Profroid QuietCO2OL Series, QuietCO2OL LT Series, QuietCO2OL MT Series, QC MT30, QC MT50 Operating Instructions Manual

...

OPERATING INSTRUCTIONS

COMMISSIONING / OPERATING / MAINTENANCE

(must be given to the end user in order to complete the operating manual during the equipment service life)

QUIETCO2OL

These operating instructions must be read at the delivery of the equipment and prior any operation on it.

Our technical department is at your disposal for any additional information (Tel : + 33 4 42 18 05 00).

This document is a translation of the French original version which prevails in all cases.

/ PED fluid group : 2

Version 9110

Modifications since the version N° 051217

Pages

- Instruction on the refrigerant charge

P5

- Clarification on the system pressure

P6

- Addition of the water cooled units

(all the

document)

- Addition of some remarks on transportation

P 14

- Warning concerning the mounting of the liquid lines

P 16

- Commissioning Instruction on water cooled units

P 18-19-20

- Recommendation on the evaporator controller selection

P 24

- Clarification of the Controller settings

P 26

- Clarification for the gascooler cleaning instructions

P 32

- Update on the service instruction

P 33-34

- Clarification of the meaning of the colour code in the refrigerant and oil charge charts

P 38

- Instruction on oil filling

P 38

The following table aggregates all the main modifications since the last version

TABLE OF CONTENTS

SAFETY 1-3

GENERAL STARTUP INSTRUCTIONS 4-5

CAUTION FOR SAFETY 6-7

COMPONENTS 8-9

SCOPE OF APPLICATION 10

DIMENSIONS 11

HANDLING OF THE UNIT 12

SELECTION OF INSTALLATION LOCATION 13-14

REFRIGERANT PIPING WORK 15-16

COMMISSIONING 17-19

OPERATING 20

REFRIGERANT CIRCUIT DIAGRAM 21-22

ELECTRICAL CONNECTIONS 23-24

USER INTERFACE 25-27

DESCRIPTION OF THE DISPLAY 28-29

MANUAL MODE FOR THE VACUUM PROCEDURE 30

CONTROL FUNCTIONS 31

MAINTENANCE 32-34

WARRANTY CONDITIONS 35-36

ECODESIGN 37

APPENDIX 1: REFRIGERANT AND OIL CHARGE 38-42

APPENDIX 2 : ALARM LIST 43-44

SAFETY

Reminder

Carbon dioxide is a colorless and odorless gas, whose presence in excess in the atmosphere can lead to discomfort, such as

headaches, difficulty concentrating, even with low levels of concentration and nausea in the case of greater than 1000 ppm.

Carbon dioxide gas is heavier than air and is located at lowest point of spaces when they aren’t

ventilated. Machinery room must be equipped with a carbon dioxide detector as required by EN 378.

In case of carbon dioxide evacuation (vacuum draw, etc …), it is important to have a connection through safety valves discharge

pipes as required by EN 378.

As professional, the installer must :

define the operating conditions of the refrigeration equipment under his own responsibility regarding the design. This device needs

to be incorporated in machines conforming to the Machines Directive. Its commissioning is only authorized if it has been

incorporated in machines which fully satisfy the legal regulations.

complete and adapt these recommendations, if necessary, by adding other safeties and /or controls according to the

refrigeration equipment’s operating conditions.

have performed all the installing, commissioning and maintenance operations by qualified professionals and conforming with

standards EN 378, EN 14276, EN 13136, EN 13313, EN 60204 and EN 60335, the EU directives, the safety rules generally

recognized, sound engineering practice, the local regulations ; as well as those which may be set up, taking into account the

evolution of the technology and the regulations.

If the installation, the commissioning, the operating, the maintenance are not realised according to this operating instructions,

the responsibility of Profroid cannot be involved.

completely inform the customer on the control, maintenance and follow-up of the refrigeration equipment.

The devices are delivered under pressurized nitrogen or dry air (make sure at reception that material is under pressure by

using a pressure gauge) ; except dry cooler, brine air cooler.

Respect the standard for transport and handling of pressure devices.

Install device in a space with sufficient ventilation regarding standards and regulations because device is under pressure of nitrogen

; except dry cooler, brine air cooler.

Very important : before performing any servicing operation on refrigeration equipment, the electric power supply must be

turned off. The contractor or the company in charge of the installation shall be responsible for carrying out the required

instructions.

Profroid disclaims any responsibility for change(s) or repair(s) on its devices made without its prior

agreement. The devices are exclusively intended for professionals, for refrigeration purposes and for their

limits of use.

The identification of device and his range of use are written on the name plate. The name plate is stuck on device. Name plat es are

located : on the coil for heat exchangers, on the frame for racks, on the housing for condensing units, on the receiver for liquid receiver

sets and for liquid sub-assembly. The name plate is joined to this operating instructions (.pdf). The complete installation must be

designed and used not to exceed the range of use. Device is designed for a maximum ambient temperature of 38°C (as standard

configuration).

The user or operator shall ensure the control and maintenance of the equipment with qualified professional complying with the

instructions below, possibly completed by the installer. For these operations, the standards and directives mentioned above remain usefull.

This is also available during the stop of the refrigeration installation.

The average life cycle for the design of our devices is of a minimum of 10 years, provided if you follow our operating

instructions. Profroid cannot be held responsible in case of violation to the recommendations of them.

Pipings of Profroid equipment are made with different types :

in copper, standard NF EN 12735 and K65

in stainless steel, standard NF EN 10217-7 (type 304L – X2CrNi18-9 ; n° 1.4307)

These pipings must be inspected regularly following standards, sound engineering practice and local regulations in the country of use.

Some heat transfer fluids can be harmful or corrosive, and their uses must be realised in relation with their risks, if there is a

leak on pipings.

1

INSTALLATION

The loading and unloading operations must be performed with adequate handling equipment (forklift, crane, etc.) using possible lifting

points provided for this purpose.

The qualified professional should be certified and will wear individual safety equipment (protective gloves, glasses, safety shoes, etc.) ;

operators will never circulate under the load during lifting operations.

During handling, the operator will ensure a good balance to prevent the equipment from swinging.

Make sure that the equipment or its accessories have not been damaged during shipping and no parts are missing.

If devices are used in a seismic area, then the installer must apply all necessary rules.

If the appliance is installed in an area for which consideration of the external fire situation is mandatory, then the installer must make

the necessary arrangements.

Enough free space all around the refrigeration equipment should be provided to facilitate maintenance operations.

The heat exchangers must be installed in locations free of any external dust or other pollutants from the neighbourhood which could

obstruct or clog the coils.

If devices are used in a corrosive area (sea side, pollutant gas, etc.), make sure that appropriate anticorrosion protection has been

provided.

Make sure that pipings are connected to the appropriate pressurized equipment (EN378-2).

All connecting pipings must be correctly supported and clamped.

For the connection of pipings, protect sensitive components located around the permanent assemblies to be made.

Before any intervention, the operator must obstruct all the openings of the circuit (+ pressurization under nitrogen) ; except dry

cooler, brine air cooler.

Discharge pipings (outlets of safety valve for example) must be installed in view to protect people and apparatus from leakage of

refrigerant.

Make sure that flexible hoses are not in contact with metal parts.

The products added for thermal and /or acoustic insulation must be neutral with respect to support materials.

The protection devices, pipings and accessories must be protected against unfavourable effects from the environment.

Make sure that access and emergency exit ways are not obstructed to comply with the local regulations.

COMMISSIONING

Prior to electrically connect the facility, make sure that the AC power line voltage and frequency ratings correspond to the indications

on the identification plate and the power voltage is within a tolerance of + 10 % with respect to the rated value.

Specific protection is provided according to the neutral system.

Any on-site wiring must comply with the legal standards in force in the country of installation (including grounding).

Before turning on a device, make sure that :

- the electric connections have been correctly made

- the clamping screws of the various terminals are correctly tightened

Check the possible presence of locking devices of compressor antivibration elements, and remove them, if they exist.

OPERATING

Do not use the refrigeration equipment or components for any utilization other than that for which it is designed.

Comply with the special manufacturers’ recommendations contained in the manufacturers’ operating instructions.

It is strictly prohibited while the device is running to remove the guards and panelling provided by the manufacturer to protect the

user and ensure his safety.

When operating, surface temperatures above 60°C and /or below 0°C may be reached. During any servicing operation, the personnel

should be extremely careful while working on the device.

Profroid is not informed to real use of partly completed machines ; their integrations and use must comply to Machines Directive and

recommendations of this operating instructions.

Results of design calculations, checks, and test reports in relation with low voltage directive are archived.

2

MAINTENANCE / RECYCLING

The device must be checked and inspected into service, regularly, by a qualified and approved personal, following rules.

The device will be subject to preventive maintenance (EN 378) :

- external visual inspection of device,

- checks of device during running,

- checks of device corrosion.

Before working on pressurized components, shut down the facility and wait until the equipment is at the ambient (room) temperature.

Before removing the guards and panelling, turn off the device. Set it aside and make sure that no power is present.

Do not use piping to access on the equipment or to store something on theequipment.

The replacement of a safety valve must be made by the same brand of the original one.

If there is modification of type and /or brand, then the professional in charge of the replacement will do a calculation sheet following

EN 13136 and /or ask Profroid some elements.

Handle regularly the device valves in view to avoid theirs blocking on.

If a personal in charge of maintenance closed a blocked valve, this personal will must avoid the possible increase of pressure in the

part of device which is isolated.

The periodic technical checks must be made following frequencies determined by standards, sound engineering practice, end user

and installer.

Report periodic checks and analyze the data. In case of abnormalities or inconsistencies, determine the cause and correct it.

In case of hanged units (evaporator as an example), it is necessary to define an exclusion zone on the ground, to avoid the presence

of persona under the equipment.

It is important to ensure that the hinge mechanisms of moving parts are operational before all manipulations (drain pan, door,

fans mounted on hinges,…).

In general, when opening any moving parts it is necessary to accompany them or slow their opening speed to avoid casing deformations.

Lockable fan switch aren’t safety accessories.

RECYCLING

Before disassembling all or part of a device, make sure that the power supply has been switched off.

Recover for recycling by means of appropriate tools the refrigerant present in the unit or in the area of intervention after isolation

of it.

Collect all used oil and deposit it in the appropriate recycling centers. Remember to drain the oil

separator. Eliminate all or part of the device in a suitable recycling center

3

GENERAL STARTUP INSTRUCTIONS

Vacuum

To avoid inclusion of air or moisture in the refrigerant circuit,

be sure to execute vacuum drying of the entire circuit before

charging refrigerant by using a vacuum pump. Vacuum the

circuit after securely carrying out airtight/pressure testing.

> When performing vacuum drying, make sure that valve

EC1 and EC3 are fully open; please refer to chapter

“Manual mode for the vacuum procedure”.

Circuits dehydration

This operation must be carried out with all valves open (including solenoid

valves) with connection to a vacuum pump:

– to the low pressure side

– to the high pressure side

The quality of drying should not be judged by the speed at which the level of

vacuum is reached but on the effective time it is held (24 hours at 0.7 mbar is a

good standard).

The total increase in pressure after that period should not be more than 2.6

mbar. The residual moisture in the system should be less than 10 ppm.

When the installation is under vacuum, an insulation check of the motor should

not be carried out. The compressors should be started before at least 1 bar of

fluid pressure is reintroduced.

This is to prevent motor winding damage.

Refrigerant and Oil Charging

– Calculate the refrigerant and oil charge prior to charging (refer to

appendix 1).

– Execute refrigerant charging immediately after evacuation.

– Charge refrigerant R744 (CO2 refrigerant).

– Do not mix with other refrigerant.

– Always use refrigerant grade R744, moisture content must be below 10

ppm.

4

GENERAL STARTUP INSTRUCTIONS

– Oil Charging must be done through the liquid service line during vacuum operation

Method of Charging

– Use Manifold Gauges and charging hoses for CO2 only.

– Use only refrigeration quality R744.

– When charging the refrigerant fix the flexible to the frame to avoid any risks

– Use a refrigerant scale to measure correct quantity charged into the system from

the R744 cylinders.

– Close the vacuum pump and break the vacuum with vapor R744 until 7-10Bar to

avoid dry ice formation. Dry ice may block hoses and pipes and charging will be

impossible. Charge vapor in both suction and liquid line.

– Control that the expansion valve at the evaporator(s) is active. Control both

electronic pressure transmitters and manifold Gauges for correct pressure

readings.

– As vapor is drawn from the R744 cylinders, pressure and temperature inside the

cylinder will decrease. Frost at the bottom exterior of the cylinder is an evidence

that liquid R744 has evaporated inside. The reduction in pressure also causes a

slower flow rate of vapor into the system. Once the flow from the cylinder has

slowed to a low level, the cold cylinder should be disconnected and allowed to

warm. After the cylinder has been warmed up, the residual R744 can be

removed. In the meantime, another warm tank can be connected to the system to

continue the charging process.

– Do not charge liquid on compressor suction line. Only Gas.

– Charge the machine only in vapour phase. The charge should be done on the

suction line. Never charge the machine with liquid. Premature wear risk

when restarting.

– Overfilling the system may cause malfunction and compressor damage.

– Sight Glass on the liquid line does not indicate correct R744 level if 100% full.

Control superheat management is inside min-max superheat settings. ¾ of filling

level in the sight glass is ok.

– Simulate transcritical conditions when charging in low ambient conditions by

blocking the air flow into the condenser/gas cooler in order to control correct

charging level.

– Run the unite and simulate thermostat cut off, defrosting cycle or manual pump

down in order to control correct operation and R744 charge.

– In case of leakage detection and repair: empty the system completely and

refill according to the first filling charge.

5

CAUTION FOR SAFETY

As professional, the installer must:

– Define the operating conditions of the refrigeration equipment

under his own responsibility regarding the design. This device

needs to be incorporated in machines conforming to the Machines

Directive. Its commissioning is only authorized if it has been

incorporated in machines which fully satisfy the legal regulations.

– Complete and adapt these recommendations, if necessary, by

adding other safeties and /or controls according to the

refrigeration equipment’s operating conditions.

– Have performed all the installing, commissioning and

maintenance operations by qualified professionals and

conforming with standards EN 378, EN 14276, EN 13136, EN

13313, EN 60204

and EN 60335, the EU directives, the safety rules generally

recognized, sound engineering practice, the local regulations; as

well as those which may be set up, taking into account the

evolution of the technology and the regulations.

– If the installation, the commissioning, the operating, the

maintenance are not realised according to this operating

instructions, the responsibility of Profroid cannot be involved.

– Completely inform the customer on the control, maintenance and

follow-up of the refrigeration equipment.

The units have been designed for 80/80/80/120bar pressure and are equipped with discharge safety

pressure switches set at 120 bar.

Any system that is designed with PS < 80 bar can represent a risk of overpressure when it stops.

When installing a QUIETCO2OL unit into a system using a lower design pressure, the installer must

protect this system against risk of overpressure (for example by installing a safety valve) and modify

the control settings accordingly.

6

CAUTION FOR SAFETY

– Do not use other than the designated refrigerant (for charging, adding

or recharging)

– Refrigerant gas leak may cause suffocation.

– Piping, equipment components and tools should be appropriate for

use with R744 (CO2 refrigerant).

– Use of unsuitable components or those designed for HFC refrigerant

may cause serious incidents such as equipment failure and rupture of

the refrigerant cycle.

– Securely place the cover on the electrical box and enclosure panel.

Incomplete attachment may lead to penetration of water and living

creatures, meaning potential current leak and fire/electrical shock.

– Do not change the set values of the safety device.

– Using the refrigeration unit with changed values may cause failure of

the safety stop function and lead to a burst or fire.

– When abnormal operation is detected, or before starting disassembly

or repair, turn off the main power switch.

– Specified components must be used for repair.

– Use of non-specified components may cause failure of the safety stop

function and lead to burst or fire.

– Incorrect moving may cause fall or dropping of the refrigeration unit,

and cause injury.

– Request a specialty operator for disposing the refrigeration unit.

– Make sure that access and emergency exit ways are not obstructed to

comply with the local regulations.

– Protect all electrical live parts from rain or snow if doing maintenance

with unit under voltage

7

COMPONENTS

Fan

Electrical compartment

Filter drier

Service valve

liquid line

Sight glass

Compressor

HP safety pressure switch

EC1 HP Control valve

EC3 Control valve

intermediate pressure

Gas cooler

HP service valve

Service valve

Suction line

LP/HP Pressure

transducer

Shut-off valves liquid line

- QUIETCO2OL air cooled :

MT Version

8

COMPONENTS

3-ways valve

Plate Heat Exchanger

By-pass valve (gas cooler)

Sight glass

Filter drier

Service valve suction line

Compressor

EC1 HP Control valve

HP service valve

LP/HP Pressure transducer

Service valve liquid line

EC3 Control valve

intermediate pressure

Regulating thermostatic

valve

Plate Heat Exchanger

(intercooler)

3-ways valve

Plate Heat Exchanger

By-pass valve (gas cooler)

Sight glass

Filter drier

Service valve liquid line

Service valve suction line

LT compressor

Parallel compressor

EC1 HP Control valve

Oil separator

HP service valve

Solenoid valve

Pressostat de sécurité

+

Transducteur de pression HP/BP

MT Version

LT Versions

- QUIETCO2OL water cooled :

8

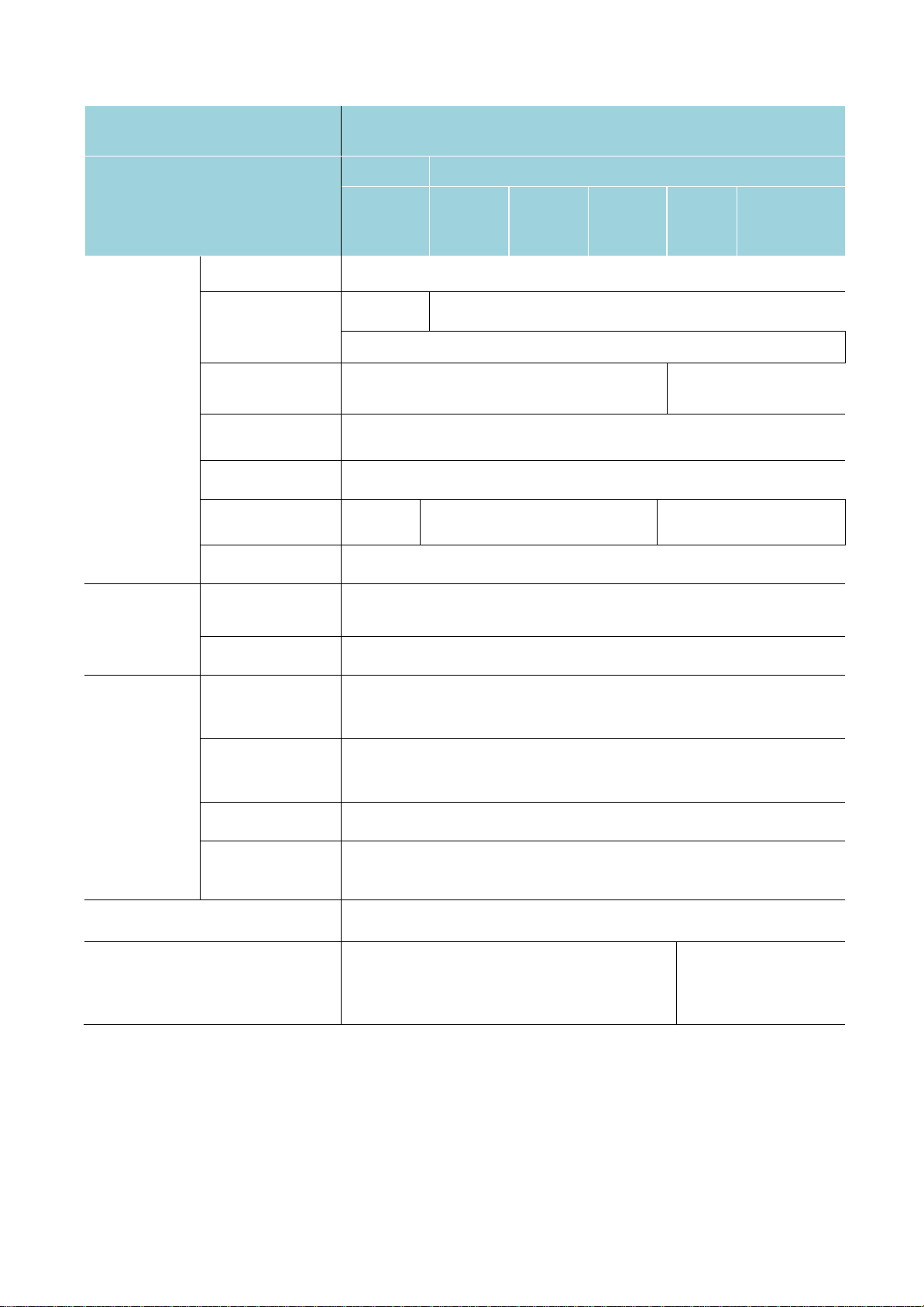

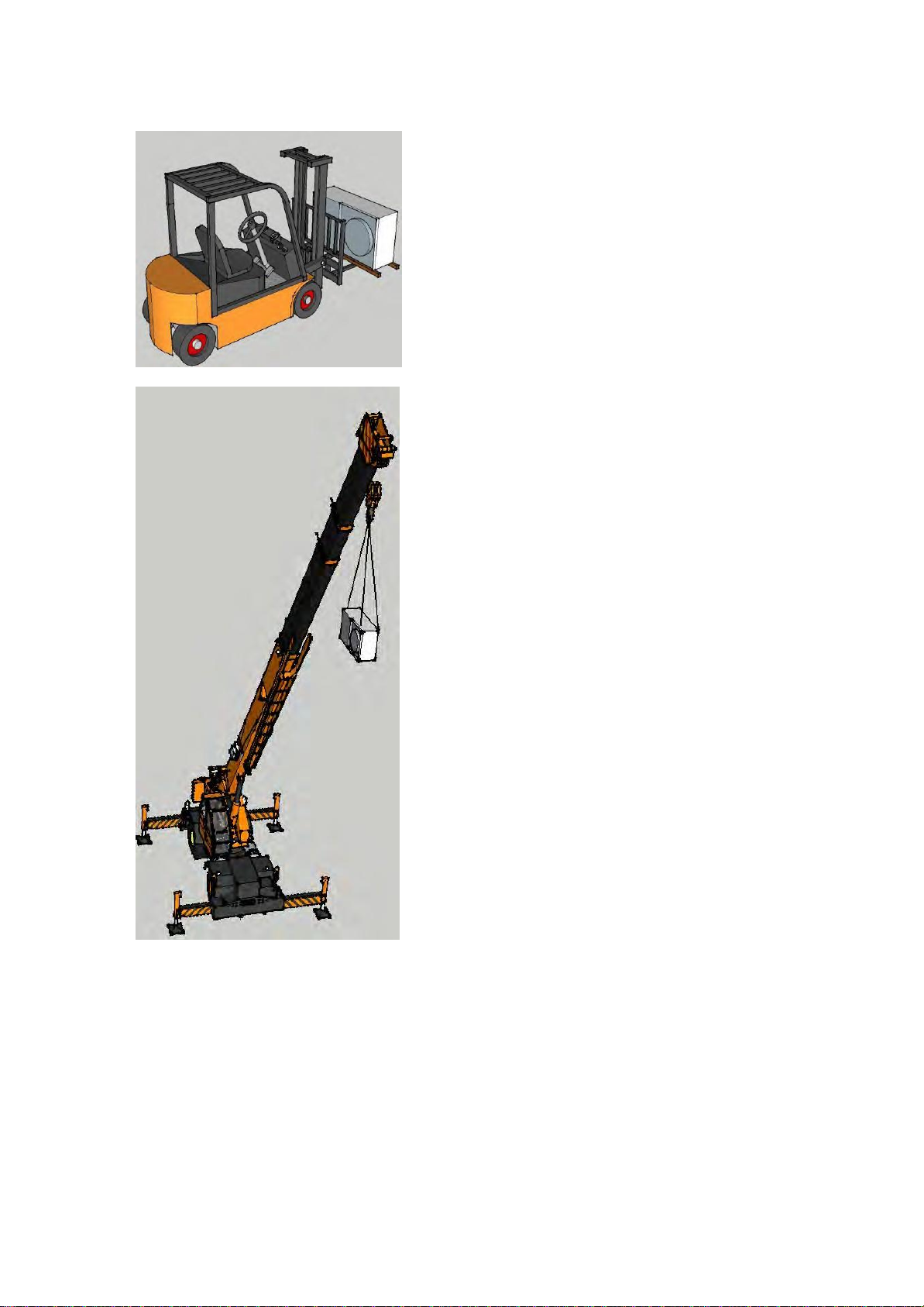

SCOPE OF APPLICATION

Produit

QUIETCO2OL serie

Compressor model

GMCC

Toshiba

QC

50MT

QC

30MT

QC

67MT

QC

100MT

QC

75LT

QC

167LT

Circuit du

fluide

frigorigène

Refrigerant

R744

Oil(Supplier)

Alternative oil

PAG

PZ100S

PAG VG100

PAG100 FUCHS

Evaporating

temperature

-18°C à +5°C

-32°C à -18°C

Suction

superheating

20K or below

Discharge gas

temperature

+120°C or below

Inverter

operation

45–100 tr/s

25–100 tr/s

45–100 tr/s (LT)

25-100 tr/s (MT)

Nominal

Revolution

70 rps

Ambient

Temperature

-15°C* / + 43°C (the ambient temperature can be -30°C if polar

kit heater is installed)

Relative

Humidity

10% – 90%

Allowed fluids

Water, Water-glycol (MPG / MEG – 60% maxi)

Water circuit

(water cooled

version)

Water inlet

temperature

-8°C to 35°C (nominal +7°C / +12°C)

Water mass

flow

Variable (depend on the capacity)

Pressure drop

(water side)

50 kPa or below

On/off cycle period

5 min or longer for on/off cycles

Liquid line temperature standard

receiver pressure settings

55 Bar (19°C)

35 Bar (0°C)

* Depending on the ambient temperature the use of the Polar kit should follow the following recommendations:

Ambient Temperature < -15°C Mandatory

Ambient Temperature < +5°C Recommended

10

DIMENSIONS

QUIETCO2OL MT serie

Air cooled

QUIETCO2OL LT

Serie Air cooled

QUIETCO2OL serie

Water cooled

QC

MT30

QC

MT50

QC

MT67

QC

MT100

QC LT75

QC LT167

QC MT

QC LT

Fig 1

Fig 3

Fig 2

Fig 4

Fig 5

Fig 6

Dimensions

Length

(mm)

1200

1200

1200

1200

1200

1200

Depth

(mm)

360

390

690

811

390

690

Height

(mm)

1028

1430

1028

1638

1028

1028

Weight (kg)

125

130

160

185

185

210

175

250

Fig 1 Fig 2

Fig 3

Fig 4

Fig 5 Fig 6

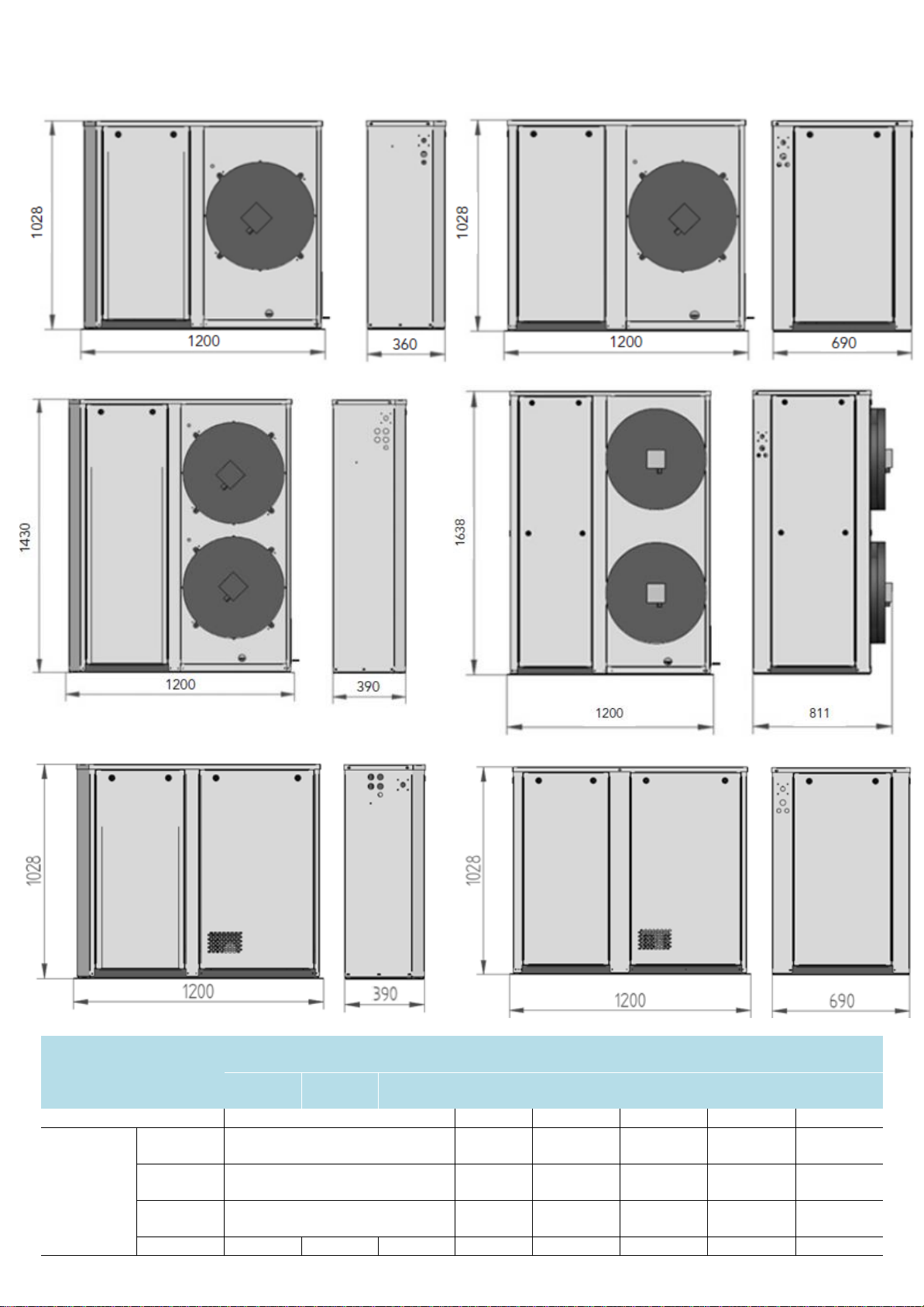

HANDLING OF THE UNIT

Carry-in Operation

- Make sure that the equipment or its

accessories have not been damaged

during shipping and no parts are

missing.

- Carry the refrigeration unit gently

by keeping the vertical position as

much as possible.

- Absolutely avoid a lay-down position

of the refrigeration unit. The loading

and unloading operations must be

performed with adequate handling

equipment (forklift, crane, etc.) using

possible lifting points provided for

this purpose.

- The qualified professional should

be certified and will wear

individual safety equipment

(protective gloves, glasses, safety

shoes, etc.) ; operators will never

circulate under the load during

lifting operations.

FORKLIFT

- When carrying the refrigeration unit

by a forklift, use a packaging wood

base or pallet for maintaining the

refrigeration unit in the vertical

position.

CRANE

– When carrying the refrigeration unit

by a crane, use a packaging wood

base or pallet for maintaining the

refrigeration unit in the vertical

position.

– Make sure that the unit is safely

secured to the lifting straps.

– During handling, the operator will

ensure a good balance to prevent the

equipment from swinging.

12

SELECTION OF INSTALLATION LOCATION

250 mm

500 mm

500 mm

1200 mm

The QUIETCO2OL Air

Cooled is intended for

outdoor installation

– The refrigeration unit must be installed

with an inclination angle 1°or below. If

devices are used in a seismic area, then

the installer must apply all necessary

rules.

– Enough free space all around the

refrigeration equipment should be

provided to facilitate maintenance

operations.

– The heat exchangers must be installed

in locations free of any external dust or

other pollutants from the neighborhood

which could obstruct or clog the coils.

– If devices are used in a corrosive area

(sea side, pollutant gas, etc.), make

sure that appropriate anticorrosion

protection has been provided.

13

SELECTION OF INSTALLATION LOCATION

2000 mm

Normal mounting

Mounting for transportation

NO air from a second unit shall be

directed towards the gas cooler of

another one!

In the case of face-to-face

installation, keep a minimum of

2000mm distance between the units.

Important: For transportation purpose the cable glands have been placed in reverse

position. Please place them in the right position before installing the unit

14

REFRIGERANT PIPING WORK

Product

Suction line

(R744)

Liquid line

(R744)

PS

MT30

9,52 mm (3/8")

9,52 mm (3/8")

80 bars

MT50

9,52 mm (3/8")

9,52 mm (3/8")

80 bars

MT67

9,52 mm (3/8")

9,52 mm (3/8")

80 bars

MT100

9,52 mm (3/8")

9,52 mm (3/8")

80 bars

LT75

9,52 mm (3/8")

9,52 mm (3/8")

80 bars

LT167

12,7 mm (1/2")

9,52 mm (3/8")

80 bars

Selection of Refrigerant Piping Size

The connection piping size for refrigeration unit is, in principle, as shown

below, but each installation should be determined by calculating pressure loss

of the piping and refrigerant flow speed and making sure no problem occurs in

the cooling capacity and oil return.

As refrigeration unit using CO2 refrigerant incurs pressure higher than when

using traditional refrigerants, it is necessary to choose adequate materials.

Make sure that piping’s are connected to the appropriate pressurized

equipment (EN378-2).

Prevent contamination of foreign objects

such as dust, metal powder, oxide scale, etc.

Since the compressor consists of high precision components, contaminants

generate scratches on the sliding surfaces, thereby increasing gas leak,

deteriorating performance, and causing excessive wear and seizure.

– Flow nitrogen gas during welding.

– Piping inside and outside must be clean.

15

REFRIGERANT PIPING WORK

Reverse-trap

P-trap

5m max height

difference

Suction line

Evaporator higher than the unit

Evaporator lower than the unit

Water OUTLET

Water INLET

Liquid line

Suction line

Dimensions :

MT30-50/LT75-167 = 1"G

MT67-100 = 1"1/4 G

Connection type : male SAE

Before any work is done on the refrigeration circuit, the holding charge must be removed.

The piping used must be of copper refrigeration quality in accordance with PED 2014/68/EC

and EN12735-1.

All piping must be correctly supported and fixed and should in no case be allowed to

restrict the operation of the gas cooler unit. For the connection of piping, protect sensitive

components located around the permanent assemblies to be made.

The products added for thermal and /or acoustic insulation must be neutral with respect to

support materials.

The protection devices, piping’s and accessories must be protected against unfavorable effects

from the environment.

The liquid line piping should be considered as an extension of the condensing unit receiver. A special

attention must be paid to the piping path and the thermal insulation. In case of exposure to heat source

(piping path exposed to the sun and not protected, piping path through non ventilated attic,…), The liquid

inside the piping can be vaporized and can cause an abnormal receiver pressure increase which could lead to

unit failure.

HYDRAULIC CONNECTIONS

Inside the unit the hydraulic circuit is in copper. The connections are protected with plastic plug.

16

COMMISSIONING

– Do not use other than the designated refrigerant (for charging, adding or recharging).

– Prior to electrically connect the facility, make sure that the AC power line voltage and

frequency ratings correspond to the indications on the identification plate and the power

voltage is within a tolerance of + 10 % with respect to the rated value.

– Specific protection is provided according to the neutral system.

– Any on-site wiring must comply with the legal standards in force in the country of installation

(including grounding).

– Before turning on a device, make sure that:

– the electric connections have been correctly made

– the clamping screws of the various terminals are correctly tightened

– Check the possible presence of locking devices of compressor antivibration elements, and

remove them, if they exist.

17

COMMISSIONING

The 3-ways valves on the water cooled version (WCO) are set from the factory. In case of replacement follow the

procedure below:

1- Complete set

Disassembly of the engine

Unscrew the engine with the dedicated tool

(control handle)

2- Check the valve position as indicated

3- Disengage the engine if necessary

18

COMMISSIONING

Thermostatic valve (water cooled version)

After replacing it make sure to set the thermostatic valve according to the factory settings. Graduation 2.5T which

correspond to a temperature of 45°C (CO2)

19

OPERATING

– Do not use other than the designated refrigerant (for charging, adding or recharging).

– Do not use the refrigeration equipment or components for any utilization other than

that for which it is designed.

– Comply with the special manufacturers recommendations contained in the

manufacturers operating instructions.

– It is strictly prohibited while the device is running to remove the guards and

panelling provided by the manufacturer to protect the user and ensure his safety.

– When operating, surface temperatures above 60°C and /or below 0°C may be

reached. During any servicing operation, the personnel should be extremely careful

while working on the device.

– Profroid is not informed to real use of partly completed machines; their integrations

and use must comply with Machines Directive and recommendations of these

operating instructions.

– Results of design calculations, checks, and test reports in relation with low voltage

directive are archived.

Water cooled QUIETCO2OL features

– The cooling fluid of the Water Cooled QUIETCO2OL must either be water or a

mixture of water and MEG or water and MPG (maximum MEG/MPG concentration:

60%).

– The inlet temperature of this fluid must be in a -8°C/+35°C range. The nominal

range is between +7°C and +12°C.

– The water circuit is equipped with a three way valve which allows regulating the by-

pass of the gascooler.

– A thermostatic control valve allows controlling the water flow which passes through

the intercooler on the LT versions. This valve operates by measuring the temperature

of the refrigerant on the CO2 outlet of the heat exchanger.

– When dimensioning the water circuit, the installer must take into account the

pressure losses of the water pipes and the exchanger(s).

– The hydraulic circuit thermal insulation is proposed in option

20

REFRIGERANT CIRCUIT DIAGRAM

QUIETCO

MT Version

OL AIR COOLED :

2

LT Version

21

REFRIGERANT CIRCUIT DIAGRAM

QUIETCO2OL WATER COOLED VERSION :

MT Version

LT Version

22

ELECTRICAL CONNECTIONS

QUIETCO2OL MT series

QUIETCO2OL LT series

QC

30MT

QC

50MT

QC

67MT

QC 100MT

QC 75LT

QC 167LT

Power supply

230 V / Single phase /

50 Hz

+ G

400 V / 3ph /50 Hz

N + G

230 V / Single

phase / 50 Hz

+ G

400 V / 3 ph /

50 Hz

N + G

Max. absorbed

current without

evaporators (Air

cooled)

13,3 A

20,7 A

27,2 A

18,5 A 18,4 A

31,4 A

Max. absorbed

current without

evaporators (Water

cooled)

12,5 A

19,9 A

26,4 A

16,5 A 17,6 A

31,4 A

Caution

Electrical compartment contains live terminals, please ensure supply is isolated before

removing the cover. Any person accessing this part of the unit should be suitably trained and

competent.

Before carrying out any maintenance work, disconnect the drive and the external control

circuits from the power supply by moving the main system switch to “off”. Once power has

been disconnected from the drive, wait at least 5 minutes before disconnecting the

electrical cables.

If consumers are powered from the condensing unit using the available circuit breakers, select

the main power supply by adding the actual consumer input current to the above values

General information

– The machine is designed in accordance with EN60204-1.

– Supplying cable must be connected on terminal of main switch.

– All cabling on site must conform to the legal standards in force in

the relevant countries and to EN60204-1.

23

ELECTRICAL CONNECTIONS

Recommendation

In order to ensure the optimal operation of the installation, we recommend the use of controller and expansion

valves from Carel connected to the unit through a Modbus connection. When using other brands of controller or

expansion valve, a special attention must be paid on the settings on site. Bad settings of these components can

lead to an instability of the system, short cycling the compressor and oil return issue, endangering the condensing

unit operation.

To avoid any overloading of the compressors, it is necessary to set a MOP (Maximum Operating Pressure) of

0°C (34,8 Bar) for MT application and a MOP of -20°C (19,7) Bar for LT applications.

24

USER INTERFACE

Types of display

There are three fundamental types of display shown to the user:

– Main display

– Menu display

– Screen for display/setting the parameters

Remark : All images below are for reference only; the user interface can be changed without prior notice.

Main display

USER PASSWORD: 1502

The software on board pRack Hecu automatically returns to the main mask 5

min after the last button was pressed. An example of the main mask is shown in

the figure, highlighting the fields and icons used.

1. Time and date

2. Main values

3. Unit status (unit off) compressors and fan status (unit on)

4. Active alarm signal and manual operation

5. Access further information mask (menu branch A.a) by

pressing Note the information shown on the main mask varies

according to the system configuration and type of control value

used (pressure, temperature)

25

USER INTERFACE

Label

Description

Unit

Min

Max

Setpoint

MT

LT

Cab03

Compressor pressure

barg

10.0

40.0

26.5

13.0

Cae24

Suction high pressure alarm threshold (absolute)

barg

60.0

Cae26

Suction low pressure alarm threshold (absolute)

barg

10.0

5.5

Caf17

Minimum on time compressor

s

0

999

120

Caf17

Minimum off time compressor

s

0

999

180

Caf17

Minimum time to start same compressor

s

0

999

310

Cag52

Max speed

rps

0.0

999.9

100.0

Cag52

Min speed

rps

0.0

99.9

25.0*

45.0*

Dab03

Gascooler setpoint

°C

12.0

38.0

22.0

Dae06

High gas cooler pressure alarm threshold

barg

0.0

6553.

120.0

Dae07

Low gas cooler pressure alarm threshold

barg

0.0

6553.

32.0

Phb28

Maximum HPV safety setpoint

barg

10.0

120.0

90.0

Phb28

Minimum HPV setpoint

barg

-1.0

150.0

40.0

Fhb22

Regulation – CO2 receiver pressure setpoint

barg

0.0

150.0

55.0 (MT)

35.0 (LT)

Screen for displaying/setting the parameters

An example of visual for displaying/setting the parameters is shown in the figure, also

highlighting the fields and icons used:

1. Parameters

2. Screen identifier

3. Menu

The display identifier details the menu branch and the mask: the first character indicates the

menu branch, while the two alphanumeric digits identify the order of the mask inside the

menu. For example mask Bab01 is the first mask in menu B.a.b

Paramètres de consigne (valeurs données à titre indicatif)

*Min. Speed MT50 : 45 rps. Min. Speed parallel compressor on LT versions : 25 rps

Risk of condensation if the CO2 pressure receiver is below 55 Bar (on MT unit)

26

USER INTERFACE

Navigation

To navigate inside the menu tree, use the following buttons.

27

DESCRIPTION OF THE DISPLAY

Level 1

Level 2

Level 3

Description

A. Unit Status

a. Main info

Information of the different operational states

b. Setpoint

Setpoint modification

c. On/Off

Regulation on/off

B. Inputs /

Outputs

a. Status

a. Digital Inputs

Configuration and status of the digital inputs

b. Analog Inputs

Configuration and status of the analog inputs

c. Digital Outputs

Configuration and status of the digital outputs

d. Analog Outputs

Configuration and status of the analog outputs

b. Manual

Management

a. Digital Outputs

Manual management of the digital outputs

b. Analog Outputs

Manual management of the analog outputs

c. BLDC Output

Manual management of the BLDC output

c. Test

a. Digital Outputs

Factory test of the digital outputs

b. Analog Outputs

Factory test of the analog outputs

C. Compressors

a. I/O status

Configuration and status of the compressor’s inputs/outputs

b. Regulation

Parameters of the compressors regulation

c. Working hours

Maintenance threshold and running time of the compressors

d. Energy Saving

Not used

e. Alarms

Configuration of the LP/HP security of the compressors

f. Configuration

Hardware configuration of the system

g. Advanced

Advanced configuration of the system

D. Condensers

a. I/O status

Configuration and status of the gascooler’s inputs/outputs

b. Regulation

Parameters of the gascooler’s regulation

c. Driver EVD

Not used

d. Energy saving

Energy saving, HP floating, winter time difference

e. Alarms

Configuration of the LP/HP security of the gascooler

f. Configuration

Hardware configuration of the system

g. Advanced

Advanced configuration of the system

E. Evaporator

a. I/O status

Configuration and status of the evaporator’s inputs/outputs

b. Configuration

Controller type connected (MPXPRO/Ultracella)

c. Regulation

Not used

d. Driver EVD

Not used

F. Other

functions

a. Oil

a. I/O status

Configuration and status of the inputs/outputs of the oil

management

b. Settings

Oil management configuration

b. Defrost

a. I/O status

Configuration and status of the defrost inputs/outputs

b. Regulation

Defrost configuration

c. Info

Remaining time before the next defrost cycle

c. Economizer

a. I/O status

Not used

b. Settings

Not used

d. Injection

a. I/O status

Configuration and status of the inputs/outputs of the liquid

injection

b. Settings

Liquid injection limit and differential

e. Heat reclaim

a. I/O status

Not used

b. Settings

Not used

Menu tree

28

DESCRIPTION OF THE DISPLAY

Level 1

Level 2

Level 3

Description

F. Other

functions

f. Generic

functions

a. Thermostats

Configuration up to 5 thermostats (digital outlets)

b. Modulations

Configuation up to 2 modulating thermostats (analog outlets)

c. Alarms

Digital inlets alarms configuration

d. Scheduler

Not used

e. I/O status

Configuration and status of the inputs/outputs of generic

functions

g. ChillBooster

a. I/O status

Not used

b. Settings

Not used

h. Transcritical

a. I/O status

Configuration and status of the inputs/outputs of the

transcritical mode

b. Settings

Transcritical mode settings

c. EVO Settings

EVO, HP valves and liquid receivers definition

G. Settings

a. Clock

a. Scheduler

Hourly/weekly scheduling

b. Adjustment

Internal clock setup (date and time)

b. Langage

Language setting of the regulator (English only at the

moment)

c. BMS

Adress and communication speed setup

d. Fieldbus

Communication port setup of the Fieldbus

e. Passwords

Access passwords and access level modification (password

modification is discouraged)

H. Safety

a. Data logging

Suction and discharge pressure data recording on the alarms

b. Prevent

Offload mode activation for high temperature or high

pressure levels

c. Alarm

configuration

Security setup

I. Info

Software version and BIOS

L. Setup

a. Preconfigurations

Not used

b. Wizard

Regulator setup erasure and back to pre-configuration menu

c. Quick

configurations

Not used

d. Defaults

Regulator setup erasure and factory reset

Menu tree

29

MANUAL MODE FOR VACUUM PROCEDURE

Remark: All images below are for reference only; the user interface can be changed without prior notice.

Main display

Password management

Insert password: user = 1502

Press enter to continue.

Main menu

Use arrows up/down to access the necessary

masks. Select “B. Inputs/Outputs” and press

enter.

Inputs/Outputs

Select “Manual management” and press Enter to continue

Use this function ONLY to manually open EC1

and EC3 valves during evacuation of the unit

I/O Manual

Select “Analog outputs” and press Enter to continue

Press enter to enable L1-Suction

Press enter to enable L1-Discharge

Use arrows and enter to set the timeout (15 min).

Once the specified time has been reached, both L1Suction and L1-Discharge manual management will

be disabled.

Once the evacuation procedure is done, either

wait for the timeout to end or go back to this

menu to disable manual management

Press enter to continue.

Manual management of HPV (EC1) valve

Use this function during evacuation of the unit

for both MT and LT models. Use arrows and

press enter to change to 100 %.

Manual management of RPRV (EC3) valve. Use

this function during evacuation of the unit, only

for MT models. Use arrows and press enter to

change to 100 %. WARNING: do not operate

EC3 on LT models, risk of compressor starting.

Press escape to go back to start menu.

30

CONTROL FUNCTIONS

Protective functions

– Compressors stops when:

– High pressure exceeds 108 bar.

– Restarts with manual reset.

– Low pressure is below 15 bar.

– Automatic reset.

– BLDC Power + Alarm. See display information. Compressor

auto reset.

– 5 times before alarm becomes manual.

– Compressor out of envelope alarm. Compressor auto reset.

– 5 times before alarm becomes manual.

– EC Gas cooler fan is protected by internal temperature sensor.

– Automatic reset.

– All alarms are visible after pressing the flashing red warning triangle.

Hold down to reset. Example here: suction pressure probe broken or

disconnected.

Alarm list

A complete list of controller alarms can be found on appendix 2.

31

MAINTENANCE

Warning

This unit restarts automatically.

Before any intervention on the unit, operator must make sure that

the main switch is safely secured.

Instructions for the service

The following instructions must be followed for all maintenance operations

– Doors should be opened only after the opening of the main switch and the

complete stop of the fans.

– The HP security pressure switch is accessible from the front door of the unit.

– The access to the fittings for the service is also possible from the front

Recommendations

If the unit is stopped for long periods of time, the fan motors should be run for at least

two hours each week.

Every month, carry out an operating check on:

– Cleanliness of coil

– Refrigerant level

Minimum every year:

– Clean the gas cooler

Instructions or recommendations appearing in the various technical advice notes and

manufacturer's service manuals should be followed precisely. Please contact our

Technical Department for any additional information.

Cleaning

Coils should preferably be cleaned with:

– Compressed air

– By brushing with non-metallic materials

Avoid all aggressive detergents which may cause eventual corrosion.

If you clean up the unit with water a special attention must be paid on the electrical parts and on the gas cooler

fins.

Replacement parts

The spare parts list is available on the QuietCO2OL product page on www.profroid.com under the rubric "Associated

documentation"

32

MAINTENANCE

Défaut

Cause probable

Action requise

1. Suction temperature too

high

Too much suction gas superheat

(above 20 K)

Examine and adjust the thermostatic

expansion valve in the evaportors

2. Suction Temperature too

low

Liquid in the suction line

Adjust the thermostatic expansion

valve

Sensor is loose or incorrectly

positioned

Check if the sensor is in contact with

the suction line and replace if

necessary

3. Suction pressure too low

Set point wrongly set

Check the set point

Too much oil in the evaporators

Clear out the oil from the

evaporator

Filter in the liquid line clogged

Examine and clean filters in liquid

line

Too much superheat of

suction gas

Adjust thermostatic expansion valves

Installation insufficiently

charged

Charge the installation with

refrigerant

4. Compressor cuts in and

out too often on LP safety

switch

See point 3

Evaporator iced over or frozen

water present in the distributor

Clean or defrost evaporator

5. Suction pressure too high

MOP

Set a MOP on the evaporator

controller (see P 24)

Restart after defrost

Wait for confirmation

Compression problem

Change compressor

6. Gas cooler pressure too

high

Insufficient flow of air into

the gas cooler

Clean the gas cooler. Check motor

fans

Installation overcharged

Drain liquid into reservoir

Air or non-condensable gas in the

HP circuit

Drain, use a vacuum pump and

recharge

7. Gas cooler pressure too

low

Fan cut-in incorrectly set

Adjust

8. Discharge temperature

too high

Too much superheat on suction

Adjust thermostatic expansion valves

Internal by-pass

Check compressors

9. Capacity too high

Problem with control system or

other automatic devices

Replace, repair or re-set

No correspondance between the

unit and the cooling demand

Check the design of the installation

10. Insufficient capacity

Problem with control system or

other automatic devices

Replace, repair or re-set

No correspondance between the

unit and the cooling demand

Check the design of the installation

33

MAINTENANCE

Défaut

Cause probable

Action requise

11. Abnormal noise in

the compressor

Bolts loose

Tighten bolts

Fluid in the suction

line

Check and re-set the expansion

valves. Check that the liquid solenoid

valves do not remain open when

machine stops

The Discharge temperature

sensor is not stable or badly

positionned

Check sensor position

Emulsion in oil crankcase

Incorrect lubrication

12. The compressor motor

does not start

Low pressure switch cuts-out

See paragraph 3

High pressure switch cuts-out

See paragraph 6

Fuses burn out

Check the cause and change fuses

Anti-short cycle time delay relay

is in operation

Wait

Internal security switched out

Check cause of increase in motor

winding temperatures

Main circuit-breaker open

Close circuit-breaker

13. Compressor works

continuously

Control system or other

automatic device fault

See paragraphs 12 et 13

Installation insufficiently

charged

Charge installation with refrigerant

Evaporators blocked or ice present

Clean and defrost evaporators

34

WARRANTY CONDITIONS OF THE REFRIGERATION UNIT

No charge warranty period is 1 year from the date of installation of the refrigeration

unit. However, the coverage of the no-charge warranty is the failed component by

supplying a replacement component.

Any failure caused by the following reason is considered chargeable even during the

warranty period.

– Failure caused by not conforming to the use condition specified in this

installation instructions

– Model selection or equipment installation design was incorrect.

– When our company has determined that the failure was generated by an error

in combining refrigeration unit models, incorrect control components such as

solenoid valve, or designing a refrigeration cycle without conforming to the

prohibited items, caution items, or instructed items indicated in the installation

instructions and on the product.

– When a problem exists in the installation work.

– When damage or breakage was generated by incorrect handling during

installation work.

– When the failure is judged as being caused by contaminants (debris, metal

powder, etc.) entering in the cycle during the installation or piping work.

– When the failure is judged as incorrect wiring work during installation and

piping work.

– When the personnel related to our company pointed out incorrect work but no

improvement was made.

– Incident caused by violating laws and regulations.

– When the system was operated by knowing large vibration or operation sound.

– When a problem was generated by a weak foundation or weak base frame.

– When operational failure was caused in the check valve or solenoid valve due

to incorrect brazing of piping connection.

– Incident was generated by locally modifying our company’s product

specification, or moving the equipment.

– Incident caused by contamination of debris in the electric components (hole

drilling for installing additional components).

– Incident generated by not complying with the specified installation location,

operating ambient temperature or operating voltage.

– Incident generated by locally modifying the company’s product specification,

performing accompanying work or moving the location, or Incident generated

without using the protective devices included in the product.

– Incident generated by incorrect operating environment or

maintenance/inspection.

35

WARRANTY CONDITIONS OF THE REFRIGERATION UNIT

– Incident caused by installing in an environment containing oil (including machine oil), water,

salt (coastal area, etc.).

– Incident caused by incorrect installation location (insufficient airflow, special environmental

condition such as water pressure, chemical substances, etc.).

– Incident caused by adjustment error of control equipment, etc.

– Incident caused by short cycle operation (each operation and stop for five min or shorter).

– Incorrect maintenance (not noticing gas leak).

– Error in repair work (wrong component, missing component, wrong attachment).

– Incident caused by overcharging or shortage of refrigerant, and insufficient refrigeration oil

(starting failure, motor cooling failure, lubricationfailure).

– Incident caused by defrosting failure.

– Incident caused by abnormal voltage.

– When air or water is judged being contaminated in the cycle.

– Incident caused by failure of power source caused by loose terminal of wiring.

– Failure of the motor or electric component caused by abnormal power voltage drop (220 V or

below) when starting after power failure and switching to emergency power source.

– Failure of the motor or electrical component caused by abnormally high voltage applied to the

source such as lightening, or excessive noise such as arc spark, etc.

– Incident caused by unspecified voltage condition, or Incident caused by applying distorted

voltage of a general-purpose inverter.

– Incident caused by using a ground fault interrupter not specified by our company.

– Incident caused by not conforming to the range of evaporating temperature, ambient

temperature, and operating voltage specified for this product.

– Incident caused by fire, earthquake, flood, lightening or other natural disaster.

– When the product is operated on a vehicle, vessel, or transport means (vibration, impact,

momentary power failure, oil surface securing, etc.).

– Incident caused by the installation or operation largely deviated from the common sense

general practice of installation, operation, adjustment, or maintenance is not warranted. In

addition, secondary damage caused by the Incident of the refrigeration machine, such as

damaged food items or loss of sales opportunity, is not compensated. Therefore, each user shall

have an alarm system for avoiding the secondary damage, or consult with our agent for

protective measures such as damage insurance.

Manufactured in France by PROFROID CARRIER S.C.S

178, rue du Fauge - ZI Les Paluds - B.P. 1152 - 13782 Aubagne Cedex - France

International : Tel. (33) 4 42 18 05 00 - Fax (33) 4 42 18 05 02

36

ECODESIGN

Rated PA max

MT Evap. Temp. =-10°C

LT Evap. Temp. =-32°C

Amb. Temp. Ta= +32°C

Q COP

SEPR

COP Validity

SEPR

VALIDITY

Annual

electric.

consum.

Rated COP

Seasonal energy

perfom. ratio

(kW)

(kWh/a)

MT30PK

2,71

6 974

1,76 YES

MT50PK

4,10

10 608

1,76 YES

MT67PK

6,04

15 016 2,47

YES

MT100PK

8,20

20 431 2,47

YES

LT75PK

2,94

11 599 1,89

YES

LT167PK

6,54

26 798 1,82

YES

Air cooled Version :

NB : Water cooled versions are not concerned by Ecodesign

37

APPENDIX 1 : REFRIGERANT AND OIL CHARGE

This appendix gives the instructions for charging the unit with R744 and additional oil.

The following assumptions have been made in order to calculate both charges:

- 90% filling factor for gascooler in partload.

- Min/Max level in receiver: 10% / 80%.

- Liquid line and suction line diameter following the specifications page 15.

- 20% filling factor for the evaporator.

Here’s an example of how to determine the required charges:

- In this case, an MT67 unit has to be installed with a 7dm3 evaporator and a 20m pipe. The

following diagrams gives the corresponding R744 and oil charge :

- Start on the crossing point of the unit (MT67) and the length of the pipe (20 meters),

- Draw a horizontal line from this point which crosses the evaporator volume line,

- Draw a vertical line from the crossing point of both lines and read both CO2 charge (at the

bottom) and additional oil charge (at the top).

- In this particular example, the R744 charge equals 7.8 kg and an additional oil charge of 60

mL is required.

-

Remark : Given the uncertainties on site concerning the real volume of the equipment, we recommend using

the complete volume of any opened oil container delivered in addition with the unit.

The installer also has to consider the zone of this crossing point for charging restrictions:

- Green zone : No restrictions

- Yellow zone : Warning : Do not pump down the liquid line into the unit, or the receiver could be

overfilled and cause compressor damage by liquid floodback. In case of service on the liquid line,

it is important to fully empty the circuit and make the complete refrigerant fill after servicing the

unit. The full load cannot be stored in the unit

- Red zone : Not allowed.

The diagrams for the different models are shown in the next pages.

These diagrams are indicative. It’s under the responsibility of the installer to ensure the proper operation of the unit

and to adjust the charge parameters.

38

APPENDIX 1 : REFRIGERANT AND OIL CHARGE AIR COOLED VERSION

39

APPENDIX 1 : REFRIGERANT AND OIL CHARGE AIR COOLED VERSION

40

APPENDIX 1 : REFRIGERANT AND OIL CHARGE WATER COOLED VERSION

Evaporator volume (based on filling factor of 20%)

Oil charge in kg

Pipe length

CO2 Charge in kg

CO2 Charge in kg

Evaporator volume (based on filling factor of 20%)

Oil charge in kg

Pipe length

41

APPENDIX 1 : REFRIGERANT AND OIL CHARGE WATER COOLED VERSION

Evaporator volume (based on filling factor of 20%)

Oil charge in kg

Evaporator volume (based on filling factor of 20%)

Oil charge in kg

CO2 Charge in kg

Pipe length

Pipe length

Charge CO2 en kg

Volume de l’évaporateur

Charge en huile en kg

Longueur de la tuyauterie

Charge CO2 en kg

CO2 Charge in kg

42

APPENDIX 2 : ALARM LIST

Code

Description écran

Reset

Delay

Action

ALU02

Regulation probe(s) missing

Automatic

Not present

Shutdown unit

ALA01

Discharge temperature probe broken or disconnected

Automatic

60 s

Related functions disabled

ALA02

Gascooler pressure probe broken or disconnected

Automatic

60 s

Related functions disabled

ALA03

External temperature probe broken or disconnected

Automatic

60 s

Related functions disabled

ALA04

General function probe A in board 1 broken or disconnected

Automatic

60 s

Related functions disabled

ALA05

General function probe B in board 1 broken or disconnected

Automatic

60 s

Related functions disabled

ALA06

General function probe C in board 1 broken or disconnected

Automatic

60 s

Related functions disabled

ALA07

General function probe D in board 1 broken or disconnected

Automatic

60 s

Related functions disabled

ALA08

General function probe E in board 1 broken or disconnected

Automatic

60 s

Related functions disabled

ALA24

Suction pressure probe broken or disconnected

Automatic

60 s

Related functions disabled

ALA25

Suction temperature probe broken or disconnected

Automatic

60 s

Related functions disabled

ALA43

Gascooler outlet temperature probe broken or disconected

Automatic

60 s

Related functions disabled

ALB01

Low common suction pressure by pressostat Num.autom.reset: / in min

Semiautomatic

Config.

Shutdown compressor

ALB02

High common condensing pressure by pressostat

Man./Autom

Config.

Shutdown compressor

ALB03

Low gascooler pressure alarm

Automatic

Config.

Fan forcing at 0%

ALB04

High gascooler pressure alarm

Automatic

Config.

Fan forcing at 100% (5 min.)

and shutdown compressor

ALB07

Fans common overload

Automatic

Config.

-

ALB15

High suction pressure alarm

Automatic

Config.

- ALB16

Low suction pressure alarm

Automatic

Config.

-

ALC01

Alarm 1 compressor 1

Man./Autom.

Config.

Shutdown compressor

ALC02

Alarm 2 compressor 1

Man./Autom.

Config.

Shutdown compressor

ALC05

Alarm comp. backup

Man./Autom.

Config.

Shutdown compressor

ALG01

Clock board error

Automatic

-

Related functions disabled

ALG02

Extended memory error

Automatic

-

Related functions disabled

ALG11

High thermostat alarms Function: 1-5

Man./Autom.

Config.

-

ALG15

Low thermostat alarms Function: 1-5

Man./Autom.

Config.

-

ALG19

High modulating alarms Function : 6-7

Man./Autom.

Config.

-

ALG23

Low modulating alarms Function : 6-7

Man./Autom.

Config.

- ALG27

Generic normal alarms Function : 8-9

Man./Autom.

Config.

-

ALG28

Generic serious alarms Function : 8-9

Man./Autom.

Config.

- ALP01

Power + nβ disconnected

Automatic

Not present

Related functions disabled

ALP03

Compressor start failure (tempt.: / max:)

Semiautomatic

Not present

5 tries, Shutdown compressor

ALP05

High discharge gas temperature

Automatic

Not present

Shutdown compressor

ALP06

Low pressure differential (insufficient lubrication)

Automatic

Config.

Shutdown compressor

ALT01

Compressors working hours

Manual

Not present

- ALT15

Low superheat alarm

Settable

Config.

Shutdown compressor

ALT17

Warning setpoint HPV gascooler press. too different from current

setpoint

Automatic

Config.

Related functions disabled

ALT18

HPV alarm high receiver pressure

Automatic

Not present

Related functions disabled

ALW01

Warning high pressure prevent

Automatic

Config.

Related functions disabled

ALW05

Warning Fans inverter

Automatic

Not present

- ALW10

Warning Low superheat

Automatic

Not present

- ALW15

Warning an error occured during auto-configur.

Automatic

Not present

-

ALW16

Warning Invalid activation of oil level inputs, check the connections

Automatic

-

-

ALW24

Power + n° Device Offline

Semiautomatic

2 s

Shutdown compressor

ALW25

Power+ n°

Semiautomatic

Not present

Shutdown compressor

ALW26

Compressor start failure (tempt. : / max.: )

Semiautomatic

Not present

-

43

APPENDIX 2 : ALARM LIST

ALW27

Envelope alarm Zone

Semiautomatic

Not present

Shutdown compressor

ALW28

High discharge gas temperature

Automatic

10 s

-

ALW29

Low pressure differential (insuff. lubrication)

Automatic

Config.

Shutdown compressor

ALW30

Inverter model not compatible (Power+ only allowed)

Automatic

Not present

-

ALW35

Low suction temperature

Automatic

Not present

Related functions disabled

ALW38

Low oil level fault

Manual

Config.

Shutdown compressor

ALW39

High oil level fault

Manual

Config.

Shutdown compressor

ALW40

-53-6679-92

Store number : !! OFFLINE !!

-

Not present

2

ALW41

-54-6780-93

Store number : Low temperature alarm [Generic Probe 1]

Display only (refer to +0300055IT MPXPRO manual)

ALW42

-55-6881-94

Store number : High temperature alarm [Generic Probe 1]

Display only (refer to +0300055IT MPXPRO manual)

ALW43

-56-6982-95

Store number : Low temperature alarm [Generic probe 2]

Display only (refer to +0300055IT MPXPRO manual)

ALW44

-57-7083-96

Store number : High temperature alarm [Generic Probe 2]

Display only (refer to +0300055IT MPXPRO manual)

ALW45

-58-7184-97

Store number : Defrost timeout

Display only (refer to +0300055IT MPXPRO manual)

ALW46

-59-7285-98

Store number : Low superheat alarm

Display only (refer to +0300055IT MPXPRO manual)

ALW47

-60-7386-99

Store number : Low suction temp. alarm

Display only (refer to +0300055IT MPXPRO manual)

ALW48

-61-74-

87-

ALZ00

Store number : MOP alarm

Display only (refer to +0300055IT MPXPRO manual)

ALW49

-62-75-

88-

ALZ01

Store number : LOP alarm

Display only (refer to +0300055IT MPXPRO manual)

ALW50

-63-76-

89-

ALZ02

Store number : Stepper driver communication error

Display only (refer to +0300055IT MPXPRO manual)

ALW51

-64-77-

90-

ALZ03

Store number : Stepper motor error

Display only (refer to +0300055IT MPXPRO manual)

ALW52

-65-78-

91-

ALZ04

Store number : Installation or config problems on EEV driver

Display only (refer to +0300055IT MPXPRO manual)

44

PROFROID CARRIER S.C.S

178, rue du Fauge - ZI Les Paluds - B.P. 1152 - 13782 Aubagne Cedex - France International : Tel. (33) 4 42 18 05 00

- Fax (33) 4 42 18 05 02

Loading...

Loading...