®

P.O. Box 898 • Pearland, TX 77588-0898

115 or 230 VOLT RFG-320H SERIES HEATED REGULATOR

INSTRUCTIONS

Before Installing, Operating or Servicing Read and Comply With These Instructions

USER RESPONSIBILITY

This equipment will perform in conformity with the description thereof contained in this manual and accompanying labels and/or inser ts when installed,

operated maintained in accordance with the instructions provided. This equipment must be checked periodically. Defective equipment should not be used.

Parts that are broken, missing, plainly worn, distor ted or contaminated, should be replaced immediately.

This equipment or any of its parts should not be altered. The user of this equipment shall have the sole responsibility for any malfunction which results

from improper use, faulty maintenance, damage, improper repair or alteration by anyone other than PROFAX.

SAFETY

A. The regulator relief valve protects only the regulator and is not intended to protect any other equipment. Be sure the equipment with which it is used also

protected by relief device(s) is such equipment cannot fully withstand cylinder pressure.

B. Never use the Regulator for gases other than labeled. Regulators with Compressed Gas Associated (CGA) number 320, 326, and 580 are designed to

withstand 3000 PSIG maximum inlet pressure. Regulators with CGA 680 inlet are designed to withstand 5500 PSIG. Do not interchange inlet fittings or

parts between 3000 PSIG max regulators and 5500 PSIG max regulators. Use of fittings or par ts other than intended could result in a hazardous

condition.

C. All connections to the Regulator must be clean. Remove dirt or other foreign matter from the Regulator and metal connecting parts with a clean lint free

cloth. Clean all metal parts that came in contact with the gas stream to remove all traces of grease or oil.

CAUTION

D. Never pressurize a Regulator that has loose or damaged parts or is in questionable condition. Never loosen a connection or attempt to remove a par t until

gas pressure has been relieved. Under pressure, gas can dangerously propel a loose part.

E. Before transporting a cylinder that is not secured on a car t suitable for such transport, remove the Regulator and recap the cylinder.

F. Stand to one side of the cylinder valve or Regulator when opening valve.

I. INTRODUCTION

This manual provides installation, operation, and service information for the PROFAX style RFG-320H Heated Single-stage Regulator. The RFG-320H

regulators are flowgauge regulators. Their operating pressure gauge is read in cubic feet per hour (cfh). The RFG-320H series regulators are for use with

nonsiphon-type cylinders. The 115-volt Regulator has a 1.5 amp heating system. The 230-volt has a .75 amp heating system. Both regulators heating

system’s consist of a 175-watt heating cartridge and a thermostat to provide automatic temperature control. The heating system prevents flow reduction and

eliminates the problem of regulator freeze up which causes reduction or stoppage of gas flow or malfunction of the regulator.

II. INSTALLATION

A. Observe the precautions listed in the SAFETY Section.

B. Before attaching the regulator, open the cylinder valve to blow out any foreign matter from the outlet and close it.

C. Connect the Regulator to the cylinder valve outlet, checking that the washer is in place on 320 CGA only. Tighten the connection nut with a proper size

wrench.

D. The 115-volt models are supplied with a short 3-wire cord and a molded grounded plug. No plug is provided on the 230-volt models, due to the diversity

of 230v. plugs.

CAUTION

To guard against potential shock and fire hazard: use a three-wire, grounded, extension cord (available from your distributor or local supplier); and

protect the circuit with a suitable fuse or circuit breaker (heaters draw total 1.5 amp for the 115-volt models and .75 amp for the 230-volt models).

Never remove ground prong from line cord plug.

E. Plug the Regulator line (or extension) cord into a grounded receptacle. The heaters draw a total load of 175 watts.

F. Connect downstream equipment hose to the adaptor. Slightly open equipment valve. Slowly open cylinder valve and purge line to discharge contaminates.

Close equipment valve seconds after pure gas starts to flow from equipment. Open cylinder valve fully and the required gas flow is ready for use.

G. Close the cylinder valve and remove line cord from the supply receptacle whenever the regulator is not in use.

H. Test all connections for leaks by applying a leak detection solution.

III. OPERATION

TO ADJUST FLOW RATE OR PRESSURE

3.1

A. With gas flowing at down stream end, slowly turn Regulator adjusting screw clockwise until desired flow or pressure is shown on operating gauge.

B. To reduce flow rate or pressure, turn adjusting screw counterclockwise while allowing gas to flow from downstream valve.

TO SHUT DOWN

3.2

A. Close cylinder valve.

B. Open downstream valve to drain lines.

C. Close downstream valve and remove line cord.

00485OG102609

(continued on back - turn page over please)

IV. SERVICE

4.1

GENERAL

SERVICE PROCEDURE

A unit which is not functioning properly should not be used until all required repairs have been completed and the unit has been tested to ascertain that it is in

proper operating condition.

Gas equipment improperly operated or maintained can be hazardous.

CAUTION

No maintenance or repair should be undertaken or attempted by anyone not having proper qualifications.

It is recommended that defective parts be replaced with a replacement par t manufactured or sold by PROFAX. Repairs with non-PROFAX parts may pose a

potential shock hazard.

IMPORTANT

Checking or repair of this equipment limited to replacement of non-pressurized external parts such as electrical components, may ordinarily be

undertaken by a competent individual having experience in the maintenance and repair of equipment of this nature. No such checking or repair should

ever be undertaken or attempted by anyone not having such qualifications.

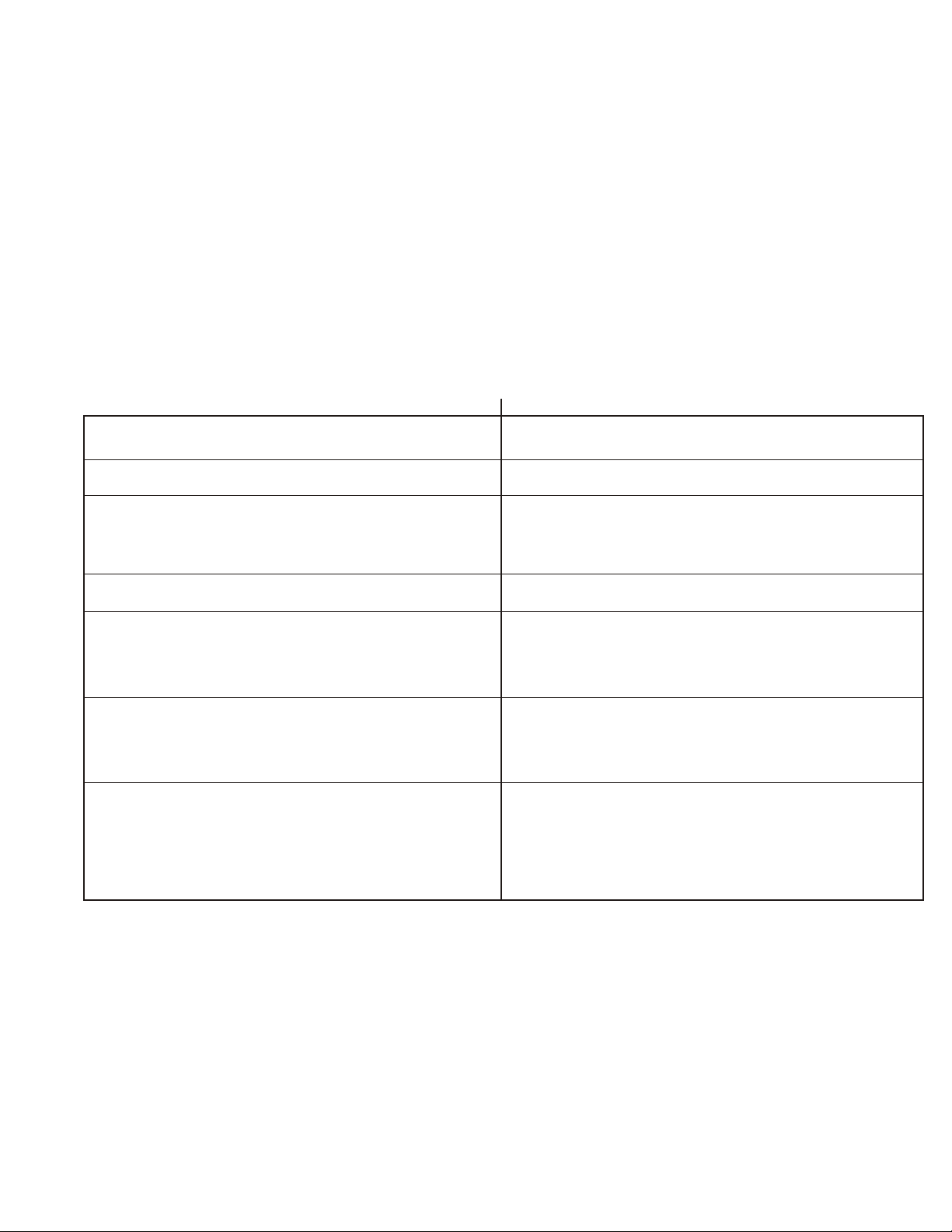

4.2 TROUBLE INDICATIONS

Typical symptoms in the accompanying table indicate Regulator malfunctions requiring repair. Replace immediately with a clean, repaired and tested, or new

Regulator.

TROUBLE SHOOTING

SYMPTOM

1. With no flow through the system (downstream valves closed and cylinder

valve open) working pressure increasing steadily above set pressure.

2. Gas leakage from spring case.

GAUGE

3. Gas Leakage

4. No return to zero.

5. Inconsistent repeat reading.

6. Gas leakage from any joint.

7. Excessive drop in working pressure or flow.

ACTION

Leak across the seat.

Field repair not advised.

Loose or damaged diaphragm.

Field repair not advised.

Damaged gauge.

Have replaced by authorized repair technician.

Damaged or loose connection (fittings, gauges, or spring case)

Have repaired by authorized repair technician.

Worn or sticking internal parts.

Filed repair not advised.

8. Gas leakage from relief valve.

9. Inadequate heat.

SPECIFICATIONS

Inlet Pressure: 3000 PSI Max

Outlet Pressure (PSI): 0 - 123

Outlet Flow (CFH): 0 - 135

Thermostatic Control: 95 to 120°F

Ambient Temperature Range: -40° to 140°F

Current Draw (115VAC): 1.5A

Current Draw (220VAC): .75A

Element Wattage: 175W

Sintered Bronze Inlet Filter: Yes

Inlet Fitting: CGA320

Outlet Fitting: 5/8 - 18 RH Female

Cylinder or upstream valve not fully opened.

open valve.

Faulty valve.

Field repair not advised.

Seat Leak.

Field repair not advised.

Heater burned out.

Have repaired by authorized repair technician.

Faulty thermostat(s).

Have repaired by authorized repair technician.

Lack of power.

Can be used with ARGON and Argon/CO2 Mixes by using a CGA580-320 adapter.

Loading...

Loading...