Pro Mach Wexxar BEL Series, Wexxar BEL 505, Wexxar BEL 505S Operation & Service Manual

OPERATION & SERVICE MANUAL 65-11-7

BEL 505 / BEL 505S

SEMI-AUTOMATIC CASE FORMER

AND PACKING STATION

65-11-07 2/5/2007

Wexxar Packaging Inc

Phone (604) 270-0811 • Fax (604) 270-7897

E-mail: sales@wexxar.com

.

BEL 505/505S SEMI-AUTOMATIC C ASE F ORMER & PACK S TATION 2

SSAAFFEETTYY CCAAUUTTIIOONN

Although the BEL 505 & 505 ‘S’ packing stations can be used in conjunction with competitive case

taper/sealers, BELCOR cannot assume responsibility for safety issues resulting from these applications

We specifically do not recommend using these packing stations in close proximity with

conventional back flap “kickers” and three-flap folders.

Be sure that:

• the main on/off valve at the air connection is shut off and that the red emergency stop button is

pushed down before connecting an air supply to the machine.

• the machine is disconnected from the air source before undertaking any maintenance or service

procedures. This is to avoid inadvertent machine actuation that could result in personal injury.

Never leave the machine unattended with the air switch on.

.

Only qualified personnel must operate the machine!

65-11-07 2/5/2007

BEL 505/505S SEMI-AUTOMATIC C ASE F ORMER & PACK S TATION 3

BEL 505

SEMI-AUTOMATIC CASE FORMER AND PACKING STATION

Standard Case Size Range:

Length Width Height

Minimum 8” (203mm) 6” (152mm) 3.5” (89mm)

Maximum 26.5” (673mm) 16” (406) Unlimited

Machine Size 37.5 (953mm) 25 (635mm) 18.5” (470mm) [min]

Case Infeed/Outfeed Height:

• UHMW Pads: 21.5” (546mm) [min] 28.5” (724mm) [max]

• Castors: 25” (635mm) [min] 32” (813mm) [max]

Power Requirements (standard):

• Compressed Air: 80-90 PSI ; 0.1 CF/Cycle

BEL 505 ‘S’

SEMI-AUTOMATIC CASE FORMER AND PACKING STATION

Standard Case Size Range

Length Width Height

Minimum 8” (203mm) 5” (127mm) 3.5” (89mm)

Maximum 16” (406mm) 15” (381mm) Unlimited

Machine Size 27.5” (700mm) 25” (635mm) 22 (560)

Case Infeed/Outfeed Height:

• UHMW Pads: 21.5” (546mm) 28.5” (724mm)

• Castors: 25” (635mm) 32” (813mm)

Power Requirements (standard):

• Compressed Air: 80-90 PSI ; 0.1 CF/Cycle

65-11-7 2/5/2007

BEL 505/505S SEMI-AUTOMATIC C ASE F ORMER & PACK S TATION 4

TABLE OF CONTENTS

INTRODUCTION.......................................................................................................... 5

ABOUT THIS MANUAL ............................................................................................................................................. 5

INSTALLATION PROCEDURES ................................................................................. 6

INSTALLING THE BEL 505 & 505 ‘S’ ........................................................................................................................6

L

EVELLING THE MACHINE ..................................................................................................................................... 6

A

IR CONNECTION ................................................................................................................................................... 7

OPERATION & ADJUSTMENT PROCEDURES.......................................................... 8

MACHINE SET-UP ADJUSTMENTS...............................................................................................................................8

C

ASE WIDTH ........................................................................................................................................................... 8

C

ASE LENGTH ......................................................................................................................................................... 9

M

AJOR FLAP FOLDER ROLLER PLATES ..............................................................................................................10

M

ACHINE OPERATION ..............................................................................................................................................11

TARTING THE MACHINE .....................................................................................................................................11

S

E

RECTING A CASE................................................................................................................................................. 11

M

ACHINE OPERATING CYCLE ............................................................................................................................. 12

TROUBLESHOOTING GUIDE ............................................................................................. 14

65-11-7 2/5/2007

BEL 505/505S SEMI-AUTOMATIC C ASE F ORMER & PACK S TATION 5

INTRODUCTION

The BEL 505 & 505 ‘S’ are designed for semi-automatic folding of new corrugated cases. The machines

combine the following functions:

1. A bottom major and minor flap folder mechanism assist in erecting flat cartons ready for packing.

2. A packing station position to fill the case with product.

The machine does not require a high level of technical knowledge to operate.

A

BOUT THIS MANUAL

The Installation section in the beginning of the manual is intended for those who will be installing and

maintaining the machine.

The Machine Set-up and Machine Operation instructions should provide a new operator with the

knowledge needed to run the machine safely and effectively.

first reading this manual.

No one should operate the machine without

Following the operating instructions is a Troubleshooting section to provide solutions to common problems that

may occur with the quality of corrugated cartons used and effectiveness of the case folding process.

A separate “Technical Reference” manual or manual section provides details on parts kits, parts identification

and machine construction for those who will service and repair the machine.

PLEASE NOTE:

Best performance with BEL machines will occur when adjusted, operated and maintained in accordance

with the instructions in this manual. We cannot be responsible for unauthorized changes to the machine

or methods of its operation.

The following information is a reference guide for our standard machines. We strive to provide up-to-date

manuals with machines but we are continually improving our products and the details in the manual

provided might not exactly match the machine at the time it is shipped. Many machines are modified in

response to customer requests or as required by the case samples supplied at the time the machine is built

and the manual may not provide a complete reference to the changes or modifications. If there are any

questions about your machine not covered by the manual, please contact us and we will do our best to

provide the additional information you need.

65-11-7 2/5/2007

BEL 505/505S SEMI-AUTOMATIC C ASE F ORMER & PACK S TATION 6

INSTALLATION PROCEDURES

INSTALLING THE BEL 505 & 505 ‘S’

Unpack the machine and remove any packing material from the interior or supports from underneath used

to protect components during shipping.

Install the legs at each of the three positions on the machine frame with one nut and washer for each leg

underneath the frame and another nut and washer on the inside. If the 505 or 505S is to be mounted on

[and supported from] the case sealer with mounting options 70-378 or 70-395, refer to the instructions

included with them.

LEVELLING THE MACHINE

If standing directly on the floor, the base of the frame should be made level to ensure personnel safety,

provide optimum performance and avoid frame stress.

Please note that the standard BEL 505 & 505 ‘S’ are intended to operate in a horizontal position.

Attempting to tilt the 505 or 505 ‘S’ toward the operator will cause excessive wear in the case width

adjustment mechanism and may case it to bind or damage the width adjustment screw. A width

adjustment equalizer option 70-380 is on BEL 505’s that are used with side-tilt mounted systems.

[Another possibility for a side-tilt system is the BEL Model 507 Tilt Packing Station. It is designed to tilt

towards the operator for case erecting and loading and then back to the horizontal position for feeding

into a sealer or onto a conveyor.]

ALIGNING THE MACHINE

The machine should be securely mounted to adjoining equipment to prevent the machine moving as it

operates. If being directly connected to a BEL case sealer, it is important that the centers of both

machines be in line for ease of case transfer between machines. When a BEL 505 is provided together

with a BEL sealer a jig is provided to further assist aligning the machines. The BEL 505 should be level

with, or slightly higher than, the case sealer conveyor.

Alignment Jig

65-11-7 2/5/2007

BEL 505/505S SEMI-AUTOMATIC C ASE F ORMER & PACK S TATION 7

AIR CONNECTION

SSAAFFEETTYY CCAAUUTTIIOONN

Make sure that the red emergency stop button is pushed down (off)

before connecting an air supply to the machine.

The air may come from either a separate source or by tapping off the supply of an adjoining case sealer.

The supply must be clean factory air and must be lubricated by the unit on the machine.

Air pressure should be set to 80 psi. for most applications with a minimum setting of 65 psi. and

maximum of 100 psi.

65-11-7 2/5/2007

BEL 505/505S SEMI-AUTOMATIC C ASE F ORMER & PACK S TATION 8

OPERATION & ADJUSTMENT PROCEDURES

SSAAFFEETTYY CCAAUUTTIIOONN

Switch off or disconnect the air supply to the machine before making any changes or

adjustments.

MACHINE SET-UP ADJUSTMENTS

Setting up the BEL 505 & 505 ‘S’ to fold a particular box size is accomplished with two main

adjustments for case width and length. There is a third adjustment to reposition the major flap folder

plates that, after initial setup, will need to be changed only where there is a large difference between cases

widths.

CASE WIDTH

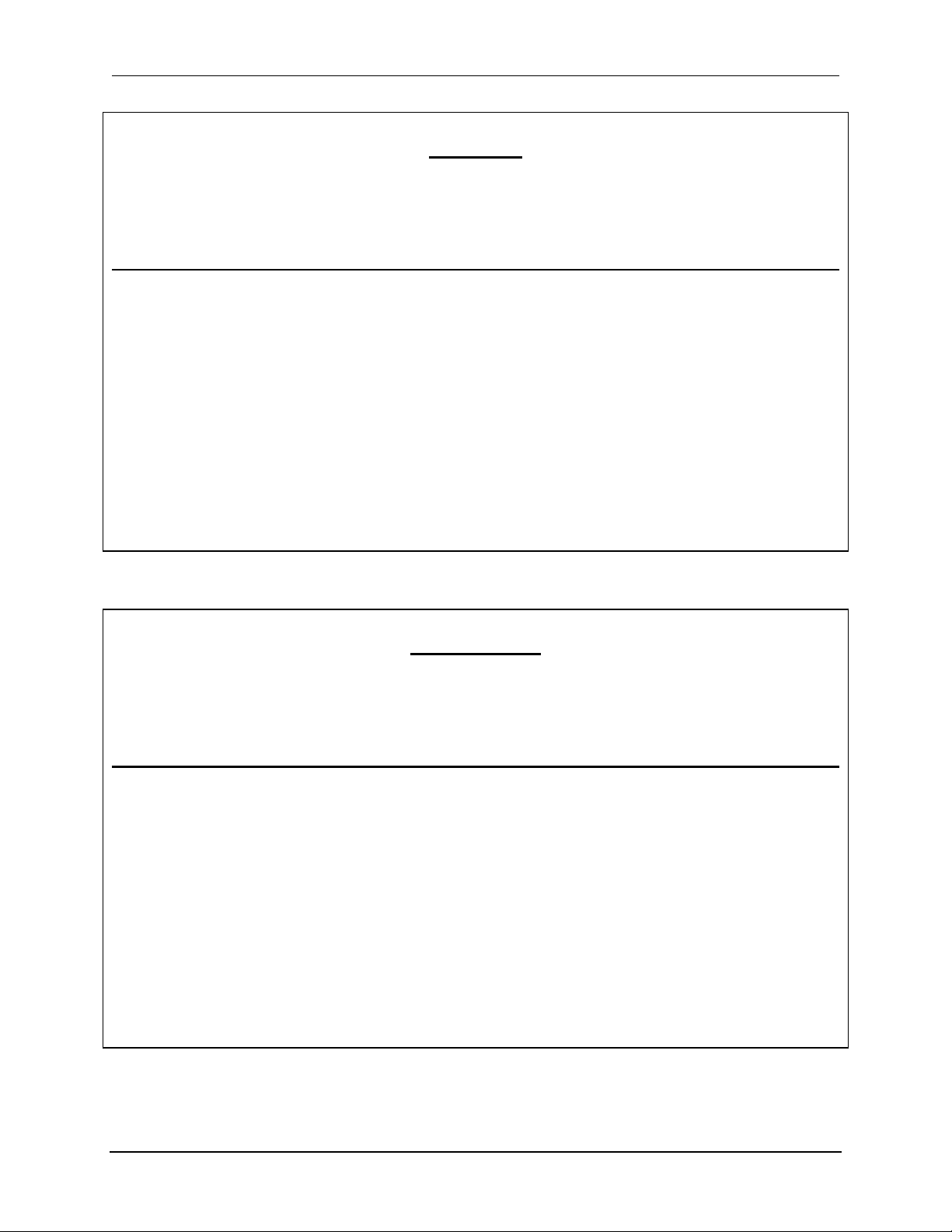

1. Loosen the hand

knobs at the end

of the BEL 505

or 505 ‘S’.

2. Attach the hand

crank supplied

with the machine

on the square

shaft that extends

from either side

of the frame.

Adjust the frame

to be wider than

the case.

3. Open a case from the flat blank and insert it into the m

4. Crank in the width adjustment until the red case

hold-down rollers are lightly gripping the sides

of the case. It should be easy to insert and

remove the case without forcing but it must

maintain contact on the white “body “ switch

roller until the case leaves the machine.

5. Re-tighten the hand knobs.

65-11-7 2/5/2007

achine.

Case holddown roller

“Body”

switch roller

BEL 505/505S SEMI-AUTOMATIC C ASE F ORMER & PACK S TATION 9

CASE LENGTH

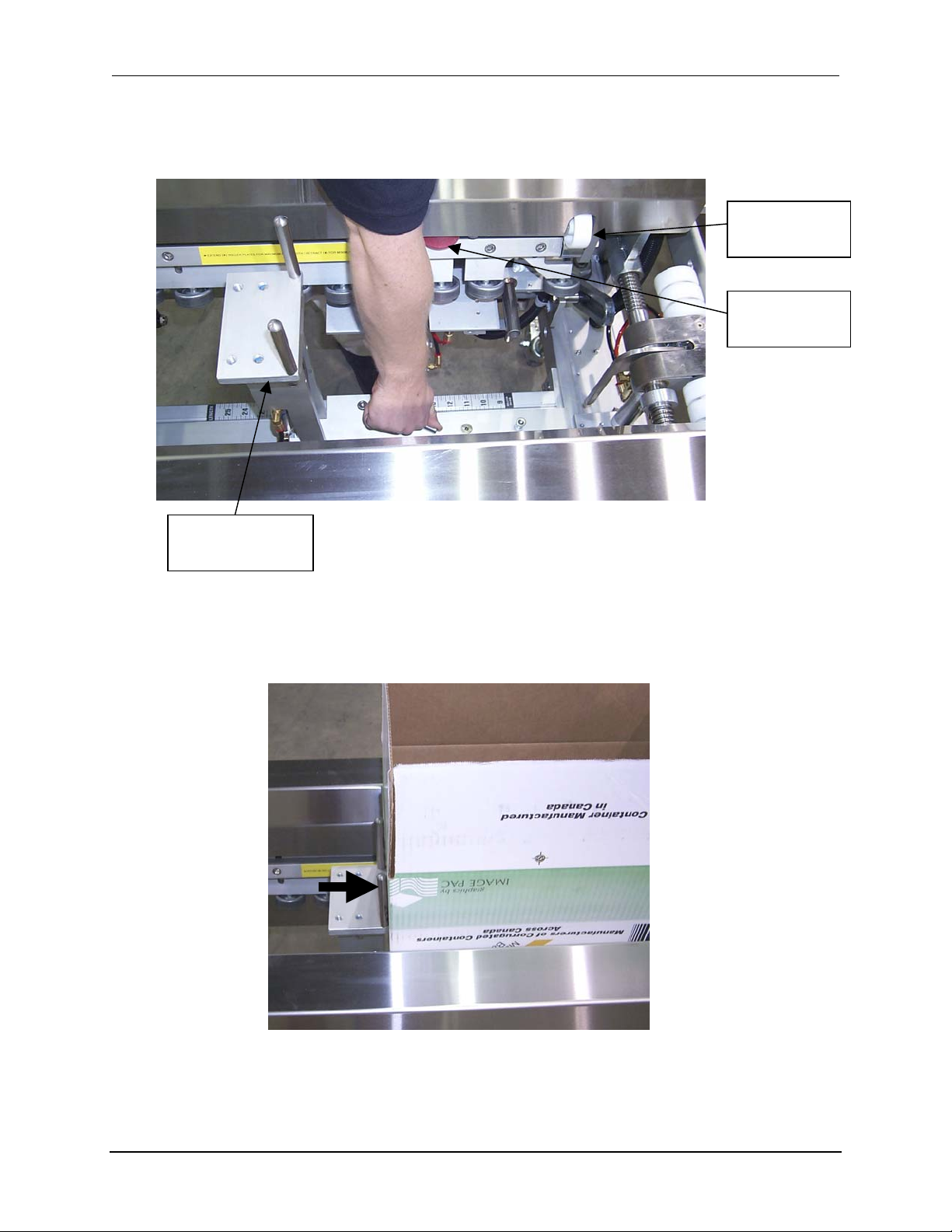

1. Remove the case and loosen the clamp at the base of the front minor flap folding “tower “

“Body”

switch roller

Case holddown roller

Minor flap

folding “tower”

2. Reinsert the case into the machine and position it ½” back from the minor flap folder at the exit end

of the machine. Push the tower forwards until it just contacts the back of the case. Remove the case

and tighten the tower clamp

65-11-7 2/5/2007

BEL 505/505S SEMI-AUTOMATIC C ASE F ORMER & PACK S TATION 10

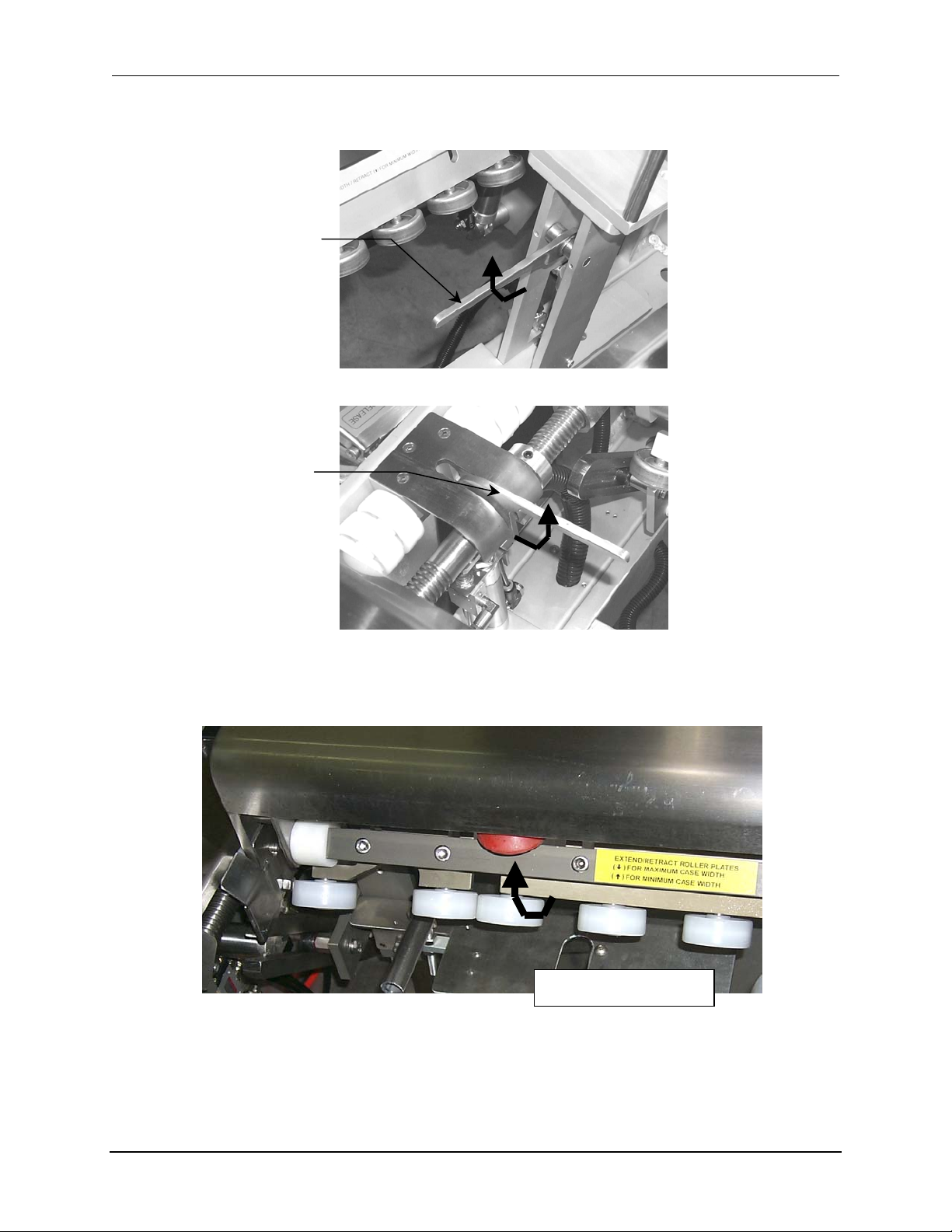

MAJOR FLAP FOLDER ROLLER PLATES

The major flap folding plates and wheels may need to be extended to provide additional support for wide

heavy cases or retracted for narrow ones.

Important Note Regarding Major Folder Plates Adjustment: Sliding the plates in towards the

machine centre increases the case bottom support but limits the minimum width adjustment when the

major flap folder wheels hit the minor folder tower. Also, extended folder plates in the down position will

wedge against the bottom control valve / flap opener bracket as the machine is adjusted for minimum

width. If forced, either of these conditions can damage machine components.

There are two major folder plates on each side of the machine, one small and one large that are adjusted

independently.

1. Loosen the four socket-head cap screws on each side that hold the folder rollers in place. Slide the

front [large] folder to the desired position and retighten the screws.

Front [large] major

flap folder plate

2. Adjust the rear [small] major folder

plate. Make sure that the plate will

not contact the “floor” switch valve

arm as it moves through its arc. For

wide cases, the small folder plate will

not be able to be extended as far as

the large plate and has a separate

adjustment for this reason.

Plate adjustment

clamp screws

Rear [small]

major folder

65-11-7 2/5/2007

“Floor” switch

valve arm

BEL 505/505S SEMI-AUTOMATIC C ASE F ORMER & PACK S TATION 11

Additional Note: For wide cases on 18” & 20” maximum width 505 versions, optional roller wheels are

mounted on extensions from the folding plates to place them closer to the centre of the box for better folding

performance and product support. Extensions may need to be removed for narrow cases run on the same

machine to avoid interference with other machine components. If your application requires these extensions and

they are not provided with your machine, contact BELCOR for information and parts.

MACHINE OPERATION

SSAAFFEETTYY CCAAUUTTIIOONN

Make sure that the main on/off valve at the air connection is shut off and that the

red emergency stop button is pushed down before connecting an air supply to the machine.

S

TARTING THE MACHINE

Prior to starting, hand swing all moving parts to check adjustment and for any mechanical

interference. Turn on main supply valve, keeping hands clear of moving parts.

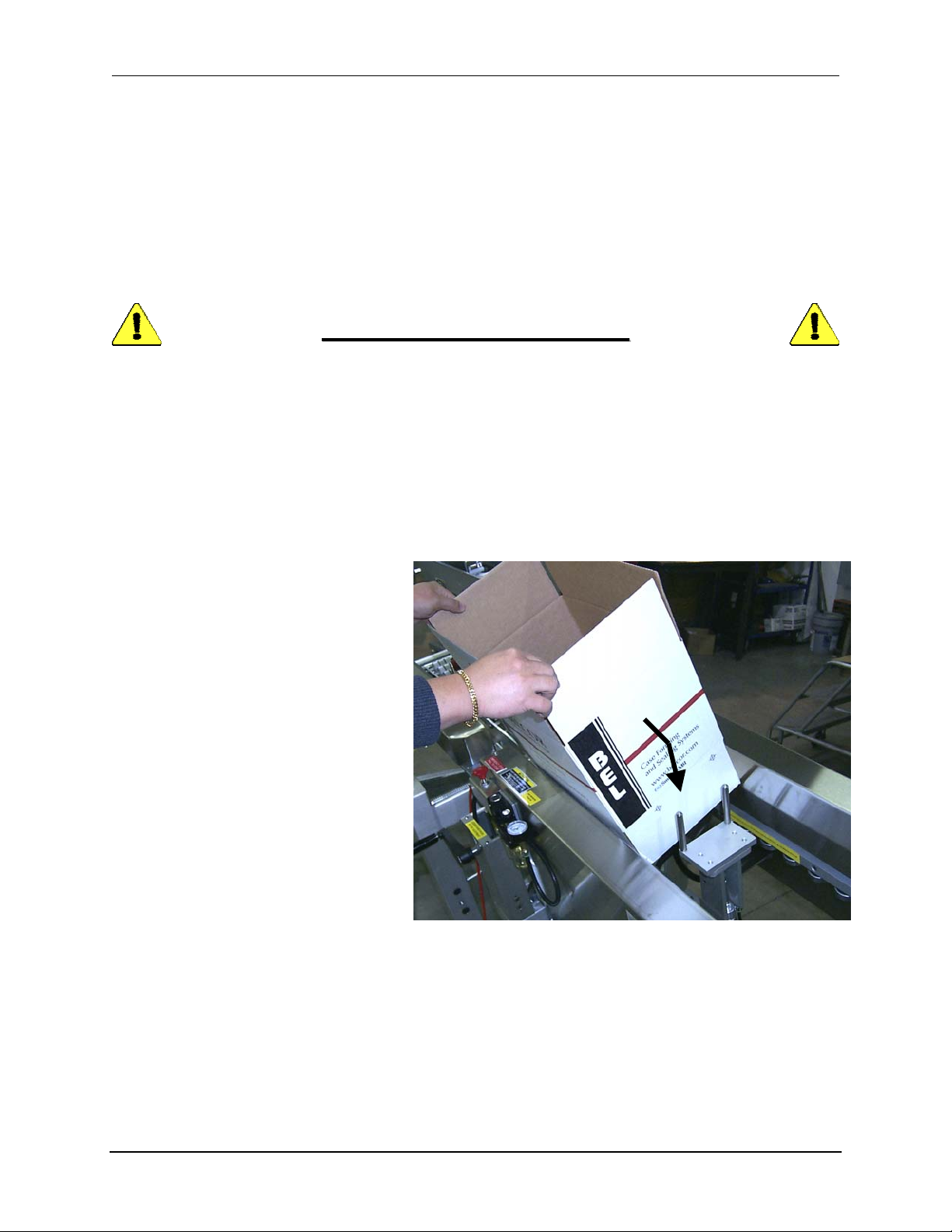

E

RECTING A CASE

1. Open a case so that it is fairly square.

2. Place the open bottom into the BEL

505 or 505 ‘S’, pushing the case all

the way down to the floor switches

3. The machine will first fold the front

and rear end minor flaps, then the two

side major flaps. The case is held in

place and is ready to fill, if desired

4. When filled, or if the case is just

erected for filling downstream, push

it out of the packing station to the

next operation

.

5. As the end of the case breaks contact

with the “body” switch, the 505 will

automatically reset ready for the next

case.

65-11-7 2/5/2007

BEL 505/505S SEMI-AUTOMATIC C ASE F ORMER & PACK S TATION 12

MACHINE OPERATING CYCLE

1. The bottom edges of the major flaps depress the actuators of the two “floor” switch valves and

the side of the case depresses the wheeled “body” switch valve. All three switches must be

actuated for the machine cycle to start.

“Body” switch

“Floor”

switches

2. The two small levers of the major (side) flap openers momentarily open the bottom major flaps

wider to clear the minor (end) flaps.

65-11-7 2/5/2007

Bottom major flap

opener

BEL 505/505S SEMI-AUTOMATIC C ASE F ORMER & PACK S TATION 13

3. The minor flap folders fold up both end flaps of the box bottom and retract.

Front [tower] Minor Flap

Folder

Front Minor Flap Folder

Rear Minor Flap Folder

[Machine out-feed end]

Rear Minor Flap Folder

4. The major flap folders then fold up both side flaps of the bottom and stay in position to support

the box for packing.

Major folder [RH

5. Pushing the box out of the machine breaks contact with the body switch inside the packing

station. The machine then resets, ready for the next case.

65-11-7 2/5/2007

Loading...

Loading...