Welders all over the world can count on Tigmaster water-soluble

purge dams for Tungsten Inert Gas (TIG or GTAW) welding of Steel

alloy or aluminum pipes.

Applications include:

• Chemical plants • Breweries

• Fabrication shops • Shipyards

• Pipelines • Utility plants

• Paper mills And more

There are many reasons to use Tigmaster purge damns, below are

the top reasons to use water-soluble paper purge dams.

5 Reasons To Use Water-Soluble Purge Dams

1. Easiest Product To Use - Simply cut to size and tape in place or,

for smaller diameter pipes, just wad a small amount into each

section. (See other side for details.)

2. Requires No Training To Install - A few easy steps provides a

quality application, even if it’s the first time you have ever tried it.

3. Saves Time And Money - Applies quickly, dissolves upon

contact with water, and costs only pennies per weld.

4. Ensures The Highest Quality Welds - And is strong enough to

dam argon or helium and still maintain an oxygen purge.

5. Nothing Left Behind In The Pipe - Not only does the paper

dissolve entirely leaving no residue, but you can get cleaner

welds without any oxidation.

00486OG110409

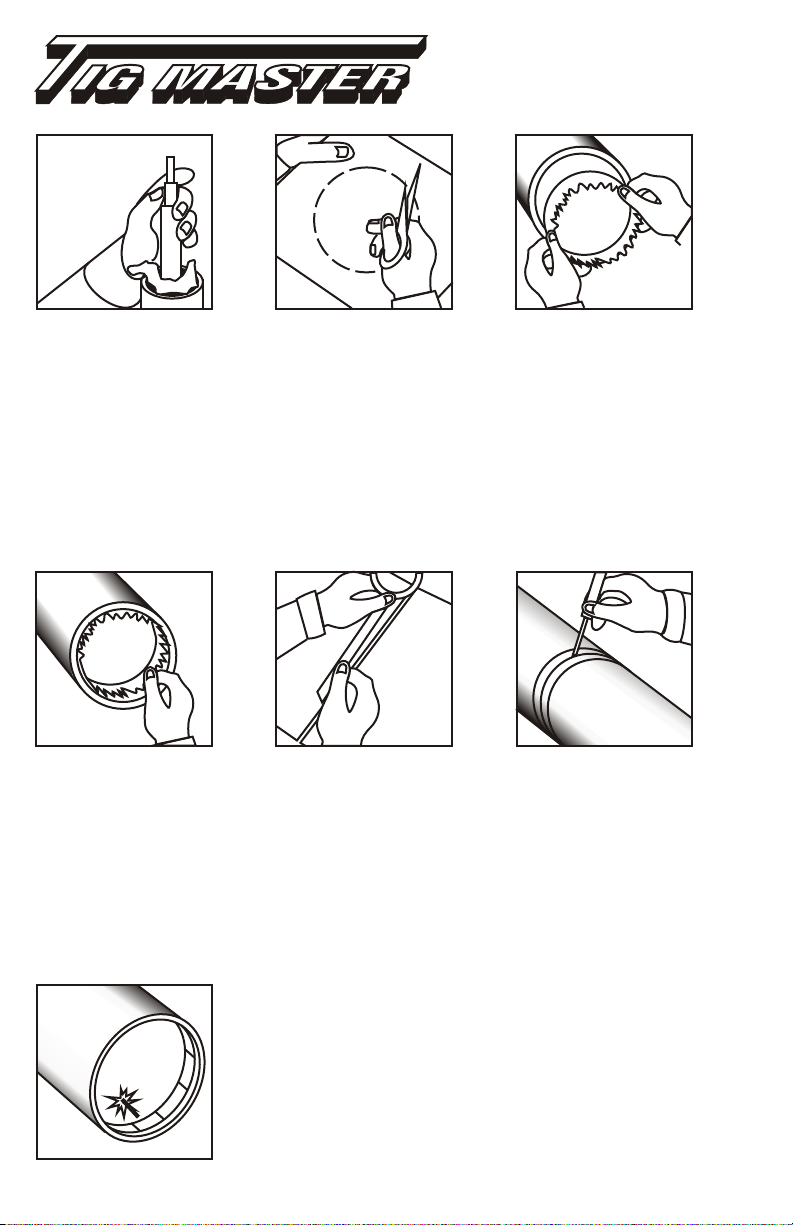

1. For small diameter pipes

(less than 4” inner

diameter), simply position

a wad of Tig Master paper

several inches down into

each section to be joined.

2. For larger pipes (4” inner

diameter and larger), cut

the paper into a circle with

a diameter several inches

larger than the pipe ID.

Example: for a 6” pipe, cut

and 8” diameter paper

circle.

3. Trace or impress the

pipe and inner diameter on

the paper and fold on this

line to form a 90 degree

lip. Insert the dam into the

pipe and with the lip

towards the weld prep.

4. Peel the tape from the

backing and tape dam in

place. Optional: Punch a

small hole in the dam to

facilitate the evacuation of

air when purging.

7. If one end of the pipe is accessible, the purge gas may be

introduced through a hole at the lower end of one dam. A vent

hole should be made at the upper end of the other dam to allow

air and gases to escape. Optional: cover the open root joint on

the outside of the pipe with tape to prevent gas leakage.

5. For pipes larger than 28”

diameter, simply splice two

or more sheets of Tig

Master paper together with

Tig Master tape, and

proceed as in steps 2, 3,

and 4.

6. After the dams are in

place, Argon may be

introduced through the root

gap with needle valve

connected to the line.

Loading...

Loading...