Profi-pumpe 1500-1, 2000-1, 750-1, 550-1, 370W-1 Operating Instructions Manual

SWIMMING POOL PUMPS

de

SCHWIMMBAD-PUMPEN

Version 19.08.

OPERATING INSTRUCTIONS

BEDIENUNGSANLEITUNG

Schwimmbadpumpe

POOL-STAR 550-1

(PO01113)

Schwimmbadpumpe

POOL-STAR 1500-1

(PO01116)

Schwimmbadpumpe

POOL-STAR 750-1

(PO01114)

Schwimmbadpumpe

POOL-STAR 2000-1

(PO01117)

Schwimmbadpumpe

POOL-STAR 1100-1

(PO01115)

Schwimmbadpumpe

POOL-STAR 370W-1

(PO01118)

Schwimmbadpumpe

POOL-STAR 1500W-400V-1

(PO01119)

Technical changes, misprints and mistakes reserved! Newest information about our products can be found online

Technische Änderungen, Druckfehler und Irrtümer vorbehalten! Aktuelle Informationen zu unseren Produkten nden Sie auf:

Schwimmbadpumpe

POOL-STAR 2000W-400V-1

(PO011120)

http://www.pro -pumpe.de

Schwimmbadpumpe

POOL-STAR 3000W-400V-1

(PO011121)

2 English

English 3

Contents

1. Introduction .......................................................................................................................... 2

2. In general ............................................................................................................................. 2

3. Ranges of application .......................................................................................................... 3

4. Operation ............................................................................................................................. 3

5 Installation ............................................................................................................................ 4

6. Servicing .............................................................................................................................. 5

7. Guarantee regulations ......................................................................................................... 5

8. Security tips .......................................................................................................................... 5

9. Recognising and repairing of mistakes ................................................................................ 6

10. Notes on Product Liability .................................................................................................... 6

11. Notes on Disposal ............................................................................................................... 7

12. EU Declaration of Conformity .............................................................................................. 7

13. Technical Data ................................................................................................................... 16

SAFETY INSTRUCTION AND WARNINGS

Please read the user manual

before using the device

Pull power plug

Warning sign Warning of electrical voltage

1. INTRODUCTION

We would like to congratulate you on the purchase of our pump. We appreciate your trust.

That‘s why funtional security and operational safety stands by us on rst place.

To prevent damage to persons or property, you should read this user manual

carefully. Please observe all safety precautions and instructions for proper use

of the pump. Failure to follow the instructions and safety precautions can result

in injury or property damage.

Please keep this manual with the instructions and safety instructions carefully

in order to at any time you can restore them. Please always download the latest

version of the user manual of www.pro-pumpe.de under „downloads“. This

shall always prevail.

2. IN GENERAL

The pumps in the catagorie Centrifugal Pumps are developed according to the newest stand of

technology, manufactured with much care and go under strict intensive controls.

The pumps have been optimized by us especially for the special requirements for circulating

and ltering large volumes of water. Make sure after unpacking the pump that the data given

on the type label agree with the included operating instructions. In the case of doubt the pump

is not to be used. Transport damages are immediately to be reported to the package distributor

and to us in witten form.

3. RANGES OF APPLICATION

These pumps are made for pumping clear water (free of mud and sand, see technical data)

The pumps are made for the following ranges of application:

l In private and in public swimming pool

l Circulating large volumes of water

l Other Clear water pumping

IMPORTANT!

The pumps are designed for pumping clean water and chemically non-aggressive liquids. Any

guarantee is void in case of improper use. They are not suitable for pumping ammable liquids

or for use in places where there is danger of an explosion. The pumps are designed for home

use in the house and garden.

These pumps are intended for private use in the home and garden. These pumps are not designed for continuous use (without interruptions). In continuous operation mode, the lifetime will

be shortened accordingly. Never run more than 5 minutes against a closed valve pump. Save

the pump against dry running (install dry run protection).

Never start and stop the pump more than 20 times per hour. When the pump clocks, any

claim under warranty is void.

Not suitable for use with solar photovoltaic panels.

4. OPERATION

The installation must be performed by a qualied professional.

Please, check each time before using, the electrical connections and the cables are not

damaged. Check before the installation whether the electrical connections are earthed

according to the statutory regulations and are installed. The pump is to be secured

through a RCD circuit breaker with release current of 30 mA. is technically correct, so

this warranty is void. It must be ensured that the pump is sufciently cooled during prolonged operation.

It is not recommended to perform even cable extensions or any other technical modications.

The lines to the pump must be installed always steadily rising. A transfer of mechanical loads or

vibrations from the pump or to the pump must be eliminated through appropriate actions (use of

rubber buffers, braided hoses, line xation, etc.).

Do not reduce the suction line. All pipe/hose connections to and from the pump must be sealed.

We recommend that you implement the suction line „as one piece“ without any interruption in

order to prevent and avoid leaks. Check pump and water lines for leaks by pressure testing min.

24 hrs.

Is dirt expected in the pump, an effective pre-lter should be installed before the pump inlet. Fill

pump and suction

pipe/hose with water. Please connect electrically pump with power supply. Start the pump. If necessary, the pump and the suction line must be relled until a normal continuous operation has

been established.

NOTE: Note: Please note that a tapering of the pump connections can lead to a defect in the

pump. The specied connection sizes should be strictly adhered to here. These are guaranteed

when using the supplied step hose adapter.

Please observe item 5.2 under „STEP HOSE ADAPTER ASSEMBLY“.

If the ow on the pressure side of the pump is severely restricted (e.g. by clogged sand lters),

water may come out of the housing.

4 English English 5

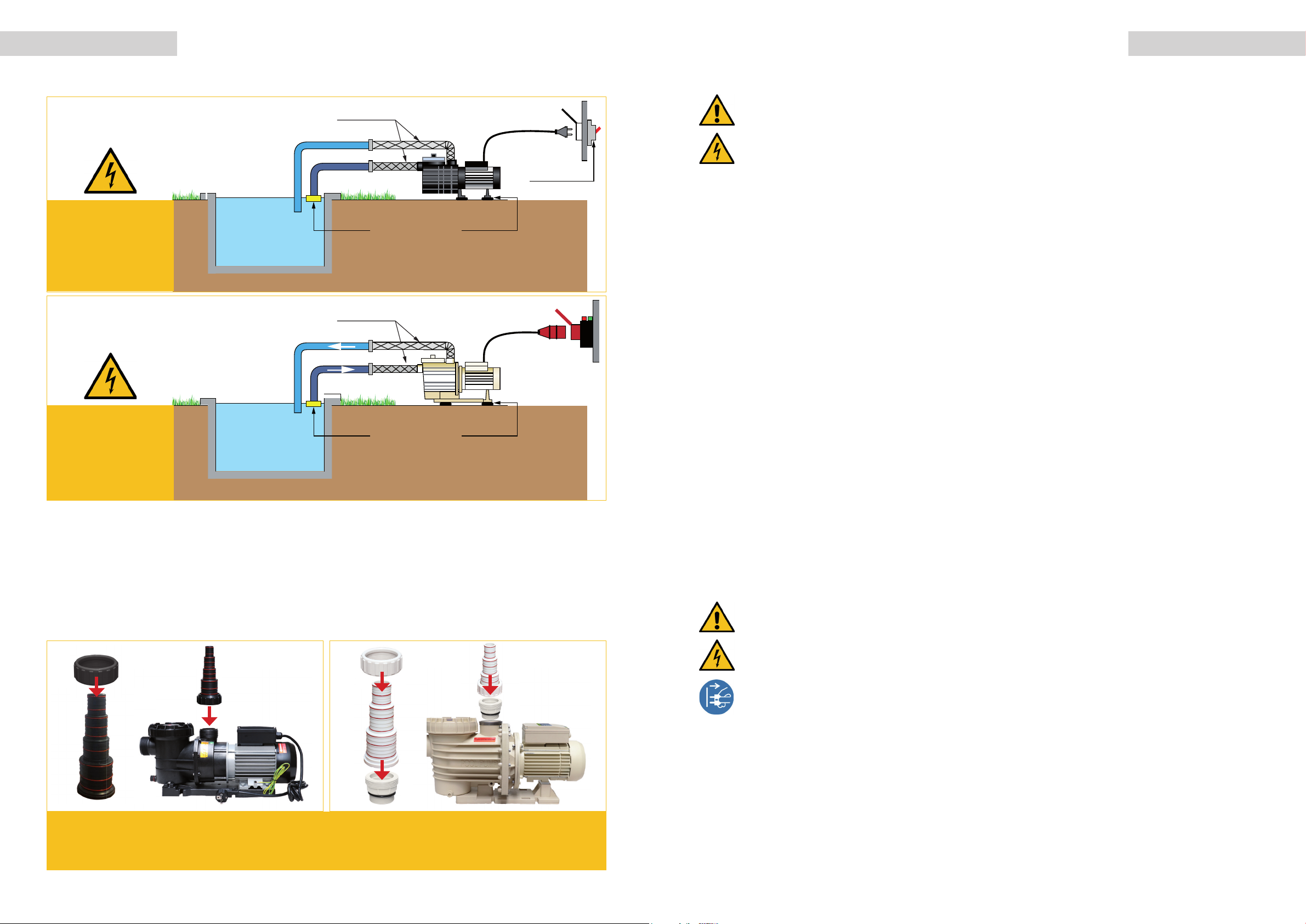

5.1 INSTALLATION

230 VOLT

A xed connection

must be provided

Flexible hose

Panzerschlauch

Skimmer

Rubber buffers

Gummipuffer

30mA ground fault

circuit interrupter*

30mA FI-Sicherung*

by the customer

from a power of

2000 watts on.

400 VOLT

A xed connection

must be provided

Flexible hose

Panzerschlauch

Skimmer

Rubber buffers

Gummipuffer

by the customer

from a power of

2000 watts on.

5.2 STEP HOSE ADAPTER ASSEMBLY

Our multi-adapters allow the use of our POOL-STAR pool pumps under different installation situations. The hose connection sizes t exactly to the respective models of POOL-STAR pumps.

6. SERVICING

It must be regularly checked the pump lter and clean if necessary. The service inter-

vals are based on the respective usage. We recommend a weekly Kontrole in much dirt

accumulation, if necessary daily inspection. Under normal pumping conditions the pump

requires no servicing. From an operating period (with clear water) of approx. 2000 hours

the mechanical components should be checked: impeller wheels, chambers, sealing

rings etc. on wear and if necessary be changed. After 3000 pumping hours the oil in

the chamber should also be changed, if necessary (only with oil-dipped engine types!).

Please, only ll it up to 80% and check the sealing rings always for density.

With abrasive materials like sand the servicing duration can become shorter.

The following controls should be carried out regularly:

l Intactness of the electric cable

l That the connection hoses are not bent or broken

l Cleanness of the pump medium

Moreover, the pump should be emptied with risk of frost, be washed out with clear water

and stored dry.

7. GUARANTEE REGULATIONS

For all manufacturing and material defects, the statutory warranty applies. In these cases we

take the replacement or repair of the pump. Shipping costs shall be borne by our company,

except as required by law. Please report the warranty on our service platform http://www.pro pumpe.de/service.php. We will inform you how to proceed with case-related. Returns please

suf cient postage. Unfortunately not prepaid returns can not be accepted because they are

ltered out before delivery. Our service we provide in Germany.

The warranty does not cover:

l Material wear (sealing rings, impeller wheels, impeller chambers)

l Unjusti ed interventions or changes in the pump

l Damages by selffault

l Improper servicing and improper use

l DRY RUNNIG (Also partially!) of the pump

Moreover, we give no damage compensation for secondary damages!

POOL-STAR 1500 (230V)

POOL-STAR 370W (230V)

POOL-STAR 550W (230V)

POOL-STAR 750W (230V)

POOL-STAR 1100W (230V)

1: Ø 25mm

2: Ø 32mm

3: Ø 38mm

4: Ø 50mm

POOL-STAR 2000 (230V)

POOL-STAR 1500 (380V)

POOL-STAR 2000 (380V)

POOL-STAR 3000 (380V)

1: Ø 38mm

2: Ø 50mm

3: Ø 64mm

l Always use the largest possible adapter connection.

l The smaller connection pieces which are not required must be removed with a standard

metal saw. When cutting, make sure that the cross-section is not tapered by possible

plastic residues and that the fl ow of water is not obstructed.

8. SECURITY TIPS

l Obey absolutely valid regulations on the electrical security

l Never run pump dry

l Pumping in ammable, as well as all other aggressive liquids is prohibited

l Pay attention to the medium temperature max. 35°C

l Never pull the pump on the electrical cable or pressure hose

l Avoid cross section narrowing

l Pay attention to the given particle size

l During longer unused times, clean the pump, wash it out with clear water, dry and store it

at room temperature

l Test wells for enough owing water (dry run danger)

l The pump is to be secured through a RCD circuit breaker with a release current of 30 mA.

l The electrical connections are always to be carried out by an authorised professional

l The pump may be used by children aged 8 years and above as well as persons with reduced

physical, sensory or mental abilities or those who lack skills, experience and knowledge only if

they are supervised. These aforementioned persons should only use the appliance while adhering to safe instructions and resulting dangers.

l Cleaning and maintenance must not be carried out by children without supervision.

l Under certain cirumstances, it is possible that that contamination of water is caused by leakage.

Loading...

Loading...