Profax SPG 250 AMP MIG User Manual

Made in U.S.A.

®

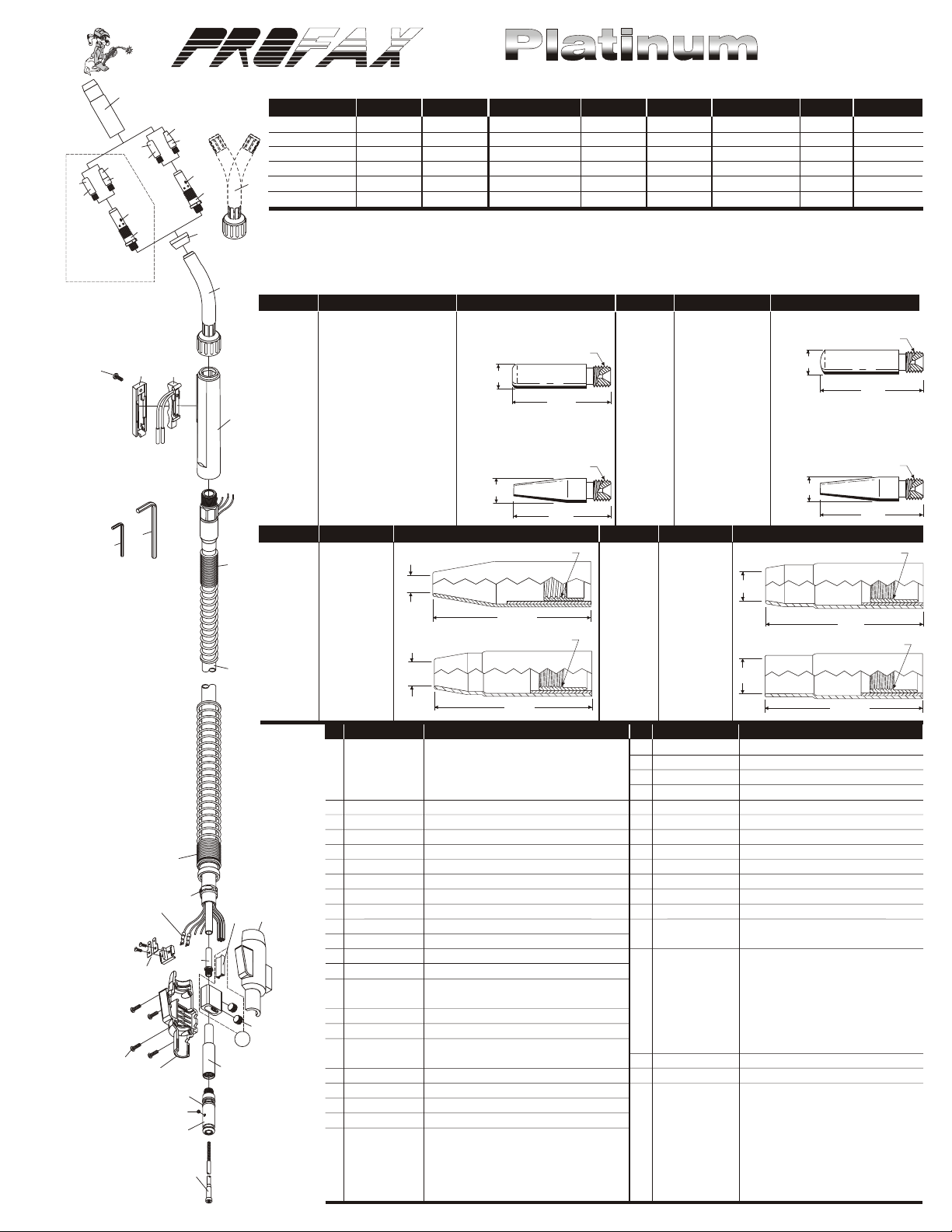

1

2d

2b

2e

2c

Optional

gas diffuser

for using 14 series

contact tips

4

10, 10a

11

14

15

P.O. Box 898 • Pearland, TX 77588-0898

2

2a

3

3a

5a

4

5

6

7

9

PART NO. LENGTH WIRE SIZE

SP250-3035-10 10’ .030-.035

SP250-4045-10 10’ .040-.045

SP250-052-10 10’ .052

SP250-3035-12 12’ .030-.035

7a

SP250-4045-12 12’ .040-.045

SP250-052-12 12’ .052

TO ORDER DIRECT CONNECT MIG GUNS

Standard - All wire feeders that accept the “PROFAX” rear adapter. e.g. SP250-3545-10

Lincoln Direct - Add an LN for the standard Lincoln ¾” dia. rear adapter. e.g. SPLN250-3545-10

®

Miller Direct Add an M. e.g. SPM250-3545-10

Euro-Quick Add an X. e.g. SPX250-3545-10

PROFAX DESCRIPTION TIP I.D.

17S-35 Contact tip .035 .044

17S-40 Contact tip .040 .049

17S-45 Contact tip .045 .054

17AS-364 Contact tip 3/64” aluminum .060

17S-52 Contact tip .052 .064

8

17ST-35 Contact tip .035 .044

17ST-40 Contact tip .040 .049

17ST-45 Contact tip .045 .054

17ST-52 Contact tip .052 .064

PROFAX DESCRIPTION

12

23CT-37 Nozzle 3/8”

SPG 250 Amp Mig Gun Packages

PART NO. LENGTH WIRE SIZE

SP250-3035-15 15’ .030-.035

SP250-4045-15 15’ .040-.045

SP250-052-15 15’ .052

SP250-3035-20 20’ .030-.035

SP250-4045-20 20’ .040-.045

SP250-052-20 20’ .052

®

Add an LP for the Lincoln Powermig 255. e.g. SPLP250-3545-10

PROFAX DESCRIPTION TIP I.D.

Recessed

M8 - 1.25 Thd.

3/8”

1.350

*Standard tip shipped with gun.

Recessed

M8 - 1.25 Thd.

3/8”

1.350

ACME Thread Nozzle

3/8” I.D.

16S-35 Contact tip .035 .044

3

16S-40 Contact tip .040 .049

16S-45 Contact tip .045 .054

16S-52 Contact tip .052 .064

16ST-35 Contact tip .035 .044

2

16ST-40 Contact tip .040 .049

16ST-45 Contact tip .045 .054

16ST-52 Contact tip .052 .064

PROFAX DESCRIPTION

23CT-62 Nozzle 5/8”

PART NO. LENGTH WIRE SIZE

SP250-3035-25 25’ .030-.035

SP250-4045-25 25’ .040-.045

SP250-052-25 25’ .052

5/8” I.D.

Flush

3/8”

Flush

3/8”

ACME Thread Nozzle

M8 - 1.25 Thd.

M8 - 1.25 Thd.

3A

1-1/2”

2A

1-1/2”

25

00347OG042810

3.300

ACME Thread Nozzle

13

23CT-50 Nozzle 1/2”

NO. PROFAX DESCRIPTION

1. 23CT-37 Nozzle 3/8” (Requires tapered tip)

23CT-50 Nozzle 1/2” (Requires tapered tip)

23CT-62 Nozzle 5/8” (Standard)

23CT-75 Nozzle 3/4”

2. 17ST See Chart

2a. 16ST See Chart

2b. 14 14 series contact tips

16

2c. 14H 14H series contact tips

2d. 14T 14T series contact tips

2e. 14HT 14HT series contact tips

17

18

24

20

3. 17S See Chart (standard)

3a. 16S See Chart

4. 44C Set screw

5. 43CT Gas diffuser (Standard)

23

19

5a. 40CT Gas diffuser (14 series tips)

6. 17SW Insulator

7. 66-45 45° swivel gooseneck

66-60 60° swivel gooseneck

7a. TF-42SP Flexible gooseneck

21

22

24

26

29

28

27

8. 82SP Handle

9. 90T Trigger w/leads

10. 91 Trigger housing w/screw

10a 91L Locking trigger housing w/screw

11. 199 Screw 8-32 x ½ inch

12. 140-6SP Support spring

13. SP210 10’ replacement cable assembly

SP212 12’ replacement cable assembly

30

SP215 15’ replacement cable assembly

SP220 20’ replacement cable assembly

SP225 25’ replacement cable assembly

1/2” I.D.

3.300

(Used on both standard & locking trigger)

23CT-75 Nozzle 3/4”

3/4” I.D.

NO. PROFAX DESCRIPTION

14. PXAL-300-25 7/32” hex wrench

15. PX44-25 5/64” hex wrench

16. PXR185-S Spring

17. PX132-12 Clamp - connector block

18. PX244 Terminal

19. PX62N Nipple

20. PX114 Separator

21. PXA-532-24 9/16”-18 ball point screws

22. PX104 Cable connector block assembly

23. PX194 Connector tab assembly

24. PXR185-H Housing

25. PXR185-SC Screws for housing (4)

26. PXR172-UA Standard connector plug

PXR172-UAG Connector plug w/gas hole

27. PXR174-C Connector, Century

PXR174-E Connector, Esab (L-Tec )

PXR172-H Connector, Hobart

PXR172-L Connector, Lincoln

PXR172-M Connector, Miller

PXR174-M Connector, Miller 75 series feeders

PXR172-T Connector, standard

29. PX224 O-ring

28. PX44C Set screw for conduit 8-32

30. PX42-23-15 15’ wire conduit assembly

PX42-3035-15 15’ wire conduit assembly

PX42-4045-15 15’ wire conduit assembly

PX42-052-15 15’ wire conduit assembly

PX42-3035-25 25’ wire conduit assembly

PX42-4045-25 25’ wire conduit assembly

PX42-052-25 25’ wire conduit assembly

PX42N3545-15 15’ nylon conduit assembly

3.300

ACME Thread Nozzle

3.300

®

®®

®

®

®

®

Electric shock can cause INJURY or DEATH.

IMPORTANT- Be sure that the power source and feeder are in the off position. Make sure input power to the power source is

disconnected at the electrical breaker box before attempting installation of this unit.

PROFAX standard rear connection for use with the TAK-1, TLAK-1, PROFAX Pro II, Pro IV, Hobart series 2000,2200,2210,2400,2410, Heavy

Duty, Model 17, Hefty, Mijit 17, Portafeed 17, Portawire 17, Por tafeed 1000, Ultrafeed 1000, Lincoln Wirematic 250 & 255, LN 10, DH10, &

SST10, Powcon PD-1, PD-IE & PDVS-1, Thermal Dynamics TA-3, TAF-2, TAF-4 & Viking 250.

®®

®

®

*Please specify feeder brand so correct trigger plug will be included.

All references to original manufacturer’s equipment numbers, and/or trade names or trademarks, are for identification and

convenience only. The trademarks and trade names are the property of their respective owners.

INSTALLATION

1.) Lay the PROFAX Mig-Gun out in a straight line.

2.) Push the brass connector end of the gun cable into the brass adapter on the outgoing side of feeder wire drive until it is fully seated.

Secure the cable with the set or hand screw in the adapter.

3.) Install the control plug assembly into mating socket on gun cable and into trigger circuit receptacle on feeder.

4.) Relieve tension and disengage drive rolls. Feed wire by hand through drive rolls, outgoing guide and adapter plug until wire is at least one

to two feet inside of PROFAX Mig-Gun.

5.) Reset drive rolls and apply proper tension. Keep gun in a straight position. Continue to feed wire through gun and contact tip by using

inch button on feeder or gun trigger.

6.) When you activate gun trigger, the contact tip and welding wire protruding from tip are electrically “HOT”. Set the power source to the

proper settings for wire size and welding application to be used. Make sure the shielding gas supply is adjusted to the proper flow rate.

Gun is now ready for operation.

GUIDELINES TO AVOID WIRE FEEDING PROBLEMS AND

TO KEEP YOUR MIG-GUN OPERATING SMOOTHLY

1.) Use only clean rust free good quality welding wire.

2.) Keep cable assembly as straight as possible, do not kink or pull cable over sharp corners or allow cart wheels or trucks to run over

cables.

3.) Make sure contact tip is tightly screwed into the gas diffuser at all times, also make sure that the gas diffuser is tightly screwed into the

conductor tube. Retighten the diffuser and tip periodically. Frequently clean contact tip and nozzles. The use of a good anti-spatter

compound will increase tip and nozzle life and make spatter removal easier. If contact tip becomes deformed or arced at the end, replace

immediately.

4.) Maintain and make certain all gun connections are secured and electrical connections are tight. New guns should have all electrical

connections retighten after several days of initial use. Check all gas hose connections on a regular basis to make sure no leakage or loss

of flow occurs.

By following these simple guidelines you will

extend the life of your new PROFAX Mig-Gun.

Keep all mechanical and electrical connections tight.

Loading...

Loading...