Page 1

s Rs!

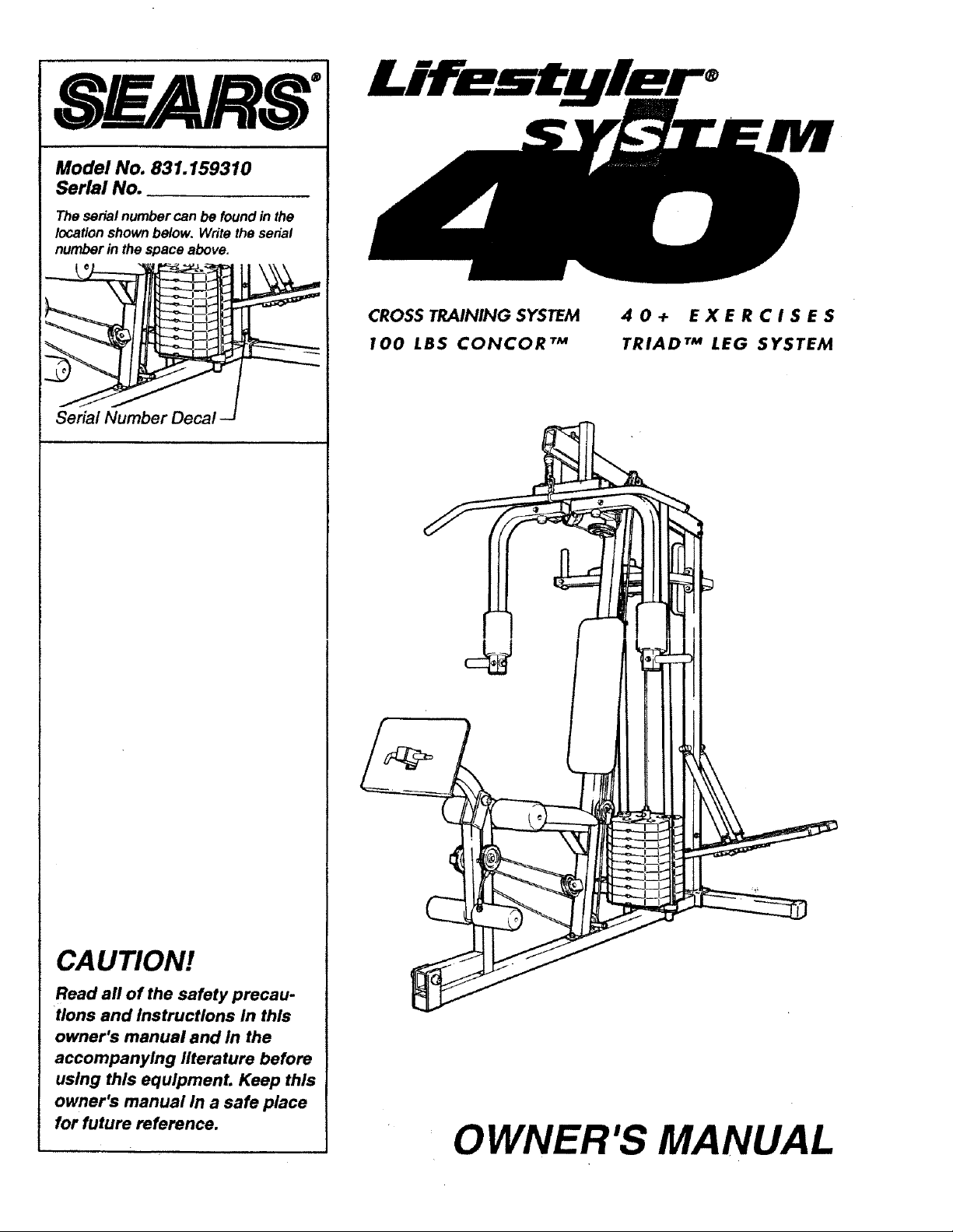

Model No. 831.159310

Serial No.

The serial number can be found in the

location shown below. Write the serial

number in the space above.

Serial Number Decal

CROSS TRAINING SYSTEM

100 LBS CONCOR TM

40+ EXERCISES

TRIAD TM LEG SYSTEM

CAUTION!

Read all of the safety precau-

tions and Instructions in this

owner's manual and in the

accompanying literature before

using this equipmenL Keep this

owner's manual in a safe place

for future reference.

OWNER'S MANUAL

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY PRECAUTIONS ................................................. 2

BEFORE YOU BEGIN ............................................................... 3

ASSEMBLY.. ..................................................................... 4

USING THE LIFESTYLER SYSTEM 40 ......................... ........................ 19

TROUBLE-SHOOTING AND MAINTENANCE ........................................... 21

PART LIST/EXPLODED DRAWING ................................................... 22

ORDERING REPLACEMENT PARTS .......................................... Back Cover

WARRANTY .............................................................. Back Cover

- IMPORTANT SAFETY PRECAUTIONS

WARNING: To reduce the risk of serious Injury, read the following Important safety precautions

before using the cross training system.

1. Read all Instructions In this owner's manual and in the accompanying literature before using

the cross training system. Use the cross training system only as described.

2. Inspect and properly tighten all parts of the cross training system each time you exercise.

Replace any worn parts Immediately.

3. Keep your hands away from moving parts other than the designated handles. Always wear

athletic shoes for foot protection.

4. Keep small children away from the cross training system at all times.

5. Never release the arms, leg lever, leg press plate, lat bar or nylon strap while weights are

raised. The weights will fall with great force.

6. Always lock the arms In the stationary position with the 4 1/2" "L" pins except when per-

forming the butterfly or reverse butterfly exercise.

,7. The reslstanne cylinders become very hot during use. Allow the resistance cylinders to cool

before touching them. Cover the floor beneath the stepper for protection. A small amount of

oll leakage Is normal for hydraulic cylinders.

8. When using the stepper, keep your feet on the pedals at all times. If you lift your feet off the

pedals, the pedals may separate from the resistance cylinders, resulting In Injury.

9. Make sure that the cables remain on the pulleys as you use the cross training system.

10. The leg press frame can strike the end of the seat frame with great force when In use. Keep

all parts of your body away from the end of the seat frame or serious Injury will occur.

11. If you feel pain or dizziness at any t!me while exercising, stop Immediately and begin cool-

Ing down. _'

WARNING: Before beglnnlng thls or any exerclse program, consult your physlclan. Thls Is

especlally Important for persons over the age of 35 or persons wlth pre-exlsUng health prob-

lems. Read all InstrucUons before uslng thls product. SEARS assumes no responslblllty for per-

sonal Injury or property damage sustalned by or through the use of thls product.

Page 3

BEFORE YOU BEGIN

Congratulations for selecting the SEARS LIFESTYLER e SYSTEM 40 cross training system. The innov-

ative LIFESTYLER SYSTEM 40 offers an impressive array of weight training and aerobic exercises to

let you enjoy true cross training workouts in the convenience of your home. Whether your goal is

improved cardiovascular fitness, a shapely, toned body or dramatic muscle size and strength, the

LIFESTYLER SYSTEM 40 wil! help you to achieve the specific results you want!

For your safety and benefit, read this owner's manual and the accompanying literature before

using the LIFESTYLER SYSTEM 40, If you have additional questions, please call our Customer

Service Department toll-free at 1-800-999-3756, Monday through Friday, 6 a.m. until 6 p.m. Mountain

Time (excluding holidays). To help us assist you, please note the product model number and serial

number before calling. The model number is 831.159310. The serial number can be found on a decal

attached to the LIFESTYLER SYSTEM 40 (see the front cover of this owner's manual for the location

of the decal).

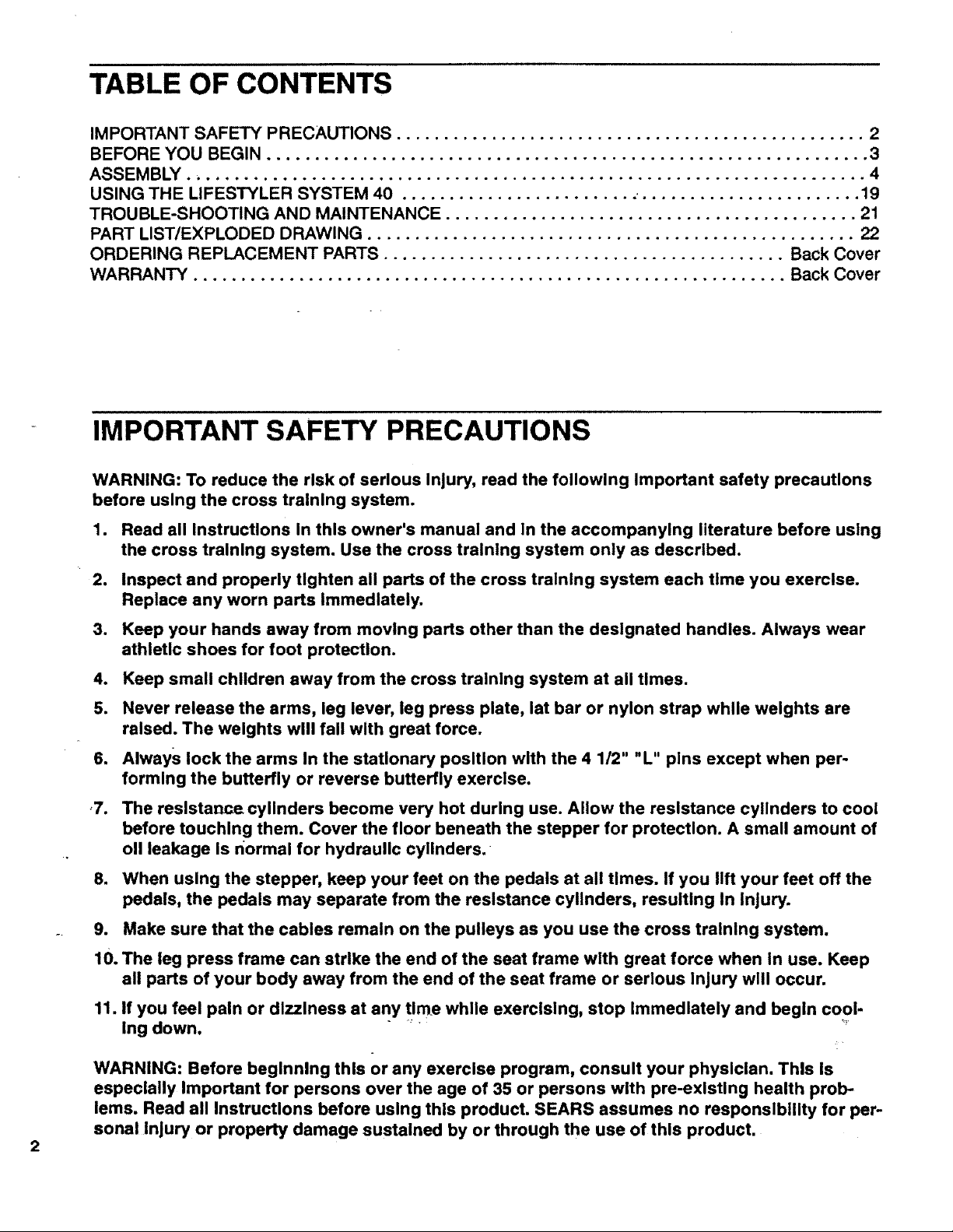

Before reading further, please examine the drawing below and familiarize yourself with the parts that

are labeled.

Lat Bar

VKR (Vertical Knee Raise)

Arms

Leg Press Plate

7" "L" Pin

High Cable

Backrest

Seat

Resistance Cylinders

Leg Lever

Low Cable

Stepper Pedals

3

Page 4

ASSEMBLY

Assembly requires two people and will take about 4 hours. The following tools (not Included) are

required: two 8" adjustable wrenches, a rubber mallet, a phillips screwdriver and a standard

screwdriver. Grease and a small bowl of soapy water are also required. As you assemble the

cross training system, read each step and examine each drawing carefully. Make sure that all parts

are oriented as shown In the drawings. Refer to the PART IDENTIFICATION (ID) CHART accompa-

nying this owner's manual for help identifying the small parts used in assembly. Due to the size and

weight of the cross training system, it should be assembled in the place where it will be used. Place all

parts of the cross training system in a cleared area and remove the packing materials; do not dispose

of the packing materials until the cross training system is completely assembled.

.

Press a 2" x 2" Outer Cap (36) onto each end

of the Stabilizer (73).

Insert two 5/16" x 2 3/4" Carriage Bolts (35)

and a 5/16" x 2 1/2" Carriage Bolt (22) up

through the Stabilizer (73).

Insert two 5/16" x 2 1/2" Carriage Bolts (22) up

through the Base (69). Slide the-end of the

Base over the two 5/16" x 2 3/4" Carriage

Bolts (35) in the Stabilizer (73).

36

35

i

36

2. Slide the Rear Upright (74) over the two

5/16" x 2 3/4" Carriage Bolts (35) in the

Stabilizer (73) and Base (69). Make sure that

the Rear Upright is turned so the pedal axles

are on the indicated side. Attach the Rear

Upright with two 5/16" Nylock Nuts (4). Do not

fully tighten the Nylock Nuts yet.

3. Slide the end of the Brace (56) that has an

oblong hole in it over the 5/16" x 2 1/2"

Carriage Bolt (22) in the Stabilizer (73). Attach

the Brace with a 5/16" Nylock Nut (4). Do not

fully tighten the Nylock Nut yet.

Attach the other end of the Brace (56) tothe

Rear Upright (74) with a 5/16" x 2 1/2 wBolt

(20), 5/16" Washer (10) and 5/16" Nylock Nut

(4).

22

//74

.._ Pedal axles

"_ must be on

_4 this side

2;

73

Tighten all Nylock Nuts used In assembly

steps 1-3.

Page 5

o

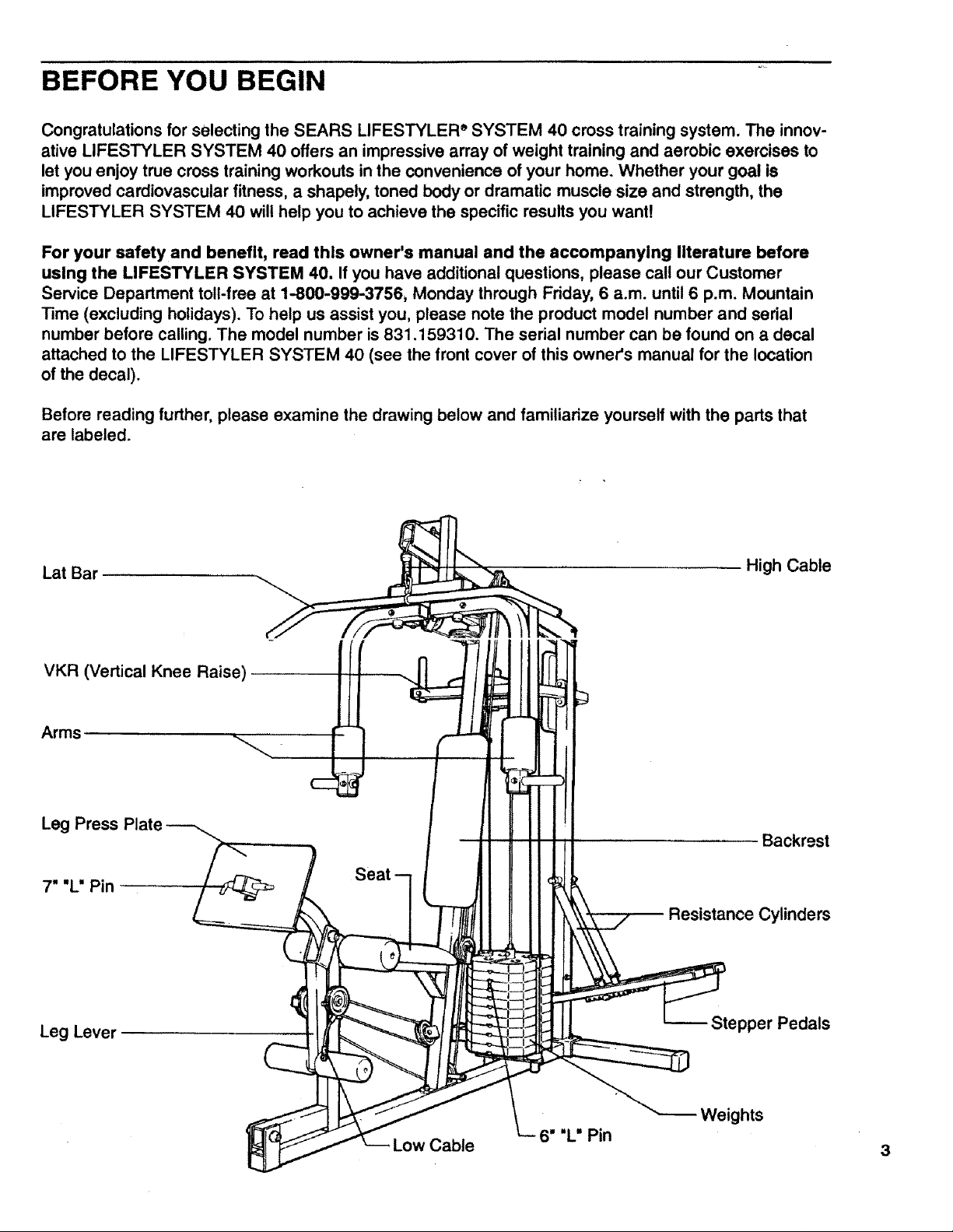

Slide the Front Upright (76) over the two

5/16" x 2 1/2" Carriage Bolts (22) in the Base

(69). Attach the Front Upright with two 5/16"

Nylock Nuts (4). Do not fully tighten the

Nylock Nuts until completeing step 24.

.

Place the Top Brace (86) on top of the Front

and Rear Uprights (76, 74). Attach the brack-

et on the Top Brace to the Front Updght with

a 5/16" x 2 3/4" Bolt (3), 5/16" Washer (10)

and 5/16" Nylock Nut (4). Do not fully tight-

en the Nylock Nuts until completeing step

24.

Attach the Top Brace (86) to the Rear Upright

(74) with two 5/16" x 2 3/4" Bolts (3) and

5/16" Nylock Nuts (4). Do not fully tighten

the Nylock Nuts until ¢ompletelng step 24.

4

5

,

Press a 1 3/4" x I 3/4" Inner Cap (28) into

3/4" Round Inner Cap (30) into each side of

the Arm Support.

Apply grease to the rod of the Arm Support (85).

Tum an Arm Support Bushing (92) so the

rounded groove is on top. Place the Arm

Support Bushing on top of the plate on the

Top Brace (86). Rest the rod of the Arm

Support (85) in the rounded groove in the

Arm Support Bushing.

.

Place the other Arm Support Bushing (92) on

top of the rod of the Arm Support (85). Place

the Bushing Bracket (91) over the Arm

Support Bushings, Attach the Bushing

Bracket to the plate on the Top Brace (86)

with four 1/4" x 3/4" Screws (24) and 1/4"

Nylock Nuts (23).

6

86

7

24

23

Page 6

Press two 1 3/4" x 1 3/4" Inner Caps (28) into

8. 8

each of the Arms (51).

Apply grease to the axles On the Arm Support

(85). Slide an Arm (51) onto the right axle.

Hold two 1 5/16" Retainer Rings (38) and a

1" Plastic Cap (37) against the lower end of

the axle. Make sure that the teeth on the

Retainer Rings bend downward. Tap the Re-

tainer Rings and Plastic Cap onto the axle.

Attach the other Arm (51) in the same manner.

Wet the lower ends of the Arms (51) and the

insides of the two 6 1/2" Foam Pads (84) with

soapy water. Slide the Foam Pads onto the

Arms until the Foam Pads are 3" from the

lower ends.

28

g.

Insert the end of a Handle (52) that has a

,_u_ th_ou it ;-'- tl-Ju -;-'-" ^'- _).

II tLU _._ I I U t;;;

II_IIL t"_1 III _=;.,_

5/16" Washer (10) and 5/16" x 3/8" Metal

Spacer (13) onto a 5/16" x 2 1/4" Bolt (14).

Insert the Bolt through the Arm and the

Handle. Slide another 5/16" Washer (10) onto

the Bolt and tighten a 5/16" Nylock Nut (4)

onto the Bolt.

Press a 1" Round Inner Cap (11) into the

Handle (52).- ....

Assemble a Handle (52) to the left Arm (51)

in the same manner.

Wet the Handles (52) with soapy water and

slide a Handle Grip (53) onto each Handle.

51

53

14

Page 7

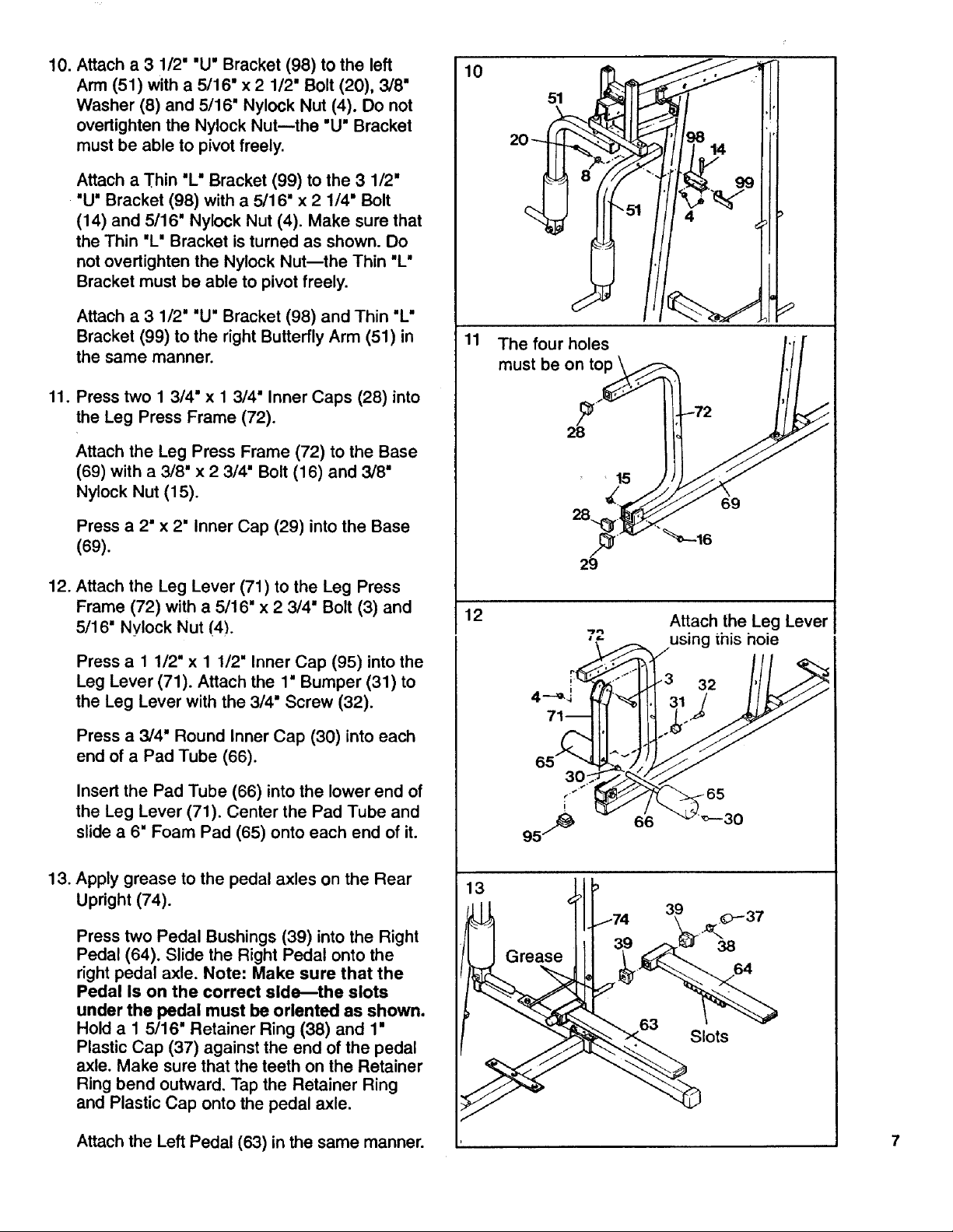

10. Attach a 3 1/2" "U" Bracket (98) to the left

Arm (51) with a 5/16" x 2 1/2" Bolt (20), 3/8"

Washer (8) and 5/16" Nylock Nut (4). Do not

overtighten the Nylock Nut--the "U" Bracket

must be able to pivot freely.

Attach a Thin "L" Bracket (99) to the 3 1/2"

"U" Bracket (98) with a 5/16" x 2 1/4" Bolt

(14) and 5/16" Nylock Nut (4). Make sure that

the Thin "L" Bracket is turned as shown. Do

not overtighten the Nylock Nut--the Thin "L"

Bracket must be able to pivot freely.

Attach a 3 1/2" "U" Bracket (98) and Thin "L"

Bracket (99) to the right Butterfly Arm (51) in

the same manner.

10

11

The four holes I'/

11. Press two 1 3/4" x 1 3/4" Inner Caps (28) into

the Leg Press Frame (72).

Attach the Leg Press Frame (72) to the Base

(69) with a 3/8" x 2 3/4" Bolt (16) and 3/8"

Nylock Nut (15).

Press a 2" x 2" Inner Cap (29) into the Base

(69).

12. Attach the Leg Lever (71) to the Leg Press

Frame (72) with a 5/16" x 2 3/4" Bolt (3) and

5/16" Nylock Nut (4).

Press a 1 1/2" x 1 1/2" Inner Cap (95) into the

Leg Lever (71). Attach the 1" Bumper (31) to

the Leg Lever with the 3/4" Screw (32).

Press a 3/4" Round Inner Cap (30) into each

end of a Pad Tube (66).

Insert the Pad Tube (66) into the lower end of

the Leg Lever (71). Center the Pad Tube and

slide a 6" Foam Pad (65) onto each end of it.

must be on t;_ ///

, 15

29_ 16

12

o 't- _ 7us=ng in=s hole

4--__ _ 31 / II L SJ

95 _ v 6"6 "_ _--30

Attach the Leg Lever

13. Apply grease to the pedal axles on the Rear

Upright (74).

Press two Pedal Bushings (39) into the Right

Pedal (64). Slide the Right Pedal onto the

right pedal axle. Note: Make sure that the

Pedal Is on the correct side--the slots

under the pedal must be oriented as shown.

Hold a 1 5/16" Retainer Ring (38) and 1"

Plastic Cap (37) against the end of the pedal

axle. Make sure that the teeth on the Retainer

Ring bend outward. Tap the Retainer Ring

and Plastic Cap onto the pedal axle.

Attach the Left Pedal (63) in the same manner.

13 J _

lots

Page 8

14,Place a Foot Pad (62) on the end of the Right

Pedal (64). Attach the Foot Pad with a 1/2"

Pan Screw (45).

Attach the other Foot Pad (62) to the Left

Pedal (63) in the same manner.

15.

Apply grease to the cylinder axles on the Rear

Upright (74).

Slide a Cylinder Spacer (48) and a Resistance

Cylinder (60) onto each cylinder axle. Hold a

1• Retainer Ring (47) and 5/8" Plastic Cap

(46) against the end of the left cylinder axle,

Make sure that the teeth on the Retainer Ring

bend outward, Tap the Retainer Ring and

Plastic Cap onto the cylinder axle. Attach a 1"

Retainer Ring (47) and 5/8" Plastic Cap (46)

to the right cylinder axle in the same manner,

45

63

,,_-- 46

15 _/Grea_e

16. Raise the Right Pedal (64) and rest it on the

hr:_ek_t _t fh_ Inw_r _nd nf th_ rinhf

Resistance Cylinder (60). Make sure that the

bracket is in one of the slots under the Pedal.

Rest the Left Pedal (63) on the bracket at the

lower end of the left Resistance Cylinder (60).

Make sure that the brackets are in the same

slots under both Pedals.

17, Attach the two VKR Arms (57) to the Rear

Upright (74) with two 5/16" x 2 3/4" Bolts (3)

and 5/16" Nylock Nuts (4),

Press a 1 1/2" x 1 1/2" Inner Cap (95) into

each VKR Arm (57),

16 I/ll IlL

i

17

95

95

60

64

63

57

4

57

Page 9

18. Attach a VKR Armrest (58) to each VKR Arm

(57) with two 1/4" x 2' Screws (9) and 1/4"

Washers (1).

Attach the VKR Backrest (59) to the Rear

Upright (74) with two 1/4" x 2 1/2" Screws (2)

and 1/4" Washers (1).

18 ._

19. Press a 1" Round Inner Cap (11) into each

end of a Handle (52).

Insert the end of the Handle (52) that has a

hole through it into the left VKR Arm (57).

Slide a 5/16" Washer (10) onto a 5/16" x 2"

Bolt (12). Insert the Bolt through the VKR

Arm and the Handle. Slide another 5/16"

Washer (10) onto the Bolt and tighten a 5/16"

Nylock Nut (4) onto the Bolt.

Assemble a Handle (52) to the right VKR Arm

(57) in the same manner.

20. Press a 1 1/2" x 1 1/2" Inner Cap (95) into the

RARt F'rAm_. (R7) Attsoh the ReS! P!Ste (_RS)

to the Seat Frame with the 1/4" x 2" Carriage

Bolt (25), a 1/4" Washer (1) and a 1/4" Nylock

Nut (23).

Attach the Seat (77) to the Seat Plate (68)

with two 1/4" x 3/4" Screws (24).

Attach the Seat (77) to the Seat Frame (67)

with a 1/4" x 2 _Screw (9) and 1/4" Washer (1).

19

_11 I"L--52

2O

77

' 1

67 _23

21. Attach the Seat Frame (67) to the Front

Upright (76) with two 5/16" x 2 3/4" Bolts (3),

5/16" Washers (10) and 5/16" Nylock Nuts

(4).

Press a 3/4" Round Inner Cap (30) into each

end of a Pad Tube (66).

Insert the Pad Tube (66) into the Seat Frame

(67). Center the Pad Tube and slide a 6" Foam

Pad (65) onto each end of it.

21

67

4<

65

9

Page 10

22. Attach the Backrest (78) to the Front Upright

(76) with two 1/4" x 2 1/2" Screws (2) and

1/4" Washers (1).

23.

Insert a 3/8" x 2 3/4" Bolt (16) into one side of

the Top Brace (86). Slide a 3/8" x 3/8" Metal

Spacer (6) onto the Bolt. Lay the ball-end of

the Short Cable (94) over a 3 1/2"Pulley (55).

Slide the Pulley and another 3/8" x 3/8" Metal

Spacer (6) onto the Bolt. Insert the Bolt

through the other side of the Top Brace and

tighten a 3/8" Nylock Nut (15) onto the Bolt.

Attach the 2" Metal Spacer (49) inside the

Top Brace (86) with a 5/16" x 2 3/4" Bolt (3)

and 5/16" Nylock Nut (4). Make sure that the

Short Cable (94) is under the 2" Metal Spacer.

22

23

15 86

6 "_" 3

94

24.

Insert the other end of the Short Cable (94)

(86) and the Front Upright (76). Lay the Cable

over a 3 1/2" Pulley (55). Hold the Pulley in

the upper end of the Front Upright.

Slide a 3/8" Washer (8) and 3/8" x 3/8" Metal

Spacer (6) onto a 3/8" x 3 1/2" Bolt (5). Insert

the Bolt through the Top Brace (86), Front

Upright (76) and 3 1/2" Pulley (55). Slide

another 3/8_x 3/8" Metal Spacer (6) and 3/8"

Washer (8) onto the Bolt and tighten a 3/8"

Jam Nut (7) onto the Bolt.

Tighten all Nylock Nuts used in assembly

steps 4-5.

25. Attach two.3 1/2" Pulleys (55) to the two "1'

Plates (75) with 3/8" x 1 3/4" Bolts (26) and

3/8" Nylock Nuts (15). Make sure that the

Pulleys are attached to the holes in the ends

of the "1" Plates.

24 r,,

0 ,J,J \

7_ ........... ,,

, \

25

55

15

75

55

r

,26

75

10

Page 11

26. Route the end of the Short Cable (94) around

the indicated 3 1/2" Pulley (55) in the "t"

Plates (75).

Insert a 3/8" x 2 3/4" Bolt (16) into one side of

the Top Brace (86). Slide a 3/8" x 3/8" Metal

Spacer (6) onto the Bolt. Lay the Short Cable

(94) over a 3 1/2" Pulley (55). Slide the Pulley

and another 3/8" x 3/8" Metal Spacer (6) onto

the Bolt. Insert the Bolt through the other side

of the Top Brace and tighten a 3/8" Nylock Nut

(15) onto the Bolt.

26

86

15

27. Press the Domed Inner Cap (34) into the

lower end of the Weight Selector (82).

Slide a Weight (79) onto the upper end of the

Weight Selector (82). Make sure that the

Weight is turned so the pin groove is down-

ward.

Insert the end of the Short Cable (94) into the

upper end of the Weight Selector (82) and

attach it with the 5/16" x 1 1/2" Bolt (33) and

a 5/16" Nylock Nut (4).

28. Wrap the ball-end of the Long Cable (93)

under a 3 1/2" Pulley (55). Attach the Pulley

to the Leg Press Frame (72) with a 3/8" x

3 1/2" Bolt (5), 3/8" Washer (8) and 3/8"

Nylock Nut (15). Make sure that the Cable is

between the Pulley and the pin on the Leg

Press Frame.

27

/

Pin Groove

28

11

Page 12

Attach a 3" "U" Bracket (97) to the Front

29. 29

Upright (76) with a 5/16" x 4" Bolt (27), 5/16"

Washer (10) and 5/16" Nylock Nut (4). The

Nylock Nut should be threaded onto the

Bolt four complete turns. The cabling will

be too short If the Nylock Nut Is overtlght-

ened.

Wrap the Long Cable (93) around a 4 1/2"

Pulley (54) as shown. Attach the Pulley to the

3" "U" Bracket (97) with a 3/8" x 1 3/4" Bolt

(26) and 3/8" Nylock Nut (15).

30. Slide a Plastic Cable Guide (18) and a 3 1/2"

Pulley (55) onto a 3/8" x 3 1/2" Bolt (5). Insert

the Bolt into the Leg Lever (71). Slide a 3/8"

Washer (8) onto the Bolt and tighten a 3/8"

Nylock Nut (15) onto the Bolt.

Pull back the Plastic Cable Guide (18) and

wrap the Long Cable (93) around the 3 1/3"

Pulley (55). Turn the Plastic Cable Guide so

it holds the Cable on the Pulley.

31.

Slide a Plastic Cable Guide (18) and a 3 1/2"

Pulley (55) onto a 3/8" x 3 3/4" Bolt (21).

Insert the Bolt into the tube on the Base (69)

and tighten a 3/8" Nylock Nut (15) onto the

Bolt.

Pull back the Plastic Cable Guide (18) and

wrap the Long Cable (93) under the 3 1/3"

Pulley (55). Turn the Plastic Cable Guide so

it holds the Cable on the Pulley.

93

26

3O

31

18

55

21 69

15

12

32.

Route the Long Cable (93) over the 3 1/2"

Pulley (55) at the lower end of the "1" Plates

(75).

Slide a Plastic Cable Guide (18) and a 3 1/2"

Pulley (55) onto a 3/8" x 3 3/4" Bolt (21).

Insert the Bolt into the tube on the Front

Upright (76) and tighten a 3/8" Nylock Nut

(15) onto the Bolt.

Pull back the Plastic Cable Guide (18) and

wrap the Long Cable (93) under the 3 1/3"

Pulley (55). Turn the Plastic Cable Guide so

it holds the Cable on the Pulley.

Page 13

33. Attach a Thick "L" Bracket (100) to the bracket

on the Top Brace (86) with a 5/16" x 3 1/4"

Bolt (19) and 5/16' Nylock Nut (4). Make sure

that the Thick "L" Bracket is turned as shown.

Slide a Plastic Cable Guide (18) and a 3 1/2"

Pulley (55) onto a 3/8" x I 3/4" Bolt (26). Insert

the Bolt into the Thick "L" Bracket (100) and

tighten a 3/8" Nylock Nut (15) onto the Bolt.

Pull back the Plastic Cable Guide (18) and

lay the Long Cable (93) over the 3 1/2" Pulley

(55). Turn the Plastic Cable Guide so it holds

the Cable on the Pulley.

34. Slide a Plastic Cable Guide (18) and a 3 1/2"

Pulley (55) onto a 3/8" x 2" Bolt (44). Insert the

Bolt into the Thin "L" Bracket (99) on the left

Arm (51) and tighten a 3/8" Nylock Nut (15)

onto the Bolt.

Pull back the Plastic Cable Guide (18) and

wrap the Long Cable (93) around the 3 1/2"

Pulley (55). Turn the Plastic Cable Guide so

it holds the Cable on the Pulley.

33

55

34

93

35. Attach a 3" "U" Bracket (97) to the Front

Upright (76) with a 5/16' x 4" Bolt (27), 5/16"

Washer (10) and 5/16' Nylock Nut (4). The

Nylock Nut should be threaded onto the

Bolt four complete turns. The cabling will

be too short If the Nylock Nut Is overtlght-

ened.

Wrap the Long Cable (93) around a 4 1/2"

Pulley (54). Attach the Pulley to the 3" "U"

Bracket (97) with a 3/8" x 1 3/4" Bolt (26) and

3/8" Nylock Nut (15).

36. Slide a Plastic Cable Guide (18) and a 3 1/2"

Pulley (55) onto a 3/8" x 2" Bolt (44). Insert the

Bolt into the Thin "L" Bracket (99) on the right

Arm (51) and tighten a 3/8" Nylock Nut (15)

onto the Bolt. Note: Make sure that the

3 1/2" Pulley is attached on the side of the

Thin "L" Bracket as shown.

Pull back the Plastic Cable Guide (18) and

wrap the Long Cable (93) around the 3 1/2"

Pulley (55). Turn the Plastic Cable Guide so

it holds the Cable on the Pulley,

35

36

54 97.

93

15 99 _93

\

\

\

\

\

\

\

13

Page 14

37. Slide the end of the Long Cable (93) onto the

end of the 3/8" x 3 1/2" Bolt (5) in the Top

Brace (86). Slide a 3/8" Washer (8) onto the

Bolt and tighten the 3/8" Jam Nut (7) onto the

Bolt. Note'- The 3/8" x 3 1/2" Bolt (5) Is the

Bolt that was used In assembly step 24.

The Bolt will already have one Nut thread-

ed onto It. The step described above will

attach the Long Cable to the remaining

threads so there will be two Nuts on the

Bolt.

37

7

86

Attach the Cable to

the same Bolt that

was used in

24

38. Slide the Leg Press Plate (70) onto the end of

the Leg Press Frame (72). Insert the 7" "L"

Pin (40) through the Leg Press Plate and one

of the four holes in the Leg Press Frame.

39. Find the lower ends of the two Weight Guides

(83) (there are holes near the upper ends of

the Weight Guides). Slide a Weight Bumper

(50) onto the lower end of each Weight

Guide. Insert the Weight Guides into the

bracket on the Base (69).

Fit theWeight Guides (83) into the recesses

in the sides of the Weight (79) on the Weight

Selector (82).

38

72

40

70

39

14

40. Insert a 5/16" x 4 1/4" Bolt (41) through the

upper end of one of the Weight Guides (83).

Slide a 2 5/8" Metal Spacer (42) onto the Bolt

and insert the Bolt into the Top Brace (86).

Tighten a ,_/16" Nylock Nut (4) onto the Bolt.

Attach the other Weight Guide (83) to the Top

Brace (86) in the same manner.

4O

41

42 86

41

Page 15

41. Raise the Weight Selector (82). Place the

remaining nine Weights (79) on the Weight

Guides (83) by tipping the Weights as shown.

Make sure that the Weights are turned so all

of the pin grooves are under the Weights and

are on the same side. Lower the Weight

Selector into the Weights.

41

Pin Grooves

42. Open a Weight Sleeve (80) and close it

around one of the Weight Guides (83). Close

the other Weight Sleeve (80) around the

other Weight Guide. Turn the Weight Sleeves

so the hinged sides are toward each other.

43. Tip the top Weight (79) as shown. Fit the low

_Ju_ Ui L;_ VV_;*yllL ZllLU _ VV_,lyllL ,._l_t_vt_ _ou),

Fit the high side of the Weight into the other

Weight Sleeve. Press the Weight and the

Weight Sleeves down until they are resting

on top of the other Weights.

42

43

8O

II \\\/I

44. Hold the open end of a Weight Sleeve Clip

(81) against one of the Weight Sleeves (80)

as shown. Firmly press the Weight Sleeve

Clip until it snaps around the Weight Sleeve.

Press the other Weight Sleeve Clip (81) onto

the other Weight Sleeve (80) in the same

manner.

44

15

Page 16

45. Press a 1" Round Inner Cap (11)into each

end of the I.at Bar (87).

46.

Remove the "HIGH PULLEY" decal from the

Decal Sheet (not shown). Apply the decal to

the side of the Top Brace (86).

Remove the "DUAL FUNCTION PRESS

ARM" decal from the Decal Sheet (not

shown). Center the decal on the front of the

Arm Support (85).

Remove the "ACTUAL RESISTANCE FOR

BENCH PRESS..." decal from the Decal

Sheet (not shown). Apply the decal to the left

Arm (51).

45

46

"HIGH PULLEY"

"DUAL

PRESS ARM"

"ACTU

RESISTANCE

FOR BENCH

PRESS..."

11

86

85

47,

Remove the "VERTICAL KNEE RAISE" decal

from the. De._._l Rhe.et (ncJt ._hnwn) Apply thp.

decal to the side of the right VKR Arm (57).

48. Remove the "LOW PULLEY" decal from the

Decal Sheet (not shown). Apply the decal to

the Leg Press Frame (72) below the indicated

3 1/2" Pulley (55).

47

!

57

"VERTICAL

KNEE RAISE"

48

16

Page 17

49. Remove the "TRIAD LEG SYSTEM" decal

from the Decal Sheet (not shown). Apply the

decal to the corner of the Leg Press Plate

(70).

49

"TRIAD LEG SYSTEM"

50. Remove the ten small decals numbered "10"

through "100" from the Decal Sheet (not

shown). Apply the decals to the ten Weights

(79) in the indicated locations. The decal

numbered "10" should be applied to the top

Weight; the decal numbered "100" should be

applied to the bottom Weight.

51. Remove the "INDEPENDENT ACTION

shown). Apply the decal to the Rear Upright

(74). The lower end of the decal should be

aligned with the cylinder axles.

Remove the "HOT" decal from the Decal

Sheet (not shown). Apply the decal to the

Rear Upright (74) above the indicated 5/16"

Nytock Nut (4).

50

51

"INDEPENDENTACTION

STEPPER"

Cylinder Axles

Remove the two "SPEED LINK" decals from

the Decal Sheet (not shown). Apply the

decals to the Left and Right Pedals (63, 64).

Make sure that both decals are turned so the

words "FAST" are toward the Upright (74).

"SPEED LINK"

Note: The words

"FAST" must be

at this end.

64

17

Page 18

52. Make sure that all parts are properly tightened. The use of all remaining parts will be explained in

USING THE LIFESTYLER SYSTEM 40, beginning on page 19 of this owner's manual.

WARNING: For your safety and benefit, attach all decals before using the cross training sys-

tem,

Before using the cross training system, make sure that both of the cables are properly routed. Pull

the ends of both cables a few times to make sure that the cables move smoothly over the pulleys.

Move the butterfly arms and the leg press plate a few times. If either of the cables does not move

smoothly, locate and correct the problem before using the cross training system. IMPORTANT: If

the cables are not properly routed, they may be permanently damaged when used with

heavy weights.

18

Page 19

USING THE LIFESTYLER SYSTEM 40

The instructions below describe how each part of the cross training system can be adjusted. See the

EXERCISE GUIDE accompanying this owner's manual to see how the cross training system should be

set up for each individual exercise.

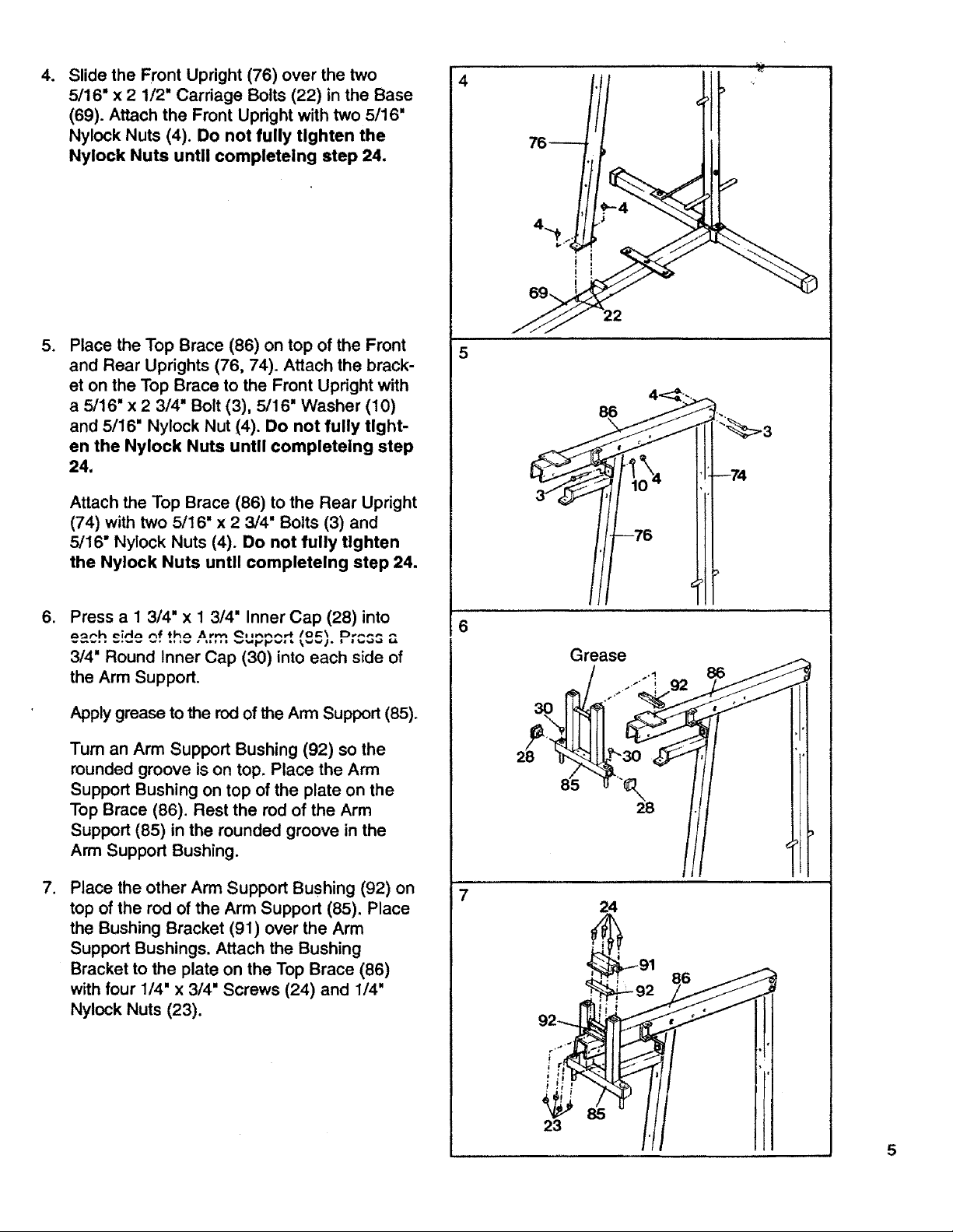

CHANGING THE WEIGHT SE'n'ING

The weight setting of the cross training system

can be changed from a minimum of 10 pounds to

a maximum of 100 pounds, in increments of 10

pounds. To select a weight setting, insert the

6" "L" Pin (96) under a Weight (79) and through

the Weight Selector (82). Turn the end of the Pin

downward.

Note: Due to the design of the cables and pul-

leys, the amount of weight will be DOUBLED

when the arms are used in the press arm

mode, and TRIPLED when the leg press plate

is used.

CHANGING THE STEPPING RESISTANCE

To vary the intensity of your workouts, the resis-

tance of the stepper pedals can be changed. To

change the resistance, lift the Pedals (63, 64) off

the brackets at the lower ends of the Resistance

Cylinders (60). Move the brackets to different

slots under the Pedals. Make sure that the brack-

ets are in the same slots under both Pedals. The

farther the Resistance Cylinders are from the

Rear Upright (74), the greater the resistance will

be.

ADJUSTING THE LEG PRESS PLATE

The Leg Press Plate (70) can be adjusted to any

of four positions. To change the position, first

remove the 7" "L" Pin (40). Move the Leg Press

Plate forward or backward and insert the "L" Pin

through the Leg Press Plate and the Leg Press

Frame (72).

/

60

64

63

70

40

72

For certain exercises, the Leg Press Plate (70)

should be removed from the Leg Press Frame

(72).

19

Page 20

USINGTHEARMSINTHEBUTrERFLYMODE

To use the Arms (51) in the butterfly mode, the

Arm Support (85) must be locked in a stationary

position. To lock the Arm Support, insert a 4 1/2"

"L" Pin (43) down through the center of the Arm

Support and the bracket on the Front Upright (76).

Set the other 4 1/2" "L" Pin (43) aside.

USING THE ARMS IN THE PRESS MODE

85

\\'

To use the Arms (51) in the press mode, the

Arms must be locked in a stationary position.

Insert the two 4 1/2" "L" Pins (43) down through

the Arm Support and the Arms. IMPORTANT:

Always lock the arms in the stationary posi-

tion with the 4 112" "L" Pins except when per-

forming the butterfly or re-verse butterfly exer-

cise.

ATTACHING THE LAT BAR OR NYLON STRAP

TO THE H!GH C.A.BLE

The Lat Bar (87) can be attached to the high

cable with a Cable Clip (89). For some exercises,

the Chain (88) must be attached between the Lat

Bar and the high cable with two Cable Clips. The

distance between the Lat Bar and the high cable

can be adjusted by attaching the Cable Clips

closer together o_rfarther apart along the Chain.

43

<

The Nylon Strap (90) can be attached to the high

cable in the same manner.

ATTACHING THE LAT BAR OR NYLON STRAP

TO THE LOW CABLE

The Lat Bar (87-) can be attached to the low cable

with a Cable Clip (89). For some exercises, the

Chain (88) must be attached between the Lat Bar

and the low cable with two Cable Clips.-The dis-

tance between the Lat Bar and the low cable can

be adjusted by attaching the Cable Ciips closer

together or farther apart along the Chain.

The Nylon Strap (90) can be attached to the high

20 cable in the same manner.

87

Page 21

TROUBLE-SHOOTING AND MAINTENANCE

Inspect and properly tighten all parts of the cross training system each time you exercise. Replace any

wom parts immediately. The cross training system can be cleaned using a damp cloth and mild non-

abrasive detergent. Do not use solvents.

ADJUSTING THE CABLES

If there is too much slack in the cables, the

cables can be adjusted. To tighten the cables,

find the 5/16" Nylock Nut (4) near the lower end

of the Front Upright (76). To tighten the cables,

hold the 5/16" x 4" Bolt (27) and turn the Nylock

Nut clockwise. If the cables cannot be tightened

enough by turning the Nylock Nut, see the

instructions below.

Locate the two 3 1/2" Pulleys (55) attached to the

"1" Plates (75). The 'T' Plates have three adjust-

ment holes for tightening the cables. Remove the

3/8" Nylock Nut (15) and 3/8" x 1 3/4" Bolt (26)

attaching the lower Pulley to the 'T' Plates. Attach

the Pulley to the next higher hole in the "1"

Plates. Turn the 5/16" Nylock Nut (4) clockwise

umii the cabies are tight (see Orawing i).

27

If the cables still cannot be tightened enough,

see the back cover of this owner's manual to

order new cables.

-26

55 _

21

Page 22

PART LIST/EXPLODED DRAWING--Model No. 831.159310

Key Part Key Part

No. No. Qty. Description No. No. Qty. Description

1 014127 10 1/4" Washer 53 112444 2 Handle Grip

2 013341 4 1/4" x2 1/2"Screw 54 113815 2 4 1/2" Pulley

3 113744 11 5/16" x 2 3/4" Bolt 55 108192 12 3 1/2" Pulley

4 012082 29 5/16" NylockNut 56 113697 1 Brace

5 104049 3 3/8"x3 1/2" Bolt 57 113698 2 VKR Arm

6 113745 6 1/2" x 3/8" Metal Spacer 58 113669 2 VKR Armrest

7 012108 2 3/8" Jam Nut 59 113700 1 VKR Backrest

8 105495 8 3/8" Washer 60 109398 2 Resistance Cylinder

9 013498 5 1/4" x-2" Screw 61 112323 4 Cylinder Bushing

10 014073 14 5/16" Washer 62 112277 2 Foot Pad

11 103343 8 1" Round Inner Cap 63 113861 1 Left Pedal

12 013442 2 5/16" x 2" Bolt 64 113860 1 Right Pedal

13 111470 4 3/8" x 3/8" Metal Spacer 65 113704 4 6" Foam Pad

14 102864 4 5/16" x2 1/4" Bolt 66 108726 2 PadTube

15 012108 14 3/8" Nylock Nut 67 113706 1 Seat Frame

16 113748 2 3/8" x 2 3/4" Bolt 68 113816 1 Seat Plate

17 113655 1 Decal Sheet 69 113709 1 Base

18 113662 6 Plastic Cable Guide 70 113857 1 Leg Press Plate

19 013231 1 5/16" x 3 1/4" B.olt 71 113710 1 Leg Lever

20 103053 3 5/16" )( 2 1/2" Bolt 72 113711 1 Leg Press Frame

21 106465 2 3/8" x 3 3/4" Bolt 73 113712 1 Stabilizer

22 100994 3 5/16" x 2 1/2" Carriage Bolt 74 113713 1 Rear Upright

23 012090 8 1/4" NylockNut 75 113760 2 "1" Plate

24 013456 6 1/4" x 3/4" Screw 76 113714 1 Front Upright

25 013330 1 1/4" x 2" Carriage Bolt 77 113715 1 Seat

26 013564 5 3/8" x 1 3/4" Bolt 78 113716 1 Backrest

"_7 Al':ll:;;_q 9 _/1R" v A" _,1+ 79 4na,_a,_ 10 _^r^;_.+

28 113666 8 1 3/4" x 1 3/4" Inner Cap 80 109976 2 Weight Sleeve

29 108874 1 2" x 2" inner Cap 81 112608 2 Weight Sleeve Clip

30 113667 6 3/4" Round Inner Cap 82 113699 1 Weight Selector

31 113668 1 1" Bumper 83 113719 2 Weight Guide

32 107428 1 3/4" Screw 84 113720 2 6 1/2" Foam Pad

33 013210 1 5/16" x 1 1/2" Bolt 85 113721 1 Arm Support

34 110726 1 Domed Inner Cap 86 113738 1 Top Brace

35 113814 2 5/16" x 2 3/4" Carriage Bolt 87 113739 1 Lat Bar

36 105723 2 . 2" x 2" Outer Cap 88 105315 1 Chain

37 113761. 4 1" Plastic Cap 89 103087 3 Cable Clip

38 113821 4 . 1 5/16" Retainer Ring 90 107048 1 Nylon Strap

39 112275 2 Pedal Bushing 91 113740 1 Bushing Bracket

40 113759 1 7""L" Pin 92 113741 2 Arm Support Bushing

41 113752 2 5/16" x4 1/4" Bolt 93 113650 1 Long Cable

42 113685 2 2 5/8" Metal Spacer 94 113649 1 Short Cable

43 105977 2 4 1/2""L" Pin 95 103833 4 1 1/2" x 1 1/2" Inner Cap

44 013580 _2 3/8" x 2" Bolt 96 113754 1 6""L"Pin

45 013162 2 1/2" Pan Screw 97 113755 2 3" "U" Bracket

46 115406 2 5/8" Plastic Cap 98 113758 2 3 1/2" "U" Bracket

47 112310 2 1" Retaining Ring 99 113756 2 Thin"L" Bracket

48 112359 2 Cylinder Spacer 100 113757 1 Thick "L" Bracket

49 113753 1 2" Metal Spacer # 113517 1 Owner's Manual

50 105433 2 Weight Bumper # 113663 1 Part Identification Chart

51 113694 2 Arm # 113822 1 Exercise Manual

52 113696 4 Handle

22 Note: "#" indicates a non-illustrated part. Specifications are subject to change without notice. Rev. 10/93

Page 23

55

44

55

4

42

86

87

4

58

42

57

23

I

84

14 |15_ 97

54

28

6

4 10

47

s

48

61

20

33

55

10

>

I

I i

I I

I

I

73

16

69

39

39

\ 37

45

23

Page 24

ORDERING REPLACEMENT PARTS

Each SYSTEM has its own MODEL NUMBER. Always mention this MODEL NUMBER when request-

ing service or repair parts for your SYSTEM.

All parts listed herein can be ordered through SEARS, ROEBUCK AND CO. SERVICE CENTERS and

most SEARS RETAIL STORES. If parts you need are not stocked locally, your order will be transmitted

to a SEARS PARTS DISTRIBUTION CENTER for handling.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING INFORMATION:

1. The MODEL NUMBER -of the product (831.159310).

2. The NAME of the product (SEARS LIFESTYLER ®SYSTEM 40 cross training system).

3. The PART NUMBER of the part(s) from the PART IDENTIFICATION (ID) CHART accompanying

this owner's manual.

4. The DESCRIPTION of the part(s) from the PART IDENTIFICATION CHART accompanying this

owner's manual.

Your SEARS SYSTEM has added value when you consider that SEARS has service units nationwide,

staffed with SEARS trainedtechnici'ans specifically trained on SEARS products, having the pads, tools

and equipment to ensure that we meet our pledge to you: "We service what we sell."

Should you ever need repair service or pads, call toll free:

For repair service: 1-800-4-REPAIR (1-800-473-7247)

For repair parts: !-800-FON-PART (I-800-366-7278)

I

For 90 days from the date of purchase, when proper assembly and maintenance procedures

detailed'in the .Owner's Manual are followed, SEARS will, free of charge, repair or replace and

install a replacement part for any defective partl when this cross training system is used in a

normal manner.

This warranty does not apply when this cross training system is used for commercial or rental

purposes.

SERVICE-IS AVAILABLE SIMPLY BY CONTACTING YOUR NEAREST SEARS SERVICE

CENTER/DEPARTMENT IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state. - '

FULL 90 DAY WARRANTY

u

I

SEARS_ ROEBUCK AND CO., DEPT. 817WA,

3333 BEVERLY ROAD, HOFFMAN ESTATES, IL 60179

Part No. 113517 10/93 © Sears, Roebuck and Co. Printed in Canada

Loading...

Loading...