Page 1

Refrigerant Recovery Machine

TM

RG6000

Operating Manual

Manuel d’utilisation

Bedienungsanleitung

Manual de operaciones

1

Page 2

Sa f e t y Pr e c a u t i o n S

WARNING : TO PREVENT PERSONAL INJURY AND / OR EQUIPMENT DAMAGE,

ALLOW ONLY QUALIFIED PERSONNEL TO OPERATE THIS UNIT. Before operating the unit,

read and follow the instructions and warnings in this manual. The operator must be familiar with air

conditioning and refrigeration systems, refrigerants, and the dangers of pressurized components. If

the operator cannot read this manual, operating instructions and safety precautions must be read and

discussed in the operator’s native language.

PRESSURIZED TANK CONTAINS LIQUID REFRIGERANT. Do not overll storage vessels, because

overlling may cause explosion and personal injury or death. Do not recover refrigerants into nonrellable containers; use only federally authorized rellable containers (DOT spec. 4BW or 4BA).

HOSES MAY CONTAIN LIQUID REFRIGERANT UNDER PRESSURE. Contact with refrigerant may

cause personal injury. Wear protective equipment, including safety goggles and protective gloves.

Disconnect hoses using extreme caution.

DO NOT BREATHE REFRIGERANT AND LUBRICANT VAPOR OR MIST. Exposure may cause

personal injury, especially to the eyes, nose, throat, and lungs. Use the unit in locations with mechani-

cal ventilation that provides at least four air changes per hour. If accidental system discharge occurs,

ventilate the work area before resuming service.

USE THE SHORTEST POSSIBLE EXTENSION CORD WITH A MINIMUM SIZE OF 14 AWG. Using

an undersized extension cord may result in electrical equipment failure.

TO REDUCE THE RISK OF FIRE, do not use the unit in the vicinity of spilled or open containers of

gasoline or other ammable substances.

DO NOT USE COMPRESSED AIR TO PRESSURE TEST OR LEAK TEST THE UNIT OR AIR

CONDITIONING SYSTEM. Some mixtures of air and R-134a refrigerant are combustible at elevated

pressures. These mixtures are potentially dangerous and may result in re or explosion causing personal injury or property damage.

DO NOT MIX REFRIGERANT TYPES THROUGH A SYSTEM OR IN THE SAME CONTAINER. Mix-

ing of refrigerants will cause severe damage to the unit and the system being serviced.

HIGH VOLTAGE ELECTRICITY INSIDE THE UNIT HAS A RISK OF ELECTRICAL SHOCK. Exposure may cause personal injury. Disconnect power before servicing the unit.

Ex p l a n a t i o n o f Sa f E t y Si g n a l Wo r d S

WARNING : Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION : Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

CAUTION : Used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

2

Page 3

ta b l e o f co n t e n t S

Understanding Refrigerant Recovery . . . . . . . . . . . . . . . . . . . . . . . .4

Standard Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Recovery Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Purge the RG6000 Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating Instructions for Bulk Liquid Systems . . . . . . . . . . . . . . . . . . .7

Push – Pull Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Liquid Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Vapor Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Purge Non-Condensable Gas from a Storage Cylinder . . . . . . . . . . . . . . . 8

Recovery Cylinder Information. . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Rebuild Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation of the Filter and Filter / Drier . . . . . . . . . . . . . . . . . . 13

Burned-out System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Explanation of Safety Signal Words . . . . . . . . . . . . . . . . . . . . . . . . .2

Warranty Statement . . . . . . . . . . . . . . . . . . . . . . . .Inside Back Cover

3

Page 4

un d e r S t a n d i n g re f r i g e r a n t re c o v e r y

Refrigerant recovery is the processs of taking refrigerant

out of a system and storing it in a cylinder. The following

information is critical to achieving the best refrigerant

recovery results.

Refrigerant

Identify the refrigerant type and quantity in the system to

be serviced.

The RG6000 unit is approved for use with the following

category III, IV, and V refrigerants (per ARI-740) :

R-12, R-22, R-134a, R-401a, R-401b,R-401c, R-402a,

R-402b, R-404a, R-406a, R-407a, R-407b, R-407c,

R-407d, R-408a, R-409a, R-410a, R-411a, R-411b,

R-412a, R-500, R-502, R-507 R-509

Filters and Filter / Driers

CAUTION : Filters prevent contamination from entering

the unit, which reduces the risk of damage to the unit

and the system being serviced.

The RG6000 unit is shipped with a lter screen installed

behind the inlet tting. Promax strongly recommends that

a clean lter screen be used for every service job. Failure

to use a lter screen will invalidate your warranty.

Promax also strongly recommends using a lter / drier

(part no. 100343; not provided) at the inlet tting. Each

in-line lter / drier must be labeled and used for only one

type of refrigerant.

Valves

WARNING : To prevent personal injury, open

service and cylinder valves SLOWLY to allow

rapid shut-off of gas flow if necessary. Once it is

determined there is no danger, the valves may be

opened fully.

Isolate large amounts of refrigerant and close valves

after use, so if a leak should develop anywhere in the

system, refrigerant will not escape to the atmosphere.

Storage Cylinders

WARNING : A storage cylinder is full when it

reaches 80% volume. DO NOT OVERFILL. Due to

liquid expansion, the cylinder could explode if filled

to more than 80% volume, possibly causing personal

injury and equipment damage. Use a scale, such

as the TIF9010A, to avoid overfilling the storage

cylinder.

Promax recommends using the optional 80% Capacity

Shutoff Kit (p/n SK-5001) with this unit. After the kit is

installed and used with a recovery cylinder having an

internal oat switch, the unit automatically shuts down

when the cylinder is 80% full. (Your unit is pre-wired at

the factory for this kit.)

Hoses

Hoses must be equipped with low-loss ttings and have

pressure ratings appropriate for the refrigerant in the

system being serviced.

Shut-off Switch

This unit has an internal, high-pressure, shut-off switch.

If system pressure rises above 550 psi, the unit shuts

off. The shut-off switch automatically resets itself after

pressure drops below 400 psi.

WARNING : The internal pressure shut-off

switch does NOT prevent cylinder overfill. If the

system shuts off automatically and is connected

to a cylinder, the cylinder may be dangerously

overfilled. Take immediate measures to relieve the

high pressure and / or cylinder overfill situation, or

personal injury may result.

Push / Pull Procedure

When recovering large amounts of liquid (over 15 lbs.),

use the Push / Pull method described in this manual.

Maximum Vacuum and Recovery Rates

To achieve the deepest nal vacuum, use an evacuated

recovery cylinder. To maximize recovery rates :

Use the shortest possible length of 3/8" or larger hose.

•

(A hose no longer than 3 feet is recommended.)

Remove unnecessary hose core depressors, and

•

remove Schrader valves from port connections.

Deformed rubber seals and core depressors in hoses,

as well as faulty or unnecessary Schrader valves, can

restrict ow.

If you are certain the refrigerant in the system being

•

serviced is clean or new, the lter screen may be

removed from the inlet tting.

Purge the RG6000 during the end of the vapor

•

recovery phase, especially when recovering large

amounts of vapor. Purge again after the recovery

process is complete and the desired vacuum has been

achieved. Refer to “Purge the RG6000 Unit” at the end

of the Standard Operating Instructions section.

Maintenance

CAUTION :

system dry and clean. Damage will occur if moisture

is allowed to enter the system.

Keep all connections to the refrigeration

4

Page 5

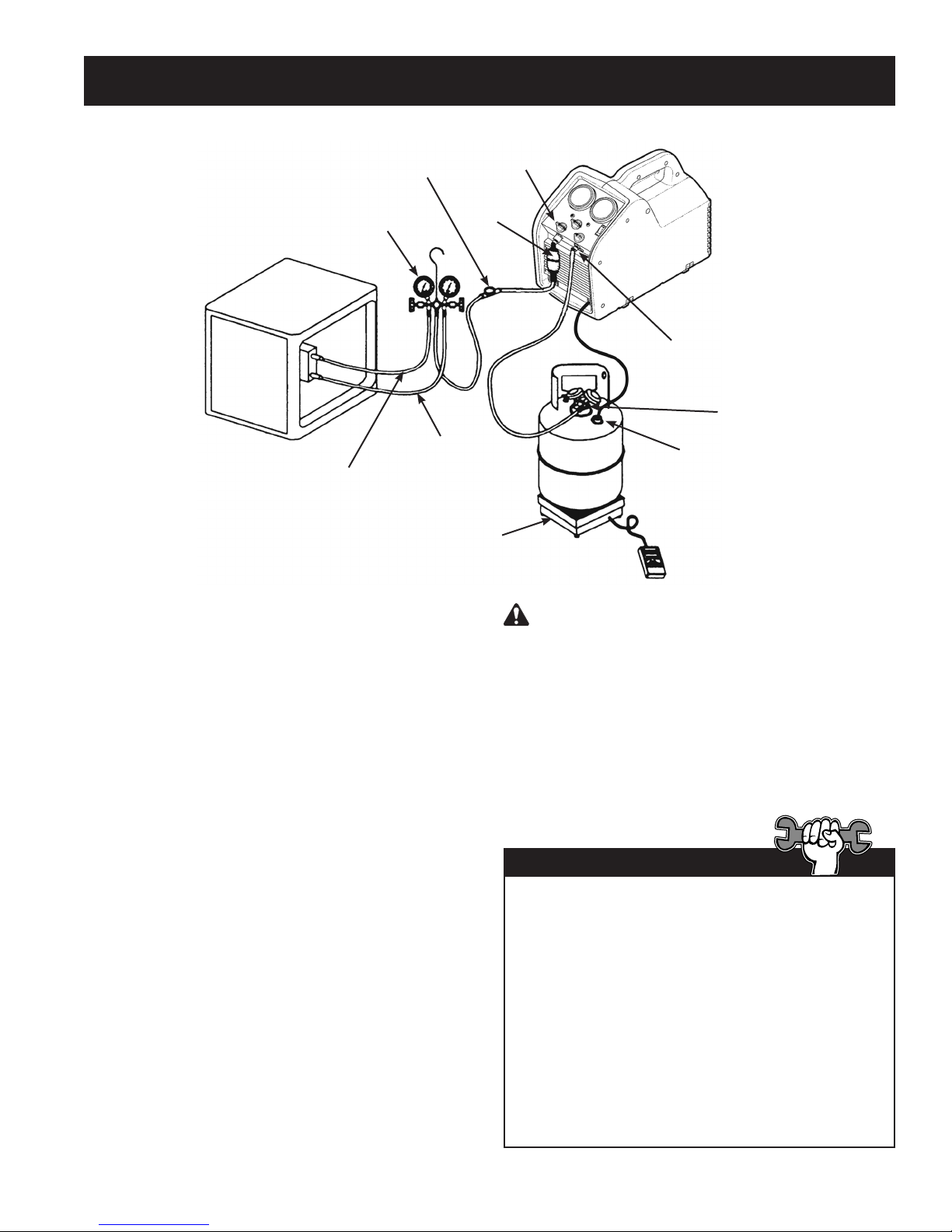

St a n d a r d oP e r a t i n g in S t r u c t i o n S

Sight

Glass

Manifold

Gauge Set

System Being

Serviced

Liquid

Vapor

The following instructions are for a standard or

“common” recovery procedure.

Setup Procedure

1. Place the RG6000 unit on a at, level surface.

2. Verify a clean lter screen is installed behind

the inlet tting.

Inlet

Fitting

Filter / Drier

Scale

WARNING : A storage cylinder is full when

it reaches 80% volume. DO NOT OVERFILL. Due

to liquid expansion, the cylinder could explode

if lled to more than 80% volume, possibly

causing personal injury and equipment damage.

Recovery

Cylinder

Outlet

Fitting

Liquid Port

Float Switch

Connection

(RG6000-KT only)

3. Connect a hose from the outlet tting of the

unit to the liquid port on the recovery cylinder.

4. Connect a hose from the inlet tting of the unit

to the output port of a manifold gauge set.

Promax recommends using a sight glass and a

lter / drier in this line.

5. Connect a hose from the liquid (low pressure)

side of the manifold gauge set to the liquid side

of the system being serviced.

6. Connect a hose from the vapor (high) side of

the manifold gauge set to the vapor side of the

system being serviced.

RG6000-KT only: Attach tank connection

harness (No. 549977) to oat switch

connection on the recovery cylinder.

7. Verify the inlet and outlet valves on the

RG6000 unit are closed.

8. Place the recovery cylinder on a scale (such as

TIF9010A) to avoid overlling the cylinder.

Tech Tips

The RG6000 will perform at its peak when voltage

entering the machine (while operating) is between

115V AC and 122V AC. Lower supply voltages

may result in difculty starting under high head

pressure, reduced performance, and / or motor

overheating.

Use an outlet that does not have other applicances

(such as lights, machines, etc.) plugged into it.

Do not use an extension cord unless needed. If

an extension cord is used, it must be 14 AWG

minimum and as short as possible to reduce

voltage drops.

5

Page 6

St a n d a r d oP e r a t i n g in S t r u c t i o n S

Recovery Procedure

1. Connect the unit to a 115V outlet.

2. Slowly open the liquid valve of the recovery

cylinder while watching hoses and connections

for leaks.

3. Set the recover / purge valve on the RG6000

unit to RECOVER.

4. Open the liquid valve on the manifold gauge

set. Note: Opening the liquid valve removes

liquid from the system rst, greatly reducing

recovery time.

5. Open the outlet valve on the RG6000 unit.

6. Toggle the power switch to the ON position.

7. Slowly open the inlet valve on the unit. Note: If the unit begins to “knock”, slowly throttle back (close)

the inlet valve until the noise stops.

8. Once the liquid has been removed from the system, open the vapor valve on the manifold gauge set to

nish evacuating the system.

9. Run the RG6000 until the desired vacuum is achieved.

10. Close the vapor and liquid valves on the manifold gauge set.

11. Turn the inlet valve on the RG6000 to the CLOSED position.

12. Toggle the power switch OFF.

Purge the RG6000 Unit

CAUTION : Always purge the RG6000 unit after

a recovery procedure. Failure to purge the

remaining refrigerant from the unit could result

in acidic degradation of internal components,

ultimately causing premature failure of the unit.

1. Verify the liquid and vapor valves on manifold

gauge set are closed (if applicable).

2. Close the valves on the system being serviced

(if applicable).

3. Verify the outlet valve on the unit is open and

the inlet valve is closed.

4. Verify the liquid valve on the recovery cylinder

is open.

5. Turn the recover / purge valve to the PURGE

position.

6. Toggle the power switch ON.

7. Slowly turn the inlet valve toward the PURGE

position. As the inlet side pressure decreases,

open the valve to the full purge position.

8. Run the unit until the desired vacuum is

achieved.

9. Close the inlet and outlet valves on the unit.

10. Toggle the power switch OFF.

11. Close the ports on the recovery cylinder.

12. Turn the recover / purge valve to the

RECOVER position.

13. Disconnect all accessories and replace the inline lter.

If you have trouble starting or re-starting the unit

due to high head pressure, rst close the inlet

valve. Then slowly turn the inlet valve toward the

purge position until the inlet pressure rises. Close

the inlet valve again and re-start the unit.

Tech Tip

6

Page 7

oP e r a t i n g in S t r u c t i o n S f o r bu l k li q u i d Sy S t e m S

“Push – Pull” Procedure

The push – pull method removes bulk liquid from a system using the pressure differential created by the

recovery machine. This method works only with large systems where the liquid is readily accessible; it may

not work on systems that contain less than 15 lbs. bulk liquid.

This method is used :

on systems with receiver cylinders.•

on systems containing more than 20 lbs. of refrigerant.•

when transferring bulk liquid refrigerant from one cylinder to another.•

Liquid Recovery

1. Place the RG6000 unit on a at, level surface.

2. Connect a hose from the outlet tting of the unit

to the vapor port on the system being serviced.

3. Connect a hose from the inlet tting of the unit

to the vapor port of a recovery cylinder. Promax

recommends using a lter / drier in this line.

4. Connect a hose from the liquid side of the

recovery cylinder to the liquid port of the

system being serviced. Promax recommends

using a sight glass in this line as a method of

determining when the liquid has been removed.

RG6000-KT only: Attach tank connection

harness (No. 549977) to oat switch connection

on the recovery cylinder.

5. Place the recovery cylinder on a scale (such as

TIF9010A) to avoid overlling the cylinder.

Filter/Drier

System Being

Serviced

6. Verify inlet and outlet valves on unit are closed.

7. Turn the recover / purge knob to RECOVER.

8. Open the recovery cylinder valves.

9. Open the outlet valve on the unit.

10. Toggle the power switch ON.

11. SLOWLY open the inlet valve on the unit.

12. When the weight reading on the scale stops

increasing, close the inlet valve on the unit

rst; then close the liquid valve on the recovery

cylinder.

13. Toggle the power switch OFF.

14. Close the valves on the recovery cylinder, and

close the outlet valve on the machine.

15. Proceed to Vapor Recovery.

Inlet

Fitting

Outlet Fitting

WARNING : Manually close the valves on both

the storage cylinder and the RG6000 unit to prevent

overfilling the cylinder. Once the siphon is started, it

can overfill the storage cylinder, even if the cylinder

is equipped with a float level sensor. The siphon can

continue even when the machine is turned off.

Vapor

Liquid

7

Sight

Glass

Scale

Vapor

Recovery

Cylinder

Liquid

Float Switch

Connection

(RG6000-KT only)

Page 8

oP e r a t i n g in S t r u c t i o n S f o r bu l k li q u i d Sy S t e m S

Vapor Recovery

1. Place the RG6000 unit on a at, level surface.

2. Connect a hose from the inlet side of the unit to

the liquid port of the system being serviced.

Tech Tip

3. Connect a hose from the outlet side of the unit

to the liquid port on a recovery cylinder.

CAUTION: The recovery cylinder should be

on a scale to avoid overlling the cylinder.

4. Open the liquid valve on the recovery cylinder.

5. Turn the recover / purge knob to RECOVER.

6. Open the outlet valve on the unit.

7. Toggle the power switch ON.

8. Slowly open the inlet valve on the unit.

9. Run the unit until the desired vacuum is

achieved.

10. Close the inlet and outlet valves on the unit.

11. Toggle the power switch OFF.

12. Close the ports on the recovery cylinder.

For a faster recovery procedure, recover from both

the liquid and vapor ports of the system being

serviced by using a tee tting or manifold gauge

set in the hose setup.

Pu r g e no n -co n d e n S a b l e ga S f r o m a St o r a g e cy l i n d e r

1. Allow the storage cylinder to sit undisturbed for

24 hours to allow air to rise to the top.

2. Connect a manifold gauge set to the cylinder.

Read the amount of pressure in the cylinder as

indicated by the output pressure gauge.

3. Determine the ambient temperature in the

room.

4. Refer to a refrigerant pressure/temperature

chart and nd the ambient temperature. Read

across the chart to the corresponding pressure

for the type of refrigerant in the cylinder.

Determine how that relates to the reading on

the gauge.

5. If the pressure reading in the cylinder is

higher than the pressure shown on the chart,

VERY SLOWLY crack open the vapor port

valve. (This is done slowly to cause as little

turbulence inside the cylinder as possible.)

Watch the pressure on the gauge decrease.

To prevent venting, add 4–5 psi to the

pressure shown on the chart.When the gauge

corresponds to that pressure, close the vapor

port valve.

6. Allow the cylinder to sit for 10 minutes and then

check pressure again.

7. Repeat the process, if necessary.

8

Page 9

re c o v e r y cy l i n d e r in f o r m a t i o n

Type of Cylinder

Use only authorized, rellable, refrigerant storage

cylinders. Federal regulations require refrigerant

to be transported only in containers meeting DOT

specs. 4BW or 4BA.

NEVER use a standard disposable 30 lb. cylinder

(the type of container in which new refrigerant is

sold) to recover refrigerant.

Working Pressure

Recovery cylinders are designed for different

working pressures. PROMAX strongly recommends

the use of 400 psi cylinders.

WARNING: To prevent personal injury, do

not exceed the rated working pressure of the

cylinder. At minimum, the RG6000 requires the

use of a 350 psi recovery cylinder.

NOTE: The use of a 400 psi cylinder is mandatory

when recovering R-410A refrigerant. Refer to the

Parts and Accessories section of this manual for

more information.

If you expect temperatures in excess of 135º F,

consult the refrigerant supplier.

Capacity

Safety codes state that closed cylinders should

not be lled with liquid over 80% of volume. (The

remaining 20% is called head pressure room.)

Do not exceed 80% of cylinder capacity. PROMAX

recommends the use of the TIF9010A Refrigerant

Scale for monitoring cylinder capacity.

Refrigerants

Cylinders and lter / driers should each be

designated for only one type of refrigerant.

If you must use a cylinder previously used for

a different refrigerant, prepare the cylinder by

completely emptying it, perform an evacuation,

purge it using dry nitrogen, and then perform

another evacuation.

Storage

Store refrigerant cylinders in a cool, dry place.

Leakage

Some cylinders have valves that were not correctly

seated when manufactured. Keeping caps on the

valves will guard against refrigerant leakage.

WARNING : To prevent personal injury, never transport an overfilled cylinder.

Refrigerant expands when it gets warm and may cause an overfilled cylinder to explode.

Storage Cylinder Temperature 60°F 70°F 100°F 130°F 150°F

STARTING WITH CYLINDER

80% BY VOLUME

Space Occupied by Liquid 80% 81% 83% 90% 94%

STARTING WITH CYLINDER

90% BY VOLUME

Space Occupied by Liquid 90% 92% 96% 100%

9

Page 10

tr o u b l e S h o o t i n g

WARNING: TO PREVENT PERSONAL INJURY AND / OR EQUIPMENT DAMAGE,

ALLOW ONLY QUALIFIED PERSONNEL TO OPERATE AND REPAIR THIS UNIT. Before operating

or repairing the unit, read and follow the instructions and warnings in this manual. The technician must

be familiar with air conditioning and refrigeration systems, refrigerants, and the dangers of pressurized

components. If the technician cannot read this manual, operating instructions and safety precautions

must be read and discussed in the technician’s native language.

Symptom Possible Cause Possible Solution

Unit will not turn on 1. Power cord not plugged in.

2. Bad power outlet.

3. Machine is in high-pressure shut-off.

4. Motor is in thermal overload.

5. Circuit breaker tripped.

Compressor tries to

start, but just buzzes

Machine pumps into

high-pressure shut-off

Slow recovery 1. Trapped liquid in system.

Circuit breaker trips 1. Low voltage at power source.

1. Low voltage at power source.

2. Extension cord too long, or too

small.

3. Head pressure too high.

1. Output valve on machine is closed.

2. Recovery cylinder valve closed.

3. Head pressure too high.

2. Restriction in refrigerant ow path.

2. Extension cord too long, or too

small.

3. Excessive load on compressor /

motor.

1. Check power cord at wall and unit.

2. Try a different outlet.

3. Reduce head pressure to below

400 psi.

4. Allow motor / unit to cool down.

5. Check / reset circuit breaker.

1. Locate / use better outlet.

2. Reduce length of extension cord.

Increase size (gauge) of extension

cord (14 AWG minimum).

3. Reduce head pressure. Turn inlet

valve slightly past closed toward

PURGE to equalize high-side / low side pressure.

1. Check output valve.

2. Check recovery cylinder valve.

3. Check output hoses for restrictions

or kinks. Reduce head pressure.

1. Momentarily cycle system compressor

to move trapped refrigerant.

2. Check inlet hose for restrictions or

kinks. Remove Schrader valves and

core depressers from hoses (if

possible). Use larger hoses.

1. Locate / use better outlet.

2. Reduce length of extension cord.

Increase size (gauge) of extension

cord (14 AWG minimum).

3. Reduce head pressure. Throttle inlet

valve to reduce load on compressor.

10

Page 11

13

14

15

re P l a c e m e n t Pa r t S

1 (left side shown)

2

Motor Relay

& Capacitor

16

17

18

}

6

7

Divider

3

4

Motor Interface

5

Counterbalance

11

10

12

9

Item Part

No. No. Qty. Description

1 550495 1 Case Half (left)

550496 1 Case Half (right)

2 550503 1 Grommet (1 ea.)

3 SK-6013 1 Motor Clamp Kit (4 pieces)

4 SK-6005 1 Motor Kit (includes motor, relay,

capacitor, hardware)

5 SK-6017 1 Compressor Kit (includes

compressor, cover, hardware)

6 Sk-6008 1 Fan Kit (includes fan, spacer

mounting hardware)

7 GA1000 1 Gauge Lens (1 ea.)

8 100124 1 Manifold Knob (red)

9 100123 1 Manifold Knob (blue)

10 100122 1 Manifold Knob (black)

11 SK-6014 1 Condenser Kit (includes condenser

assembly, hardware)

19

Inlet / Outlet

Tubes

RG6000-KT

only

8

Item Part

No. No. Qty. Description

12 551628 1 Power Cord

13 SK-6012 1 Bezel Kit (includes bezel, power

switch, circuit breaker, power entry

module, hardware)

14 SK-6001 1 Inlet Fitting / Filter Screen Kit

(includes inlet tting, lter screen,

o-ring)

15 550502 1 Foot (1 ea.)

16 SK-6003 1 Low-side Gauge Kit (includes

low-side gauge, lens)

17 SK-6022 1 High-side Gauge Kit (includes

high-side gauge, lens)

18 SK-6016 1 Manifold Kit (includes manifold

assembly, hardware)

19 549977 1 Tank Connection Harness

(RG6000-KT only)

11

Page 12

re b u i l d ki t S a n d ac c e S S o r i e S

Part

No. Description

SK-5001 80% Tank Shut-off Kit

SK-6001 Filter Screen Replacement Kit

SK-6002 Filter / Drier Kit (includes lter / drier, 6 inch hose)

SK-6005 Motor Replacement Kit

SK-6006 Compressor Rebuild Kit (includes piston seals, valves, springs, o-rings)

SK-6007 Valve Rebuild / Replacement Kit (includes inlet /oulet valves and springs, o-rings)

SK-6008 Fan Replacement Kit

SK-6012 Bezel Replacement Kit

SK-6014 Condenser Replacement Kit

SK-6015 Piston Seal Rebuild Kit (includes piston seals, energizer o-ring, wear bands)

SK-6016 Manifold Replacement Kit

SK-6017 Compressor Replacement Kit

SK-6022 Gauge Replacement Kit

TIF9010A Refrigerant Scale

17572 Recover Cylinder (50 lb. capacity, 400 psi working pressure, capacity sensor)

12

Page 13

ma i n t e n a n c e

CAUTION : To prevent personal injury, disconnect the RG6000 from the power supply before

performing maintenance.

Installation of the Filter and Filter / Drier

1. Before performing a refrigerant recovery, always inspect and clean the filter screen in the inlet fitting on

the RG6000 unit. Replace the filter screen (p/n SK-6001) if necessary. A filter screen greatly reduces

the risk of damage to the unit by preventing foreign material from entering the unit and the system

being serviced. Failure to use a filter screen will invalidate the warranty.

Promax also strongly recommends using an in-line filter / drier (p/n 100343) in the inlet line.

Filter

Screen

Inlet

Fitting

Filter /Drier

p/n 100343

Burned-out System

1. Use two high-acid capacity lter / driers in series when recovering from a “burned-out” system. Promax

recommends Alco type EK-162-F or Sporlan type C-162-F lters.

When you have nished recovering from the system, ush the RG6000 with a small amount of clean

refrigerant and refrigerant oil to purge any foreign substances left in the unit.

Storage

1. Empty refrigerant from the unit into a storage cylinder. Liquid refrigerant left in the unit’s condenser may

expand, causing damage to components.

2. Completely evacuate the RG6000 of any residual refrigerant and purge it with dry nitrogen before

putting it in storage for a long period of time.

13

Page 14

fu l l on e -ye a r li m i t e d wa r r a n t y

ei n j ä h r i g e ga r a n t i e

Unit Serial No.

This product is warranted to be free from defects in workmanship, materials and

components for a period of one year from date of purchase.

The following restrictions apply:

1. This warranty is non-transferable. All warranty claims must be made within the

warranty period. Proof of purchase must be supplied with the product when returned.

2. The warranty applies to product in normal use only, as described in this operating

manual. The product must be maintained and serviced as specied.

3. If the product fails, it will be repaired or replaced at the option of the manufacturer

(SPX). Warranty service claims are subject to factory inspection for product defects.

The manufacturer is the sole determiner of warranty coverage. If during the warranty

evaluation it is determined that proper maintenance was not performed, or that the

product has been used in any way other than the purpose for which it was designed,

the manufacturer reserves the right to void the warranty.

4. Normal wear items (seals, lters, etc.) are specically excluded from this warranty,

unless found by the manufacturer to be defective.

This warranty does not apply if the product or product part is damaged by accident, misuse,

tampering with, or modifying in anyway. The manufacturer is not responsible for any

additional costs associated with a product failure including, but not limited to, loss of work

time, loss of refrigerant, or unauthorized shipping and/or labor charges.

Use of this product with any unauthorized refrigerants or chemicals will void the warranty.

Warranty Service:

1. Outside of the United States of America, contact your local Promax distributor.

2. Inside the United States of America, call 1-800-327-5060 for a Return Material

Authorization (RMA) number. Instructions on where to send the product will be

provided.

Serien-Nr. des Geräts

Es wird garantiert, dass dieses Produkt während des Zeitraums von einem Jahr ab Kaufdatum

frei von Material-, Komponenten- und Verarbeitungsfehlern ist.

Es gelten folgende Beschränkungen:

1. Diese Garantie ist nicht übertragbar. Alle Garantieansprüche müssen innerhalb der

Garantieperiode eingereicht werden. Beim Umtausch muss der Kaufbeleg vorgelegt

werden.

2. Diese Garantie gilt für ein Produkt, das gemäß den Anweisungen in dieser

Bedienungsanleitung verwendet wurde. Das Produkt muss gemäß den

Anweisungen gewartet und instandgesetzt werden.

3. Bei einem Ausfall des Produkts wird es nach Ermessen des Herstellers (SPX) repariert

oder ausgetauscht. Reparaturansprüche unter der Garantie unterliegen einer werksseitigen

Inspektion auf Produktschäden. Allein der Hersteller kann die Garantiedeckung

bestimmen. Wenn im Laufe der Inspektion festgestellt wird, dass keine

ordnungsgemäßen Wartungsarbeiten durchgeführt wurden oder dass das Produkt

auf eine andere Art und Weise verwendet wurde als die, für die sie konzipiert wurde,

behält sich der Hersteller das Recht vor, die Garantie für ungültig zu erklären.

4. Normale Verschleißteile (Dichtungen, Filter usw.) sind von der Garantie

ausgeschlossen, es sei denn, sie wurden vom Hersteller für defekt befunden.

Diese Garantie wird ungültig, wenn das Produkt oder dessen Teile durch Unfall oder falschen

Gebrauch beschädigt, manipuliert oder modiziert wurde. Der Hersteller kommt nicht für

Nebenkosten auf, die durch den Produktausfall entstehen, einschließlich, aber nicht beschränkt

auf, Arbeitsausfall, Verlust von Kältemittel oder nicht autorisierte Versand- und/oder

Arbeitskosten.

Bei Verwendung dieses Produkts mit nicht zugelassenen Kältemitteln oder Chemikalien

wird die Garantie ungültig.

Reparaturen unter der Garantie:

1. Außerhalb der Vereinigten Staaten wenden Sie sich an Ihren Promax

Vertriebshändler.

2. Innerhalb der Vereinigten Staaten rufen Sie 1 800-327-5060 (gebührenfrei) an

und lassen sich eine RMA-Nummer (Rücksendenummer) geben. Sie erhalten

Anweisungen darüber, wohin Sie das Produkt senden können.

ga r a n t i e l i m i t é e c o m P l è t e d’u n a n ga r a n t Í a l i m i t a d a c o m P l e t a P o r u n a ñ o

Nº de série de l’appareil

Ce produit est garanti contre les défauts matériels et de fabrication pour une durée d’un an

à compter de la date d’achat.

Toutefois, les restrictions suivantes s’appliquent :

1. Cette garantie est non transférable. Toute réclamation au titre de la garantie doit être

soumise durant la période de garantie. La preuve d’achat doit être fournie avec le

produit lors d’un retour.

2. La garantie s’applique uniquement au produit utilisé dans des conditions de

fonctionnement normales conformément au manuel d’utilisation. Il doit être entretenu et

réparé conformément aux spécications.

3. Si le produit fait l’objet d’une défaillance, il sera réparé ou remplacé à la discrétion du

fabricant (SPX). Les réclamations au titre de la garantie sont sujettes à l’inspection en

usine du produit défectueux. La couverture de la garantie est à la seule discrétion du

fabricant. Si l’évaluation de la garantie démontre qu’aucun entretien approprié n’a été

effectué ou que le produit a été utilisé dans un but autre que celui pour lequel il a été

conçu, le fabricant se réserve le droit d’annuler la garantie.

4. Les composants d’usure normale (joints, ltres, etc.) sont exclus de cette garantie,

à moins que le fabricant ne constate qu’ils sont défectueux.

Cette garantie n’est pas applicable si le produit ou les éléments du produit sont endommagés

à la suite d’un accident, d’un usage abusif, d’une altération ou d’une modication quelconque.

Le fabricant ne peut être tenu responsable de tout coût supplémentaire lié à la défaillance

du produit incluant, sans toutefois s’y limiter, les interruptions de fonctionnement, la perte de

uide frigorigène, la contamination des uides frigorigènes et l’expédition et/ou les frais de

main-d’œuvre soumis par des ateliers non autorisés.

L’utilisation de ce produit avec des uides frigorigènes ou produits chimiques non autorisés

annulera la garantie.

Assistance à la garantie :

1. À l’extérieur des États-Unis, communiquez avec le concessionnaire Promax de votre

région.

2. Aux États-Unis, composez le 1-800-327-5060 pour obtenir un numéro d’autorisation

de retour d’article. Des directives sur l’endroit où retourner le produit vous seront

fournies.

Número de serie de la unidad

Se garantiza que este producto no posee defectos de mano de obra, materiales y

componentes por el período de un año a partir de la fecha de compra.

Aplican las siguientes restricciones:

1. Esta garantía no es transferible. Todo reclamo de garantía se debe hacer dentro del

período de garantía. Se debe proveer un comprobante de compra con el producto al

devolverlo.

2. La garantía aplica al producto en uso normal únicamente, como lo indica este manual

de funcionamiento. El producto debe contar con un servicio y mantenimiento según lo

especicado.

3. Si falla el producto, será reparado o reemplazado a discreción del fabricante (SPX).

Los reclamos de servicio de garantía están sujetos a inspección autorizada de

defectos del producto. El fabricante es el único determinante de la cobertura de la

garantía. Si durante la evaluación de la garantía se determina que no se ha llevado a

cabo el mantenimiento apropiado, o que el producto ha sido utilizado para diferentes

propósitos de los que fue diseñado, el fabricante se reserva el derecho de invalidar

esta garantía.

4. Los elementos normales de desgaste (sellos, ltros, etc.) están especícamente

excluidos de la garantía, a menos que el fabricante los encuentre defectuosos.

Esta garantía no se aplica si el producto o parte del producto es dañado accidentalmente,

por uso inadecuado o ha sido alterado o modicado de cualquier manera. El fabricante

no es responsable de los costos adicionales relacionados con fallas en el producto, que

incluyen pero no se limitan a: tiempo improductivo, pérdida de refrigerante o envío no

autorizado y/o cargos por mano de obra.

La utilización de este producto con cualquier refrigerante o químico no autorizado invalidará

esta garantía.

Servicio de garantía:

1. Fuera de los Estados Unidos de América, contacte a su distribuidor de Promax local.

2. Dentro de los Estados Unidos de América, llame al 1-800-327-5060 para obtener un

número de Autorización de retorno de material (RMA). Se proveerán instrucciones

sobre a dónde enviar el producto.

Page 15

OwatOnna, Mn 55060

PhOne : 800.327.5060

Fax: 866.287.7222

www.PrOMaxrecOvery.cOM

© 2008 SPX

Form No. 551691

Rev. B, 27 January 2010

Designed & Engineered in the USA

Manufactured in China

Conçu et mis au point aux États-Unis

Fabriqué en Chine

Entworfen und entwickelt in den USA

Hergestellt in China

Diseñado en EE.UU.

Fabricado en China

Loading...

Loading...