Page 1

®

®

PRO

JANUARY 2005 EFFECTIVE

WITH SERIAL NUMBER

IIx

& PRO

PRO IIx A-10000

PRO IVx A-50000

IVxIVx

7199

OWNER’S MANUAL

Page 2

P.O. BOX 898

PEARLAND, TX 77588-0898

®

(281) 485-6258

INDEX

SECTION 1 SAFETY

Safety Symbols and Words ........................................................................................... 1

Safety Precautions ........................................................................................................ 2 - 3

SECTION 2

Specifications & Warranty ............................................................................................. 4

SECTION 3 INSTALLATION

Connecting the Wire Feeder & Welding Gun .................................................................... 5

Control Panel ............................................................................................................... 6

Threading Welding Wire and Adjusting Tension .............................................................. 6

Spool Brake Adjustment ............................................................................................... 6

Optional 115/24 VAC Transformer Installation ............................................................... 7

®

TS1 Contactor Terminal Strip Operation ......................................................................... 7

SECTION 4 CHARTS & TABLES

Drive Roll Kit and Guide Chart ...................................................................................... 8

Welding Cable Selection Table ...................................................................................... 8

RC1 Pin Reference ....................................................................................................... 9

Interconnecting and Extension Cords ............................................................................ 9

SECTION 5

Maintenance ................................................................................................................ 10

Overload Protection ...................................................................................................... 10

SECTION 6

Troubleshooting .......................................................................................................... 11

Circuit Diagram ........................................................................................................... 12

SECTION 7

Parts List ........................................................................................................................ 13 - 17

AVAILABLE THROUGH YOUR

WELDING SUPPLY DISTRIBUTOR

Copyright 2005 by PROFAX; Pearland, Texas

All Rights Reserved

No page or part of any page in this catalog may be reproduced in

any form without permission of copyright owner shown above.

Page 3

®

®

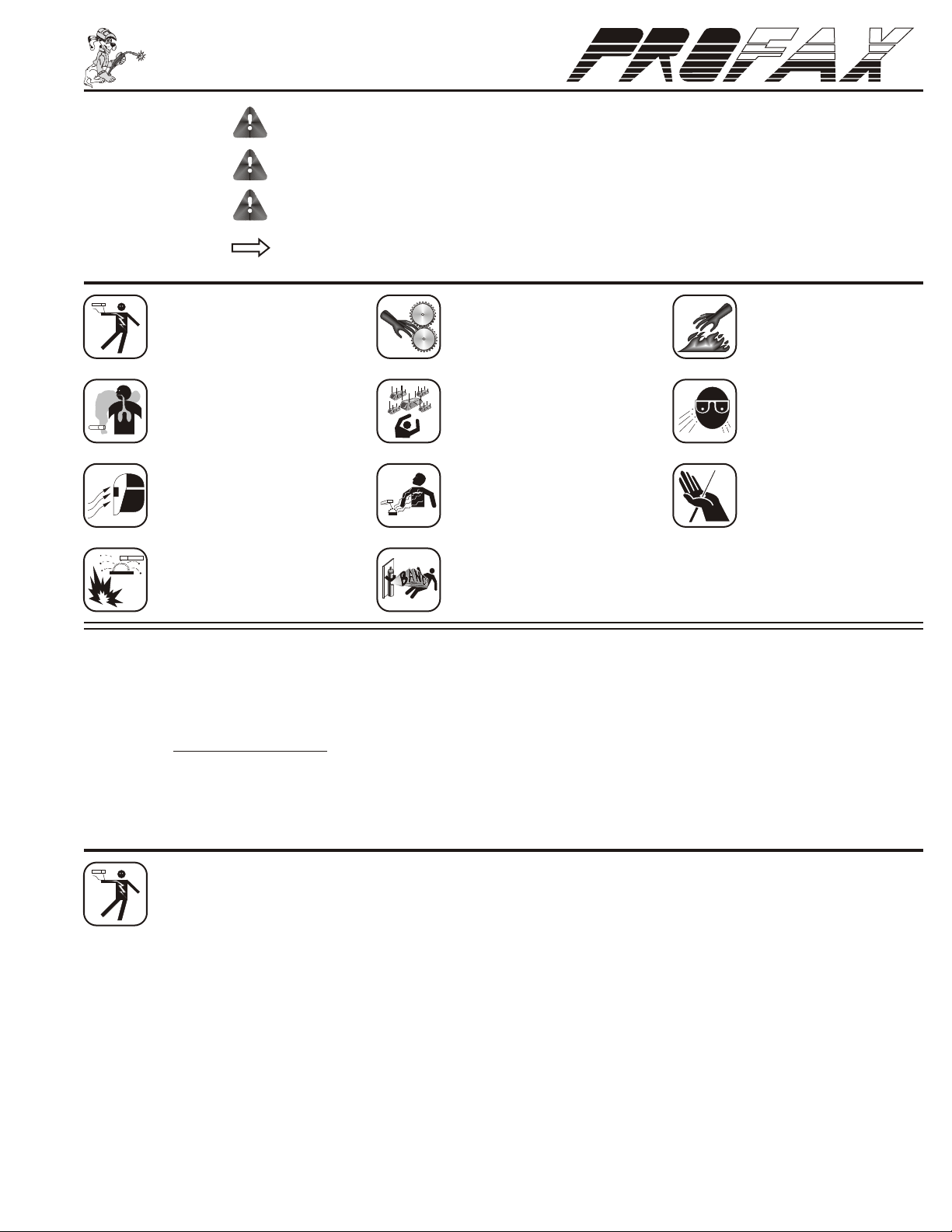

Safety Section 1

ALERT - Read carefully - used with warning and caution words

WARNING - Serious injury or death can happen

CAUTION - Minor injury or equipment damage can happen

NOTE - Gives instructions for proper operation of equipment.

Electrical shock

can kill

Smoke, fumes,

and gases

Arc rays, molten

materials, and sparks

Moving parts

can main

Falling equipment

can injure

Electromagnetic

fields

Hot parts can burn

Flying debris can

injure eyes

Welding wire can

puncture skin

Welding can

cause fires

Cylinders can

explode

IMPORTANT - PROTECT YOURSELF AND OTHERS!

REMEMBER THAT SAFETY DEPENDS ON YOU.

The operator, supervisor, and helper must read and understand all warning and safety information provided in these

instructions. Serious injury or death could result if welding and cutting equipment is not properly installed, used, and

maintained. Training and proper supervision are most important for a safe work place. Installation, operation, repair work, and

maintenance must be performed by qualified personnel. Retain these instructions for future use. Additional recommended safety

and operating information is referenced in each section.

ELECTRICAL SHOCK CAN CAUSE INJURY OR DEATH

Electrical equipment must be installed and maintained in accordance with the National Electrical Code, NFPA 70, and all local codes. Maintain MigGuns, Electrode Holders, Tig Torches, Plasma Torches, Work Clamp, Welding Cable, and Welding Machines in good, safe operating condition. Replace

worn or damaged insulation. Do not try to repair or service equipment while the power is still on. Do not service or repair equipment unless you are

trained and qualified to do so. The Electrode and Work (or Ground) circuits are electrically “HOT” when equipment power is on. At no time should you touch the

Electrode and Electrical Ground at the same time with bare skin or wet clothing while the power is on. Insulate yourself from work and ground using dry insulation.

When welding in damp locations make certain the insulation is large enough to cover your full area of physical contact with work and ground. Ground the work (metal

to be welded) to a good electrical earth ground. Keep gas cylinders, chains, wire ropes, hoists, cranes, and elevators away from any part of the electrical path.

Always be sure the work cable makes a good electrical connection with the metal being welded. Occasionally check all ground connections to determine if they are

mechanically strong and electrically adequate for the current required. The ground connection should be as close as possible to the area being welded. Never touch

electrically “HOT” parts of electrode holders connected to two welding power sources at the same time. The voltage between the two can be the total of the open

circuit voltage of both power sources. When the welding or cutting process requires values of open circuit voltages in alternating current machines higher than 80

volts, and direct current machines higher than 100 volts, adequate insulation or other means must be provided to prevent the operator from making accidental contact

with the high voltage. The use of reliable automatic controls for reducing no load voltage is recommended to reduce shock hazard. When not welding for any

substantial period of time, make certain that no par t of the electrode circuit will accidentally make contact with the work or ground. Never immerse Mig-Guns,

Electrode Holders, Tig Torches, Plasma Torches, or Electrodes in water for cooling.

REFERENCES: See Safety and Operating References A,F,H, and I.

1

Page 4

® ®

®

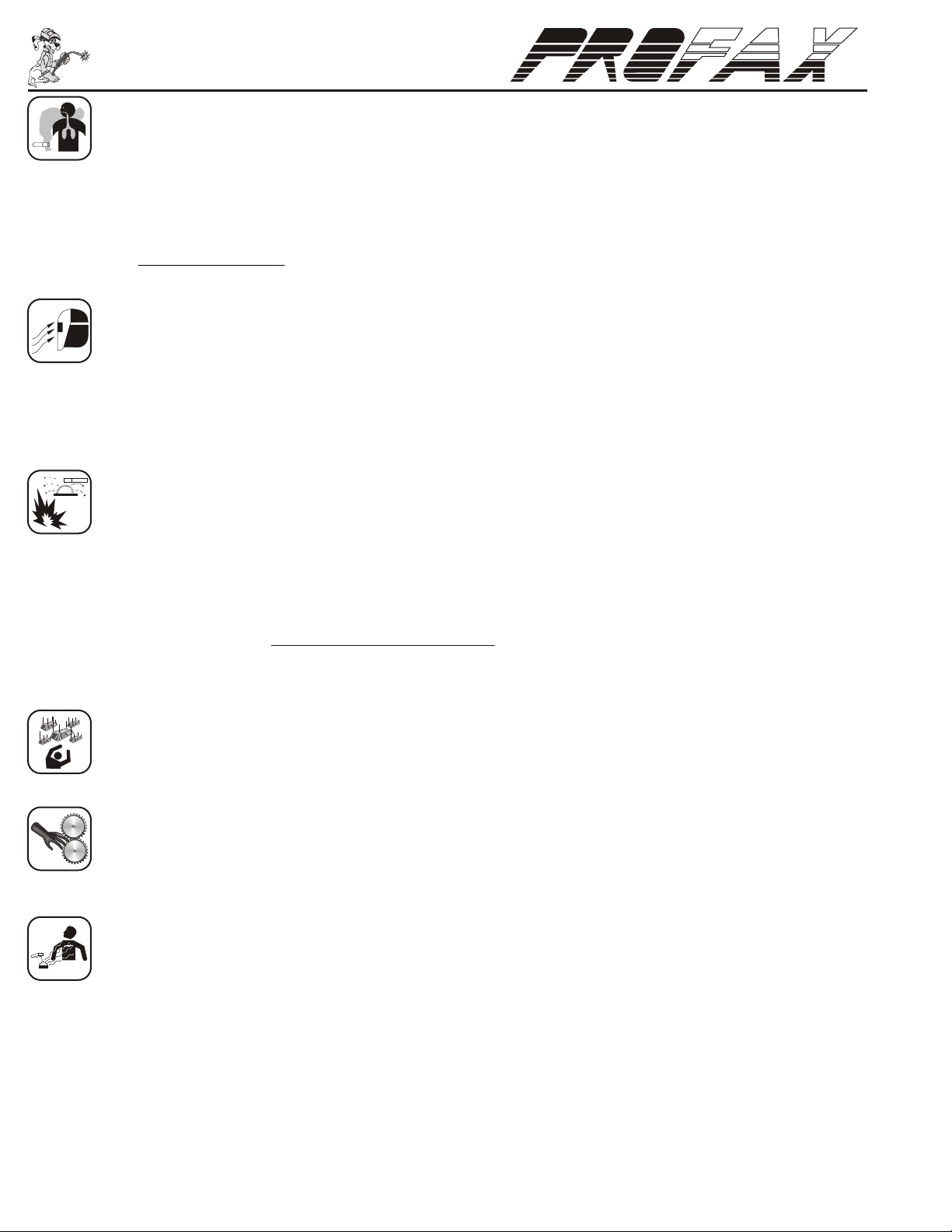

SMOKE, FUMES, AND GASES CAN BE DANGEROUS TO YOUR HEALTH

Keep smoke, fumes, and gases from your breathing zone and the general area. Smoke, fumes, and gases from the welding or cutting process are of

various types and strengths, depending on the kind of base metal being welded on. To ensure your safety, do not breathe these fumes or gases.

Ventilation must be adequate to remove smoke, fumes, and gases during the welding procedure to protect operators and others in the immediate area.

Do not weld in locations where chlorinated hydrocarbon vapors are coming from degreasing, cleaning, or spraying operations. Vapors of chlorinated solvents can form

the toxic gas “phosgene” when exposed to ultraviolet radiation from an electric arc. All solvents, degreasers, and potential sources of these vapors must be removed

from the welding area. Shielding gases used for arc welding can displace air and cause injury or death. Fumes produced by welding or cutting, especially in confined

areas, can cause discomfort and physical harm if inhaled over an extended period of time.

Always provide adequate ventilation in the welding and cutting area to insure breathing air is safe. Use air-supplied respirators if ventilation is not adequate to remove

all fumes and gases. Never Ventilate with Oxygen, because oxygen supports and vigorously accelerates fire.

REFERENCES: See Safety and Operating References A,B,C,H, and I.

ARC RAYS, MOLTEN MATERIAL, AND SPARKS CAN CAUSE EYE AND SKIN INJURY

Always wear approved eye, ear, and body protection. Remove any and all combustible material from the work area. Never attempt to weld or cut

without a proper head shield, and lens, that conforms to federal guidelines. A number 12 to 14 shade filter lens provides the best protection from arc

radiation. A cover plate protects your eyes from sparks. Protect other nearby personnel from arc rays and sparks. Use approved shielding curtains and

appropriate goggles. Warn them not to watch the arc or expose themselves to arc rays, sparks, or molten material.

Always wear protective clothing and gloves which will not allow skin to become exposed to arc rays, heat, or molten material. Wear ear plugs to protect ears from

sparks. Flammable hair preparations should not be used when welding or cutting. If possible, welding should be done in a booth that has been painted with an

ultraviolet absorbing material such as zinc oxide and a low reflective finish such as lamp black, or shall be enclosed by similarly painted and noncombustible screens.

REFERENCES: See Safety and Operating References A,B,H, and I.

WELDING SPARKS CAN CAUSE FIRES AND EXPLOSIONS

Remove any and all combustible materials from the work area. If this is not possible, cover them to prevent the welding sparks from starting a fire.

Fires & explosions are caused by any combustibles reached by the arc, flame, flying sparks, hot slag, or heated materials. Do not wear any gloves or

clothing that has oil or a fuel type material on it. Always have a properly working and OSHA approved Fire Extinguisher near and be sure everyone has

proper training in its use.

Do not weld, heat, or cut drums or containers that have held combustibles. All hollow spaces, cavities, and containers should be vented prior to cutting, welding, or

heating for they may explode. Make sure proper steps have been taken to insure that venting procedures will not form flammable or toxic vapors from substances

inside containers. Purging with inert gas is recommended. Use only iner t gases or inert gas mixes as required by the process.

Special precautions should be used to prevent hazardous situations when using compressed gas. Use of combustible compressed gases can cause

explosions resulting in personal injury or death. Never Use Oxygen for Cleaning or Purging. Arcing against any compressed gas cylinder can cause cylinder damage

or explosion. Read and follow the instructions on compressed gas cylinders, Associated Equipment, and CEA Publication P-1, “Precautions for safe handling of

compressed gases in Cylinders” available from the Compressed Gas Association, 1235 Jefferson Davis Hwy, Arlington, Va. 22202.

REFERENCES: See Safety and Operating References A,D,E,F,G, and H.

Safety

FALLING EQUIPMENT

Lift only the unit to be moved without any running gear, accessories or gas cylinders that may be attached to it. Use equipment of a proper size to lift

and move the unit. Falling equipment can cause personal injury and equipment damage.

MOVING PARTS MAY CAUSE INJURY

Have only qualified people remove guards or covers for performing maintenance and troubleshooting. Moving par ts such as cooling fans can maim

fingers or hands and catch loose clothing. Keep tools, hands, hair and clothing away from moving parts. Be sure to reinstall all panels and guards before

operating equipment.

"EMF" ELECTRO MAGNETIC FIELDS

The study of the biological effects of low frequency electric and magnetic fields does not yet let us interpret the results in a single coherent context.

However, there now seems to be an extremely large amount of scientific analysis based on experimentation, at the cellular level and from studies on

animals and humans, that clearly show low frequency magnetic fields interacting with and producing changes in biological systems. Current scientific

understanding of the evidence does not allow definite conclusions concerning advise on avoiding risks. Therefore, the current procedures recommended for

*pacemaker users are also recommended for all humans and other biological systems. To reduce the effects of low frequency electric and magnetic fields, use the

following recommendations:

1. Welding cables should be kept close together by twisting or taping together.

2. Draping or coiling welding cables around the body should be avoided.

3. Welding cables should be kept away from the operator to one side.

4. Work clamp should be connected as close as possible to the area being welded.

5. Operator should not be between the work clamp and the location of the weld being made.

6. Welding power source and cables should be kept as far away as practically possible.

*Note: Pacemaker Wearers - Consult your doctor for complete information.

REFERENCES: See Safety and Operating Reference J.

Page 5

®

CYLINDERS

Shielding gas cylinders are under high pressure and if damaged can explode. Protect from welding and electrical arcs, excessive heat and mechanical

shocks. Secure cylinders in an upright position by changing to a cylinder rack or stationary support. Use only the cor rect shielding gas for the process.

Never use unmarked cylinders or rely on color markings to denote contents. Keep cylinder caps securely on cylinders unless in use. Turn face away

when opening a cylinder valve. Open cylinder valves slowly then backseat or fully open valve to prevent valve body leaks. Use regulators and hose of a sufficient type

for the compressed gas used. Never connect a regulator to a cylinder with a gas it is not compatible with. Do not transfill cylinders and keep valves closed and

cylinder caps installed on empty cylinders. Never use a cylinder for other than its intended use.

REFERENCES: See Safety and Operating Reference G.

HOT PARTS

Hot parts can cause serious burns. The area at and near the work being welded should be handled with proper gloves. Proper clothing should be worn

to prevent spatter or chipped slag from causing burns. Never pick up welded material until it has properly cooled.

REFERENCES: See Safety and Operating References A, B, H, & I.

FLYING DEBRIS CAN INJURE EYES

Wearing proper eye protective lenses can prevent debris from damaging the eye. Wear safety glasses with side shields or face shields.

REFERENCES: See Safety and Operating References B.

WELDING WIRE CAN PUNCTURE SKIN

Position the unit away from any part of the body, other people, and metal when threading.

REFERENCES: See Safety and Operating References A.

Safety

Safety and Operating References

A) ANSI Z49.1, “Safety in Welding and Cutting”

B) ANSI Z87.1, “Practice for Occupational and Educational Eye and Face Protection”

C) ANSI Z88.2, “Standard Practice for Respiratory Protection”

ANSI: American National Standard Institute, 1430 Broadway, New York, NY 10018

D) AWS F4.1, “Recommended Safe Practices for Welding and Cutting Containers”

AWS: The American Welding Society, P.O. Box 351040, 550 NW Lejeune Rd., Miami, FL 33135

E) NFPA 51B, “Fire Prevention in Cutting and Welding Processes”

F) NFPA-70, “National Electrical Code”

NFPA: National Fire Protection Association, Batterymarch Park, Quincy, MA 02269

G) CGA P-1, “Precautions for Safe Handling of Compressed Gases in Cylinders”

CGA: Compressed Gas Association, 1235 Jefferson Davis Hwy., Arlington, Va 22202

H) Code of Federal Regulations (OSHA) 29 CFR 1910

US: U.S. Government Printing Office, Washington, DC 20402

I) CSA Standard W117.2, “Safety in Welding, Cutting and Allied Processes”

CSA: Canadian Standards Association, 178 Rexdale Blvd., Rexdale, Ontario, Canada M9W 1R3

J) OTA-BP-E-53 Biological Effects of Power Frequency Electric & Magnetic Fields - Background Paper US Congress,

Office of Technology Assessment, General Conclusions Section, Washington D.C: US Government Printing Office, May 1989.

32

Page 6

Section 2

® ®

®

Specifications & Warranty

SPECIFICATIONS

Type of input power required Single-Phase 24 VAC, 7 Amperes, 50/60 Hertz. (If the power source has only

from power source. 115 VAC power available, use the optional (St./No. 9045) 115/24 VAC transformer)

Maximum weld circuit rating. 100 Volts, 500 Amperes, 100% Duty Cycle

Required welding power source. (CV) Constant Voltage with contactor

Wire feed speed 30 to 650 IPM

Wire size range .023 (.6mm) to 1/16 in. (1.6mm)

Dimensions Length: 22.25 in. (565mm) x Width: 10 in. (254mm) x Height 11 in. (279mm)

PRO IIx Net: 28 lbs. (12.7 Kg.) Ship: 30 lbs. (13.6 Kg.)

Weight PRO IVx Net: 30 lbs. (13.6 Kg.) Ship: 32 lbs. (14.5 Kg.)

(Add 4 lbs. (1.8 Kg.) If optional 115/24V transformer (p/n 9045) is factory installed.)

WARRANTY

LIMITED WARRANTY - Subject to the terms and conditions hereof, PROFAX, Pearland, TX warrants its products to be

free from defects in workmanship and material at the time of delivery by PROFAX.

PROFAX will honor warranty claims on products as a result of failure from a defect for a time period as listed below for

the particular product line, from date of sale to the original user.

Consumable products manufactured by PROFAX ....................................................... 30 days

Contactors, Meters and Resale consumable products ................................................ Original Manufacturer's Warranty

Mig Guns, Flux Cored Guns, and Spool Guns .............................................................. 90 days

Gouging, Plasma, Tig Torches and CO2 Heaters .......................................................... 90 days

Control, Extension, Interconnect and Adapter Cords ................................................... 90 days

Twist-lock, Multi-pin Plugs, and Connectors ............................................................... 90 days

®®®

Esab , Lincoln , Miller and PROFAX Drive Rolls ........................................................ 90 days

Remote Fingertip, Hand and Foot Controls ................................................................. 90 days

Fan Motors, Rheostats, Diodes and Brushes .............................................................. 90 days

Spool Gun Controls ................................................................................................... 1 year

Pro II Tig ................................................................................................................... 1 year

Welding Power Sources and Wire Feeders ................................................................. 3 years

Shelf Life before Warranty Starts ................................................................................ 1 year

Upon the return of the merchandise at user's expense, PROFAX reserves the right to either repair or replace as

necessary.

This is the only warranty either expressed or implied covering our products.

MAILING SHIPPING

P.O. Box 898 1603 North Main

Pearland, TX 77588-0898 Pearland, TX 77581-2803

Page 7

®

CAUTION!

Section 3 Installation

NOTE:

Read and understand the safety information in Section 1 before attempting installation.

CONNECTING THE WIRE FEEDER

1

2

Note: Route all cables and hoses through cable

clamp.

3

1. Attach weld cable from power source to

power block.

2. Attach gas hose from flowmeter regulator

to gas inlet fitting.

(5/8-18 right hand inert gas)

3. Attach control cable from power source to

RC1 receptacle.

SEE SECTION 4 FOR DRIVE ROLL AND CONTROL CABLE SELECTION

CONNECTING THE WELDING GUN

3

1. Euro-Quick Mig Gun

2. Securing Nut

3. Euro-Quick Adapter

2

1

Align and insert Euro-Quick style Mig Gun into adapter. Secure the Mig Gun by tightening the securing nut to the Euro-Quick Adapter.

54

Page 8

® ®

® ®

CONTROL PANEL

1. Wire Speed Control

2. Power Switch and Power "ON" Light

3. Euro-Quick Adapter

3

2

1

THREADING WELDING WIRE AND ADJUSTING TENSION

TIGHTEN

WOOD

1. Release pressure arm(s) by sliding the tension 5. Holding the mig gun out straight, feed the welding wire

adjustment lever(s)down. through the mig gun by using the gun trigger.

2. Route the welding wire through the inlet guide 6. Reinstall the contact tip.

across the drive roll(s) and into the outlet guide. 7. To adjust drive roll pressure - hold the mig gun no less

Slide at least six inches of wire into the outlet guide. than four inches up from a wood surface. Press the

3. Close pressure arm(s) and secure by sliding the gun trigger to feed wire and tighten the wire tension adjust

tension adjustment lever(s) up until locked in place. ment knob to the point where the wire does not slip.

4. Remove the mig gun contact tip. 8. Cut off wire and close cover.

NOTE: Too much wire tension will damage motor, cause erratic feeding and excessively wear drive rolls

SPOOL BRAKE ADJUSTMENT

TENSION

NUT

TIGHTEN

1. Tension should be adjusted with wire spool on feeder.

2. Remove wire spool securing nut.

3. Turn the tension adjustment nut to the right to increase braking tension.

4. Adjust until a slight force is felt as you turn the spool by hand.

5. Install wire spool securing nut.

SPINDLE

ASSY.

SPOOL

SECURING NUT

NOTE: Too much brake tension will cause erratic feeding.

Page 9

InstallationInstallation

OPTIONAL 115/24 VAC TRANSFORMER INSTALLATION

TS2 SET FOR

115 VAC OPERATION

TS2 SET FOR

24 VAC OPERATION

JUMPER

LINKS

YELLOW

YELLOW

WHITE

BLACK

1. Remove hinged cover.

2. Locate TS2 terminal strip.

3. Remove the two jumper links from TS2.

4. Install the 115/24 VAC transformer (St./No. 9045) onto it's mounting holes using the supplied four 8/32 screws, washers,

lockwashers and nuts.

5. Cut the transformer wires back so as to neatly reach their respective TS2 terminal listed in step 6.

6. Install the supplied spade wire terminals to the transformer wires.

7. Connect the transformer wires to terminal strip TS2 as follows:

White to Terminal 1

Yellow to Terminal 2

Yellow to Terminal 3

Black to Terminal 4

8. Install the hinged cover making sure not to trap and or pinch any wiring.

CAUTION!

Jumper links on TS2 must be removed when

installing the 9045 115V transformer option.

Failure to remove links will cause the pc board

to fail and void warranty.

TS1 CONTACTOR TERMINAL STRIP OPERATION

CONTACT

CLOSURE

CONTACT

CLOSURE

1 2 3

1

2 3

VOLTAGE

FEEDBACK

CONTACT CLOSURE OPERATION

This setting is for welding power sources that require a normally open set of

contacts to operate the contactor. When the normally open set of contacts on K1

relay close it completes the circuit and energizes the contactor. Pins F and E on RC1

will give contact closure operation by the wire feeder when the TS1 jumper is from

terminal 1 to 2.

VOLTAGE

FEEDBACK

VOLTAGE FEEDBACK CONTACTOR OPERATION

This setting is for power sources that require voltage feedback to operate the

contactor. When K1 relay closes voltage will be sent back to the welding power

source to energize the contactor. This setting is normally used with the 115/24 VAC

transformer option (St./No. 9045) to send 115 VAC back to the welding power

source to operate the contactor circuit. Pins F and B on RC1 will give voltage

feedback operation by the wire feeder when the TS1 jumper is from terminal 2 to 3.

76

Page 10

Section 4

® ®

® ®

Charts & Tables

DRIVE ROLL, KIT AND GUIDE CHART

PRO IIx PRO IVx

WIRE DIAMETER KIT NO. KIT NO. TYPE DRIVE ROLL INLET GUIDE OUTLET GUIDE INTER. GUIDE

.023/.025(.6mm ) 9095x 9110x V 9054 9070 9085 9131

.030 (.8mm ) 9095x 9110x V 9054 9070 9085 9131

.035 (.9mm ) 9096x 9111x V 9055 9071 9086 9131

.045 (1.2mm ) 9097x 9112x V 9056 9071 9086 9131

V - KNURLED

.030 (.6mm ) 9098x 9113x VK 9057 9070 9085 9131

.035 (.8mm ) 9099x 9114x VK 9057 9071 9085 9131

.045 (1.2mm ) 9100x 9115x VK 9058 9071 9086 9131

.052 (1.4mm ) 9101x 9116x VK 9059 9072 9087 9131

1/16 in. (1.6mm ) 9101x 9116x VK 9059 9072 9087 9131

PRESSURE ROLLS

FLAT SMOOTH --- --- --- 9052 STANDARD - FURNISHED WITH WIRE FEEDER -

CAN BE USED WITH V & V-KNURLED FEED ROLLS

FLAT KNURLED --- --- --- 9053 OPTIONAL - USED WHEN EXTRA DRIVE IS

NEEDED ON CORED WIRES

WELDING CABLE SELECTION TABLE

Total Cable (Copper) Length In Weld Circuit Not Exceeding

100 ft. 150 ft. 200 ft. 250 ft. 300 ft. 350 ft. 400 ft.

(30m) or Less (45 m) (60 m) (70 m) (90 m) (105 m) (120 m)

Welding 10 To 60% 60 Thru 100% 10 Thru 100%

Amperes Duty Cycle Duty Cycle Duty Cycle

100 4 4 4 3 2 1 1/0 1/0

150 3 3 2 1 1/0 2/0 3/0 3/0

200 3 2 1 1/0 2/0 3/0 4/0 4/0

250 2 1 1/0 2/0 3/0 4/0 2-2/0 2-2/0

300 1 1/0 2/0 3/0 4/0 2-2/0 2-3/0 2-3/0

Page 11

Charts & Tables

As viewed facing

rear of feeder.

RC 1 PIN REFERENCE

PIN PIN INFORMATION

A* 115 VAC power input through fuse F3 in respect to pin G

G

B Voltage return from pins A or D.

F

H

E

D

* CAUTION! - 115 VAC should not be connected to pins A & G unless the 115/24 VAC transformer option (p/n 9045) is installed.

A

B

C

C Not used

D 24 VAC power input through fuse F2 in respect to pin G

E Contact closure to pin F in respect to TS1 jumper on terminals 1 & 2.

F Relay common to pins B & E in respect to TS1 jumper position.

G Circuit common for 24 and 115 VAC input power.

H Case ground

INTERCONNECTING & EXTENSION CORDS

NOTE: Control Cords come in 10 ft., 25 ft., 50 f t. & 100 ft. lengths and consist of an 8 Socket Plug,

Multi-conductor Cord(s) and necessary Wires or Plugs to connect to the power source.

When ordering - Add the length required to the end of the part number. (Example: 9225-10)

POWER SOURCE CORD END PLUG DESCRIPTION

FOR CONNECTION TO ST./NO. FROM WIRE FEEDER TO:

PLUG ONLY 9046 8 Socket Plug Only - Connects to rear of wire feeder

EXTENSION CORD 9240 8 Socket Free Hanging Plug to 8 Pin Free Hanging Female Receptacle.

( Extends between the wire feeder and the interconnecting cord. )

UNIVERSAL CORD 9225 7 Individual wires

PROFAX 9237 10 Pin Plug

®

AIRCO 9234 115V Male Plug on Power Cord and 2 Prong Twistlock Female on Contactor Cord

9226 3 Prong Male Twistlock on Power Cord and 2 Prong Twistlock Female on Contactor Cord

HOBART 9232 115V Male Plug on Power Cord and 5 Pin Plug on Contactor Cord

L - TEC 9230 7 Flat Pin Male Plug (AMP Style)

LINCOLN 9228 5 Individual Wires with Spade Connectors for Terminal Strip Hookup

®

9233 19 Pin Plug

®

9231 19 Pin Plug

®

9229 14 Pin Plug

MILLER 9226 3 Prong Male Twistlock on Power Cord and 2 Prong Twistlock Female on Contactor Cord

POWCON 9235 14 Pin Plug (only power sources w/115 VAC available at plug.)

THERMAL DYNAMICS 9227 14 Pin Plug

®

9227 14 Pin Plug

®

®

98

Page 12

Section 5

® ®

® ®

Maintenance

WARNING WARNING

Electrical shock can kill

A. DO NOT TOUCH LIVE

electrical parts.

B. Disconnect input power

before servicing.

Read and understand the safety information in Section 1 of this manual.

Moving parts can main

Disconnect input power

before servicing.

CAUTION Maintenance should be performed by qualified personnel only.

DAILY

1. Clean drive rolls.

A. Clean with a towel and wire brush.

B. If a solvent is required use one that will leave NO residue.

C. DO NOT USE - penetrating oils or anti-spatter spray on drive rolls.

2. Inspect all connections to make sure that they are clean and tight.

3. Inspect all cables and hose for cracks, tears and frayed wires. Repair as necessary.

MONTHLY

Hot parts can burn

Allow for cooling periods.

1. Inspect and repair any cables or hoses that are cracked or frayed.

2. Replace any cables or hoses that have been overheated or that have more than one repair in any six foot section.

3. Blow out or vacuum any particles from the wire drive area.

4. Clean any buildup of metal particles on or around the drive roll shafts.

5. Replace any terminal connections that show to have arced out or cannot be tightened.

3 MONTHS

1. Remove hinged cover and blow out or vacuum component area

2. Inspect for wear and replace if necessary, drive and pressure rolls, roll axles, gears and gear bushings.

3. Disassemble ,inspect and repair or replace if necessary all control cord multi-pin plugs with frayed wire or deteriorated wire

insulation.

4. Replace inlet, intermediate and outlet guides.

5. Replace mig gun liner and connector plug "O" rings

6. Replace unreadable labels.

OVERLOAD PROTECTION Disconnect all electrical power before checking fuses.

FUSES:

F1 - 7A -Fast Acting

Protects motor from overload

F2 - 7A - Slo-Blo

For wire feeder overload protection when operating on

24VAC power.

F3 - 3A - Slo-Blo

USED ONLY WITH 115/24 VAC TRANSFORMER INSTALLED

Protects wire feeder from overload

Page 13

Section 6

Troubleshooting

Troubleshooting should only be done by qualified personnel

with a working knowledge of electrical circuits.

TROUBLE REMEDY

Unit completely inoperative. 1. Turn power switch on.

2. Check F3 fuse if using 115/24 VAC transformer option.

3. If using 115/24 VAC transformer option check to see if transformer was

installed properly.

4. Check F2 fuse if operating from a 24 VAC power source.

5. Check control cord plugs and connections.

6. Check input power to feeder.

Wire does not feed. 1. Check for proper drive roll size and proper drive roll tension.

2. Check for drive roll obstructions.

3. Check mig gun trigger, trigger leads, cord and plug.

4. Check fuses

5. Have an authorized service station check motor and PC board.

Wire feeds as soon as power is turned on. 1. Check mig gun trigger, trigger leads, cord and plug for shorted wires.

2. Check for shorted or frayed wires touching in RC2 receptacle.

Wire feeds erratically. 1. Readjust drive roll tension.

2. Spool brake too tight.

3. Wrong size drive rolls and or wire guides.

4. Worn drive rolls and or guides.

5. Inlet or outlet guide touching drive rolls preventing proper tension

adjustment.

5. Dirty mig gun liner.

6. Improperly installed mig gun liner.

7. Worn contact tube.

8. Worn drive roll axles and or drive gear bushings.

9. Have an authorized service station check motor and PC board.

Gas valve rattles loudly with erratic 1. Check for a short between the weld cable and the mig gun trigger leads.

or slow wire speed. 2. Check gas valve components for tightness.

Gas does not flow but wire feeds OK. 1. Check gas supply and flowmeter to see if they are on and allowing gas to flow.

2. Check to see if gas flow is reaching gas solenoid connection at feeder.

3. Check gas solenoid valve.

Motor runs slowly. 1. Check for correct input voltage.

2. Check for correct voltage to motor.

3. Have an authorized service station check the motor and PC board.

Wire feeder operates OK but will not weld. 1. Ground cable not or badly connected.

2. Weld cable not connected to wire feeder.

3. Power cable not connected to power block.

4. Contactor not being energized in power source.

Check:

A. K1 relay

B. TS1 jumper placement

C. Control cord wiring

1110

Page 14

® ®

® ®

Troubleshooting

0-27VDC

OUT WITH

REF. TO R2

WHEN RC2

PROFAX 9001

PC BOARD

24VAC IN

WITH SW1

115vac

127

GW

11

RB

OB

R

IS CLOSED

ON

8

B

SB

S

5 6 9 10

U

4

PW

R2

CW

T2

R

F1

24vac

M

OPTIONAL

4

2

1

S

RC2

(Trigger Recpt.)

S

P

SW1

UW

W

3

TS2

Jumper links on TS2

must be removed when

installing this option.

Required for 115VAC operation

GS

24VAC OUT

WHEN RC2

IS CLOSED

3

PW

W

32

YB

CIRCUIT DIAGRAM

P

K1

1 2

O

N

F

BW = BLACK/WHITE

GW = GREEN/WHITE

OB = ORANGE/BLACK

PW = PURPLE/WHITE

RB = RED/BLACK

SB = GRAY/BLACK

UW = BLUE/WHITE

YB = YELLOW/BLACK

WIRE COLOR CODE

B = BLACK

G = GREEN

N = BROWN

O = ORANGE

P = PURPLE

R = RED

S = GRAY

U = BLUE

W = WHITE

Y = YELLOW

Contact closure operation

between F & E with TS1

jumper on terminals 1 & 2

TS1

1

E

B

YB

G

W

H

G

GND

YB

F3

F2

Y

BW

D

A

RC1

24V

115V

COMMON

Voltage feedback operation

between F & B with TS1

jumper on terminals 2 & 3

Page 15

Section 6

Parts

PARTS

MANUAL

1312

Page 16

® ®

® ®

21

11

10

29

30

31

7

18

19

49

47

4

(See Figure B)

3

(See Figure A)

22

36

20

46

38

2

1

16

37

5

52

(Optional)

17

48

9

44

53

56

55

57

13

12

39

6

23

50

14

58

33

26

28

24

8

25

43

27

54

Page 17

PartsParts

PART ELEC. QTY.

ITEM NO. MKGS. DESCRIPTION PRO IIx PRO IVx

1 9002 M MOTOR, 24VDC 160 RPM 1

2 9003 M MOTOR, 24VDC 160 RPM 1

3 9004 WIRE DRIVE ASSY. 2 ROLL (see figure A) 1

4 9005 WIRE DRIVE ASSY. 4 ROLL (see figure B) 1

5 9012 BASE 1 1

6 9014 DIVIDER PANEL 1 1

7 9080 FRONT PANEL 1 1

8 9013 HINGED COVER 1 1

9 9015 COVER HASP 1 1

10 9081 FACEPLATE 1

11 9182 FACEPLATE 1

12 9018 SPOOL SUPPORT 1 1

13 9017 SPINDLE ASSY. 1 1

14 9001 PC BOARD 1 1

15 8999 TERMINAL TOOL, PC Board (Not Shown) 1 1

16 9007 INLET GUIDE HOLDER 1 1

17 INLET GUIDE LINER (see DRIVE ROLL, KIT and GUIDE chart ) 1 1

18 9028 R2 POTENTIOMETER, 10K, 1T, 2W 1 1

19 9029 INSULATOR, potentiometer 1 1

20 9008 DRIVE MOUNT INSULATOR 1 1

21 9157 EURO-QUICK ADAPTER 1 1

22 LINER, adapter block (see DRIVE ROLL, KIT and GUIDE chart ) 1 1

23 9177 DIVIDER, insulator 1 1

24 9176 TOP COVER, insulator 1 1

25 9020 GS GAS SOLENOID, 24VAC 1 1

26 9172 HOSE, gas solenoid 1 1

27 9021 FITTING, gas solenoid inlet 1 1

28 9173 CLAMP, gas solenoid hose 2 2

29 9022 SW1 POWER SWITCH 1 1

30 9030 KNOB, potentiometer 1 1

31 9031 BRAKE, felt 1 1

33 9033 RC1 POWER RECEPTACLE, amphenol 1 1

35 9035 TERMINAL, trigger receptacle (Not Shown) 2 2

36 9010 POWER BLOCK 1 1

37 9011 POWER CABLE 1 1

38 9024 FOOT, rubber 4 4

39 6100 FUSE HOLDER 3 3

40 9038 F1 FUSE, 7 amp, 250V fast acting (Not Shown) 1 1

41 9039 F2 FUSE, 7 amp, 250V Slo-Blo (Not Shown) 1 1

42 9040 F3 FUSE, 3 amp, 250V Slo-Blo (Not Shown) 1 1

43 9041 TS1 TERMINAL STRIP, 3 pole 1 1

44 9042 TS2 TERMINAL STRIP, 4 pole 1 1

45 9043 JUMPER, terminal strip (Not Shown) 3 3

46 9025 SCREW INSULATOR, wire drive 2 2

47 9026 INSULATING WASHER, wire drive 2

48 9009 CLAMP, cable 1 1

49 9023 SPACER BLOCK 1

50 9027 GROMMET, rubber 2 2

52 9045 T2 TRANSFORMER, (optional) 115/24VAC 100VA 1 1

53 9047 LABEL, TS2 1 1

54 9048 LABEL, TS1 1 1

55 9049 LABEL, fuses 1 1

56 9051 LABEL, schematic 1 1

57 9142 LABEL, PROFAX 22

58 9036 LABEL, safty 1 1

1514

Page 18

®

®

Parts

FIGURE A

5

4

3

11

10

9

1

7

6

8

13

14

2

12

15

16

17

10

8

5

4

6

7

18

11

12

16

9

FIGURE B

17

16

3

1

19

13

2

14

15

Page 19

®

®

FIGURE A PARTS LIST PRO IIx WIRE DRIVE 2 ROLL ASSEMBLY P/N 9004

ITEM PART NO. DESCRIPTION QTY.

1 9143 WIRE DRIVE HOUSING 1

2 9144 SCREW, guide retention, and motor mounting 5

3 9145 PRESSURE ARM 1

4 9134 AXLE, pressure roll 1

5 9136 GEAR, pressure roll 1

6 9052 PRESSURE ROLL, flat smooth 1

7 9053 PRESSURE ROLL, knurled ( optional ) 1

8 9135 CIRCLE CLIP, pressure roll axle 1

9 9146 PIVOT PIN, pressure arm 1

10 9147 SPACER 1

11 9148 SPRING, lift 1

12 9149 CIRCLE CLIP, pressure arm pivot pin 1

13 9150 TENSION AJUSTER 1

14 9151 RETAINING PIN, tension adjuster 1

15 9129 GEAR, drive 1

16 9130 SCREW, drive roll retention 2

17 9126 SCREW, drive gear retention 1

18 9128 KEY, motor shaft (Not Shown) 1

19 9152 SNAP RING, motor shaft (Not Shown) 1

Parts List

FIGURE B PARTS LIST PRO IVx WIRE DRIVE 4 ROLL ASSEMBLY P/N 9005

ITEM PART NO. DESCRIPTION QTY.

1 9153 WIRE DRIVE HOUSING 1

2 9154 SCREW, guide retention 3

3 9145 PRESSURE ARM 2

4 9155 PIVOT PIN, pressure arms 1

5 9149 CIRCLE CLIP, pressure arm pivot pin 4

6 9156 SPRING, lift 1

7 9147 SPACER 2

8 9134 AXLE, pressure roll 2

9 9135 CIRCLE CLIP, pressure roll axle 2

10 9136 GEAR, feed and pressure roll 4

11 9052 PRESSURE ROLL, flat smooth 2

12 9053 PRESSURE ROLL, knurled ( optional ) 2

13 9132 AXLE, drive roll 2

14 9133 WASHER, drive roll retention 2

15 9127 SCREW, gear retention 3

16 9150 TENSION ADJUSTER 2

17 9151 RETAINING PIN, tention adjuster 2

18 9131 INTERMEDIATE GUIDE (see Drive Roll, Kit and Guide Chart) 1

19 9137 GEAR, main drive 1

20 9128 KEY, motor shaft (Not Shown) 1

21 9152 SNAP RING, motor shaft (Not Shown) 1

22 9138 SCREW, motor mounting (Not Shown) 3

17

Page 20

Loading...

Loading...