Profire Energy PF3100, PF3100-00A/C, PF3101-00A Series Manual

PF3100 MANUAL

REV: 1.0

with UI, BMS Controller, Network Expansion,

Modbus RS-485, Ion Pilot, and Thermocouple Cards

IMPORTANT SAFETY INFORMATION

Ambient Operating Temperature Range -40°C to +60°C

GENERAL WARNINGS

Installation & use must conform to the directions in this guide.

System must be properly connected to earth-ground for effective operation of flame detection circuitry.

Electrical devices connected to the controller must meet certain electrical standards and be within voltage limits.

Replacement fuses must be ceramic and of correct rating.

Avoid unauthorized replacement of the fuse.

MODELS: PF3100-00A/C, PF3101-00A

Warnings

1. This equipment is suitable for use in Class I, Div 2, Groups A, B, C, and D hazardous locations or non-hazardous

locations only.

2. WARNING – EXPLOSION HAZARD – Do not disconnect equipment while the circuit is live or unless the area is

known to be free of ignitable concentrations.

3. WARNING – EXPLOSION HAZARD – Substitution of components may impair suitability for Class I, Div 1

hazardous locations.

MODELS: PF3102-00A

Warnings

1. This equipment is suitable for use in Class I, Div 1, Groups A, B, C, and D hazardous locations or non-hazardous

locations only.

2. WARNING – EXPLOSION HAZARD – Do not disconnect equipment while the circuit is live or unless the area is

known to be free of ignitable concentrations.

3. WARNING – EXPLOSION HAZARD – Substitution of components may impair suitability for Class I, Div 1

hazardous locations.

4. The flame rods are not intended to be installed and mounted in a Class I, Division 1 or Division 2 hazardous

location. Routing and installation of the flame rods shall be in accordance with the Canadian Electrical Code or

National Electrical Code as per local requirements.

5. CAUTION – Conduit seal required within 18” of enclosure. Div 2 seal not required.

MODELS: PF3103-00B

Warnings

1. This equipment is suitable for use in Class I, Div 1, Groups A, B, C, and D hazardous locations or non-hazardous

2. WARNING – EXPLOSION HAZARD – Do not disconnect equipment while the circuit is live or unless the area is

3. WARNING – EXPLOSION HAZARD – Substitution of components may impair suitability for Class I, Div 1

4. This assembly must be used with approved Profire probes and thermowells to maintain hazardous locations

locations only.

known to be free of ignitable concentrations.

hazardous locations.

certification.

E474004

PRIMARY SAFETY CONTROL

FOR USE IN HAZARDOUS LOCATIONS

TABLE OF CONTENTS

Introduction 1

Modules 1

Features 2

Specifications 2

Mounting Considerations 3

Installation Warnings 4

Wiring Pinouts 4

Wiring 5

PFRN Power and Communication 7

Display User Interface 8

Menu Map 9

Operation 15

Troubleshooting 16

System Errors 17

Resetting to Defaults 17

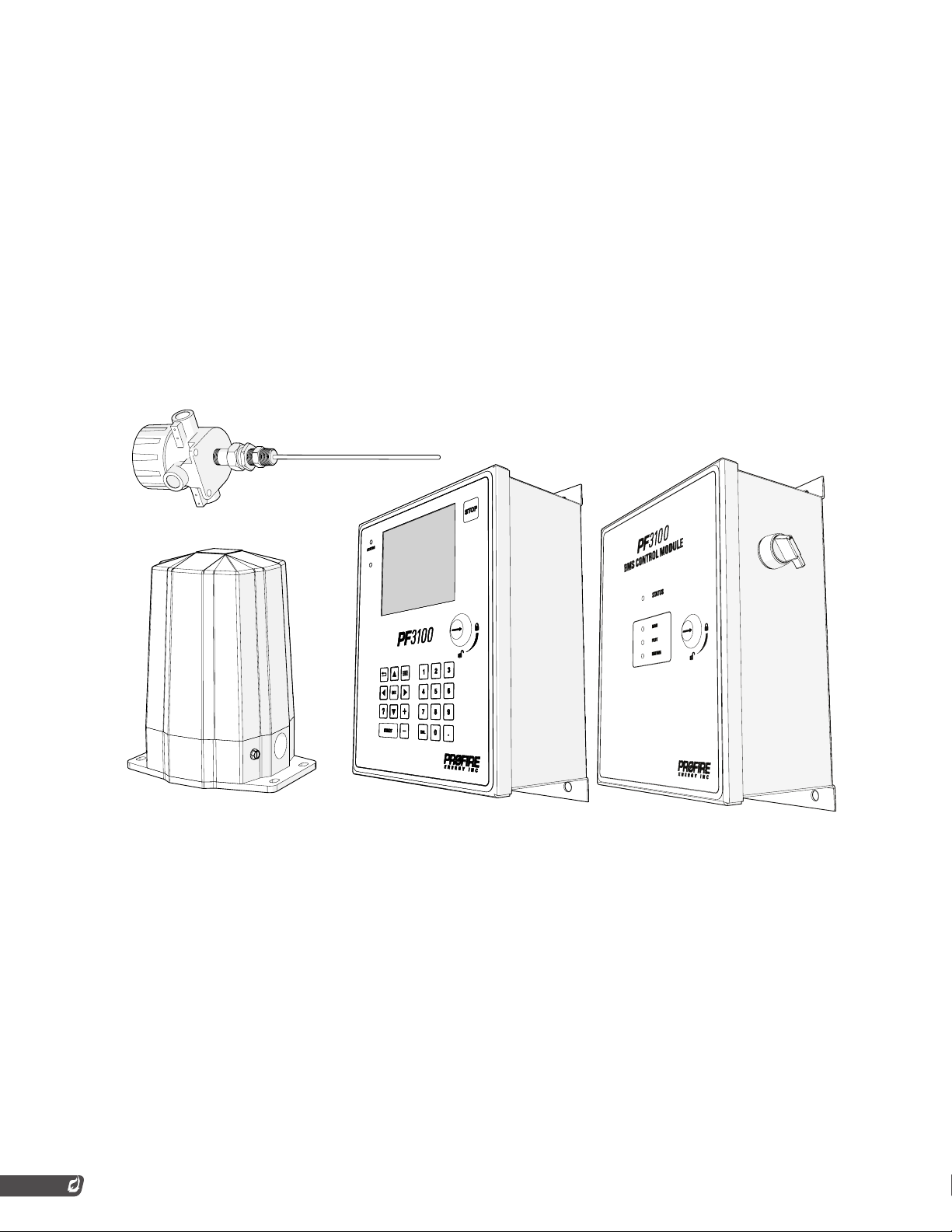

PF3100 MODULE FAMILY

INTRODUCTION

The PF3100 burner management system consists of individual building blocks called modules which can

be mixed and matched to form a complete solution. Each module performs a specific function and is

intended to be installed close to the device they are measuring or controlling. This simplifies wiring and

reduces issues with noise and signal loss compared to centralized control systems. This also allows the

user to purchase only the modules which are necessary for a given application. The modules interact with

one another using a network based communication method to perform a given task safely.

MODULES

UI Module

UI Network Module

UI BMS Module

UI BMS Network Module

UI Modbus Module

UI Modbus BMS Module

BMS Module

BMS Network Module

Ion Pilot Module

Type K Temperature Module

1

FEATURES

• Can view the status of other modules through the PFRN network from the UI Module

• Multiple UIs can show the same info on each screen

• Able to mount the UI away from the burner

• Simple indication of overall status through LEDs allowing end-users to check statuses from afar

• UI’s LCD screen shows statuses of overall system, individual modules, and groups of modules

• Numeric keypad is on the UIX enclosure for easy data entry

• Data logging and field firmware updates

• BMS modules in BMS enclosures can be placed near the burner housing away from the UI interface

• BMS Controller cards provide power to other modules through PFRN ports

• Network cards allow for connections to many other modules to form a single communication network

SPECIFICATIONS

Card Specs

Specs UI Card Network Card BMS Card Modbus Card Ion Pilot Card Thermocouple

Card Type Interface Network Controller IO IO IO

Power Method Power

Voltage Input 36 VDC through

Number of Ports 1 PFRN Port 5 PFRN Ports 5 PFRN Ports 4 PFRN Ports 1 PFRN Port 1 PFRN Port

Fuse Rating N/A 6.3 A 10 A 500 mA N/A N/A

Fuse Part

Number

Fuse MFG N/A Schurter Schurter Schurter N/A N/A

Consumer

PFRN

N/A 3412.0113.22 1.2514 3412.0113.22 N/A N/A

Power Producer Power Producer Power Producer Power

Consumer

12/24 VDC 12/24 VDC 12/24 VDC 36 VDC through

PFRN

Card

Power

Consumer

36 VDC through

PFRN

Enclosure Specs

Specs UIX Enclosure BMS Enclosure AUX Enclosure EPX Enclosure TLX Enclosure

Dimensions Width 30.9 cm

Hazloc Rating Class I Div 2 Class I Div 2 Class I Div 2 Class I Div 1 Class I Div 1

Operating

Temperature

Storage

Temperature

(12.15 in)

Height 23.4 cm

(9.23 in)

Depth 13.4 cm

(5.28 in)

-40°C to 60°C -40°C to 60°C -40°C to 60°C -40°C to 60°C -40°C to 60°C

-40°C to 60°C -40°C to 60°C -40°C to 60°C -40°C to 60°C -40°C to 60°C

Width 30.9 cm

(12.15 in)

Height 23.4 cm

(9.23 in)

Depth 13.4 cm

(5.28 in)

Width 30.9 cm

(12.15 in)

Height 23.4 cm

(9.23 in)

Depth 13.4 cm

(5.28 in)

Top Width 11.7 cm

(4.61 in)

Base Width 16.8

cm (6.63 in)

Height 21.7 cm

(8.53 in)

Depth 13.3 cm

(5.25 in)

(Body Type)

Standard ½” NPT

Head Connection

2

MOUNTING CONSIDERATIONS

Orientation

The UIX, CTX, and AUX enclosures should be mounted upright.

The EPX and TLX enclosures can be mounted in whichever direction makes sense for

the application.

Location

1. The UI Module is typically mounted in an operator-safe, easily accessible area. The

recommended mounting height is 1.5m (5ft) above where the operator will be standing

for ease of use. If there is a BMS card in the UIX enclosure with the UI card, then you

will need to adjust the location accordingly.

2. Mount any BMS enclosures near the corresponding valve train.

3. The Thermocouple card is included inside of a head connection (TLX enclosure) with a

thermocouple probe. The Type K Temperature module comes ready to install into the

thermowells of each tank. Install in a Div 1 rated thermowell.

4. The Ion Pilot module should be located within 50 feet of the pilot it is igniting.

5. The Network and Modbus cards will typically be mounted inside of a UIX, CTX, and AUX

enclosure. Must be within max PFRN run length of 250 ft.

HAZARDOUS LOCATION MOUNTING

In order to maintain the hazardous location rating for the EPX Enclosure, the following conditions must be

met.

The EPX Enclosure lid must be tightened down until it is flush with the base. The locking

screw must be installed into the base.

Each unused base port must be sealed with pipe plugs. Use our plugs or figure out

appropriately rated plugs that are equivalent.

Any base ports in use must be sealed within 18 inches of the EPX Enclosure. All fittings must

have at least 5 threads of engagement.

3

INSTALLATION WARNINGS

Before installing the PF3100, please review the following list of warnings.

Failure to observe the following may result in death, electrocution,

property damage, product damage, and/or government fines.

1. For burners greater than 12.5 MMBtuh, additional modules may be required for use with

the PF3100 system.

2. It is recommended that the low fire feature be used with anything above 1 MMBtuh. To

use the PF3100 on burners greater than 5 MMBtuh, the Proof of Closure feature must

be used.

3. Failure to properly ground the pilot assembly back to the PF3100’s Ion terminal may

result in accidental electrocution, product damage, or failure to ignite the pilot.

4. The PF3100 generates 20kV - 40kV at its high voltage output terminal which can cause

cardiac arrest. Do not touch or place any object near the ignition coil’s high voltage

terminal or connected ignition wire while the product is operating. Even without making

physical contact with the terminal, it is possible to draw a spark from several inches

away, especially if the pilot bracket is not properly grounded.

5. Make sure that the PF3100 enclosures are securely closed each time after opening

the enclosure. This protects the internal circuitry from moisture damage and other

environmental concerns. Moisture damage is not covered by the product warranty if the

door has been left open.

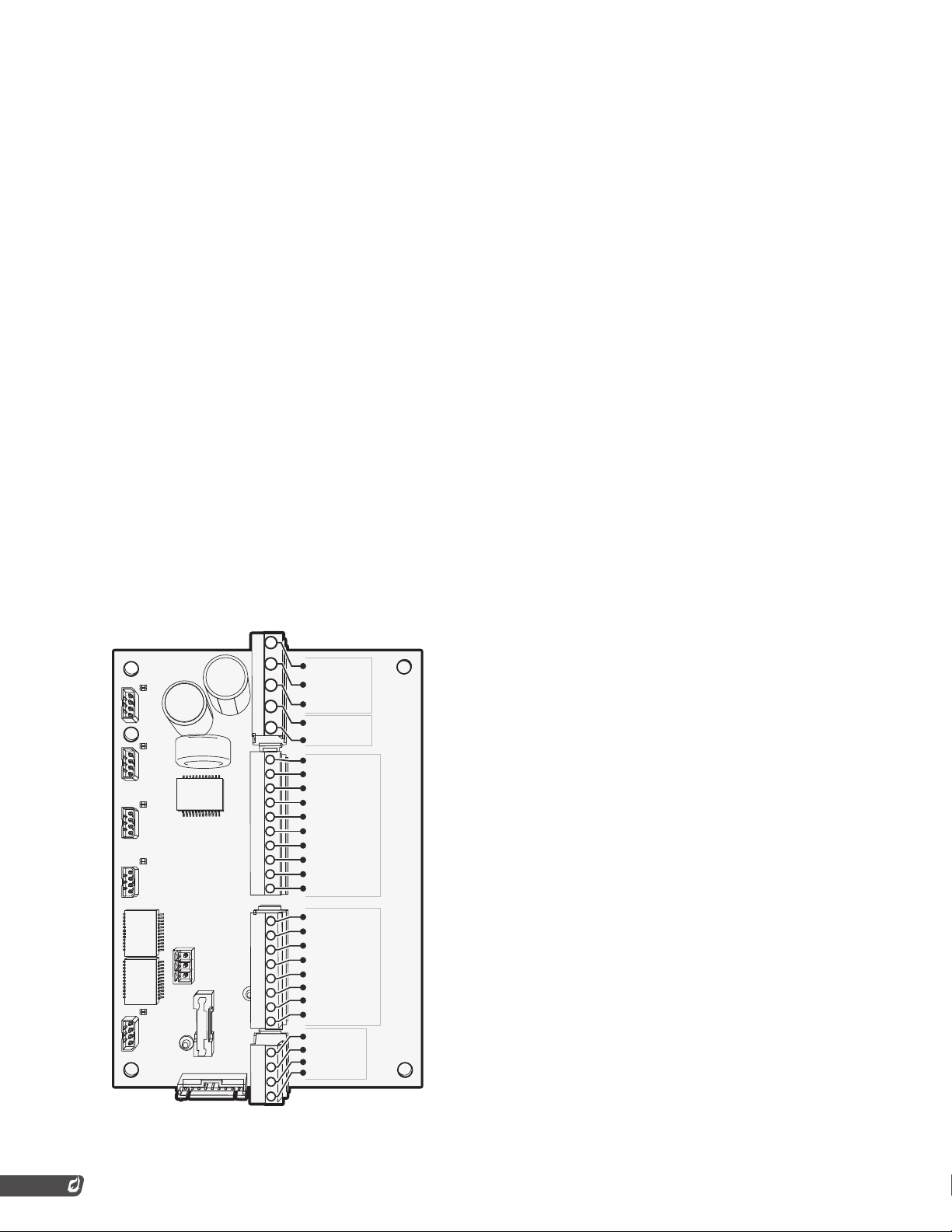

WIRING PINOUTS

/ VDC

/ VDC

COMMON

COMMON

EARTH GND

EARTH GND

STATUS

STATUS

HFV

HFV

HFV +

HFV +

SSV

SSV

SSV +

SSV +

SSV

SSV

SSV +

SSV +

Pilot -

Pilot -

Pilot +

Pilot +

Aux Out - (4-20mA)

Aux Out - (4-20mA)

Aux Out + (4-20mA)

Aux Out + (4-20mA)

START

START

START +

START +

POC

POC

POC +

POC +

AUX IN

AUX IN

AUX IN +

AUX IN +

ESD

ESD

ESD +

ESD +

PRESSURE

PRESSURE

PRESSURE +

PRESSURE +

LEVEL

LEVEL

LEVEL +

LEVEL +

Power

Power

Input

Input

Output

Output

Relay

Relay

Powered Outputs Dry Contact Inputs

Powered Outputs Dry Contact Inputs

Dry Contact

Dry Contact

4-20mA /

4-20mA /

Inputs

Inputs

*Output terminals are limited to 4A max current draw. 4-20 mA output terminals are limited to 20mA.

4

Loading...

Loading...