Page 1

®

®

Owner’s Manual

00110OG011905

MHC-3 & MHC-3GD34A

REMOTE AMPERAGE CONTROLS

®

FOR MILLER WELDING POWER SOURCES

Note: Please read and understand the entire contents of this manual, with direct attention on the safety

material throughout this manual. This manual was intended for use by trained and qualified persons

to install, operate and/or service this unit. DO NOT allow untrained personnel to install, operate or

service this unit. Call your welding supply distributor if you do not fully understand these instructions.

Page 2

®

SAFETY

WARNING! Read and understand all safety messages in this and the welding power source owner's manual.

ELECTRIC SHOCK can kill.

• Do not touch live electrical parts

• Keep all panels in place.

• Keep yourself insulated from the work

WELDING can cause fire and explosion.

• Do not weld on closed containers.

• Watch for fire

WARRANTY

LIMITED WARRANTY - Subject to the terms and conditions hereof,

PROFAX, Pearland, TX warrants it's products to be free from defects in

workmanship and material at the time of delivery by PROFAX.

PROFAX will honor warranty claims on products as a result of failure from

a defect for a time period as listed below for the particular product line,

from date of sale to the original user.

Consumable products manufacturered by PROFAX......................... 30 Days

Resale consumable products.................... Original Manufacturer's Warranty

Mig Guns, Flux Cored Guns, Spool Guns........................................ 90 Days

Arc Gouging Torches, Plasma, Tig Torches & CO2Heaters.............. 90 Days

Remote Fingertip, Hand/Foot Controls............................................ 90 Days

Voltage Controls & Spool Guns...................................................... 90 Days

Spool Gun Controls....................................................................... 1 Year

Welding Power Sources & Wire Feeders......................................... 3 Year

Shelf Life Before WARRANTY Starts ........................................... 1 Year

Upon return of the merchandise at user's expense, PROFAX reserves the

right to either repair or replace as necessary.

This is the only warranty either expressed or implied covering

PROFAX products.

SMOKE, FUMES AND GASES can be

hazardous to your health.

• Keep head away from fumes and smoke.

• Ventilate work area

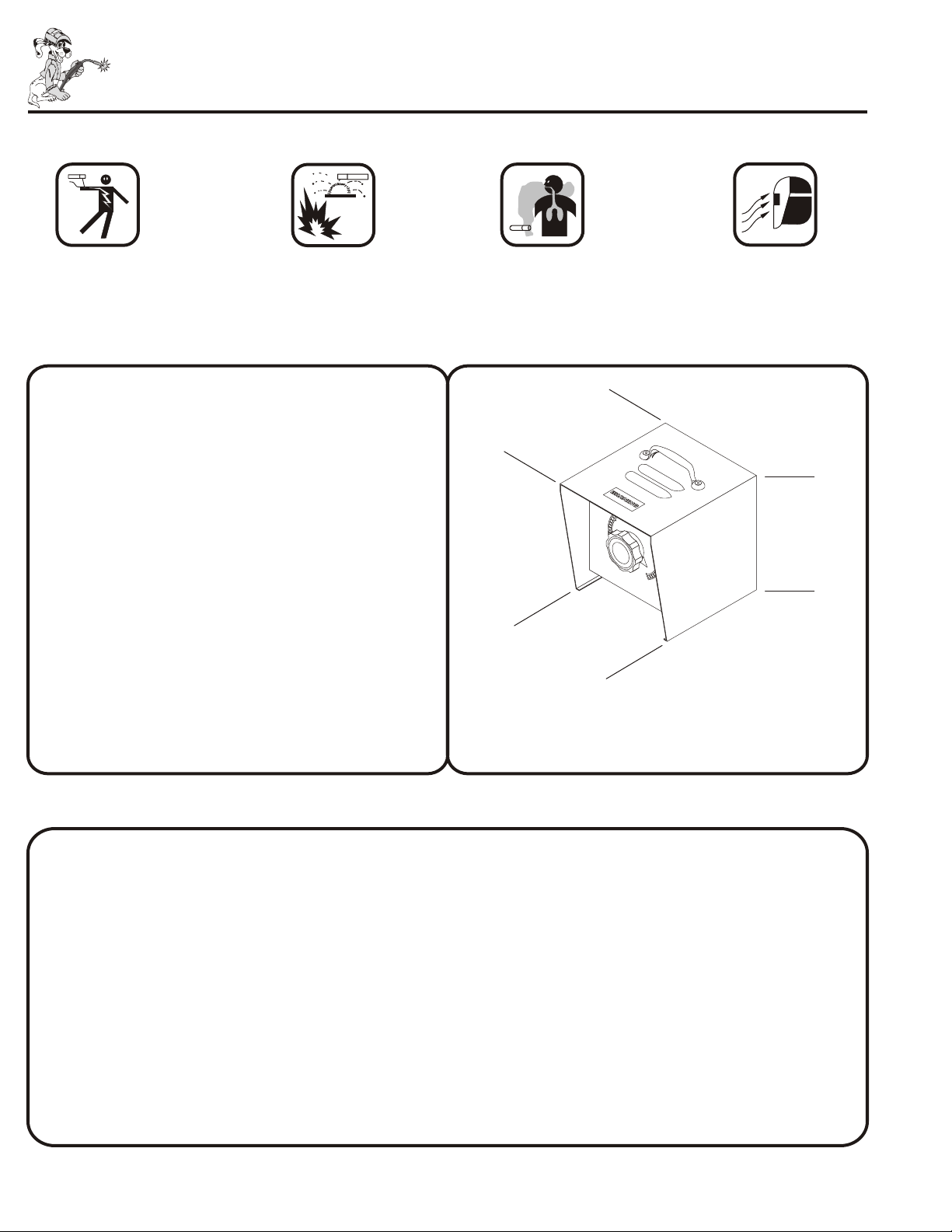

DIMENSIONS

D

W

HEIGHT 9 in. (229 mm )

WIDTH 7 in. (178 mm )

DEPTH 8 in. (203 mm )

ARC RAYS can burn eyes and skin.

• Wear correct body protection

• Wear welding helmet with filter.

H

INSTALLATION

WARNING! Electric Shock can kill.

• Do not touch live electrical parts.

• Shut off welding power source and disconnect all electrical power.

• Shut off engine before making electrical connections.

• Keep all panels securely in place.

CAUTION! Incorrect installation can damage unit.

• Double check installation instructions

1. Turn off welding power source or stop engine on welding generator.

2. TWISTLOCK PLUG:

• Make connection by aligning plug to mating receptacle on power source, inserting plug into the receptacle

and turning clockwise as far as it will go.

3. If the power source has a Contactor Switch - place it into the STANDARD or PANEL position.

4. If the power source has a Current or Voltage control switch - place it in the REMOTE position.

1 2

Page 3

MAINTENANCE

1. Turn off engine and/or disconnect all electrical power before performing maintenance.

2. EVERYDAY:

• Turn control fully from 0 to 100 taking care not to force the control past it's stopping points.

3. EVERY 3 MONTHS:

• Inspect repair and/or replace any cracked parts or frayed cords.

• Replace any unreadable labels.

TROUBLESHOOTING

1. NO AMPERAGE OR VOLTAGE CONTROL

• Check switches and controls on power source for proper position.

Remote Contactor Switch ------------Standard position (contactor on)

Remote Current or Voltage Switch --- Remote position

• Check plug on hand control to see if it is connected properly to receptacle on power source.

• Check control, cord and plug for broken wires or parts.

2. NO OUTPUT

• Check weld output on welding power source or generator.

(see power source owners manual)

®

REMOTE HAND CONTROL SELECTION GUIDE

MODEL PART NO. LENGTH COMPATIBLE EQUIPMENT

MHC-3 MHC-3 No Cord Used on all MILLER equipment that has the 030-653

MHC-3-25 25ft. Cord (15 ohm) rheostat.

MHC-3-50 50ft. Cord 330, 340, & 360 ABP, CP750E, DIALARC HF, FC6E,

MHC-3-100 100ft. Cord MK IV EXPRESS , MK VIII -2, SR150, SR200, 300, 400, & 600,

MP30E, 45E, 65E & 75E, SRH222, 303, 333, 404, 555 & 666

MHC-3GD34A MHC-3GD34A No Cord Used on all MILLER engine drive equipment that uses

MHC-3GD34A-25 25ft. Cord the 605-960 (34 ohm) rheostat.

MHC-3GD34A-50 50ft. Cord BIG 20G , BIG 25D , BIG BLUE 250D, BIG BLUE 251D,

MHC-3GD34A-100 100ft. Cord BIG 40 , BIG 40 D, BIG D4, BIG BLUE 400D,

BIG BLUE 400D AIRPAK , WD-5, WILDCAT 350G & 350D

REMOTE MCGD-40A Remote facilities for installing the MHC-3GD34A remote hand

FACILITIES control onto MILLER engine driven power sources that have the

605-960 (34ohm) rheostat.

®®

Miller is the trademark of Miller Electric Mfg. Co.

®® ® ®

®® ®

®®

®

®

®®

®

®

WIRING DIAGRAMS

PX030-653 Rheostat

REAR VIEW

PX605-797

Twistlock Plug

REAR VIEW

PX 605-960 Rheostat

REAR VIEW

Silver

9328

Twistlock Plug

REAR VIEW

White

Green

Black

MHC-3

WH

X

Y

Green

Black

White

Brass

MHC-3GD34A

Page 4

ISOMETRIC EXPLODED PARTS VIEW

®

®

& REPLACEMENT PARTS

4

1

9

3

9

7

5

2

10

6

8

ITEM PART NO. DESCRIPTION MHC-3 MHC-3GD34A

1 PX030653 Rheostate - 15 ohm - 150 Watt 1

PX605960 Rheostate - 34 ohm - 300 Watt 1

2 LHCK Knob 1

MHCK Knob 1

3 MHT Top Cover 1 1

4 LMH Handle 1 1

5 7026 Strain Relief Assembly 1 1

6 9283 Cord - Size 14/3 (order by ft.) 1

9285 Cord - Size 12/3 (order by ft.) 1

7 LHB Base 1

MHB Base 1

8 PX605-797 Plug - Twistlock 1

9328 Plug - Twistlock 1

9 9142 Label - PROFAX 2

10 9300 Label - MHC-3 1

9303 Label - MHC-3GD34A 1

3

Loading...

Loading...