anchor closure

2. Extraction lever

3. Load lever

4. Lateral shift lever

5. Trendelemburg movement lever

1

5

2

3

1 2 3 4 5

4

17

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

03 OPERATION

03.1 Commands PB-410/5

1. Extraction lever

2. Load lever

3. Lateral shift lever

4. Trendelemburg movement lever

4

1

2

1 2 3 4

3

18

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

03 OPERATION

03.2 Manual system elements

LATERAL SHIFT

Operate the lever located on the rear right side of the bench,

exerting a little eort on it with the foot accompanying this

movement with its slide with the hands.

The total lateral displacement is 300 mm.

LONGITUDINAL DISPLACEMENT PB-410/3 MODEL

Operate the lever located on the front right side of the

bench, exerting a little eort on it with the foot accompanying this movement with its slide with the hand.

The total longitudinal displacement is 360 mm.

300

360

19

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

03 OPERATION

03.2 Manual system elements

TRENDELEMBURG (Proclive / Declive)

The movement is produced while pressing the side lever,

when released it will lock the position.

· Trendelemburg proclive position(1):

In this position the bench lifts from the position in which the

patient’s head is located.

· Trendelemburg declive position (2):

In this position the bench lifts from the position in which the

patient’s feet are located.

ZERO POSITION OR REST POSITION

1

2

Zero position, also known as rest position is that the bench

is completely horizontal and folded upon itself.

20

0º

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

03 OPERATION

03.3 Loading and unloading

From the position in which the bench has remained after unloading (A):

LOADING

• Load the stretcher until it is locked by the closure (1)

• Fold the loading ramp (2)

• Pull the load lever (3)

• Pull the bench to zero position or rest position (B)

• Slide the tray until hearing ‘clack’, locking position completed (C)

• The scoop stretcher can be saved by xing it to the front hooks (4)

UNLOADING

• Extract the tray with the extraction lever (5)

• The tray will automatically tilt to load position (A)

• Open the loading ramp (2)

• Release the stretcher closure by operating the lever (1)

• The stretcher will slide outward, hold it with the hands (A)

• Extract the stretcher

EFFORT LOAD POSITION TO HORIZONTAL POSITION KG

· VACUUM BENCH 16

· BENCH + STRETCHER PC650 EMPTY 25

· BENCH + STRETCHER PC650 + DUMMY 80KG 21

A

1

2

3

B

C

4

5

21

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

03 OPERATION

03.4 Scoop stretcher fastening

FOR MODELS PB-410 • PB-410/3

FIXING

To place PC 335 and PC 337 scoop stretchers, slide the scoop

stretcher face down, between the stretcher anchor sheet

and the tray until it butts with clamp grippers. Once contact

is made, securely tighten it until it axed.

EXTRACTING

To extract the scoop stretcher, pull it hard until it is unlatched from the clamp grippers.

For your convenience, we recommend to take the stretcher

by the roller to use more force.

FOR MODELS PB-410/4

FIXING

To place PC 335 and PC 337 scoop stretchers, slide the scoop

stretcher face down, between the stretcher anchor sheet

and the tray until it butts with clamp grippers. Once contact

is made, securely tighten it until it axed.

EXTRACTING

To extract the scoop stretcher, pull it hard until it is unlatched from the clamp grippers.

For your convenience, we recommend to take the stretcher

by the roller to use more force.

22

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

03 OPERATION

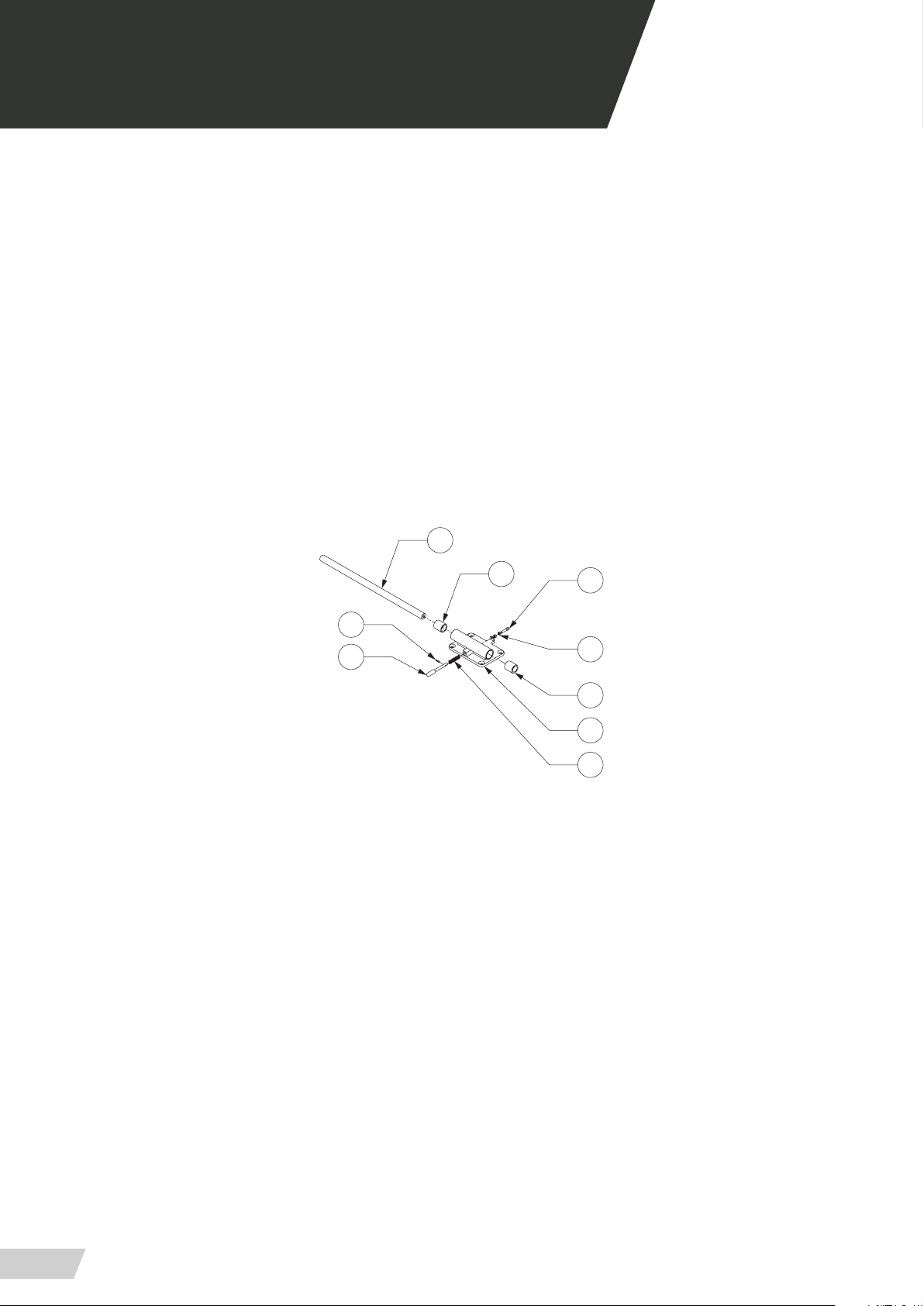

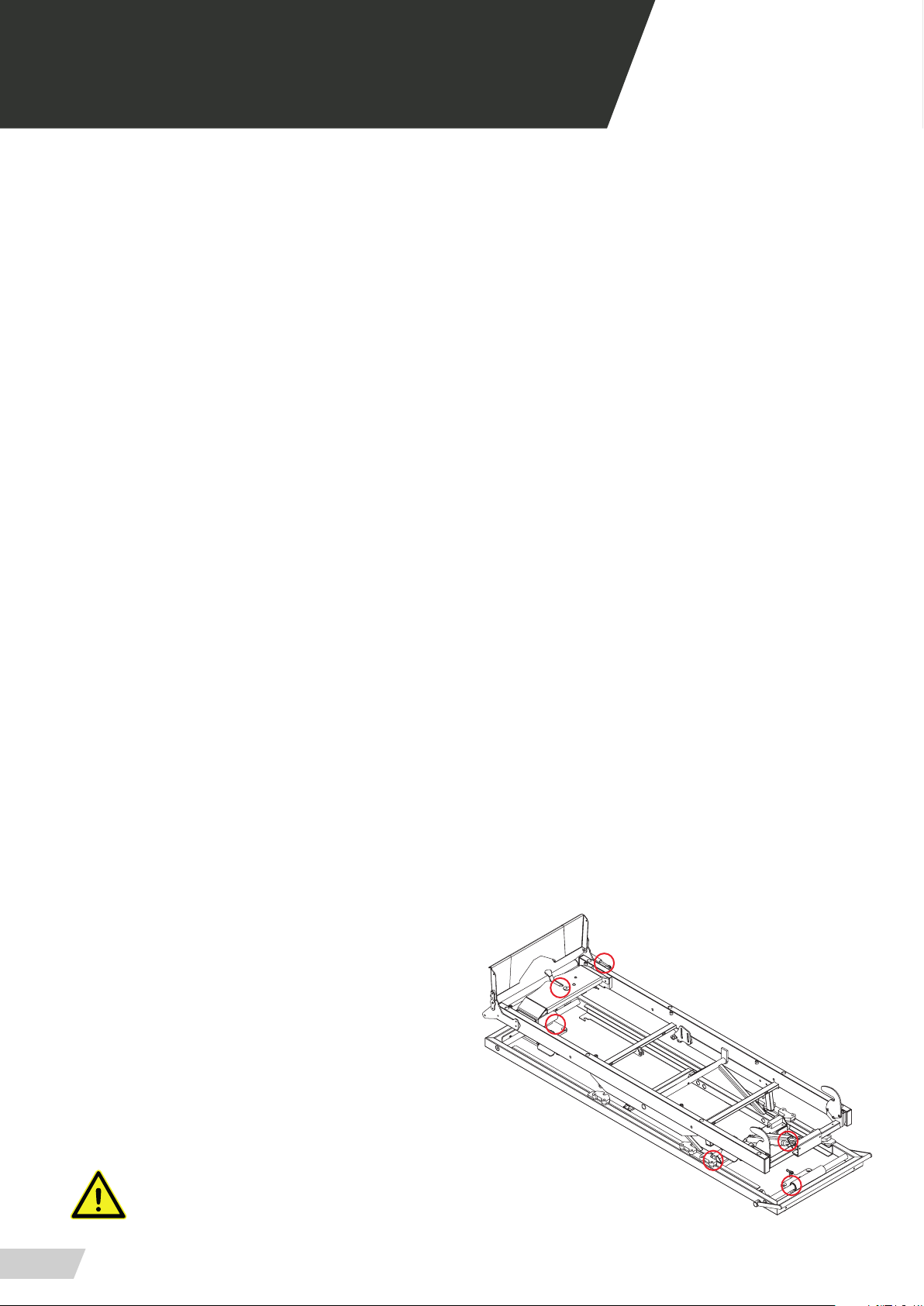

03.5 Tensors

To adjust tension in the drive cables, the bench has four sets

of tensors for its regulation (depending on model):

1. LATERAL SHIFT LEVER

Double set of tensors located on each of the attachment

plates on the oor.

1

2. FRONT LEVERS

Double set of tensors located on the front area of the

platform.

3. SIDE LEVERS

Simple tensor located on the right area of the upper

platform.

2

3

23

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

03 OPERATION

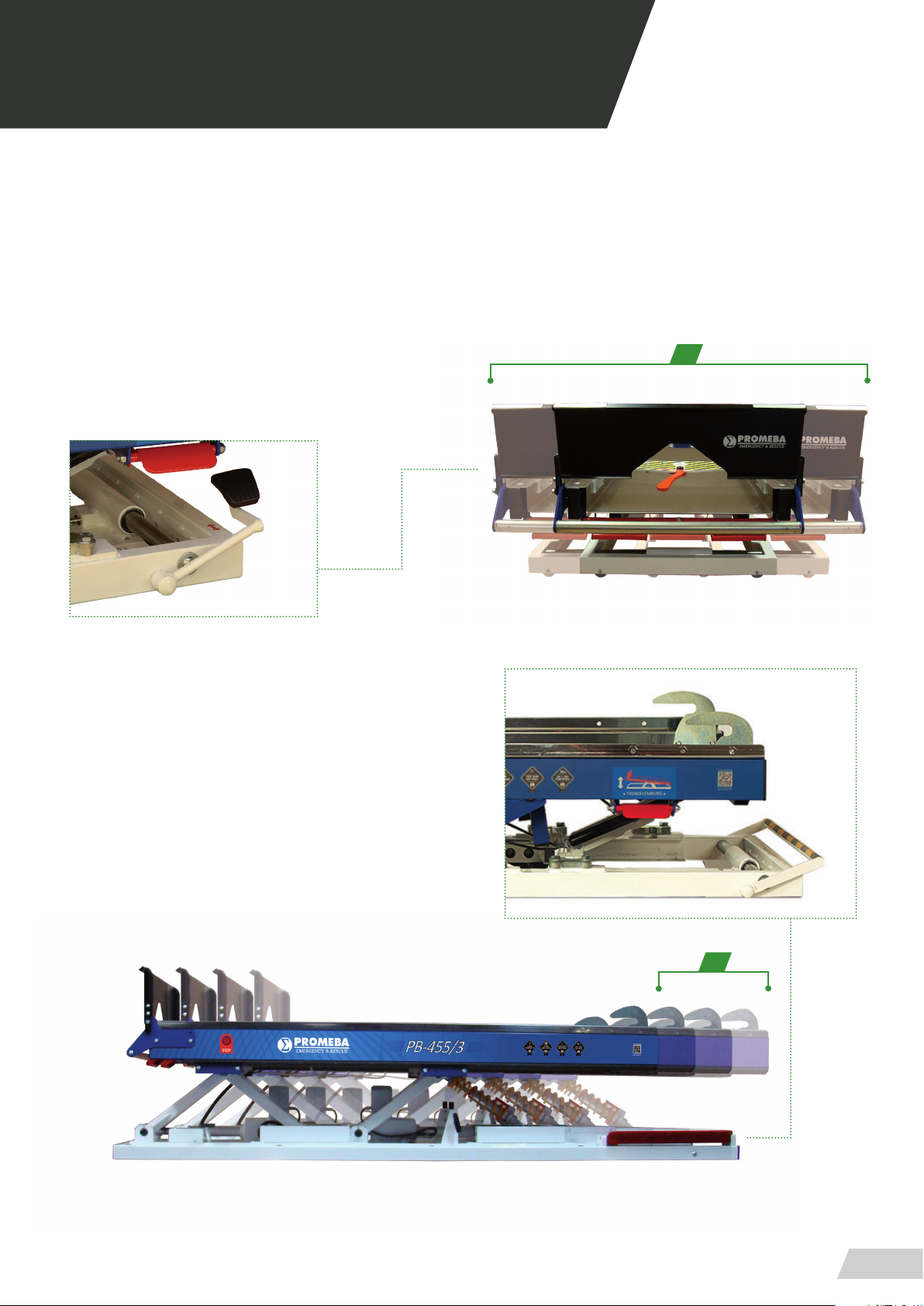

03.6 Loading angle setting

For having loading and downloading of the stretcher with

optimal conditions, it is very important to put the stretcher

support the most horizontal possible.

LOADING THE STRETCHER

Once you have installed denitely the support stretcher

into the ambulance, put the ramp open and adjust the

inclination of the strecther support with the front right

handle (CARGAR/LOADING).

The optimal position may be that the stretcher front wheels

attack rest on the roller ramp, that’s when the loading

process will be more soft and easy (see photo 1).

ADJUST THE LOADING ANGLE

After the rst step, you have to set the top tray as the photo

2 shown.

These parts keep the angle xed for the next operations.

You have to loosen the screws, put the white roller over the

support stretcher base (see photo 2) and tighten the screws

back (see photo 3).

1

2

You have to do this operation as many times as you need

according to the stretcher and/or the ambulance use.

OPTIMAL SETTINGS ARE ESSENTIALS FOR A SOFT AND EASY

LOADING

3

24

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

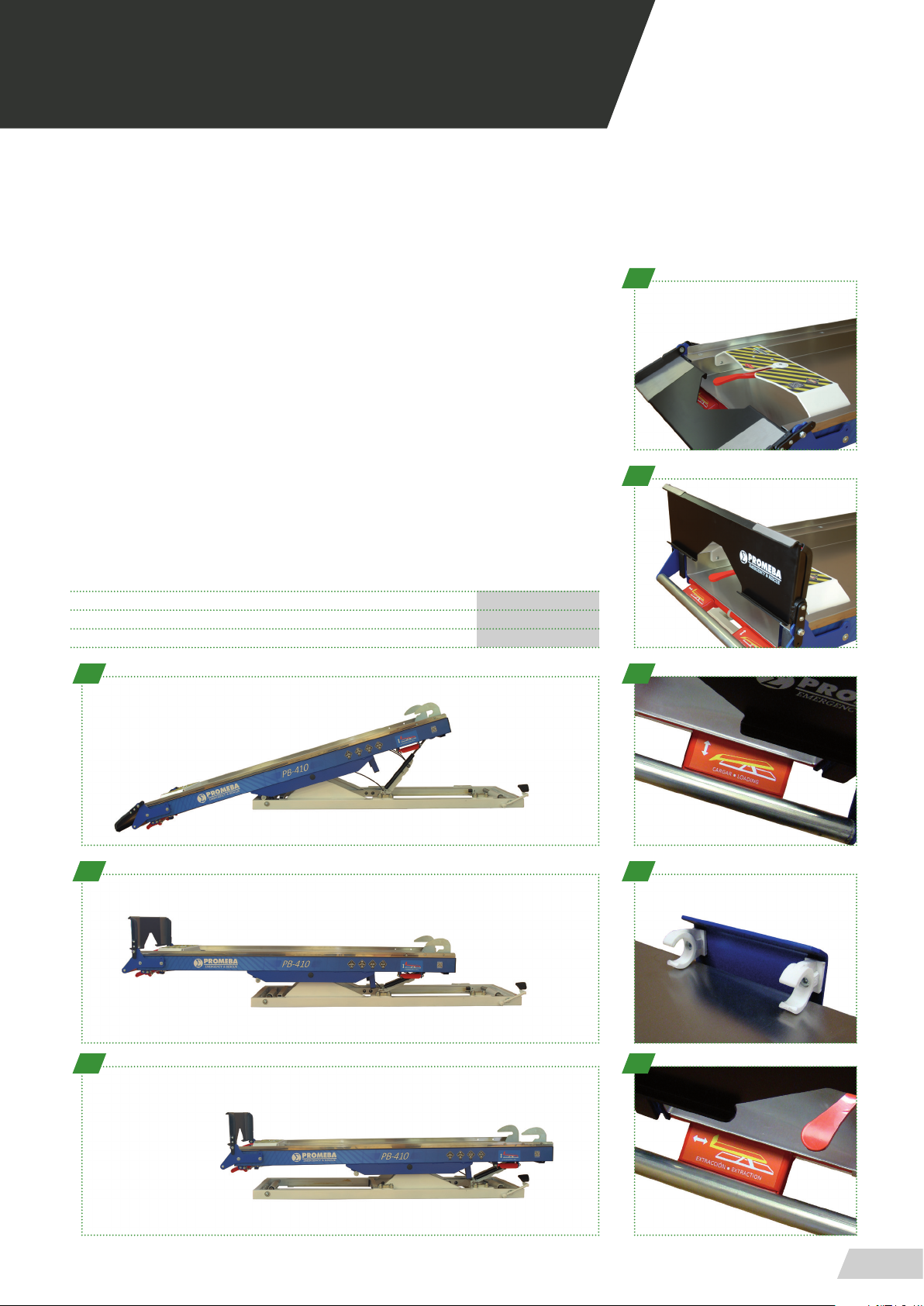

04 MOUNTING AND COMPONENTS

04.1 Main exploded views PB-410 SERIES

MODEL PB-410 • PB-410/3 (PAGE 26)

TOP PLATFORM

MODEL PB-410/4 (PAGE 28)

MODEL PB-410/5 (PAGE 30)

BASE PLATFORM

PB-410 SERIES (PAGE 32)

GUIDE BASE PLATFORM

MODEL PB-410 • PB-410/4 • PB-410/5 (PAGE 36)

MODEL PB-410/3 (PAGE 38)

BASE PLATFORM MOUNTING PLATES

PB-410 SERIES (PAGE 34)

25

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

04.2 Top platform exploded view PB-410 • PB-410/3

1.02

1.20

1.19

1.21

1.17

1.26

1.25

1.24

1.23

1.22

1.16

1.08

1.09

1.01

1.03

1.04

1.05

1.06

1.07

1.15

1.14

1.13

1.18

26

1.12

1.11

1.10

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

04.3 Bill of materials: TOP PLATFORM PB-410 • PB-410/3

ELEMENT CODE - DESCRIPTION UNITS

1.01 PB4100-04260 - BANDEJA ACERO INOXIDABLE 1

1.02 PB4100-04461 - TERCER PUNTO ANCLAJE DELANTERO 2

1.03 PB4100-04392 - TOPE CAMILLA PALAS 1

1.04 PB4100-04420 - BRIDA SUJECIÓN CAMILLA PALAS 2

1.05 PB4100-00361 - EJE GIRO MANETA LATERAL 2

1.06 PB4100-00302 - MANETA DESBLOQUEO LATERAL 2

1.07 PB4100-04012 - SUBCONJUNTO PLATAFORMA SUPERIOR 1

1.08 PB4100-04732 - PLETINA REGULACIÓN CARGA 2

1.09 PB4100-04740 - CASQUILLO REGULACIÓN PLATAFORMA 2

1.10 PB4106-00032 - SOPORTE LATERAL RAMPA 2

1.11 PB4200-03120 - SOPORTE AMORTIGUADOR RAMPA 1

1.12 PB4100-04402 - MANETA FRONTAL DERECHA 1

1.13 PB4100-04620 - CASQUILLO MANETAS DELANTERAS 1

1.14 PB4100-04161 - SUBCONJUNTO EJE GIRO MANETAS DELANTERAS 1

1.15 PB4100-04542 - MANETA FRONTAL IZQUIERDA 1

1.16 TAPPLA-30X20 - TAPON PLASTICO INTERIOR 30X20 4

1.17 PB4200-03172 - SUBCONJUNTO RAMPA CORTA 1

1.18 PB4100-04821 - SUBCONJUNTO RODILLO PB-410 1

1.19 PB4200-03112 - SUBCONJUNTO SOPORTE AMORTIGUADOR RAMPA 1

1.20 PB4200-03140 - AMORTIGUADOR RAMPA RAIL 1

1.21 TAPPLA-80X30 - TAPON PLASTICO INTERIOR 80X30 4

1.22 31204101 - ARANDELA FIJACIÓN CIERRE POSTERIOR 1

1.23 PB4100-04662 - PALANCA CIERRE POSTERIOR 1

1.24 PB4400-03130 - MUELLE PALANCA CIERRE POSTERIOR 1

1.25 105/4-CATUB - CASQUILLO TUBO CIERRE POSTERIOR 1

1.26 PB4100-04632 - SUBCONJUNTO CIERRE POSTERIOR 1

27

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

04.4 Top platform exploded view PB-410/4

2.27

2.26

2.25

2.24

2.23

2.02

2.01

2.19

2.18

2.17

2.20

2.03

2.22

2.21

2.04

2.05

2.06

2.15

2.07

2.16

2.08

2.14

2.13

2.12

2.11

2.10

2.09

28

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

04.5 Bill of materials: TOP PLATFORM PB-410/4

ELEMENT CODE - DESCRIPTION UNITS

2.01 PB4104-04260 - BANDEJA ACERO INOXIDABLE ALTA 1

2.02 PB4100-04461 - TERCER PUNTO ANCLAJE DELANTERO 2

2.03 PB4104-04082 - TOPE CAMILLA PALAS PB-410/4 1

2.04 PB4100-00361 - EJE GIRO MANETA LATERAL 1

2.05 PB4100-00302 - MANETA DESBLOQUEO LATERAL 1

2.06 PB4104-04012 - SUBCONJUNTO PLATAFORMA PB-410/4 1

2.07 PB4100-04732 - PLETINA REGULACIÓN CARGA 2

2.08 PB4100-04740 - CASQUILLO REGULACIÓN PLATAFORMA 2

2.09 PB4104-00032 - SOPORTE LATERAL RAMPA ALTA 2

2.10 PB4200-03120 - SOPORTE AMORTIGUADOR RAMPA 1

2.11 PB4100-04402 - MANETA FRONTAL DERECHA 1

2.12 PB4100-04620 - CASQUILLO MANETAS DELANTERAS 1

2.13 PB4100-04161 - SUBCONJUNTO EJE GIRO MANETAS DELANTERAS 1

2.14 PB4100-04542 - MANETA FRONTAL IZQUIERDA 1

2.15 TAPPLA-30X20 - TAPON PLASTICO INTERIOR 30X20 4

2.16 PB4200-03172 - SUBCONJUNTO RAMPA CORTA 1

2.17 PB4100-04821 - SUBCONJUNTO RODILLO PB-410 1

2.18 PB4200-03112 - SUBCONJUNTO SOPORTE AMORTIGUADOR RAMPA 1

2.19 PB4200-03140 - AMORTIGUADOR RAMPA RAIL 1

2.20 PB4550-01330 - TERMINALES CADENA GUIA CABLE ACTUADOR 2

2.20 TAPPLA-80X30 - TAPON PLASTICO INTERIOR 80X30 4

2.21 TAPPLA-80X30 - TAPON PLASTICO INTERIOR 30X30 4

2.22 PB4104-04032 - SUPLEMENTO PLATAFORMA PB-410/4 2

2.23 31204101 - ARANDELA FIJACIÓN CIERRE POSTERIOR 1

2.24 PB4100-04662 - PALANCA CIERRE POSTERIOR 1

2.25 PB4400-03130 - MUELLE PALANCA CIERRE POSTERIOR 1

2.26 105/4-CATUB - CASQUILLO TUBO CIERRE POSTERIOR 1

2.27 PB4104-04042 - SUBCONJUNTO CIERRE POSTERIOR PB-410/4 1

29

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

04.6 Top platform exploded view PB-410/5

3.01

3.18

3.17

3.20

3.19

3.06

3.02

3.07

3.03

3.04

3.05

3.08

3.09

3.10

3.11

3.16

3.12

3.15

3.14

3.13

30

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

04.7 Bill of materials: TOP PLATFORM PB-410/5

ELEMENT CODE - DESCRIPTION UNITS

3.01 PB4105-04260 - BANDEJA ACERO INOXIDABLE 1

3.02 PB4105-04092 - REFUERZO ANTERIOR SAFATA PLANA LARGA 1

3.03 PB4100-00302 - MANETA DESBLOQUEO LATERAL 1

3.04 PB4100-00361 - EJE GIRO MANETA LATERAL 1

3.05 TAP-PLATØ25 - TAPON PLASTICO FINAL Ø25 2

3.06 PB4105-04102 - SUBCONJUNTO REFUERZO PLATAFORMA PB-410/5 1

3.07 PB4100-04012 - SUBCONJUNTO PLATAFORMA 1

3.08 TAPPLA-30X20 - TAPON PLASTCO INTERIOR 30X20 4

3.09 105/4-CATUB - CASQUILLO TUBO Ø14X7 2

3.10 PB4106-00032 - SOPORTE RAMPA 2

3.11 PB4200-03120 - SOPORTE AMORTIGUADOR RAMPA 2

3.12 PB4100-04402 - MANETA FRONTAL DERECHA 1

3.13 PB4010-00151 - SUJETACABLES MANETAS FRONTALES 2

3.14 PB4100-04620 - CASQUILLO MANETAS DELANTERAS 1

3.15 PB4100-04161 - SUBCONJUNTO EJE GIRO MANETAS FRONTALES 1

3.16 PB4100-04542 - MANETA FRONTAL IZQUIERDA 1

3.17 PB4100-04821 - SUBCONJUNTO RODILLO PB-410 1

3.18 PB4200-03172 - SUBCONJUNTO RAMPA CORTA 1

3.19 PB4106-00012 - REFUERZO POSTERIOR BANDEJA PLANA CON RAMPA 1

3.20 TAPPLA-80X30 - TAPON PLASTICO INTERIOR 80X30 4

31

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

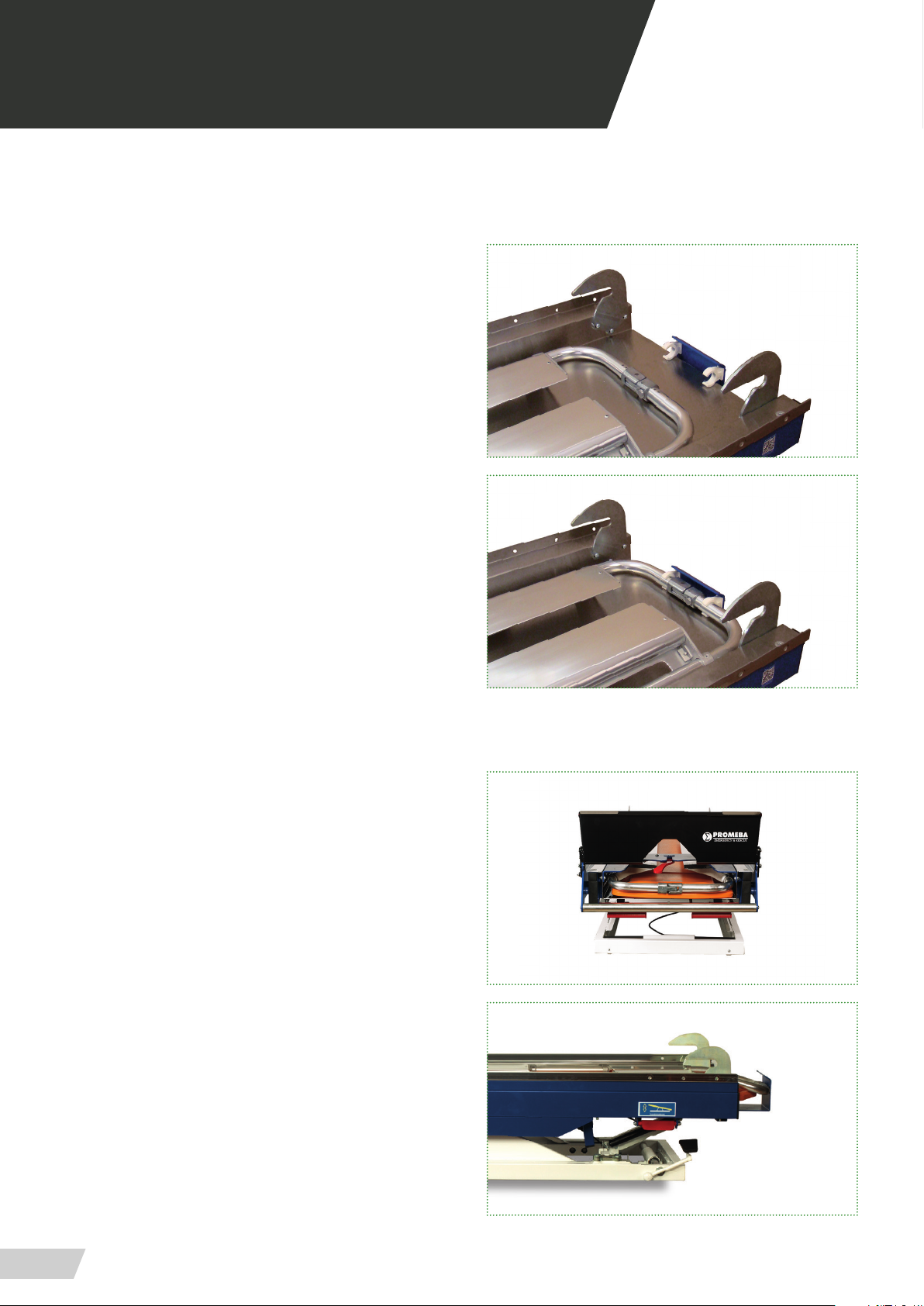

04 MOUNTING AND COMPONENTS

04.8 Base platform exploded view SERIE PB-410

4.03

4.07

4.01

4.16

4.14

4.10

4.02

4.04

4.05

4.08

4.09

4.13

4.12

4.06

4.11

4.15

32

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

04.9 Bill of materials: BASE PLATFORM SERIE PB-410

ELEMENT CODE - DESCRIPTION UNITS

4.01 PB4100-03012 - SUBCONJUNTO CARRO PLATAFORMA BASE 1

4.02 PB4100-00352 - SOPORTE MECLOCK CHAPA 1

4.03 PB4100-00270 - VÁSTAGO FIJADOR MECLOCK 1

4.04 PB4100-00341 - SOPORTE FIJADOR MECLOCK 1

4.05 PB4100-00401 - SUJECCIÓN INTERIOR AMORTIGUADOR 1

4.06 PB4100-00291 - VALDA FIJACIÓN CARRO 1

4.07 VAR DIAM20A482 - EJE VARILLA CALIBRADA 1

4.08 PB4100-00411 - SUJECIÓN SUPERIOR AMORTIGUADOR 1

4.09 PB4100-00380 - AMORTIGUADOR STABILUS 1

4.10 PB4100-03110 - RUEDA NYLON GUIAS CARRO 4

4.11 PB4100-03212 - SUBCONJUNTO SUFRIDERA CARRO 2

4.12 PB4100-01020 - MUELLE COMPRESIÓN 1

4.13 PB4100-00391 - EJE GIRO SOPORTE FIJADOR 2

4.14 CAPAP2030P10 - CASQUILLO TEFLÓN REF-PAP 20X30 P10 4

4.15 PB4100-03230 - CASQUILLO TEFLON 18X25 P10 2

4.16 TAPPLA-40X30 - TAPON PLÁSTICO INTERIOR 40X30 2

33

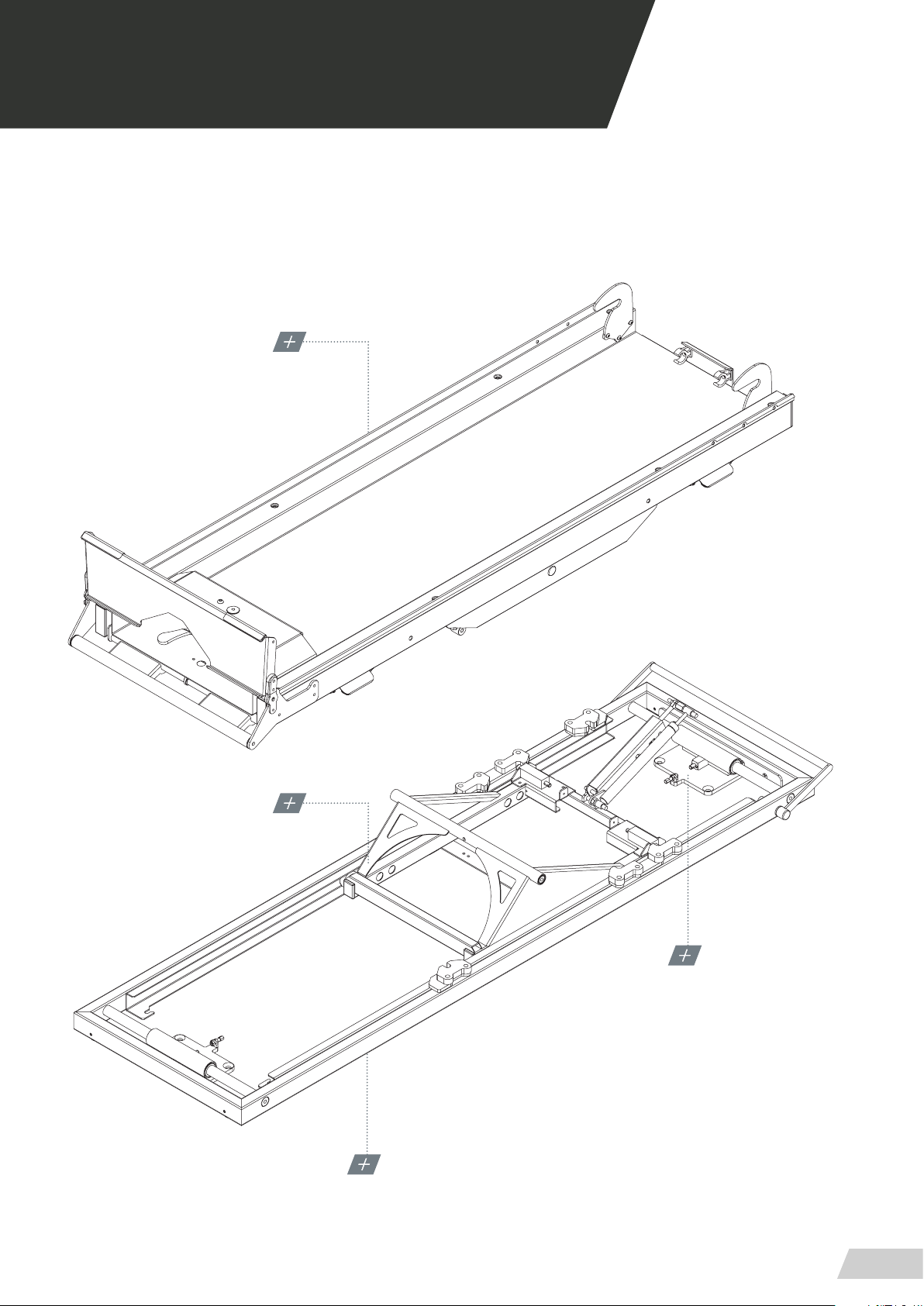

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

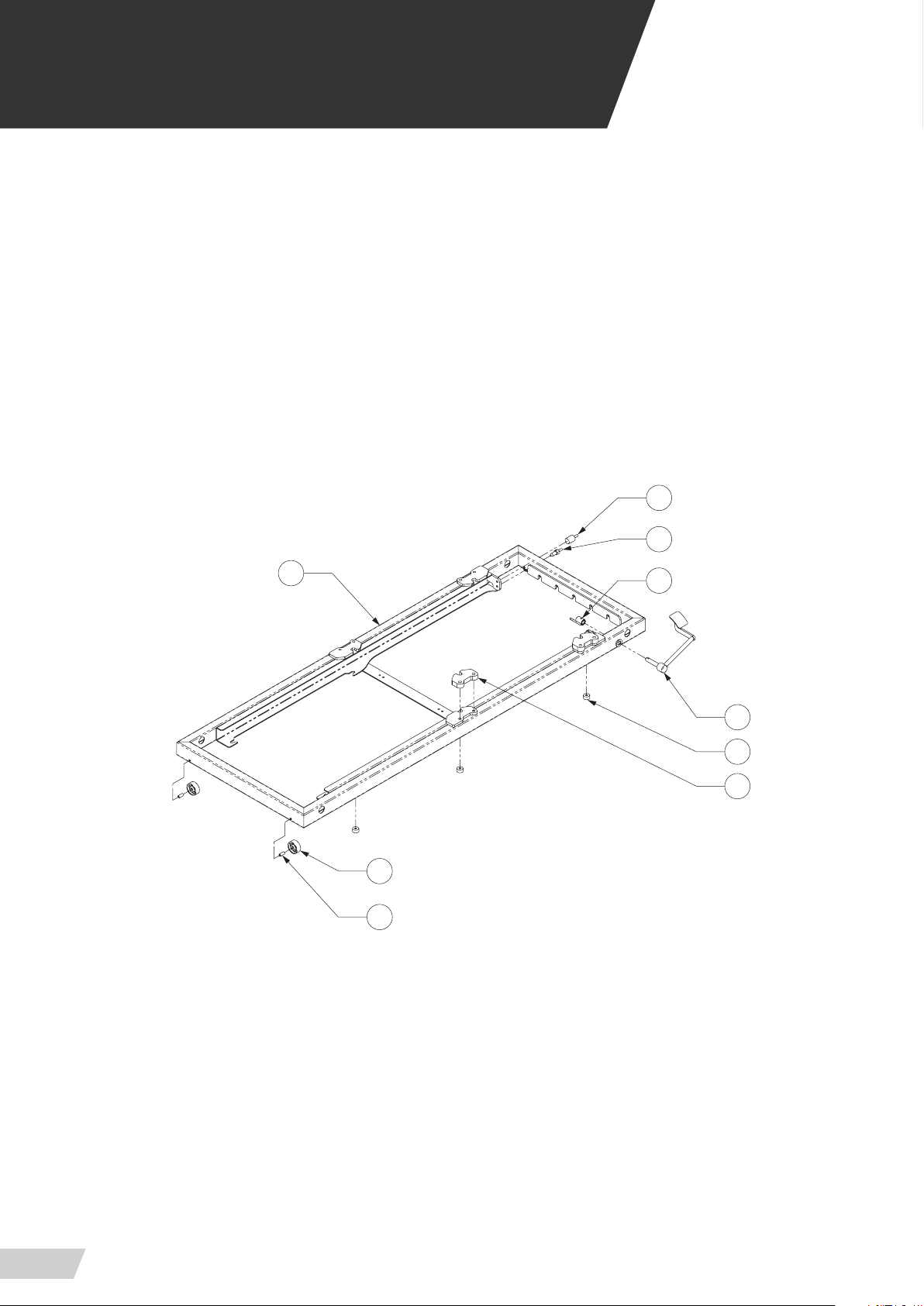

04.10 Base platform mounting plates exploded view SERIE PB-410

5.08

5.01

5.04

5.03

(2 SETS FOR BENCH)

5.06

5.07

5.03

5.02

5.05

34

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

04.11 Bill of materials: BASE PLATFORM MOUNTING PLATES SERIE PB-410

ELEMENT CODE - DESCRIPTION UNITS

5.01 PB4100-00290 - VALDA FIJACIÓN 1

5.02 PB4100-01012 - SUJECIÓN PLETINA COLLADA 1

5.03 KH2540 - COJINETE DE BOLAS 2

5.04 PB4100-02160 - GUIA MOVIMENT LATERAL 1

5.05 303-339 - MUELLE COMPRESIÓN 55X13.75X2 1

5.06 PB4010-00040 - TENSOR UNIVERSAL 1

5.07 31301071 - TUERCA DIN-934 M7 CINCADA 2

35

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

04.12 Base platform exploded view PB-410 • PB-410/4 • PB-410/5

6.01

6.04

6.03

6.06

6.05

6.07

6.02

6.08

6.09

36

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

04.13 Bill of materials: GUIDE BASE PLATFORM PB-410 • PB-410/4 • PB-410/5

ELEMENT CODE - DESCRIPTION UNITS

6.01 PB4100-02012 - SUBCONJUNTO GUIA 1

6.02 PB4100-02271 - FIJACIÓN LONGITUDINAL 2

6.03 PB4100-02251 - BALDA FIJACIÓN LATERAL 2

6.04 TEM-6 (20X20) - TOPE EGAÑA M-6 (TS20-25) 2

6.05 PB4100-02282 - SUBCONJUNTO PALANCA MOVIMIENTO LATERAL 1

6.06 PB4100-02332 - SUBCONJUNTO ACTUADOR MOVIMIENTO LATERAL 1

6.07 PB4100-02240 - DISCO APOYO MOVIMIENTO LATERAL 6

6.08 CD750RUEGUIA - RUEDA NYLON DIAM. 40MM 4

6.09 CD208C8X1A18 - CASQUILLO 8X1 A 18 4

37

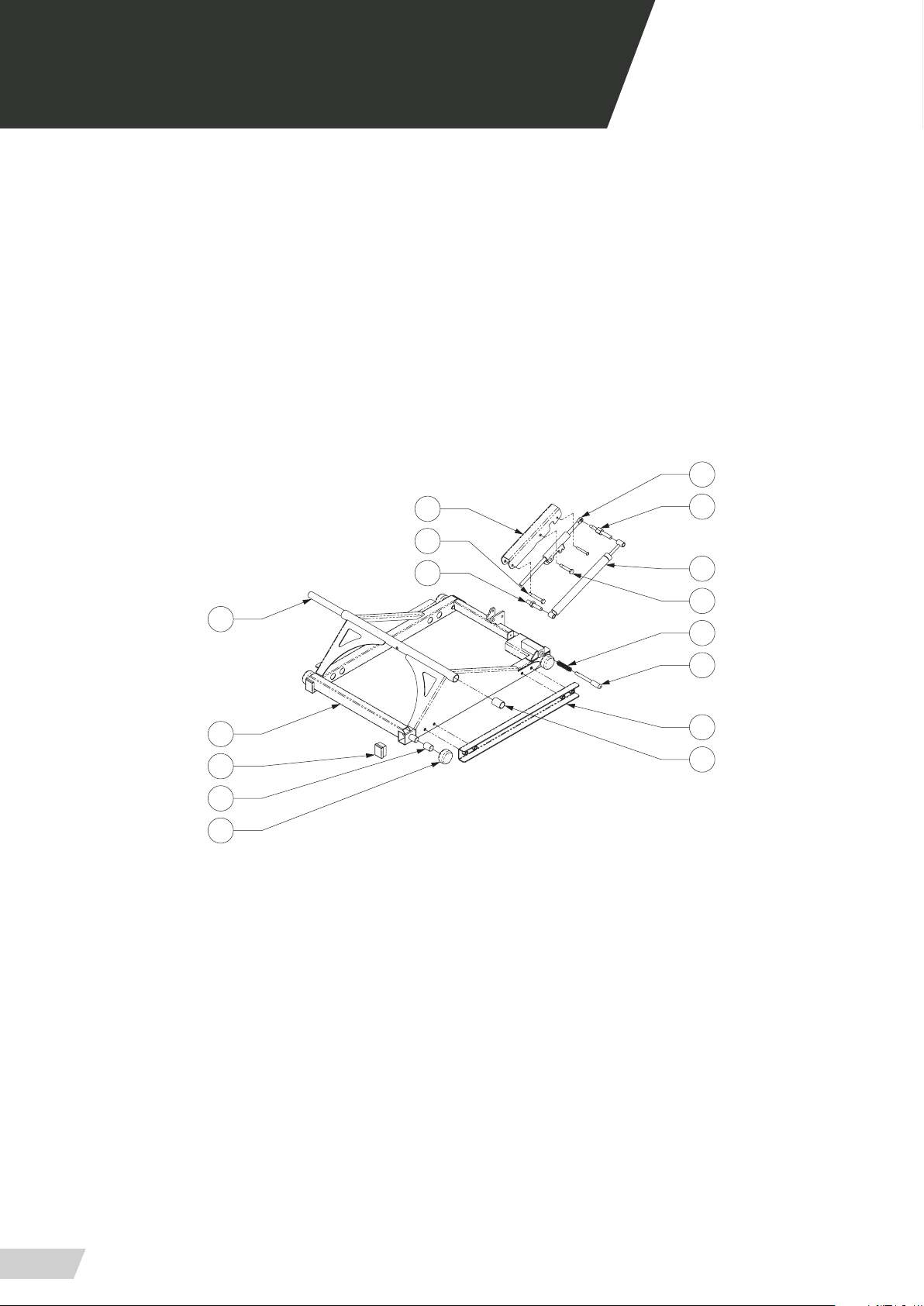

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

04.14 Base platform exploded view PB-410/3

7.03

7.02

7.04

7.01

7.05

7.06

7.07

38

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

04 MOUNTING AND COMPONENTS

04.15 Bill of materials: GUIDE BASE PLATFORM PB-410/3

ELEMENT CODE - DESCRIPTION UNITS

7.01 PB4100-02012 - SUBCONJUNTO GUIA 1

7.02 PB4103-02271 - FIJACIÓN LONGITUDINAL PB-410/3 4

7.03 PB4100-02271 - FIJACIÓN LONGITUDINAL 2

7.04 PB4103-02102 - SUBCONJUNTO PALANCA MOVIMIENTO LATERAL 1

7.05 PB4100-02332 - SUBCONJUNTO ACTUADOR MOVIMIENTO LATERAL 1

7.06 CD750RUEGUIA - RUEDA NYLON DIAM. 40MM 4

7.07 CD208C8X1A18 - CASQUILLO 8X1 A 18 4

39

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

05 GENERAL MAINTENANCE

CLEANING

It is essential to keep the equipment clean to ensure a

proper use and durability of the set. A thorough clean

must be done periodically, especially in areas exposed

to dirt that may be damaged such as gears, connectors,

switches, etc.

Do not use high-pressure cleaning systems, they can

damage the product.

CONTROLS AND SELECTORS

Due to the intense and continuous use of mobile elements such as commands and switches, periodically

examine its proper operating.

There may be failures in micro-switches and wiring, inspect the attachments and the electrical or mechanical

connections that may exist.

GREASE

WEAR AREAS

Inspecting regularly on the system compo-nents for

signs of wear is a preventive measure that can reduce

breakdowns. Check possible lubricant leakages, grooves or bearing in poor condition.

MECHANICAL FIXING

We generally call mechanical xing elements to the

components used to x the product as a whole, mainly

screws and derivatives.

To some terms of use, due to vibrations or impacts certain elements may lose their tightening torque or xing

properties.

Periodically review that there are no loose elements,

especially on moving parts of the set. Please note and

always respect the recommended tightening torques.

REPLACEMENT OF COMPONENTS

Generally, every moving part should be greased. Our

products leave the factory completely greased and lubricated. However, it is possible that the elements are

degreased over time and the use of the product, either

by lubrication loss or dirt. Clean and grease periodically the aected areas according to the manufacturer’s

specications.

Check for loose, missing or worn parts. Perio-dically

examine every moving element to make sure that components are tighten.

This manual does not include procedures for all parts.

Qualied service personnel should replace cables, switches and certain mecha-nical parts without step-bystep procedures.

The qualied service personnel should contact our

commercial department for information about ordering spare parts and its installation.

MAKE SURE TO KEEP THESE AREAS FREE OF WATER AND HUMIDITY.

TAKE SPECIAL CARE NOT TO WET THEM WHILE WASHING THE SET.

40

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

06 LEGAL NOTICES

This document may contain technical inaccuracies or

typographical errors.

Changes are periodically added to the information

herein; these changes will be incorporated in new editions of the publication.

Promeba, S.L. reserves the right to make, if considered

appropiate, any modication or improvement to the

products described in this publication.

Promeba, S.L. may have patents or patent applications

which address themes described in this document. The

possession of this document does not entitle no license to these patents.

The information contained in this document does not

aect or change the specications or product warranties of Promeba, S.L.

No part of this document shall operate as express or

implied license or compensation under the intellectual

property rights of Promeba, S.L. or third party.

All the information contained in this document has

been obtained in specic environments and it is presented as an illustration. The results obtained in other

operating environments may vary.

Promeba, S.L. may use or distribute the information

that the client provides in whatever way they see t,

without incurring any obligation with the client.

41

USER GUIDE // BENCH PB-410 SERIES

Review 09/19

07 PRODUCT WARRANTY

Promeba, S.L. warrants that their products have suc-

cessfully passed all quality controls, both functional

and material. The warranty period is 2 years from the

date of purchase.

This warranty will only be granted when the original

invoice or sales receipt (indicating the date of purchase, model and the distributor’s name) is presented together with the defective product during the warranty

period. Promeba, S.L. reserves the right to not oer

the free warranty service if the indicated documents

are not presented or if the information provided by the

consumer is false, incomplete or illegible.

1. This warranty shall not apply if the model’s name or the

serial number has been altered, removed, disappeared or

is illegible.

2. This warranty does not cover transportation costs or

risks associated with the transport of the product to and

from Promeba, S.L.

3. This warranty does not cover any of the following cases:

A. Regular maintenance and reparation or replacement

of parts from the normal wear and use.

B. Consumables (components that may need periodic replacements during the product’s life, such as non-rechargeable batteries, bulbs, etc.)

C. Damages or defects resulting from the use, operation

or improper treatment of the product and not caused by

a normal use of it.

D. Damages arising from:

ii. Use of components not supplied with the product

or incorrect installation of accessory parts previously

untested.

iii. States or defects of the system in which the product

is incorporated with the exception of other products of

Promeba, S.L. designed for its use with the product.

iv. Product use with accessories, peripheral units and

other products of a type, condition or standard not established by Promeba, S.L.

v. The manufacturer or distributor shall be solely responsible for determining the sending of parts for its reparation or the replacement of the product in its entirety. In no circumstance shall operators be send to such

reparation or product replacement.

Except in the cases mentioned above, Promeba, S.L.

shall not give any guarantees in relation to the product, operation, accuracy, reliability or adaptability for

an equipment logical purpose or any other type. If this

exception is not lawful or established in the law, Pro-

meba, S.L. shall limit or exclude their guarantees only

to the extent that the applicable law permits it.

The only obligation of Promeba, S.L. regarding this

warranty is to repair or replace the parts subjected to

the terms and condition of this warranty.

Promeba, S.L. is not liable for loss or damages to products, this warranty or others, including economic loss

or not assessable damage; the price paid for the product; loss of prots, incomes, information, usufruct or

use of the product or associated products or indirect

loss or damage, accidental or critical.

i. Improper use, including:

- Treatment resulting in damages or physical changes,

surface or appearance changes of the product.

- Installation, use or storage of the product in a manner

inconsistent with the instructions described by Promeba,

S.L.

- Product maintenance in a manner inconsistent with the

instructions of Promeba, S.L. for a proper maintenance.

- Installation or product use in a manner inconsistent with

the technical or security standards of the country where it

is used or installed.

42

This clause refers to whether the loss or damage is due

to a product deterioration or inoperability associated

to defects or unavailability of Promeba, S.L. that caused a downtime, user’s time loss or a business interruption.

In the cases in which the law prohibits or limits these

responsibility exclusions, Promeba, S.L. shall exclude

or limit their responsibility only to the extent that the

law allows. For example, many countries forbid the exclusion or limitation of damages caused by negligence,

gross negligence, wilful misconduct, fraud and similar

acts. The responsibility of Promeba, S.L. in this warran-

ty shall not exceed, in any case, the price paid for the

product, but if the applicable law permits only responsibility limitations of major responsibilities, these shall

be applied.

All rights reserved. Variations can be done whitout notice.

Promeba, S.L. is to be considered not responsible for damages caused by the lack or the wrongness

of the information here mentioned.

PROMEBA, S.L.

ER-0687/1998

Ctra C-16 Km 59.5 · 08650 Sallent (Barcelona) · SPAIN

T. 93 837 12 00 · Fax 93 820 61 08

promeba@promeba.com · www.promeba.com

Loading...

Loading...