Professional Sound Corporation Solice Operation Manual

Solice Audio Mixer

Operation Manual

For mixers with pcb version 3.0

Professional Sound Corp

Copyright 2009

Table of Contents:

ntroduction 4

I

Safety Warnings 4

Overview 4

Construction 5

INPUT SECTION:

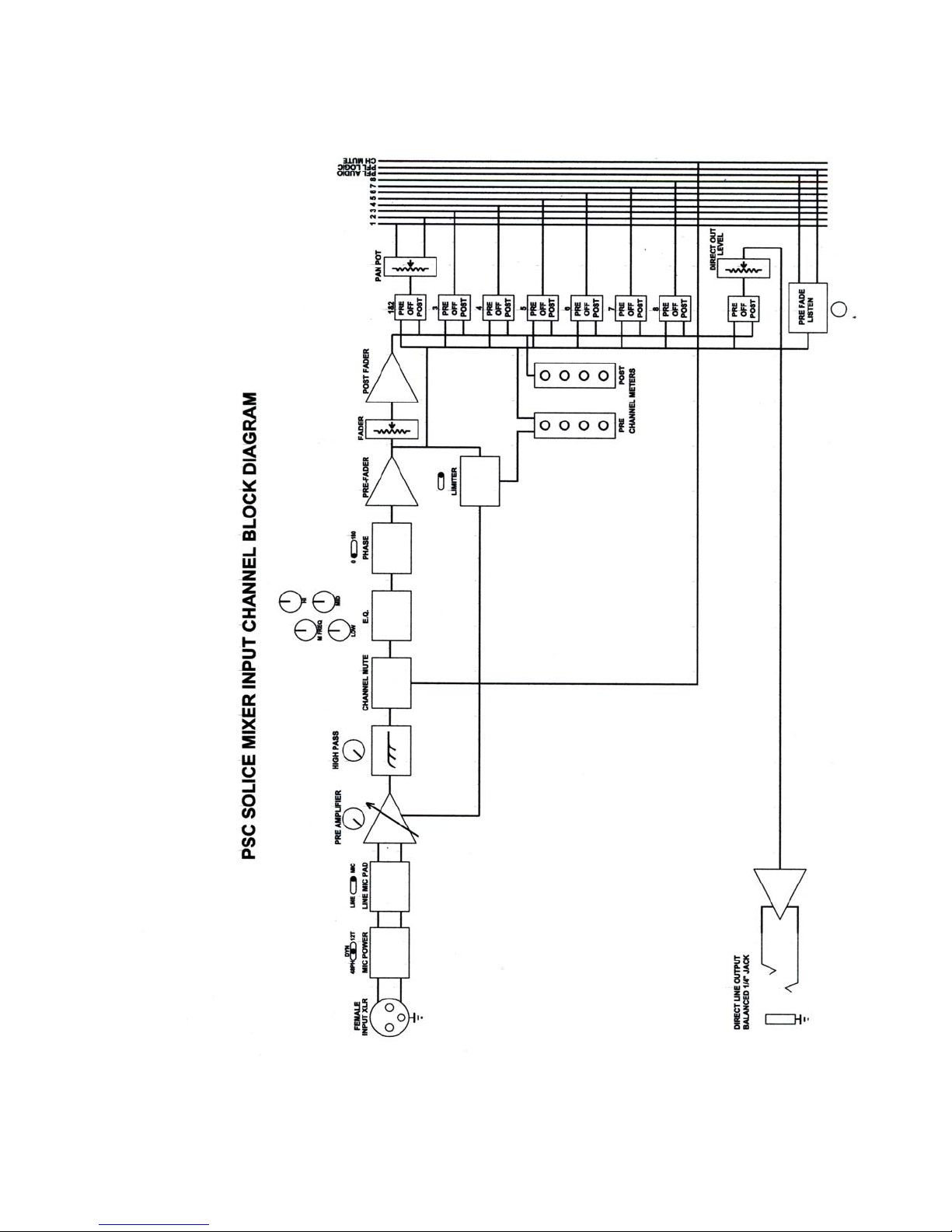

Block Diagram 7

Input Panel View 8

Line / Microphone Input 9

Microphone Powering 9

Pre-Amplifiers 9

Gain Settings 9

High Pass Filters 10

Equalization 10

Limiters 10

Phase Reversal 10

Channel Assignment Switches 11

Channel Fader 12

Pre-Fade Listen Switch 12

Dedicated Line Outputs 12

Channel Ganging 13

Output Section panel View 14

2

Power Switch 14

Remote Roll 14

Reference Oscillator 15

Internal Slate Microphone 15

External Slate Microphone 16

Private Line 16

Comm System 16

Tape/Direct (Tape Returns) 17

M-S Stereo Decoding 17

Headphone Selections & Volume 17

Speaker Output 18

iPod Input 18

Peak Reading Meters 18

Main Output Faders 19

Rear Panel View 19

Main XLR Outputs 19

External Power Connection 19

Multi-Pin Connection 20

Specifications 21

Mixer Connector Pin Outs 22

RoHS 25

CE Mark 26

Warranty 27

3

Introduction

Thank you for purchasing the Professional Sound Corporation Solice Portable

Audio Mixer. The Solice Mixer is the result of our desire to provide you with a

comprehensive, yet simple to use portable mixer. This mixer has been designed

to handle multi-camera shots as well as multi-track recording. The Solice Mixer

provides extreme flexibility in signal routing, very high quality audio and field

friendly ergonomics in a compact, robust package. This new mixer design is the

result of several years work in developing our latest audio circuitry. Many of the

Solice’s design ideas came from you, our customers. We hope you will enjoy

using your Solice Audio Mixer for years to come.

Safety Warnings

The Solice Audio Mixer has been designed to be inherently safe to use. It

operates from low voltage DC only. The design complies with all current safety,

environmental and RF emission regulations. The safe use of this product is

determined primarily by the user. Please read and understand this entire user’s

manual before using your new Solice Mixer. Proper cabling is a must in, on and

around film and television production sets. Please always maintain proper and

safe headphone monitoring levels. If improperly used, this mixer can output

headphone levels that may result in permanent hearing loss. The owner and/or

user are to determine safe operating levels and maintain these levels at all times.

Professional Sound Corp, it’s owners, officers and employees accept no

responsibility for misuse of this mixer, whether intentional or not that may result

in personal injury and/or property damage. In addition, PSC reserves the right to

be held harmless for any liability caused by the use of this mixer with any other

equipment.

Overview

The Solice Portable Audio Mixer provides eight inputs each offering the following

comprehensive list of features:

• Precision, Super Low Noise Pre-amplifier developed by PSC

• Switchable Line or Microphone Input levels

• Phase Reversal

• Peak Detecting, Fast Acting Limiting

• 12T or 48PH Microphone Powering

• Fully Variable Pre-Amp Gain

• Fully Variable High Pass Filter

• Pan Pot for Assignment to Outputs 1 & 2

• Pre-Fade Listen

• Both Pre-Fader and Post Fader Channel Meters

• Pre-Fader or Post Fader Signals can be Individually Routed to any Output

Buss.

4

The Solice Mixer also provides a host of output capabilities:

• 8 main Balanced Outputs on Full Size XLR’s

• Peak Reading, Sun Light Readable LED Meters

• Slate Microphone

• Reference Tone Oscillator

• Tape Returns

• Stereo, M-s Decoding and Mono headphone Selections

• Separate Headphone Feeds For 2 Booms and 1 Director

• Private Line Function

• Duplex Boom Communication

• Little Lite BNC Jack

• Remote Roll Function

Construction

The Solice Mixer’s chassis forms a solid foundation for the mixer’s electronics.

The chassis is precision laser cut from sheet aircraft grade aluminum using a

state of the art laser made in Sweden. Laser cutting of the aluminum results in

less distortion of the panel than traditional hole punching. The resulting panel is

then formed using automated CNC controlled press brakes. The structural side

panels (located behind the billet aluminum sides) are then hand TIG welded on a

heavy, flat surface table. The final chassis is re-checked for straightness and

measured to insure all dimensions are within design specification.

The finished chassis is then Chem film plated so that it will resist corrosion and

offer years of trouble free service. The final step is the application of the epoxy

powder coat paint. This “powder” painting process uses an electrical charge to

attract the paint to the surface of the mixer. It provides superior adhesion and is

an environmentally friendly process as it does not release toxic solvents into the

air.

All silk-screen lettering on the Solice Mixer is applied to the back side of tough

Lexan tm overlays. Printing the lettering and graphics on the back side of a clear

overlay provides years of wear free use. Your fingers only rub against the sturdy

surface of the clear Lexan rather than wearing the lettering off as happens with

standard top surface silk-screening. After years of use, if your Lexan overlays

begin to get scratched or damaged, they can be replaced to re-new the

appearance of your Solice mixer.

The aluminum side panels are milled from solid billets using a Fadel CNC milling

center. After milling and de-burring, they are chem. Film plated for corrosion

resistance and then given a two-stage powder coat consisting of metallic silver

followed by a clear blue. Please note that if you ever remove these side panels,

5

you must use the same type and size screws when re-installing them. The use

of longer screws will interfere with the electronics within the mixer and cause

mixer damage.

The Solice mixer’s dust cover is formed from solid aluminum. It is easily

removed by simply pressing the two thumb buttons and sliding the cover towards

yourself.

6

Block Diagram

7

Input Channel Panel View

CHANNEL METERS, PRE-FADER and POST-FADER

PRE-AMPLIFIER GAIN CONTROL

HIGH PASS FILTER

HIGH FREQUENCY E.Q.

MID FREQUENCY ADJUST (PARAMETRIC)

MID FREQUENCY E.Q.

LOW FREQUENCY E.Q.

PAN POT, CHANNEL LINE OUT LEVEL ADJUST

LINE/MIC INPUT SELECTION, MICROPHONE POWER

LIMITER, AUDIO PHASE REVERSAL

MIX 1 & 2 (PAN POT) SELECT, LINE OUT SELECT

MIX BUSS 3 SELECT, MIX BUSS 4 SELECT

MIX BUSS 5 SELECT, MIX BUSS 6 SELECT

MIX BUSS 7 SELECT, MIX BUSS 8 SELECT

PRE-FADE LISTEN SWITCH

8

Line or Microphone Input Levels

The Solice mixer has been designed and optimized to provide excellent preamplification of microphone level signals. In order to accept line level signals, an

input pad must be switched in. The Solice mixer contains switchable 40dB input

pads for this purpose. The switch is located on the front panel just below the Pan

pot. It is Labeled “L” for Line level signals and “M” for Microphone level signals.

Microphone Powering

The Solice Mixer is equipped to provide both 12T and 48PH microphone

powering to DIN standards. Each input channel has an individual power filter on

each of the 12T and 48PH power lines. This provides isolation between input

channels and helps keep the noise floor down when using powered

microphones. 12T microphone powering should only be used when powering

12T design microphones such as Sennheiser 416T. 48PH microphone

powering should only be used with 48PH microphones. When using dynamic

style microphones, the microphone powering should be switched off. You should

also turn off the microphone powering when using wireless receivers.

Pre-Amplifiers

The Pre-amplifiers used in the Solice Mixer were originally designed for our

Miranda Mixer. This design is the result of many engineering hours. This new

super low-noise design uses the latest in high performance semiconductors. The

semiconductors used in the pre-amplifier design offer impressive specifications

while consuming reasonable amounts of power. The fully variable gain structure

of the pre-amplifiers allows for gain changes on the fly. You no longer have to

worry about those coarse “stepped” gain changes found in other mixer designs.

The rotary gain control offers 55dB of adjustment range for extreme flexibility.

This allows the Solice mixer to work with low gain Dynamic microphones as well

as high gain condenser microphones.

Gain Setting

Because the Solice Mixer is equipped with both Pre-fader and Post-fader input

channel meters you can easily adjust both pre-amplifier gain and channel fader

settings quickly and easily. The Pre-fader meter can be used to properly set the

pre-amplifier gain. Simply adjust the gain setting until the meter occasional

“peaks” to the top “0” LED. Once set, you can mix without worry as you have

approximately 18dB of additional headroom in the pre-amplifier before clipping

occurs. The Post-fader meter can be used when routing post-fader audio to the

direct line output for multi-track recording. We believe that these two small

meters will be very helpful in your mixing endeavors.

9

Loading...

Loading...