Page 1

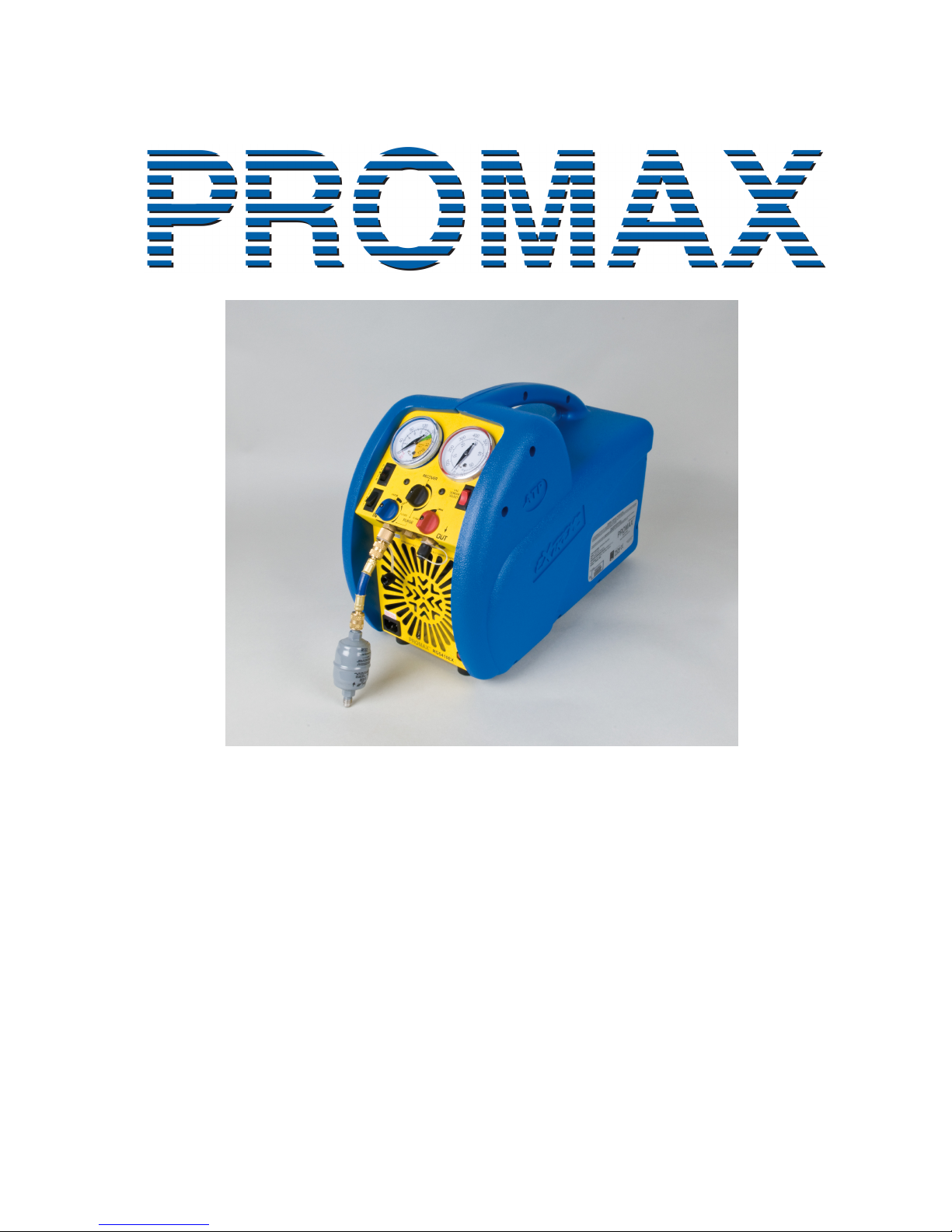

USERS OPERATING MANUAL

RG5410A-EXTREME

Advanced Test Products

Lürriper Str. 62

41065 Mönchengladbach | Germany

Tel: +49 (0)2161 59906-0 Fax: +49 (0)2161 59906-16

www.atp-europe.de ✦ info@atp-europe.de

Page 2

Advanced Test Products RG5410A-EXTREME

TABLE OF CONTENTS

I) Safety precautions

A) The safe way is the only way! 1

B) Refrigerant gas recovery & containment 2

II) Important general information 3

III) Operational procedures

A) Operating your RG5410A-EXTREME 4-6

Use of the Low Pressure Switch 6

B) Set-up procedures 7-9

C) Purging the non-condensable gases 10

IV) Diagrams

A) Part list 11

B) Refrigerant flow diagram 12

C) Wiring diagram 13

V) Safety pressure switch 14

VI) Care and maintenance 15

VII) Technical data 16

VIII) Helpful hints 17-19

IX) Troubleshooting 20

Design specifications and material are subject to change without notice.

REV 08-2013!

This manual may not be reproduced in any way, shape or form without express written consent of

Advanced Test Products.

Page 3

Advanced Test Products RG5410A-EXTREME

1

THE SAFE WAY IS THE ONLY WAY!

NOTE! If you are not a qualified refrigerant service technician,

do not use this equipment

1. The technician should always wear goggles and gloves when working on

refrigeration systems.

2. Be sure that any room where you are working is thoroughly ventilated,

3. Always think before acting. Familiarity breeds carelessness and carelessness can

be harmful to your health or, worse, result in death.

4. Read the Material Safety Data Sheets (MSDS) on all compounds with which you

are likely to come in contact. Read MSDS on refrigerant and refrigerant oil. Obtain

MSDS sheets from your refrigerant supplier.

5. Never use oxygen when testing for leaks. Any oil in contact with oxygen under

pressure will form an explosive mixture.

6. Refrigerant systems are generally electrically driven and controlled. Be sure to

disconnect the unit from the power source before servicing it.

7. Always store refrigerant containers in a cool, dry place.

8. Always open service and cylinder valves slowly. This allows quick control of the flow

of gasses if there is any danger. Once it is determined that there is no danger, the

valves may be opened fully.

9. Do not mix refrigerant in a system, a tank or anywhere else. Each type of refrigerant

must have its own tank, filters, etc.

10. If moisture enters the refrigerant system, it is likely to cause considerable damage.

Keep everything connected with the refrigeration system thoroughly dry and clean.

11. To reduce the risk of fire, avoid the use of extension cords as they may overheat. If

you must use an extension cord iit should be a minimum of 14 AWG and not longer

than 25ft.

This equipment should be used in locations with mechanical ventilation providing at

least four air changes per hour, or the equipment should be located at least 45cm

(18”) above the floor. Do not use this equipment in the vicinity of spilled or open

containers of gasoline or any other flammable liquid.

Page 4

Advanced Test Products RG5410A-EXTREME

2

REFRIGERANT GAS

RECOVERY & CONTAINMENT

Safety comes first. Read all safety information for the safe handling of refrigerant

including the Material Safety Data Sheet provided by your refrigerant supplier. Never

operate unit in an explosive environment. Wear safety glasses and protective gloves.

Work area must be well ventilated. This unit should only be operated by a qualified

technician.

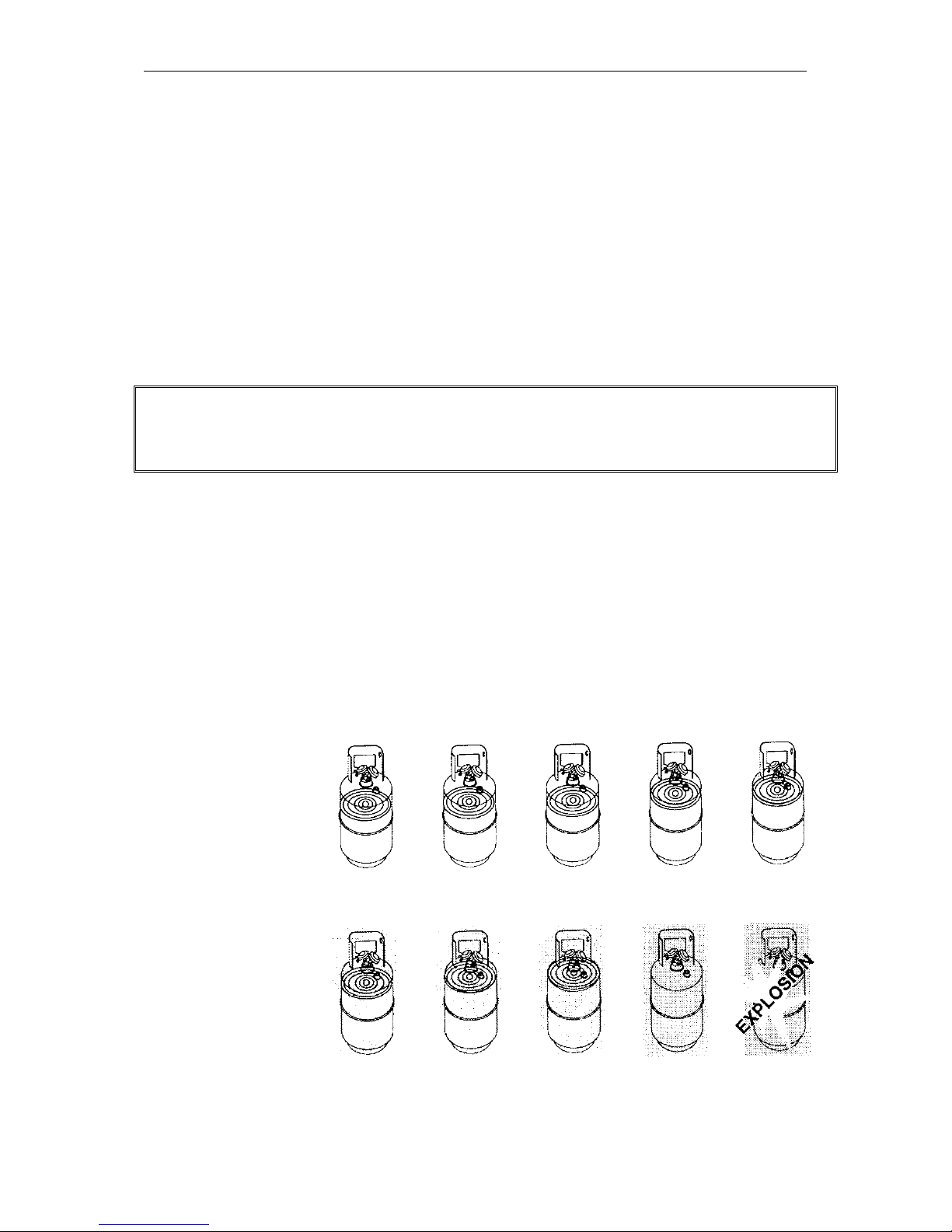

*** CAUTION: REFRIGERANT STORE CONTAINERS ***

Use only approved cylinders with a minimum of 41 bar working pressure that serve the

current regulations.

NOTE: Recovery cylinders are designed for different pressures. Do not exceed the

working pressure of each cylinder.

Safety codes recommend that closed tanks not be filled over 80% of volume with liquid.

The remaining 20% is called head pressure room.

NEVER TRANSPORT AN OVERFILLED CYLINDER.

Refrigerant expands when it gets warm and may cause a tank to explode if overfilled.

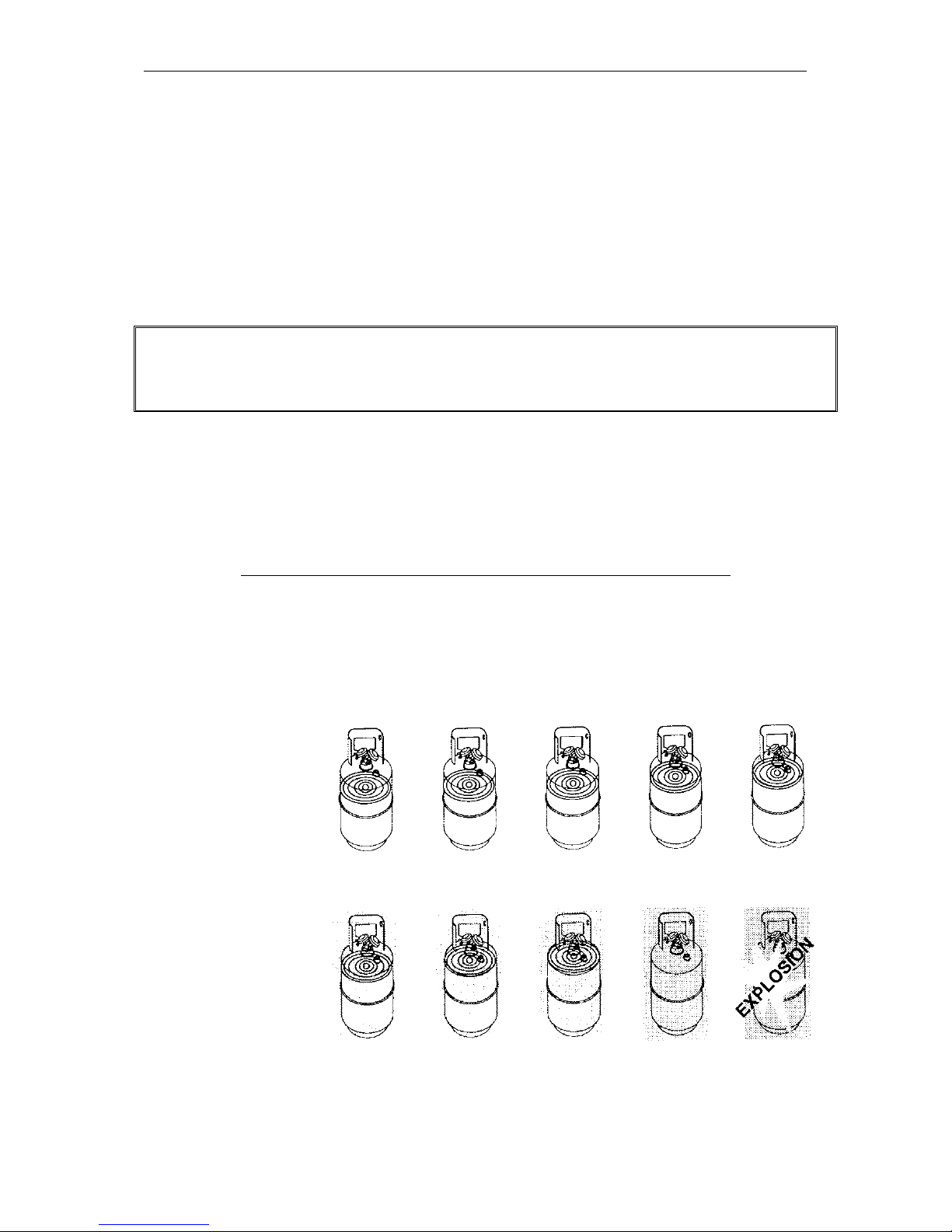

CYLINDER TEMP. 16 °C 21 °C 38 °C 54 °C 66 °C

STARTING WITH

CYLINDER 80%

FULL BY VOLUME

SPACE OCCUPIED

BY LIQUID

STARTING WITH

CYLINDER 90%

FULL BY VOLUME

SPACE OCCUPIED

BY LIQUID

80 % 81% 83% 90% 94%

90% 92% 96% 100%

Page 5

Advanced Test Products RG5410A-EXTREME

3

IMPORTANT

GENERAL INFORMATION

Before operating the RG5410A-EXTREME recovery unit, read the following:

1. Always isolate large amounts of refrigerant and close off valves after use so if a leak

should develop anywhere in the system the refrigerant does not escape.

2. Storage cylinders sometimes have valves that are not properly seated when

manufactured. Keeping caps on these valves will guard against refrigerant leakage.

3. Always operate the unit on a flat level surface.

4. Your RG5410A-EXTREME has one internal high-pressure shut-off switch. If the

pressure inside the system should go above 38,5 bar (550 psi), the system will

automatically shut itself off.

CAUTION

The 38,5 bar (550 psi) switch does not prevent tank overfill. If your system shuts

off on high pressure and is connected to your tank, you may have overfilled your

tank and created a very dangerous situation! Take immediate measures to relieve

any high pressure and/or tank overfill.

5. WARNING! Never overfill storage tanks. Overfilling may cause tanks to explode.

6. A scale must be used to avoid overfilling the storage tank.

7. Tanks and filters should be designated for one refrigerant only. Before using a tank

previously used for another refrigerant, completely empty the tank, evacuate it,

purge the tank using dry nitrogen, and re-evacuate it.

8. Special care should be taken when recovering from a burned-out system. Use two

high acid capacity filters, in series. Alco type EK-162-F or Sporlan type C-162-F are

recommended.

9. When you have finished recovering from the system, flush your RG5410AEXTREME with a small amount of refrigerant oil and a small amount of clean

refrigerant to purge off any foreign substances left in the unit.

10. Always empty refrigerant from the unit into a storage tank; see Self Purge/Auto

Evacuate procedure. Liquid refrigerant left in the condenser may expand, causing

damage to components.

Page 6

Advanced Test Products RG5410A-EXTREME

4

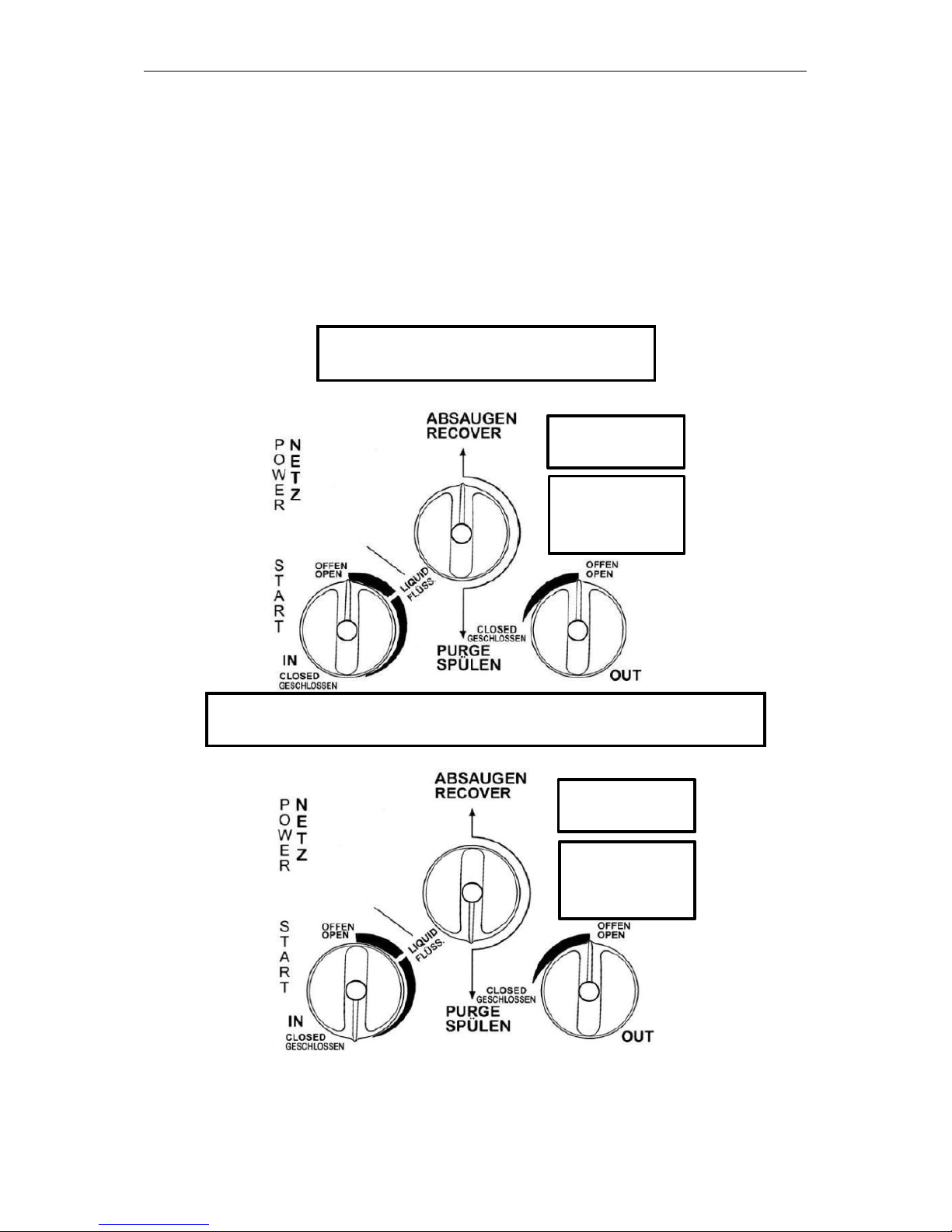

OPERATING YOUR RG5410A-EXTREME

Connect your RG5410A-EXTREME to a 230 V outlet. Switch the main power switch to

the ON position. You should hear the fan running. Press the compressor start switch.

This "momentary" switch will start the compressor. It may be necessary, under certain

circumstances, to press this switch more than once to start the compressor.

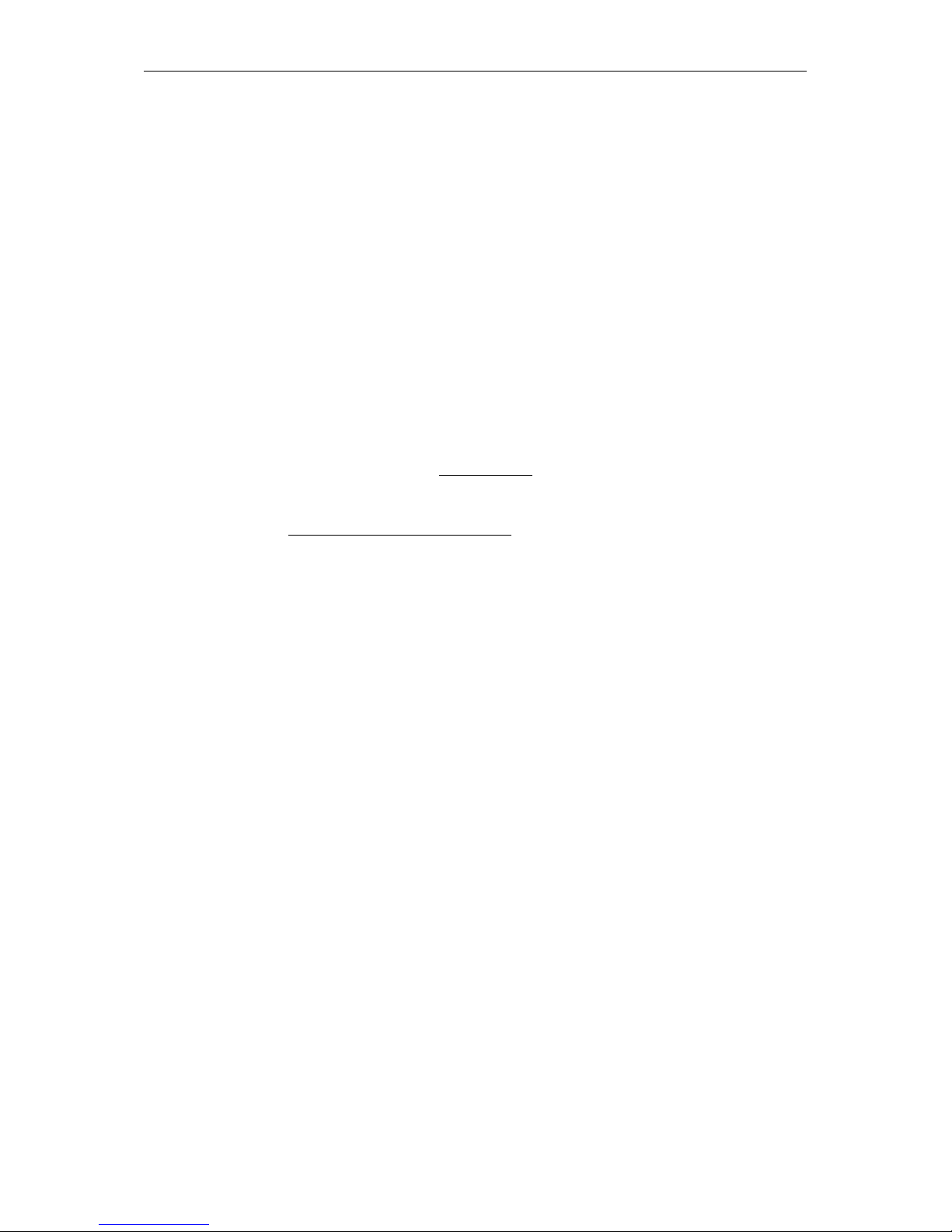

OPERATIONAL PROCEDURES

Do not turn this valve

while unit is running.

Close input valve, turn

machine off, switch to

Purge position and restart machine.

VAC

SENSOR

SELECT

ON

OFF

Do not turn this valve

while unit is running.

Close input valve, turn

machine off, switch to

Purge position and restart machine.

VAC

SENSOR

SELECT

ON

OFF

NOTE: To change from Recovery mode to Purge:

Close the Input port, turn the unit off (to prevent high pressure shutoff),

switch to Purge position and restart the unit.

NORMAL RECOVERY

SELF PURGE / AUTO EVACUATE

Page 7

Advanced Test Products RG5410A-EXTREME

5

OPERATING YOUR RG5410A-EXTREME

Procedure for Normal System Recovery

1. Inspect the RG5410A-EXTREME thoroughly to insure that it is in good operating

condition.

2. Make sure all connections are correct and tight.

3. Open the liquid port of the recovery cylinder (always open valves slowly to check

hoses and connections for leaks).

4. Make sure the Recover/Purge valve is set on Recover.

5. Open the output port of the RG5410A-EXTREME.

6. Open the liquid port on the manifold gauge set; opening the liquid port will remove

the liquid from the system first, greatly reducing the recovery time (after the liquid

has been removed, open the manifold vapor port to finish evacuating the system).

7. Connect your RG5410A-EXTREME to a 230 V outlet.

a) Switch the main power switch to the ON position. You should hear the

fan running.

b) Press the compressor start switch. This "momentary" switch will start

the compressor (it may be necessary, under certain circumstances, to

press this switch more than once to start the compressor).

8. Slowly open the input port on the RG5410A-EXTREME.

a) If the compressor starts to knock, slowly throttle back the input valve

until the knocking stops.

b) If the input valve was throttled back, it should be fully opened once the

liquid has been removed from the system (the manifold vapor port

should also be opened at this time).

9. Run until minimum EPA required vacuum is achieved.

a) Close the manifold vapor and liquid ports.

b) Close the RG5410A-EXTREME input port.

c) Shut unit off and proceed with the Self Purge procedure on the next

page.

10. Always purge the RG5410A-EXTREME after each use. Failure to purge the

remaining refrigerant from the RG5410A-EXTREME could result in the acidic

degradation of internal components, ultimately causing premature failure of the unit.

CAUTION

When pumping liquid, do not allow the RG5410A-EXTREME to operate with the

input valve too far open, causing the compressor to knock. Doing so may stall the

compressor.

Page 8

Advanced Test Products RG5410A-EXTREME

6

OPERATING YOUR RG5410A-EXTREME

Procedure for Purging Remaining Refrigerant From the RG5410A-EXTREME

1. Close the ports of the system being serviced that are connected to the input

port of the RG5410A-EXTREME.

2. Close the input port on the RG5410A-EXTREME.

3. Turn off RG5410A-EXTREME.

4. Turn the Recover/Purge valve to the purge position.

5. Restart the RG5410A-EXTREME.

6. Run until desired vacuum is achieved.

7. Close the ports on the recovery tank and the RG5410A-EXTREME.

8. Turn the RG5410A-EXTREME off.

9. Return the Recover/Purge valve to the recover position.

10. Disconnect and store all hoses.

11. Replace the in-line filter on your RG5410A-EXTREME after every time excessive

contaminant is encountered.

The use of the Low Pressure Switch

The RG5410A-EXTREME is equipped with a low pressure switch which is selectable

ON/OFF (VAC SENSOR SELECT). When the low pressure switch is switched ON the

unit will automatically switch off at 0,45 bar absolute. When the Low pressure Switch is

switched OFF the unit will continue to pump down the system even when the vacuum

stage has been reached.

VAC

SENSOR

SELECT

ON

OFF

Page 9

Advanced Test Products RG5410A-EXTREME

7

RG5410A-EXTREME REFRIGERANT RECOVERY

ADDITIONAL INFORMATION

To achieve the deepest final vacuum, use the tank cooling method to lower the head

pressure on the recovery tank. Repeat as necessary to achieve the desired vacuum

level.

NOTE: If there is no liquid in the recovery tank, then the cooling method will not work. In

this case, use an empty tank that has been fully evacuated to achieve the final vacuum

level required.

To maximize recovery rates use the shortest possible length of 3/8” or larger hose. A

hose no longer than 3’0” is recommend. Always remove all unnecessary hose core

depressors and Schrader valves from port connections (using the proper valve core

tool) for maximum throughput. Deformed rubber seals and core depressors in hoses

and faulty or unnecessary Schrader valves can restrict flow by up to 90%.

If the tank pressure exceeds 31,5 bar, use the tank cooling procedure to reduce the

tank pressure. When recovering large amounts of liquid, use the “PUSH/PULL” method

of recovery (see diagram below).

CAUTION: When using the “PUSH/PULL” method, you must use a scale to prevent

overfilling the storage tank. Once the “PUSH/PULL” siphon is started, it can continue

and overfill the storage tank even if the tank is equipped with a float level sensor. The

siphon can continue even when the machine is turned off. You must manually close the

valves on the tank and the unit to prevent overfilling the recovery tank.

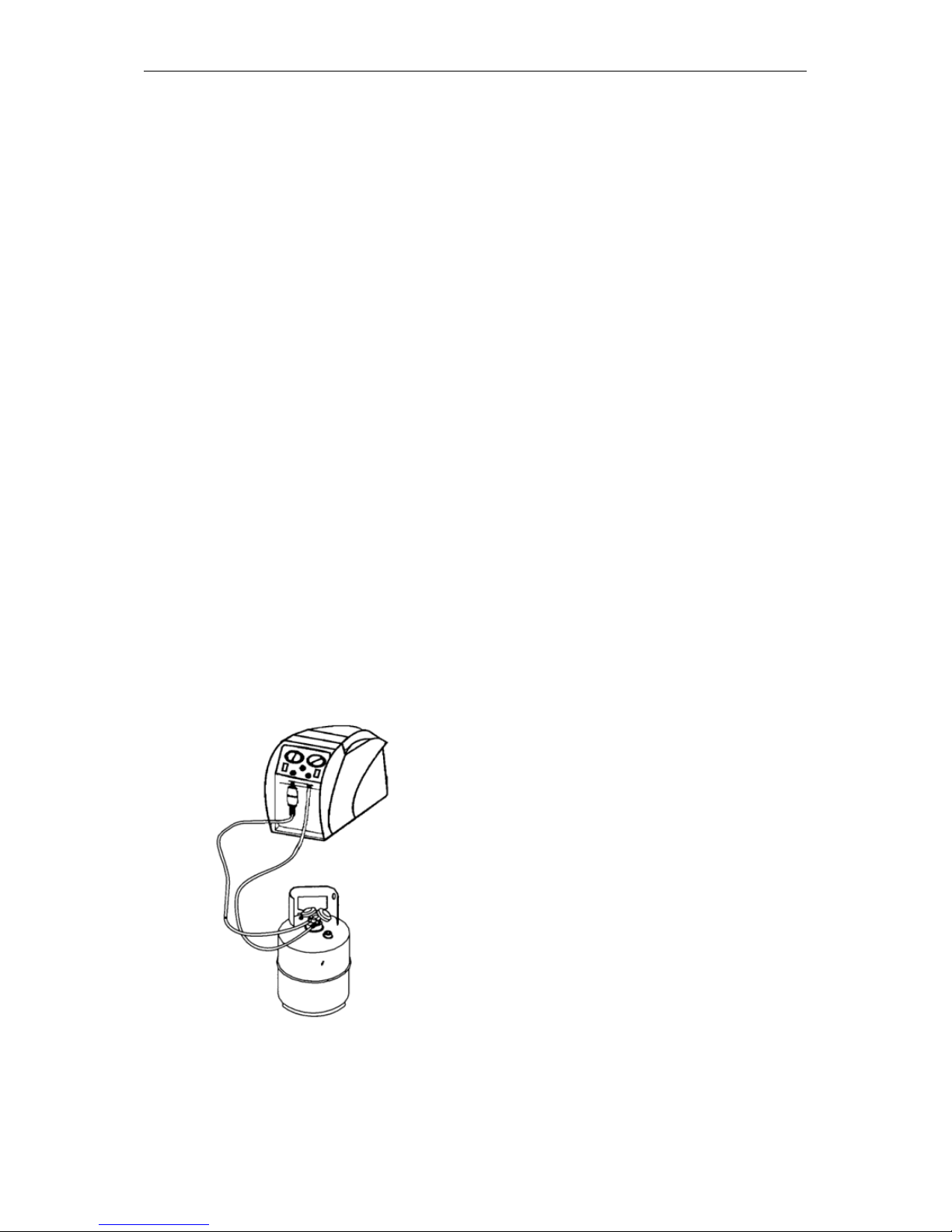

SET-UP DIAGRAM FOR TANK PRE OR SUB COOLING

PROCEDURE

INPUT

OUTPUT

VAPOR

LIQUID

To start you must have a minimum of

2,5 kg of liquid refrigerant in the tank.

Throttle the output valve so that the

output pressure is 7 bar (100 psi)

greater than the input pressure, but

never more than 31,5 bar (450 psi).

Run until the tank is cold.

Page 10

Advanced Test Products RG5410A-EXTREME

8

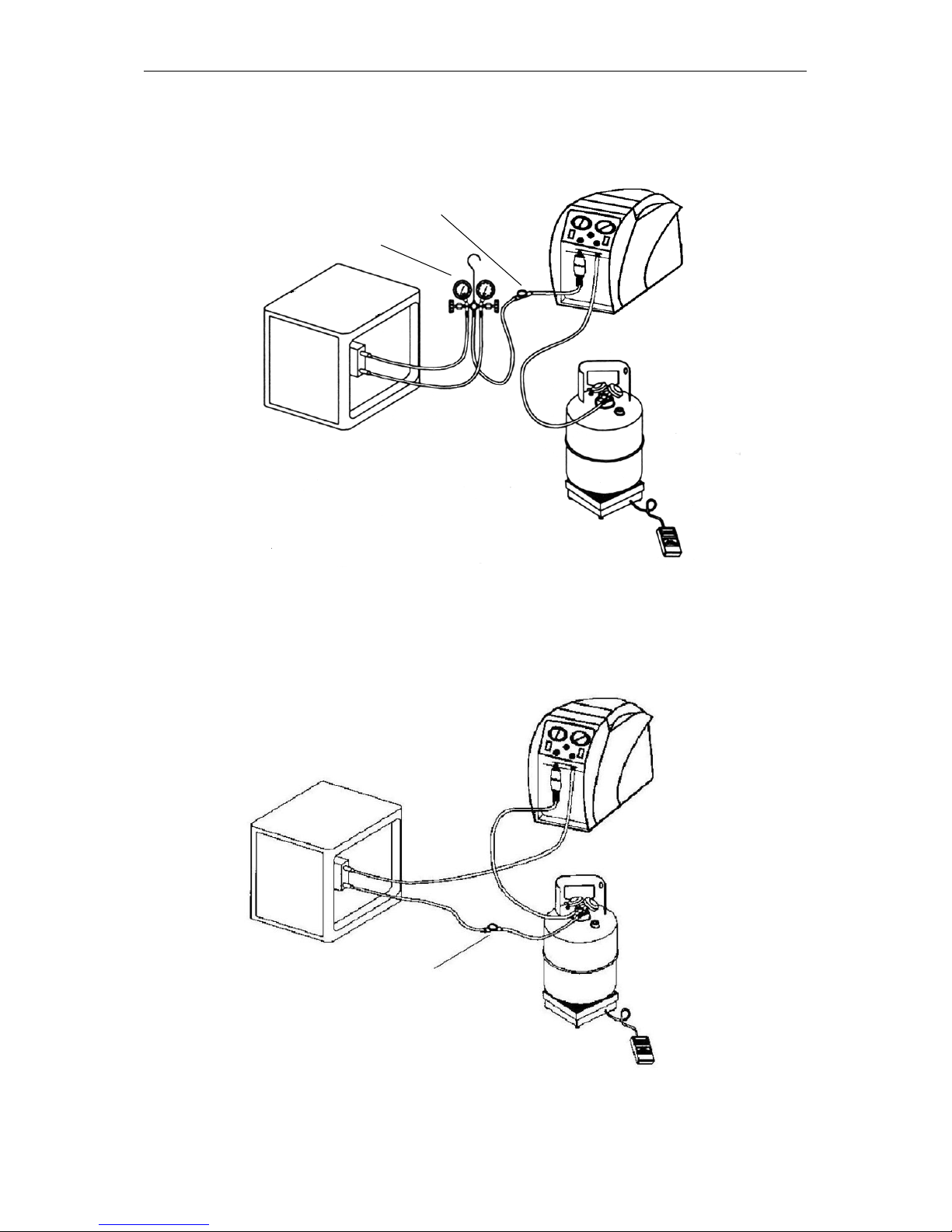

SET-UP DIAGRAM FOR REFRIGERANT RECOVERY

This method is the fastest method for recovering vapor refrigerant.

MANIFOLD GAUGE SET

(OPTIONAL) MOISTURE

SIGHT GLASS

INPUT

OUTPUT

LIQUID

A scale must be used

to avoid overfilling the

storage tank.

SYSTEM

BEING

SERVICED

VAPOR

LIQUID

SET-UP DIAGRAM FOR “PUSH/PULL” METHOD

Push pull only works with large systems where the liquid is readily accessible. Do not

use this method on systems that contain less than 15 pounds as it may not work.

SYSTEM

BEING

SERVICED

LIQUID

VAPOR

VAPOR

LIQUID

OUTPUT

OPTIONAL MOISTURE

INDICATING SIGHT GLASS

INPUT

The sight glass is used to provide a method of

determining the moisture content and quality of a

system’s refrigerant.

A scale must be

used to avoid

overfilling the

storage tank.

Page 11

Advanced Test Products RG5410A-EXTREME

9

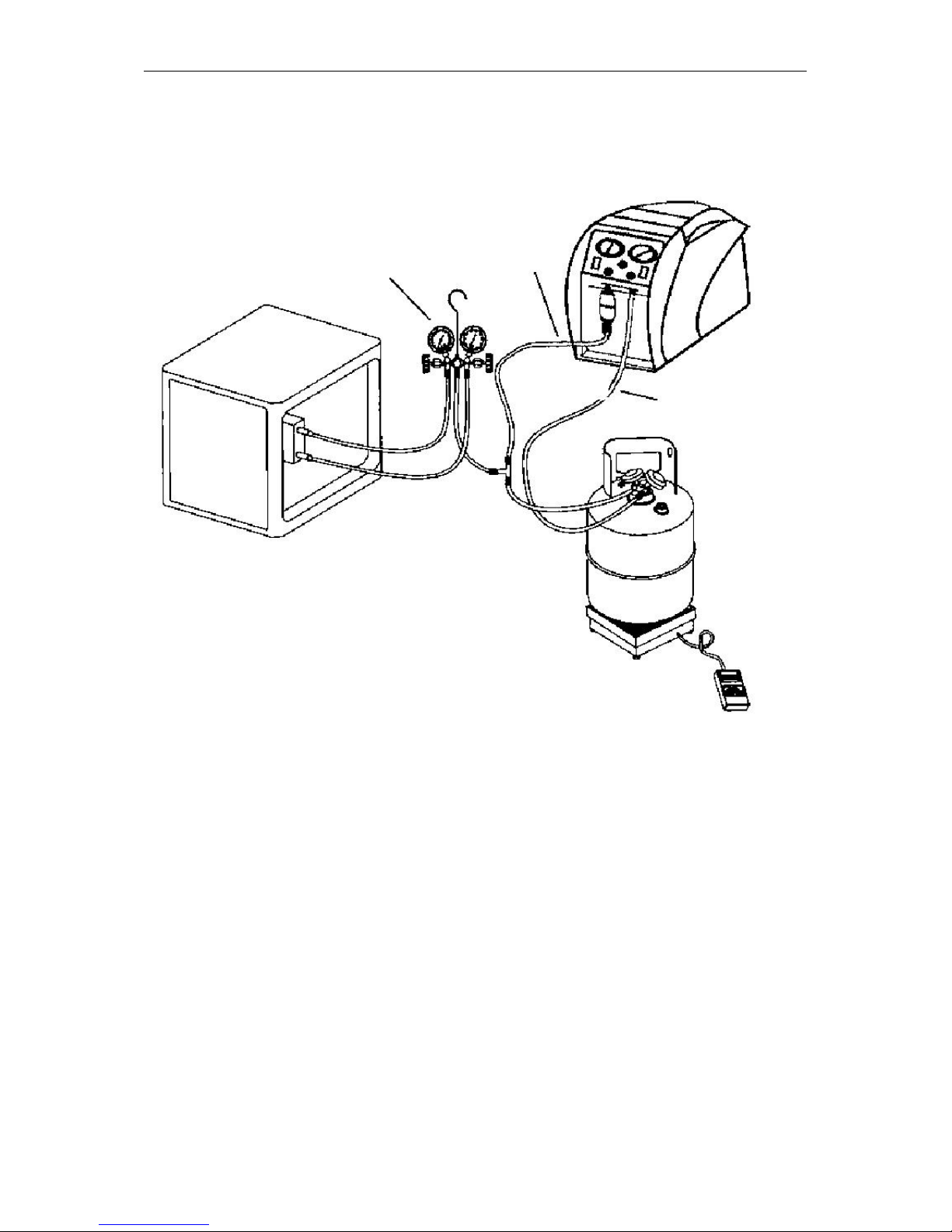

OPTIONAL RECOVERY / TANK PRE OR SUB

COOLING FOR FIXED HOSE SET UP

SYSTEM

BEING

SERVICED

LIQUID

VAPOR

VAPOR

LIQUID

MANIFOLD GAUGE SET

INPUT

OUTPUT

A scale must be used

to avoid overfilling the

storage tank.

Normal recovery:

Tank Vapor valve is closed.

Tank pre or sub cooling:

Tank Vapor valve is open and both Manifold Gauge Set valves are closed. Follow

above procedure.

Page 12

Advanced Test Products RG5410A-EXTREME

10

RG5410A-EXTREME RECOVERY

Purging the non-condensable gasses from identified refrigerant in a tank

1. Allow the tank to sit undisturbed for 24 hours. (This allows the air to rise to the top).

2. Connect a manifold to the tank and read the amount of pressure in the tank by

looking at the output pressure gauge.

3. Determine the ambient temperature in the room.

4. Refer to a Refrigerant pressure/temperature chart. Find the temperature on the chart

and look across to the corresponding pressure for the type of refrigerant in the tank.

Determine how that relates to the reading on the gauge.

5. If the pressure reading is higher than the pressure shown on the chart, very slowly

(so as not to cause turbulence inside the tank) crack open the vapor port valve.

Watch the pressure on the gauge decrease. To prevent venting, add 0,3 - 0,35 bar

(4 - 5 psi) to the pressure shown on the chart. When the gauge corresponds to that

pressure, close the vapor port valve.

6. Allow the tank to sit for 10 minutes and check the pressure again.

7. Repeat the process again if necessary.

Page 13

Advanced Test Products RG5410A-EXTREME

11

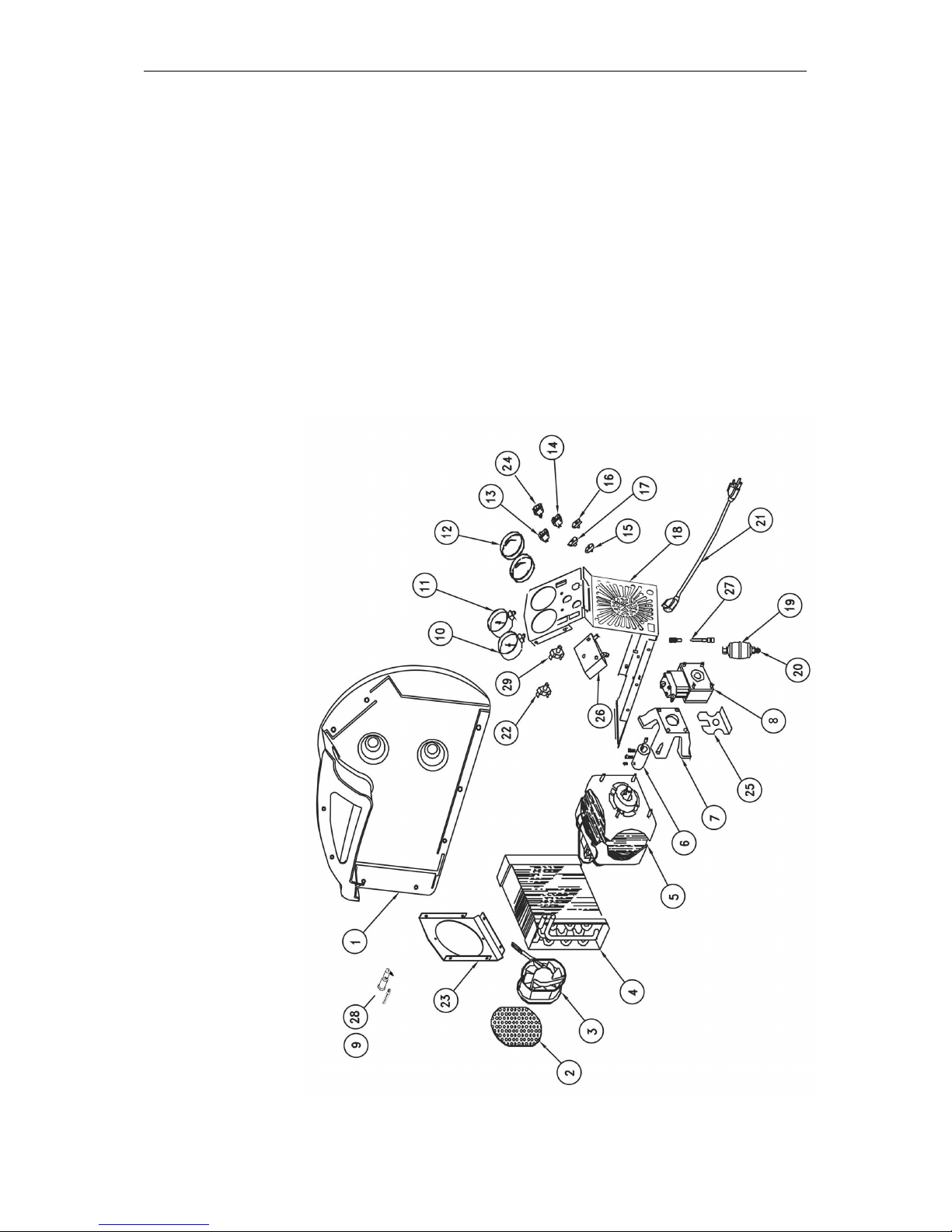

PARTS LIST RG5410A-EXTREME

Pos. Description Part No.

1 Plastic case 111-200119-TAB

2 Fan grill 100505

3 Axial fan EL1818

4 Condenser CD1201

5 Motor 105-200446-001

6 Coupler 534483

7 Bell housing CP1001

8 Compressor 535398ASM

9 Fuse – 5x20mm 140-200347-001

10 Input gauge 534487

11 Output gauge 534488

12 Gauge lens GA1000

13 ON/OFF switch EL1310

14 Start switch EL1309

15 Blue knob 100123

16 Red knob 100124

17 Black knob 100122

18 Front panel 110-201120-001

19 Filter 100343

20 Flare cap NB6501

21 Power cord 135-200341-001

22 High Pressure switch 100339

23 Rear panel 536762

24 Select Switch 105-200396-001

25 Compressor Bracket 100207

26 Manifold 105-200808-001

27 Hose 4“ 100345

28 Fuse holder 100419

29 VAC Sensor 113726

- Check Valve 116418

- Run Capacitor 536755

Page 14

Advanced Test Products RG5410A-EXTREME

12

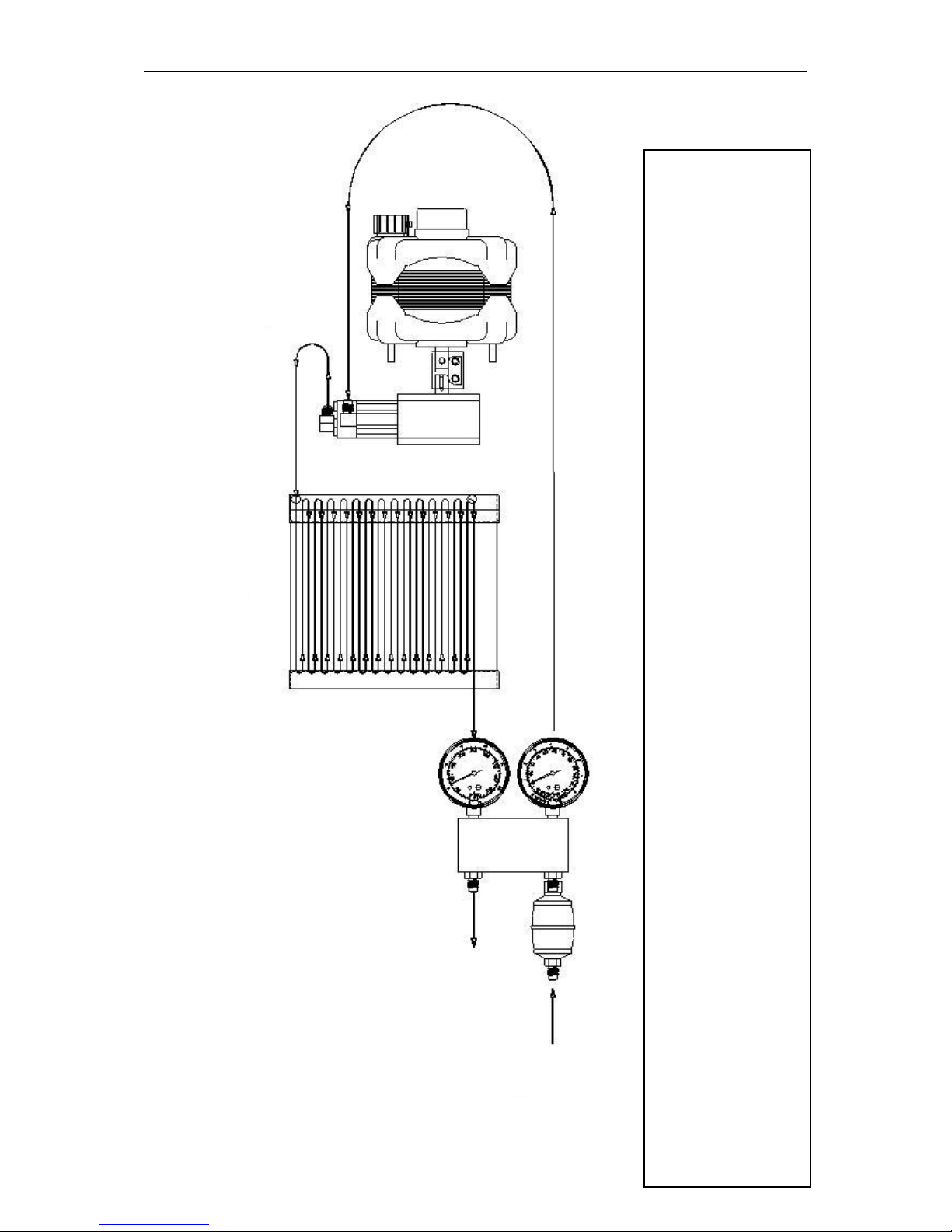

REFRIGERANT FLOW DIAGRAM

NOTE: A filter must always be used. Failure to use a filter will invalidate your warranty.

The use of a filter will greatly reduce the risk of damage to your RG5410A-EXTREME by preventing foreign material

from entering the unit.

Special consideration for filtration must be given when you know you are servicing a machine that has "Burned Out".

We recommend the use of two size 162 filter driers, in line, to be used for that job and that job only.

INPUT

CONDENSER

COMPRESSOR

MOTOR

Page 15

Advanced Test Products RG5410A-EXTREME

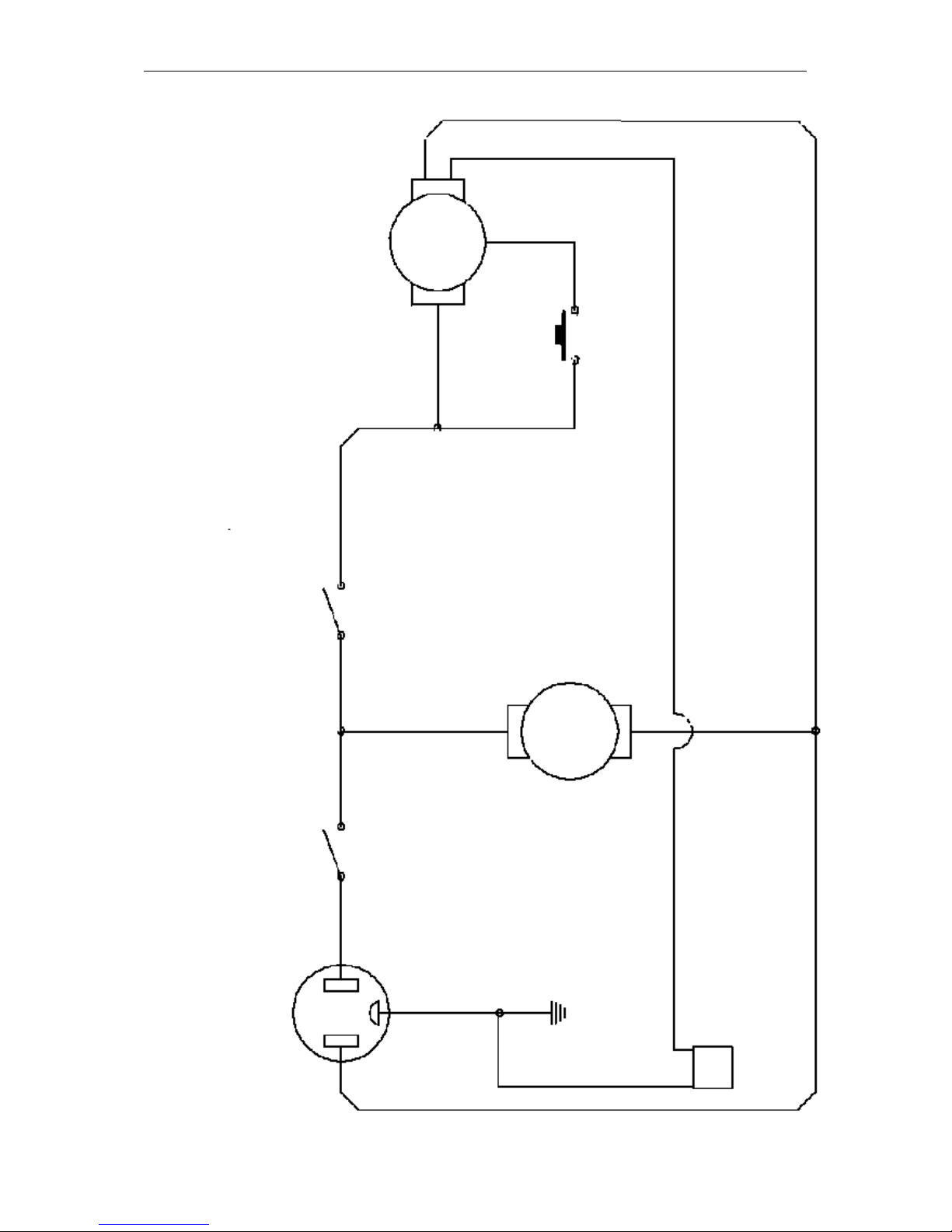

13

Plug AC Male

Power switch

High pressure switch

Fan motor

3 pin connector for

up-grade

1/2 HP motor

wht

wht

brn

red

3

2

1

6

RG5410A-EXTREME WIRING

DIAGRAM

Page 16

Advanced Test Products RG5410A-EXTREME

14

SAFETY PRESSURE SWITCH (WITH

MANUAL RESET FUNCTION)

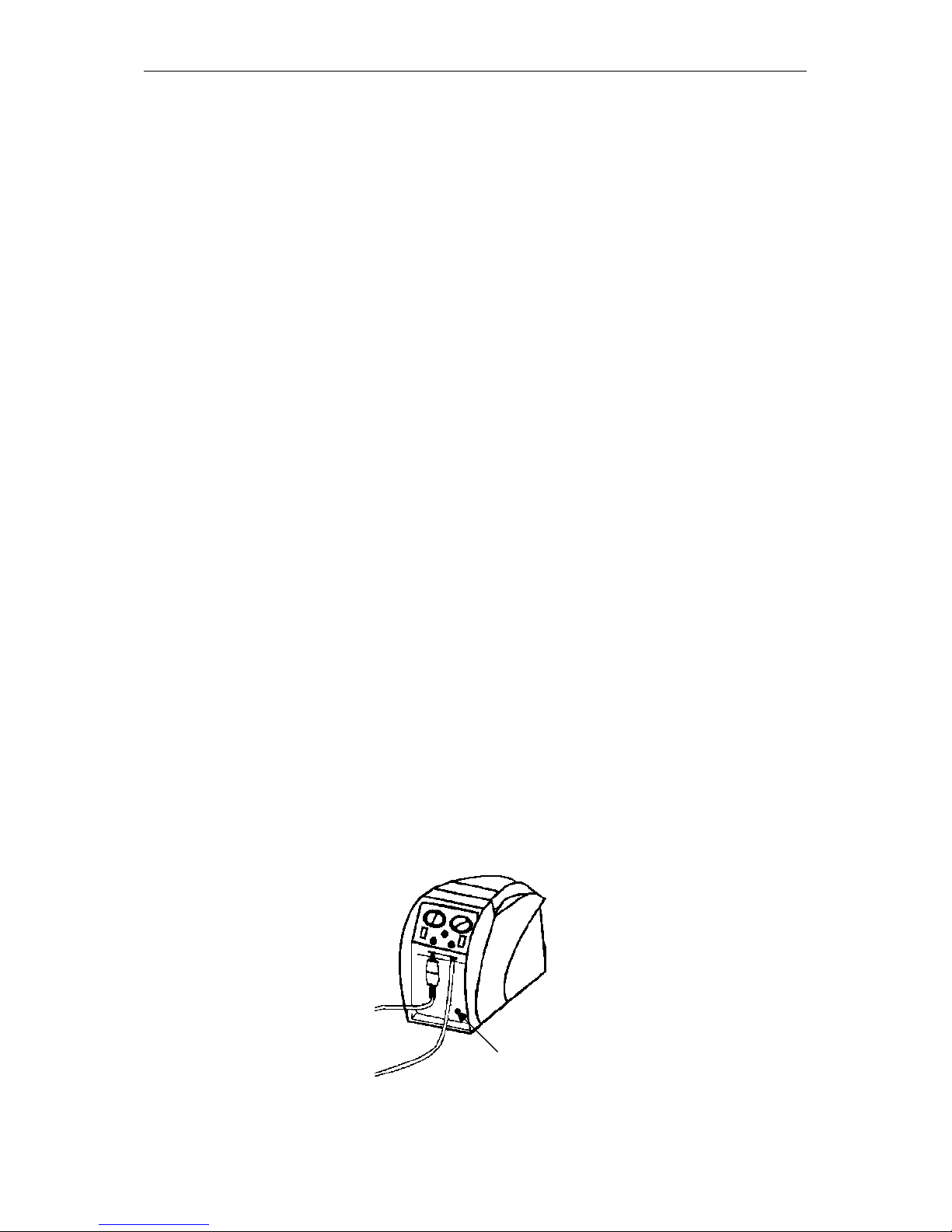

The RG5410A-EXTREME is equipped with an internal Safety Pressure Switch. If the

pressure inside the system exceeds 38,5 bar, the system is switched off automatically.

If the Safety Pressure Switch is activated automatically whilst filling a bottle, it could be

caused by the bottle becoming overfilled.

This is a very dangerous situation! You should take steps immediately to reduce the

overpressure and/or to eliminate the overfilling of the bottle.

If the Safety Pressure Switch switches the unit off...

The following precautions should be taken if the Safety Pressure Switch is activated:

a) Suspected overfilling of the recovery bottle

Connect the recovery bottle to another bottle with spare capacity so that the pressure is

reduced to a safe level. This action should also reduce the pressure in the output line

from the RG5410A-EXTREME. Proceed as normal after resetting the Safety Pressure

Switch (see below).

b) Cause of activation of Safety Pressure Switch unknown

1) Check that the recovery bottle is not overfilled.

2) Close the system valves, recovery bottle valves and RG5410A-EXTREME valves.

3) Disconnect RG5410A-EXTREME from flexible pipes.

4) Disconnect RG5410A-EXTREME from the power supply.

5) Open the input and output valves very slowly.

6) Investigate the reason for the failure.

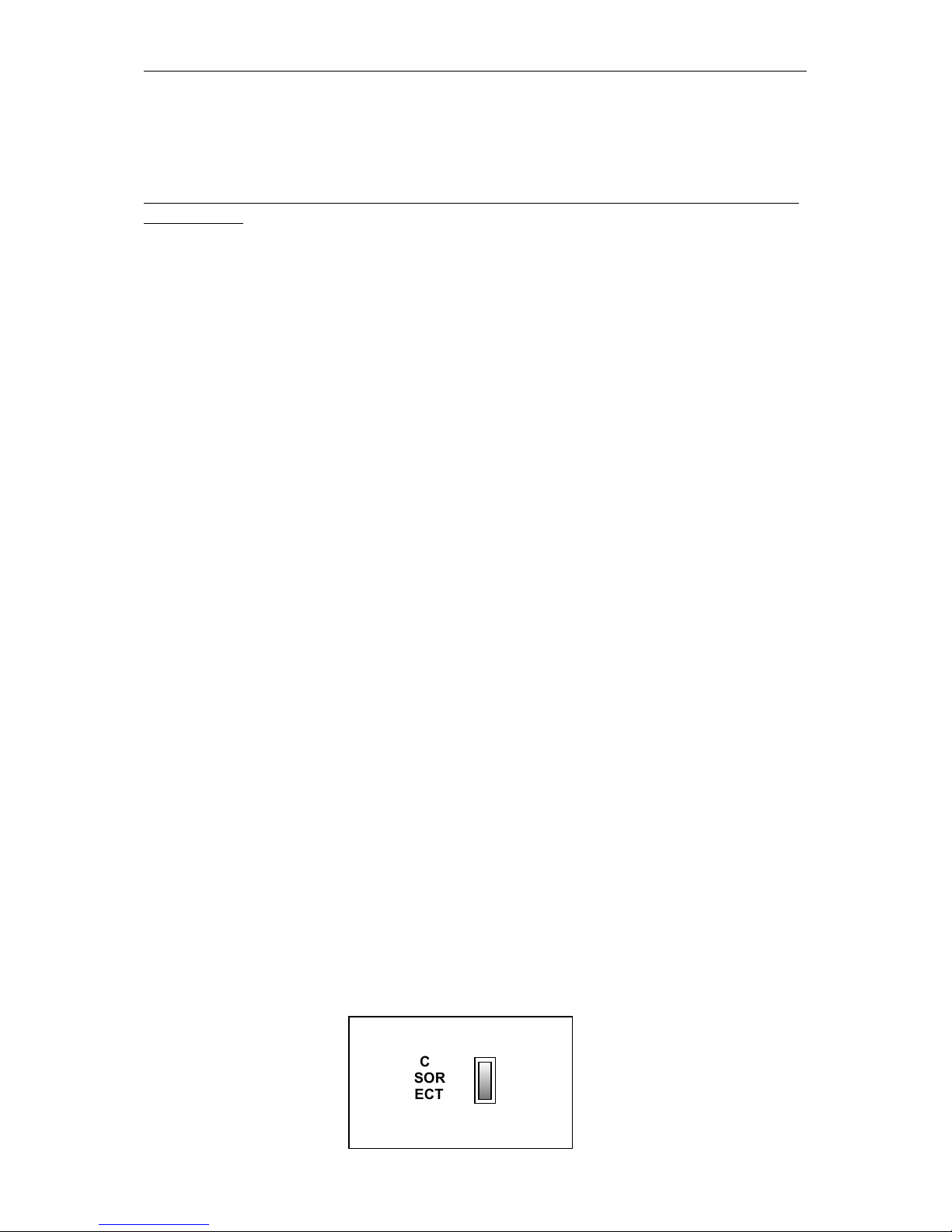

Once activated the Safety Pressure Switch has to be reset manually as follows:

I) Remove the black protection cover to reveal the reset button (see picture below).

II) Reset by pushing the reset button with a tool such as a screwdriver.

III) Replace the cover.

Remove this part in order to

Reset the pressure switch.

Page 17

Advanced Test Products RG5410A-EXTREME

15

CARE AND MAINTENANCE OF YOUR

RG5410A-EXTREME

A filter must always be used and should be replaced frequently. Failure to use a filter

will invalidate your warranty. The use of a filter will greatly reduce the risk of damage to

your RG5410A-EXTREME by preventing foreign material from entering the unit.

Special consideration for filtration must be given when you know the machine you are

servicing has "burned out". We recommend the use of two size 162 filter driers, in line,

to be used for that job and that job only. We also recommend that a clean filter be used

for every service job. Each filter should be labeled and used exclusively for one type of

refrigerant only.

Do not use this unit in the vicinity of spilled or open containers of gasoline or other

combustible liquids

Avoid the use of extension cords. If you must use an extension cord it should be a

minimum of 14 AWG and not longer than 25 ft. Not using an extension cord will greatly

reduce the risk of fire.

Always purge the unit of any refrigerant left after completing a service job. Refrigerant

left in the machine can expand and may cause damage to components.

If the unit is to be stored or not used for any length of time, we recommend that it be

completely evacuated of any residual refrigerant and purged with dry nitrogen.

Whenever you perform any type of maintenance work on your RG5410A-EXTREME,

insure that it is disconnected from the power supply before you begin.

Page 18

Advanced Test Products RG5410A-EXTREME

16

TECHNICAL SPECIFICATIONS

Type RG5410A-EXTREME

Application Refrigerant recovery Gas or Vapor

Suitable refrigerants R12, R22, R134A, R401A, R401B, R401C, R402A, R402B,

R404A, R406A, R407A, R407B, R407C, R407D, R408A,

R409A, R410A, R411A, R411B, R412A, R500, R502, R507,

R509

Power Source 230V / 50 Hz

Power 380 W

Dimensions 330 x 229 x 483 mm

Weight 14,5 kg

RPM´s 1437 U/min

Max. working pressure 550 p.s.i. (38,5 bar)

Fuse 5x20mm, slow blow, 8A 250V

Safety Device Safety pressure switch type P100 DA

with manual reset (550 p.s.i. / 38,5 bar)

ATTENTION

The RG5410A-EXTREME should not be used with inflammable gases

nor with gases containing ammonia.

Page 19

Advanced Test Products RG5410A-EXTREME

17

HELPFUL HINTS FOR REFRIGERANT

RECOVERY

Refrigerant recovery has come a long way in a few short years.

On the surface it’s simply the process of taking refrigerant out of a system and putting it

into a tank. However, this simple process can quickly become problematic if a few items

are overlooked. The following are some tips and pointers we’ve accumulated over the

last few years that can save you time and make the process go smoother.

First you need to identify the refrigerant type and quantity in the system you are

servicing.

If you determine it’s a burnout, you need a special tank (a tank that’s identified as

containing burnout or other unidentified gases), and you need to use extra filtration prior

to recovery.

If, on the other hand, you know the gas in the system is relatively clean or new, then a

new tank should be used. If you’re planning on putting the refrigerant back into the

same system after you have finished the service or if the refrigerant is going to be

reclaimed, then use a tank that has the same refrigerant in it. A word of caution about

the Environmental Protection Agency (EPA): If you use a variety of refrigerant gasses in

your service work - as evidenced by your refrigerant purchases - and you only own one

tank, you are asking for trouble. You would be well advised to own at least one tank for

every refrigerant type serviced, plus an extra for burnouts and other unknowns.

Planning Ahead

Knowing the quantity of refrigerant is important for planning storage requirements, as

well as planning for the actual recovery. For instance, any system with more than 5lbs.

of refrigerant is likely to have areas where the liquid can get trapped.

The key to a quick recovery procedure is to get the liquid out first, and then get the

remaining vapor out. However most systems are not “recovery friendly.” That is they

don’t have access ports at their lowest points. If some units you’re servicing are on

maintenance contracts, you would save significant time by installing access ports at all

of the lowest points in the system, where liquid is likely to accumulate. Since most

systems don’t have these ports you need to be prepared to boil of the trapped liquid

with a heat gun, when ever it’s found. An indicator of trapped liquid in a system is frost

or condensation forming on the plumbing or components where the liquid is trapped.

The trapped liquid may be in an area that is not visible. In all cases trapped liquid in a

system during recovery causes the recovery process to slow down, regardless of the

size or type of machine

If you are unable to locate the trapped liquid (but you know it’s there, because the

recovery job is taking “forever”), turn on the system compressor (if it’s operable) for a

few seconds. This will get the refrigerant moving to another part of the system and in.

Page 20

Advanced Test Products RG5410A-EXTREME

18

HOSES AND VALVES

Hoses and Schrader valves have a large impact on recovery speed. In general, the

larger the hose, the less friction on the flow of refrigerant and the quicker the recovery

time. Many contractors are now using 3/8” lines for the input to the recovery machine,

even if those lines originate out of 1/4” fittings.

Schrader valves must be removed from the connection prior to an expedient

recovery. Most wholesalers sell a tool for removing these cores, while keeping the

connection sealed. The core depressor, in the end of the hose, should also be removed.

These two items can turn a 20 minute job into one that goes on for hours. So, be sure to

remove Schrader valves and core depressors before every recovery job.

Another hose consideration is the little rubber grommet at the end of the hose that

makes a seal with the flare fitting. We’ve seen these seals so worm and deformed that

when the hose is connected to the flare fitting the grommet virtually seals off the the

connection. This is probably never noticed in charging, because the pressure opens the

grommet, but during recovery (or with suction) the deformed grommet severely restricts

the flow of refrigerant.

Refrigerant Recycling

Current regulations state that used refrigerant shall not be sold, or used in a different

owner’s equipment, unless the refrigerant has been laboratory analyzed and found to

meet the requirements of ARI 700 (latest edition). As a result, recycling and verifying

ARI 700 conformance isn’t economically justified in most cases. It’s still a great idea to

do as much cleaning of refrigerant going back into the same system (or owners

system) as possible. We recommend using the largest, high-acid capacity filter that are

economically feasIble. Put these filters on the suction or inlet side of the recovery unit.

Change filters often.

The recovery of large amounts of liquid refrigerant can sometimes carry with it large

quantities of oil, if the system being serviced doesn’t have an adequate oil separator

installed. If this recovered refrigerant isn’t going to be liquid charged back into the same

system, you might want to separate the refrigerant from the oil in order to

measure the oil (to know how much oil to charge back into the system). However

refrigerant sent back for reclaim does not need to have the oil removed. One of the

simplest and most cost effective ways to achieve this is to use a 30 or 50 lb. tank in line

with your recovery machine. Connect the the system to the liquid port of the tank then

from the vapor port of the tank connect to the input of your recovery machine a second

tank, for storing refrigerant, should then be connected to the output of the recovery

machine. If you encounter large amounts of liquid you will need to put a band heater

around the first tank.

When the recovery job is complete the oil can be removed, from the first tank, by

applying a small amount of pressure, using nitrogen, to one of the ports and

expressing the oil from the other. If you are going to remove the oil from the vapor port

you will need to turn the tank upside down. Always wear safety glasses when

performing this operation as the oil may be acidic and could cause severe burning.

Page 21

Advanced Test Products RG5410A-EXTREME

19

KEEPING THE DIRT OUT

During the recovery process your recovery machine can be exposed to debris that can,

potentially, damage it. Including brazing spatter and copper and brass slithers. Further

contamination can be introduced from the refrigerant storage tanks. To

prolong the life of your recovery machine always use an in-line filter.

Whenever you are charging a system from a recovery cylinder it is a good idea to use

an in-line filter to protect the system from contamination. Again, change your

in-line filters often.

Getting the Liquid Out (See “Push/Pull-Method”)

Push-pull is a method of removing bulk liquid from a system using the pressure

differential created by the recovery machine. Push-pull will generally not work on

smaller systems because there is no bulk liquid reservoir to create a siphon from.

Push-pull is mostly used on systems with a receiver tank or those with greater than 20

lbs. of refrigerant, or when transferring from one tank to another. The rate of liquid

transfer is very much dependent on hose size, with larger hoses providing much

better throughput.

Another trick is to chill the tank, if it’s partially filled, prior or during recovery. This

operation will lower the pressure in the storage tank and therefore speed up recovery.

There must be a minimum of 5 lbs of liquid refrigerant in the tank you wish to chill. This

operation can be performed prior to or during the recovery. See the two set up diagrams

and procedures on page 8 of this manual.

There is nothing magic here, you are simply using your recovery machine to make a

refrigerator where the tank is the evaporator. By throttling the output valve, you’re

effectively creating a capillary tube or an expansion device, but you need to adjust the

backpressure to suit the conditions and the refrigerant. Five to ten minutes of chilling

can produce some very dramatic tank cooling, depending on the conditions. If there are

any non-condensable in the tank this process will not work. Also the greater the quantity

of refrigerant in the tank the longer the process will take.

Page 22

Advanced Test Products RG5410A-EXTREME

20

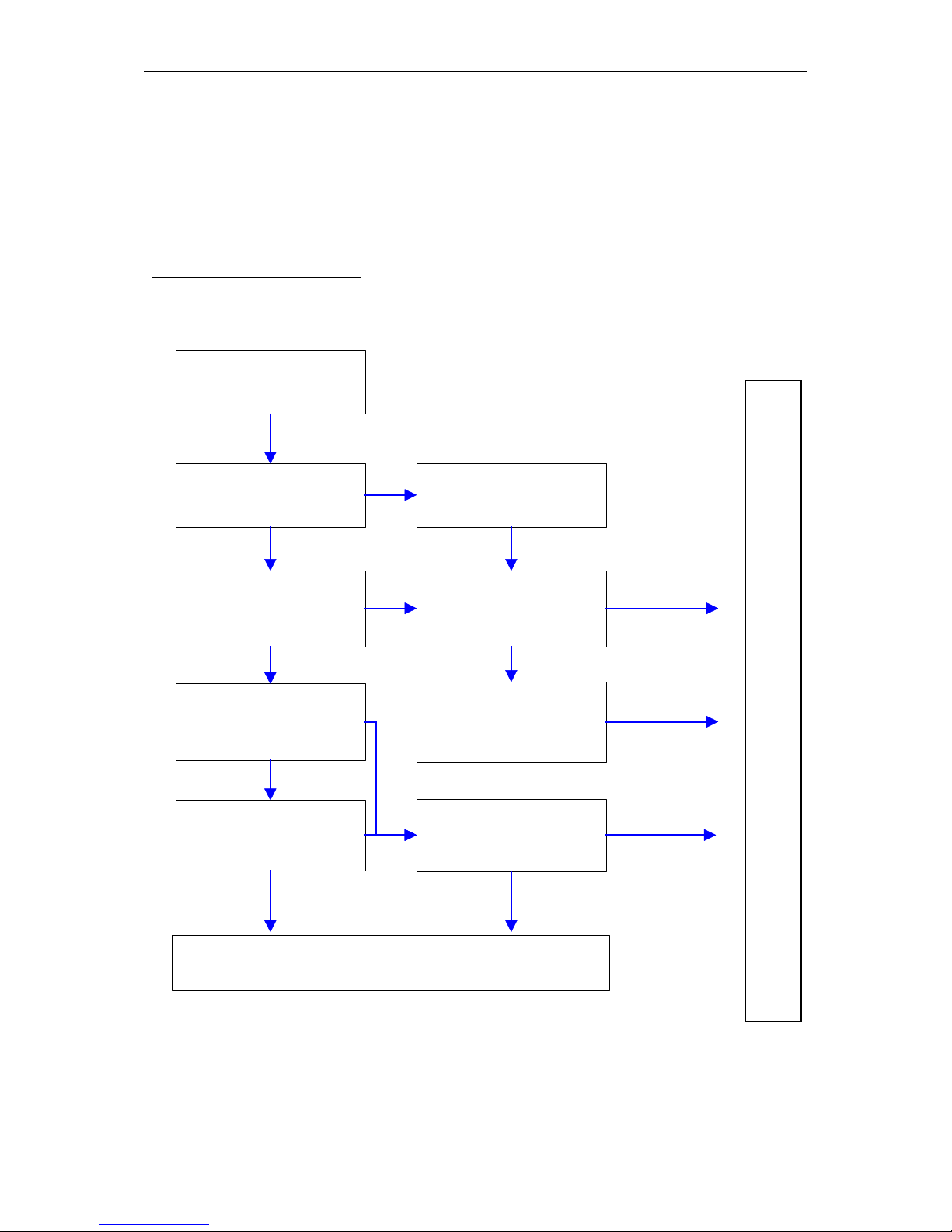

TROUBLESHOOTING YOUR

RG5410A-EXTREME

The safe way is the only way

Read and understand all safety information contained in this manual

before servicing the unit.

Connect unit to 220 V outlet

Fan is running when power

switch is in "ON" position?

Compressor starts when

start switch is pressed

Unit pumps into high

pressure shut off?

Power supply ok?

TROUBLESHOOTING ENDS

Are your hoses tight? Do

you have leaks?

Unit pulls into a vacuum?

Is unit in high pressure shut

off?

Are valves open?

Reset button pushed?

yes

no

yes

yes

no

ye

no

yes

yesnoyes

no

j

yes

yes

C

O

N

T

A

C

T

P

R

O

M

A

X

S

E

R

V

I

C

E

Page 23

BENUTZERHANDBUCH

RG5410A-EXTREME

Page 24

Advanced Test Products RG5410A-EXTREME

2

INHALTSVERZEICHNIS

I) Sicherheitshinweise

A) Sicherheit ist oberstes Gebot 1

B) Kältemittelabsaugungs- und Serviceverfahren 2

II) Wichtige allgemeine Informationen 3

III) Betriebsverfahren

A) Betrieb des RG5410A-EXTREME 4-6

Gebrauch des Niederdruckschalters 6

B) Aufbau / Anschluss 7-9

C) Evakuierung der nicht kondensierbaren Gase 10

IV) Pläne und Listen

A) Teileliste 11

B) Kältemittel-Flussdiagramm 12

C) Schaltplan 13

V) Sicherheitsdruckbegrenzer (SDBK) 14

VI) Pflege und Wartung 15

VII) Technische Daten 16

VIII) Nützliche Hinweise zur Kältemittelabsaugung 17-20

IX) Störungssuche 21

X) Garantie 22

Irrtum sowie Änderungen der technischen Daten und Materialien ohne vorherige Ankündigung

vorbehalten.

Dieses Handbuch darf ohne ausdrückliche schriftliche Genehmigung von ADVANCED TEST

PRODUCTS auf keinerlei Weise und in keiner Form vervielfältigt werde.

Page 25

Advanced Test Products RG5410A-EXTREME

1

SICHERHEIT IST OBERSTES GEBOT

HINWEIS: Nur sachkundige, im Umgang mit Kältemitteln geschulte Personen

dürfen dieses Gerät bedienen.

1. Bei Arbeiten an Kälteanlagen sind stets Schutzbrille und Handschuhe zu tragen.

2. Die Räume, in denen das Gerät betrieben wird, müssen gut belüftet sein, vor allem

bei Verdacht auf ein Leck. Kältemitteldämpfe sind gesundheitsschädlich und

möglicherweise tödlich.

3. Zuerst denken, dann handeln! Vertrautheit mit einem Gerät verführt zu Unaufmerksamkeit, und Unaufmerksamkeit kann zu Gesundheitsschäden oder gar zum

Tode führen.

4. Lesen Sie die Sicherheitsdatenblätter sämtlicher Verbindungen durch, mit denen

Sie in Kontakt kommen können. Lesen Sie die Sicherheitsdatenblätter des Kältemittels und Kältemaschinenöls. Sicherheitsdatenblätter können Sie von Ihrem

Kältemittellieferanten anfordern.

5. Verwenden Sie niemals Sauerstoff zur Prüfung auf Lecks. Jede Art von Öl, die in

Kontakt mit unter Druck stehendem Sauerstoff gelangt, ergibt eine explosive

Mischung.

6. Kälteanlagen werden im allgemeinen elektrisch betrieben und gesteuert. Trennen

Sie die Anlage vor der Ausführung von Wartungsarbeiten vom Netz.

7. Kältemittelbehälter sind stets an einem kühlen, trockenen Ort aufzubewahren.

8. Service- und Flaschenventile sind stets langsam zu öffnen. Besteht eine Gefahr,

kann der Gasfluß schnell unterbunden werden. Steht fest, daß keine Gefahr

besteht, können die Ventile vollständig geöffnet werden.

9. Unterschiedliche Kältemittel dürfen weder in Anlagen noch in Flaschen noch sons

gemischt werden. Für jedes Kältemittel ist eine eigene Flasche, ein eigener Filter

usw. erforderlich.

10. Tritt Feuchtigkeit in eine Kälteanlage ein, kann dies beträchtliche Schäden verursachen. Sämtliche Teile der Kälteanlage sind stets trocken und sauber zu halten.

11. Um das Risiko von Bränden zu verringern sollten Sie keine Verlängerungskabel

verwenden, da sich diese überhitzen können. Sollte es jedoch unumgänglich sein,

ein Verlängerungskabel zu verwenden, so sollte dieses ein Minimum von 14 AWG

besitzen (Querschnittsfläche Kabel: 2 mm²) und nicht länger als 7,5m sein. Dieses

Gerät darf in Räumen eingesetzt werden, bei denen durch mechanische

Lüftungsmaßnahmen mindestens vier Luftwechsel in der Stunde gewährleistet sind,

oder das Gerät muss sich mindestens 45 cm oberhalb des Bodens befinden.

Dieses Gerät darf nicht in der Nähe von verschüttetem Benzin oder offenen

Behältern mit Benzin oder anderen brennbaren Flüssigkeiten eingesetzt werden.

Page 26

Advanced Test Products RG5410A-EXTREME

2

RG5410A-EXTREME

KÄLTEMITTELABSAUGUNGS- UND

SERVICEVERFAHREN

Sicherheit steht an erster Stelle. Lesen Sie alle Sicherheitsinformationen zur sicheren

Handhabung von Kältemitteln sowie die Sicherheitsblätter Ihres Kältemittellieferanten

durch. Der Betrieb des Gerätes in explosionsgefährdeten Umgebungen ist unzulässig.

Tragen Sie stets Schutzbrille und Schutzhandschuhe. Das Gerät darf nur in gut

belüfteten Räumen betrieben werden. Nur sachkundige, im Umgang mit Kältemitteln

geschulte Personen dürfen dieses Gerät bedienen.

*** VORSICHT: KÄLTEMITTELFLASCHEN ***

Nur zugelassene und geprüfte, den relevanten Normen entsprechende Flaschen mit

einem zulässigen Betriebsdruck von mindestens 41 bar dürfen verwendet werden.

HINWEIS: Kältemittel- und Recyclingflaschen sind für unterschiedliche Drücke

ausgelegt. Der Arbeitsdruck der Flaschen darf nicht überschritten werden.

Die Sicherheitsvorschriften empfehlen, geschlossene Flaschen zu nicht mehr als 80%

ihres Volumens mit Flüssigkeit zu füllen. Die restlichen 20% werden als Kopfraum

bezeichnet.

DER TRANSPORT ÜBERFÜLLTER KÄLTEMITTELFLASCHEN IST UNZULÄSSIG.

Kältemittel dehnen sich bei Erwärmung aus – überfüllte Flaschen können bersten.

FLASCHENTEMP. 16 °C 21 °C 38 °C 54 °C 66 °C

AUSGANGSFÜLLUNG

80 VOL%

FLÜSSIGKEITSFÜLLGRAD

AUSGANGSFÜLLUNG

90 VOL%

FLÜSSIGKEITSFÜLLGRAD

80 % 81% 83% 90% 94%

90% 92% 96% 100%

Page 27

Advanced Test Products RG5410A-EXTREME

3

WICHTIGE ALLGEMEINE

INFORMATIONEN

Vor Betrieb des Absaugerätes RG5410A-EXTREME sind unbedingt folgende

Informationen durchzulesen:

1. Große Kältemittelmengen sollten isoliert werden, und nach Gebrauch sollten die

Ventile geschlossen werden, so daß im Falle eines Lecks in der Anlage kein

Kältemittel austreten kann.

2. Neue Kältemittelflaschen werden in einigen Fällen mit nicht richtig sitzenden Ventilen

geliefert. Kappen auf solchen Ventilen können das Austreten von Kältemittel

verhindern.

3. Das Gerät ist stets auf einer ebenen Fläche zu betreiben.

4. Das RG5410A-EXTREME ist mit einem internen Sicherheitsdruckbegrenzer

ausgerüstet. Überschreitet der Druck im System 38,5 bar, wird das System

automatisch abgeschaltet.

ACHTUNG

Auch ein Sicherheitsdruckbegrenzer (SDBK) kann die Überfüllung der Flasche

nicht verhindern. Wird das System bei hohen Drücken abgeschaltet und ist mit

einer Flasche verbunden, wurde die Flasche möglicherweise überfüllt. Dies ist ein

äußerst gefährlicher Zustand ! Maßnahmen zum Abbau des Überdrucks und/oder

zur Beseitigung der Überfüllung sind sofort zu treffen.

5. WARNUNG! Kältemittelflaschen dürfen niemals überfüllt werden. Überfüllung kann

zum Bersten der Flaschen führen.

6. Während des Absaugvorganges müssen Kältemittelflaschen gewogen werden um

ein Überfüllen der Flaschen auszuschließen.

7. Flaschen dürfen nur für jeweils ein Kältemittel verwendet werden. Bevor Sie eine

Flasche verwenden, die zuvor für ein anderes Kältemittel verwendet wurde, ist die

Flasche vollständig zu entleeren und zu evakuieren. Anschließend ist die Flasche mit

trockenem Stickstoff zu spülen und erneut zu evakuieren.

8. Bei der Absaugung einer ausgebrannten Anlage ist besondere Vorsicht geboten. In

solchen Fällen sind zwei in Serie geschaltete Filter mit hoher Säurekapazität zu

verwenden. Empfohlen werden Filter des Typs C-162-F von Sporlan. (Promax

Teil Nr. FL-1201)

9. Nach beendigter Absaugung ist das RG5410A-EXTREME mit einer geringen Menge

Kältemaschinenöl und einer geringen Menge sauberen Kältemittels zu spülen, um im

Gerät verbliebene Fremdsubstanzen zu entfernen.

10.Kältemittel ist stets aus dem Gerät in eine Flasche zu pumpen. Im Verdichter

verbleibendes Kältemittel kann sich ausdehnen und das Gerät beschädigen.

Page 28

Advanced Test Products RG5410A-EXTREME

4

BETRIEB DES RG5410A-EXTREME

Schließen Sie das RG5410A-EXTREME an eine 230 V-Steckdose an. Schalten Sie den

Netzschalter ein (ON-Position). Der Lüfter läuft. Drücken Sie zum Starten des

Kompressors den Kompressor-Starttaster. In manchen Fällen ist es eventuell

erforderlich, diesen Taster mehrmals zu drücken, um den Kompressor zu starten.

BETRIEBSARTEN

Das schwarze Ventil darf

bei laufendem Gerät

nicht betätigt werden.

Einlassventil schließen,

Gerät ausschalten.

In Purge-Position

schalten und Gerät

erneut starten.

Das schwarze Ventil darf

bei laufendem Gerät

nicht betätigt werden.

Einlassventil schließen,

Gerät ausschalten.

In Purge-Position

schalten und Gerät

erneut starten.

HINWEIS: Wechsel vom Absaug- zum Spülmodus:

Einlaßventil schließen, Gerät ausschalten (um Hochdruckabschaltung zu

vermeiden), auf Spülposition (PURGE) umschalten und Gerät erneut starten.

NORMALES ABSAUGEN

SELBSTSPÜLUNG / AUT. EVAKUIERUNG

Page 29

Advanced Test Products RG5410A-EXTREME

5

BETRIEB DES RG5410A-EXTREME

Betriebsart RECOVER: („normales Absaugen von Kältemittel“)

1. Vergewissern Sie sich, daß das RG5410A-EXTREME keine äußeren Schäden

aufweist.

2. Stellen Sie sicher, daß alle Anschlüsse und Verbindungen korrekt und fest

angeschlossen sind.

3. Stellen Sie sicher, daß das „Recover/Purge“ Ventil auf Recover eingestellt ist.

4. Öffnen Sie die Ventile des zu wartenden Systems langsam.

5. Öffnen Sie das Flüssigkeitsventil der Manometerventil.

6. Stellen Sie das Einlaßventil am RG5410A-EXTREME auf die Position „Liquid“

(flüssig.

7. Stellen Sie das Auslassventil am RG5410A-EXTREME auf die Position „OPEN“

(offen.

8. Öffnen Sie das Flüssigkeitsventil der Kältemittelflasche.

9. Schließen Sie das RG5410A-EXTREME an eine 230V Spannungsquelle an.

a)Stellen Sie den Netzschalter des RG5410A-EXTREME in die Position

„ON“, dadurch wird zunächst nur der Ventilator aktiviert.

b) Drücken Sie nun den Kompressor-Starttaster um das RG5410AEXTREME in Betrieb zu setzen.

10. Nachdem Sie sich überzeugt haben das alles ordnungsgemäß funktioniert, sollten

Sie das Einlaßventil des RG5410A-EXTREME langsam in die Stellung „OPEN“

drehen, jedoch nur soweit, dass kein lautes Schlagen (Klopfen) auftritt. Dieses

Schlagen bzw. Klopfen des Kompressors tritt nur dann auf, wenn der Verdichter

zuviel Flüssigkeit pumpt.

11. Betreiben Sie das RG5410A-EXTREME bis das erforderliche Vakuum erreicht wird.

12. Nach der Beendigung der Kältemittelabsaugung sollte auch das RG5410AEXTREME vom Kältemittel befreit werden (siehe Funktion „Selbstentsorgung

/Purge“).

ACHTUNG

Beim Absaugen von flüssigem Kältemittel sollte das Einlaßventil nicht zu weit

geöffnet werden da es sonst zu lauten Schlägen (Klopfen) des Kompressors

kommen kann. Dieses Schlagen bzw. Klopfen des Kompressors tritt nur dann auf

wenn der Verdichter zu viel Flüssigkeit pumpt, dadurch kann der Motor

abgewürgt werden.

Page 30

Advanced Test Products RG5410A-EXTREME

6

BETRIEB DES RG5410A-EXTREME

Betriebsart PURGE : („Evakuierung verbliebener Kältemittelreste im RG5410AEXTREME“)

1. Schließen Sie die Ventile des zu wartenden Systems welches am Einlaßventil des

RG5410A-EXTREME angeschlossen ist.

2. Schließen Sie das Einlaßventil am RG5410A-EXTREME (Position „CLOSED“).

3. Schalten Sie das RG5410A-EXTREME aus.

4. Stellen Sie nun das „Recover/Purge“ Ventil auf Position PURGE.

5. Starten Sie nun das RG5410A-EXTREME.

6. Betreiben Sie das RG5410A-EXTREME bis das gewünschte Vakuum erreicht ist.

7. Schließen Sie das Flüssigkeitsventil der Kältemittelflasche.

8. Schließen das Auslassventil am RG5410A-EXTREME (Position „CLOSED“).

9. Schalten Sie das RG5410A-EXTREME ab.

10. Stellen Sie nun das „Recover/Purge“ Ventil wieder auf Position RECOVER.

11. Entfernen Sie alle Zuleitungen vom RG5410A-EXTREME.

12. Wechseln Sie nach jedem Absaugen stark verschmutzter Kältemittel immer den

Einlassfilter am RG5410A-EXTREME.

Die Bedienung des

Niederdruckschalters

Das RG5410A-EXTREME ist mit einem Niederdruckschalter ausgerüstet, den man bei

Bedarf ein- bzw. ausschalten kann (ON/OFF VAC SENSOR SELECT). Bei aktiviertem

Nieder-druckschalter schaltet das Gerät bei einem Druck von 0,45 bar absolut ab. Ist

der Niederdruckschalter ausgeschaltet, saugt das Gerät auch nach Erreichen dieses

Druckniveaus kontinuierlich weiter.

VAC

SENSOR

SELECT

ON

OFF

Page 31

Advanced Test Products RG5410A-EXTREME

7

VORBEREITUNG FÜR KÄLTEMITTELABSAUGUNG

Um den maximalen Endunterdruck zu erreichen, ist mit Hilfe des Flaschenkühlungsverfahrens der Kopfdruck in der Absaugflasche zu verringern. Wiederholen Sie dieses

Verfahren, bis der gewünschte Unterdruck erreicht ist.

HINWEIS: Enthält die Absaugflasche keine Flüssigkeit, funktioniert dieses Kühlverfahren nicht. In diesem Falle kann zum Erreichen des erforderlichen Endunterdrucks

eine vollständig evakuierte leere Flasche verwendet werden.

Zur Maximierung der Absauggeschwindigkeit sollten möglichst kurze Schläuche mit

einem Durchmesser von mindestens 3/8" verwendet werden. Eine maximale Schlauchlänge von ca. 90 cm wird empfohlen. Um den maximal möglichen Durchsatz zu

erreichen, sind alle unnötigen Tuyau abaisse de baseund Schraderventile unter

Verwendung geeigneter Ventileinsatzwerkzeuge von den Anschlüssen zu entfernen.

Verformte Gummidichtungen und Kerndrücker in Schläuchen oder defekte oder

unnötige Schraderventile können den Fluß um bis zu 90% vermindern.

Wenn der Druck in der Flasche den Wert 31,5 bar überschreitet, müssen Sie die

Flasche kühlen. Benutzen Sie hierfür den Aufbau für die Vor- oder Nachkühlung der

Flasche. Wenn Sie größere Mengen an flüssigem Kältemittel absaugen benutzen Sie

die unten angeführte „DRUCK-ZUG-METHODE“.

ACHTUNG: Bei Verwendung der „DRUCK-ZUG-METHODE" ist eine Waage

erforderlich, um das Überfüllen der Flasche zu vermeiden. Wurde der "DRUCK-ZUGSIPHON" erst einmal eingeleitet, kann er sich fortsetzen und die Flasche auch dann

überfüllen, wenn diese mit einem Schwimmer-Füllstandssensor ausgerüstet ist. Die

Siphonwirkung kann sich sogar bei abgeschaltetem Gerät fortsetzen. Sie müssen die

Ventile an der Flasche und am Gerät von Hand schließen, um das Überfüllen der

Flasche zu verhindern.

AUFBAU FÜR VOR- ODER NACHKÜHLUNG DER

FLASCHE

EINLASS

AUSLASS

DAMPF

FLÜSSIGKEIT

Zu Beginn dieses Verfahrens muß die

Flasche mindestens 2,5 kg flüssiges

Kältemittel enthalten.

Drosseln Sie das Auslassventil, so daß der

Ausgangsdruck 7 bar höher als der

Einlaßdruck ist. Er darf jedoch in keinem

Falle 31,5 bar überschreiten.

Betreiben Sie das Gerät mit diesem

Aufbau, bis die Flasche kalt ist.

Page 32

Advanced Test Products RG5410A-EXTREME

8

AUFBAU FÜR KÄLTEMITTELABSAUGUNG

Dies ist das schnellste Verfahren zur Absaugung von gasförmigen Kältemitteln.

MANOMETERBATTERIE

(OPTIONAL)

FEUCHTIGKEITS-

SCHAUGLAS

EINLASS

AUSLASS

FLÜSSIGKEIT

Um Überfüllung der

Flasche zu verhindern,

muß eine Waage

verwendet werden.

ZU

WARTENDES

SYSTEM

DAMPF

FLÜSSIGKEIT

AUFBAU FÜR "DRUCK-ZUG-METHODE"

Die Druck-Zug-Methode funktioniert nur bei großen Anlagen, bei denen die Flüssigkeit

gut zugänglich ist. Diese Methode sollte bei Anlagen, die weniger als 7 kg enthalten,

nicht angewandt werden, da sie dann eventuell nicht funktioniert.

ZU

WARTENDES

SYSTEM

FLÜSSIGKEIT

DAMPF

DAMPF

FLÜSSIGKEIT

AUSLASS

OPTIONALES FEUCHTIGKEITS-

SCHAUGLAS

EINLASS

Das Schauglas gibt Aufschluß über den Feuchtigkeitsgehalt und die Qualität des in einer Anlage enthaltenen

Kältemittels.

Um die Überfüllung der

Flasche zu verhindern, muss

eine Waage

verwendet werden.

Page 33

Advanced Test Products RG5410A-EXTREME

9

OPTIONALE ABSAUGUNG / FLASCHENKÜHLUNG

FÜR FESTE SCHLAUCHSYSTEME

Aufbau für Absaugung mit betriebsbereitem Flaschenkühlschlauch

ZU

WARTENDES

SYSTEM

FLÜSSIGKEIT

DAMPF

DAMPF

FLÜSSIGKEIT

MANOMETERBATTERIE

EINLASS

AUSLASS

Um Überfüllung der

Flasche zu verhindern,

muss eine Waage

verwendet wenden.

Normale Absaugung:

Dampfventil der Flasche ist geschlossen.

Vor- oder Nachkühlung der Flasche:

Dampfventil der Flasche ist offen und beide Ventile der Manometerventil sind

geschlossen; siehe Kühlungsverfahren auf Seite 7.

Page 34

Advanced Test Products RG5410A-EXTREME

10

ABSAUGEN MIT DEM

RG5410A-EXTREME

Evakuierung der nicht kondensierbaren Gase aus einem Kältemittel in einer

Flasche

8. Lassen Sie die Flasche 24 Stunden lang ungestört stehen. Hierdurch können die

nicht kondensierbaren Gase nach oben steigen.

9. Schließen Sie die Manometerventil an die Flasche an und lesen Sie den Druck in

der Flasche ab.

10. Bestimmen Sie die Umgebungstemperatur im Raum.

11. Vergleichen Sie die Temperatur mit dem Druck des betreffenden Kältemittels.

Verwenden Sie hierfür die zugehörigen Temperatur- und Drucktabellen.

12. Wenn der abgelesene Druck höher ist als der angegebene Druck in der

Drucktabelle, öffnen Sie langsam das Ventil für Dampf. Führen Sie dies sehr

langsam aus, um Turbulenzen in der Flasche zu vermeiden. Beobachten Sie, wie

der Druck am Manometer abfällt. Addieren zu dem Druck der in den Drucktabellen

angegeben ist 0,3 bis 0,35 bar. Schließen Sie das Ventil für den Dampfanschluss an

der Flasche wenn die Manometeranzeige mit diesem Druck übereinstimmt.

13. Lassen Sie die Flasche 10 Minuten lang ruhig stehen und messen Sie den Druck

erneut.

14. Wenn nötig wiederholen Sie den oben beschriebenen Vorgang.

Page 35

Advanced Test Products RG5410A-EXTREME

11

TEILELISTE RG5410A-EXTREME

Pos. Bezeichnung Teilen.

1 Kunststoffgehäuse 111-20119-TAB

2 Lüftergitter 100505

3 Axiallüfter EL1818

4 Verflüssiger CD1201

5 Motor 105-200446-001

6 Kupplung 534483

7 Flansch CP1001

8 Kompressor 535398ASM

9 Sicherung 5x20mm 140-200347-001

10 Einlassmanometer 534487

11 Auslassmanometer 534488

12 Manometer Glas GA1000

13 Netzschalter EL1310

14 Startschalter EL1309

15 Einlassknopf 100123

16 Auslassknopf 100124

17 Modusumschalter 100122

18 Frontplatte 110-201120-001

19 Filter 100343

20 Kappe NB6501

21 Netzkabel 135-200341-001

22 Hochdruckschalter 100339

23 Rückplatte 536762

24 Niederdruckschalter 105-200396-001

25 Kompressorhalter 100207

26 Verteiler 105-200808-001

27 Schlauch 4“ 100345

28 Sicherungshalter 100419

29 Niederdrucksensor 113726

- Rückschlagventil 116418

- Führen Kondensator 536755

Page 36

Advanced Test Products RG5410A-EXTREME

12

KÄLTEMITTEL-FLUSSDIAGRAMM

HINWEIS: Ein Filter ist stets zu verwenden. Bei Nichtverwendung eines Filters besteht kein Anspruch auf Garantieleistung.

Durch Verwendung eines Filters wird das Risiko von Beschädigungen des RG5410A-EXTREME durch in das Gerät

eindringende Fremdsubstanzen beträchtlich verringert.

Die Filterung ist besonders beim Absaugen ausgebrannter Anlagen von großer Bedeutung. Wir empfehlen den Einsatz von zwei

in Serie geschalteten Filtertrocknern der Größe 162, die ausschließlich für die betreffende Anlage verwendet werden sollten.

EINLASS

VERFLÜSSIGER

KOMPRESSOR

MOTOR

Page 37

Advanced Test Products RG5410A-EXTREME

13

VERDRAHTUNGSPLAN RG5410A-EXTREME

Sicherung

Gelb

Braun

Lüfter

Braun

Braun

Braun Blau Blau Netzschalter Startknopf Hochdrucksensor Niederdrucksensor

Niederdruck-

schalter

Buchse für Netzkabel

Schwarz

Neutral

Schwarz

Neutral

Weiß

Rot

Rot

½ PS

Motor

Page 38

Advanced Test Products RG5410A-EXTREME

14

.SICHERHEITSDRUCKBEGRENZER

(SDBK)

Das RG5410A-EXTREME ist mit einem internen Sicherheitsdruckbegrenzer

ausgerüstet. Überschreitet der Druck im System 38,5 bar, wird das System automatisch

abgeschaltet.

Auch ein Sicherheitsdruckbegrenzer (SDBK) kann die Überfüllung der Flasche nicht

verhindern. Wird das System bei hohen Drücken abgeschaltet und ist mit einer Flasche

verbunden, wurde die Flasche möglicherweise überfüllt. Dies ist ein äußerst

gefährlicher Zustand ! Maßnahmen zum Abbau des Überdrucks und/oder zur

Beseitigung der Überfüllung sind sofort zu treffen.

Wenn der Sicherheitsdruckbegrenzer auslöst ...

Sollte der Sicherheitsdruckbegrenzer aufgrund von Fehlbedienung oder sonstiger

Umstände ansprechen, sind folgende Maßnahmen zu treffen:

a) Überfüllung der Flasche

Verbinden Sie die Flasche mit einer zweiten Flasche, welche noch eine ausreichende

Füllmenge aufnehmen kann, so dass der Druck auf ein sicheres Maß reduziert wird.

Hierdurch wird ebenfalls der Druck in der Ausgangsleitung des RG5410A-EXTREME

reduziert. Fahren Sie danach normal fort, nachdem der Sicherheitsdruckbegrenzer

zurückgesetzt wurde (siehe unten).

b) Grund der Auslösung des Sicherheitsschalters ist unbekannt

1) Eventuell vorhandenen Überdruck in der Kältemittelflasche abbauen.

2) Die Ventile des zu wartenden Systems schließen

3) Das RG5410A-EXTREME von allen Schlauchverbindungen trennen

4) Das Ein- und Auslassventil am RG5410A-EXTREME langsam öffnen

5) Das RG5410A-EXTREME von der Netzversorgung trennen

6) Die Fehlerursache feststellen

Der Sicherheitsdruckbegrenzer muß manuell zurückgestellt werden, um das RG5410AEXTREME wieder in Betrieb nehmen zu können:

I) Schwarze Schutzkappe am RG5410A-EXTREME entfernen (siehe Bild unten)

II) Mit geeignetem Werkzeug (Schraubendreher) Reset-Knopf vom SDBK zurücksetzen.

III) Schwarze Schutzkappe am RG5410A-EXTREME befestigen.

Diese schwarze Kappe entfernen

um den Sicherheitsdruckbegrenzer

zurückzusetzen.

Page 39

Advanced Test Products RG5410A-EXTREME

15

PFLEGE UND WARTUNG

Ein Filter ist stets zu verwenden und häufig zu wechseln. Bei Nichtverwendung eines

Filters besteht kein Anspruch auf Garantieleistung. Durch die Verwendung eines Filters

wird das Risiko von Beschädigungen des RG5410A-EXTREME durch in das Gerät

eindringende Fremdsubstanzen beträchtlich verringert.

Bei der Absaugung einer ausgebrannten Anlage ist besondere Vorsicht geboten. In

solchen Fällen sind zwei in Serie geschaltete Filter mit hoher Säurekapazität zu

verwenden. Empfohlen werden Filter des Typs C-162-F Sporlan (Promax Teil Nr. FL-

121), welche nur hierfür eingesetzt werden sollen.

Wir empfehlen, für jede Absaugung einen sauberen Filter zu verwenden. Filter sollten

gekennzeichnet und nur für jeweils eine Kältemittelart eingesetzt werden.

Dieses Gerät darf nicht in der Nähe von verschütteten, feuergefährlichen Stoffen oder

offenen Behältern mit brennbarem Inhalt eingesetzt werden.

Um das Risiko von Bränden zu verringern sollten Sie keine Verlängerungskabel

verwenden. Sollte es jedoch unumgänglich sein, ein Verlängerungskabel zu verwenden,

so sollte dieses ein Minimum von 14 AWG besitzen (Querschnittsfläche Kabel: 2mm²)

und nicht länger als 7,5m sein.

Nach Abschluss jedes Absaugungsvorgangs sind im Gerät verbleibende

Kältemittelreste zu entfernen. Im Gerät verbleibendes Kältemittel kann sich ausdehnen

und das Gerät beschädigen.

Wird das Gerät gelagert oder über längere Zeit nicht genutzt, empfehlen wir die vollständige Evakuierung verbleibender Kältemittelreste und Spülung mit trockenem

Stickstoff.

Vergewissern Sie sich immer, dass bei Wartungsarbeiten an ihrem RG5410AEXTREME der Netzstecker gezogen ist.

Page 40

Advanced Test Products RG5410A-EXTREME

16

TECHNISCHE DATEN

RG5410A-EXTREME

Anwendung gasförmiges und flüssiges Absaugen von Kältemitteln

Kältemitteleignung R12, R22, R134A, R401A, R401B, R401C, R402A, R402B,

R404A, R406A, R407A, R407B, R407C, R407D, R408A,

R409A, R410A, R411A, R411B, R412A, R500, R502, R507,

R509

Anschlußspannung 230V / 50 Hz

Anschlußleistung 380 W

Abmessungen 330 x 229 x 483 mm

Gewicht 14,5 kg

Drehzahl 1437 U/min

max. zulässiger

Betriebsüberdruck 38,5 bar

Sicherung 5x20mm, träge, 8A 250V

Sicherheitseinrichtung Sicherheitsdruckbegrenzer für steigenden Druck

Type P100 DA, Abschaltdruck 38,5 bar

(manueller Reset notwendig)

ACHTUNG

Das RG5410A-EXTREME darf nicht mit brennbaren oder

ammoniakhaltigen Gasen betrieben werden.

Page 41

Advanced Test Products RG5410A-EXTREME

17

NÜTZLICHE HINWEISE ZUR

KÄLTEMITTELABSAUGUNG

Die Absaugung von Kältemitteln hat sich in den letzten Jahren grundlegend

weiterentwickelt.

Oberflächlich betrachtet ist es ein einfacher Prozess, indem das Kältemittel aus der

Kälteanlage genommen und in eine Kältemittelflasche abgefüllt wird. Dieser einfach

erscheinende Prozess kann jedoch schnell zu Problemen führen, wenn einige

Einzelheiten übersehen werden. Im folgenden sind einige Tipps und Hinweise

zusammengestellt, die aus den Erfahrungen der letzten Jahre resultieren und für einen

zeitsparenden und reibungslosen Ablauf sorgen sollen.

Als erstes sollten Sie die Art und Menge des Kältemittels der zu wartenden Anlage

bestimmen.

Wenn Sie feststellen, dass es sich um eine ausgebrannte Anlage handelt, benötigen

Sie eine spezielle Flasche, welcher für Kältemittel aus ausgebrannten Anlagen und

unbekannte Gase ausgewiesen ist. Weiterhin ist eine vorhergehende Filtration vor dem

Absaugen erforderlich.

Wenn Sie andererseits wissen, dass es sich um ein relativ sauberes bzw. neues

Kältemittel in der Anlage handelt, sollte eine neue Flasche verwendet werden. Wenn

Sie planen, das Kältemittel nach der durchgeführten Wartung zurück in die Kälteanlage

zu führen oder das Kältemittel wieder verwendet werden soll, benutzen sie bitte eine

Flasche, welche die gleiche Art von Kältemittel enthält.

Ein Hinweis im Bezug auf die Umweltschutzorganisation: Wenn Sie eine Vielzahl von

Kältemitteln verwenden - resultierend aus ihrem Kältemittelbezug - und nur eine

Flasche für Wartungsarbeiten besitzen, so werden Sie Unannehmlichkeiten bekommen.

Sie sind gut beraten, für jeden Typ von Kältemittel aus Anlagen, die gewartet werden

sollen, eine Flasche zur Aufbewahrung plus einer weiteren für Kältemittel aus

ausgebrannten Anlagen sowie unbekannte Kältemittel zu besitzen.

Für die zukünftige Planung:

Die Menge des Kältemittels ist wichtig für die Planung des Lagerbedarfs sowie für die

aktuelle Absaugung. So muss zum Beispiel jedes System mit einer Kältemittelmenge

von mehr als 2,27 kg Auffangzonen für flüssiges Kältemittel haben.

Eine Möglichkeit zur raschen Absaugung des Kältemittels besteht darin, zuerst den

flüssigen Anteil aus der Anlage abzulassen und im Anschluss daran den verbleibenden

dampfförmigen Anteil zu entfernen. Die meisten Anlagen erlauben es jedoch nicht, das

Kältemittel auf einfache Art und Weise aus dem Kältekreislauf zu entfernen. Der Grund

hierfür liegt darin, dass sich keine Auslassstellen am tiefsten Punkt der Anlage

befinden. Wenn Anlagenteile aufgrund eines Wartungsvertrages zu warten sind lässt

sich bedeutend Zeit einsparen, indem Auslassstellen an den tiefsten Punkten

angebracht werden, an welchen sich das flüssige Kältemittel ansammelt. Da die

meisten Anlagen keine solchen Auslassstellen besitzen müssen Sie darauf vorbereitet

sein, das, wenn immer Sie angesammeltes, flüssiges Kältemittel finden, dieses mit

einer Heizpistole zum kochen gebracht werden muss. Ein Indikator für angesammeltes

Kältemittel in einer Anlage ist Frost oder Kondensat der sich an der Stelle der

Rohrleitungen oder Anlagenkomponenten bildet an welcher das Kältemittel

eingeschlossen ist. Das eingeschlossene Kältemittel kann sich in einem Bereich

befinden der nicht einzusehen ist. Auf jeden Fall verlangsamt angesammeltes

Page 42

Advanced Test Products RG5410A-EXTREME

18

Kältemittel den Prozess der Kühlmittelabsaugung, unabhängig vom Typ oder der Größe

der verwendeten Maschine.

Wenn es nicht möglich ist, das angesammelte Kältemittel zu lokalisieren (aufgrund des

lange andauernden Prozesses der Absaugung besteht jedoch Gewissheit, dass sich

Kältemittel angesammelt hat), sollten sie den Verdichter der Anlage (wenn möglich) für

einige Sekunden lang einschalten. Dies bewirkt, dass das eingeschlossene Kältemittel

zu einer anderen Stelle in der Anlage hin verschoben wird.

SCHLÄUCHE UND VENTILE

Schläuche und Schraderventile haben einen großen Einfluss auf die Geschwindigkeit

der Kältemittelabsaugung. Im allgemeinen gilt: Je größer der verwendete Schlauch,

desto geringer ist die Reibung im fließenden Kältemittel und umso kürzer ist die zum

Absaugen benötigte Zeit. Viele Betreiber benutzen heutzutage 3/8´´ Schläuche zum

Eingang in die Absaugvorrichtung, obwohl die Anschlüsse aus ¼´´ bestehen.

Es ist ratsam, Schraderventile aus der Verbindung zu entfernen, bevor mit der

Absaugung begonnen wird. Die meisten Großhändler bieten ein Werkzeug zur

Entfernung dieser Teile an wobei die Verbindung verschlossen bleibt. Der Tuyau

abaisse de baseam Ende des Schlauches sollte auch entfernt werden. Diese beiden

Maßnahmen können verhindern, dass eine Absaugung, welche im Normalfall einige

Minuten Zeit in Anspruch nimmt, sich über Stunden hinzieht. Stellen Sie also bitte

sicher, dass vor jeder Kältemittelabsaugung Schraderventile und Tuyau abaisse de

baseentfernt werden.

Ein weiterer Punkt der bei den Schläuchen beachtet werden soll ist die Gummidichtung

in Verbindung zu den Anschlüssen. Die Dichtringe können sich so erwärmt und

deformiert haben, dass sie beim Anschluss der Schläuche die Verbindung absperren.

Dies fällt beim Befüllen der Anlage kaum auf, denn der Druck öffnet den Dichtring, doch

während der Kältemittelentleerung (oder beim Absaugen) hemmt die Dichtung dem

Fluss des Kältemittels enorm.

Wiederverwertung des Kältemittels

Gültige Vorschriften besagen, dass benutztes Kältemittel nicht verkauft werden oder in

fremden Anlagen verwendet werden darf, bevor es labortechnisch untersucht worden ist

und den Anforderungen der ARI 700 (letzte Ausgabe) genügt. Daraus resultiert die

Tatsache, dass es in den meisten Fällen unwirtschaftlich ist, Kältemittel wieder

aufzubereiten und zu prüfen, ob es die Anforderungen nach ARI 700 erfüllt. Es ist

jedoch weiterhin sinnvoll das Kältemittel so weit wie möglich zu reinigen und es in die

gleiche Anlage (oder Anlagen des gleichen Betreibers) zurückzuleiten. Wir empfehlen

die Verwendung der größtmöglichen Filter mit hoher Säurekapazität die wirtschaftlich

vertretbar ist. Benutzen Sie diese Filter auf der Saug- bzw. Einlassseite der

Absaugmaschine. Wechseln Sie bitte häufig den Filter.

Beim Ablassen von großen Mengen an flüssigem Kältemittel kann sich in diesem oft

eine beachtliche Menge an Öl befinden, wenn in der zu wartenden Anlage kein

passender Ölabscheider installiert ist. Wenn das entfernte Kältemittel nicht wieder im

flüssigen Zustand in die gleiche Anlage zurückgefüllt werden soll, so möchten Sie unter

Umständen das Öl vom Kältemittel trennen um die Ölmenge zu bestimmen (um zu

Page 43

Advanced Test Products RG5410A-EXTREME

19

wissen, wie viel Öl in der Anlage nachzufüllen ist). Auf jeden Fall ist in Kältemitteln,

welches zurückgeleitet werden sollen, eine Trennung des Öls nicht notwendig.

Eine der einfachsten und kostengünstigsten Möglichkeiten zur Abscheidung des Öls

besteht darin, dass eine Flasche von 13,61 bis 22,68 kg Füllmenge vor die

Absaugmaschine geschaltet wird. Verbinden Sie die Anlage mit dem

Flüssigkeitsanschluss der Flasche. Den Dampfanschluss der Flasche verbinden Sie mit

dem Eingang der Absaugmaschine. Nun schalten Sie eine zweite Flasche am Ausgang

der Absaugmaschine an, welche das Kältemittel speichert. Wenn es sich um große

Mengen von flüssigem Kältemittel handelt, so benötigen sie einen Vorwärmer bei der

ersten Flasche.

Wenn die Absaugung beendet ist, kann das Öl aus der ersten Flasche entfernt werden,

indem ein geringer Druck an einen Anschluss der Flasche angelegt wird (benutzen Sie

Nietrogen) und das Öl auf der anderen Seite herausgedrückt wird. Wenn Sie das Öl aus

dem Dampfanschluss der Flasche herausdrücken wollen, so müssen Sie die Flasche

herumdrehen. Tragen Sie bei dieser Durchführung immer eine Schutzbrille, da das Öl

Säuren enthalten kann welche schwere Verbrennungen verursachen können.

VORBEUGUNG GEGEN

VERSCHMUTZUNG

Während des Absaugprozesses kann ihre Absaugmaschine Ablagerungen von

Schmutz aus Lot, Kupfer- oder Messingspänen ausgesetzt sein welche Schäden

verursachen können. Weitere Verschmutzungen können durch den Lagerbehälter des

Kältemittels verursacht werden. Um die Lebensdauer ihrer Absaugmaschine zu

verlängern verwenden Sie bitte immer einen Einlassfilter.

Wenn immer Sie eine Anlage befüllen wollen, ist es sinnvoll, einen Einlassfilter zu

verwenden um Verunreinigungen vorzubeugen. Auch hier gilt wieder: Wechseln Sie den

Filter möglichst oft.

Ablassen des flüssigen Kältemittels (Siehe Abbildung „Zug-Druck-Methode“)

Die Zug-Druck-Methode, welche verwendet wird um große Mengen von Kältemittel aus

der Anlage zu entfernen, basiert auf dem Druckunterschied, der durch die

Absaugmaschine erzeugt wird. Die Zug-Druck-Methode kann im allgemeinen nicht bei

kleineren Anlagen angewendet werden, weil sich in diesen nicht genügend flüssiges

Kältemittel befindet, woraus sich ein Siphon ausbilden kann.

Die Zug-Druck-Methode wird meistens bei Anlagen angewendet, die einen

Vorratsbehälter beinhalten oder deren Menge an Kältemittel 9,07 kg übersteigt.

Weiterhin findet sie Anwendung bei der Überführung des Kältemittels von einer Flasche

in einen anderen. Der Flüssigkeitstransport hängt sehr stark von der Größe der

verwendeten Schläuche ab. Mit großen Schläuchen lässt sich ein wesentlich besserer

Durchsatz erreichen.

Eine weitere Vereinfachung der Absaugung lässt sich erreichen, wenn der Behälter vor

oder während der Kältemittelabsaugung bei teilweiser Füllung gekühlt wird. Diese

Maßnahme senkt den Druck in der Flasche und beschleunigt die Absaugung. Als

Mindestmenge müssen 2,27 kg flüssiges Kältemittel in der Flasche sein die Sie kühlen

möchten. Die Kühlung kann vor oder während der Absaugung durchgeführt werden.

Page 44

Advanced Test Products RG5410A-EXTREME

20

Beachten Sie bitte die beiden Anschlussdiagramme für diese Vorgehensweise in dieser

Bedienungsanleitung.

Bei dieser Vorgehensweise benutzen Sie die Absaugmaschine, um eine Kälteanlage

aufzubauen, in welcher die Flasche der Verdampfer ist. Wenn Sie das Auslassventil

drosseln, schaffen Sie dadurch ein Kapillarrohr oder eine Expansionseinrichtung. Sie

müssen den Rückdruck einstellen um die Bedingungen auf das Kältemittel anzupassen.

Eine Kühlung von 5 bis 10 Minuten kann, in Abhängigkeit von den vorherrschenden

Bedingungen, eine enorme Abkühlung der Flasche bewirken. Wenn sich nicht

Kondensierbares in der Flasche befindet funktioniert dieser Prozess nicht. Je größer die

in der Flasche befindliche Menge an Kältemittel ist, desto länger wird dieser Prozess

dauern.

Page 45

Advanced Test Products RG5410A-EXTREME

21

STÖRUNGSSUCHE

Sicherheit steht an erster Stelle

Vor Ausführung irgendwelcher Wartungsarbeiten am RG5410A-

EXTREME sind sämtliche Sicherheitshinweise gründlich

durchzulesen.

Page 46

Advanced Test Products RG5410A-EXTREME

22

EINJAHRESGARANTIE

SERIENNR. ________________________

PROMAX -PRODUKTE SIND GARANTIERT FREI VON MÄNGELN, DIE AUF MATERIAL- ODER

FERTIGUNGSFEHLER ZURÜCKZUFÜHREN SIND. DIE GARANTIEZEIT BETRÄGT EIN JAHR UND BEGINNT MIT

DEM KAUFDATUM.

FOLGENDE EINSCHRÄNKUNGEN GELTEN:

1. DIE GARANTIE GILT FÜR PRODUKTE, DIE BESTIMMUNGSGEMÄSS UND GEMÄSS BEDIENUNGS-

ANLEITUNG BENUTZT WERDEN. DAS PRODUKT IST AUSSERDEM ZU WARTEN WIE IN DER BEDIENUNGSANLEITUNG BESCHRIEBEN.

2. BEI EINEM AUSFALL DES PRODUKTES WIRD DIESES IM ERMESSEN VON Advanced Test Products

ENTWEDER REPARIERT ODER ERSETZT.

3. SÄMTLICHE TRANSPORTKOSTEN SIND VOM KÄUFER ZU TRAGEN.

4. DER GARANTIEANSPRUCH UNTERLIEGT DER UNTERSUCHUNG AUF PRODUKTMÄNGEL IM WERK.

WIRD BEI DIESER UNTERSUCHUNG FESTGESTELLT, DASS KEIN FILTER VERWENDET WURDE ODER

DASS DER FILTER NICHT ORDNUNGSGEMÄSS GEWARTET WURDE ODER DASS DAS GERÄT NICHT

BESTIMMUNGSGEMÄSS VERWENDET WURDE, BEHÄLT SICH Advanced Test Products DAS RECHT VOR,

DIE GARANTIE ALS NICHTIG ZU ERKLÄREN.

5. ALLE GARANTIEANSPRÜCHE MÜSSEN BEI Advanced Test Products WÄHREND DER GARANTIEZEIT

UNTER VORLAGE DES KAUFBELEGS GELTEND GEMACHT WERDEN. DIESE GARANTIE IST NICHT

ÜBERTRAGBAR.

6. BITTE BEACHTEN SIE, DASS KEIN GARANTIEANSPRUCH BESTEHT, FALLS DAS GERÄT ODER TEILE

DES GERÄTES DURCH UNFALL, GEWALTANWENDUNG, UNSACHGEMÄSSE VERWENDUNG, VOM

EIGENTÜMER ODER DRITTEN VORGENOMMENE ÄNDERUNGEN ODER REPARATURVERSUCHE

BESCHÄDIGT WURDE.

7. TEILE, DIE NORMALER ABNUTZUNG UNTERWORFEN SIND (DICHTUNGEN, FILTER USW.), SIND VON

DER GARANTIE AUSGENOMMEN, AUSSER ES WIRD VON Advanced Test Products FESTGESTELLT,

DASS SIE MANGELHAFT SIND.

8. DIESE GARANTIE IST AUSSCHLIESSLICH UND TRITT AN STELLE VON ETWAIGEN ANDEREN GARANTIEN

JEDWEDER ART (AUSDRÜCKLICH ODER IMPLIZIT), DIE FÜR DEN KÄUFER VERFÜGBAR SEIN MÖGEN.

GARANTIEANSPRÜCHE:

Garantieansprüche sind folgendermaßen geltend zu machen:

1. Senden Sie die Garantiekarte innerhalb von 14 Tagen nach dem Kaufdatum zusammen mit einer Kopie Ihres

Kaufbeleges ein.

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

GARANTIEKARTE

Bitte ausfüllen und zur Registrierung Ihres Garantieanspruchs innerhalb von 14 Tagen nach Kaufdatum zusammen mit einer Kaufbelegkopie einschicken.

Name des Käufers Firmenname Telefon

Firmenanschrift PLZ, Ort, Land

Modell Seriennr. Kaufdatum Händler Verkäufer

Bitte kreisen Sie Ihr primäres Tätigkeitsfeld ein.

Kfz, Handel, Wohnungsbau, nur Service, nur Installation (alles Zutreffende einkreisen)

Wie wurden Sie auf unsere Produkte aufmerksam? (EINE Kategorie einkreisen)

Postwerbung, Anzeige in Fachzeitschrift, Empfehlung durch:

Welche Funktionen waren für Sie von größtem Interesse? (alles Zutreffende einkreisen)

Hohe Produktivität, geringe Kosten, geringer Wartungsaufwand, Handling, andere:

Page 47

Advanced Test Products RG5410A-EXTREME

1

MANUEL D‘UTILISATION

RG5410A-EXTREME

Page 48

Advanced Test Products RG5410A-EXTREME

2

TABLE DES MATIÈRES

I) La sécurité

A) La sécurité d‘abord 1

B) La Récupération et les Bouteilles 2

II) Informations générales importantes 3

III) Récupération

A) Les procédures 4-6

Utilisation du pressostat BP 6

B) Les schémas de raccordement 7-9

C) Evacuation des gaz non condensables 10

IV) Schémas

A) Pièces détachées 11

B) Circuit hydraulique 12

C) Schéma électrique 13

V) Sécurité Haute Pression 14

VI) Entretien de votre RG 5410A-E 15

VII) Spécifications Techniques 16

VIII) Indications utiles pour l’aspiration des fluides frigorigènes 17-19

IX) Recherche de panne éventuelle 20

Erreurs ainsi que changements des dates techniques et matériaux sont réservés sans annonce

préalable.

Ce manuel d’utilisation ne doit en aucun cas être reproduit sans autorisation expresse écrite de

Advanced Test Products.

Page 49

Advanced Test Products RG5410A-EXTREME

1

LA SECURITE D‘ABORD

Cet appareil ne doit être utilisé que par un technicien qualifié en vertu 92-1271 7

Décembre1992 relatif à la manipulation de certains fluides frigorigènes dans les

équipements frigoriques et climatiques.

1. Se protéger avec des lunettes et des gants.

2. S’assure que la pièce dans laquelle vous travaillez est bien ventilée,

particulièrement s‘il y a une fuite dans le système. Il y a danger à partir d’une

certaine concentration de fluide dans l‘atmosphère.

3. Toujours penser avant d’agir. Les habitudes sont dangereuses. Une erreur peut

être fatale.

4. Consulter:

Les notices des matériels que vous allez utiliser.

Les consignes de sécurité concernant la manipulation des fluides frigorigènes.

5. Ne jamais utiliser d’oxygène pour les recherches de fuites. Le mélange d’huile avec

celui d’oxygène sous pression peut être explosif.

6. Couper le courant avant d’intervenir sur les circuits électriques.

7. Toujours utiliser des bouteilles de récupération éprouvées et contrôlées par le

Services des Mines et les stocker dans un endroit frais et sec.

8. Toujours ouvrir les vannes de service et de la bouteille de récupération lentement.

Cela permet de contrôler efficacement si l’écoulement du fluide se fait sans risque.

Lorsque le technicien a déterminé que tout est normal, il peut les ouvrir

complètement.

9. Ne jamais mélanger les fluides frigorigènes dans les bouteilles de récupération ou

n’importe où ailleurs. Chaque fluide doit avoir sa propre bouteille, filtre, etc.

10. L’humidité est la cause de nombreux problèmes. Conserver chaque compassant

fermé, sec et propre.

11. Afin de réduire les risques d’incendie n’utilisez pas de rallonges électriques, car

celles-ci peuvent surchauffer. S’il est inévitable d’utiliser une rallonge, celle-ci doit

avoir un minimum de 14 AWG (section câble: 2mm2 ) et ne pas être plus longue

que 7,5m. Afin

de réduire les risques d’incendie, ne jamais utiliser un prolongateur électrique trop

long et pas suffisamment dimensionné qui pourrait surchauffer. Cet appareil doit

être utilisé dans une ambiance permettant un taux de renouvellement d’air d’au

moins 4 fois le volume par heure. Ne jamais utiliser cette machine dans une

atmosphère contenant des produits inflammables ou explosifs.

Page 50

Advanced Test Products RG5410A-EXTREME

2

RG5410A-EXTREME

LA RÉCUPÉRATION DES FLUIDES

FRIGORIGÈNES & LES BOUTEILLES DE

RÉCUPÉRATION

La sécurité d’abord. Lire attentivement toutes les notices des matériels de sécurité

concernant la manipulation des fluides y compris celles données par votre fournisseur

de fluides frigorigènes. Ne jamais utiliser cet matériel en atmosphère contenant des

produits inflammables ou explosifs. Porter des lunettes et des gants de sécurité.

Travailler dans une ambiance ventilée. Cet appareil ne doit être utilisé que par un

technicien qualifié.

*** Manipuler les bouteilles de récupération avec précaution***

ATTENTION :

Ne jamais utiliser les bouteilles dans lesquelles sont vendus les fluides frigorigènes

neufs comme bouteilles de récupération.

N’utiliser que des bouteilles de récupération éprouvées et contrôlées par la Service

des Mines.

Les bouteilles ont une pression d’utilisation minimum 41 Bar.

Ne jamais dépasser la pression indiquée sur l’emballage.

Ne jamais remplir à 100 % en liquide les emballages. Les règles de sécurité

imposent de remplir au maximum à 80 % en liquide, les 20% restant servent à

l’expansion du liquide.

Le fluide se dilate avec la température et peut causer l’explosion de la bouteille si celleci est remplie à 100% en liquide et n’est pas équipée d’une soupape de sécurité.

Temp.de la 16 °C 21 °C 38 °C 54 °C 66 °C

Bouteille

Niveau de

Liquide de Base

80 VOL%

Niveau de

Liquide

Niveau de

Liquide de Base

90 VOL%

Niveau de Liquide

80 % 81% 83% 90% 94%

90% 92% 96% 100%

Page 51

Advanced Test Products RG5410A-EXTREME

3

INFORMATIONS GÉNÉRALES

IMPORTANTES

Ces règles sont d’ordre général et ne sont pas spécifiques à cet équipement

Avant d’utiliser cet équipement, lire ce qui suit

1. Toujours isoler les grandes quantités de fluide frigorigènes et fermer les vannes de

maniéré à éviter toute fuite à atmosphère.

2. Remettre les nouveaux bouchons sur les vannes des bouteilles, elles peuvent fuir.

3. Travailler sur un sol stable et horizontal.