Profax 600 AMP WATER COOLED MIG User Manual

®

PROFAX DESCRIPTION

PWC-35-12 12’ water cooled mig gun .035 wire

1

10

PWC-45-12 12’ water cooled mig gun .045 wire

PWC-364A-12 12’ water cooled mig gun 3/64” aluminum wire

PWC-52-12 12’ water cooled mig gun .052 wire

PWC-116-12 12’ water cooled mig gun 1/16” wire

2

PWC-116A-12 12’ water cooled mig gun 1/16” aluminum wire

PWC-564-12 12’ water cooled mig gun 5/64” wire

3

4

5

6

7

7a

12

7b

6

0

0

11

18

25

9

20

8

A

17

16

15

M

P

14

P

A

R

T

S

18

26

25

20

24

15

16

L

I

27

S

T

19

23

28

17

21

32

22

24

All guns shipped with

31

29

30

matching quick

connects for water.

TO ORDER DIRECT CONNECT WATER COOLED GUNS

Standard - All wire feeders that accept the PROFAX rear adapter ........................... e.g. PWC-35-12

® ®

Lincoln Direct - Add an LN for the standard Lincoln ¾” dia. rear adapter........................e.g. PWCLN-35-12

® ®

Miller Direct - Add an M for all Miller rear adapters .................................................... e.g. PWCM-35-12

Euro-Quick - Add an X for all Euro-Quick rear adapters............................................... e.g. PWCX-35-12

All other Lincoln machines use the PROFAX standard rear adapter........ e.g. PWC-35-12

P.O. Box 898 • Pearland, TX 77588-0898

PROFAX DESCRIPTION

PWC-35-15 15’ water cooled mig gun .035 wire

PWC-45-15 15’ water cooled mig gun .045 wire

PWC-364A-15 15’ water cooled mig gun 3/64” aluminum wire

PWC-52-15 15’ water cooled mig gun .052 wire

PWC-116-15 15’ water cooled mig gun 1/16” wire

PWC-116A-15 15’ water cooled mig gun 1/16” aluminum wire

PWC-564-15 15’ water cooled mig gun 5/64” wire

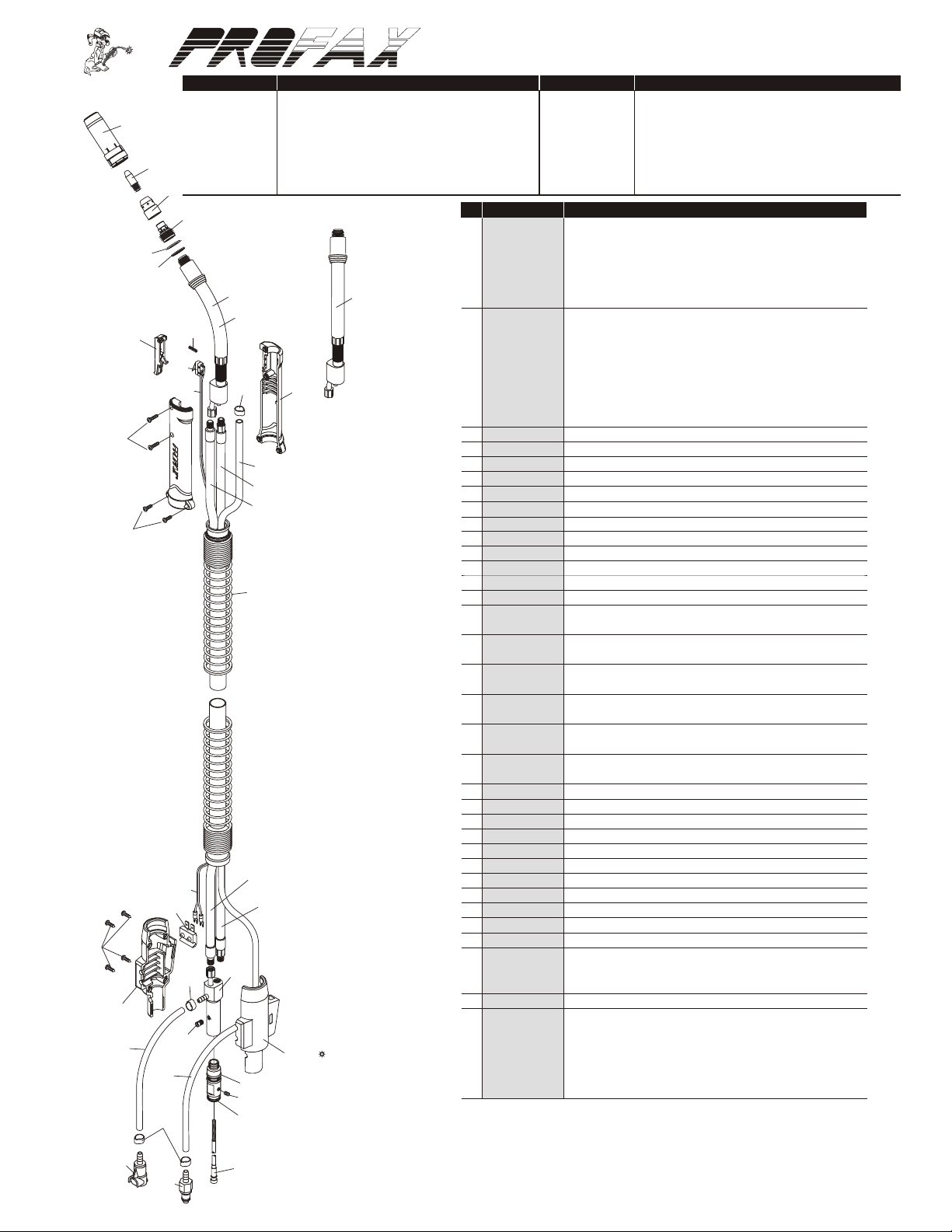

NO. PROFAX NO. DESCRIPTION

1. 26W50F Nozzle 1/2” flush

26W62F Nozzle 5/8” flush

26W75F Nozzle 3/4” flush

26W50R Nozzle 1/2” recessed

26W62R Nozzle 5/8” recessed (Standard)

26W75R Nozzle 3/4” recessed

2. 16W35 Contact tip .035 .044 I.D.

16W45 Contact tip .045 .054 I.D.

16W364A Contact tip 3/64” A .060 I.D.

16W52 Contact tip .052 .062 I.D.

16W116 Contact tip 1/16” .073 I.D.

16W116A Contact tip 1/16” A .078 I.D.

16W564 Contact tip 5/64” .093 I.D.

16W332 Contact tip 3/32” .109 I.D.

3. 26HTI Insulator, hi-temp

4. 56W Gas diffuser

5. 228 O-ring, hi-temp

6. 229 Washer, insulating

7. 66W50 Gooseneck assembly 50° (Standard)

7a. 66W50S Optional gooseneck assembly 50° (2” shorter)

7b. 66W180 Optional gooseneck assembly straight

8. 86W Handle, with screws

9. 126SS Short screw for handle (2 req’d)

10. 96T Trigger

11. 96S Switch

12. 196 Spring, trigger

13. 600-12 12’ Hose cable assembly (complete set)

600-15 15’ Hose cable assembly (complete set)

14. 601-12 12’ Outer cover assembly

601-15 15’ Outer cover assembly

15. 602-12 12’ Red power cable assembly

602-15 15’ Red power cable assembly

16. 603-12 12’ Conduit assembly

603-15 15’ Conduit assembly

17. 604-12 12’ Blue water in hose assembly, w/fittings

604-15 15’ Blue water in hose assembly, w/fittings

18. 605-12 12’ Switch assembly, w/switch & terminals

605-15 15’ Switch assembly, w/switch & terminals

19. 606 Red water out hose assembly, w/fittings

20. 168 Hose clamp (2 req’d)

21. 188 Hose clamp (2 req’d)

22. 66M Male quick connect fitting

23. 66F Female quick connect fitting

24. R186-H Housing, with screws

25. R185-SC Screw for housing and handle (6 req’d)

26. 194 Connector tab assembly

27. 608W Block assembly

28. 1R-W Screw plug

29. 44C Set screw for liner, 8-32

30. R174-T Connector, Standard

R174-L Connector, Lincoln

R174-M Connector, Miller

31. 224 O-ring for standard connector

32. 44-3545-15 15’ liner for .035-.045 wire

44N-3545-15 15’ liner for .035-.045 aluminum wire

44-116-15 15’ liner for .052-1/16” wire

44N-116-15 15’ liner for 1/16” aluminum wire

44-564-15 15’ liner for 5/64” wire

44-332-15 15’ liner for 3/32” wire

®

®

®

600 Amp Water Cooled Mig Gun

Made in U.S.A.

AMPS DUTY CYCLE TYPE/GAS MIX

600 100% FLUX CORE

500 100% 80-20, 98-2,

RATINGS

CO2, 75-25,

PULSE MIG,

95-5, 92-8

Electric Shock can cause INJURY or DEATH.

IMPORTANT: Before installing this equipment be sure that the input power to the welding power source has been disconnected at the electrical

breaker box, and that the power switch on the power source and wire feeder are in the off position.

See safety information sheet supplied with this manual.

The PROFAX 600 amp water cooled Mig-gun comes standard with a PROFAX TWECO style rear connection that will mate to the PXTAK-1 or

®

PXTLAK-1 adapter block, or direct connect to any wire feeder that will accept this type of connection. See direct connect versions and

ordering information on the opposite side of this page. Contact your welding supply distributor for availability of any direct connect version not

listed.

All references to original manufacturer’s equipment numbers, and/or trade names or trademarks, are for

identification and convenience only. The trade names and trademarks are the property of their respective owners.

INSTALLATION

1. Lay the gun out in a straight line and make sure that the gun is equipped with the proper contact tip and conduit for the type and size of

wire to be used. Also make sure that the adapter, wire feeder guides and drive rolls are correct for the type and size of wire to be used.

2. Push the brass connector end of the gun cable into the outgoing side of the adapter block or drive housing until it is fully seated. Secure

the connector.

3. Install the trigger control cord to the mig gun and to the mating trigger receptacle on the wire feeder.

4. Relieve tension and disengage drive rolls on feeder. Cut wire end straight and feed wire by hand through wire feeder guides and into the

PROFAX mig gun at least one to two feet.

5. Reset drive rolls and apply proper tension. Keeping the gun in a straight position, continue to feed wire through the gun by using the wire

feeder inch button or gun trigger. Contact tip may need to be removed for wire to feed through properly.

CAUTION SHOULD BE TAKEN NOT TO POINT GUN AT FACE OR BODY WHEN FEEDING WIRE.

6. Install the supplied quick connect fittings onto your coolant circulator. The female fitting should be connected to the water out side and the

male fitting to the water return side.

7. Attach the quick connect fittings on the PROFAX Mig-gun to the quick connect fittings on the coolant circulator. Fill the circulator with

clean coolant composed of an ethylene glycol and water mixture, such as PROFAX part no. PX7-2850. Turn the circulator on and verify

that the flow is at least ½ gallon per minute, with a maximum pressure of 75 psi.

IMPORTANT: Always turn the circulator on before you weld, and run the circulator for at least one minute after you stop welding. Use

only an ethylene glycol and water coolant; never use plain water as this can cause corrosion inside the gun. Check the

coolant level and cleanliness daily, and change the coolant every three months to avoid algae growth. Dirty coolant can

clog the quick connect fittings and coolant passages in the gun, reducing coolant flow. DAMAGE CAUSED BY

INSUFFICIENT COOLANT FLOW IS NOT COVERED BY WARRANTY.

CAUTION!: When you activate the gun trigger, the contact tip and wire protruding from the tip are electrically “HOT”.

8. Set the power source to the proper settings for the wire size and welding application. Make sure the shielding gas and coolant are on and

adjusted to the proper flow rates.

GUIDELINES TO AVOID WIRE FEEDING AND COOLING PROBLEMS

1. Use only clean, rust free wires of good quality.

2. Keep cable assembly as straight as possible. Do not kink or pull cable around sharp corners or allow cart wheels or tr ucks to run over

cables.

3. Make sure contact tip is tightly screwed into gas diffuser. Frequently clean contact tip and nozzle. Use anti-spatter compounds to facilitate

spatter removal. If contact tip hole becomes deformed or shows arcing, replace immediately.

4. Verify often that all gun connections are secured and electrical connections are tight. Check all gas and water connections on a regular

basis to make sure no leakage or loss of flow occurs.

5. Always turn the coolant circulator on before using your PROFAX Mig-gun. Verify that the coolant is clean, and that the flow rate is at least

1/2 gallon per minute.

BY FOLLOWING THESE SIMPLE GUIDELINES YOU WILL

EXTEND THE LIFE OF YOUR PROFAX MIG-GUN

00189OG020410

Loading...

Loading...