© 2017 erie water treatment TM-EN-PF-SOF-Rev2017.01

Technical Manual

WATER SOFTENER

Models:

PF-SOF1-SIM

PF-SOF1-ALT

PF-SOF1-PRL

PF-SOF1,5-SIM

PF-SOF1,5-ALT

PF-SOF1,5-PRL

PF-BTA

TABLE OF CONTENT & INSTALLATION RECORD

Page 2

Table of content & Installation record ..................................................................................... Page 2

Warning & Safety instructions ................................................................................................. Page 3

Operating conditions & Requirements .................................................................................... Page 4

Assembly .................................................................................................................................. Page 5

Installation ............................................................................................................................... Page 7

Commissioning ......................................................................................................................... Page 9

Electronic control panel ........................................................................................................... Page 10

Maintenance ............................................................................................................................ Page 16

Troubleshooting ....................................................................................................................... Page 18

Electrical wiring diagrams ........................................................................................................ Page 20

Default configuration parameter settings - PF-SOF1 ............................................................... Page 21

Default configuration parameter settings - PF-SOF1,5 ............................................................ Page 22

Composition overview ............................................................................................................. Page 23

Exploded view - PF-SOF1-SIM .................................................................................................. Page 24

Exploded view - PF-SOF1-ALT & PF-SOF1-PRL ......................................................................... Page 26

Exploded view - PF-SOF1 - Timer assembly ............................................................................. Page 28

Exploded view - PF-SOF1 - Valve body ..................................................................................... Page 30

Exploded view - PF-SOF1,5-SIM ............................................................................................... Page 32

Exploded view - PF-SOF1,5-ALT & PF-SOF1,5-PRL ................................................................... Page 34

Exploded view - PF-SOF1,5 - Timer assembly .......................................................................... Page 36

Exploded view - PF-SOF1,5 - Valve body .................................................................................. Page 38

Exploded view - PF-SOF1,5 - Piston assembly.......................................................................... Page 40

Exploded view - PF-BTA-Simplex .............................................................................................. Page 42

Exploded view - PF-BTA-Duplex ............................................................................................... Page 43

Technical data - PF-SOF1 .......................................................................................................... Page 44

Technical data - PF-SOF1,5 ....................................................................................................... Page 46

Technical data - PF-BTA ............................................................................................................ Page 48

WARNING & SAFETY INSTRUCTIONS

Page 3

Before you begin the installation of the appliance, we advise you read

and carefully follow the instructions contained in this manual. It contains

important information about safety, installation, use and maintenance of

the product. The actual system that you have received, may differ from

the pictures/illustrations/descriptions in these Instructions.

Failure to follow the instructions could cause personal injury or damage

to the appliance or property. Only when installed, commissioned and

serviced correctly, the appliance will offer you many years of trouble-free

operation.

The appliance is intended to 'soften' the water, meaning it will remove

hardness minerals; it will not necessarily remove other contaminants

present in the water. The appliance will not purify polluted water or make

it safe to drink!

Installation of the appliance should only be undertaken by a competent

person, aware of the local codes in force. All plumbing and electrical

connections must be done in accordance with local codes.

Before setting up the appliance, make sure to check it for any externally

visible damage; do not install or use when damaged.

Use a hand truck to transport the appliance. To prevent accident or

injury, do not hoist the appliance over your shoulder. Do not lay the

appliance on its side.

Keep these Instructions in a safe place and ensure that new users are

familiar with the content.

The appliance is designed and manufactured in accordance with current

safety requirements and regulations. Incorrect repairs can result in

unforeseen danger for the user, for which the manufacturer cannot be

held responsible. Therefore repairs should only be undertaken by a

competent technician, familiar and trained for this product.

In respect of the environment, this appliance should be disposed of in

accordance with Waste Electrical and Electronic Equipment

requirements. Refer to national/local laws and codes for correct recycling

of this appliance.

OPERATING CONDITIONS & REQUIREMENTS

Page 4

OPERATING PRESSURE MIN-MAX: 1,4-8,0 bar / 20-116 psi

this appliance is configured to perform optimally at an

operating pressure of 3 bar (45 psi) ±½ bar (7 psi); in case of a

lower or higher operating pressure the performance may be

affected negatively!

check water pressure regularly; it may fluctuate severely

depending on the time of day, the day of the week or even the

season of the year.

take into account that night time water pressure may be

considerably higher than day time water pressure.

install a pressure reducer ahead of the appliance if necessary.

install a pressure booster, if it is likely that water pressure may

drop below the minimum.

OPERATING TEMPERATURE MIN-MAX: 2-48 °C / 35-120 °F

do not install the appliance in an environment where high

ambient temperatures (e.g. unvented boiler house) or freezing

temperatures can occur.

the appliance cannot be exposed to outdoor elements, such as

direct sunlight or atmospheric precipitation.

do not install the appliance too close to a water heater; keep at

least 3 m (10 ft) of piping between the outlet of the appliance

and the inlet of the water heater; water heaters can sometimes

transmit heat back down the cold pipe into the appliance;

always install a check valve at the outlet of the appliance.

ELECTRICAL CONNECTION:

this appliance only works on 24 VAC; always use it in

combination with the supplied transformer.

in case of damage to the power supply cable of the transformer,

immediately disconnect the transformer from the power outlet

and replace the transformer.

make sure to plug the transformer into a power outlet, which is

installed in a dry location, with the proper rating and overcurrent protection.

ASSEMBLY

Page 5

CONTENT CHECK

Actual parts that you have received, may differ from the

pictures/illustrations in these Instructions!

For ease of transportation and installation, the softening

resin is NOT loaded in the pressure tank, but delivered in

separate bags of 25 ltr; it must be loaded on-site, after

positioning of the pressure tank.

Check the content of the system, using the Composition

Overview in these Instructions. Identify and lay-out the

different components to facilitate the assembly.

SIMPLEX

(PF-SOF1-SIM & PF-SOF1,5-SIM)

A Simplex system consists of 1 single softening module

(pressure tank, resin, control valve and accessories).

During normal operation, the Simplex system delivers

softened water. As soon as it initiates a regeneration, it

automatically goes into hard water bypass, guaranteeing

uninterrupted supply of untreated water

It is possible to upgrade a Simplex system to a Duplex Parallel

system, by adding a second Simplex system.

DUPLEX ALTERNATING

(PF-SOF1-ALT & PF-SOF1,5-ALT)

A Duplex ALTERNATING system consists of 2 Simplex systems,

that:

- are hydraulically installed in parallel;

- are electronically interconnected by means of an

InterConnect cable;

- have a Normally Closed solenoid operated diaphragm

valve (so called Service Valve) in the outlet of each

Simplex system; this Service Valve is controlled by the

electronic timer of the Simplex system and is activated

during the service cycle to open the outlet of the

respective Simplex system;

- share 1 brine tank, that contains 2 brine valves.

During normal operation, only 1 of the 2 Simplex systems is

in service, while the other one is regenerating or ‘in

standby’! As soon as the first Simplex system initiates a

regeneration, the second system goes into service,

guaranteeing uninterrupted supply of treated water. In case

of a power failure, both Service Valves will be deactivated,

meaning the outlet of both Simplex systems will be closed off,

cutting off the water supply (potentially hard water!) to the

application.

DUPLEX PARALLEL

(PF-SOF1-PRL & PF-SOF1,5-PRL)

A Duplex PARALLEL system consists of 2 Simplex systems,

that:

- are hydraulically installed in parallel;

- are electronically interconnected by means of an

InterConnect cable;

- have a Normally Open solenoid operated diaphragm valve

(so called Service Valve) in the outlet of each Simplex

system; this Service Valve is controlled by the electronic

timer of the Simplex system and is activated during the

entire duration of the regeneration, to close-off the

control valve's standard 'hard water bypass during

regeneration';

- share 1 brine tank, that contains 2 brine valves.

During normal operation, both Simplex systems are in

service, doubling the service flow rate! When one of the

Simplex systems initiates a regeneration, it immediately

communicates it's status to the other Simplex system via the

InterConnect cable, to make sure the other Simplex system

remains in service, guaranteeing uninterrupted supply of

treated water. In case of a power failure, both Service Valves

will be deactivated, meaning the outlet of both Simplex

systems will be open, guaranteeing uninterrupted supply of

water.

For correct assembly, repeat the different assembly steps,

until both Simplex systems are assembled and positioned

correctly.

For large installations, with an important need for treated

water, 2 or more Duplex systems can easily be installed in

parallel hydraulically, to double/triple/... the flow rate and

softening capacity.

RESIN LOADING

1. Move the pressure tank to the correct installation

location; position it on a flat and level surface. Make sure

to leave enough space for ease of service.

2. Position the riser assembly upright and centred in the

pressure tank; plug the top of the riser tube with a piece

of tape or clean rag, to prevent resin from entering the

tube.

3. Add water to the pressure tank to a height of ±30 cm from

the bottom; this water will protect the bottom of the

pressure tank and the bottom distributor, during filling of

the pressure tank.

4. Place a funnel on the pressure tank opening and fill the

pressure tank with resin; make sure the riser assembly

remains centered in the pressure tank.

5. Rinse the pressure tank opening to remove any resin

beads from the threaded section.

6. Unplug the top of the riser tube.

CONTROL VALVE

only for PF-SOF1

1. Make sure the O-ring in the riser insert and the tank O-

ring (around the threaded section of the control valve) are

in the correct position.

2. Screw the top distributor onto the control valve.

3. Lubricate the threaded section of the pressure tank, the

top of the riser tube and the tank O-ring of the control

valve; use a silicon-based lubricant.

4. Lower the control valve straight down onto the riser tube,

until the riser tube is correctly inserted in the riser insert;

then push it down firmly and screw it onto the pressure

tank.

ASSEMBLY

Page 6

only for PF-SOF1,5

Picture 1

1. On the brass valve seat:

make sure the O-ring in the riser insert is in the correct

position;

install the top distributor and fix it by means of the 2

stainless steel screws;

install the tank O-ring in the groove on the flange

around the threaded section.

2. Lubricate the threaded section of the pressure tank, the

top of the riser tube and the tank O-ring of the valve seat;

use a silicon-based lubricant.

3. Lower the valve seat straight down onto the riser tube,

until the riser tube is correctly inserted in the riser insert

inside the valve seat; then push it down firmly and screw

it onto the pressure tank.

4. Install the valve seat O-ring in the groove on the valve

seat.

5. Install the control valve onto the valve seat; mind the

alignment pin!

6. Bolt the control valve to the valve seat by means of the 4

stainless steel bolts; tighten firmly.

BRINE TANK ASSEMBLY (PF-BTA) (optional)

Picture 2&3

1. Move the brine tank to the correct installation location;

position it on a flat and level surface. Make sure to leave

enough space for ease of service.

2. Insert the polytube into the brine line connection on the

control valve (); make sure to push the polytube in all

the way; tighten the nut.

3. Remove the lid from the brine tank.

4. Remove the lid from the brine well.

5. Make sure the correct elbow connection is installed on

the brine valve (⅜” for PF-SOF1 or ½” for PF-SOF1,5);

replace if necessary.

6. Run the polytube from the control valve through the hole

in the sidewall of the brine tank, to the inside of the brine

tank.

7. Only for PF-SOF1,5: insert the reinforcement tube in the

end of the ½” polytube.

8. Insert the polytube into the elbow connection on the

brine valve; make sure to push the polytube in all the way.

9. Only for PF-SOF1,5: tighten the nut.

10. Install the lid on the brine well.

11. Add water to the brine tank to a height of ±10 cm from

the bottom.

12. Add salt to the brine tank.

13. Install the lid on the brine tank.

INSTALLATION

Page 7

INLET & OUTLET

In case of high concentration of impurities in the inlet

water, we recommend the installation of a sediment filter,

ahead of the appliance.

We strongly recommend the use of flexible hoses to

connect the appliance to the water distribution system; use

hoses with a large diameter in order to limit the pressure

loss.

We strongly recommend the installation of a bypass

system (not included with this product!) to isolate the

appliance from the water distribution system in case of

repairs. It allows to turn off the water to the appliance, while

maintaining full-flow (untreated) water supply to the user.

only for PF-SOF1-SIM:

SIMPLEX with factory bypass (optional)

Picture 4

= mains water supply (untreated water)

= inlet of control valve (untreated water)

= outlet of control valve (treated water)

= application (treated water)

1. Screw the factory bypass onto the in/out ports on the

control valve (&); make sure to install the gasket

seals. Tighten the nuts firmly by hand.

2. Screw the connection kit with nuts onto the factory

bypass (&); make sure to install the gasket seals.

Tighten the nuts firmly by hand.

3. Connect the mains water supply to the adaptor on the

inlet port of the factory bypass ().

4. Connect the application to the adaptor on the outlet port

of the factory bypass ().

only for PF-SOF1-SIM:

SIMPLEX with 3-valve connection kit (not included)

Picture 5

= inlet of control valve (untreated water)

= outlet of control valve (treated water)

1. Install the 3-valve connection kit.

2. Screw the connection kit with nuts onto the in/out ports

on the control valve (&); make sure to install the

gasket seals. Tighten the nuts firmly by hand.

3. Connect the IN valve of the 3-valve connection kit to the

adaptor on the in port of the control valve ().

4. Connect the OUT valve of the 3-valve connection kit to the

adaptor on the out port of the control valve ().

5. Connect the mains water supply to the inlet of the 3-valve

connection kit.

6. Connect the application to the outlet of the 3-valve

connection kit.

only for PF-SOF1-ALT and PF-SOF1-PRL:

DUPLEX with multiple valve connection kit (not incl.)

Picture 6

= inlet of control valve (untreated water)

= outlet of control valve (treated water)

= Service Valve

1. Install the multiple valve connection kit.

2. Screw the connection kit with nuts onto the in/out ports

on the control valve (&); make sure to install the

gasket seals. Tighten the nuts firmly by hand.

3. Screw the Service Valve () onto the adaptor at the out

port of the control valve (); make sure to respect the

flow direction (see indication arrow on the bottom of the

Service Valve); use an appropriate sealant.

4. Connect the IN valve of the multiple valve connection kit

to the adaptor on the in port of the control valve ().

5. Connect the OUT valve of the multiple valve connection

kit to the outlet of the Service Valve ().

6. Repeat steps 2-5 for both Simplex systems.

7. Connect the mains water supply to the inlet of the

multiple valve connection kit.

8. Connect the application to the outlet of the multiple valve

connection kit.

only for PF-SOF1,5-SIM:

SIMPLEX with 3-valve connection kit (not incl.)

Picture 7

= inlet of control valve (untreated water)

= outlet of control valve (treated water)

= PVC elbow

= inlet of flow meter

= outlet of flow meter

1. Install the 3-valve connection kit.

2. Insert the adaptors in the in/out ports on the control valve

(&); make sure not to damage the O-rings. Install the

nuts and tighten them firmly by hand.

3. Screw the PVC elbow () onto the adaptor at the out port

of the control valve (); use an appropriate sealant.

4. Insert the adaptors in the in/out ports on the flow meter

(&); make sure not to damage the O-rings. Install the

nuts and tighten them firmly by hand.

5. Screw the flow meter () into the PVC elbow (); make

sure to respect the flow direction (see indication arrow);

use an appropriate sealant.

6. Connect the flow meter cable from the control valve to

the flow meter; secure it by means of the screw.

7. Connect the IN valve of the 3-valve connection kit to the

adaptor on the in port of the control valve ().

8. Connect the OUT valve of the 3-valve connection kit to the

adaptor on the out port of the flow meter ().

9. Connect the mains water supply to the inlet of the 3-valve

connection kit.

10. Connect the application to the outlet of the 3-valve

connection kit.

only for PF-SOF1,5-ALT and PF-SOF1,5-PRL:

DUPLEX with multiple valve connection kit (not incl.)

Picture 8

= inlet of control valve (untreated water)

= outlet of control valve (treated water)

= PVC elbow

= inlet of flow meter

= outlet of flow meter

= Service Valve

1. Install the multiple valve connection kit.

2. Insert the adaptors in the in/out ports on the control valve

(&); make sure not to damage the O-rings. Install the

nuts and tighten them firmly by hand.

INSTALLATION

Page 8

3. Screw the PVC elbow () onto the adaptor at the out port

of the control valve (); use an appropriate sealant.

4. Insert the adaptors in the in/out ports on the flow meter

(&); make sure not to damage the O-rings. Install the

nuts and tighten them firmly by hand.

5. Screw the flow meter () into the PVC elbow (); make

sure to respect the flow direction (see indication arrow);

use an appropriate sealant.

6. Connect the flow meter cable from the control valve to

the flow meter; secure it by means of the screw.

7. Screw the Service Valve () onto the adaptor on the out

port of the flow meter (); make sure to respect the flow

direction (see indication arrow on the bottom of the

Service Valve); use an appropriate sealant.

8. Connect the IN valve of the multiple valve connection kit

to the adaptor on the in port of the control valve ().

9. Connect the OUT valve of the multiple valve connection

kit to the outlet of the Service Valve ().

10. Repeat steps 2-9 for both Simplex systems.

11. Connect the mains water supply to the inlet of the

multiple valve connection kit.

12. Connect the application to the outlet of the multiple valve

connection kit.

DRAIN

We recommend the use of a stand pipe with P-trap.

To prevent backflow from the sewerage system into the

appliance, always install and use an air gap (drain adaptor

with air gap included with PF-SOF1), to connect the drain

hoses to the sewerage system.

Always use separate drain hoses for the control valve(s)

(discharge of rinse water) and the brine tank overflow.

Lay-out the drain hoses in such a way that pressure loss

is minimized; avoid kinks and unnecessary elevations.

Make sure that the sewerage system is suitable for the

rinse water flow rate of the appliance.

only for PF-SOF1

Picture 9

1. Install the drain adaptor to the sewerage system; it fits

over a 32 mm pipe or inside a 40 mm pipe adaptor. Ensure

a permanent and watertight connection.

2. Connect a 13 mm hose to the drain connection of the

control valve (); secure it by means of a clamp.

3. Run the drain hose to the drain adaptor and connect it to

one of the hose barbs; secure it by means of a clamp. This

drain line operates under pressure, so it may be installed

higher than the appliance.

4. For Duplex: repeat steps 1-3 for both Simplex systems.

only for PF-SOF1,5

Picture 10

1. Connect a pipe to the 1” BSP Male drain connection of the

control valve (); use an appropriate sealant.

2. Run the pipe to the sewerage system and connect it,

ensuring sufficient air gap between the end of the pipe

and the sewerage system. This drain line operates under

pressure, so it may be installed higher than the appliance.

3. For Duplex: repeat steps 1-2 for both Simplex systems.

PF-BTA: brine tank assembly (optional)

1. Install the air gap to the sewerage system; it fits over a

32 mm pipe or inside a 40 mm pipe adaptor. Ensure a

permanent and watertight connection.

2. Connect a 13 mm hose to the overflow elbow on the brine

tank; secure it by means of a clamp.

3. Run the drain hose to the air gap and connect it to one of

the hose barbs; secure it by means of a clamp. This drain

line does NOT operate under pressure, so it may NOT be

installed higher than the brine tank.

SERVICE VALVES

(only for Duplex)

Picture 11

1. Plug the DIN plug on the connection cable of the Service

Valve into the DIN socket at the back of the electronic

timer head of the respective control valve ().

COMMISSIONING

Page 9

ELECTRICAL

1. Connect the appliances power cord to the transformers

output.

2. Plug the transformer into an electrical outlet.

PRESSURIZING

1. Put the bypass system in 'bypass' position.

2. Make sure the electronic controller(s) of the appliance is

(are) in service mode.

3. Open the mains water supply.

4. Open a cold treated water faucet nearby the appliance

and let the water run for a few minutes until all air is

purged and all foreign material that may have resulted

from the installation is washed out; close the tap.

5. Gently pressurize the appliance, by putting it into service:

close the 'BYPASS' valve;

open the 'OUT' valve;

slowly open the 'IN' valve.

6. After 2-3 minutes, open a cold treated water faucet

nearby the appliance and let the water run for a few

minutes until all air is purged from the installation and the

resin bed is rinsed (it is normal for the rinse water to show

some discoloration!); close the tap.

7. Check the appliance and all hydraulic connections for

leaks.

8. For Duplex: repeat steps 5-7 for both Simplex systems.

ELECTRONIC CONTROL PANEL

1. Program the electronic controller.

2. For Duplex: repeat step 1 for both Simplex systems.

ADJUSTMENT RESIDUAL HARDNESS

(only for PF-SOF1)

In practice the residual hardness is influenced by the

inlet pressure, flow rate and hardness of the incoming

untreated water. When adjusting the residual hardness,

make sure these conditions are similar to the actual

operating conditions.

ON CONTROL VALVE

Picture 12.a

1. Adjust the residual hardness of the water that leaves the

softener, by means of the adjusting screw, incorporated

at the right side of the control valve:

to raise the residual hardness: turn the screw counter

clockwise;

to reduce the residual hardness: turn the screw

clockwise.

2. Measure the residual water hardness with a water

hardness test kit; readjust if necessary.

WITH FACTORY BYPASS (optional)

Picture 12.b

1. Adjust the residual hardness of the water that leaves the

softener, by means of the adjusting screw, incorporated

in the 'outlet' valve of the factory bypass:

to raise the residual hardness: turn the screw counter

clockwise.

to reduce the residual hardness: turn the screw

clockwise.

2. Measure the residual water hardness with a water

hardness test kit; readjust if necessary.

INITIATE A REGENERATION

1. Manually initiate a regeneration, by pressing the scroll

button; the display will show:

2. Leave the appliance in this position; the count-down

timer will count down to 0 sec and start a regeneration;

to save time you may skip, or terminate prematurely, the

second cycle of the regeneration by pressing the scroll

button once, as soon as the display indicates that the

system is in the second regeneration position.

3. For Duplex: repeat steps 1-2 for both Simplex systems.

INTERCONNECT CABLE

(only for Duplex)

Picture 13

1. Connect the control valves to each other by means of the

InterConnect cable; simply plug the DIN plugs on the

InterConnect cable in the DIN sockets at the back of the

electronic timer of each control valve ().

INITIATE ALTERNATING MODE

(only for Duplex Alternating)

1. On one of the 2 control valves, manually initiate a

regeneration, by pressing the scroll button; the display

will show:

2. Leave the appliance in this position; the count-down

timer will count down to 0 sec and start a regeneration.

3. Press the scroll

button repeatedly, to advance the

control valve through the regeneration cycles and put it

in Standby mode, until the display shows:

Regen in 10 sec

Regen in 10 sec

Stdby 1000 L -

ELECTRONIC CONTROL PANEL

Page 10

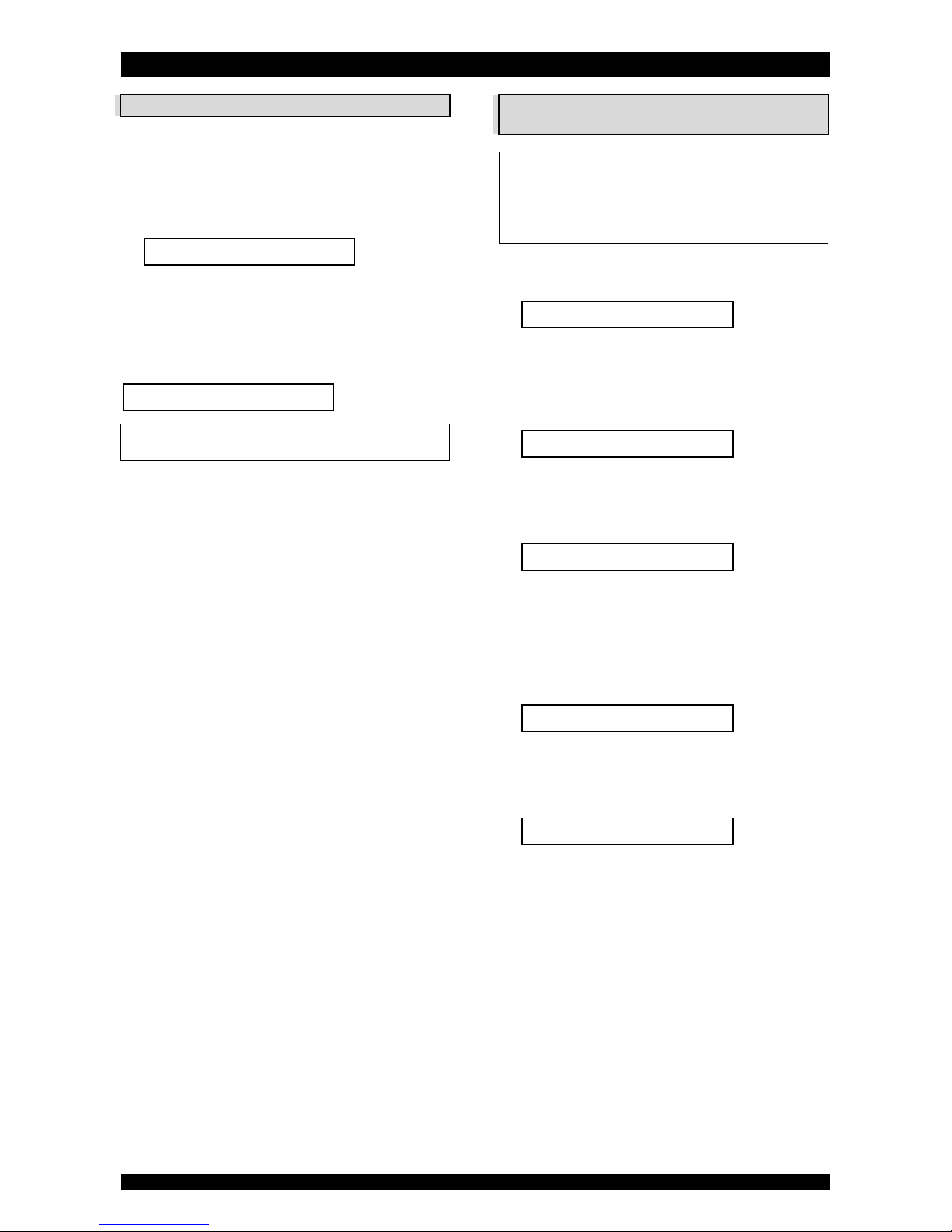

Picture 14

symbol

button

function

SCROLL

to advance to the next

parameter

UP

to increase the value of the

parameter

DOWN

to decrease the value of the

parameter

POWER-UP

After power-up the display will show the installed software

version for a period of 5 seconds.

POWER FAILURE

In the event of a power failure, the program will remain

stored in the NOVRAM® during an undefined period, while an

incorporated SuperCap will maintain the correct time of day

during a period of several hours; consequently, in case of

prolonged power failure, the time of day might not be

maintained; if this happens, the time of day will be reset to

8:00 when the power supply is re-established, while the

indication will flash, indicating that the time of day needs to

be set.

When the power failure occurs during the execution of an

automatic regeneration, the control valve will remain in its

last position; when the power supply is re-established, the

control valve will return to the service position, stay there for

60 sec. and restart a complete regeneration from the

beginning.

TIMER FAILURE

In the event of a timer failure, the display will show the

message:

If powering off/on the appliance doesn’t solve this problem,

professional service is required.

MAINTENANCE REMINDER

Once the maintenance interval is reached, the display will

intermittently show the message:

While the appliance will continue to operate normally, it is

recommended to have preventive maintenance performed

by a professional.

SERVICE MODE

In service mode the display shows:

Simplex, Duplex Parallel: the time of day and the

remaining capacity:

Duplex Alternating: the systems status (Service or

Standby) and the remaining capacity:

REGENERATION MODE

In regeneration mode the display shows:

Simplex, Duplex Parallel: the total remaining

regeneration time and remaining cycle time:

Duplex Alternating: the total remaining regeneration

time and remaining cycle time:

When the regeneration is finished, the system remains in

Standby, until the other system starts a regeneration:

The control valve can be reset to service mode at any time by

pressing the scroll button, as such manually advancing it

through the regeneration cycles.

CHECKING THE FLOW METER

In case of water usage, the remaining capacity counter in the

service display will count back. This way the correct

functioning of the water meter can be verified.

MANUAL REGENERATION

It is possible to manually initiate an immediate regeneration

or a delayed regeneration (at the preprogrammed time of

regeneration).

1. Press the scroll

button; the display will show:

If the control panel is left in this position, the

countdown timer will countdown to 0 sec and start an

immediate regeneration.

To cancel this mode, press the scroll

button before

the countdown timer has reached 0 sec; the display

will show:

If the control panel is left in this position, a delayed

regeneration will be started at the indicated

preprogrammed time of regeneration.

To cancel this mode, press the scroll

button; the

control panel will return to the service mode.

Service Required

Rgn:123 CycY:456

8:01 1000L -

Srvc 1000L -

Stdby 1000L -

Rgn:123 CycY:456

Stdby 1000L -

Maintenance Now

Regen in 10 sec

Regen @ 2:00

ELECTRONIC CONTROL PANEL

Page 11

HOLIDAY MODE

It is possible to put the appliance in holiday mode; this will

prevent automatic regeneration from taking place, yet will

ensure the appliance is automatically regenerated at the end

of the holiday cycle.

1. Press the scroll

button repeatedly until the display

shows:

Press the up

or down button to activate the

holiday mode by setting the number of full days away

from home, or deactivate the holiday mode (OFF).

Once the control panel is back in service mode, the display

will show:

The holiday mode is automatically cancelled when a

regeneration is manually initiated!

PROGRAMMING INSTRUCTIONS -

BASIC SETTINGS

Before entering the programming mode, make sure that

the appliance is in the service mode.

In case no button is pressed in a period of 5 min, the

control panel will automatically return to the service mode;

any changes made will NOT be saved!

1. Press the scroll

button and hold it for 2 sec until the

display shows:

Press the up

or down button to set the

language.

2. Press the scroll

button again; the display will show

(does not apply to Duplex Alternating!):

Press the up

or down button to set the time of

day.

3. Press the scroll

button again; the display will show:

Press the up

or down button to set the unit of

measure for water hardness. Make sure it is identical

to the unit of measure of the water hardness test kit

or water analysis report that is used to determine the

hardness of the incoming untreated water!

4. Press the scroll

button again; the display will show:

Press the up

or down button to set the hardness

of the incoming untreated water.

5. Press the scroll

button again; the display will show:

Press the up

or down button to save the settings

into the NOVRAM® and exit the programming mode.

Holiday: OFF

8:01 Holiday

Language:English

Set time: 8:01

Set Hardn: XX °f

HardUnit: °f

Exit

ELECTRONIC CONTROL PANEL

Page 12

PROGRAMMING INSTRUCTIONS -

CONFIGURATION PARAMETERS

Before entering the programming mode, make sure that

the appliance is in the service mode.

All configuration parameters on this appliance have

been pre-programmed in the factory, to offer optimal

performance in a wide range of applications and situations.

Nevertheless it may be necessary or desirable to change any

of these parameters, to further optimize the appliances

performance or to adapt it to the specific requirements of

the installation. See table at the end of this manual for

default configuration parameter settings.

In case no button is pressed in a period of 5 min, the

control panel will automatically return to the service mode;

any changes made will NOT be saved!

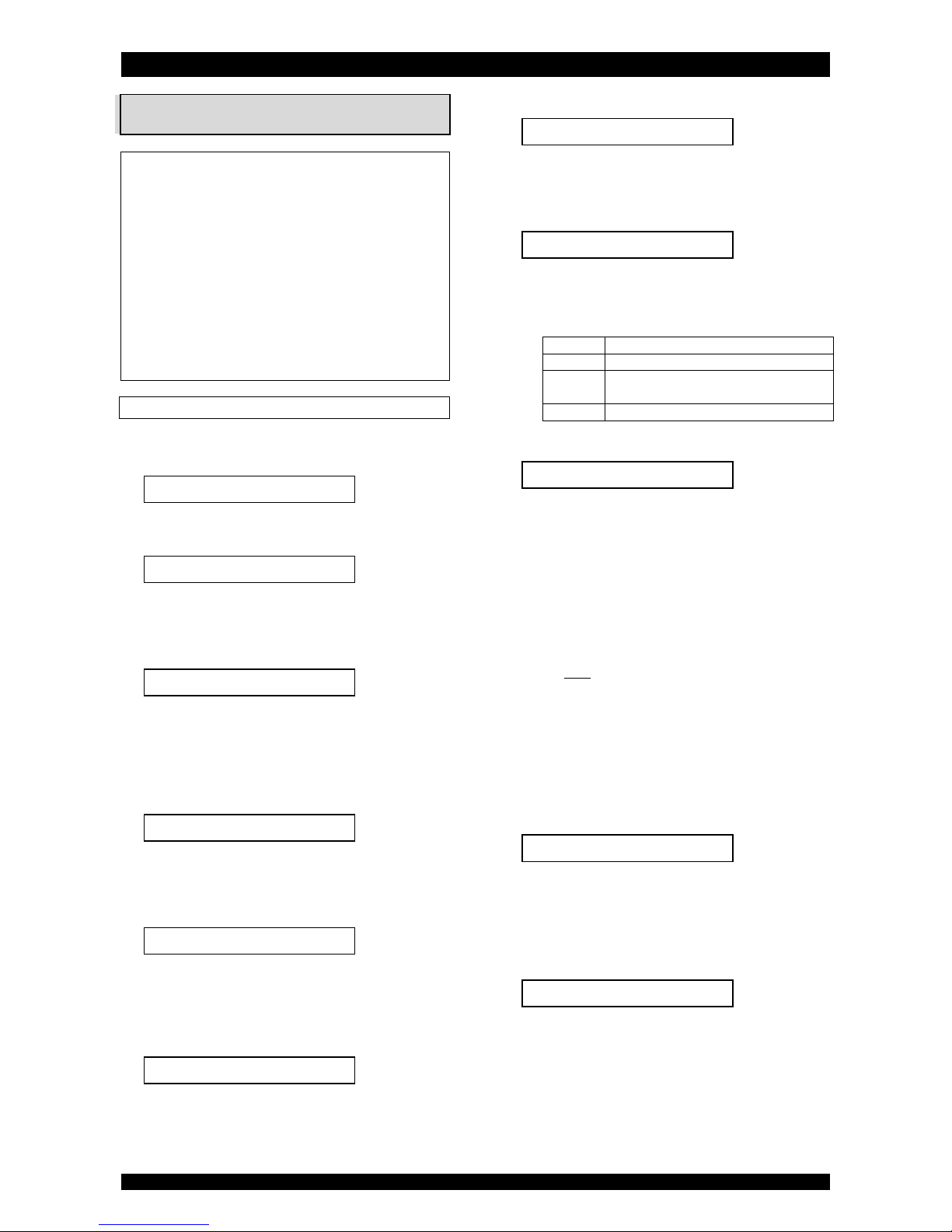

only for PF-SOF1-SIM & PF-SOF1,5-SIM

1. Press the scroll

button and hold it for 6 sec until the

display shows:

2. Within 10 sec, press the up

button; the display will

show:

Press the up

or down button to set the units of

measure (Metric or US).

3. Press the scroll

button again; the display will show:

Press the up

or down button to activate the

maintenance reminder function by setting the

maintenance interval, or deactivate the maintenance

reminder function.

4. Press the scroll

button again; the display will show:

Press the up

or down button to set the

exchange capacity per litre of resin.

5. Press the scroll

button again; the display will show:

Press the up

or down button to set the age

correction factor (%/year) to compensate for capacity

loss of the resin due to aging.

6. Press the scroll

button again; the display will show:

Press the up

or down button to set the volume

of resin.

7. Press the scroll

button again; the display will show:

Press the up

or down button to set the number

of days between regenerations.

8. Press the scroll

button again; the display will show:

Press the up

or down button to set the length

of the regeneration cycle.

Press the scroll

button again to advance to the next

regeneration cycle.

Cycle 1

Backwash

Cycle 2

Brine draw/slow rinse

Cycle 3

Fast rinse/brine tank refill (PF-SOF1)

Fast rinse (PF-SOF1,5)

Cycle 4

Brine tank refill (PF-SOF1,5)

9. Press the scroll

button again; the display will show:

Press the up

or down button to set the

regeneration mode:

Dlyd/Immd: when the remaining capacity equals

the reserve capacity, a delayed regeneration at

the programmed time of regeneration is started;

however when the remaining capacity equals 0

before the programmed time of regeneration is

reached, an immediate regeneration is started.

Immediate: when the remaining capacity equals

0, an immediate regeneration is started.

Note: Delayed manual regeneration is not

available when this regeneration mode is

selected.

Delayed: when the remaining capacity equals the

reserve capacity, a delayed regeneration at the

programmed time of regeneration is started.

10. Press the scroll

button again; the display will show

(only when the regeneration mode is set to ‘Delayed’ or

‘Dlyd/Immd’):

Press the up

or down button to set the time of

regeneration.

11. Press the scroll

button again; the display will show

(only when the regeneration mode is set to ‘Dlyd’ or

‘Dlyd/Immd’):

Press the up

or down button to set the reserve

capacity:

Variable: the reserve capacity is calculated

automatically, based on the registered daily water

usage.

Fxd: press the scroll

button again and press the

up or down button to set the reserve

capacity to a fixed amount.

Cycle 1: XX min

System Check

Regen @ 2:00

Resin:XXX liters

ExCap:5.5°f M3/L

Override: 7 days

Regen:Dlyd/Immd

Rsrv Variable

Units:Metric

MaintInt: 24mths

Age corr.: 2.0%

ELECTRONIC CONTROL PANEL

Page 13

12. Press the scroll

button again; the display will show:

Press the up

or down button to save the

program into the NOVRAM® and exit the

programming level.

only for PF-SOF1-ALT & PF-SOF1,5-ALT

The 2 Simplex systems, that make up a Duplex system,

must be programmed individually; the program does NOT

necessarily have to be the same on the 2 Simplex systems!

1. Press the scroll

button and hold it for 6 sec until the

display shows:

2. Within 10 sec, press the up

button; the display will

show:

Press the up

or down button to set the units of

measure (Metric or US).

3. Press the scroll

button again; the display will show:

Press the up

or down button to activate the

maintenance reminder function by setting the

maintenance interval, or deactivate the maintenance

reminder function.

4. Press the scroll

button again; the display will show:

Press the up

or down button to set the

exchange capacity per litre of resin.

5. Press the scroll

button again; the display will show:

Press the up

or down button to set the age

correction factor (%/year) to compensate for capacity

loss of the resin due to aging.

6. Press the scroll

button again; the display will show:

Press the up

or down button to set the volume

of resin.

7. Press the scroll

button again; the display will show:

Press the up

or down button to set the number

of days between regenerations.

8. Press the scroll

button again; the display will show:

Press the up

or down button to set the length

of the regeneration cycle.

Press the scroll

button again to advance to the next

regeneration cycle.

Exit

Cycle 1: XX min

System Check

Resin:XXX liters

ExCap:5.5°f M3/L

Units:Metric

MaintInt: 24mths

Age corr.: 2.0%

Override: 7 days

ELECTRONIC CONTROL PANEL

Page 14

Cycle 1

Backwash

Cycle 2

Brine draw/slow rinse

Cycle 3

Fast rinse/brine tank refill (PF-SOF1)

Fast rinse (PF-SOF1,5)

Cycle 4

Brine tank refill (PF-SOF1,5)

9. Press the scroll

button again; the display will show:

Press the up

or down button to save the

program into the NOVRAM® and exit the

programming level.

10. Repeat steps 1-9 for both Simplex systems.

only for PF-SOF1-PRL & PF-SOF1,5-PRL

The 2 Simplex systems, that make up a Duplex system,

must be programmed individually; the program does NOT

necessarily have to be the same on the 2 Simplex systems!

1. Press the scroll

button and hold it for 6 sec until the

display shows:

2. Within 10 sec, press the up

button; the display will

show:

Press the up

or down button to set the units of

measure (Metric or US).

3. Press the scroll

button again; the display will show:

Press the up

or down button to activate the

maintenance reminder function by setting the

maintenance interval, or deactivate the maintenance

reminder function.

4. Press the scroll

button again; the display will show:

Press the up

or down button to set the

exchange capacity per litre of resin.

5. Press the scroll

button again; the display will show:

Press the up

or down button to set the age

correction factor (%/year) to compensate for capacity

loss of the resin due to aging.

6. Press the scroll

button again; the display will show:

Press the up

or down button to set the volume

of resin.

7. Press the scroll

button again; the display will show:

Press the up

or down button to set the number

of days between regenerations.

8. Press the scroll

button again; the display will show:

Press the up

or down button to set the length

of the regeneration cycle.

Press the scroll

button again to advance to the next

regeneration cycle.

Cycle 1: XX min

System Check

Resin:XXX liters

ExCap:5.5°f M3/L

Override: 7 days

Exit

Units:Metric

MaintInt: 24mths

Age corr.: 2.0%

ELECTRONIC CONTROL PANEL

Page 15

Cycle 1

Backwash

Cycle 2

Brine draw/slow rinse

Cycle 3

Fast rinse/brine tank refill (PF-SOF1)

Fast rinse (PF-SOF1,5)

Cycle 4

Brine tank refill (PF-SOF1,5)

9. Press the scroll

button again; the display will show:

Press the up

or down button to set the

regeneration mode:

Immediate: when the remaining capacity equals

0, an immediate regeneration is started.

Note: Delayed manual regeneration is not

available when this regeneration mode is

selected.

Dlyd/Immd: when the remaining capacity equals

the reserve capacity, a delayed regeneration at

the programmed time of regeneration is started;

however when the remaining capacity equals 0

before the programmed time of regeneration is

reached, an immediate regeneration is started.

Delayed: when the remaining capacity equals the

reserve capacity, a delayed regeneration at the

programmed time of regeneration is started.

10. Press the scroll

button again; the display will show

(only when the regeneration mode is set to ‘Delayed’ or

‘Dlyd/Immd’):

Press the up

or down button to set the time of

regeneration.

11. Press the scroll

button again; the display will show

(only when the regeneration mode is set to ‘Delayed’ or

‘Dlyd/Immd’):

Press the up

or down button to set the reserve

capacity:

Variable: the reserve capacity is calculated

automatically, based on the registered daily water

usage.

Fxd: press the scroll

button again and press the

up or down button to set the reserve

capacity to a fixed amount.

12. Press the scroll

button again; the display will show:

Press the up

or down button to save the

program into the NOVRAM® and exit the

programming level.

13. Repeat steps 1-12 for both Simplex systems.

DIAGNOSTICS MODE

In the Diagnostics mode several operating parameters

can be consulted; particularly during a service intervention,

these parameters can be helpful to identify the cause of a

problem or malfunction.

Before entering the Diagnostics mode, make sure that

the appliance is in service mode.

In case no button is pressed in a period of 5 min, the

control panel will automatically return to the service mode!

Accessing the Diagnostics mode

1. Press the scroll

button and hold it for 6 sec until the

display shows:

2. Within 10 sec, press the down

button; the display will

show:

You are now in the Diagnostics mode.

Press the scroll

button to advance to the next

diagnostics parameter.

Available diagnostics parameters

Regen X days ago: number of days since last

regeneration.

In Srvc: total number of days in service.

# of Regens: number of regenerations since installation.

TotVol: total volume of treated water since installation.

LastRgn@: consumed capacity at last regeneration.

InstFlow: instantaneous flow rate through appliance.

AvgVol: calculated average daily water usage.

Capacity: calculated capacity between regenerations.

Hardness: setting of water hardness.

Rsrv: setting of reserve capacity.

Regen @: setting of time of regeneration.

Override: setting of number of days between

regenerations.

Cycle X: setting of length of corresponding regeneration

cycle.

Units: control is programmed for Metric units.

MTR: setting of the water meter.

Capacity: control is programmed for hardness setting.

Regen: setting of the regeneration mode.

Valve Type: setting of valve type.

MP Resets: number of resets of the microprocessor.

Memory Reset: number of corrupt memory start-ups.

EZRSDg: software version.

CapToUse: remaining capacity.

Exiting the Diagnostics mode

1. Press the scroll

button repeatedly until the display

shows:

Press the up

or down button to exit the

Diagnostics mode.

Regen XXdays ago

System Check

Exit

Regen:Immediate

Rsrv Variable

Regen @ 2:00

Exit

MAINTENANCE

Page 16

RECOMMENDATION

Notwithstanding the reliability of the appliance, we strongly

recommend to have it serviced and maintained on a regular

basis by a competent and duly trained technician. He will be

able to determine the appropriate maintenance interval for

the appliance, depending on your specific application and the

local operating conditions. The advantages of performing

regular maintenance are:

regular check of the local operating conditions (water

quality, pressure, etc);

regular control and adjustment of the settings of the

appliance, to guarantee it operates at maximum

efficiency;

minimize the risk of unexpected break-down.

Contact your dealer or installer for more information, or visit

our website.

ROUTINE CHECKS

Regularly the user should perform a basic check to verify if the

appliance is functioning correctly, on the basis of the

following control points:

1. Check settings of electronic control panel.

2. Measure water hardness before/after appliance.

3. Check drain line from control valve; there shouldn’t be

any water flow (unless appliance is in regeneration).

4. Check drain line from brine tank overflow; there shouldn’t

be any water flow.

5. Check appliance and surrounding area; there shouldn’t be

any water leakages.

BYPASSING THE APPLIANCE

Occasionally it may be necessary to put the appliance

hydraulically in bypass, i.e. to isolate it from the water

distribution system; f.e.:

in case of an urgent technical problem;

when it is not necessary to supply treated water to the

application.

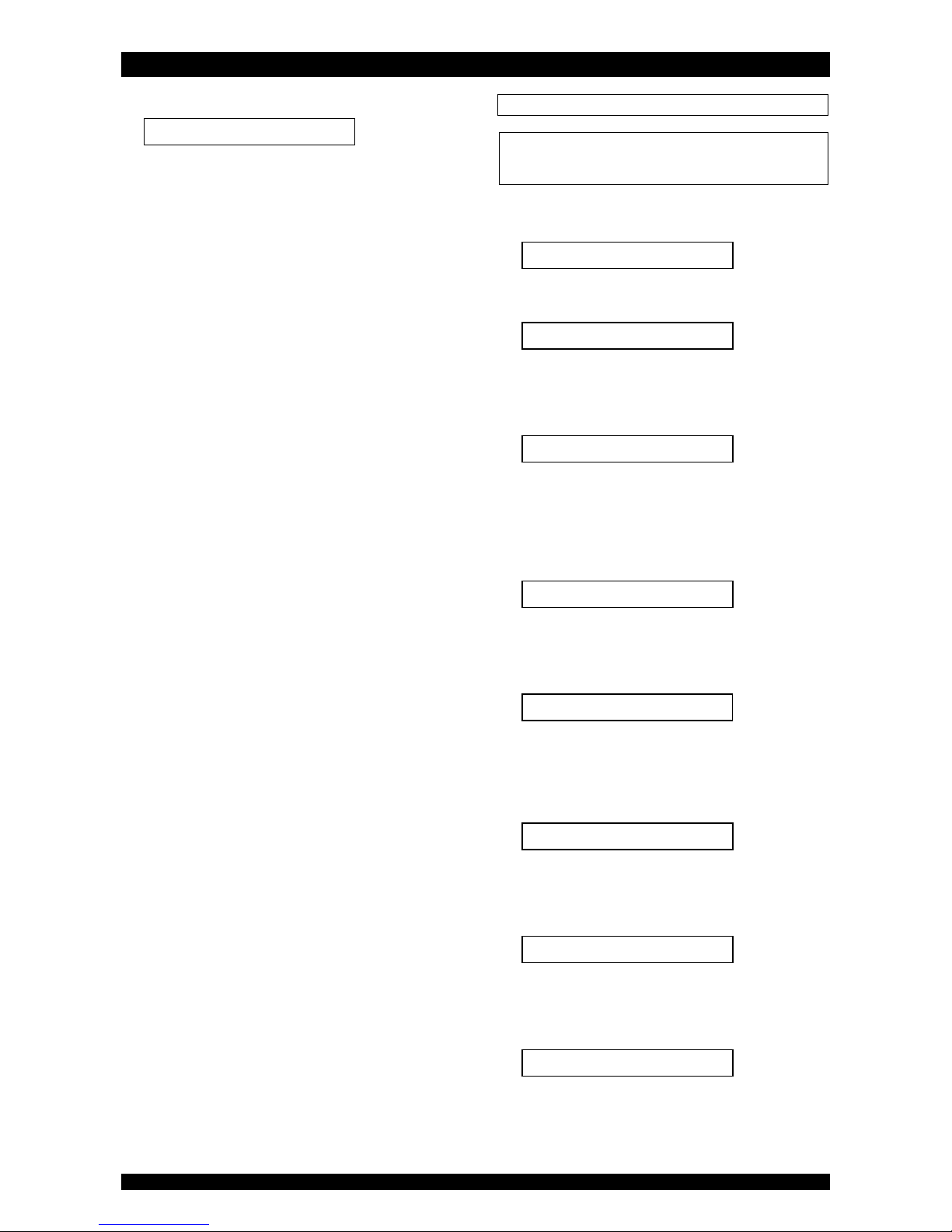

WITH FACTORY BYPASS (optional) (only for PF-SOF1)

Picture 15.a

SERVICE POSITION

= inlet valve to appliance is OPEN

= outlet valve from appliance is OPEN

Picture 15.b

BYPASS POSITION

= inlet valve to appliance is CLOSED

= outlet valve from appliance is CLOSED

Picture 15.c

MAINTENANCE POSITION

= inlet valve to appliance is OPEN

= outlet valve from appliance is CLOSED

WATER CONDITIONER SALT

This appliance needs 'brine' for its periodic regenerations.

This brine solution is made from water, that is automatically

dosed in the brine tank by the control valve, and water

conditioner salt. The user should make sure that the brine

tank is always kept full of water conditioner salt. Therefore he

should periodically check the salt level inside the brine tank

and refill it if necessary. Simply lift the brine tank cover to

check the salt level inside the brine tank.

Ideally the level of water conditioner salt inside the brine tank

is kept between 1/3 and 2/3. A lower level of water

conditioner salt can cause insufficient brine saturation,

resulting in a loss of softening capacity. A higher level of water

conditioner salt can cause salt bridging (hard crust or salt

bridges in the brine tank). When you suspect salt bridging:

carefully pound on the outside of the brine tank to break

loose the salt bridges;

using a broom (or like blunt tool) carefully push the salt to

break it apart;

pour warm water over the top of the salt to dissolve it.

RESIN CLEANER

Other contaminants (f.e. iron) present in the feed water can

cause the resin bed to foul up, resulting in a loss of softening

capacity. An approved resin cleaner can be used periodically

to thoroughly clean the resin bed.

SANITIZING THE APPLIANCE

This appliance is manufactured from premium quality

material and assembled in safe conditions to assure it is clean

and sanitary. If installed and serviced correctly, this appliance

will not infect or contaminate your water supply. However, as

in any 'device' plumbed-in in your water distribution system,

a proliferation of bacteria is possible, especially in case of

'stagnant water'. Therefore this appliance is equipped with a

'days override' feature, that will automatically rinse the resin

bed periodically, even in case of low or absence of water

usage.

If the power supply to the appliance is disconnected for a

longer period of time, we recommend, when the power

supply is re-established, to manually initiate a complete

regeneration.

NORMALLY CLOSED SERVICE VALVES

(only for PF-SOF1-ALT & PF-SOF1,5-ALT)

Picture 16

= automatically operated = normally closed

= manually operated = constantly open

The Normally Closed Service Valve in the outlet of each

Simplex system will only be opened when it is powered. To

manually open the Normally Closed Service Valve (f.e. in case

of a power failure), simply turn the white solenoid coil

counter clockwise.

Page 17

TROUBLESHOOTING

Page 18

PROBLEM

CAUSE

SOLUTION

Hard (untreated) water

to service

Open or defective bypass

Close or replace bypass

Simplex only: appliance in regeneration

Wait until regeneration finishes or manually

advance regeneration to end

Duplex only: one of the Simplex systems in

regeneration and Service Valve not closing off

properly

Refer to problem “Service Valve not closing off

properly”

No salt in brine tank

Add salt and initiate regeneration manually

Salt bridging in brine tank

Break salt bridge(s) and initiate regeneration

manually

Change in raw water hardness

Measure hardness of incoming untreated water and

adjust programming accordingly

Appliance fails to start a regeneration

Refer to problem “Appliance fails to start a

regeneration”

PF-SOF1 only: valve body and timer out of

synchronisation

Synchronize valve body and timer

Control valve fails to draw brine

Refer to problem “Valve fails to draw brine”

Decreasing exchange capacity of resin

Clean or replace resin bed

Loss of resin

Refer to problem “Loss of resin”

Leak at riser tube

Verify that riser tube is seated correctly and is not

cracked

Residual hardness in

treated water

Bypass not completely closed

Close bypass

PF-SOF1 only: mixing valve open

Verify setting of mixing valve

Appliance fails to start

a regeneration

Faulty electrical supply

Verify electrical service (fuse, transformer,...)

Defective flow meter

Clean and/or replace flow meter

Defective PCB

Replace PCB

Defective drive motor

Replace drive motor

Appliance uses too

much salt

Excessive water in brine tank

Refer to problem “Excessive water in brine tank”

Appliance regenerates too frequently

Verify program

Excessive water in

brine tank

Control valve fails to draw brine

Refer to problem “Control valve fails to draw brine”

Improper refill time setting

Verify that refill time corresponds to the proper salt

level and amount of resin

Missing refill flow control

Verify that refill flow control is installed and

properly sized

Leak from control valve to brine tank

PF-SOF1 only: check synchronisation between valve

body and timer

PF-SOF1,5 only: check brine line shut-off valve of

valve body

Salt taste in treated

water

Excessive water in brine tank

Refer to problem “Excessive water in brine tank”

Injector undersized

Verify injector selection and operating pressure

Improper brine/slow rinse time setting

Verify that brine/slow rinse time corresponds to the

proper salt level and amount of resin

Loss of water pressure

Mineral or iron build-up in resin tank

Clean resin bed and control valve; increase

regeneration frequency

Plugged lower and/or upper distributor

Verify that distributors are free of debris

Drain line from control

valve flows

continuously

Appliance in regeneration

Wait until regeneration finishes or manually

advance regeneration to end

Faulty electrical supply

Verify electrical service (fuse, transformer,...)

Defective drive motor

Replace drive motor

PF-SOF1 only: defective micro switch

Replace micro switches

PF-SOF1,5 only: defective optical switch

Replace optical switch

Defective PCB

Replace PCB

PF-SOF1 only: valve body and timer out of

synchronisation

Synchronise valve body and timer

Drain line from brine

tank overflow flows

continuously

Excessive water in brine tank

Refer to problem “Excessive water in brine tank”

TROUBLESHOOTING

Page 19

PROBLEM

CAUSE

SOLUTION

Control valve fails to

refill brine tank

Improper refill time setting

Verify that refill time corresponds to salt level and

amount of resin

Plugged refill flow control

Clean refill flow control

Loss of resin

Lower and/or upper distributor damaged

Replace distributor(s)

Leak between riser tube and upper distributor

Verify that riser tube is seated correctly and is not

cracked

Control valve fails to

draw brine

Low operating pressure

Check operating pressure; must be higher than 1,4

bar

Plugged injector

Clean injector

Restricted drain line

Verify drain line for kinks or restrictions

Restricted brine line

Verify brine line for kinks or restrictions

Leak in brine line

Verify brine line and connections for air leakage

No water in brine tank

Refer to problem “Control valve fails to refill brine

tank”

Control valve cycles

continuously

PF-SOF1 only: defective micro switch

PF-SOF1,5 only: defective optical switch

Replace micro switches

Replace optical switch

Duplex Parallel: both

Simplex systems

regenerate

simultaneously

InterConnect communication does not

function correctly

Check connections of InterConnect cable(s)

Defective PCB

Replace PCB

Duplex Alternating:

both Simplex systems

are in service

simultaneously

InterConnect communication does not

function correctly

Check connections of InterConnect cable

Defective PCB

Replace PCB

Defective Service Valve

Replace Service Valve

ELECTRICAL WIRING DIAGRAMS

Page 20

PF-SOF1

= position switches

= flow meter

= power lead

= drive motor

= PF-SOF1-SIM: service valve NO (optional)

PF-SOF1-PRL: service valve NO

PF-SOF1-ALT: service valve NC

= InterConnect socket

= key pad

PF-SOF1,5

= optical switch

= flow meter

= power lead

= drive motor

= PF-SOF1,5-SIM: service valve NO (optional)

PF-SOF1,5-PRL: service valve NO

PF-SOF1,5-ALT: service valve NC

= InterConnect socket

= key pad

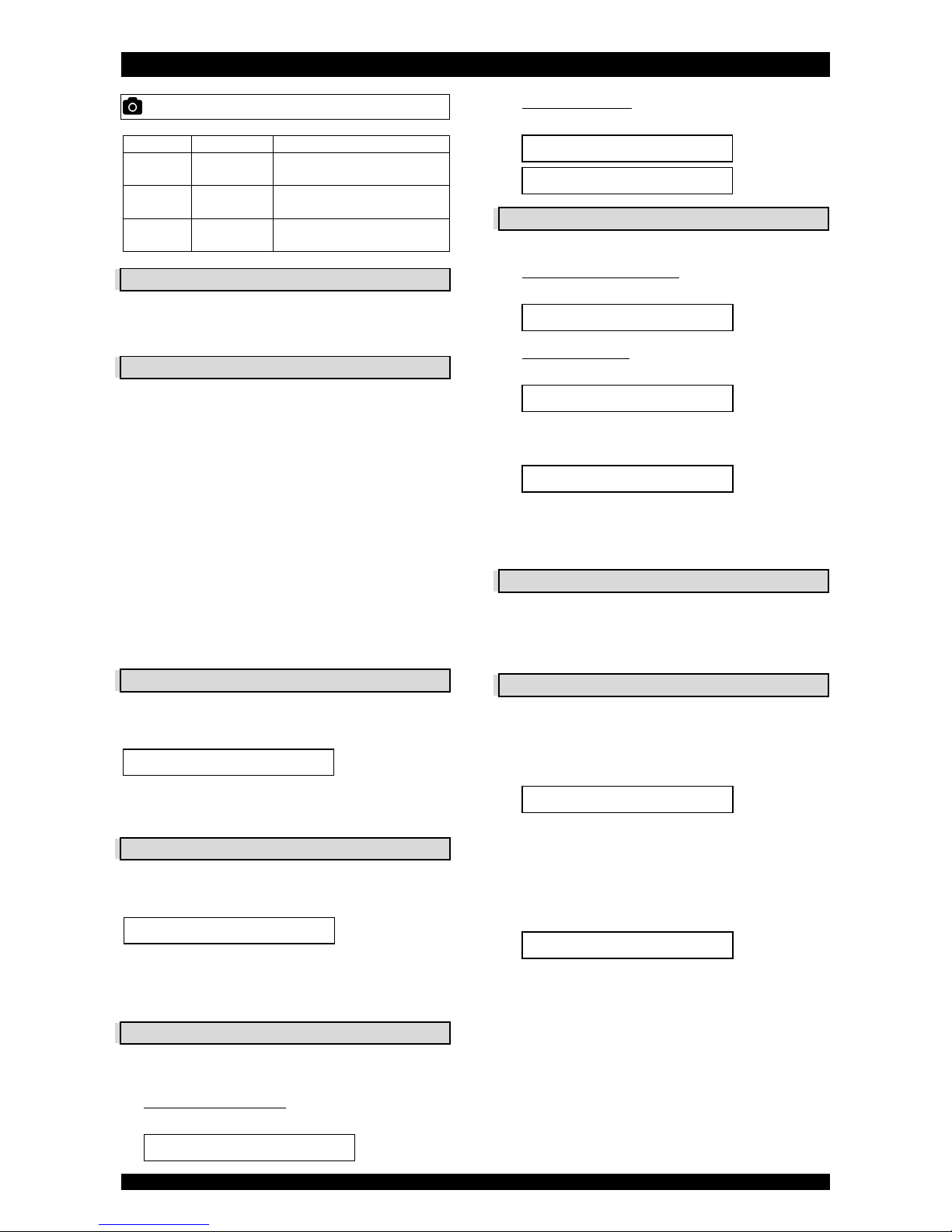

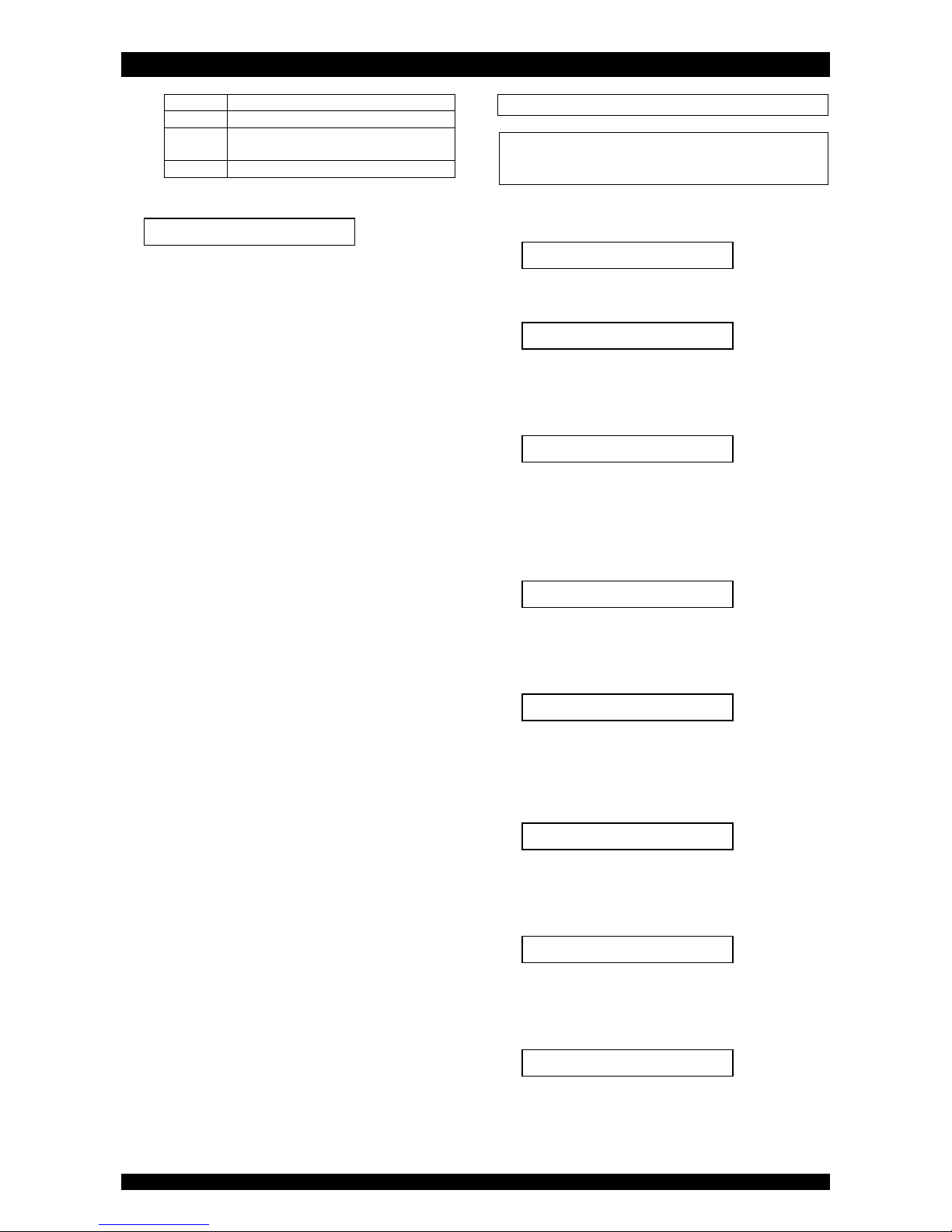

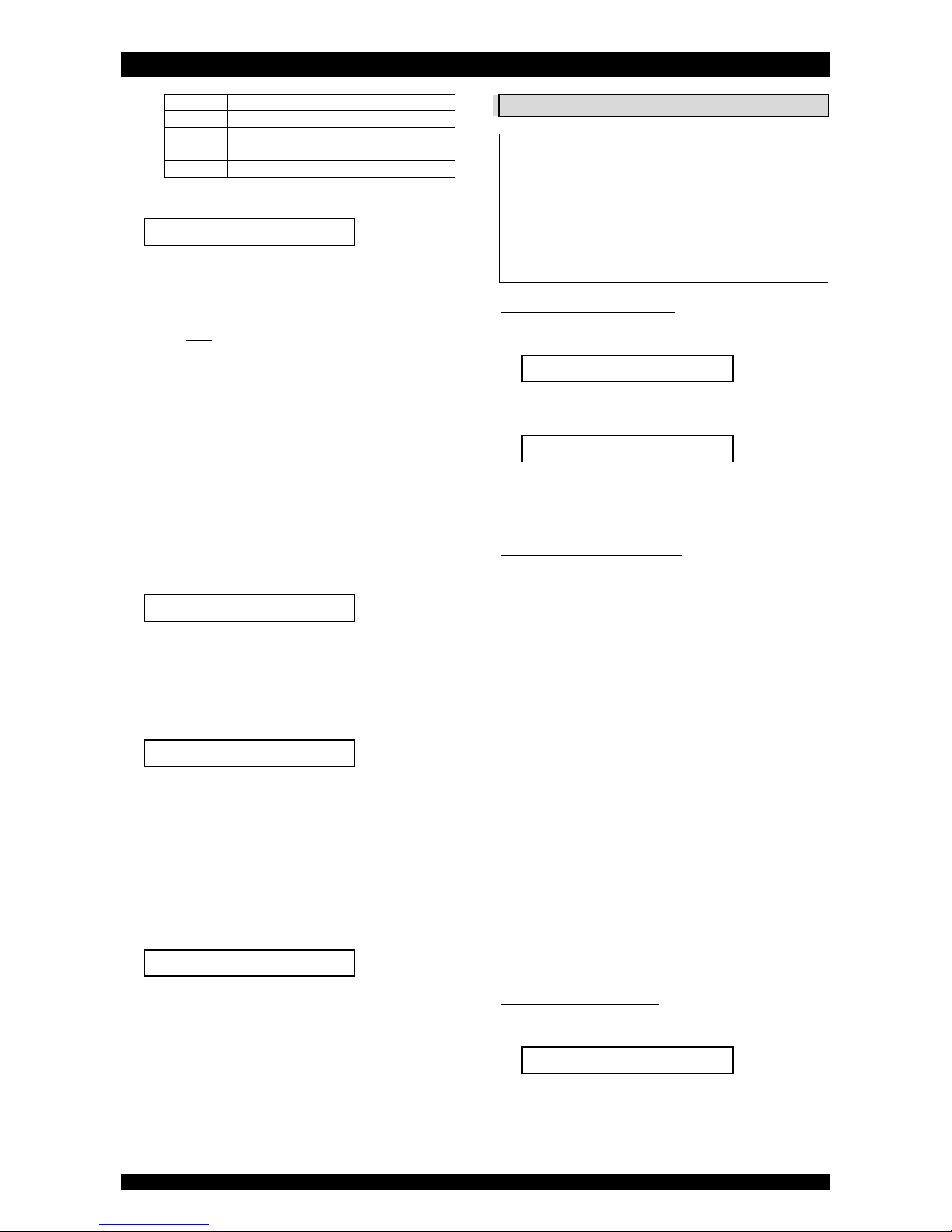

DEFAULT CONFIGURATION PARAMETER SETTINGS - PF-SOF1

Page 21

Model

PF-SOF1-SIM

Resin

25

50

75

100

150

Units

Metric

Metric

Metric

Metric

Metric

MaintInt (mths)

24

24

24

24

24

Exchange capacity per liter resin (°f M3/L)

(1) (2)

5,5

5,5

5,5

5,5

5,5

Age correction (%)

2.0

2.0

2.0

2.0

2.0

Resin (liters)

25

50

75

100

150

Override (days)

7 7 7 7 7

Cycle 1: BACKWASH (min)

5 5 5 5 5

Cycle 2: BRINE DRAW/SLOW RINSE (min)

48

76

104

77

87

Cycle 3: FAST RINSE/REFILL (min)

(2)

6 6 9

12

17

Regen

Dlyd/Immd

Dlyd/Immd

Dlyd/Immd

Dlyd/Immd

Dlyd/Immd

Regen @

2:00

2:00

2:00

2:00

2:00

Rsrv

Variable

Variable

Variable

Variable

Variable

(1) When the Hardness Unit is changed in the Basic Settings, the Exchange capacity per liter resin is automatically converted to the new Hardness Unit.

(2) When the Exchange capacity per liter resin is changed, the refill cycle time needs to be adjusted accordingly.

Model

PF-SOF1-ALT

Resin

25

50

75

100

150

Units

Metric

Metric

Metric

Metric

Metric

MaintInt (mths)

24

24

24

24

24

Exchange capacity per liter resin (°f M3/L)

(1)(2)

5,5

5,5

5,5

5,5

5,5

Age correction (%)

2.0

2.0

2.0

2.0

2.0

Resin (liters)

25

50

75

100

150

Override (days)

7 7 7 7 7

Cycle 1: BACKWASH (min)

5 5 5 5 5

Cycle 2: BRINE DRAW/SLOW RINSE (min)

48

76

104

77

87

Cycle 3: FAST RINSE/REFILL (min)

(2)

6 6 9

12

17

(1) When the Hardness Unit is changed in the Basic Settings, the Exchange capacity per liter resin is automatically converted to the new Hardness Unit.

(2) When the Exchange capacity per liter resin is changed, the refill cycle time needs to be adjusted accordingly.

Model

PF-SOF1-PRL

Resin

25

50

75

100

150

Units

Metric

Metric

Metric

Metric

Metric

MaintInt (mths)

24

24

24

24

24

Exchange capacity per liter resin (°f M3/L)

(1)(2)

5,5

5,5

5,5

5,5

5,5

Age correction (%)

2.0

2.0

2.0

2.0

2.0

Resin (liters)

25

50

75

100

150

Override (days)

7 7 7 7 7

Cycle 1: BACKWASH (min)

5 5 5 5 5

Cycle 2: BRINE DRAW/SLOW RINSE (min)

48

76

104

77

87

Cycle 3: FAST RINSE/REFILL (min)

(2)

6 6 9

12

17

Regen

Immediate

Immediate

Immediate

Immediate

Immediate

(1) When the Hardness Unit is changed in the Basic Settings, the Exchange capacity per liter resin is automatically converted to the new Hardness Unit.

(2) When the Exchange capacity per liter resin is changed, the refill cycle time needs to be adjusted accordingly.

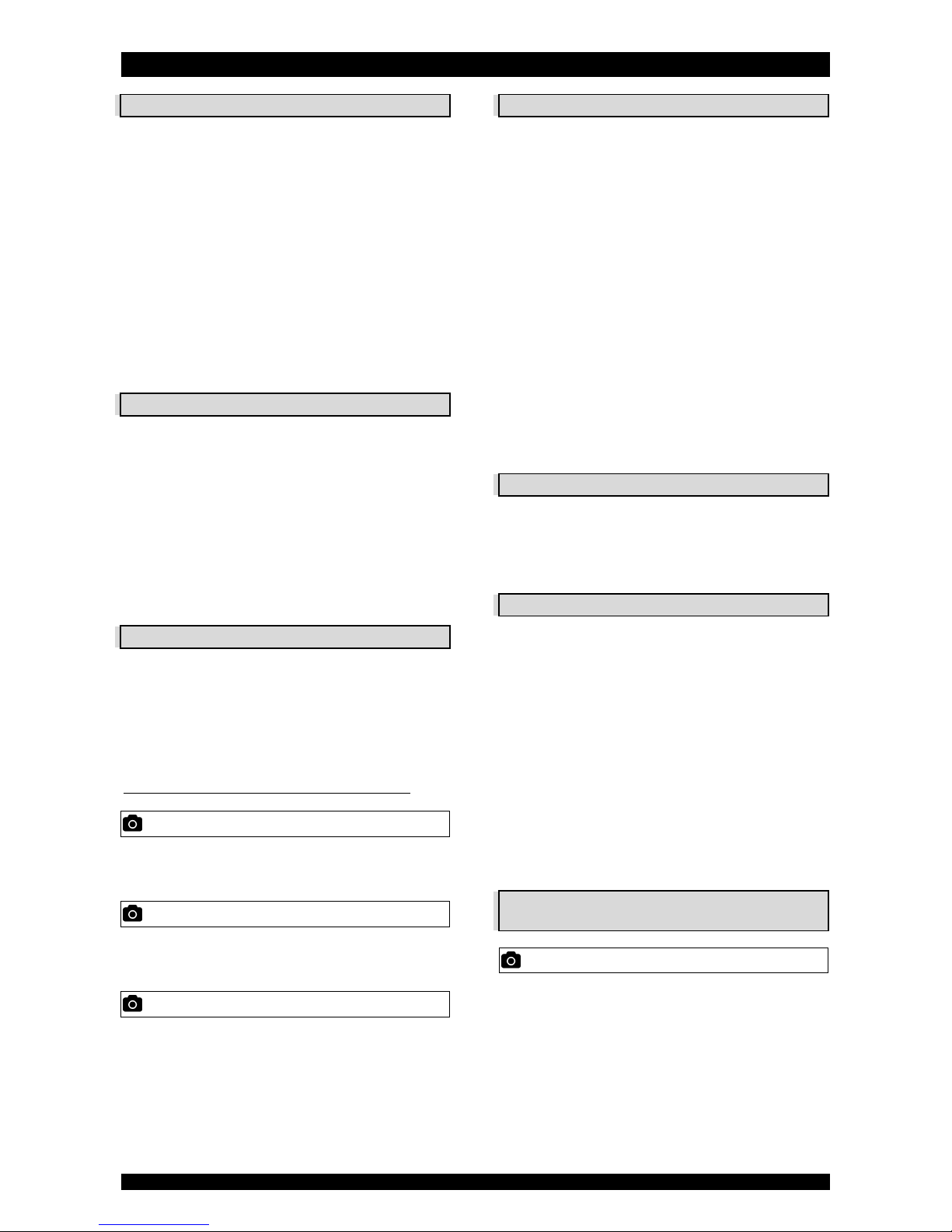

DEFAULT CONFIGURATION PARAMETER SETTINGS - PF-SOF1,5

Page 22

Model

PF-SOF1,5-SIM

Resin

75

100

150

200

250

350

500

Units

Metric

Metric

Metric

Metric

Metric

Metric

Metric

MaintInt (mths)

24

24

24

24

24

24

24

Exchange capacity per liter resin (°f M3/L)

(1)(2)

5,5

5,5

5,5

5,5

5,5

5,5

5,5

Age correction (%)

2.0

2.0

2.0

2.0

2.0

2.0

2.0

Resin (liters)

75

100

150

200

250

350

500

Override (days)

7 7 7 7 7 7 7

Cycle 1: BACKWASH (min)

5 5 5 5 5 5 5

Cycle 2: BRINE DRAW/SLOW RINSE (min)

43

39

58

42

53

62

88

Cycle 3: FAST RINSE (min)

(2)

11

14

17

16

16

13

14

Cycle 4: REFILL (min)

5 7 10 8 10

14

20

Regen

Dlyd/Immd

Dlyd/Immd

Dlyd/Immd

Dlyd/Immd

Dlyd/Immd

Dlyd/Immd

Dlyd/Immd

Regen @

2:00

2:00

2:00

2:00

2:00

2:00

2:00

Rsrv

Variable

Variable

Variable

Variable

Variable

Variable

Variable

(1) When the Hardness Unit is changed in the Basic Settings, the Exchange capacity per liter resin is automatically converted to the new Hardness Unit.

(2) When the Exchange capacity per liter resin is changed, the refill cycle time needs to be adjusted accordingly.

Model

PF-SOF1,5-ALT

Resin

75

100

150

200

250

350

500

Units

Metric

Metric

Metric

Metric

Metric

Metric

Metric

MaintInt (mths)

24

24

24

24

24

24

24

Exchange capacity per liter resin (°f M3/L)

(1)(2)

5,5

5,5

5,5

5,5

5,5

5,5

5,5

Age correction (%)

2.0

2.0

2.0

2.0

2.0

2.0

2.0

Resin (liters)

75

100

150

200

250

350

500

Override (days)

7 7 7 7 7 7 7

Cycle 1: BACKWASH (min)

5 5 5 5 5 5 5

Cycle 2: BRINE DRAW/SLOW RINSE (min)

43

39

58

42

53

62

88

Cycle 3: FAST RINSE (min)

(2)

11

14

17

16

16

13

14

Cycle 4: REFILL (min)

5 7 10 8 10

14

20

(1) When the Hardness Unit is changed in the Basic Settings, the Exchange capacity per liter resin is automatically converted to the new Hardness Unit.

(2) When the Exchange capacity per liter resin is changed, the refill cycle time needs to be adjusted accordingly.

Model

PF-SOF1,5-PRL

Resin

75

100

150

200

250

350

500

Units

Metric

Metric

Metric

Metric

Metric

Metric

Metric

MaintInt (mths)

24

24

24

24

24

24

24

Exchange capacity per liter resin (°f M3/L)

(1)(2)

5,5

5,5

5,5

5,5

5,5

5,5

5,5

Age correction (%)

2.0

2.0

2.0

2.0

2.0

2.0

2.0

Resin (liters)

75

100

150

200

250

350

500

Override (days)

7 7 7 7 7 7 7

Cycle 1: BACKWASH (min)

5 5 5 5 5 5 5

Cycle 2: BRINE DRAW/SLOW RINSE (min)

43

39

58

42

53

62

88

Cycle 3: FAST RINSE (min)

(2)

11

14

17

16

16

13

14

Cycle 4: REFILL (min)

5 7 10 8 10

14

20

Regen

Immediate

Immediate

Immediate

Immediate

Immediate

Immediate

Immediate

(1) When the Hardness Unit is changed in the Basic Settings, the Exchange capacity per liter resin is automatically converted to the new Hardness Unit.

(2) When the Exchange capacity per liter resin is changed, the refill cycle time needs to be adjusted accordingly.

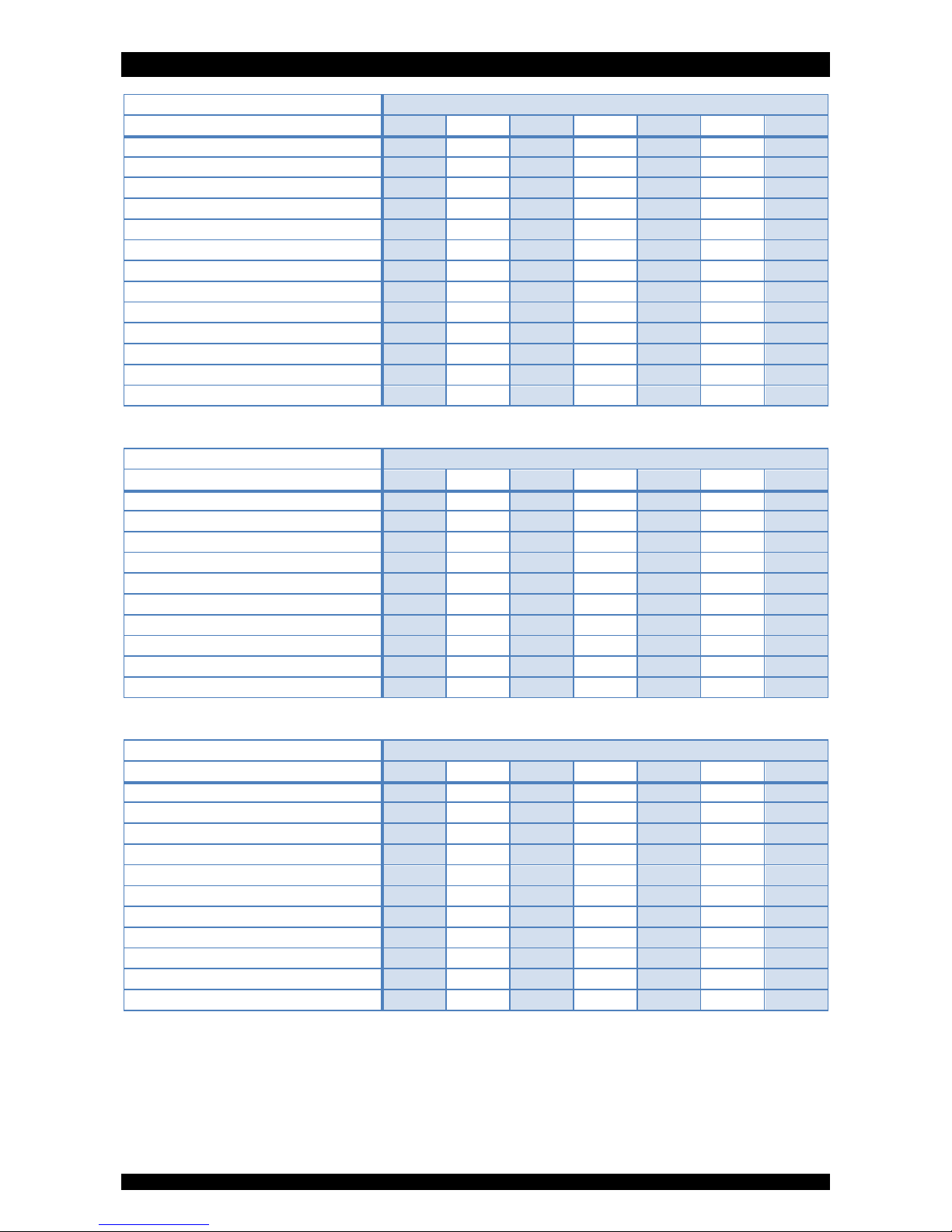

COMPOSITION OVERVIEW

Page 23

Model

Resin

volume

PN

Control valve, incl. transformer,

1” BSP Male connections

InterConnect

cable

Service Valve

1” BSP Female

Pressure tank,

incl. distributor assy

Resin

(25 ltr bag)

ltr model

# # model # model # #

PF-SOF1-SIM

25

35810

2400VS/J4JB/PRL1

1 0 / 0 10x35 1 1

50

35811

2400VS/J1KD/PRL1

1

0 / 0

12x48 1 2

75

35812

2400VS/J1LD/PRL1

1

0 / 0

13x54 1 3

100

35813

2400VS/J2MD/PRL1

1

0 / 0

14x65 1 4

150

35814

2400VS/J2ND/PRL1

1

0 / 0

16x65 1 6

PF-SOF1-ALT

2 x 25

35815

2400VS/J4JB/ALT

2 1 NC

(1)

2 10x35 2 2

2 x 50

35816

2400VS/J1KD/ALT

2 1 NC

(1)

2 12x48 2 4

2 x 75

35817

2400VS/J1LD/ALT

2 1 NC

(1)

2 13x54 2 6

2 x 100

35818

2400VS/J2MD/ALT

2 1 NC

(1)

2 14x65 2 8

2 x 150

35819

2400VS/J2ND/ALT

2 1 NC

(1)

2 16x65 2 12

PF-SOF1-PRL

2 x 25

35820

2400VS/J4JB/PRL1

2 1 NO

(2)

2 10x35 2 2

2 x 50

35821

2400VS/J1KD/PRL1

2 1 NO

(2)

2 12x48 2 4

2 x 75

35822

2400VS/J1LD/PRL1

2 1 NO

(2)

2 13x54 2 6

2 x 100

35823

2400VS/J2MD/PRL1

2 1 NO

(2)

2 14x65 2 8

2 x 150

35824

2400VS/J2ND/PRL1

2 1 NO

(2)

2 16x65 2 12

(1) NC = Normally Closed

(2) NO = Normally Open

Model

Resin

volume

PN

Control valve, incl. transformer,

flow meter, 1,5” BSP Male connections

InterConnect

cable

Service Valve

1,5” BSP Female

Pressure tank,

incl. distributor assy

Resin

(25 ltr bag)

ltr model

# # Model # model # #

PF-SOF1,5

-SIM

75

35825

EV1.5VS/J/5A/40/12

1 0 / 0 13x54 1 3

100

35826

EV1.5VS/J/5A/50/12

1

0 / 0

14x65 1 4

150

35827

EV1.5VS/J/5A/60/12

1

0 / 0

16x65 1 6

200

35828

EV1.5VS/J/5/80/20

1

0 / 0

18x65 1 8

250

35829

EV1.5VS/J/5/100/20

1

0 / 0

21x62 1 10

350

35830

EV1.5VS/J/6/150/20

1

0 / 0

24x72 1 14

500

35831

EV1.5VS/J/6/200/20

1

0 / 0

30x72 1 20

PF-SOF1,5

-ALT

2 x 75

35832

EV1.5VS/J/5A/40/12/ALT

2 1 NC

(1)

2 13x54 2 6

2 x 100

35833

EV1.5VS/J/5A/50/12/ALT

2 1 NC

(1)

2 14x65 2 8

2 x 150

35834

EV1.5VS/J/5A/60/12/ALT

2 1 NC

(1)

2 16x65 2 12

2 x 200

35835

EV1.5VS/J/5/80/20/ALT

2 1 NC

(1)

2 18x65 2 16

2 x 250

35836

EV1.5VS/J/5/100/20/ALT

2 1 NC

(1)

2 21x62 2 20

2 x 350

35837

EV1.5VS/J/6/150/20/ALT

2 1 NC

(1)

2 24x72 2 28

2 x 500

35838

EV1.5VS/J/6/200/20/ALT

2 1 NC

(1)

2 30x72 2 40

PF-SOF1,5

-PRL

2 x 75

35839

EV1.5VS/J/5A/40/12

2 1 NO

(2)

2 13x54 2 6

2 x 100

35840

EV1.5VS/J/5A/50/12

2 1 NO

(2)

2 14x65 2 8

2 x 150

35841

EV1.5VS/J/5A/60/12

2 1 NO

(2)

2 16x65 2 12

2 x 200

35842

EV1.5VS/J/5/80/20

2 1 NO

(2)

2 18x65 2 16

2 x 250

35843

EV1.5VS/J/5/100/20

2 1 NO

(2)

2 21x62 2 20

2 x 350

35844

EV1.5VS/J/6/150/20

2 1 NO

(2)

2 24x72 2 28

2 x 500

35845

EV1.5VS/J/6/200/20

2 1 NO

(2)

2 30x72 2 40

(1) NC = Normally Closed

(2) NO = Normally Open

EXPLODED VIEW - PF-SOF1-SIM

Page 24

EXPLODED VIEW - PF-SOF1-SIM

Page 25

(*) Recommended Spare Part

Item

PN

Description

Remark

(*)

1

PT/1035/BA

Pressure tank 10x35

25 Ltr

PT/1248/BA

Pressure tank 12x48

50 Ltr

PT/1354/BA

Pressure tank 13x54

75 Ltr

PT/1465/BA

Pressure tank 14x65

100 Ltr

PT/1665/BA

Pressure tank 16x65

150 Ltr 2

E8000

Softening resin

multiple of 25 ltr

3 38534

Riser tube assembly

to be cut to length

4 28/298/11

Transformer 230/24V - 50 Hz, 24VA, EuroT plug

28/298/18

Transformer 230/24V - 50 Hz, 24VA, UK plug

5

287/166

Top distributor

6

2400VS/J4JB/PRL1

Control valve

25 Ltr

2400VS/J1KD/PRL1

Control valve

50 Ltr

2400VS/J1LD/PRL1

Control valve

75 Ltr

2400VS/J2MD/PRL1

Control valve

100 Ltr

2400VS/J2ND/PRL1

Control valve

150 Ltr 7

568/303/1

Connection kit 1” BSP male

8

H1015/2

Brine line polytube

to be ordered per meter

9

38522

Drain hose

to be ordered per meter

10

74163

Air gap with double hose barb

11

38521

Clamp, drain hose (2x)

EXPLODED VIEW - PF-SOF1-ALT & PF-SOF1-PRL

Page 26

EXPLODED VIEW - PF-SOF1-ALT & PF-SOF1-PRL

Page 27

(*) Recommended Spare Part

Item

PN

Description

Remark

(*)

1

PT/1035/BA

Pressure tank 10x35

25 Ltr

PT/1248/BA

Pressure tank 12x48

50 Ltr

PT/1354/BA

Pressure tank 13x54

75 Ltr

PT/1465/BA

Pressure tank 14x65

100 Ltr

PT/1665/BA

Pressure tank 16x65

150 Ltr 2

E8000

Softening resin

multiple of 25 ltr

3 38534

Riser tube assembly

to be cut to length

4 28/298/11

Transformer 230/24V - 50 Hz, 24VA, EuroT plug

28/298/18

Transformer 230/24V - 50 Hz, 24VA, UK plug

5

287/166

Top distributor

6

2400VS/J4JB/ALT

Control valve for Duplex Alternating

PF-SOF1-ALT-25 Ltr

2400VS/J1KD/ALT

Control valve for Duplex Alternating

PF-SOF1-ALT-50 Ltr

2400VS/J1LD/ALT

Control valve for Duplex Alternating

PF-SOF1-ALT-75 Ltr

2400VS/J2MD/ALT

Control valve for Duplex Alternating

PF-SOF1-ALT-100 Ltr

2400VS/J2ND/ALT

Control valve for Duplex Alternating

PF-SOF1-ALT-150 Ltr

2400VS/J4JB/PRL1

Control valve for Duplex Parallel

PF-SOF1-PRL-25 Ltr

2400VS/J1KD/PRL1

Control valve for Duplex Parallel

PF-SOF1-PRL-50 Ltr

2400VS/J1LD/PRL1

Control valve for Duplex Parallel

PF-SOF1-PRL-75 Ltr

2400VS/J2MD/PRL1

Control valve for Duplex Parallel

PF-SOF1-PRL-100 Ltr

2400VS/J2ND/PRL1

Control valve for Duplex Parallel

PF-SOF1-PRL-150 Ltr

7 568/303/1

Connection kit 1” BSP male

8

74136

Service valve, Normally Closed

PF-SOF1-ALT

74137

Service valve, Normally Open

PF-SOF1-PRL

9 74089

Brass adaptor 1” male

10

H1015/2

Brine line polytube

to be ordered per meter

11

74069

InterConnect cable

12

38522

Drain hose

to be ordered per meter

13

74163

Air gap with double hose barb

14

38521

Clamp, drain hose (4x)

EXPLODED VIEW - PF-SOF1 - TIMER ASSEMBLY

Page 28

EXPLODED VIEW - PF-SOF1 - TIMER ASSEMBLY

Page 29

(*) Recommended Spare Part

Item

PN

Description

Remark

(*)

1

70971

Power lead with plug

2

72263

Clamp 3 72519

Flow meter cable

4

28/8/7

Strain relief, flow meter cable

5

71502

Screw, timer cover (3x)

6

15/222

Screw, back plate (2x)

7

74135

Socket and cable assembly, Service Valve

8

72369

Back plate

9

75157

Worm coupling

10

15/222

Screw, drive motor assembly (2x)

11

74267

Cable clamp

12

70312

Strain relief, power lead

13

74105

Socket & cable assembly, InterConnect

14

75158

Retaining ring, worm drive shaft

15

72261

Drive motor

16

75156

Worm drive shaft

17

70965

Switch cam

18

568/386

Bracket, micro switches

19

568/310

Gear, switch cam

20

15/184/7

Locking screw, switch cam

21

15/173/12

Screw, micro switches (2x)

22

72451

Micro switch assy

23

71679

Cable set, drive motor

24

15/102

Screw, PCB (2x)

25

74167

Printed Circuit Board, Alternating

PF-SOF1-ALT

74106

Printed Circuit Board, Simplex & Parallel

PF-SOF1-SIM & PF-SOF1-PRL

26

72614

Timer cover assembly

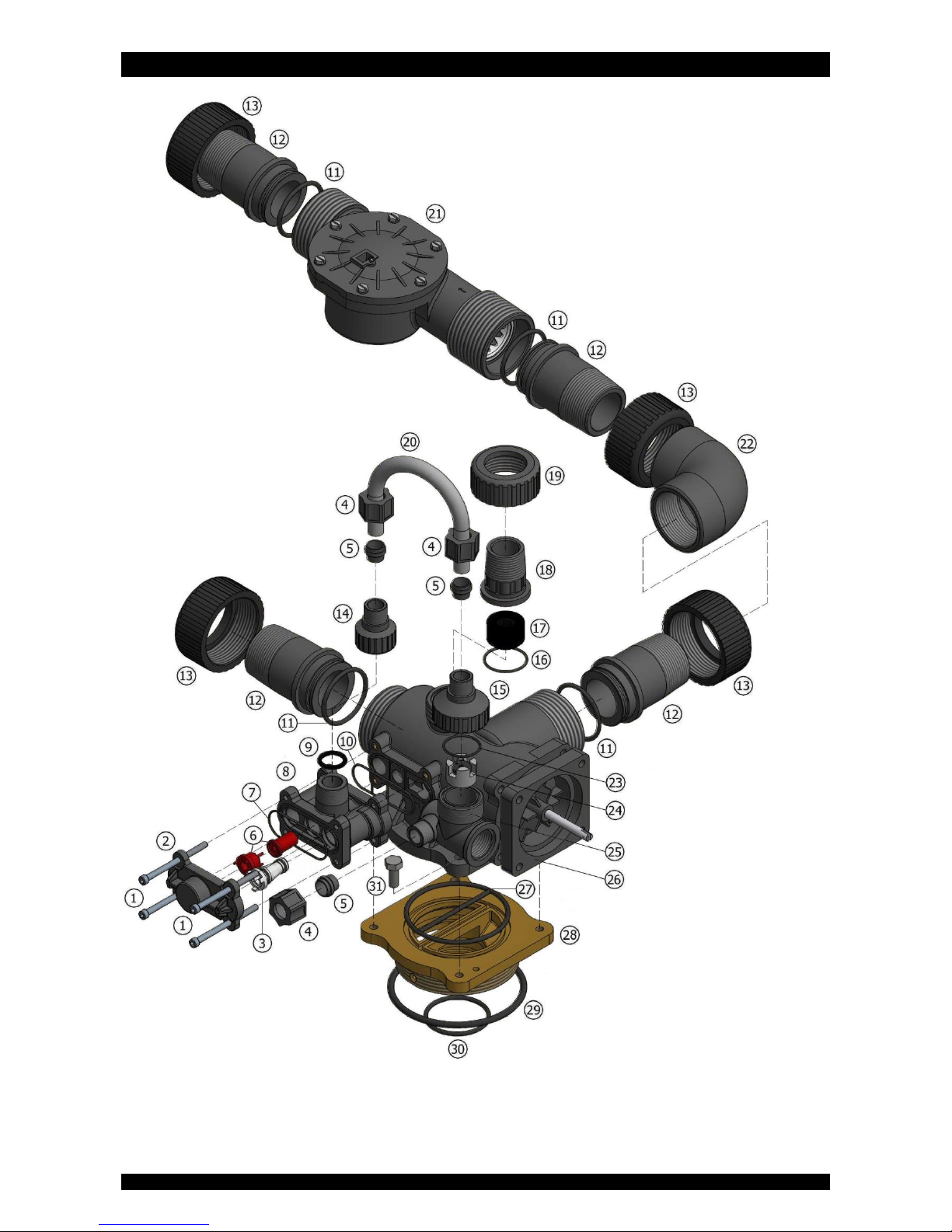

EXPLODED VIEW - PF-SOF1 - VALVE BODY

Page 30

EXPLODED VIEW - PF-SOF1 - VALVE BODY

Page 31

(*) Recommended Spare Part

Item

PN

Description

Remark

(*)

1

21/83

Drain connection

2

568/271/J

Drain Line Flow Control J (9,8 Ltr/min)

25 Ltr

568/271/K

Drain Line Flow Control K (13,2 Ltr/min)

50 Ltr

568/271/L

Drain Line Flow Control L (15,1 Ltr/min)

75 Ltr

568/271/M

Drain Line Flow Control M (18,9 Ltr/min)

100 Ltr

568/271/N

Drain Line Flow Control N (22,7 Ltr/min)

150 Ltr 3

72678

Bolt, valve cover (6x)

4

568/254/3

Valve cover

5

185/154/1

O-ring, valve cover

6

186/112

O-ring, Teflon

7

72327

Washer, PE

8

568/260

Worm gear

9

568/259

Rotor cam

10

185/041/1

O-ring, rotor

11

568/345/2

Rotor plate

12

568/256

Seal disk

13

568/383

Insert plate

14

568/384

Gasket

15

51/5/105

Spring, float valve

16

568/270/4