PROMAG

STARCREM 30/60 IngleseUTILIZZATORE (USER)

le macchine per il gelato

USE AND MAINTENANCE

INSTRUCTION MANUAL:

"CUOCICREMA" MACHINE

STARCREM 30/1 INV

STARCREM 60/1 INV

with R404A

USER INSTRUCTIONS

STARCREM 60/1 INVSTARCREM 30/1 INV

02 - 2002

STARCREM 30/1 INV - STARCREM 60/1 INV

2

PROMAG

The technical data for each machine model is

shown in the enclosed tables and on the data

plate located on the rear side of the machine.

This data is used as a reference when

performing inspections or checks.

Bar code

A = air condensation

W = water condensation

Manufacturer

PROMAG

Via Benaco 4

20098 San Giuliano Milanese

Milano Italy

Tel. 02 - 98296.1

Telefax 02 - 98.80.232

This plate is an exact

copy of that located on

the rear side of the

machine, for this reason

the manual forms an

integral part of the

machine and must be

kept together with it.

Safe machine operation is assured by correctly following the

instructions given in this manual. Therefore, we suggest you keep the

manual in a safe place where it can be readily consulted as required.

USER INSTRUCTIONS

PROMAG

GB

STARCREM 30/1 INV - STARCREM 60/1 INV

pag.

pag.

7/60

INSTRUCTIONS FOR USER

INSTRUCTIONS FOR TECHNICIAN-INSTALLER61/76

A

B

77/89pag.

SPARE PARTS

USER INSTRUCTIONS

3

STARCREM 30/1 INV - STARCREM 60/1 INV

4

INTRODUCTION

PROMAG

This manual gives all assembly, operating and

maintenance instructions required for assuring

excellent operating results and a long machine

service life.

Before starting to use the machine,

read these instructions and follow them

very carefully.

Please do not hesitate to contact us for

any assistance you may require.

Failure to abide by the norms included in this

manual will invalidate the guarantee.

If the machine is sold or otherwise put into another

person's possession,ensure that the manual

accompanies the machine therefore allowing the

new owner to correctly follow the operating

procedures and abide by the relative precautions.

The present "CUOCICREMA" machine,

is a multi-functional machine, destined exclusively

for pastry products (cream cooking) and ice cream

making (preparation and/or pasteurization of ice

cream mixture).

Never try to repair the machine yourselves,

as any attempt to make repairs by incompetent

persons will not only be dangerous but may also

cause serious injuries.

In the case of a malfunction, contact the distributor

from whom the machine was bought.

They can give you the address of the Authorized

Service Centre closest to you.

Only use original spare parts for any necessary

replacements.

If you decide to no longer use the machine,

we advise you to cut the electrical cord so that it

cannot be used (after disconnecting the plug from

the power socket).

In addition:

- Under no circumstances should the refrigerant

gas or compressor oil be allowed to escape and

thus contaminate the environment.

- See that the machine is disassembled and that

the parts are disposed of in accordance with the

national regulations in force.

Do not utilize the "CUOCICREMA" for any other use

other than that described above.

A similar use shall be considered improper.

This machine is designed to be used by adults.

Keep children away from the machine;

they should not be allowed to play with it.

Any attempt to modify this machine will not only

invalidate the guarantee but is also extremely

dangerous.

In order to assure efficient, correct machine

operation carefully follow the manufacturer's

instructions and only allow professionally qualified

personnel to perform any necessary maintenance.

This machine contains H.C.F.C. gas which could be

harmful to the environment in the case of incorrect

maintenance operations or disassembly.

Therefore, any such operations must be done in

accordance with the national regulations in force,

and must only be performed by authorized

maintenance personnel.

PROMAG reserves the right to make any and all

modifications reemed necessary in order to keep

the machine updated - technically or otherwise as well as to allow it to meet the requirements of

certain individual countries.

For any additional information or technical help you

may require, please contact your authorized service

centre.

USER INSTRUCTIONS

PROMAG

GB

This manual is made

up of three parts:

Part A:

instructions and information for

the User and

the Technician-Installer

Copy of the conformity declaration found with the machine

I) La ditta PROMAG, con la firma del suo delegato alla sicurezza del prodotto, dichiara sotto la propria esclusiva responsabilità

che la macchina:

2) The company PROMAG hereby declares under its own sole responsibility, through the signature of its product safety manager, that

the machine:

3) La société PROMAG, parla signature de son délégué à fa sécurité du produit, déclare sous sa propre et exclusive responsabilité

que la machine:

4) Die Firma PROMAG erklärt unter ihrer ausschließlichen Verantwortung mit der Unterschrift ihres Beauftragten für die ProduktSicherheit, daß die Maschine:

5) Het bedrijf PROMAG verklaart hierbij uitsluitend op eigen verantwoordelijkheid, door middel van de handtekening van zijn

manager produktveiligheid, dat de machine:

6) La empresa PROMAG, mediante la firma de su encargado para la seguridad del producto, declara bajo su propia y exclusiva

responsabilidad que la máquina:

7) A firma PROMAG, com a assinatura do seu delegado para a segurança do produto, declara sob a própria e exclusiva

responsabilidade que a máquina:

Part B:

instructions and information for

the Technician - the Shipper

the Installer - the Maintenance Man the Repair Man

STARCREM 30/1 INV - STARCREM 60/1 INV

Part C:

electrical diagrams

and spare parts

8) Firmaet PROMAG erklærer hermed, gennem den produktsikkerhedsansvarliges underskrft og under eget ansvar, at maskinen:

9) Yhtiö PROMAG vakuuttaa täten tuoteturvallisuudesta vastaavansa allekirjoittamana ja omalla vastuullaan, että kone:

10) Härmed intygar företaget PROMAG, genom underskrift av sin produktsäkerhetsansvarige och på eget ansvar, att maskinen:

11) Firmaet PROMAG erklærer herved, ved den produktsikkerhetsansvarliges underskrift og under sitt eneansvar, at maskinen:

STARCREM 30/60 Matr..................

1) preparatore e pastorizzatore di prodotti per pasticceria e gelateria, è conforme ai requisiti essenziali previsti dalle Direttive CEE

89/392, 91/368, 89/336, 73/23 e 93/68.

2) preparing and pasteurizing machine for pastry and ice cream products, complies with the essential requirements indicated in

EEC directive 89/392, 91/368, 89/336, 73/23 and 93/68.

3) machine pour la prèparation et la pasteurisation de produits pour pâtisserie et glacerie, est conforme aux conditions requises

essentielles prévues par les directives CEE 89/392, 91/368, 89/336, 73/23 et 93/68.

4) Maschine für die Vorbereitung und Pasteurisierung von Konditorei- und Speiseeisprodukten, den grundlegenden, von den

EWG-Richtlinien 89/392, 91/368, 89/336, 73/23 und 93/68 gestellten Anforderungen genügt.

5) machine voor het bereiden en pasteuriseeren van producten voor gebak en consumptieijs, voldoet aan de essentiële

voorwaarden vervat in de EEG-Richtlijnen 89/392, 91/368, 89/336, 73/23 en 93/68.

6) preparador y pasteurizador de productos para pastelería y helados, es conforme a los requisitos esenciales prevístos por las

Directivas CEE 89/392, 91/368, 89/336, 73/23y 93/68.

7) Preparador e pastorizador de produtos para confeitaria e sorveteria, é feita conforme os resuisitos principais previstos pelas

Normas CEE 89/392, 91/368, 89/336, 73/23 e 93/68.

8) maskine til tilberedning og pasteurisering af konditorkager og is-produkter overensstemmer med de væsentligste krav anført i

EU direktiv 89/392, 91/368, 89/336, 73/23 og 93/68.

9) konditoria-ja jäätelötuotteiden valmistus-ja pastörointikone noudattaa EU direktiiveissä 89/392, 91/368, 89/336, 73/23 ja 93/68

ilmaistuja olennaisia vaatimuksia.

10) för tillagning samt pastörisering av bakverk och glassprodukter uppfyller de väsentliga kraven i EU-direktiv 89/392, 91/368, 89/

336, 73/23 och 93/68.

11) maskin for tilberedning og pasteurisering av deig-og iskremprodukter er i samsvar med de vesentligste krav angitt i EUdirektiv 89/392, 91/368, 89/336, 73/23 og 93/68.

The operating instructions form an integral part of the machine. - The machine user must not perform any of the operations

described in parts B and C; these must only be carried out by a qualified technician. - The user is therefore informed that if he

attempts to do so he will compromise the safety and health standards with which the machine is designed and built.

USER INSTRUCTIONS

5

STARCREM 30/1 INV - STARCREM 60/1 INV

6

INFORMATION FOR THE USER AND TECHNICIAN-INSTALLER

PROMAG

General Information

Thank you for having chosen this machine.

Please read the instructions in this manual

carefully; they will assure long machine

service life.

We can guarantee that only the very best

materials have been used for this machine,

that it has been very carefully tested,

and that we are always ready to serve and

assist you in the best possible way.

IMPORTANT PRECAUTIONS

When the machine is being installed,

make sure that a disconnecting switch is

installed on the power supply line by a qualified

technician.

Always ensure that the plug is disconnected

from the mains before putting your hands inside

the machine or before performing cleaning or

maintenance operations.

HELPFUL ADVICE

When manufacturing your products only use

the very best ingredients, in order to fully

satisfy even your most demanding customers.

Obtain all basic ingredients from well-established

firms that have a proven reliability.

When making your products follow the

instructions very carefully and do not try

to change the recipe in any way.

Always keep the machine spotlessly clean.

(Contact a qualified technician whenever

maintenance is required).

Never clean the machine using a water jet

under pressure.

Always ensure that the plug is disconnected

from the mains before removing the housing,

side panels or any other protection in order to

carry out any operation within the inner part

of the machine.

(Such operations must only be performed by a

qualified technician)

For all necessary repair work always contact one of PROMAG's assigned maintenance

firms.

If any of the operating, cleaning or maintenance instructions given in this manual are not

carefully followed, and an accident occurs, PROMAG cannot be held responsible.

Thanking you once again, we wish you all the best.

USER INSTRUCTIONS

PROMAG

GB

A 1

STARCREM 30/1 INV - STARCREM 60/1 INV

INSTRUCTIONS FOR THE USER AND THE TECHNICIAN-INSTALLER

Environmental conditions

page

A

8

A 2

A 3

A 4

A 5

A 6

A 7

A 8

A 9

A 10

A 11

A 12

A 13/A 14

A 15

A 16

A 17

A 18/A19

A 20

Machine description

Number of users and type of work

Productive cycle

Operating modes

Precautions

Safety devices

Machine use

Description of external components

Correct use of product dispensing cock

Scraping blades

Description of internal components

Dangerous points on the machine

Protection measures for dangerous machine areas

Risks information

Recommendations on prevention measures to be adopted

Installation/Use of machine

Machine preparation

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

9

10

10

10

11

12/14

15

16/19

20/21

22

23

24/25

26

26/27

27/28

29

29

A 21

A 22

A 23

A 24

A 25

A 26

A 27

A 28

A 29

A 30

A 31

A 32

A 33

A 34/45

A 46

A 47

A 48

Operation

Program check

Inverter manual operation

Inverter semiautomatic operation

Cycle A Pastry cream

Cycle B High temperature pasteurization for ice cream mix

Cycle C Low temperature pasteurization for ice cream mix

Cycle D solidification of plain chocolate

Cycle G Bavarian cream

Cycle H Fruit jam

Cycle I Cooling

Cycle L Manual Cooking

Cycle M - N Personalized

Significance of programmable parameters

Stop modes

Black out

Anomalies

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

30/31

32

33

33/34

34/35

36/37

38/39

40

41

42

43

44

45

46/52

53

53

54

A 49

A 50

A 51

A 52

A 53

A 54

Operations to be performed after use

Dismantling

Technical characteristics

Dimensions

Programming table inverter Starcrem 30/1 INV

Tabella programmazione inverter Starcrem 60/1 INV

USER INSTRUCTIONS

page

page

page

page

page

page

55

56

57

58/59

60

60

7

STARCREM 30/1 INV - STARCREM 60/1 INV

8

A 1 - ENVIRONMENTAL CONDITIONS

The machine must not be kept in a room where the

temperature can drop below 0° C.

The machine is not designed for installation in

atmospheres where there is a risk of explosion.

A 1.1

MACHINE OPERATING NOISE LEVELS

The acoustical pressure level produced by the

machine is shown on the enclosed technical

diagram.

Measurements were made throughout the operating

cycle using a class 1 instrument held

at the point where the user stands in relation to the

machine (as indicated in the sketch).

PROMAG

Level of continuous acoustical pressure measured

with a ponderation "A" filter.

STARCREM 30 - STARCREM 60

dB (A) 61 ÷ 65

USER INSTRUCTIONS

PROMAG

GB

Significance of trade-mark names

STARCREM 30 = 30 litres

STARCREM 60 = 60 litres

Function:

MULTIFUNCTIONAL MACHINE TO BE USED EXCLUSIVELY FOR PASTRY

PRODUCTS (CREAM COOKING) AND ICE CREAM MAKING

(PREPARATION AND/OR PASTEURIZATION OF ICE CREAM MIXES,

MAINTENANCE AND/OR MATURING OF ICE CREAM MIXES).

For technical data of machines, see enclosures.

Machine components

The machine is complete with a main frame with a stainless

steel structure, the base of which is provided with four

wheels, one at each corner.

STARCREM 30/1 INV - STARCREM 60/1 INV

A 2 - MACHINE DESCRIPTION

On opening any one of the two lids, all machine

operations will be interrupted and "OPEN" will appear

on the display.

As already mentioned, the motors are mounted on

motor bearings.

Above are served by a magnetic safety microswitch.

On lifting the motor bearings, all operations of the

machine are interrupted and "OPEN" will appear on

the display.

The frame is parallelpipedal, containing the cylinder,

electric box and cooling system.

The cylinder is mounted vertically, disposing of a cooling

system on external surface (containing refrigerating gas),

a heating system (containing water) and a deep basin

(containing water), in which resistances are located, and

whereby heating is carried out with "bain-marie" method,

a particular characteristic of Promag.

The low speed and high speed mixer shafts are

immersed in the cylinder. They are connected to

respective motors, the latter being assembled onto motor

bearings.

The main cooling system elements comprise: a

compressor, a condenser, a thermostatic valve and a

compressor pressure switch.

The cylinder diposes of an outlet which is located on the

front side of the machine. This opening may be closed

with a cock, provided with a piston with two O-ring seals.

The manual cock commanding the small washing

shower unit is located on the upper left front side of

the machine.

The small shower unit is situated on the bottom of the

cylinder in the right-hand corner.

A control panel, facing inwards, is located on the upper

front side of the machine, where an electronic card

may be found.

Control buttons are accessible on control panel.

The electric box, as described above, is also included

inside the frame and is positioned on the rear side of

same.

Water connections for cooling system are present on

the rear side of the machine, in addition to those for

drinking water for small shower unit.

Electric feed cables are also present.

Above closes outlet at the level of container edge. This

solution guarantees a perfect hygiene, as the mix

contained in the cylinder has no chance of stagnating in

the stub pipe.

The outlet diameter may also be reduced for the

discharge of extremely liquid mixes.

Two half-lids are located at the upper part of the cylinder,

served by two magnetic safety microswitches.

USER INSTRUCTIONS

9

STARCREM 30/1 INV - STARCREM 60/1 INV

10

A 3 - NUMBER OF USERS AND TYPE OF WORK

The machine is designed to be used by one

operator only, in charge of loading product to be

processed, setting productive cycle and

subsequent recovery of product through cock.

A 4 - PRODUCTIVE CYCLE

The user opens the front half-lid (34) and pours the

product into the cylinder, closing same.

He starts up productive cycle, after having set

appropriate parameters with buttons (36).

He unloads product by using special cock (37).

PROMAG

A 5 - OPERATING MODES

The machine is designed for a single type of

continuous operation, on pressing heating or

maintenance buttons.

Machine stops automatically.

Machine is also designed for manual operation on

pressing buttons for low speed stirring, intermittent

low speed stirring, high speed stirring.

USER INSTRUCTIONS

PROMAG

GB

STARCREM 30/1 INV - STARCREM 60/1 INV

A 6 - PRECAUTIONS

Danger points

The machine has certain danger points and areas where

accidents may occur if the following precautions are not

observed.

- It is forbidden and very dangerous to approach machine

cylinder when same is turned on or in motion.

- It is forbidden and very dangerous to carry out

any repairs on system, whether mechanical or electrical,

when the machine is functioning.

Refer to enclosures for electric and water systems.

- It is forbidden to use the machine without operatorís

supervision.

- It is forbidden and very dangerous to come too near

and/or touch with any part of the body and/or any type of

object the shaft bars: low speed and high speed mixers

project from cylinder covers

until reaching motor bearings.

For the same reason do not approach relative motors

from rear side of motor casing.

- It is forbidden and very dangerous to introduce parts of

the body or any type of object into the product outlet.

- It is dangerous to touch machine ON/OFF wall switch

with wet hands.

- It is strictly forbidden to open electric box.

- It is forbidden and very dangerous to approach

the machine with magnetic materials, as they

would interfere with magnetic safety microswitches

located under the two cylinder half-lids and under the

right shoulders of the motor bearings

(For the user only)

It is forbidden and very dangerous for user to carry out any intervention which should

be done by a TECHNICIAN/INSTALLER.

Removal of protective coverings and access to internal parts of machine, in addition to all internal

maintenance operations, repairs, installation, transport and unpacking must be

carried out by qualified personnel.

USER INSTRUCTIONS

11

STARCREM 30/1 INV - STARCREM 60/1 INV

12

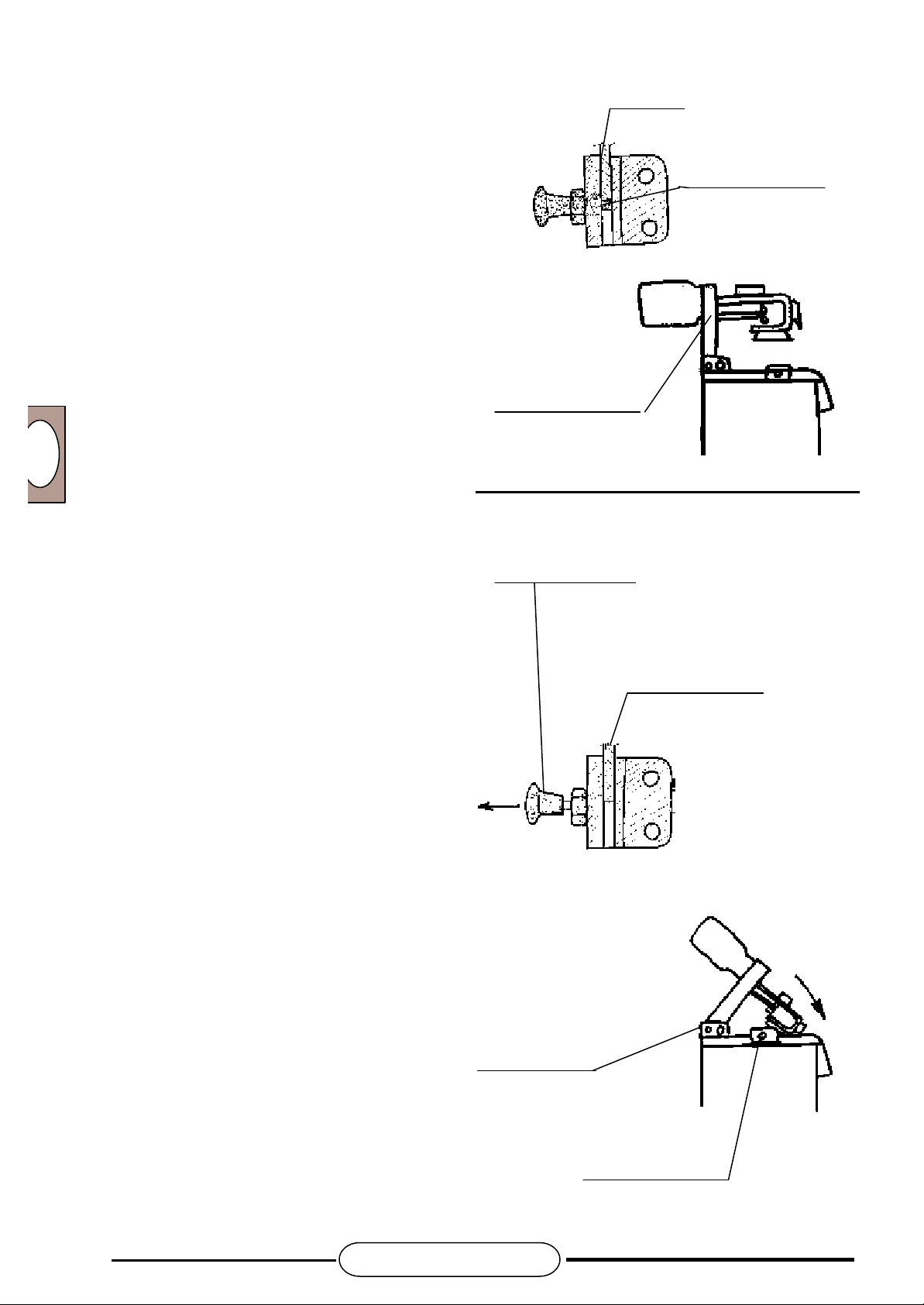

A 7 - SAFETY DEVICES

PROMAG

A 7.1

Three magnetic microswitches are mounted onto the

STARCREM machines (19) (20) (21).

Microswitch (19) is located on the front left-hand side

under the cylinder.

Microswitch (20) is located on the rear right-hand

side under the cylinder.

Microswitch (21) is located on the rear left-hand side

under the cylinder.

Their purpose is to block any machine operation

should the front half-lid [(microswitch (19)], motor

bearings [(microswitch (20)], rear half-lid

[(microswitch (21)], be opened or lifted with the

machine in operation.

22

A 7.2

There is a machine stop button (7) located on the

control panel at the front of the machine which, when

pressed, stops any machine operation.

A 7.3

- 12 Volt control panel.

21

19

22 Blocking device for motor bearings

20 36

7

21 Rear left-hand microswitch

19 Front left-hand microswitch

20 Rear right-hand microswitch

USER INSTRUCTIONS

PROMAG

GB

A 7.5

The STARCREM machines also have a safety device

to block the motor bearings (22).

The purpose of this is to prevent motor bearings falling

onto cylinder plane, should the latter be lifted for either

cleaning of mixer shafts or for any other reason.

A 7.5a

Normal position of motor bearings with machine in

operation. The motor bearing leans on cylinder plane

and disconnected blocking device.

STARCREM 30/1 INV - STARCREM 60/1 INV

Motor bearing

A 7.5b

Turnover phase of motor bearings.

The motor bearing may be lifted subsequent to

unscrewing of closing handwheel screws.

Perform above operation with extreme care, so that

motor bearing does not fall on cylinder plane,

subsequently hitting operator and causing serious

damage.

Blocking

device

Hinge pin

Cylinder plane

Until motor bearing is not in a vertical position, the

relative safety blocking device will not be activated;

therefore, as already mentioned, it is the operatorís

responsibility to take precautions, utilizing the

necessary measures to prevent risks of crushing,

entangling, or cutting with regard to persons, animals

or objects.

Closing handwheel

USER INSTRUCTIONS

13

STARCREM 30/1 INV - STARCREM 60/1 INV

14

PROMAG

A. 7.5c

Motor bearing entirely upturned: motor bearing has

been completely lifted, therefore now in vertical

position. Only in this position will the blocking

security device be activated, causing the block pip

to protrude.

In this manner, the motor bearing cannot fall onto the

cylinder plane and cleaning and washing operations

may be safely performed.

However, it is always necessary to check that above

device is functioning properly, together with wear of

same.

Should any deterioration be detected, please

contact authorized technical service.

Motor bearing left

shoulder

Blocking pip

Motor bearing in

vertical position

A. 7.5e

Closing of motor bearing on cylinder plane.

In order to carry out this operation, it is necessary to

unblock security device.

With the right hand, firmly maintain motor bearing in

vertical position; contemporarily pull the security

device knob towards the left with the left hand.

Slightly lower motor bearing, until block pip grazes

over left shoulder of motor bearing. In this position,

safety block may no longer be activated.

Firmly grip motor bearing with both hands,

subsequently lowering same onto cylinder plane.

Carry out this operation extremely carefully, avoiding

that motor bearing falls abruptly onto cylinder plane,

subsequently hitting operator and causing serious

damage.

When closing motor bearing, it is operatorís

responsibility to be careful, taking necessary

precautions to prevent risks of crushing, entangling

and cutting with respect to persons, animals or

things.

When the motor bearing is on the cylinder plane,

block it with two closing handwheels.

Safety device knob

Motor bearing left

shoulder

Hinge pin

Closing handwheel

USER INSTRUCTIONS

PROMAG

GB

STARCREM 30/1 INV - STARCREM 60/1 INV

A 8 - MACHINE USE

Use according to norms.

STARCREM machines are expressly designed to

cook cream, being multifunctional and only

destined for pastry products (cream cooking), ice

cream making (preparation and/or pasteurization of

ice cream mixes), maintenance and/or maturing of

ice cream mixes.

Use for any other purpose will not conform to the

norms.

The manufacturer is not responsible for any

damages deriving from improper use.

Any risks will be borne by user.

Manufacturerís safety, operational and maintenance

regulations must be observed.

The norms in force regarding accident prevention

and other acknowledged technical safety

regulations must also be observed.

Only properly trained and qualified personnel may

use, maintain or repair the machine.

The machine is mainly manufactured in stainless

steel AISI 304, together with plastic material as for

the food industry.

Any arbitrary modifications made to the machine will

exonerate manufacturer from any eventual damages

deriving therefrom.

The machine may only be used with original

accessories and spare parts made by the

manufacturer.

USER INSTRUCTIONS

15

STARCREM 30/1 INV - STARCREM 60/1 INV

16

A 9 - DESCRIPTION OF EXTERNAL COMPONENTS (front view)

PROMAG

35) Rear half-lid

34) Front half-lid

40) Hinge

41) Closing handwheel

43) Shower cock

45) Outlet for

dense products

39) Motor bearing

38) Motor casing

42) Small shower

36) Control panel

37) Product outlet cock

44) Slide

47) Fixed rear wheels

48) Rotating front wheels

A 9 - DESCRIPTION OF EXTERNAL COMPONENTS

(top view without motor casing)

49) Motor bearing

blocking device

46) Outlet for

liquid products

USER INSTRUCTIONS

PROMAG

GB

STARCREM 30/1 INV - STARCREM 60/1 INV

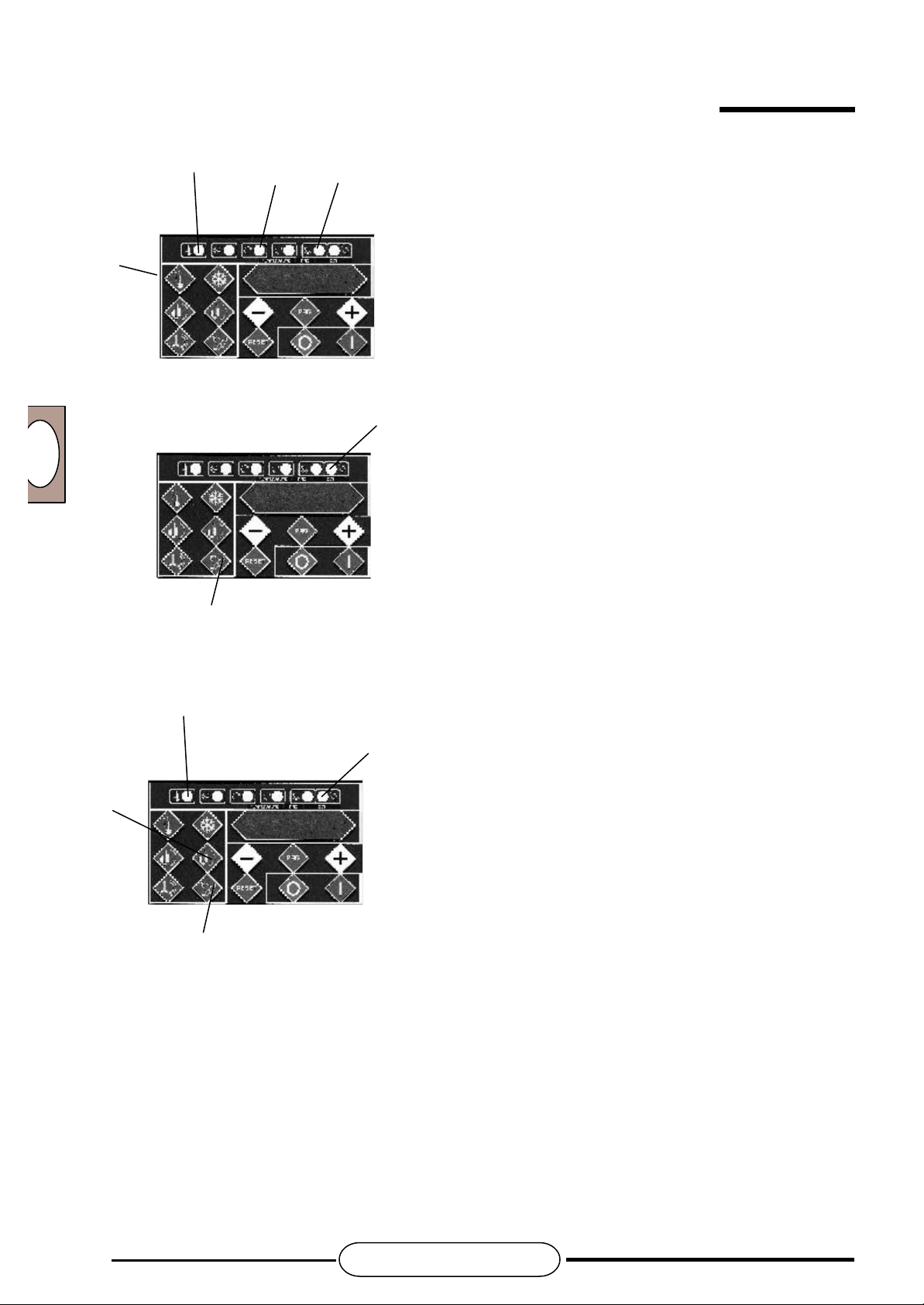

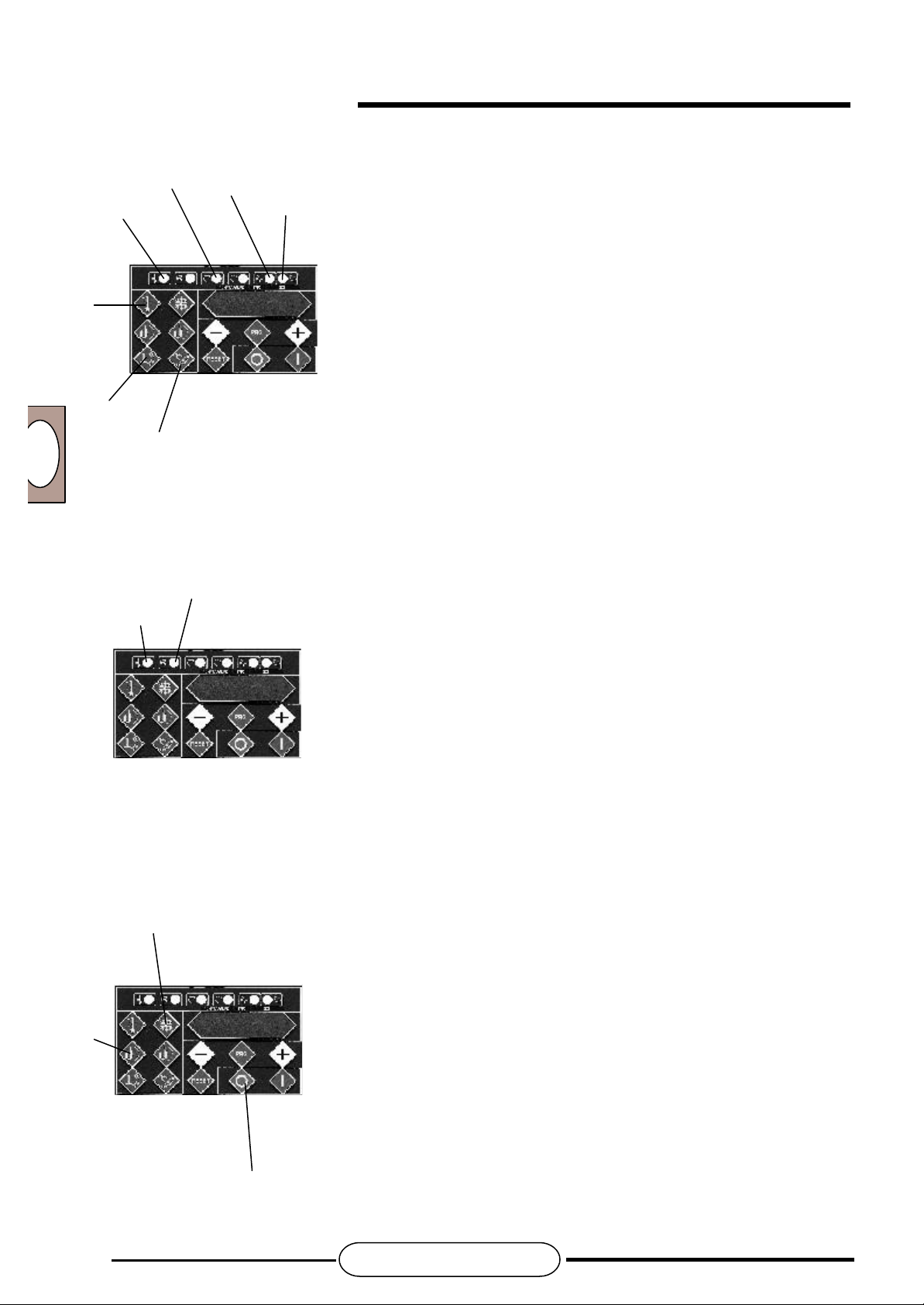

A 9 - DESCRIPTION OF EXTERNAL COMPONENTS (Control panel )

15) ON-OFF low speed motor led

14) Start-up led for cooling and

maintenance cycle

2) Start button for cooling and

maintenance cycle

13) Start-up led for

cooking cycle

1) Start button for cooking

cycle

3) Low speed motor

ON-OFF button

16) Manual start-up led for low

speed intermittent motor

17) High speed motor ON-OFF led

6) Button for

parameter

increase

7) High speed motor

ON-OFF button

4)Low speed intermittent

motor manual start-up

button

8) Bell setting button

5) Button for parameter

reduction

9) Reset

button

12) Program button

10) Emergency

stop button

USER INSTRUCTIONS

17

STARCREM 30/1 INV - STARCREM 60/1 INV

18

A 9 - DESCRIPTION OF EXTERNAL COMPONENTS PRODUCT OUTLET COCK

Cock security lock

Piston guide rod

PROMAG

Bush

Piston bearing

Setscrew

Outlet lock for liquid mixes

Knob

Piston rod

OR Seal

Cylinder

Outlet for dense mixes

Piston guide rod bearing

Outlet for liquid mixes

USER INSTRUCTIONS

PROMAG

GB

27) Wall ON/OFF switch

STARCREM 30/1 INV - STARCREM 60/1 INV

A 9 - DESCRIPTION OF EXTERNAL COMPONENTS (rear view)

25) Electric cable

for high speed

mixer motor

28) Electric cable

26) Electric cable

for low speed

mixer motor

29) Air extraction fan

30) Drinkable water

inlet for small

washing shower

31) Cooling system

water inlet

In order to avoid mineral deposits in the tubes and condenser, caused by water hardness, it is

recommended to install a water softener.

32) Water outlet

USER INSTRUCTIONS

19

STARCREM 30/1 INV - STARCREM 60/1 INV

20

A 10 - CORRECT USE OF PRODUCT DISPENSING COCK

In order to use the product dispensing cock correctly,

the following must be carried out:

begin productive cycle after having carried out cleaning

operations indicated in specific paragraph.

However, remember that mechanical parts in contact with

food must be perfectly sterilized, whilst those in motion

or sliding must be subsequently lubricated,

using advised products or similar.

A - Check that guide rod, piston bush and 2 OR

seals are duly lubricated. Push piston guide rod bearing

against slide.

Tighten the dowel on the right-hand side with

special setscrew wrench.

B - Place cock safety lock in vertical position.

C - Place liquid mix outlet lock in downward position.

D - Assemble piston group onto guide rod with piston bush.

Centering of bush with rod should be carried out carefully,

thereby avoiding any damage to bush during introduction,

wearing out external edges of same.

Cock safety lock

Piston

Piston bush

Guide rod

PROMAG

Liquid mix outlet

lock

Setscrew

OR seals

E - Screw setscrew until contact is made with guide rod.

A 10.2

Cock disassembly

Repeat previous operations in opposite sense.

A 10.3

Cock closing

A - Push the piston group towards the dense mix outlet.

The movement direction must be perpendicular to outlet.

IN NO WAY MUST GUIDE ROD OR PISTON GROUP BE FORCED

IN DIFFERENT DIRECTION, as disalignment of guide could be

caused, with consequential erroneous centering of piston in outlet.

Assembled cock

B - Introduce piston into the outlet with a smooth movement, avoiding

that any metallic parts of the two components come into contact with

one another. Push piston until reaching stop.

C - Lower the cock safety lock.

D - This will guarantee closing position, also in the presence of strong

mixing vibrations in the cylinder towards outside.

USER INSTRUCTIONS

Working surface

PROMAG

GB

A 10.4

Extraction of liquid mix

A - Once the cock is closed, pull the lock upwards to discharge

liquid mixes.

B - Place the cock safety lock in vertical position.

C - Pull piston group in perpendicular direction with respect to

outlet, until lock for liquid mix outlet rests against the setscrew.

At this point, the mix will be discharged from the lower part of the

outlet, through the stub pipe with a diameter suitable for liquid

mixes.

Attention:

After every extraction of liquid mixes, wash the cock

perfectly, using the proper swabs. Subsequently, sterilize

using the proper hygienic solutions.

A 10.4

Extraction of dense mix

A - When liquid mix is ready to be discharged, lower outlet

lock.

STARCREM 30/1 INV - STARCREM 60/1 INV

Cock

B - Pull piston group in perpendicular direction with respect

to outlet, until same rests against the setscrew.

C - Very slightly turn piston group around guide rod.

D - Push piston group, leaning it on outlet.

At this point, a small quantity of the mix will be discharged

from the lower part of the outlet through the pipe stub with a

diameter suitable for liquid mixes, whilst the majority will be

discharged from the front part of the outlet for dense mixes.

Attention:

After every extraction of dense mixes, wash the cock

perfectly, using the proper swabs. Subsequently,

sterilize using the proper hygienic solutions.

A 10.5

ATTENTION

Never unscrew cock screws. The only screw which

may be unscrewed, for cleaning purposes, is that

supporting the piston guide rod.

Cock

USER INSTRUCTIONS

21

STARCREM 30/1 INV - STARCREM 60/1 INV

22

A 11 - SCRAPING BLADES

A 11.1

The slow speed beater shaft is provided with two blades made of teflon,

which function is to scrape the tank wall and at the same time to stir the

product.

A 11.2

Blade assembly

In order to assemble the blades, the motor bearing must

be in vertical position.

With regard to above, reference should be made to

paragraphs on safety devices, dangerous points on the

machine and other risks, inviting the user, technicianinstaller or any other person to strictly follow instructions

contained therein.

PROMAG

Scraping blade for cylinder wall

No responsibility will be assumed for improper use of

the machine or operations carried out which are not in

compliance with safety regulations.

The blades are hooked on, mating hole with head,

pushing blade until resting against slot.

A 11.2

Disassembly of blades

Proceed as indicated for assembly, but with reverse

sequence.

Scraping blade for cylinder bottom

USER INSTRUCTIONS

PROMAG

GB

STARCREM 30/1 INV - STARCREM 60/1 INV

Informative notes for user, but strictly concerning technician-installer

A 12 DESCRIPTION OF INTERNAL COMPONENTS STARCREM 30 - 60

Cylinder

Dehydrator filter

Electric box

Security valve

Humidity indicator

Thermostatic valve

Warmgases solenoid valve

Pressure switch

Compressor wiring box

Gas tap (high

pressure mains tap)

Compressor

Pressure control valve

Electrovalve

Water discharge filter

Water condenser

Filling group

Electrovalve

USER INSTRUCTIONS

23

STARCREM 30/1 INV - STARCREM 60/1 INV

24

A 13 - DANGEROUS POINTS ON THE MACHINE

Definition of dangerous areas with relative warning modalities;

general description of protection measures adopted.

PARTS IN MOTION TAKE CARE OF

HANDS

A 13.1)

Danger of entangling and dragging.

Danger of cutting and crushing.

- High speed mixer shaft.

- Low speed mixer shaft.

- Blades.

- Product outlet with cock open or

disassembled.

PROMAG

A 13.4)

Dangerous electric voltage

- General electric panel.

- Motor compressor.

- Motors.

A 13.2)

Thermal danger:

hot and cold parts.

- Cooling system.

- Compressor connection tube,

condenser.

- Cylinder.

A 13.3)

Dangerous pressure:

- Cooling system under

pressure.

USER INSTRUCTIONS

PROMAG

GB

STARCREM 30/1 INV - STARCREM 60/1 INV

A 14 - DANGEROUS POINTS ON MACHINE

with motor bearings in vertical position and during opening

High speed mixer shaft

Low speed mixer shaft

Magnetic

microswitch

In order to lift motor bearing bracket, grip onto

Magnetic

microswitch

A 14.1)

Danger of cutting, entangling, crushing, dragging

- High speed mixer shaft

- Low speed mixer shaft

- Blades

- Left and right brackets of motor bearing

- Motor bearing

- Motor casing

- Cylinder edge

- Cylinder bottom

-Small fans of high speed mixer shaft.

Never grip onto high speed mixer shaft as this

operation would unbalance same and jeopardize

ATTENTION:

low speed mixer shaft.

operation.

Magnetic

microswitch

USER INSTRUCTIONS

25

STARCREM 30/1 INV - STARCREM 60/1 INV

26

A 15 - PROTECTION MEASURES FOR DANGEROUS MACHINE AREAS

PROMAG

A 15.1

The machine is equipped with a casing, preventing

access to internal part of machine, together with

moving parts.

Above casing is fixed with screws.

Casing (fixed with screws) may only be removed by

qualified personnel and authorized by Promag.

A 15.2

Manual access to cylinder outlet is very difficult and

nevertheless it is only possible when cock has been

disassembled or is in open position.

The distances of the liquid mix and dense mix outlets

from the lateral surface of the cylinder and therefore

from the scraping blades and relative low speed shaft

is considerable, thereby preventing access of body

parts and avoiding above-mentioned dangers.

A 15.3

Access to high speed mixer shaft and low speed mixer

shaft is possible only by lifting the front and/or rear halflid and/or motor bearing. With above operations, the

three safety magnetic microswitches interrupt all

machine operations, stopping rotation motion of same.

A 15.4

During cleaning phase of two shafts, the motor bearing

is lifted in vertical position.

It is impossible for same to fall backwards, thereby

crushing hands or upper limbs of operator, as in this

position the motor bearing lock device is automatically

activated, as previously described.

A 16 - INFORMATION ON OTHER RISKS IMPOSSIBLE TO ELIMINATE,

DESPITE MEASURES ADOPTED BY DESIGNER

Other risks involved using the machine are:

A 16.1

Danger of entangling and dragging.

Please note that it is absolutely forbidden to come

into contact with mobile parts inside the cylinder (high

speed mixer shaft, low speed mixer shaft) whilst the

machine is functioning, with any object whatsoever or

part of the body, as this could result in jamming,

crushing and/or cutting.

Danger exists if, for imprudent cleaning operations

with cleaning rods or similar and with the machine still

in operation, one attempts access to cylinder through

the liquid mix outlet or through the cylinder pipe

union, with tap either disassembled or open. In case

of danger, press the STOP button.

A 16.2

Dangerous pressures

The cooling system still remains under pressure

even when the machine is off.

Before carrying out maintenance operations on same,

eliminate this type of risk.

A 16.3

Thermal danger

Please note that on water and cooling systems both hot

and cold mechanical parts exist, protected by special

casings.

Besides, any contact with same is absolutely

forbidden, thereby avoiding burning risks.

Danger exists in the case of repair and/or with internal

inspection of machine when same is still functioning or

recently turned off. (Remember that these operations

must be carried out by qualified personnel, authorized

by Promag).

Danger also exists when processing mixes whose final

heating temperature is high and when cylinder lid is

opened for product inspection.

If user is near the cylinder, steam produced by liquid

mix may hit his face, causing burning. Danger also

exists if hands or other parts of the body are introduced

into the mix. It is absolutely forbidden to introduce

hands or any other part of the body into the hot mix. It

is absolutely forbidden to bring face or other parts of

the body near the cylinder.

In case of danger, press the STOP button.

USER INSTRUCTIONS

PROMAG

GB

A 16.4

Danger of cutting, entangling and crushing

During washing and cleaning operations, the motor

bearing is lifted and placed in vertical position. As

already mentioned, there is no danger of same falling

and crushing hands or upper limbs, as in this position

the motor bearing lock device is automatically

activated, as described above. Danger still exists,

however, if, during opening of motor bearing, operator

fails to take a firm grip of same, owing to wet hands or

similar, or lacks sufficient strength.

In this case, the motor bearing would fall on the

cylinder plane, hitting any object in its way, causing

crushing, cutting and entangling between itself and the

edge of the cylinder, in addition to cylinder plane.

It is absolutely forbidden to place the machine in an

environment unsuitable for its appropriate use.

It is absolutely forbidden to move the machine and/or

its components in an irregular manner, thereby

jeopardizing its stability and reliability.

In case of danger, push the STOP button.

A 16.5

Danger also exists when approaching the machine

(especially with motor bracket open) with magnetic

materials, as same would interfere with safety magnetic

microswitches located under the two cylinder half-lids

and under the right shoulder of the motor bearing. In

this case, if the machine were operating, the two

STARCREM 30/1 INV - STARCREM 60/1 INV

motors would start up, causing the respective shafts to

rotate, dragging anything in contact around with them.

It is absolutely forbidden to approach the machine with

magnetic materials or interfere with safety magnetic

switches on purpose.

In case of danger, press the STOP button.

A 16.6

Dangerous electric voltage

During repair and/or maintenance operations,

(operations nevertheless permitted only by qualified

personnel, authorized by Promag), it is possible that

technician needs access to control panel, motor

compressor, motors or any other electric or

electromechanical component.

Danger exists if these operations are carried out without

having previously cut off electricity from mains, using a

special disconnecting device provided for during

machine installation, or even worse, when the machine

is in operation.

It is absolutely forbidden to gain access to electric and/

or electromechanical parts, without having previously

turned off machine with special disconnecting device.

In case of danger, press the STOP button.

A 17 - RECOMMENDATIONS ON PREVENTION MEASURES TO BE ADOPTED

A 17.1

Safety regulations.

In order to maintain the machine in a perfect state

and guarantee a safe operation for user, we advise

that following regulations are scrupulously followed.

This machine must only be used for the purpose for

which it has been originally designed.

Any other use is to be considered improper and

therefore dangerous.

During handling, loading and unloading of machine, be

very careful in choosing lifting points.

Do not leave machine exposed to atmospheric agents

(rain, sun, etc.).

Do not permit machine to be used by children or

inexperienced persons.

Machine must not be used by untrained personnel.

Maintain machine in perfect operating state, always

utilizing the various protections provided for, having

periodical maintenance carried out by professionally

qualified personnel.

Before connecting the machine, control that plate data

corresponds to that of electric and water distribution

network, (the plate is situated at the rear part of the

machine).

USER INSTRUCTIONS

27

STARCREM 30/1 INV - STARCREM 60/1 INV

28

PROMAG

Assure that machine is perfectly grounded, as foreseen

by safety regulations in force.

It is necessary that this fundamental safety requisite is

respected: in the case of doubt, ask for a careful

control of the plant by professionally qualified people.

Check that plant electric power is suitable to the

maximum absorbed power of the machine.

In case of doubt, revert to a qualified person, who must

control that the plant cable section is suitable for

absorbed power of machine.

Do not touch the machine with either wet or damp

hands or feet

Do not use the machine barefoot

Do not use extensions in rooms destined for

bathrooms or shower rooms

Do not pull the feed cable to disconnect the machine

from mains.

A 17.2

In order to avoid dangerous overheating, it is

necessary to wind up the entire feed cable.

Before carrying out any maintenance operation,

disconnect machine from mains, using plant

disconnecting device.

temperature of 100° C and well secured to the drain collector.

For cleaning operations, scrupulously follow

instructions laid down by manufacturer.

Do not block suction or dissipation grilles.

After having disconnected the machine, only qualified

personnel may have access to control panel.

When washing stainless steel, it is absolutely

In case of breakdown and/or poor functioning of

machine, disconnect the main disconnecting device,

abstaining from any attempt to repair or intervene

directly, reverting only to professionally qualified and

authorized personnel.

Eventual product repair will have to be carried out by

manufacturing company or by an authorized Service

Centre, only using original spare parts.

Machine safety could be compromised, if above

instructions are not observed.

A 17.3

Never utilize water to turn out fires occurring on electric

parts, but a dry powder fire extinguisher.

The machine must be turned off when not in use.

Do not modify protections and remove them only when

machine is no longer operative and disconnected from

mains.

Should you decide to no longer use this type of

machine, disconnect same by removing feed cable

from mains.

Discharge line must be in a position to resist a continuous

USER INSTRUCTIONS

PROMAG

GB

The cream cooking machine must be

positioned so that rear part is at least 20 cm

from wall or any object, thereby permitting free

air circulation.

Block the wheels with fitted brakes. It is

advisable to leave a space between the sides

of the machine and surrounding walls, thereby

facilitating cleaning operations.

A 19.1 OPERATION START-UP

STARCREM 30/1 INV - STARCREM 60/1 INV

A 18 - INSTALLATION

20 cm

A 19 - USE OF MACHINE

OFF will appear on display.

A 19.2

Open the tap of water mains.

2

1

A 19.3

Connect to power with

relative switch especially

provided for during

installation.

A 19.4

O F F

11

A 20 - MACHINE PREPARATION

It is advisable that first work cycle after machine installation is carried out with cylinder full of water rather than mix,

in order to control the various work phases.

To carry out above, proceed as follows:

- Check that OFF is written on display

- Lift the lid and pour water into the cylinder for a quantity not lower than advised minimal values reported in

technical specifications.

- Press button (11) and the temperature of the water in the cylinder will appear on display, together with previously

set program and cycle achievement set.

- Press button (1) and (2) and the cycle will begin.

- Complete the cycle, empty the cylinder through the extraction cock.

USER INSTRUCTIONS

29

STARCREM 30/1 INV - STARCREM 60/1 INV

30

PROMAG

A 21 - OPERATION

A 21.1

STARCREM machines have been designed to satisfy customerís needs to the utmost, together with those of

technician-installer/repairer.

With above philosophy, the mix is processed and electronically controlled.

forbidden to use steel shavings, wool or brushes.

33

27

For protection of environment and machine itself,

please abstain from using corrosive or polluting

products, not exceeding advised quantities.

A 21.2

MACHINE START-UP

Open the water mains tap (33), insert the wall switch (27)

as mentioned above.

OFF will appear on display.

Open the front half-lid and introduce the mix.

The quantities are specified in the following table.

Model Minimum Maximum

STARCREM 30

STARCREM 60

Close half-lid.

On pushing button (11), display will indicate

temperature measured by product probe and the program

previously set.

It should be pointed out that on pressing this button,

machine is prepared for subsequent

setting phases.

The appearance of temperature on display, is to be

intended as equivalent to ON position (machine in

operation).

15 Litri

30 Litri

30 Litri

60 Litri

2 0 A 9 5

At this point, all buttons of control panel are active, whilst

with OFF position, on pressing same,

no response would be given as machine is not operative.

11

USER INSTRUCTIONS

PROMAG

GB

COOKING CYCLE START-UP

Button 1

STARCREM 30/1 INV - STARCREM 60/1 INV

A 21. 3

At this point, two possibilities exist:

START-UP OF COOLING CYCLE - NIGHT PRESERVATION FOR

CYCLES D -E -F

Button 2.

COLD MIXING

Button 3

(manual operation of

low speed mixer)

COLD MIXING:

button 7

(manual operation of high speed mixer)

PROGRAM CHECK:

button 12.

RESET:

button 9

(all program values are based on

STANDARD values).

SWITCHING ON OR OFF OF ACOUSTIC

SIGNALS:

button 8

USER INSTRUCTIONS

31

STARCREM 30/1 INV - STARCREM 60/1 INV

32

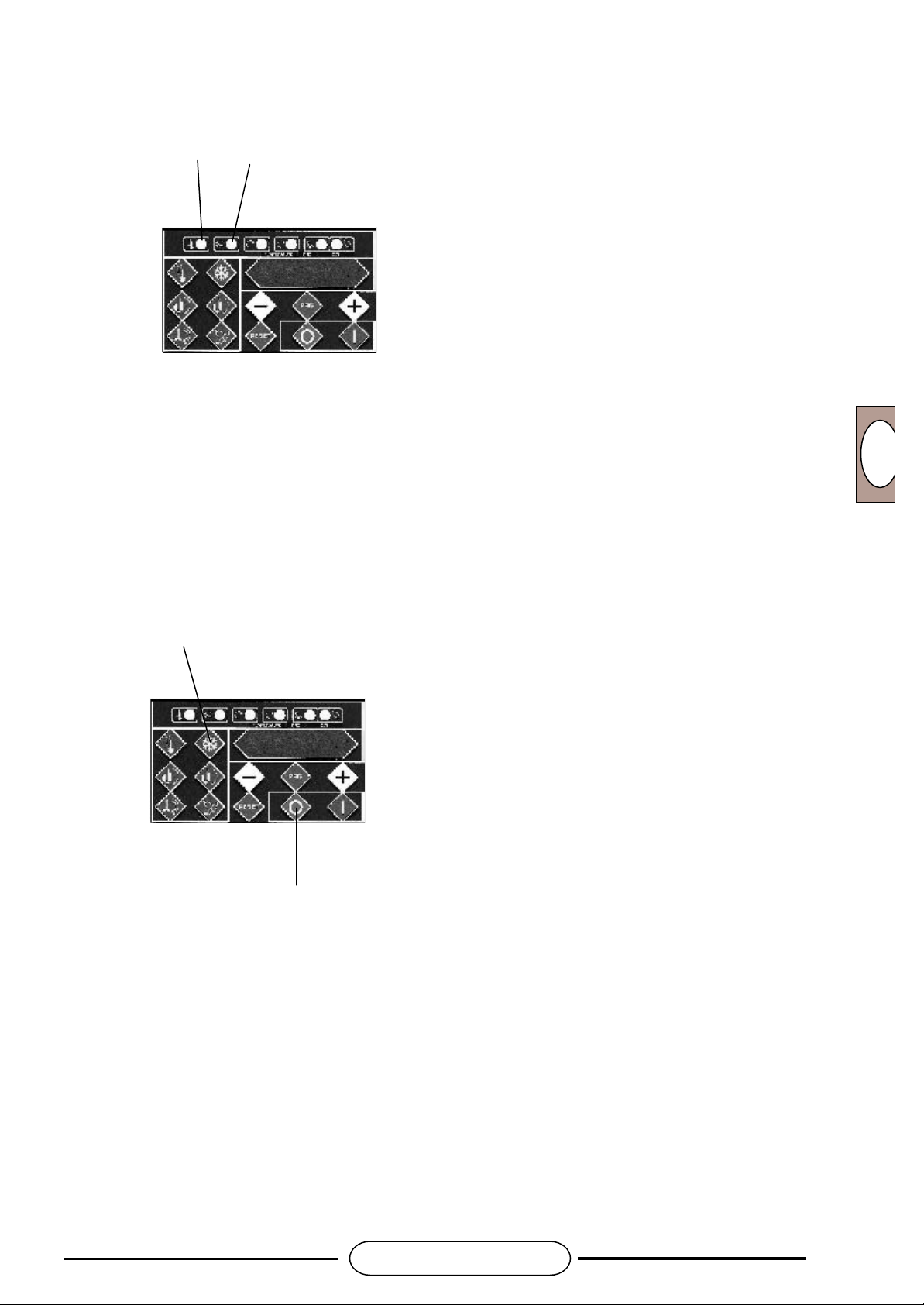

A 22 - PROGRAM CHECK

O F F

10

A

12

PROMAG

PROGRAM CHECK:

A 22.1

Display must be in OFF position.

On the contrary, press button 10.

A 22.2

Press button (12).

Letter A will appear on display.

With buttons (-) or (+) desired cycle may be selected.

A 22.3

On pressing button (12) again, all set parameters of the

selected cycle will be evidenced in sequence on display.

A 22.4

On pressing button (12) again, program is quitted and

display will visualize OFF.

O F F

12

10

A

EXAMPLE:

A 22.5

Press button (10).

OFF will appear on display.

A 22.6

Press button (12).

Letter A will appear on display (pastry cream).

A 22.7

Press button (12).

1A, 2A, 3A will appear in sequence on display.

A 22.8

Having checked program by pressing button (12) again,

program is quitted and last program set will appear on

display.

USER INSTRUCTIONS

PROMAG

GB

°C

1

7

STARCREM 30/1 INV - STARCREM 60/1 INV

A 23 - INVERTER MANUAL OPERATION

A 23.1

Press the button (7) ON, the tank temperature and the

selected program will be on display.

A 23.2

Press the button (3) slow beating and the last digit on display

will indicate the speed.

Through the buttons (+/-) you can change the speed.

When stopping the motor with the same button (3) the speed

will be stored.

If you stop the motor with the button (OFF) or a black-out

occurs, the speed will not be stored and consequently the

motor will starts at speed 1 (standard).

3

9

°C

A 24 - INVERTER SEMIAUTOMATIC OPERATION

A 24.1

In this function you can change the speeds within a program

A-M-N, or D-E-F and also to store at what temperatures

those changes were made.

The program will be stored and it can be consequently

recalled automatically.

Press the button ON (7), and the tank temperature will be on

7

display.

Press the button RESET (9) for 5", wait for the acoustic

signal and release.

A 24.2

Select one of the above mentioned programs and press the

cooking start button (1).

During water filling step, the machine runs at speed 1.

1

USER INSTRUCTIONS

33

STARCREM 30/1 INV - STARCREM 60/1 INV

34

A 24.3

While cooking, there are 3 steps in which we can change the speed,

P0

9

V1

9

namely:

- P0

- P1

- P2

Once at the 1st temperature set, where you may wish to change the

speed, press the button RESET (9) and P0 will blink on the display; with

buttons (+/-) it is possible to change P1, P2.

A 24.4

Press again RESET (9) and V1 will blink on the display; with buttons (+/-) you

can change the speed.

The speed is stored only when no futher changes are made for 5".

In order to modify the speed in cooking pause, vary P3.

P4, P5, P6 are steps where we can change the speed during cooling cycle.

P7 to be used to change the speed in storage mode.

Changes canot be seen.

PROMAG

A 25 - CYCLE A Pastry cream

1

13

7

13

8

14

15

15

17

16

18

18

A 25.1

Visualize cycle A on display (see program check).

Press button (1) (cooking cycle start-up button). Led 13 will come on. Electrovalve

will load water for 2 minutes.

During loading time, the low speed "motor" (led 15 alight) and high speed "motor"

(led 17 alight) will start up at a distance of 5 seconds from one another.

Once water loading has finished, (electrovalve in OFF position), the relay of the first

resistance is activated.

After 5 seconds, the relay of the second resistance.

Activation of ringing device 12 A (temperature alarm during cooking).

Led 18 is alight.

At programmed temperature 6A (temperature at end of high speed mixing), the high

speed "motor" turns off.

Above may occur also manually, by pressing button (7) (ON/OFF high speed motor

button). Led 17 is off.

A 25.2

During cooking cycle an acoustic signal 12A is possible, lasting for five seconds, for

the introduction of ingredients.

Activation of this acoustic signal is visualized by led 18.

Above may be cancelled by pressing button (8). Led 18 is off.

On reaching final cooking temperature 2A, pause time starts at final cooking temperature 10A. The electric resistances are disactivated.

The display in position of fourth or fifth digit (figure or letter) proceeds with a COUNTDOWN (backwards) in minutes until end of pause.

Once time has expired (00), the display SET visualizes temperature 3A of cycle end

[through button (12)].

The electrovalve opens for pre-cooling until final pre-cooling 4A temperature. Led

(14) lights up and led (13) turns off.

USER INSTRUCTIONS

PROMAG

GB

3

14

2

10

16

11

STARCREM 30/1 INV - STARCREM 60/1 INV

A 25.3

Interval ON/OFF times of low speed mixer are 8A (OFF time low speed motor

during intermittent phase) and 9A (ON time of low speed motor during intermittent

phase).

During the cooling phase to temperature 13A, it is possible to set a 5-second

alarm signal.

At the end cycle temperature 3A, the compressor turns off , together with low

speed motor with alternated operation (led 14 off, led 16 off).

When the product temperature rises to 2°C with respect to 3A, the compressor

and motor with intermittent operation start functioning again until reaching 3A.

A 25.4 Option for patsry cream static storage (A-M-N)

DIP 8 in ON position enables the static storage of pastry cream.

When reaching the cooling temperature set (3A, 3M, 3N) the compressor will stop

and will restart when the temperature raises by 2° C as to the value set.

Parameter A18 taht can be programmed 0÷5 minutes determines the operation

time for low speed beater

Parameter A19 determines pause time for the beater and can be programmed

1÷4 hours.

If parameter A18 has value 0, low speed beater will not restart.

3

A 25.5

In order to extract the product, open the tap in dense mix position and press ke (10)

(OFF), button (11) (last program set and activation of functions of all buttons) and

button (3) (continuous low speed mixing).

A 25.6

Pressing button (3) again, the machine remains in STAND-BY position.

The low speed mixer stops.

On pressing button (3) again, the low speed mixer restarts operation.

To maintain product left in the cylinder, press button (2).

When the temperature is over 2°C with respect to SET 3A, the compressor and

alternated low speed mixer will start functioning until reaching 3A.

N.B. The SET 2A and 3A can be changed even when cycle is in progress.

USER INSTRUCTIONS

35

STARCREM 30/1 INV - STARCREM 60/1 INV

36

A 26 - CYCLE B High temperature pasteurization for ice cream mix

A 26.1

17

13

1

Visualize cycle B (see program check).

Press button (1) (cooking cycle start-up button).

Led 13 will light up.

Electrovalve will load water for 1 minute.

During loading time, the low speed "motor" (led 15 lit)

and high speed "motor" (led 17 lit) will start up at a

distance of 15 seconds from one another.

A 26.2

Once water has been loaded (electrovalve in OFF

position), resistance 1 relay is activated.

After 5 seconds, resistance 2 relay.

Ringing device 12B is activated (led 18 alight).

Above may be cancelled with button (8).

(led 18 turned off).

PROMAG

4

13

8

18

A 26.3

The first two digits show the temperature variation on

display, the third digit, the program selected.

During heating it is possible to have a 5-second

acoustic signal for introduction of ingredients.

During acoustic signal led 18 flashes.

This acoustic signal can be cancelled with button (8)

(led 18 off).

A 26.4

During the heating phase it is possible to turn off low

speed "motor" manually with button (4).

On reaching programmed final cooking temperature

2B, electric resistances are disconnected, led 13

flashes for the pause time at the final cooking temperature 10B.

USER INSTRUCTIONS

PROMAG

GB

2

3

13

8

14

STARCREM 30/1 INV - STARCREM 60/1 INV

A 26.5

The last two digits of display start COUNT-DOWN of

pause time in minutes.

Once pause time has terminated, the pre-cooling

phase begins.

The electrovalve functions until final pre-cooling temperature 4B is reached (led 13 is off and led 14 is

alight).

At temperature 5B refrigeration compressor will

come on, turning off at temperature 3B. SET indicates

temperature 3B (through button 12).

A 26.6

During cooling phase, motors may be turned on and

off manually. At programmed temperature 3B,

refrigeration compressor turns off, together with low

speed motor (if functioning).

High speed motor continues to turn if 11 B is ON.

It stops if OFF.

A 26.7

When product temperature increases by 2°C with

respect to SET 3B, the compressor starts up.

Similarly, high speed motor starts up until newly

reaching 3B.

Should button (10) "OFF" be mistakenly pressed

during cooling stage, press button (3) "ON" and

button (2) to continue cooling.

A 26.8

In order to extract product, open tap to liquid mix

position.

USER INSTRUCTIONS

37

STARCREM 30/1 INV - STARCREM 60/1 INV

38

A 27 - CYCLE C low temperature pasteurization of ice cream mix

PROMAG

1

13

15

17

18

A 27.1

Visualize cycle C on display (see program check).

Press button (1) (cooking cycle start-up button).

Led 13 will light up.

Electrovalve will load water for 1 minute.

During loading time, the low speed "motor" (led 15 lit)

and high speed "motor" (led 17 lit) will start up at a distance

of 15 seconds from one another.

A 27.2

Once water has been loaded (electrovalve in

OFF position), relay is activated, together with resistance

1.

After 5 seconds, relay and resistance 2.

Ringing device 12C is activated (led 18 alight).

Above may be cancelled with button (8).

(led 18 turned off).

The first two digits show temperature variation on display,

the third digit shows the program selected.

4

13

8

8

18

A 27.3

During heating it is possible to have a 5-second acoustic

signal for introduction of ingredients.

During acoustic signal led 18 flashes.

This acoustic signal can be cancelled with button (8) (led

18 off).

During the heating phase it is possible to turn off low

speed "motor" manually with button (4).

On reaching programmed final cooking temperature 2C,

electric resistances are disconnected, led 13 flashes for

the pause time at the final cooking temperature 10C.

USER INSTRUCTIONS

PROMAG

GB

STARCREM 30/1 INV - STARCREM 60/1 INV

13

14

A 27.4

The last two digits of display start COUNT-DOWN of

pause time in minutes.

Once pause time has terminated, the pre-cooling

phase begins.

The electrovalve functions until final pre-cooling temperature 4B is reached (led 13 is off and led 14 is

alight).

At temperature 5C, refrigeration compressor turns

on, turning off at temperature 3C.

SET shows temperature 3C (through button 12).

A 27.5

During cooling phase, motors may be manually

turned off and on. If in operation, refrigeration

compressor, together with low speed "motor" will

turn off at programmed temperature 3C.

The high speed "motor" continues to turn if 11C is

ON.

It stops if on OFF position.

3

2

10

A 27.6

When product temperature increases by 2°C with

respect to SET 3C, the compressor starts up.

In same manner, high speed "motor" also starts up

until reaching 3C again.

Should "OFF" button (10) be mistakenly pressed

during cooling phase, press "ON" button (2) to con-

tinue cooling.

A 27.7

In order to extract product, open tap in liquid mix

position.

USER INSTRUCTIONS

39

STARCREM 30/1 INV - STARCREM 60/1 INV

40

A 28 - CYCLE D Solidification of plain chocolate

A 28.1

Visualize cycle D on display (see program check).

Start-up cycle D by pressing button (1).

Resistances will be activated in sequence.

After 5 seconds low speed mixer will be activated.

At melting temperature 2D, COUNT-DOWN with resistances OFF will appear on

display.

At the end of COUNT-DOWN, the electrovalve and refrigeration compressor will

start operating.

At temperature 4D, STOP of electrovalve will appear.

At temperature 14D, compressor will start operating and alternated movement

will begin.

Operation for a time 15D with a pause 16D until temperature 3D.

In order to reach solidification temperature 17D, first resistance is started up.

After five minutes, the acustic signal will be on, the bell and the temperature

leds will blink.

Above temperature is maintained with a precision of ±1°C.

PROMAG

A 28.2

Manual short solidification cycle

On terminating the solidification cycle and pressing cooking button, a short

solidification cycle begins.

Led 13 will be flashing and the two resistances will be activated with the low

speed mixer in operation until reaching temperature 19D.

At this temperature, there will be a pause of five minutes, with electrovalve and

refrigerator operating for the time 15D and 16D.

Once set 20D has been reached, refrigerator will stop.

Temperature led will flash for five minutes.

Maintenance with a precision of ± 1°C.

A 28.3

Automatic short solidification cycle with parameter 23D different from zero.

The manual solidification cycle is repeated at programmed intervals (one hour,

two hours, three hours).

A 28.4

Overnight preservation of chocolate

At any moment during short solidification process, heating cycle will begin by

pressing button (2) and led 14 will flash.

Low speed mixer will remain in operation until temperature 18D for ten minutes.

After ten minutes the low speed mixer functions every thirty minutes for five

minutes.

Maintenance with a precision of ±1°c.

USER INSTRUCTIONS

PROMAG

GB

13

1

13

8

14

15

17

18

STARCREM 30/1 INV - STARCREM 60/1 INV

A 29 - CYCLE G Bavarian cream

A 29.1

Visualize cycle G on display (see program check).

Press button (1) (cooking cycle start-up button).

Led (13) will come on.

Electrovalve will load water for 1 minute.

During loading time, the low speed "motor" (led 15 lit) and high speed

"motor" (led 17 lit) will start up at a distance of five seconds from one

another.

On terminating water loading (electrovalve on OFF position) relay and

resistance 1 are activated.

After five seconds relay and resistance 2 (only if 13G is ON).

During cooking cycle, it is possible to have a 5-second acoustic signal 12 G

(led 18 lit).

During signalling led 18 flashes.

Signalling may be interrupted with button (8) (led 18 off).

During the cooking phase high speed mixer may be manually excluded with

button (7).

At final cooking temperature 2G, electric resistances are disconnected and

the pause phase 10G begins.

Led 18 flashes.

A 29.2

First two digits show temperature variation on display.

Third digit shows program selected.

Fourth and fifth digits show first SET of achievement of started cycle.

On reaching programmed final cooking temperature 2G, electric

resistances are no longer active, led 13 flashes for the pause time at the

final cooking temperature 10G.

The last two digits on display start COUNT-DOWN of pause time in minutes.

On termination of pause time, low speed pre-cooling phase begins (led 13

off, led 14 on).

The electrovalve operates until final pre-cooling temperature 4G is reached.

At temperature 5G the refrigeration compressor comes on, turning off at

temperature 3G.

SET indicates temperature 3G.

When product temperature increases by 2°C with respect to SET 3G, the

compressor starts operating.

3

3

10

11

A 29.3

In order to extract product, open tap to dense mix position and press button

(10) (OFF), button (11) (last program set and activation of functions of all

buttons) and button (3) (low speed continuous mixing).

Press button (3) again: the machine remains in STAND-BY.

Low speed mixer stops.

By pressing button (3) again, the low speed mixer starts operating again.

To maintain product remained in cylinder press button (2).

When temperature exceeds 2°C with respect to SET 3G, the compressor

and low speed alternated mixer will start operating until reaching 3G.

USER INSTRUCTIONS

41

STARCREM 30/1 INV - STARCREM 60/1 INV

42

A 30 - CYCLE H Fruit jam

A 30.1

Visualize cycle H on display (see program check).

Press button (1) (cooking cycle start-up button).

Led 13 will light up.

The electrovalve will load water for 1 minute.

During loading time, low speed "motor" (led 15 lit) and high speed "motor" (led 17

lit) will start up at a distance of 1 minute from one another.

On termination of water loading (electrovalve OFF), relay and resistance 1 are

activated.

After five seconds the relay and resistance 2.

During the cooking cycle it is possible to have a 5-second acoustic signal 12H

(led 18 alight).

During signalling led 18 flashes.

Signalling may be turned off by pressing button (8) (led 18 off).

During cooking the high speed mixer can be manually excluded with button (7).

A 30.2

At final cooking temperature 2H, electric resistances are deactivated and pause

phase 10 H begins.

Led 13 flashes.

Temperature variation is shown on display by first two digits. Third digit shows

program selected. Fourth and fifth digits show first SET of achievement of started

cycle.

On reaching programmed final cooking temperature 2H, electric resistances are

no longer active, led 13 flashes for the pause time at the final cooking temperature

10H.

The last two digits on display start COUNT-DOWN of pause time in minutes.

On termination of pause time, low speed pre-cooling phase begins (led 13 off, led

14 on).

The electrovalve operates until final pre-cooling temperature 4H is reached.

At temperature 5H the refrigeration compressor comes on, turning off at temperature 3H.

SET indicates temperature 3H with a 5-second acoustic signal at end of cycle.

Low speed "motor" is functioning.

When product temperature increases by 2°C with respect to SET 3H, the

compressor starts operating.

1

7

13

13

15

8

17

18

14

PROMAG

3

2

A 30.3

In order to extract product, open tap to dense mix position and press button (10)

(OFF), button (11) (last program set and activation of all button functions) and

button (3) (low speed continuous mixing).

Press button (3) again: the machine remains in STAND-BY position.

Low speed mixer stops.

By pressing button (3) again, the low speed mixer starts operating again.

To maintain product remained in cylinder press button (2).

When temperature exceeds 2°C with respect to SET 3H, the compressor and low

speed alternated mixer will start operating until

10

USER INSTRUCTIONS

PROMAG

GB

STARCREM 30/1 INV - STARCREM 60/1 INV

A 31 - CYCLE I Cooling

2

A 31.1

Visualize cycle I on display (see program check).

Press button (2).

Pre-cooling electrovalve starts up if temperature

measured is over 14 I.

Refrigeration compressor starts up if temperature

measured is less than 5 I.

Manual high speed mixer motor starts up.

Manual continuous low speed mixer motor starts up.

Manual alternated low speed mixer motor starts up.

If times 8 I and 9 I have been set and if temperature

is less than 7 I.

A 31.2

If cooling cycle has taken place with high speed

mixer motor with 11 I: OFF, at the temperature of 3 I

the compressor will be turned off.

If the cooling cycle has taken place with the alternated

low speed mixer, at the temperature of 3 I,

compressor will turn off, together with low speed

mixer.

When temperature increases by 2°C with respect to

3 I, refrigeration compressor will start up again,

together with alternated mixing up to 3 I.

USER INSTRUCTIONS

43

STARCREM 30/1 INV - STARCREM 60/1 INV

44

A 32 - Cycle L Manual Cooking

18

13

1

18

17

PROMAG

A 32.1

Visualize cycle L on display (see program check).

Press button (1) (cooking cycle start-up button).

Led 13 will light up.

Electrovalve will load water for 1 minute.

On terminating water loading (electrovalve on OFF

position) relay and resistance 1 are activated.

After five seconds relay and resistance 2.

12L temperature alarm during cooking.

Start-up of manual high speed motor.

Start-up of manual low speed motor.

Led 18 is alight.

A 32.2

Motors may also be turned off manually by pressing

button (7) (high speed motor ON/OFF button).

Led 17 is off.

During cooking, an acoustic signal 11L and 12L may be

obtained for five seconds for introduction of ingredients.

Activation of this acoustic signal is visualized by led 18.

Led flashes during acoustic signals.

Signals may be cancelled by pressing button (8).

Led 18 is off.

On reaching final cooking temperature 2L, pause time

begins at final cooking temperature 10 L.

Electric resistances are no longer active.

Pause phase is indicated by flashing led 13.

In the fourth and fifth digit position (figure or letter) the

display carries out a COUNT-DOWN (backwards) in

minutes until end of pause.

Should the 10L value be zero, the 2L temperature is

controlled with 1t=2°C.

7

8

USER INSTRUCTIONS

PROMAG

GB

STARCREM 30/1 INV - STARCREM 60/1 INV

A 33 - CYCLE M-N Personalized

1

13

7

13

8

14

15

15

16

17

18

18

A 33.1

Only parameters which user will insert during programming will vary, according

to recipes.

A 33.2

Visualize cycle M-N on display (see program check).

Press button (1) (cooking cycle button).

Led (13) will come on.

Electrovalve will load water for 1 minute.

During loading time, the low speed "motor" (led 15 lit) and high speed "motor"

(led 17 lit) will start up at a distance of five seconds from one another.

On terminating water loading (electrovalve on OFF position) relay of first

resistance is activated.

After five seconds relay of second resistance.

Activation of signalling 12 M-N (temperature alarm during cooking stage).

At programmed temperature 6M-N (temperature at end of high speed mixing)

the high speed "motor" turns off.

The motor may also be turned off manually, by pressing button (7) (high speed

motor ON/OFF button). Led 17 is off.

A 33.3

During cooking cycle, it is possible to have a 5-second acoustic signal 12M-N

for introduction of ingredients.

Presence of this acoustic signal is visualized by led 18.

Same can be cancelled by pressing button (8). Led 18 is off.

On reaching final cooking temperature 2M-N, pause time begins at final cooking

temperature 10 M-N.

Electric resistances are no longer activated.

The display in fourth and fifth digit position (figure or letter) carries out COUNTDOWN (backwards) in minutes until end of pause time. Once time has expired

(00), the display SET visualizes temperature 3M-N of cycle end [(through button

(12)].

The electrovalve opens for pre-cooling until final pre-cooling temperature 4MN. The led (14) lights up and led (13) turns off.

Refrigeration compressor starts up at temperature 5A and at temperature 7M-N

the low speed mixer passes from continuous operation to intermittent operation

(led 15 off, led 16 alight).

A 33.4

ON/OFF interval times of low speed mixer are 8M-N (OFF time low speed

motor during intermittent stage) and 9M-N (ON time low speed motor during

intermittent stage).

A 33.5

LED LIGHT UP

Leds display process stage of machine.

Each led is associated with a button function, as specified by identical

symbology.

Lit led signifies operation in progress.

Unlit led signifies no operation.

USER INSTRUCTIONS

45

STARCREM 30/1 INV - STARCREM 60/1 INV

46

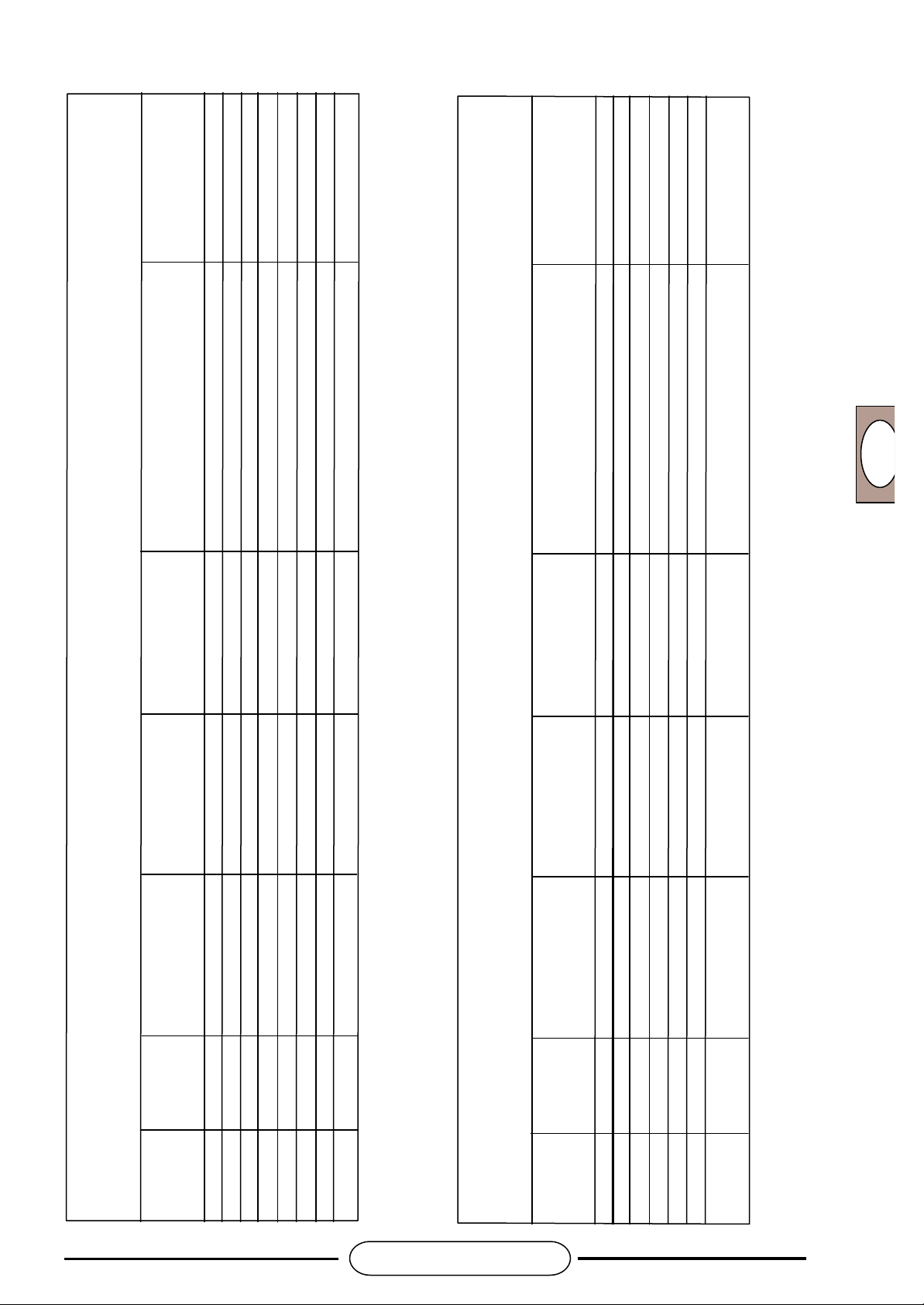

123456789

101112

MIN. VALUE

PROGRAM.

SET STAND.

+10

110

9970709960

120

120

99

99

1

°C°C°C°C°C°C°C

SECONDS

SECONDS

MINUTES

°C

-

1°C

1°C

1°C

1°C

1°C

1°C

1°C

5 seconds

5 seconds

1 minute

1°C

-

0956

6060953015

15

001