Contents

Model: FLT-09 User Guide

Caution

Specifications

Dimensional Drawing

Components

Assembly

Operation

Reset Procedure

Troubleshooting

1

2

3

4

5-6

7

7

8

01

Caution

Ensure no obstacles are in the desk's path. Ensure the

tabletop is not touching any walls. Ensure all cords are

appropriate length to accommodate the change in height.

Keep children away from electric height-adjustable desks, control units, and handsets. There is a

risk of injury and electric shock.

Keep all electrical components away from liquids.

Do not sit or stand on the desk frame. Do not crawl or lie under the desk frame.

Warning

Pinch Point

Keep hands and

fingers clear.

Do not place any objects taller than 20" underneath the desk.

During the Reset Procedure, the desk will retract 7mm below the lowest normal operating

height, ensure no obstacles impede this motion of travel.

02

Specifications

Input Voltage 120VAC, 60 Hz

Output Voltage 24VDC

Stroke (movement) 25.5"

Height Range (without tabletop) 23.5” - 49”

Weight Capacity (load) 330 lbs (110 lbs per leg)

No Load Speed 1.57"/s

Full Load Speed 1.18"/s

Duty Cycle 10% (2 minutes on, 18 minutes off)

Operating Noise < 50 dB

Frame Material SPCC/ SPHC Steel

Finish Powder Coat - Grey(RAL7045)

Leveling Adjustable Leveling Feet

Low Power Mode Standby < 0.1W

Certification UL and BIFMA United Certificate

Feature Description

Soft Start and Stop

The tablelift will accelerate to maximum speed and

deccelerate to a stop to ensure smooth travel.

Memory Presets

Anti-Collision

The Smart Remote has the ability to save preset height locations

for convenience. Set the numbered buttons on the Smart Remote

for quick and seamless adjustment.

The Anti-Collision feature will help protect the tablelift against obstacles

which impede the motion of travel. There are 3 force settings which can

be detected during travel, 22lbs, 33lbs, and 44lbs.

03

Maximum Width - 75.3"

Dimensional Drawing

2"

Minimum Width - 43.4"

22.6"

27.5"

1.2"

Extended - 49"

Retracted - 23.5"

*Feet and column style may vary slightly

04

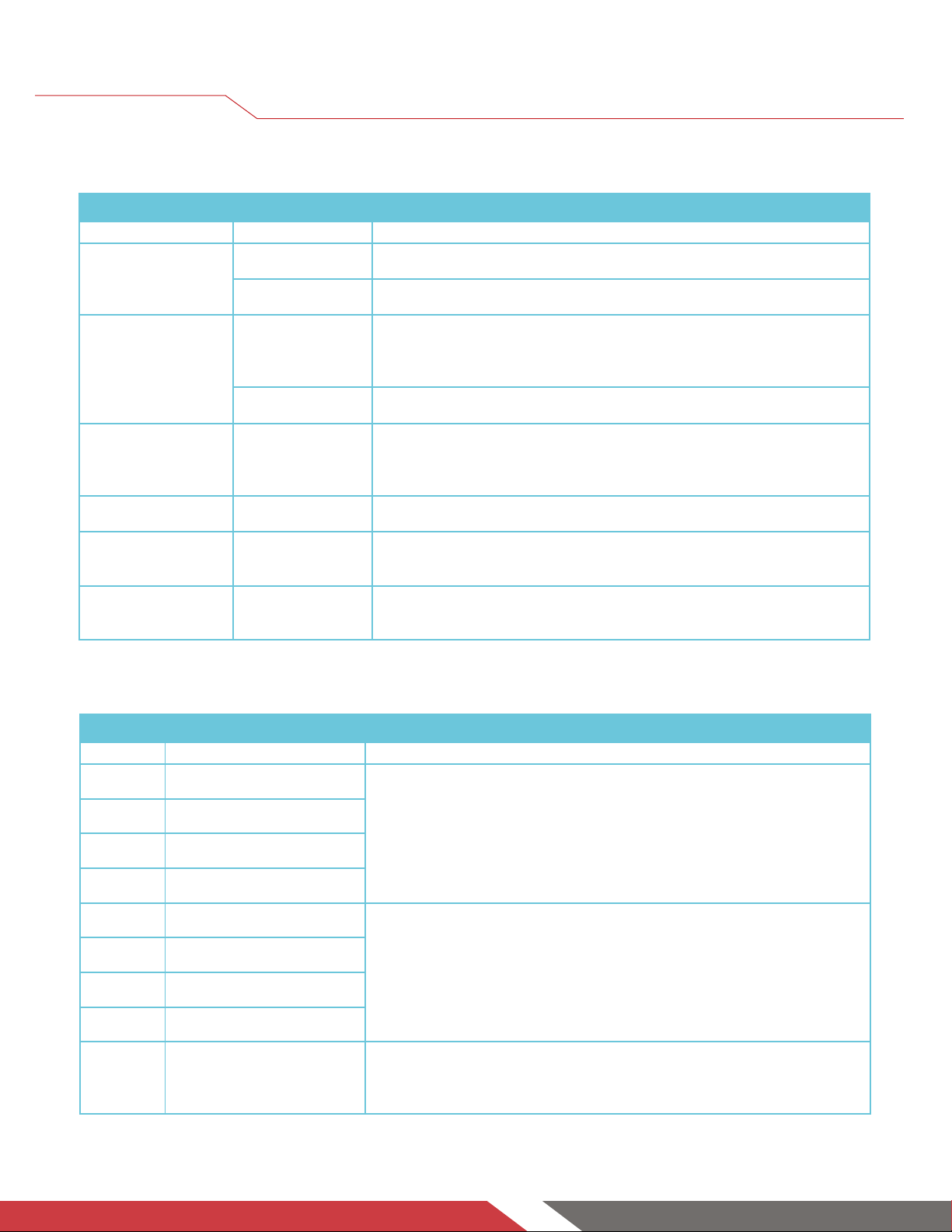

Components

Tools

Parts

4mm Allen Wrench (included)

1 2

6 7 8 9 10

11 12

x5 x2

x4 x1

x20

Phillips Head Screwdriver

and/or Power Drill

3 4 5

x3

x4

x2

13

x1

x3

x16

Tape Measure

x2

x28

Parts Diagram

10

3

9

2

1

10

7

6

4

9

8

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

Description

Feet

Leg

Side Bracket

Frame 1

Frame 2

Center Rail

120° Frame 1

120° Frame 2

M6x14 Machine Screw

M6x10 Machine Screw

M6x35 Machine Screw

M6x20 Wood Screw

M6x16 Wood Screw

Qty

3

3

3

1

1

4

1

1

16

24

4

2

14

05

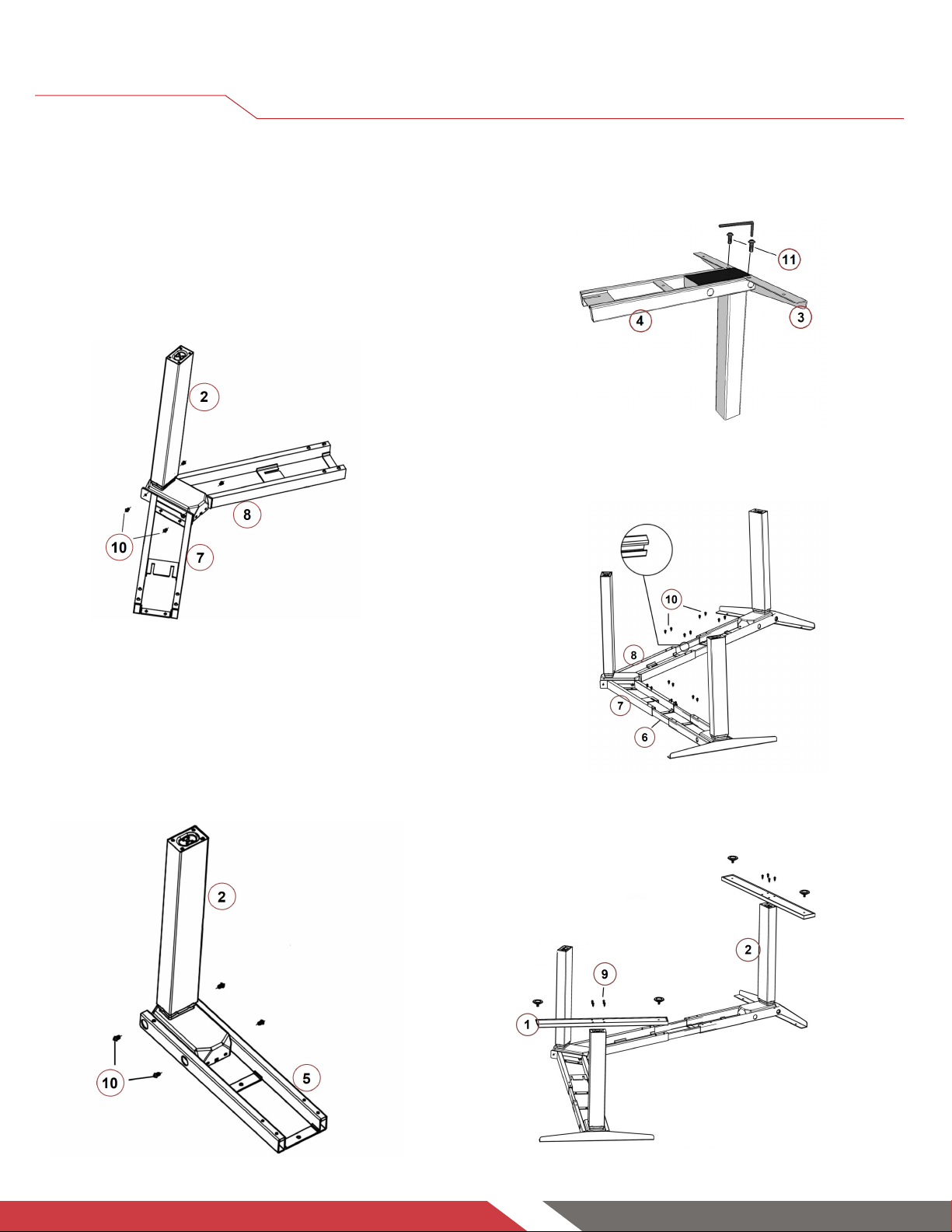

Assembly

STEP 1

Attach the 120° Frames (7,8) to one of the Legs (3) as shown

in the picture below. Line up the holes on the Leg with the

holes on the Frames.

Use the supplied Allen Wrench to insert four M6x10

Machine Screws (10) through the holes on the Frame

(7,8) going into the Leg (1). Rotate each screw just a few

turns until all four are inserted, then tighten them.

STEP 3

Slide the Side Brackets (3) into both Frames (4,5).

Attach the brackets using two M6x35 Machine Screws

(11).

STEP 4

Slide the Center Rails (6) into the 120° Frames (7,8) and

attach them into position using sixteen of the M6x10

Machine Screws (10).

STEP 2

Place one of the Legs (3) into one of the Frames (5)

and line up the holes.

Use the supplied Allen Wrench to insert four M6x10

Machine Screws (10) through the holes on the Frame

(5) going into the Leg (3). Rotate each screw just a

few turns until all four are inserted, then tighten them.

Repeat the process for the other Leg and Frame.

STEP 5

Attach each Foot (1) to each Leg (2) with four M6x14

Machine Screws (9) and tighten them.

06

Assembly

STEP 6

Place the assembled three-leg frame onto the

underside of your tabletop. Adjust the width of the frame

to fit your tabletop by sliding the two halves apart.

We recommend leaving at least 1.25" of the tabletop

extending beyond the assembled frame. Make sure

to center the Side Brackets (3).

STEP 7

If your tabletop has pre-drilled holes, skip ahead to Step

8. If not, lock the position of the Center Rails using eight

of the M6x10 Machine Screws (10). Make sure the

screws make contact with the Center Rails (6) by sliding

them as needed.

STEP 8

Ensure that the wood screws are not too long for

your tabletop.

STEP 9

Connect the cable from each Leg (1) directly into the

control box. Use cable extenders when necessary.

Then connect the hand remote cable to the control box.

Use the adhesive-backed cable clips to secure the

cables so they are not loose and in the way.

STEP 10

We recommend having two people for this step. Flip

the fully assembled desk by the legs (not by the

tabletop).

IMPORTANT

Prior to normal operation, please complete a Reset

Procedure outlined in the next section.

If possible, pre-drill pilot holes to ease the installation

process. Attach the frame to the tabletop using four of

the M6x16 Wood Screws (12).

Attach the hand remote so the front of the remote is

lined up with the tabletop edge. Place the remote

anywhere along the edge so that you'll have easy

access to it. Use two of the M6x20 Wood Screws (13) to

attach and secure the remote to the tabletop. Do not

over-tighten the screws as this could cause damage to

the components.

07

Operation

Normal Operation

Using the wired remote, press and hold the 'Up' button to raise the table lift. To lower the table lift, press and hold

the 'Down' button. The 'Up' and 'Down' buttons are momentary controlled, when they are released, the table lift will

stop immediately.

To set a preset location, move the table lift to the desired height. Press the 'M' button followed by a numbered

button. The LED display will flash an 'S', followed by an 'S - Number'. This will indicate that the preset has been saved.

To use a preset, press any of the numbered buttons and the table lift will begin to move to the preset position. It is

important to ensure that no obstacles impede the motion of travel. To stop the table lift, press any button.

If the table lift does not function as intended or the LED display flashes "RSt", please follow the Reset Procedure

outlined in the next section.

Setting the LED Display

Using the wired smart remote, retract the table lift to the lowest position. Press and

hold the 'Down' button again until the LED display flashes "RST".

Press and hold the 'M' button until the LED display flashes the starting height (if

the display returns to "RSt" before the next step, repeat this step).

To change the value of the starting height, use the 'Up', 'Down' to increase and

decrease by 0.1. Use the '1', '2' to increase and decrease by 1s. Use the '3', and '4'

buttons to increase or decrease by 10s.

Once the correct value is displayed, wait 5 seconds until the LED display flashes

"RSt". Follow the Reset Procedure outlined in the next section to save the new

starting height.

Note: the LED display has a tolerance of ±0.1.

Reset Procedure

WARNING: During the Reset Procedure, the table lift will retract 7mm below the lowest normal operating height,

please ensure that no obstacles impede this motion of travel.

1. Move the table lift to the lowest position. (If there is an 'RSt' displayed on the remote, continue

to step 3.)

2. To initiate the Reset Procedure, press and hold the down button on the remote until "ASr" is

displayed. Release the down button.

3. Press and hold the down button on the remote, the table lift will begin to retract 7mm lower

than the lowest normal operating height. To stop motion at any time, let go of the down button.

4. Once the table lift has completed the Reset Procedure, height will be displayed on the remote.

08

Troubleshooting Guide

Problem Possible Cause Corrective Action

Remote LED is off.

Low power mode

activated

Connection issue

Press any button on the remote and LED will activate.

Disconnect and reconnect the RJ-45 remote connector. Ensure connection is

secure and cable is not damaged.

Troubleshooting

Table lift does not

move when motion

control buttons are

pressed.

Table lift travels at a

significantly slower

speed than rated

specification.

Unusual noise during

travel.

Table lift stops abruptly

during travel.

Table lift is not level. Out of sync

Limit switch reached

Connection issue

Weight issue Ensure weight capacity has not exceeded the maximum load rating.

Weight issue Ensure weight capacity has not exceeded the maximum load rating.

Obstacle

Follow "Setting Limit Switches" instructions to remove the programmed limit. If

maximum or minimum height limit has been reached, please move the system

in the opposite direction.

Disconnect and reconnect the Lifting Columns, Control Box, AC Power, and

Remote.

Ensure there are no obstacles in the path of the table lift. If the movement

continues to fail, initiate the Reset Procedure.

Disconnect and reconnect all cables (Lifting Column, Control Box, AC Power,

and Remote), then initiate the Reset Procedure.

Error Codes (remotes with LED display)

Error Code Error Summary Description

E01 M1 overcurrent protection

E02 M2 overcurrent protection

E03 M3 overcurrent protection

E04 M4 overcurrent protection

All columns stop moving and remote displays E01-E04. Ensure that the total

weight capacity of the table lift has not been exceeded and that no obstacles

obstruct the movement. Press any key and remote will display

RST, initiate the Reset Procedure. If the issue persists, disconnect and

reconnect all of the lifting columns, including the main power. Repeat the Reset

Procedure.

E07 M1 hall error

E08 M2 hall error

E09 M3 hall error

E10 M4 hall error

H01

Over heat /duty cycle

protection

All columns stop moving and remote displays E07-E10. Ensure that all columns

are still properly connected to the control box. Check to see if any cables have

been damaged. Press any key and remote will display RST, initiate the Reset

Procedure. If the issue persists, disconnect and reconnect all of the lifting

columns, including the main power. Repeat the Reset Procedure.

All columns stop moving, remote displays H01 (if LED screen available). Allow

the system to rest for 16 minutes, use normally. Follow the Duty Cycle rating to

ensure no issues arise from overheating.

Loading...

Loading...