E-1

WARNING

• When inserting the Compact Panel Computer PS-3700A(Pentium®4M-1.7GHz Model) (hereafter

referred to as the "PS-A")'s power cord into the PS-A's AC Connector, check first that the PS-A's

power supply is completely turned OFF, via a breaker, or similar unit.

• Before either plugging in or unplugging a board or interface connector, be sure to turn the PS-A’s

power OFF.

• Whenever changing the Backlight, to prevent electric shocks and burns, be sure to turn OFF the

PS-A's power and wear protective gloves.

• After the PS-A’s backlight burns out, unlike the PS-A’s “Standby Mode”, the touch panel is still

active. If the operator fails to notice that the backlight is burned out and touches the panel, a

potentially dangerous machine miss-operation can occur.

If your PS-A's backlight suddenly turns OFF, use the following steps to determine if the

backlight is actually burned out.

1) If your PS-A is not set to "Standby Mode" and the screen has gone blank, your backlight is

burned out.

2) Or, if your PS-A is set to Standby Mode, but touching the screen does not cause the

display to reappear, your backlight is burned out.

• Do not open or remodel the PS-A unit, since it may lead to a fire or electric shock.

• Do not use power beyond the PS-A's specified voltage range. Doing so may cause a fire or an

electric shock.

• Do not use the PS-A in an environment where flammable gases are present, since operating the

PS-A may cause an explosion.

• The PS-A uses a lithium battery for backing up its internal clock data. If the battery is incorrectly

replaced (i.e. its + and - sides are reversed), the battery may explode. When changing the

battery, please contact your local PS-A distributor.

• Do not use the PS-A unit as a warning device for critical alarms that can cause serious operator

injury, machine damage or production stoppage. Critical alarm indicators and their control/activator units must be designed using stand-alone hardware and/or mechanical interlocks.

• To prevent operator injury or machine damage, be sure to design your machine operation system so that the machine will not malfunction due to a communication fault between the PS-A

and its host controller.

• Do not use PS-A touch panel switches in life-related or important disaster prevention situations. For

safety related switches, such as an emergency switch, be sure to use a separate mechanical switch.

• The PS-A is not appropriate for use with aircraft control devices, aerospace equipment, central

trunk data transmission (communication) devices, nuclear power control devices, or medical life

support equipment, due to these devices inherent requirements of extremely high levels of

safety and reliability.

• When using the PS-A with transportation vehicles (trains, cars and ships), disaster and crime

prevention devices, various types of safety equipment, non-life support related medical devices,

etc. redundant and/or failsafe system designs should be used to ensure the proper degree of

reliability and safety.

WARNINGS

T o pr event this unit from malfunctioning :

• In order to extend the lifetime of the hard disk, Pro-face recommends you set the Windows [Control panel]-[Power Management option]-[Turn off hard disks] selection to turn the hard disk off

when the unit is not being operated. A setting of 5 minutes is recommended.

• Do not strike the PS-A's touch panel with a hard or heavy object, or press on the touch panel with

excessive force, since it may damage the display.

• Do not install the PS-A where the temperature will exceed its specified range.

• Be sure that water, liquids or metal particles do not enter the PS-A, since it may cause a malfunction or a short circuit.

• Avoid installing the PS-A where sudden, large changes in temperature may occur . These changes

may cause condensation to form inside the unit, possibly causing a malfunction.

• To prevent excessive heat from building up inside the PS-A, do not install it where its ventilation

holes may be blocked. Also, do not install or store the PS-A near high temperature equipment.

• Do not install or store the PS-A in direct sunlight or where high levels of dust exist.

• Since the PS-A is a precision instrument, do not install or store it where either strong shocks or

excessive vibration may occur.

• Do not install or store the PS-A in an area containing chemicals or chemical fumes.

• Do not use paint thinner or organic solvents to clean the PS-A's case or screen.

• Due to the danger of unforeseeable accidents, back up all PS-A data regularly.

• After turning this unit OFF, be sure to wait a few seconds before turning it ON again. If the unit is

started too soon, it may not start up correctly.

E-2

The PS3700A-T41-ASU-P41 is a UL/CSA listed product (UL File No. E220851). Please pay

special attention to the following instructions when applying for UL/CSA approval for machinery

which includes this PS-A unit.

The PS-A conforms as a component to the following standards:

UL508 Industrial Control Equipment

CAN std C22.2 No.14-1995, CAN/CSA22.2 No.60950

PS3700A-T41-ASU-P41 (UL Registration Model No.:3180046-01)

- Equipment with a PS-A unit mounted in it requires UL/CSA evaluation for the combination of the PSA and equipment.

- The PS-A must be used as a built-in component of an end-use product.

- Use the PS-A indoors only.

- When connecting the PS-A’s power cord, be sure to use a cord that is appropriate for the current

and voltage used and that has conductive wires that are 0.75 mm2 or larger.

- When using the PS-A in an end-use product, be sure to install the PS-A unit's power cut-off

switch where the operator can easily reach it.

- Danger of explosion if backup battery is incorrectly replaced. Should be replaced only with

same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer’s instructions.

- Be sure the unit the PS-A is built into uses a UL508 compatible structure.

The PS3700A-T41-ASU-P41 is a CE marked, EMC compliant product.

<Complies with the following Standards>

• Safety

EN60950

• EMI

EN61000-6-4, EN55011(Group 1, Class A)

• EMS (EN61000-6-2)

EN61131-2, EN61000-4-2, EN61000-4-3, EN61000-4-4, EN61000-4-5, EN61000-4-6,

EN61000-4-8, EN61000-4-11, EN61000-4-12

• FCC

47 CFR Part15 Class A

If the following requirements are not met, the PS-A may fail to meet EN60950 standard requirements.

• The PS-A must be used as a built-in component of an end-use product.

• Use the PS-A indoors only.

• When connecting the PS-A’s power cord, be sure to use a cord that is appropriate for the

current and voltage used and that has conductive wires that are 0.75 mm2 or larger.

• When using the PS-A in an end-use product, be sure to install the PS-A unit's power cut-off

switch where the operator can easily reach it.

• There is a danger of explosion if the backup battery is incorrectly replaced. This battery should

be replaced only with same or equivalent type recommended by the manufacturer. Dispose of

used batteries according to the manufacturer’s instructions.

• Be sure the PS-A unit's enclosure is an EN60950 approved sheet steel structure.

CE Marking Notes

UL/CSA Application Notes

DIS TRI BUTEU R C O NSEI L DEPUI S 1985

System

Email :

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

hvssystem@hvssystem.com

Site web : www.hvssystem.com

Distribué par :

E-3

The following items are included in the PS-A's package. Before using the PS-A, please confirm

that all items listed here are present.

This unit has been carefully packed, with special attention to quality. However, should you find anything

damaged or missing, please contact your local PS-A distributor immediately.When you order a PS-A

unit built to your specifications, that PS-A package should include each optional item's Installation

Guide. Please use that guide to check the contents of each optional item's package.

Package Contents

PS-A Unit (1)

(PS3700A-T41-ASU-P41)

Installation Fasteners (4/set ×2 )

Installation Gasket (1)

USB Cable Clamp (1)

• Be careful when installing the PS-A not to damage the built-in HDD.

• The Power Cord included in the FP unit’s package is designed only for

AC100V or AC115V use. Any other voltage will require a different cord.

AC Power Cord Clamp (1)

CD-ROM (1)

• The CD-ROM included in this package contains a User Manual, RAS-API

Reference Manual, and PS-A Series Utility and Driver files. Please refer to

PDF manuals.

Installation Guide (1)

<This Guide>

Installation

Guide

AC Power Cord (1)

E-4

The PS-A unit's CD-ROM contains the following PDF manual files.

- Compact Panel Computer PS-3700A (Pentium® 4M - 1.7GHz Model) User Manual (psap4e.pdf )

- PS Series Type A (Pentium® 4M - 1.7GHz Model) API Reference Manual (psap4ape.pdf)

Reading a PDF file requires installation of the Adobe Corporation's Acrobat® Reader.

Acrobat

®

Reader Installation:

To install the Acrobat® Reader software, follow the steps given below.

1) This software, in the form of a self-extracting file, is located in this CD-ROM in the folder titled

[reader]. Use the Explorer software to find the file [Reader\Eng\ar505enu.exe], and double-click

on the file icon to begin the Reader installation.

2) After installation begins, follow the instructions given.

Viewing the PDF manual:

To view the PDF manual contained in this CD-ROM, follow the steps given below.

1) Use the Explorer software to locate the file [Manual\Eng\psap4e.pdf or psap4ape.pdf] in

the folder titled [Manual].

2) Double-click on the PDF file's icon. Acrobat® Reader will automatically start and the first

page of the PDF manual will appear.

About The Manual

E-5

1 Part Names

1 : Display / Touch Panel

2 : Power Lamp LED (POWER)

10

1

12

15

14

18

16

21

20

19

22

3

4

7

11

13

17

2324

25262728 29

Top

Bottom

Sides

Rear

Front

2

5

6

LED PS-A Status

Green

Normal Operat ion

(Power On)

Orange

Sy st em Monitor Error

Touch Panel Self Test Erro

r

Orange/Red Backlight is not functioning

3 : IDE Access Lamp

LED PS-A Status

Green Current ly us ing I DE I /F

4 : Front Packing

5 : Hardware Reset Switch (RESET)

6 : USB Connector (1 port)

[USB Ver. 1.1 compatible]

*1

7 : Arm Attachment Screw Holes

[VESA 75mm]

8 : Power Switch

9 : Expansion Board Support

10 : FD Drive

11 : CD-ROM Drive

12 : PCMCIA Connectors (PCMCIA)(2 ports)

13 : Rear Cover

14 : Mouse Connector (MOUSE)

15 : Keyboard Connector (KEYBOARD)

16 : Expansion Slot

17 : LAN Connector (LAN)

[10 BASE-T /100 BASE-TX]

18 : USB Connectors (2 ports)

[USB Ver. 2.0 compatible]

19 : RS-232C Connector (COM1)

[+5V/RI Changeover]

20 : RS-232C Connector (COM2)

[+5V/RI Changeover]

21 : RS-232C Connector (COM3)

[RS-422/RS-485 Changeover]

22 : RS-232C Connector (COM4)

23 : Line Input Connector (LINE IN)

24 : Speaker Output Connector

(SPEAKER)

25 : Mike Input Connector (MIC IN)

26 : Printer Connector (LPT1)

27 : Cooling FAN

28 : CF Card Slot

29 : AC Inlet Connector

9

8

*1 USB HUB and USB Ver. 2.0 compatible devices cannot be connected.

E-6

Unit:mm [in]

2 Dimensions

Front

Top

100 [3.94]

282 [11.10]

5 [0.20]

395 [15.55]

294 [11.57]

383 [15.08]

Side

• Prior to attaching peripheral units to the PS-A, be sure the PS-A’s power

cord is disconnected from the main power supply.

• To prevent an electrical shock, be sure to disconnect the PS-A’s power cord

from the power supply before connecting the cord or any peripheral devices to the PS-A.

PS-A Unit

External Dimensions

(with Installation Fasteners installed)

100 [3.94]

160 [6.30]

5 [0.20]

394.8 [15.54]

404.8 [15.94]

Bottom

165 [6.50]

Front

Right Side

293.8 [11.57]

303.8 [11.96]

Left Side

Top

Unit:mm [in]

160 [6.30]

160 [6.30]

E-7

Electrical

Environment

3 General Specifications

• When using any of the PS-A’s optional devices, be sure to check

that device’s specifications for any special conditions or cautions that

may apply to its use.

• Be aware that not only does the Hard Disk have a fixed lifetime,

but that accidents can always occur. Therefore, be sure to back up

your Hard Disk’s data regularly, or prepare another Hard Disk unit

that can be used for backup.

Rated Voltage A C100V / AC240V

Volta ge Supply Range AC85V to AC265V

Rat e d Fr e que nc y 50/60Hz

Allowable Volta ge Drop

1cycle or less

(pause occurrences must be more than 1 s econd apart )

Power Consum pt ion 150VA or les s

Voltage E ndura nc e

A C 1500V 20mA for 1 minute

(between charging and FG terminals)

Insulation Resistance

10MΩ or higher at DC 500V

(between charging and FG terminals)

Ambient Operating Temperature

Storage Temperature

Ambient Humidity

St or age H um idit y

Air Purity (Dust)

Pollut ion D egr e e

Corrosive Gases

When using

HDD

4.9m/s

2

at 10Hz to 25Hz in X, Y, Z direction

s

for 30 minutes

When NOT

using HDD

9.8m/s

2

at 10Hz to 25Hz in X, Y, Z direction

s

for 30 minutes

Nois e Im munity

(Impuls e N ois e)

Nois e Im munity

(First transient burst noise)

Electrostatic Discharge Immunity

Noise Voltage : 1500Vp-p (v ia noise simulator)

Pulse Dur at ion : 50 ns, 500ns, 1µs

Rise Time : 1ns

Power Line : 2kV IEC 61000-4-4

COM Port : 1 k V IEC 61000- 4- 4

4kV IEC 61000-4- 2

V ibration Resistance

Free of dust

Pollut ion Degree 2

Free of corrosiv e gas es

+5

o

C to +50 oC (W hen Us ing HDD)

0 oC to +50 oC (When NOT Using HDD)

-10

o

C to + 60 oC

10%RH to 85%RH

(Non condensing, wet bulb t emperature : 2 9oC or less)

10%RH to 85%RH

(Non condensing, wet bulb t emperature : 2 9oC or less)

E-8

• The Hard Disk lifetime given here may be reduced due to unforeseen environmental factors, however, generally speaking, the disk

should last for 20,000 hours (of operation) or approximately 5

years, whichever comes first at an operating temperature of 20

o

C

and 333 hours of operation per month. (HDD access frequency of

20% or less)

• Using the Hard Disk in an environment that is excessively hot

and/or humid will shorten the disk’s usage lifetime. A wet bulb

temperature of 29

o

C or less is recommended. This is equivalent to

the following data.

• In order to extend the lifetime of the hard disk, Pro-face recom-

mends you set the Windows [Control panel]-[Power Management

option]-[Turn off hard disks] selection to turn the hard disk off

when the unit is not being operated. A setting of 5 minutes is

recommended.

• When using CD-ROM Drive, be sure to use the PS-A unit where

no excessive vibration. It causes data read error.

* 1 The front face of the PS-A unit, installed in a solid panel, has been tested using condi-

tions equivalent to the standard shown in the specification . Even though the PS-A unit’s

level of resistance is equivalent to this standard, oils that should have no effect on the

PS-A can possibly harm the unit. This can occur in areas where either vaporized oils are

present, or where low viscosity cutting oils are allowed to adhere to the unit for long

periods of time. If the PS-A’s front face protection sheet becomes peeled off, these conditions can lead to the ingress of oil into the PS-A and separate protection measures are

suggested. Also, if non-approved oils are present, it may cause deformation or corrosion

of the front panel’s plastic cover. Therefore, prior to installing the PS-A, be sure to

confirm the type of conditions that will be present in the PS-A’s operating environment.

If the installation gasket is used for a long period of time, or if the unit and its gasket are

removed from the panel, the original level of the protection cannot be guaranteed. To

maintain the original protection level, Pro-face recommends that you replace the installation gasket regularly.

Structural

Temperature Humi dity

at 35

o

C no higher than 64%RH

at 40

o

C no higher than 44%RH

Grounding 100

Ω

or less, or your country’s applicable standard

Ratings

*1

Equivalent to IP65f (JEM 1030)

(When Not Using front-face USB Port unit)

Design Type: Modular

Installation m ethod: Panel / VESA Arm

Cooling Method Via Cooling Fans (for Unit/ for CPU)

Weight Approx. 8.0kg (17.6Ib)

Dime nsions ( W x H x D) 395 mm [15.55 in] x 294 mm [11.57 in.] x 100 mm [3.94 in.]

E-9

Serial Interface (COM1,COM2,COM3,COM4)

RS-232C Interface (COM1, COM2, COM3, COM4)

15

69

4 Interfaces

Pin A rr a nge m e nt PIN# Signal Condition Direc tion

1 CD Carrier Detect Input

2 RXD Receiv e Dat a Input

3 TXD Send Data Output

4 DTR Data Terminal Ready Output

5 GND Signal Ground 6 DSR Data Set Ready Input

7 RTS Request S end Output

8 CTS Clear Send Input

9 RI / 5V Ring Indicate In/Output

FG FG Frame Ground -

RS-422 Interface (COM3)

Pin# Signal Condition Direction

1 RXA Receive Dat a (+ ) Input

2 RXB Receive Data (-) Input

3 TXA Send Data (+) Output

4 NC No Connection 5 GND Ground 6 NC No Connection 7 TXB Send Data (-) Output

8 NC No Connection 9 NC No Connection -

FG FG Frame Ground -

RS-485 Interface (COM3)

Pin# Signal Condition Direction

1 DATA+ Send/Receiv e Data (+) In/ Out p ut

2 DATA- Send/Receive Data (-) In/Output

3 NC No Connection 4 NC No Connection 5 GND Signal Ground 6 NC No Connection 7 NC No Connection 8 NC No Connection 9 NC No Connection -

FG FG Frame Ground -

E-10

Switches

The following switch settings corresponding to each Serial Interface need to be

signified. To set the switches, remove the PS-A’s Rear Cover and locate the following switches, next to the PS-A’s circuit board. For information about attach-

ing/removing the Rear Cover,

5. Installation Removing and Install-

ing the Rear Cover The switches are located as follows;

COM1

PCI

AB

C

D

COM3

BAT

• COM3 and COM4 cannot be used for +5V Output.

• Do not connect any pins to COM3 [NC].

• No. 5 pin (GND) for RS-232C (COM1,COM2,COM3, COM4) is the

signal ground. Be sure to connect the GND terminal to the other

unit’s SG (signal ground) terminal.

• Be sure to confirm what settings will be used by the other device

when setting the switches. Failure to do so can result in a unit malfunction or damage.

• Whenever changing any PS-A switch settings, be sure to first turn

the PS-A’s power supply OFF. Failure to do so can cause a PS-A

malfunction.

• Connect the FG terminal line to the connector cover's PS-A connector attachment screw.

• FG and SG terminals are internally connected in the PS-A. When

connecting to another device, be sure to create an SG shorting loop

in your system.

Use inch type (#4-40UNC) threads to hold the cable's set (attachment) screws

in place.

RI

5

V

RI

5V

COM4

USB

O

N

12345678

E-11

TXD

RTS

SW4

SW5

SW7

SW6

SW8

TXA

TXB

RXA

COM3

RXB

Switch

Location

Switch Name

Compatible

I/F

Description

A +5V/RI Changeover SW COM1

B +5V/RI Changeover SW COM2

C Serial Mode Select SW COM3

8-point dip switch. Designates COM3 communication settings.

For Serial Mode Select SW details, see Table (1).

The factory settings are all OF F. (RS-232C)

D

Touch Panel's

Communication

Changeover SW

COM4

USB

Changes the Touch Panel communication method. (Serial <--->

USB) The factory setting is USB.

(If "Serial" is selected, COM4 cannot be used.)

Changes # 9 pin (RI <---> 5V).

The factory setting is RI.

Table (1) Serial Mode Select SW

( The factory settings are all OFF. Compatible I/F: COM3 )

*1 Be sure to keep the settings, "OFF".

*2 If you use termination resistance, base your setiings on your connection specifications.

The COM3 compatible Serial Mode Select Switches (SW4 to SW8) operate

as shown in the circuit diagram below.

Fig. 1 Serial Mode Select Switches (SW4 to SW8) circuit diagram

SW

No.

Description ON O FF RS-232C RS-422 RS-485

1

Used by the system Reserved Reserved

OFF

*1

OFF*1OFF

*1

2

Changes COM3's

communciation method

RS-422/RS-485 RS-232C

OFF ON ON

3

Changes COM3's

communciation method

RS-422/RS-485 RS-232C

OFF ON ON

4

Changes TX data's output

mode

TX dat a out put is

controlled v ia

the RTS signal.

TX dat a out put is

NOTcontrolled via the RTS

signal. (nor mally out put )

OFF ON/OFF ON

5

Switches t he TX termination

resist ance ON/OFF

Inserts termination

resist ance of 220Ω

between TXA and TXB.

No ter mination

OFF ON

ON/OF

F

*2

6

Switches t he RX termination

resist ance ON/OFF

Inserts termination

resist ance of 220Ω

between RX A and RXB.

No ter mination

OFF ON

ON/OF

F

*2

7

Switches t he s hor t ing of TXA

and RXA ON or OFF

Short s TXA and RX A

(RS-485 mode)

No short ing

(RS-422 mode)

OFF OFF ON

8

Switches t he s hor t ing of TXB

and RXB ON or OFF

Short s TXB and RXB

(RS-485 mode)

No short ing

(RS-422 mode)

OFF OFF ON

E-12

Keyboard / Mouse Interface

PS/2 compatible Keyboard / Mouse Interface

Ethernet Interface (10BASE-T / 100BASE-TX)

This interface complies with the IEEE802.3 Ethernet communication standard

(10BASE-T / 100BASE-TX) and uses an RJ-45 type modular jack connector (8

points).

CF Card Interface

This interface accepts a CF Card, and connects to IDE.

Electrical Specifications

O.D : Open Drain

T.S : 3 state I/O

TTL : TTL Input

D-sub 25 pin (Female)

Screw Size: (4-40): Inch Type

13 1

25 14

Pin

No.

SPP/ECP

Mode

Signal

Name

EPP

Mode

Signal

Name

Direction

Electrical

Specif.

Pin

No.

SPP/ECP

Mode

Signal

Name

EPP

Mode

Signal

Name

Direction

Electrical

Specif.

1 STRB WRITE

In/Output

O.D/T.S

*1

14 AUTOFD DSTRB

In/Output

O.D/T.S

*1

2DATA0DATA0

In/Output

O.D 15 ERROR ERROR

Input

TTL

3DATA1DATA1

In/Output

O.D 16 INIT INIT

In/Output

O.D/T.S

*1

4DATA2DATA2

In/Output

O.D 17 SLCTIN ADSTRB

In/Output

O.D/T.S

*1

5DATA3DATA3

In/Output

O.D 18 GND GND

6DATA4DATA4

In/Output

O.D 19 GND GND

7DATA5DATA5

In/Output

O.D 20 GND GND

8DATA6DATA6

In/Output

O.D 21 GND GND

9DATA7DATA7

In/Output

O.D 22 GND GND

10 ACKNLG ACKNLG

Input

TTL 23 GND GND

11 BUSY WAIT

Input

TTL 24 GND GND

12 PE PE

Input

TTL 25 GND GND

13 SLCT SLCT

Input

TTL

* 1 Pins 1, 14, 16 and 17 will become O.D when the SPP mode specification is used. If the

mode changes to ECP or EPP, these pins will become T.S

Printer Interface (LPT1)

This interface conforms to Centronics standards.

E-13

USB Interface

This interface is for connecting USB compatible devices.

The USB port on the unit's Front face is USB Ver. 1.1 compatible. USB HUB and

USB Ver. 2.0 compatible devices cannot be connected. The USB ports (2 ports) on

the unit's Bottom face are USB Ver. 2.0 compatible.

PCMCIA Interface (PCMCIA)

These interfaces (2) are used to attach a PCMCIA Type II units.

Sound Interface

This interface uses 3 mini-pin jack connectors.

Expansion Unit Interface

This interface is used to attach a PCI unit.

5 Installation

• Before installing the PS-A into a cabinet or panel, check that the instal-

lation gasket is securely attached to the unit.

• A gasket which has been used for a long period of time may have scratches

or dirt on it, and could have lost much of its water resistance. Be sure to

change the gasket at least once a year, or when scratches or dirt become visible.

• The corresponding gasket is CA3-WPG15-01.

• Be sure the gasket's seam is not inserted into any of the unit's corners,

only in the straight sections of the groove. Inserting it into a corner may

lead to its eventually tearing.

• To ensure the installation gasket's maximum level of moisture resis-

tance, be sure the gasket's seam is inserted as shown into the

panel's bottom face.

Confirm the Installation Gasket's Positioning

It is strongly recommended that you use the installation gasket.

Place the PS-A on a level surface with the display panel facing downward.

Check that the PS-A’s installation gasket is seated securely into the gasket’s groove,

which runs around the perimeter of the panel’s frame.

Gasket

Rear of PS-A unit

• When installing the PS-A unit, or when attaching an optional item to the PS-A

unit, do not hold the PS-A unit by its rear-face fan cover while performing the

work. Doing so may damage the fan cover or cause the cover to fall off.

E-14

Installation

Fastener

Panel

PS-A

• Do not tighten the screws with too much force, since it can damage

the PS-A unit.

• The torque necessary to create a drip-resistant seal is 0.5 N•m.

• Depending on the installation panel's thickness, etc., the number of installation fasteners used may need to be increased to provide the desired level of

moisture resistance.

Attach the Installation Fasteners from Inside the Panel

The following figures show the eight (8) insertion slot locations of the PS-A

installation fasteners. Insert the hook section into the slot and tighten the

fastener with a screwdriver, as shown.

Insertion Slots

Top View

Bottom View

Right Side Left Side

Create a Panel Cut

Insert the PS-A into the panel from the front.

under 4-R3[0.12]

Unit: mm [in.]

Panel

Panel thickness

1.6mm[0.06in] to

10mm[0.39in]

PS-A

383.5

[15.10 ]

+1

0

PS-A

Panel

+0.04

0

282.5

+1

0

+0.04

0

11.12

E-15

• To enhance the PS-A's maintainability, operability and ventilation,

allow at least 100 mm clearance between the PS-A and other objects.

(The clearance must be large enough to allow you to install or

uninstall option units and to attach connectors.)

• Standard installation for the PS-A unit is in a vertical panel. If the PS-

A unit is to be installed in a slanted panel, the panel should not incline

more than 30° from the vertical.

• If the PS-A panel is to be installed in a slanted panel that inclines

more than 30°, use forced-air cooling to ensure the ambient operation

temperature does not exceed 50° C.

• Horizontal installation (that is, rotating the panel so that one of its

sides is the base) is not supported.

Installation Requirements

(unit: mm[in.])

50

[1.97]

Attaching the PS-A to a VESA Arm or to the Wall

To attach the unit to an Arm or to a wall, use the attachment screws to attach a

commercial-type arm or wall mount adaptor to the PS-A's rear face. (Screw hole to

screw hole width: VESA 75mm)

Please refer to each device's installation guide for installation instructions.

The VESA Arm attachment screw hole dimensions are as follows;

(unit: mm[in.])

Rear Face

Insert and tighten the four (4) M4 screws. (6mm or shorter.) The torque required for

these screws is only 0.7 to 0.8 N.m.

75[2.95]

75[2.95]

50

[1.97]

50

[1.97]

50

[1.97]

50

[1.97]

50

[1.97]

50

[1.97]

E-16

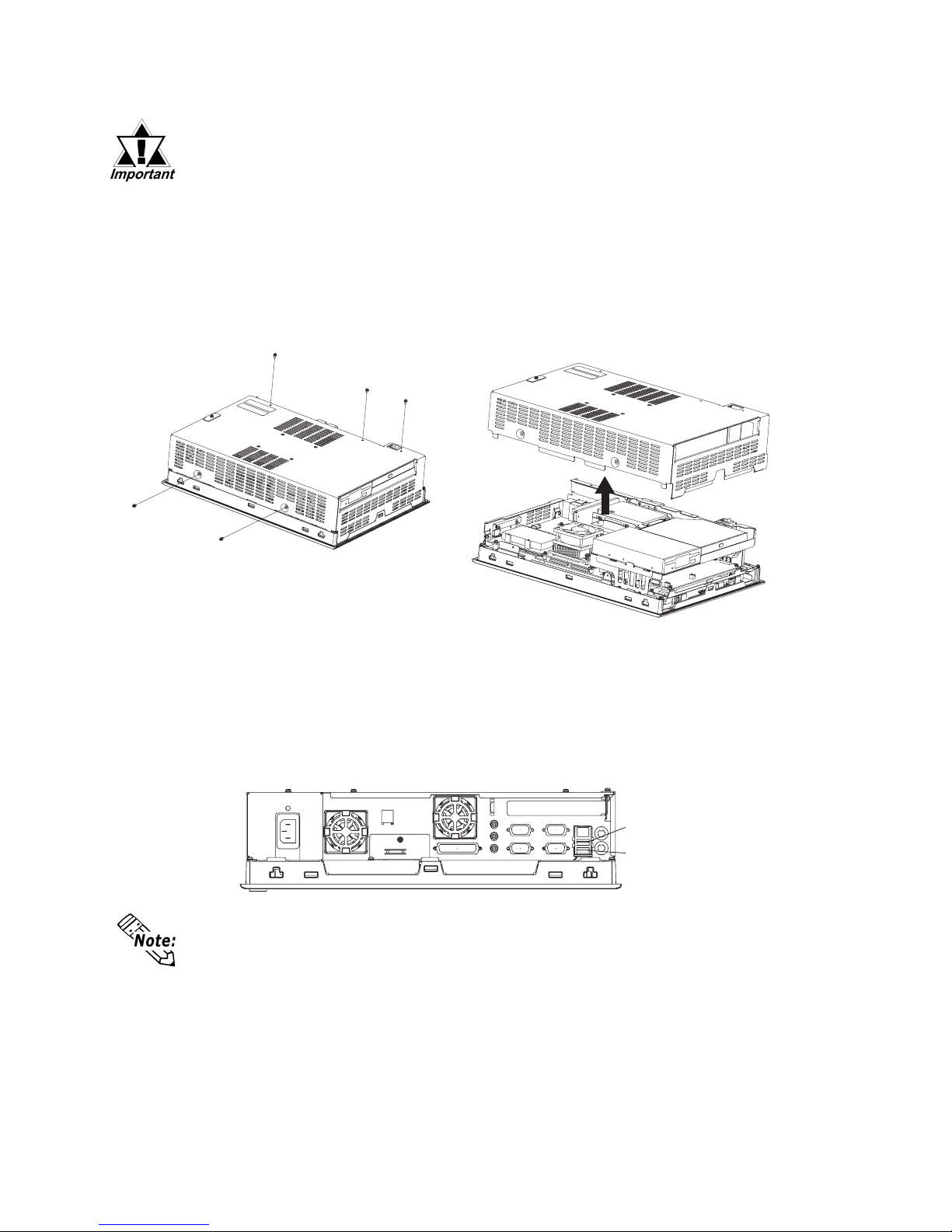

Removing and Installing the Rear Cover

• Use a screwdriver to loosen or tighten the screws. Be sure not to

tighten screws too tightly, since it may damage the equipment.

• Be careful when removing or installing any screws that they do not

fall inside the PS-A.

Lay the PS-A unit on its side and remove the five (5) cover attachment screws. Slide

the rear cover up to remove it in the direction shown. (When reattaching the screws,

use a torque of 0.5 to 0.6N•m.)

USB Cable Clamp Installation

This holder prevents the USB cable from becoming disconnected due to vibration, etc.

1) Place the PS-A unit face-down on a flat surface as shown below. Your PS-A unit has two

USB connectors.

When using only one of the USB ports, be sure to use the lower USB connector.

This allows you to securely clamp the USB cable in the cable clamp.

Upper USB Connecto

r

Lower USB Connecto

r

E-17

Clamp

Bridge

USB Cables

Cable Collars

Removal

T o remove the clamp from the USB cables, push down on the clamp strap’s clip to release it while

pulling up on the clamp.

Clamp

Strap Clip

Attachment

As shown below , insert the USB Cable Clamp’s band through the Bridge. Pass the USB cables

through the Cable Clamp’s band and securely tighten the clamp band around the cables.

• Be sure the clamp is securely holding the USB cable’s plug and collar.

• Be sure the clamp is positioned as shown below, with the clamp pointing

upwards - not to the side. This is to keep the clamp from interfering with

nearby connectors and their cables.

E-18

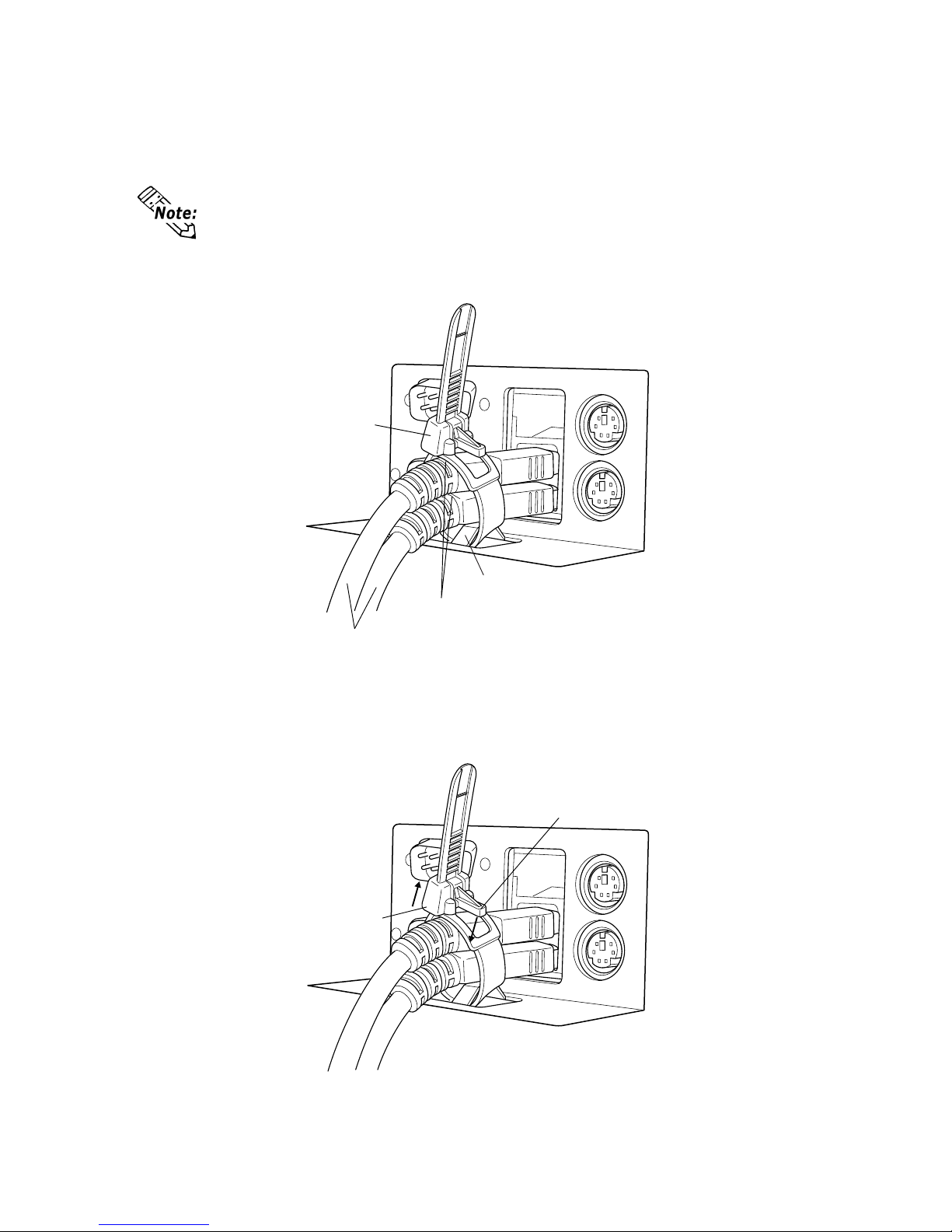

Installing the AC Power Cord Clamp

• Be sure to connect the power cord only after confirming that the

PS-A unit rear face power switch is turned OFF.

Attaching the AC Power Cord

1) Open the AC Power Cord Clamp and insert the AC Power Cord as shown in fig. 1. Then,

close the Cord Clamp until it clicks into place and locks around the AC Power Cord Collar.

• The Cord Clamp has four teeth for locking. These are to adjust the amount of

grip used to hold the AC Power Cord Collar.

6 Wiring

• To avoid an electric shock, check that the PS-A's power supply is

turned OFF, via a breaker, or similar unit before connecting the

PS-A's power cord to the AC connector.

• To avoid the dangers of fire, electric hazards and equipment damage, be sure to use only the specified voltage when operating the

PS-A.

WARNINGS

*1 L : AC Input Terminal-live line

N : AC Input Terminal-neutral line

FG : Ground Terminal connected to the PS-A chassis

Insert the power cord (AC inlet plug) into the PS-A's bottom face AC connector.

N

L

FG

AC Connector

*1

Figure 1

AC Plug Collar

AC Plug

Cord Clamp

• The Power Cord included in the PS-A unit’s package is designed only for

AC100V or AC115V use. Any other voltage will require a different cord.

E-19

• If the power supply voltage exceeds the PS-A unit's range, connect a

voltage transformer.

• Between the line and the ground, be sure to use a low noise power supply.

If there is still an excessive amount of noise, connect a noise reducing

transformer.

Be sure any constant or insulating transformer used has a capacity of

200VA or more.

7 Power Supply Cautions

Please pay special attention to the following instructions when connecting

the AC Connector to the PS-A unit.

3) Insert the Cord Clamp Lock Pin into the PS-A’s Lock Pin Hole.

4) Adjust the Lock Pin’ s Lock T ab length until it is securely held.

Removing the AC Power Cord

1) While lifting up on the Lock Pin’ s Lock T ab Release, pull the AC Plug, Plug Collar and Cord

Clamp backwards to disconnect it from the PS-A.

2) Open the Cord Clamp and remove the AC Power Cord from the Cord Clamp.

Figure 2

2)

3)

4)

Cord Clamp Lock Pin

Lock Pin Hole

Lock Tab Release

Cord Clamp

AC Plug

AC Plug Collar

2) Connect the AC plug to the PS-A’ s AC connector, as shown in fig. 2.

AC Connector

E-20

10 Replacing the Backlight

9 Input/Output Signal Line Cautions

• Input and Output signal lines must be separated from the power control cables

for operational circuits.

• If this is not possible, use a shielded cable and the shield should be grounded.

• To improve noise immunity, it is recommended to attach a ferrite core to the

power cord.

Using any backlight other than the model written above may

cause an accident or PS-A unit malfunction.

8 Grounding Cautions

• When attaching a wire to the PS-A's bottom face FG terminal, (on the AC

Connector), be sure to create an exclusive ground.

*1

• FG and SG terminals are internally connected in the PS-A. When connecting

to another device, be sure to create an SG shorting loop in your system.

*1 Use a grounding resistance of 100Ω, a wire of 2mm2 or thicker, or your country's

applicable standard.

• Input and Output signal lines must be separated from the power control cables

for operational circuits.

• To increase the noise resistance, be sure to twist the ends of the power cord

before connecting it to the PS-A unit.

• The PS-A unit's power cord should not be bundled with or kept close to main

circuit lines (high voltage, high current), or input/output signal lines.

• Connect a surge absorber to handle power surges.

• Ground the lightning surge absorber and the PS-A separately.

• Select a lightning surge absorber which will not exceed the allowable circuit voltage, even when the voltage rises to the maximum.

• To reduce noise, make the power cord as short as possible.

Note

Please be aware that Digital Electronics Corporation shall not be held

liable by the user for any damages, losses, or third party claims arising

from the uses of this product.

The PS-A unit's backlight is user replacable. For an explanation of how to replace

the PS-A's backlight, please refer to the Installation Guide which comes with the

replacement backlights (sold separately). The corresponding backlight is CA3BLU15-01.

DIS TRI BUTEU R C O NSEI L DEPUI S 1985

System

Email :

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

hvssystem@hvssystem.com

Site web : www.hvssystem.com

Distribué par :

Loading...

Loading...