Profi-pumpe PSM01134U, PSM01135U Operating Instructions Manual

Inverter pump control

Inverter pumpensteuerung

Version 18.12.

OPERATING INSTRUCTIONS

BEDIENUNGSANLEITUNG

de

Technical changes, misprints and mistakes reserved! Newest information about our products can be found online

Technische Änderungen, Druckfehler und Irrtümer vorbehalten! Aktuelle Informationen zu unseren Produkten nden Sie auf:

http://www.pro-pumpe.de

INVERTER-PUMPENSTEUERUNG 2-1,1KW

unverkabelt (IPC-2-UV)

(PSM01134U)

INVERTER-PUMPENSTEUERUNG 3-2,2KW

unverkabelt (IPC-3-UV)

(PSM01135U)

Contents

1. Introduction ......................................................................................................................... 2

2. In general ............................................................................................................................ 2

3. Installation ........................................................................................................................... 3

4. Wiring .................................................................................................................................. 3

5. Operation ............................................................................................................................. 4

6. Security tips ......................................................................................................................... 5

7. Servicing ............................................................................................................................. 7

8. Maintenance ....................................................................................................................... 8

9. Guarantee regulations ........................................................................................................ 8

10. Recognising and repairing of mistakes ............................................................................... 8

11. Notes on Product Liability .................................................................................................. 8

12. Notes on Disposal .............................................................................................................. 9

13. EU Declaration of Conformity ............................................................................................ 9

14. Technical Data ................................................................................................................. 20

2 English English 3

SAFETY INSTRUCTION AND WARNINGS

Please read the user manual

before using the device

Pull power plug

Warning sign Warning of electrical voltage

1. INTRODUCTION

We would like to congratulate you on the purchase of our Inverter pump control. We appreciate your

trust. That‘s why funtional security and operational safety stands by us on rst place.

To prevent damage to persons or property, you should read this user manual carefully. Please observe all safety precautions and instructions for proper use of the

device. Failure to follow the instructions and safety precautions can result in injury

or property damage.

Please keep this manual with the instructions and safety instructions carefully in

order to at any time you can restore them. Please always download the latest version

of the user manual of www.pro-pumpe.de under „downloads“. This shall always

prevail.

3. INSTALLATION

The installation must be performed by a qualied professional.

Please, check each time before using, the electrical connections and the cables are not

damaged. Check before the installation whether the electrical connections are earthed

according to the statutory regulations and are installed.

Also, it is NOT recommended to perform, for example, a cable extension. It is not certain

whether this modication is technically correct, so this warranty is void.

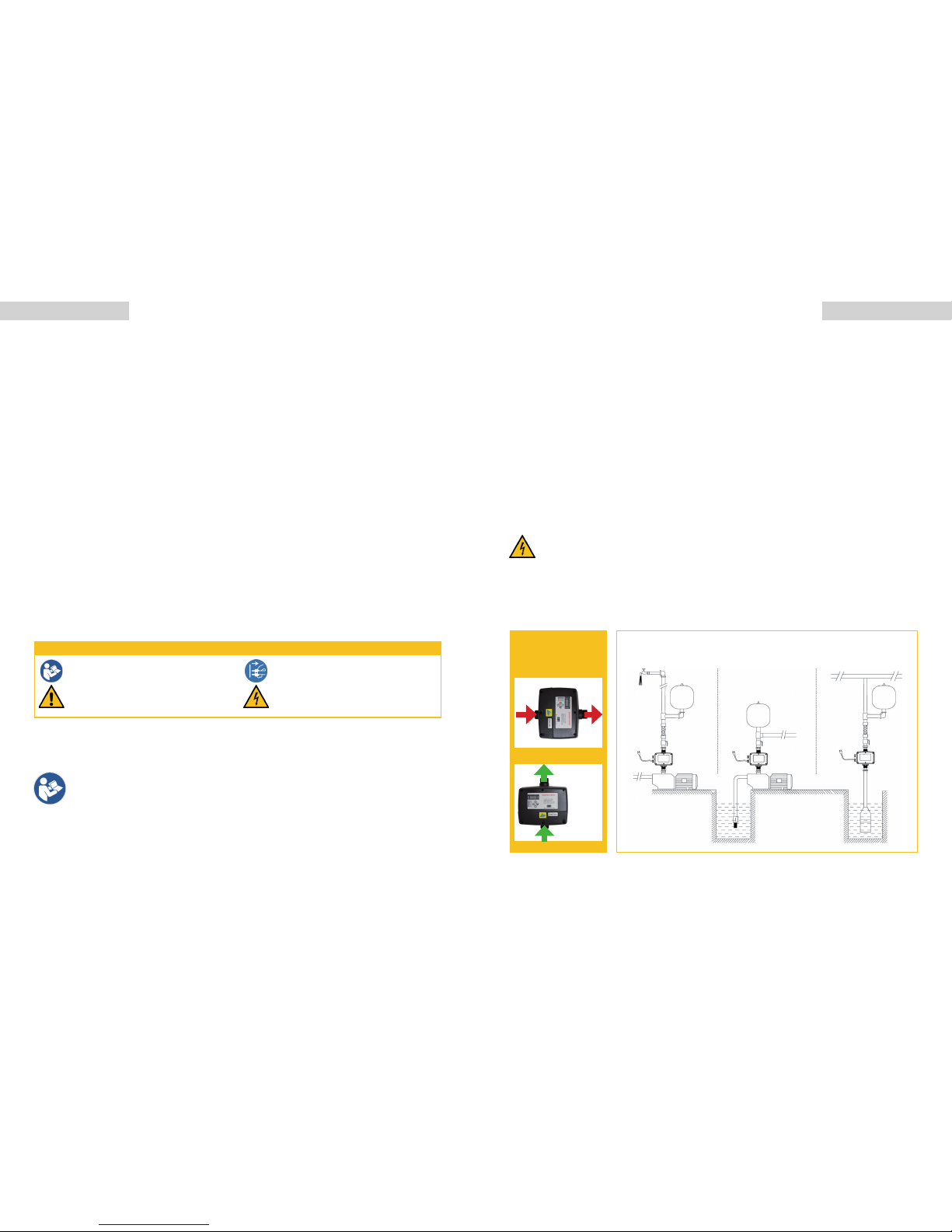

3.1 IPC-2-UV / IPC-3-UV

Single-phase Inverter

Water booster

installation mode

Self-priming pump

installation of water

supply mode

Submersible pump

installation of water

supply mode

The device must not

be installed horizon-

tally.

X

3

2. IN GENERAL

The inverter pump control is a switching device which can automatically switch an electrical consumer (pump) on and off. The device monitors the pressure and the ow in the pressure line. Depending on the pressure or the ow rate, it switches on and off of the inverter pump control one or more

electrical loads (MAX 10A) to the pump control.

The inverter controls can be easily operated with pumps with integrated non-return valve/ap can be

used.

The inverter pump control should only be used for non-abrasive clear water without deposits and

other dirt. In the opposite case, an effective pre-lter with a mesh size not larger than 0.2 mm must

be installed in front of the unit.

After unpacking the unit, make sure that the lter dimensions indicated on the nameplate are correct.

data correspond to the intended operating conditions. In case of doubt, do not operate the unit.

Transport damage must be reported immediately to the forwarding company and to us in writing.

PRESSURE

TANK

PRESSURE

TANK

PRESSURE

TANK

4 English English 5

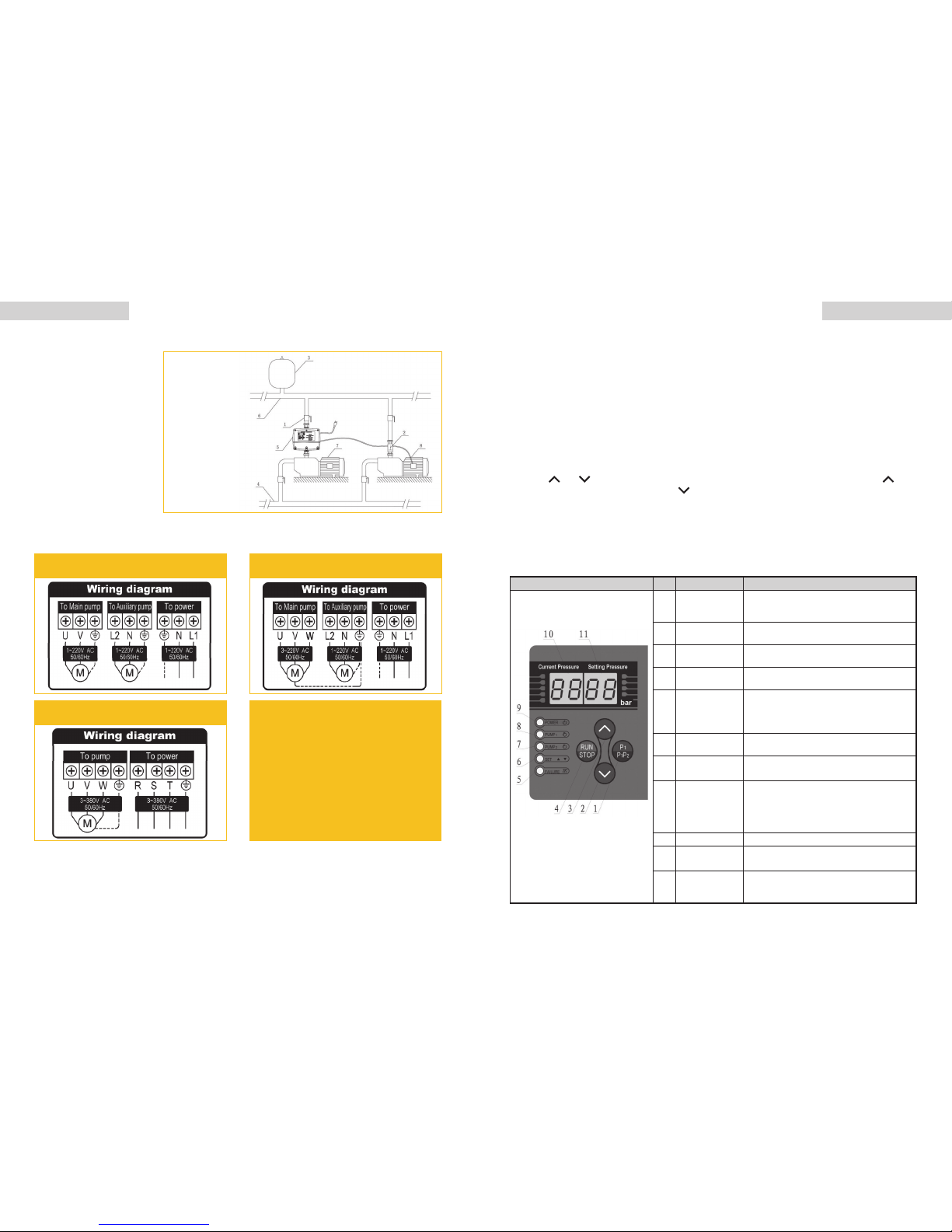

INVERTER

PUMPENSTEUERUNG

IPC-2-UV / IPC-3-UV

Double Pump Installation

4. WIRING: IPC-2-UV / IPC-3-UV

Wiring Diagram and Instruction

Additionally

required parts

1. Ball valve

2. Check valve

3. Pressure tank

4. Inlet pipe

5. Inverter

6. Outlet pipe

7. Main pump

8. Auxiliary pump

Single-phase in and single-phase out

(with auxiliary pump)

Three-phase in and three-phase out

wiring diagram

Single-phase in and three-phase out

(auxiliary pump)

1. Don‘t connect the AC main circuit power

supply and output terminals U, V, W.

2. Wiring after the power cut off.

3. To verify the inverter rated voltage and the

input supply voltage are consistent

4. The inverter can‘t be done the dielectric

voltage withstand Test.

5. Terminal screw tightening torque 1.7N.m.

6. Make sure the ground terminal is connected

before wiring the main circuit terminals.

7. Connect the input power after installing the

panel,when the power is connected, don‘t

remove the panel

5. OPERATION

5.1 IPC-2-UV / IPC-3-UV

5.1.1 Checking before Operation

1. Check the input power and surroundings is comply with the conditions of using.

5.1.2 Button and Function Instruction PC-2-UV

Schematic Diagram No. Name or Function Instruction

1

Start or stop

button of auxiliary

pump

Start auxiliary pump manually, press it, the

pump runs

2 Reduce button

Press the button one time can reduce 0.1bar,

long time press can reduced rapidly

3 Increase button

Press the button one time can increase 0.1bar,

long time press can increase rapidly

4

RUN/STOP

button

It can start the pump manually, press this button

to exit the water shortage state

5

Water shortage

indicator

The indicator flash , it means the pipe is watershort. It will restart in setting time and the

interval time for restart is 8S, 1min , 10min ,

30min , 1h , 2h ....restart

6

Pressure setting

indicator

The light is flashing when working in the setting

pressure value

7

auxiliary pump

indicator

When the pump stop automatically,the indicator

lights,when stop pump manually,the indicator is off

8 Pump indicator

When the main pump speed operating state or

standby state,the indicator flash quickly.when

the main pump at the constant speed (constant

pressure) work state, the indicator flash slowly.

when the indicator is off,the main pump stop

9 Power indicator Indicator lights up when power is connected.

10

Current pressure

display

Display value indicates the current pipe network

pressure value,unit:bar

11

Set pressure

display area

Display value indicates the current setting

pressure value,unit:bar. Factory default Settings

is 3bar

2. Check whether the pressure sensor is connected with the system .

3. Check whether the product is installed rmly .

4. The pump starts (it is essential to refer to the operating instructions for the pump to nd out

what conditions must be met before starting up the pump) after connection is veried. If the

pump is three phase, please check whether the direction of motor revolve is correct. If the motor

rotates inversely, please exchange the terminal of UV, WV or WU, also it can be reversed adjust

through the slide switch.

5.1.2 Operating Steps

1. Connect power ,pressure display “00.00”bar, the power indicator lights.

2. Open the outlet valve,press “RUN” and start the pump

3. Any conditions can press “STOP”, and stop the pump

4. Press “

” or “ ” can check the working pressure, if want to change the pressure press “ ” to

increase the setting pressure or press “

” to reduce the setting pressure

5. Open the tap after setting pressure, the inverter will take frequency speed control on pump according to the water using status .Observing whether the pump is running normally, the pressure

showed in the display whether is constant. If it does, the installation and debugging is nished,

content to remove the faults and debug it again .

PRESSURE

TANK

6. SECURITY TIPS

l Obey absolutely valid regulations on the electrical security

l To avoid shocks and re risks, read and follow closely the following instructions:

• Always unplug the device from the mains before carrying out any work on it.

• Be sure that the electric line connecting the device to the mains and the extension

leads have a cross-section suitable for pump power and be sure that the electrical connections are far away from any water source

• When Flow guard is used for swimming pools, ponds and fountains if is necessary to

use an automatic RCD with IDn = 3OmA protection.

Warning: when the pump stops, the pipes are under pressure consequently we recom-

mend opening a tap to discharge the system before carrying out any work.

l The electrical connections are always to be carried out by an authorised professional.

l The device may be used by children aged 8 years and above as well as persons with reduced

physical, sensory or mental abilities or those who lack skills, experience and knowledge only if

they are supervised. These aforementioned persons should only use the appliance while adhering to safe instructions and resulting dangers.

l Cleaning and maintenance must not be carried out by children without supervision.

THE MANUFACTURER EXPLAINS:

l To take over no responsibility in the case of accidents or damages on the basis of carelessness

or disregard to the instructions in this book.

l To reject every responsibility for the damages which originate from the improper use of the device.

No. Code name Schematic Diagram Instruction

1

Over-Voltage

protection

When the voltage is higher than 270V shows this code, if the Voltage is lower than 260V, then recover to normal working situation

2

Under-Voltage

protection

When the voltage is lower than 100V shows this code, if the Voltage is higher than 110V, then recover to normal working situation

3

Thermal

protection

When radiator temperature get to 80 °C shows this code,if the

temperature lower than 60 °C,then recover to normal working

situation

4 Sensor error

When pressure sensor damaged or disconnect shows this code,

recover to normalworking situation after people check troubleshooting

5

Over pressure

protection

When pipe pressure equal to 99% of pressure sensor pressure

shows this code,if the the pressure lower than 96% of the pressure

sensor pressure,then recover to normal working situation

6

Open phase

protection

When inputed three phase power open phase shows this code,

recover to normal working situation after people check troubleshooting

7

Overload

protection

When exceed the setcurrent or load power shows this code, reco-

ver to normal working situation after people check troubleshooting

Over-current

When motor with short circuit or over-current problems shows

5.1.4 Code and Instruction IPC-2-UV / IPC-3-UV

No. Code name Schematic Diagram Instruction

1

Over-Voltage

protection

When the voltage is higher than 270V shows this code, if the Vol-

tage is lower than 260V, then recover to normal working situation

2

Under-Voltage

protection

When the voltage is lower than 100V shows this code, if the Vol-

tage is higher than 110V, then recover to normal working situation

3

Thermal

protection

When radiator temperature get to 80 °C shows this code,if the

temperature lower than 60 °C,then recover to normal working

situation

4 Sensor error

When pressure sensor damaged or disconnect shows this code,

recover to normalworking situation after people check trouble-

shooting

5

Over pressure

protection

When pipe pressure equal to 99% of pressure sensor pressure

shows this code,if the the pressure lower than 96% of the pressure

sensor pressure,then recover to normal working situation

6

Open phase

protection

When inputed three phase power open phase shows this code,

recover to normal working situation after people check trouble-

shooting

7

Overload

protection

When exceed the setcurrent or load power shows this code, recover to normal working situation after people check troubleshooting

8

Over-current

or short circuit

protection

When motor with short circuit or over-current problems shows

this code, recover to normal working situation after people check

troubleshooting

5.1.3 Button and Function Instruction IPC-3-UV

Schematic Diagram No. Name or Function Instruction

1 Reduce button

Press the button one time can reduce 0.1bar,

long time press can reduced rapidly

2 Increase button

Press the button one time can increase 0.1bar,

long time press can increase rapidly

3

RUN/STOP

button

It can start the pump manually, press this button

to exit the water shortage state

4

Current pressure

display

Display value indicates the current pipe network

pressure value,unit:bar

5 Power indicator Indicator lights up when power is connected.

6 Pump indicator

When the main pump speed operating state

or when motor is in speed governing state,the

indicator flash quickly. When the main pump at

the constant speed work state or water shortage, the indicator flash slowly. When it stop

automatically,the indicator is on. When it stop

manually ,the indicator is off.

7

Pressure setting

indicator

The light is flashing when working in the setting

pressure value

8

Water shortage

indicator

The indicator flash , it means the pipe is watershort. It will restart in setting time and the

interval time for restart is 8S, 1min , 10min ,

30min , 1h , 2h ....restart

9

Set pressure

display area

Display value indicates the current setting

pressure value,unit:bar. Factory default Settings

is 3bar

7. SERVICING

It may happen occasionally that dirt is retained in the internal check valve and this is no longer

seals 100%. The rst remedy should be always trying to ush the check valve free. For this purpose, eg. As the Garden side faucet on full blast, so that the pump at full rated power promotes

about 30 minutes water. Is then the timing is not clear, the unit must be replaced. Prior to installation of the new device, the pump is in, free to ush any case, as previously described. Opening the

device on non-return valve is prohibited and always results in the loss of any existing warranty. In

addition, persons could be dangerous when Operating a clocking pump occur, so that the pump

may be operated under any circumstances continue. Until the device replacement, the pump must

be taken out of service. For abrasive materials such as sand, shortening the Maintenance period

and the device lifetime.

The following checks should be carried out regularly:

l functional test (min. every 3 months)

l integrity of the power cord

l Clean the guide lines (eg no buckling)

l Clean the media (no sand, no sludge)

6 English English 7

Loading...

Loading...