Pro-face PS3650A-T42, PS3650A-T42-24V, PS3650A-T42S-24V, PS3651A-T42, PS3651A-T42-24V Hardware Manual

...

36$36$6HULHV

+DUGZDUH0DQXDO

Preface

Thank you for purchasing a Pro-face PS-3650A/PS-3651A Series Unit (Hereafter referred to as the PS-A unit).

Before operating your PS-A unit, be sure to read this manual to familiarize yourself with the PS-A unit’s operation

procedures and functions.

NOTICE

1. Copying this manual’s contents, either in whole or in part, is prohibited without the express permission of Digital

Electronics Corporation, Japan.

2. The information contained in this manual is subject to change without notice.

3. If you find any errors or omissions in this document, please contact Digital Electronics Corporation to report your

findings.

4. Regardless of Clause 3 above, Digital Electronics Corporation shall not be held responsible for any damage,

losses or third-party damage resulting from the use of this product.

Product names used in this manual are the trademarks / registere d trademarks of their respective owners.

© 2009 Digital Electronics Corporation. All rights reserved.

1

Essential Safety Precautions

All safety-related procedures stated in this document must be followed to operate the PS-A unit correctly and safely. Be

sure to read this and any related documents thoroughly to understand the correct operatio n and f unctions of the PS-A unit.

Safety Icons

Throughout this manual, these icons provide essential safety information for PS-A unit operation procedures requiring

special attention. These icons indicate the following levels of danger:

Indicates situations where severe bodily injury, death or major equipment

damage can occur.

Indicates situations where slight bodily injury or minor equipment damage can

occur.

Indicates actions or procedures that should NOT be performed.

Indicates actions or procedures that MUST be performed to ensure correct

unit operation.

System Design

Do not create PS-A unit touch panel switches that could possibly endanger the safety of personnel or

equipment. A malfunction of the PS-A unit, its I/O unit(s), cable(s), or other related equipment can cause

unexpected output signals, leading to a serious accident. Be sure to design all important machine

operation switches so they are operated via a separate control system, and not via the PS-A unit.

Do not create PS-A unit touch panel switches to control machine safety operations, such as an

emergency stop switch. Install these switches as separate hardware switches, otherwise severe bodily

injury or equipment damage can occur.

Be sure to design your system so that a communication fault between the PS-A unit and its host controller

will not cause equipment to malfunction. This is to prevent any possibility of bodily injury or equipment

damage.

Do not use the PS-A unit as a warning device for critical alarms that can cause serious operator injury,

machine damage or can halt system operation. Critical alarm indicators and their control/activator units

must be designed using stand-alone hardware and/or mechanical interlocks.

Do not use the PS-A unit with aircraft control devices, aerospace equipment, central trunk data transmission (communication) devices, nuclear power control devices, or medical life support equipment, due to

these devices’ inherent requirements of extremely high levels of safety and reliability.

2

When using the PS-A unit with transportation vehicles (trains, cars, and ships), disaster and crime prevention devices, various types of safety equipment, and medical devices that are not life-support related, use

redundant and/or failsafe system designs to ensure proper reliability and safety.

After the PS-A unit’s backlight burns out the touch panel is still active, unlike the PS-A unit’s “Standby

Mode”. If the operator fails to notice that the backlight is burned out and touches the panel, a potentially

dangerous machine operation error can occur. Therefore, do not create PS-A unit touch panel switches

that may cause injury and/or equipment damage.

If your PS-A unit’s backlight suddenly turns OFF, use the following steps to determine if the backlight is

actually burned out.

1) If the PS-A unit’s “Backlight Control” is not set and the screen has gone blank, your backlight is burned

out.

2) If the PS-A unit’s “Backlight Control” is set to Standby Mode and the screen has gone blank, and

touching the screen or performing another input operation does not cause the display to reappear, your

backlight is burned out.

Handling

Do not modify the PS-A unit. Doing so may cause a fire or an electric shock.

Do not operate the PS-A unit in an environment where flammable gases are present, since it may cause

an explosion.

Wiring

To prevent an electric shock be sure to disconnect your PS-A unit’s power cord from the power supply

before wiring the PS-A unit.

Do not use voltage beyond the PS-A unit’s specified range. Doing so may cause a fire or an electric

shock.

Maintenance

Do not connect or disconnect Host and PS-A unit communication cables while the PS-A unit is turned ON.

The PS-A unit uses a lithium battery for backing up its internal clock data and the battery may explode if it

is replaced incorrectly. When replacement is required, use a Pro-face-designated replacement product.

SEE

4.6 Replacing the Internal Battery (page4-15)

3

Installation

Be sure all cable connectors are securely attached to the PS-A unit. A loose connection may cause

incorrect input or output signals.

Wiring

Be sure to ground the PS-A unit’s FG wire separately from other equipment FG lines. Also, be sure to use

2

a grounding resistance of 100Ω or less and a 2mm

Otherwise, electric shock or malfunctions may result.

Be sure to use only the designated torque to tighten the PS-A unit’s terminal block screws. If these screws

are not tightened firmly, it may cause a short-circuit, fire or incorrect unit operation.

Be sure that metal particles and wiring debris do not fall inside the PS-A unit. They can cause a fire,

malfunction or incorrect unit operation.

or thicker wire, or your country’s applicable standard.

Maintenance

Do not reset or turn the PS-A unit OFF, or insert or remove the CF Card while the PS-A unit’s CF Card or

hard disk is being accessed. Otherwise, CF Card and the hard disk internal data may be damaged or lost.

Unit Disposal

When the product is disposed of, it should be disposed of in a manner appropriate to, and in accordance

with, the user country's industrial machinery disposal/recycling standards.

General Safety Precautions

Do not press on the PS-A unit’s display with excessive force or with a hard object, since it can damage the

display. Also, do not press on the touch panel with a pointed object, such as the tip of a mechanical pencil

or a screwdriver, since doing so can damage the touch panel.

Do not install the PS-A unit where the ambient temperature exceeds the specified range. Doing so may

cause a unit malfunction.

To prevent abnormally high temperatures from occurring inside the PS-A unit, do not restrict or block the

PS-A unit’s rear-face ventilation slots.

Do not operate the PS-A unit in areas where large, sudden temperature changes can occur. These

changes can cause condensation to form inside the PS-A unit, possibly causing it to malfunction.

Do not allow water, liquids or metal fragments to enter inside the PS-A unit’s case, since they can cause

either a malfunction or an electric shock. For use in Pollution Degree 2 environment.

Do not operate or store the PS-A unit in locations where it can be exposed to direct sunlight, high

temperatures, excessive dust, moisture or vibration.

4

Do not operate or store the PS-A unit where chemicals evaporate, or where chemicals are present in the air.

Corrosive chemicals : Acids, alkalines, liquids containing salt

Flammable chemicals : Organic Solvents

Do not use paint thinner or organic solvents to remove dirt or oil from the PS-A unit’s surface. Instead, use

a soft cloth moistened with a diluted neutral detergent.

Do not use or store the PS-A unit in areas with direct sunlight, since the sun’s ultraviolet rays may cause

the LCD’s quality to deteriorate.

Do not store the PS-A unit in an area where the temperature is lower than that recommended in the PS-A

unit’s specifications. Doing so may cause the LCD display’s liquid to congeal, which can damage the LCD.

Also, if the storage area’s temperature becomes higher than the specified level, the LCD’s liquid may

become isotropic, causing irreversible damage to the LCD. Therefore, only store the PS-A unit in areas

where temperatures are within the PS-A unit’s specifications.

After turning OFF the PS-A unit, be sure to wait at least 5 seconds before turning it ON again. The PS-A

unit may not operate correctly if it is restarted too quickly.

Due to the possibility of unexpected accidents, be sure to back up the PS-A unit’s data regularly.

LCD Panel Usage Precautions

• The LCD panel’s liquid contains an irritant. If the panel is damaged and any of this liquid contacts your skin,

immediately rinse the area with running water for at least 15 minutes. If the liquid gets in your eyes, immediately rinse

your eyes with running water for at least 15 minutes and consult a doctor.

• The PS-A unit’s LCD screen may flicker or show unevenness in the brightness of certain images or at some contrast

settings. This is an LCD characteristic and not a product defect.

• Some LCD screens may have differences in brightness and tone. Please be aware of this difference when using

multiple units side by side.

• Depending on the ambient temperature, LCD screens may sometimes look whitish (at high temperatures) or blackish

(at low temperatures). This is an LCD characteristic and not a product defect.

• Some of PS-A unit’s LCD screens may contain light and dark pixels. This is an LCD characteristic and not a product

defect.

• Extended shadows, or “Crosstalk” may appear on the LCD screen. This is an LCD characteristic and not a product defect.

• The color displayed on the PS-A unit’s LCD screen may appear different when seen from outside the specified

viewing angle. This is an LCD characteristic and not a product defect.

• When the same image is displayed on the PS-A unit’s screen for a long period, an afterimage may appear when the

image is changed. This is an LCD characteristic and not a product defect.

• To prevent an afterimage:

• Set the PS-A unit’s display OFF feature when you plan to display the same screen image for a long period of time.

• Change the screen image periodically and try to not display the same image for a long period of time.

5

This manual uses the following icons:

Indicates a warning or a product limitation. Be sure to follow the instructions

given with this icon to ensure the safe operation of the PS-A unit.

Contains additional or useful information.

Information Symbols

(1) (2)

* Indicates useful or important supplemental information.

SEE

Indicates steps used to accomplish a given task.

Be sure to follow these steps in the order they are written.

Indicates pages containing related information.

About the Manuals

For the detailed information on PS-A series, refer to the following manuals.

• PS-3650A/PS-3651A Series Hardware Manual

• PS-3650A/PS-3651A Series Reference Manual

• PS-3650A/PS-3651A Series API Reference Manual

• Installation Guides for various optional items

• PS-A specifications may change when optional items are used. Check the

optional item installation guides’ specifications for variances, if any.

The manuals can be downloaded from Pro-face Home Page, “Otasuke Pro!”.

“Otasuke Pro!” URL

http://www.pro-face.com/otasuke/

6

PS-3650A/PS-3651A Series Model Names

The term “PS-3650A/PS-3651A” Series refers to the following model numbers:

Series Models Type

PS-3650A

Series

PS-3651A

Series

PS3650A-T42

PS3650A-T42S

PS3650A-T42-24V

PS3650A-T42S-24V

PS3651A-T42

PS3651A-T42S

PS3651A-T42-24V

PS3651A-T42S-24V

• For the models other than the above listed PS-3650A/PS-3651A Series, please refer to the

following PDF manual:

"PS-3650A/PS-3651A Series User Manual"

The manuals can be downloaded from the Pro-face home page.

http://www.pro-face.com/otasuke/

PS-3650A Series AC Power Supply Type

PS-3650A Series DC Power Supply Type

PS-3651A Series AC Power Supply Type

PS-3651A Series DC Power Supply Type

Model name

PS365

PS-3650A/PS-3651A Series Model Name Indication

∗ A-T42

abc

∗ - ∗

0 PCI expansion slot type

a

1 Fan less type

none RAS port type

b

S Serial 2 port type

none AC Power Supply Type

c

24V DC Power Supply Type

7

Package Contents

The following items are included in the PS-A unit’s package. Before using the PS-A unit, please check that all items listed

here are present.

PS-A Unit (1)

English and Japanese

Installation Guides (one of each)

Installation

Guide

Installation Fasteners (4/set)

Installation Gasket (1)

(Attached to the PS-A unit)

Power Plug (1)

(Attached to the PS-A unit)

AC Power Supply

Type 5.08mm

[0.2 in.] pitch

• If your PS-A unit contains a built-in accessory, that accessory’s Installation Guide will also be

included in the PS-A unit’s packing box. Please che ck that al l item s no rmally i ncl uded with t hat

DC Power Supply

Type 7.62mm

[0.3 in.] pitch

USB Holder (2) sets

(USB Holder (1) + USB Cover (2)) x 2

accessory are also included in this box.

This unit has been carefully packed, with special attention to quality. However, should you find anything damaged or

missing, please contact your local PS-A distributor immediately.

8

• UL listed products

Installation prerequisites for standards

Industrial Control Equipment refer to UL508

• c-UL listed products

Process Control Equipment

• Product List

Product Model No.

PS3650A-T42

PS3650A-T42S 99

PS3651A-T42

PS3651A-T42S 99

PS3650A-T42-24V

PS3650A-T42S-24V 99

PS3651A-T42-24V

PS3651A-T42S-24V 99

For the detailed certification's information, refer to the Pro-face Home page.

Registration Model

3480801-02

3480801-01

3480801-12

3480801-11

refer to CSA-C22.2

No.142

No.

see [a] in the

“Product List“

see [b] in the

“Product List“

UL c-UL

[a] [b]

99

99

99

99

UL/c-UL File No.: E220851

<Cautions>

Be aware of the following items when building the PS-A into an end-use product:

• The PS-A unit’s rear face is not approved as an enclosure. When building the PS-A unit into an end-use product, be

sure to use an enclosure that satisfies standards as the end-use product’s overall enclosure.

• The PS-A unit must be used indoors only.

• Install and operate the PS-A with its front panel facing outwards.

• If the PS-A is mounted so as to cool itself naturally, be sure to inst all it in a v ertical panel. Also, it’s recommended that

the PS-A should be mounted at least 50 mm [1.97 in.] away from any other adjacent structures or machine parts. The

temperature must be checked on the final product in which the PS-A is installed.

• For use on a flat surface of a Type 4X (Indoor Use Only) and/or Type 12 Enclosure.

• Type 4X (Indoor Use Only) and/or 12 Enclosure, when the hatch for Front USB Port is secured by screw.

Type 1 Enclosure, when the hatch for Front USB Port is open.

o

• The temperature rating of field installed conductors: 75

The safety certificate can be downloaded from Pro-face Home Page.

Home Page URL

http://www.pro-face.com/

C only.

9

CE Marking

PS3650A-T42, PS3650A-T42S, PS3651A-T42, PS3651A-T42S, are CE marked products that conform to EMC directives and Low-voltage directive.

PS3650A-T42-24V, PS3650A-T42S-24V, PS3651A-T42-24V, PS3651A-T42S-24V are CE marked products that conform to EMC directives.

For the detailed information on CE Marked, be downloaded and refer the Declaration of Conformity from Pro-face Home

Page.

Home Page URL

http://www.pro-face.com/

FCC Statement

United States FCC Part 15, Subpart B, Class A EMI Compliance Statement:

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful int erference in which case the

user will be required to correct the interference at his or her own expense.

10

Contents

Preface...................................................................................................................... 1

Essential Safety Precautions ....................................................................................2

Information Symbols .................................................................................................6

About the Manuals .................................................................................................... 6

PS-3650A/PS-3651A Series Model Names..............................................................7

PS-3650A/PS-3651A Series Model Name Indication................................................7

Package Contents .................................................................................................... 8

Installation prerequisites for standards .....................................................................9

CE Marking ............................................................................................................. 10

FCC Statement .......................................................................................................10

Contents...................................................................................................................11

Chapter 1 Overview

1.1 System Design................................................................................................1-2

1.2 Accessories ....................................................................................................1-3

1.2.1 Optional Item ........................................................................................................1-3

1.2.2 Maintenance Items ...............................................................................................1-3

1.3 Part Names and Functions.............................................................................1-4

1.4 Prior to Operating the PS-A Unit.....................................................................1-7

1.4.1 Front Access Mask ...............................................................................................1-7

1.4.2 Power Supply........................................................................................................1-7

Chapter 2 Specifications

2.1 General Specifications....................................................................................2-2

2.1.1 Electrical ...............................................................................................................2-2

2.1.2 Environmental.......................................................................................................2-2

2.1.3 Structural...............................................................................................................2-4

2.2 Performance Specifications............................................................................2-5

2.2.1 Performance Specifications..................................................................................2-5

2.2.2 Display..................................................................................................................2-7

2.2.3 Touch Panel ..........................................................................................................2-7

2.2.4 Expansion Slot......................................................................................................2-7

2.3 Interface Specifications...................................................................................2-8

2.3.1 Serial Interfaces (COM1/COM2)...........................................................................2-8

2.3.2 RAS Interface (RAS)...........................................................................................2-11

2.4 DIP Switches ................................................................................................2-14

2.5 Dimensions...................................................................................................2-20

11

2.5.1 PS-3650A Series External Dimensions ..............................................................2-20

2.5.2 PS-3651A Series External Dimensions ..............................................................2-22

2.5.3 Panel Cut Dimensions ........................................................................................2-23

2.5.4 Installation Fasteners . .........................................................................................2-23

Chapter 3 Installation and Wiring

3.1 Installation.......................................................................................................3-2

3.1.1 Installation Procedures ........................................... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .3-2

3.2 Peripheral Devices Installation....................................................................... 3-7

3.2.1 Main Memory Installation........ ... ... .... ... .................................................................3-7

3.2.2 PCI Board Installation....................... ... ... ... ... .... ... ... ... .... ... ... .................................3-9

3.2.3 PCMCIA (PC Card) Installation/Removal ...........................................................3-11

3.2.4 CF Card Insertion/Removal ................................................................................3-12

3.2.5 HDD Unit Installation............................... ... ... .... ... ... ... .... .....................................3-14

3.2.6 USB Holder Attachment/Removal.......................................................................3-17

3.3 Wiring Precautions........................................................................................3-19

3.3.1 Connecting the Power Cord . ... ... ... .... ... ...............................................................3-19

3.3.2 Connecting the Power Supply.............................................................................3-23

3.3.3 Grounding............................ ... ... ... .... ... ....................................... ... ... ... ... .... ........3-24

3.3.4 I/O Signal Line Placement ..................................................................................3-24

Chapter 4 Maintenance

4.1 Cleaning the Display.......................................................................................4-2

4.2 Cleaning the Fan Filter ...................................................................................4-3

4.3 Periodic Check Points.....................................................................................4-5

4.4 Replacing the Installation Gasket...................................................................4-6

4.5 Replacing the Backlight..................................................................................4-8

4.5.1 Backlight Replacement Procedure for PS-3650A Series......................................4-9

4.5.2 Backlight Replacement Procedure for PS-3651A Series....................................4-12

4.6 Replacing the Internal Battery......................................................................4-15

12

1 Overview

1. System Design

2. Accessories

3. Part Names and Functions

4. Prior to Operating the PS-A Unit

This chapter describes peripheral devices that can be connected to PS-A Series units, as well as the names and

functions of the PS-A Series components.

1-1

PS-3650A/PS-3651A Series Hardware Manual

1.1 System Design

The following diagram illustrates the standard range of items that can be connected to the PS-A unit.

PS-3650A/PS-3651A Series

Front of PS-A unit

Side of PS-A unit

Inside PS-A unit

RAS Connector

LAN Connector

Bottom of PS-A unit

(2 ports)

Speaker Out Connector

CF Card Slot

(1 port, TypeII)

Expansion Board

Slot *

SATA Connector

Main Memory

Connector

3

COM1/COM2

4

*

LAN1:10BASE-T/100BASE-TX Cable (commercial type)

LAN2:10BASE-T/100BASE-TX/1000BASE-T Cable (commercial type)

5

(1 port)

*

Serial Cable

RAS Cable (Your own cable)

Pin-jack Cable

(commercial type)

CF Cards

CF

PCI Board

(commercial type)

*²

HDD Unit

DIM Module

*¹*²

*¹*²

Peripherals

(commercial type)

Hub

Central Network Line

Speaker

PCMCIA Slot

(1 port, TypeII)

USB Connectors

(4 ports)

USB Connector

(1 port)

*1 Built-in accessory only

*2 The Pro-face's optional devices used with the PS-A. Please refer to “1.2 Accessories” for details.

*3 COM2 is an interface for Serial 2 port type model only.

*4 RAS is interface for RAS port type model only.

*5 PS-3651A Series does not have an expansion board slot. PS-3650A Series only does.

USB 1.1 Compatible

Peripherals(commercial type)

PCMCIA Card

(commercial type)

CF Card Adaptor

USB 2.0 Compatible

Peripherals(commercial type)

*²

CF

CF Cards

• This diagram shows only the PS-A unit’s internal layout and connectable devices.

The user’s actual design may differ.

*²

1-2

1.2 Accessories

All accessories listed here are produced by Pro-face.

1.2.1 Optional Item

Product Name Model No. Description

Chapter 1 Overview

DIM module

Hard Disk Unit

CF Card

CF Card Adapter GP077-CFAD10

PSA-DDR512 Memory module 512MB

PSA-DDR1G Memory module 1GB

PS365XA-HD60

PS365XA-HD250

CA3-CFCALL/128MB-01 Type 1 128MB

CA3-CFCALL/256MB-01 Type 1 256MB

CA3-CFCALL/512MB-01 Type 1 512MB

CA6-CFCALL/1GB-01 Type 1 1GB

CA8-CFCALL/2GB-01 Type 1 2GB

1.2.2 Maintenance Items

Product Name Model No. Description

Installation Fastener CA3-ATFA LL-01

HDD Unit mounted a Type 2.5 Hard Disk

(60GB without OS)

HDD Unit mounted a Type 2.5 Hard Disk

(250GB without OS)

Used for read/write of CF Card data via a

PS-A unit’s PCMCIA slot.

Used to install the PS-A unit into a solid

panel (4 pieces per a set).

Provides dust and moisture resistance

Installation Gasket CA3-WPG12-01

Replacement Backlight CA8-BLU12XGA-01 Backlight for replacement

Protective panel sheet CA5-DFS10-01

DC Power Supply

Connector (Straight)

AC Power Supply

Connector (Straight)

CA7-DCCNL-01

CA7-ACCNL-01

when PS-A unit is installed into a solid

panel.

Disposable sheet that protects the PS-A

unit’s screen from dust.

(5 sheets/set) (Hard type)

DC Power Supply Connector

(5 connectors/set)

AC Power Supply Connector

(5 connectors/set)

1-3

PS-3650A/PS-3651A Series Hardware Manual

1.3 Part Names and Functions

The following images are of a PS-3650A/PS-3651A Series unit.

Front

(Common in PS-3650A/PS-3651A Series)

A: Power LED / RAS Status lamp (POWER)

This status LED indicates the power current and

operation status. The following table shows the

display colors and corresponding status.

A

B

C

D

E

LED Status

Green (lit) Norma l operation (power is ON).

Green

(blinking)

Orange (lit) System monitor error.

Orange/ Red

(blinking)

Not lit Power is OFF.

B: HDD/IDE Access lamp (DISK)

LED Status

Green (lit) HDD or IDE is accessed.

Not lit Neither HDD nor IDE is accessed.

Orange (lit)

Red (lit)

System is NOT running (Soft OFF

state).

Backlight error.

PS-A unit is in operation with backup

battery

PS-A unit is in operation with backup

battery

C: Front Cover

D: Hardware Reset Switch (RESET)

E: Front USB Interface (USB)

1 port, USB 1.1 Compatible.

Uses a “Type-A” connector.

Power supply voltage DC5V ±5%

Each port:

Output current

Maximum

communication distance

500mA (max.)

4 ports total:

500mA (max.)

5m

1-4

Chapter 1 Overview

IJK

F: Power Switch

AC Power Supply Type only

L

F

G: Power Supply Connector

G

H

For connection, attach a power plug (included) to the

power cable.

H: Mask Cover

I: Expansion Board Base

J: Expansion Board Cover

Rear

(PS-3650A Series AC Power Supply Type)

IJK

I

I

L

Rear

(PS-3650A Series DC Power Supply Type)

K: Expansion Board Support

L: Fan Unit

M: Memory Slot Cover

N: DISK Cover

G

H

F

G

H

M

Rear

(PS-3651A Series AC Power Supply Type)

M

Rear

(PS-3651A Series DC Power Supply Type)

N

G

H

N

1-5

PS-3650A/PS-3651A Series Hardware Manual

O

P

Left Side

(PS-3650A Series)

O

O: USB Interface (USB)

4 ports, USB 2.0 Compatible.

Uses a “TYPE-A” connector.

Power supply voltage DC5V ±5%

Each port:

Output current

Maximum

communication distance

P: PCMCIA Slot Cover

500mA(max.)

4 ports total:

500mA(max.)

5m

Left Side

(PS-3651A Series)

QR S T U

V

Bottom

(PS-3650A Series)

QRST U

Bottom

(PS-3651A Series)

P

Q: Ethernet Interface (LAN1 / LAN2)

LAN1: 10BASE-T, 100BASE-TX auto changeover

LAN2: 10BASE-T, 100BASE-TX, 1000BASE-T

auto changeover

R: Speaker Output Interface (SPEAKER OUT)

Mini pin jack connector.

S: RAS interface (RAS) / Serial Interface (COM2)

RAS port type:

RAS port. D-Sub 9 (socket)

Serial 2 port type:

RS-232C port. D-Sub 9 (plug)

T: Serial Interface (COM1)

RS-232C, RS-422, RS-485 port. D-Sub9 (plug)

U: CF Card Cover

V: Expansion Slot

This is a slot that is mounted on a PCI board.

1-6

1.4 Prior to Operating the PS-A Unit

1.4.1 Front Access Mask

When you open the PS-A’s front maintenance hatch, there are a front USB port and a Hardware Reset Switch.

If you want to restrict access or prevent unintentional access from the Front USB port or Hardware Reset

Switch, change the settings of the DIP Switch on the circuit board in PS-A unit for Front Access Mask.

See the following for DIP Switch details.

Chapter 1 Overview

SEE

2.4 DIP Switches (page2-14)

1.4.2 Power Supply

The PS-A unit’s power supply has three states; Non-energized, Active State (Normal), and Soft OFF State*1.

Each state is outlined in the following.

Power State :

Screen of PS-A :

Power LED :

Non-energized

OFF

OFF

PS-As

power On

*2

Active State (Normal)

ON

Green Lighting

PS-A’s system

activated

Shut down by

Windows program

Soft OFF

OFF

Green Blinking

System

Stop

Hardware Reset

Switch ON or

RAS Input Start

Power Switch OFF,

Remove Power

Cable

*

for Normal State

2

for Non-energized

State

*1 The Soft OFF refers to the state that Windows

®

has been shut down and the power is provided only for

the electric circuit to boot system. This Soft OFF State is different from what is System Standby set by

®

Windows

.

*2 See " RAS Input Start (page2-12)" for details. This feature is only available for RAS port type.

1-7

PS-3650A/PS-3651A Series Hardware Manual

1-8

2 Specifications

1. General Specifications

2. Performance Specifications

3. Interface Specifications

4. Dimensions

This chapter describes the general, functional, and interface specifica tions of the PS-A unit, as well as ext ernal

dimensions.

2-1

PS-3650A/PS-3651A Series Hardware Manual

2.1 General Specifications

2.1.1 Electrical

PS-3650A/PS-3651A Series

AC Power Supply Type

(PS3650A-T42/

PS3651A-T42/

PS3650A-T42S/

PS3651A-T42S)

Input Voltage AC100/240V DC24V

Rated Voltage AC85 to 265V DC19.2 to 28.8V

Rated

Frequency

Power

Supply

Voltage Endurance

Insulation Resistance DC500V 10MΩ(min.) (between charging and FG terminals)

Allowable

Voltage Drop

Power

Consumption

In-Rush Current

1 cycle or less (Voltage drop

interval must be 1s or more.)

PS-3650A Series:110VA or less

PS-3651A Series:95VA or less

AC100V (room temperature):

AC240V (room temperature):

AC1,500V 20mA for 1 minute

(between charging and FG

50/60Hz -

30A or less

50A or less

terminals)

PS-3650A/PS-3651A Series

DC Power Supply Type

(PS3650A-T42-24V/

PS3651A-T42-24V/

PS3650A-T42S-24V/

PS3651A-T42S-24V)

5ms (max.)

PS-3650A Series

PS-3651A Series

(room Temperature)

AC1,000V 20mA for 1 minute

(between charging and FG

:80W or less

:40W or less

30A or less

terminals)

2.1.2 Environmental

Surrounding Air

Temperature

Storage Temperature -20 to +60°C

Ambient Humidity

Storage Humidity

Physical

Dust 0.1mg/m

Pollution Degree For use in Pollution Degree 2 environment

Corrosive gas Free of corrosive gas

Atmosphere

(Using height)

PS-3650A Series PS-3651A Series

0 to 50°C: without HDD

5 to 50°C: with HDD

10%RH to 90%RH

(Not condensing, wet bulb temperature: 39°C or less. Wet bulb

temperature with HDD: 29°C or less.)

10%RH to 90%RH

(Not condensing, wet bulb temperature: 39°C or less.)

3

and below (non-conductive levels)

800 to 1,114hPa

(-300 to +2,000m)

0 to 50°C: without HDD

5 to 45°C: with HDD

2-2

Vibration Resistance

Mechanical

Noise Immunity

(via noise simulator)

Electrostatic

Electrical

Discharge Immunity

Noise Immunity

(Fast Transient Burst Noise)

• When using any of the PS-A unit’s optional devices, be sure to check that

device’s specifications for any special conditions or cautions that may apply to its

use.

• Be aware that not only does the Hard Disk/SSD have a fixed lifetime, but that

accidents can always occur. Therefore, be sure to back up your Hard Disk/SSD's

data regularly, or prepare another Hard Disk/SSD unit that can be used for

backup.

Chapter 2 Specifications

< without HDD >

IEC61131-2 compliant

5Hz to 9Hz single-amplitude 3.5mm

9Hz to 150Hz constant-accelerated velocity 9.8m/s

X, Y, Z directions for 10 cycle (100 minutes)

< with HDD>

10Hz to 57Hz single-amplitude 0.0375mm

57Hz to 150Hz constant-accelerated velocity 4.9m/s

X, Y, Z directions for 10 cycle (80 minutes)

Noise Voltage: 1,500Vp-p (via noise simulator)

Pulse Duration: 50ns, 500ns, 1µs

Rise Time: 1ns

6kV (complies with IEC61000-4-2 Level 3)

Power supply line: 2kV (IEC61000-4-4)

COM port: 1kV (IEC61000-4-4)

2

2

• The Hard Disk lifetime given here may be reduced due to unforeseen

environmental factors. The following table shows the Hard Disk lifetime general

factors.

PS365XA-HD60 PS365XA-HD250

Factors

Lifetime

Operating temperature: 20°C,

333 hours of operation per month.

(HDD access frequency of 20% or

less)

20,000 hours (of operation) or

approximately 5 years, whichever

comes first.

Operating temperature: 20°C,

732 hours of operation per month.

(HDD access frequency of 50% or

less)

30,000 hours (of operation) or

approximately 5 years, whichever

comes first.

• Using the Hard Disk in an environment that is excessively hot and/or humid will

shorten the disk’s usage lifetime . A we t bu l b te mp e rature of 29°C or less is

recommended. This is equivalent to the following data.

Temperature at 35°C at 40°C

Humidity no higher than 64% RH no higher than 44% RH

• In order to extend the lifetime of the hard disk, Pro-face recommends you set

Windows

®

to turn the hard disk off when the unit is not being operated. A setting

of 5 minutes is recommended.

• Do not vibrate the hard disk continuously at the same frequency. Doing so may

cause the hard disk to reduce transfer speeds or stop temporarily.

2-3

PS-3650A/PS-3651A Series Hardware Manual

2.1.3 Structural

Grounding

Structure

Cooling Method Forced cooling by fan Natural air circulation

Installation

Weight

External

Dimensions

*1 The front face of the PS-A unit, installed in a solid panel, has been tested using conditions

equivalent to the standards shown in the specification. Even though the PS-A unit’s level of

resistance is equivalent to these standards, oils that should have no effect on the PS-A unit

can possibly harm the unit. This can occur in areas where either vaporized oils are present,

or where low viscosity cutting oils are allowed to adhere to the unit for long periods of time.

If the PS-A unit’s front face protection sh eet becomes peeled off, these conditions can lead

to the ingress of oil into the PS-A unit and separate protection measures are suggested. Also,

if non-approved oils are present, it may cause deformation or corrosion of the front panel’s

plastic cover. Therefore, prior to installing the PS-A unit be sure to confirm the type of conditions that will be present in the PS-A unit’s operating environment.

If the installation gasket is used for a long period of time, or if the unit and its gasket are removed from the panel, the original level of the protection cannot be guaranteed. To maintain

the original protection level, be sure to replace the installation gasket regularly.

Grounding resistance of 100 Ω, 2mm

country’s applicable standard. (Same for FG and SG terminals)

W313mm [12.32in.] × H239mm

[9.41in.] × D103mm [4.06in.]

PS-3650A Series PS-3651A Series

2

or thicker wire, or your

Rating*1: Equivalent to IP65f (Only not using Front USB)

figuration: Built-in type

Installation method: Embedding

Approx. 4.5kg [9.9lb]

(unit only)

Approx. 3.8kg [8.4lb]

(unit only)

W313mm [12.32in.] × H239mm

[9.41in.] × D60mm [2.36in.]

2-4

Chapter 2 Specifications

2.2 Performance Specifications

2.2.1 Performance Specifications

PS-3650A Series PS-3651A Series

CPU Intel® Celeron M 1.5GHz Intel® ULV Celeron M 1GHz

L2 Cache Memory 1MB (Built in the CPU) 512KB (Built in the CPU)

Main Memory SO-DIMM socket 256MB to 1GB (PC2700)

Chipset Intel

Graphic Accelerator Built in Intel

BIOS FirstBIOS Embedded Pro (Phoenix Technologies Co.)

Graphics XGA (1,024 × 768 dots)

Video Memory

COM1: RS-232C / RS-422 / RS-485 switched option

RS-232C is RI/+5V changeover

Connector: D-Sub 9 pin (plug)

Serial Interface

*1

COM2: RS-232C (RI fixed)

Connector: D-Sub 9 pin (plug)

LAN1: Realtek RTL8100CL

IEEE802.3i / IEEE802.3u

10BASE-T / 100BASE-TX Auto Changeover

Network

Interface

Connector: Modular Jack (RJ-45)

LAN2: Realtek RTL8110SCL

IEEE802.3i / IEEE802.3u / IEEE802.3ab

10BASE-T / 100BASE-TX / 1000BASE-T Auto Changeover

Connector: Modular Jack (RJ-45)

Front face: USB 1.1 (Low/ Full Speed 12 Mbps) × 1 port

Side face: USB 2.0 (High Speed 480 Mbps) × 4 ports

USB

Interface

Connector: USB TYPE-A

Power supply voltage: DC5V ±5%

Output current: Each port: 500mA (max.), Total 5 ports (Front and Left):

500mA (max.)

Interface

The maximum communication distance: 5m

General-Purpose Input 2ch

RAS

Interface

*2

(DIN1 can be common with external reset input),

General-Purpose Output 2ch

Connector: D-Sub 9 pin (socket)

Speaker Output

Interface

Serial ATA

Stereo Speaker output

Connector: Mini Pin Jack

Serial ATA Rev.1.0 X 1

2.5” HDD Unit

CF Card slot

IDE

Primary Master or Primary Slave

Connector: Type I / II X 1slot

PC Card slot

PCMCIA

Corresponding to CARD BUS (Excluding ZOOM VIDEO, SOUND

functions)

Connector: Type II X 1slot

PCI

Clock Accuracy

*3

PCI Rev. 2.2 (33MHz) None

± 180 sec. / month (timing error depending on the situ ation at normal

*1 COM2 is an interface for Serial 2 port type only.

*2 RAS is an interface for RAS port type only.

®

855GME + ICH4

®

855GME

8 to 64MB (UMA method)

temperature and power-off)

2-5

PS-3650A/PS-3651A Series Hardware Manual

*3 The RTC clock built in the PS-A unit has a timing error. The range of the error will be between +300

to -300 sec. / month, depending on the PS-A unit’s conditions such as lifetime usage or temperature

difference. If you use the PS-A unit in a system that is very dependent on timing, adjust the clock at

regular intervals.

2-6

2.2.2 Display

Display Type TFT Color LCD

Resolution W1,024 x H768 pixels

Dot pitch W0.24mm [0.01in.] x H0.24mm [0.01in.]

Effective Display Area W245.76mm [9.68in.] x H184.32mm [7.26in.]

Color/Shade level 262,144 colors

Backlight CCFL (user replaceable)

Brightness control 4 levels of adjustment

Contrast Adjustment None

View Angles

Backlight Service Life

2.2.3 Touch Panel

Type Resistive Film (analog)

Resolution 1,024 x 1,024

Service Life 1,000,000 times or more

Chapter 2 Specifications

Horizontal Direction: 120 degrees, Vertical Direction: 100 degrees

(Contrast ratio: CR is 10 or greater, or TYP value)

60,000hrs. or more (at ambient temperature 25°C and continuous

operation - period until backlight brightness decreases to 50% or

backlight starts to flicker)

2.2.4 Expansion Slot

Slot Type PCI 2.2 (5V)

Size 174.63mm [6.88in.] × 106.68mm [4.20in.]

Output Voltage DC5V DC12V DC-12V DC3.3V

Consumption Current 1.5A 0.5A 0.1A 0.5A

*1

*1 Available only for PS-3650A Series.

2-7

PS-3650A/PS-3651A Series Hardware Manual

2.3 Interface Specifications

This section describes the specifications of each interface of the PS-A Series unit.

2.3.1 Serial Interfaces (COM1/COM2)

The PS-A unit side connector is a D-Sub 9 pin plug type.

Use #4-40 (UNC)

for connections.

• Do not connect any pins to [NC].

• Connect the FG terminal line to the shell.

• This PS-A unit's serial port is not isolated. When the host (PLC) unit is also not

isolated, and to reduce the risk of damaging the RS-232C/RS-422/RS-485 circuit,

be sure to connect the pin #5 SG (Signal Ground) terminal.

• FG and SG terminals are internally connected in the PS-A unit. When connecting

to another device, be sure not to create an SG shorting loop in your system.

COM1

COM1 can be changed to RS-232C, RS-422 or RS-485. (The factory setting is RS-232C.) To change this

setting, open the PS-A unit's Fan Unit or Memory Slot Cover and set the DIP Switches on the circuit board to

the desired position.

SEE

2.4 DIP Switches (page 2-14)

• Make sure to turn off the power supply before using the DIP Switches. Adjusting

the DIP Switches while power is supplied may cause malfunction.

2-8

Pin

Arrangement

5

1

(PS-A side)

*1 To change pin #9's RI/+5V setting, open the PS-A unit's Fan Unit or Memory Slot Cover and

9

6

set the slide Switch to the desired position. Please refer to 2.4 DIP Switches (page 2-14)

Pin No.

1 CD Input Carrier Detect

2 RD(RXD) Input Receive Data

3 SD(TXD) Output Send Data

4 ER(DTR) Output Data Terminal Ready

5 GND(SG) - Signal Ground (SG)

6 DR(DSR) Input Data Set Ready

7 RS(RTS) Output Request to Send

8 CS(CTS) Input Send Possible

9CI(RI)/+5V

Shell FG -

Signal Name Direction Description

*1

Input/

Output

RS-232C

Called status display/+5V Output

(Switching available)

Frame Ground (Common with

SG)

Chapter 2 Specifications

Pin No.

Signal Name Direction Description

1 RDA Input Receive Data A (+)

2 RDB Input Receive Data B (-)

3 SDA Output Send Data A (+)

4 NC - No Connection

5 GND - Signal Ground (SG)

6 NC - No Connection

7 SDB Output Send Data B (-)

8 NC - No Connection

9 NC - No Connection

Shell FG - Frame Ground (Common with SG)

Pin No.

Signal Name Direction Description

RS-422

RS-485

1 DATA + Input / Output Send/Receive Data (+)

2 DATA - Input / Output Send/Receive Data (-)

3 NC - No Connection

4 NC - No Connection

5 GND - Signal Ground (SG)

6 NC - No Connection

7 NC - No Connection

8 NC - No Connection

9 NC - No Connection

Shell F G - Frame Ground (Common with SG)

2-9

PS-3650A/PS-3651A Series Hardware Manual

COM2

This interface is used to connect an RS-232C serial cable.

• COM2 is an interface for Serial 2 port type only.

Pin Arrangement Pin No.

1 CD Input Carrier Detect

2 RD(RXD) Input Receive Data

3 SD(TXD) Output Send Data

4 ER(DTR) Output Data Terminal Ready

5

1

9

6

5 GND(SG) - Signal Ground (SG)

6 DR(DSR) Input Data Set Ready

7 RS(RTS) Output Request to Send

(PS-A side)

8 CS(CTS) Input Clear to Send

9 CI(RI) Input Called status display

Shell FG -

RS-232C

Signal Name Direction Description

Frame Ground

(Common with SG)

2-10

2.3.2 RAS Interface (RAS)

The PS-A unit side connector is a D-Sub 9 pin socket type.

Chapter 2 Specifications

Use #4-40 (UNC)

for connections.

• RAS is an interface for RAS port type only.

Pin Arrangement Pin No. Signal Name Description

1+12 V

Output Current: 100mA or less

Output Voltage: DC12V±5%

2 DOUT0(+) Data out 0(+)

1

5

6

9

3 DOUT1(+) Data out 1(+)

4 DIN0(+) Data in 0(+)

5 DIN1(+) Data in 1(+)

*1

6 GND Ground

(PS-A side)

7 DOUT0(-) Data out 0(-)

8 DOUT1(-) Data out 1(-)

9 DINCOM Data in common

*1 This pin can be used as the RAS Input Start or the external reset in-

put. The factory setting is General-Purpose Input (Data Input).

• Be sure to use only the rated voltage level when using pin # 1 (+12V) for external

power output. Failure to do so can lead to unit malfunction or accident.

2-11

PS-3650A/PS-3651A Series Hardware Manual

General-Purpose Input (DIN 0, 1)

Input Voltage DC12V to 24V

Input Method Sink / Source Input

Input Current 10mA (DC24V)

Input Resistance 3.6kΩ

Input Points 2 points (common with externa l rese t in p ut )

Operation Range

Isolation Method Photocoupler Isolation

Dielectric Strength Voltage 500V or more

(Interface Circuit)

+5V

R

ON voltage DC10V or more

OFF voltage DC3V or less

1.8k

1/10W

Ω

1.8k

Ω

1/10W

DIN0(+) pin # 4

DIN1(+) pin # 5

No polarity - for Sink /

Source input

DC12V

to 24V

PC357

R

DINCOM pin # 9

Cable

switch or other

switching device

• General-Purpose Input (DIN) level must be 1.5 seconds or longer to be detected.

It may not detect under 1.5 seconds.

• Be sure the voltage value between terminals is controlled via the input voltage, so

that the PS-A unit is operated within its recommended range. If the input voltage

exceeds this range, a malfunction or PS-A unit damage may occur.

• The Sink/Source input can be used even if the DIN(-), and RESET(-) are positive,

and DIN(+), RESET(+) are negative. Be sure to operate the unit within the

recommended voltage range.

RAS Input Start

RAS Input Start*1 *2 is a function which allows input to DIN1(+) to start the PS-A unit from Hibernate or Soft

OFF state.

After the input start, DIN1(+) can be used as General-Purpose Input.

Input signal electric specifications is the same as General-Purpose Input

2-12

• PS-A unit will be restarted if you shut down Windows® during DIN(+) input. To

change PS-A unit to Soft OFF state, set DIN1(+) input OFF before shutting down

®

Windows

.

*1 To use RAS Input Start, set System Set SW 2 No.3 to ON. See "2.4 DIP Switches (page 2-14)" for DIP

Switches details.

*2 Available only for RAS port type.

General-Purpose Output (DOUT 0, 1)

Rated Voltage DC12V to 24V

Maximum Load Current 120mA/point

Chapter 2 Specifications

Out Voltage Drop

1.5V or less

(at 100mA load current)

Output Points 2 points

Isolation Method Photocoupler Isol ation

Dielectric Strength Voltage 500V or more

External Power Supply DC12V / 100mA

( Interface Circuit )

+5V

R

PC357

4.7kΩ

DOUT0(+) pin # 2

DOUT1(+) pin # 3

SSTA06

DOUT0(-) # 7

DOUT1(-) # 8

Cable

Load

1

*

DC12V

to

24V

• Be sure to operate the unit within its maximum load current. If the maximum load

current exceeds this range, a malfunction or PS-A unit damage may occur.

• Design your electrical system by adding the load current and voltage values to

the terminal voltage. If load current value used is large, the voltage drop of 1.5V

or less will occur between the terminals.

• When connecting an induction load, be sure to connect the protection diode (*1),

as shown in the diagram above.

2-13

PS-3650A/PS-3651A Series Hardware Manual

2.4 DIP Switches

The DIP Switches are mounted on the circuit board under the Fan Unit or the Memory Slot Cover. For details

on how to remove the Fan Unit or the Memory Slot Cover, refer to the following section.

SEE

3.2.1 Main Memory Installation (page 3-7)

• Make sure to turn off the power supply before using the DIP Switches. Adjusting

the DIP Switches while power is supplied may cause a unit malfunction or damage.

• Be sure to confirm which settings will be used by other connected devices and

set the DIP Switches accordingly. Failure to do so can result in a unit malfunction

or damage.

DIP Switch Locations

Switch

Location

A System Set SW1

B

C System Set SW2

Switch Name Description

Serial Mode Select

SW

2-14

10-point DIP Switch. For the switches details, see System Set

SW 1 (page2-15).

10-point DIP Switch. Designates COM1 communication settings.

For the switches details, see Serial Mode Select SW (page2-

17).

4-point DIP Switch. For the switches details, see System Set

SW 2 (page2-19).

Chapter 2 Specifications

System Set SW 1

SW No. Description ON OFF Notes

1 Used for the system. Reserved Reserved Factory Settings: ON

2 Used for the system. Reserved Reserved Factory Settings: OFF

3

4

Change Hardware Reset

Switch mode.

Disable/enable Hardware

Reset Switch.

5 Used for the system. Reserved Reserved Factory Settings: OFF

6

Disable/enable Access to the

Front USB port.

7 Used for the system. Reserved Reserved Factory Settings: OFF

Disable/enable Detecting the

8

middle point during touching

two points simultaneously.

9 Used for the system. Reserved Reserved Factory Settings: OFF

Changes COM1's # 9 pin

10

(RI <---> +5V).

Enabled only when RS-232C

mode

Power

button

Reset SW Factory Settings: OFF

Disabled Enabled Factory Settings: OFF

Disabled Enabled Factory Settings: OFF

Disabled Enabled Factory Settings: OFF

+5V

Output

RI Factory Settings: OFF

Table 1) System Set SW 1

Change Hardware Reset Switch mode

*1

• Power button mode

When the Hardware Reset Switch on the front of the PS-A unit is pressed, the Windows

operation setting is executed.

®

For Windows

XP, the option selected in [When I press the power button on my comp uter] from [Control

panel]-[Power Options]-[Advanced] occurs.

• Reset SW mode

The PS-A unit restarts when pressing the Hardware Reset Switch on the front of the PS-A unit.

Disable/Enable Hardware Reset Switch

*1

When disabled, you cannot reset using Hardware Reset Switch while the system is running.

When enabled, Hardware Reset Switch operates in the mode set on Switch No.3.

®

power button

*1 In SOFT OFF state, pressing Hardware Reset Switch will start the PS-A unit regardless of settings.

For more details about SOFT OFF state, please refer to 1.4.2 Power Supply (page 1-7).

2-15

PS-3650A/PS-3651A Series Hardware Manual

DIsable/enable Access to the Front USB port.

When "disabled" is selected, the front USB port cannot be used after you turn on the PS-A unit.

®

The front USB port is available only for Windows

used.

Disable/enable Detecting the middle point during touching tw o points simultaneously.

When two points are pushed simultaneously, it is considered that middle point between the two points is

touched according to the nature of the analog resistive touch panel. If a switch or other part is located on the

middle point, it will be detected and may be operated without any touches. To prevent such a switch from

malfunction during two points are pushed simultaneously, set Switch Number 8 to ON.

Even, drug control could not be operated very smoothly.

. Make sure to disable the function when another OS is

2-16

Serial Mode Select SW

The factory setting is RS-232C. Only Switch No.1 is set to ON.

Switch

Description ON OFF RS-232C RS-422

No.

Changes

COM1’s

1

communication

method

Changes

COM1’s

2

communication

method

Changes

COM1’s

3

communication

method

Changes TX

data’s output

4

mode

Switches the

TX termination

5

resistance ON/

OFF

Switches the

RX termination

6

resistance ON/

OFF

Switches the

shorting of TXA

7

and RXA ON or

OFF

Switches the

shorting of TXB

8

and RXB ON or

OFF

RS-232C

RS-422/

RS-485

RS-422/

RS-485

TX data output

is controlled

via the RTS

signal.

Inserts

termination

resistance of

220Ω between

TXA and TXB.

Inserts

termination

resistance of

220Ω between

RXA and

RXB.

Shorts TXA

and RXA (RS485 mode)

Shorts TXB

and RXB (RS485 mode)

RS-422/

RS-485

ON OFF OFF OFF

RS-232C OFF ON ON ON

RS-232C OFF ON ON ON

TX data output

is NOT

controlled via

the RTS signal.

(normally

output)

No

termination

No

termination

OFF

OFF ON ON/OFF

OFF ON ON/OFF

No shorting

(RS-422

OFF OFF ON ON

mode)

No shorting

(RS-422

OFF OFF ON ON

mode)

ON/

OFF

Chapter 2 Specifications

RS-485

(Data is not

automatically

controlled via

the RTS

signal.)

automatically

controlled via

*1

ON OFF

*2

ON/OFF

*2

ON/OFF

RS-485

(Data is

the RTS

signal.)

*1

*2

*2

RTS Automatic

9

control mode

(enabled only

when RS-485

10 OFF OFF OFF ON

mode)

The data is

*1

automatically

controlled via

the RTS

signal.

The data is not

automatically

controlled via

the RTS signal.

OFF OFF OFF ON

Table 2) Serial Mode Select SW

*1 This setting determines whether or not the TXD output driver is automatically controlled via the RTS

signal.

*2 If you use the termination resistance, base your settings on the connection specifications.

2-17

PS-3650A/PS-3651A Series Hardware Manual

Serial Mode Select SW (SW4 toSW10) operate as shown in the circuit diagram below.

*1

2-18

*1 To enable RTS automatic control of the TX output driver, be sure to set SW No. 9 and 10 ON, and set

SW No.4 OFF.

To enable control of the TX output driver via RTS signals, be sure to set SW No. 9 and 10 OFF, and set

SW No.4 ON.

System Set SW 2

Chapter 2 Specifications

Switch

No.

Changeover of Master / Slave

1

setting for primary CF Card I/F

2 Used for the system. Reserved Reserved Factory Settings: OFF

3 RAS Input Start Setting

4 Used for the system. Reserved Reserved Factory Settings: OFF

*1 See “ RAS Input Start (page2-12)” for RAS Input Start details. This feature is only available for

RAS port type.

Description ON OFF Notes

Master Slave Factory Settings: ON

*1

Enabled Disabled Factory Settings: OFF

Table 3) System Set SW 2

2-19

PS-3650A/PS-3651A Series Hardware Manual

2.5 Dimensions

The following dimensions apply to PS-3650A/PS-3651A Series units.

(This figure shows an AC Power Supply Type. DC Power Supply Type has same dimensions.)

2.5.1 PS-3650A Series External Dimensions

Unit: mm [in.]

301[11.85]

Top

313[12.32]

Front

239[9.41]

103[4.06]

60[2.36]

5[0.20]

227[8.94]

side

2-20

Dimensions with installation fasteners

130[5.12]

Top

Chapter 2 Specifications

130[5.12]

249 [9.80]

side

Front

Bottom

side

130[5.12]130[5.12]

2-21

PS-3650A/PS-3651A Series Hardware Manual

2.5.2 PS-3651A Series External Dimensions

Unit: mm [in.]

301[11.85]

Top

313[12.32]

Front

Dimensions with installation fasteners

Top

60[2.36]

5[0.20]

239[9.41]

side

130[5.12]130[5.12]

227[8.94]

2-22

side

130[5.12]

Front

Bottom

249[9.80]

side

130[5.12]

2.5.3 Panel Cut Dimensions

Panel cut dimensions for both PS-3650A Series and PS-3651A Series are the same.

Unit: mm [in.]

301.5

+1

-0

+0.04

[11.87 ]

-0

Chapter 2 Specifications

≤ 3 [0.12]

r

-0

+0.04

-0

+1

227.5 [8.96 ]

• Please read “3.1.1 Installation Procedures (page 3-2)” before designing the Panel Cut.

2.5.4 Installation Fasteners

Unit: mm [in.]

M6

16 [0.63]

11[0.43]

16.6 [0.65]

31 [1.22]

∅10[0.39]

2-23

PS-3650A/PS-3651A Series Hardware Manual

2-24

3 Installation and

Wiring

1. Installation

2. Peripheral Devices Installation

3. Wiring Precautions

3-1

PS-3650A/PS-3651A Series Hardware Manual

3.1 Installation

3.1.1 Installation Procedures

This section describes the procedures and precautions for installing the PS-A unit.

Follow the steps given below when installing the PS-A unit.

Check the Installation Gasket’s Seating

It is strongly recommended that you use the installation gasket, since it absorbs vibration in addition to

repelling water.

For the procedure for attaching the installation gasket, refer to the following.

SEE

4.4 Replacing the Installation Gasket (page4-6)

• Before installing the PS-A unit into a cabinet or panel, check that the installation

gasket is securely attached to the unit.

• A gasket which has been used for a long period of time may have scratches or dirt

on it, and could have lost much of its dust and drip resistance. Be sure to change

the gasket periodically (or when scratches or dirt become visible).

Creating a Panel Cut

Create the correct sized opening required to install the PS-A unit, using the installation dimensions given.

The installation gasket and the installation fasteners are required when installing the PS-A unit.

SEE

2.5.3 Panel Cut Dimensions (page2-23)

Panel

Panel Cut

Area

3-2

• Check that the installation panel or cabinet’s surface is flat, in good condition and has no jagged

edges.

• Even if panel thickness is within recommend range for "Panel Cut Dimensions", the panel could

warp, depending on panel's material and installation location of PS-A or other devices. To prevent panel warpage, the installation surface may need to be strengthened .

Chapter 3 Installation and Wiring

• Panel thickness should be from 1.6mm [0.06 in.] to 10.0mm [0.39 in.]. Decide the

panel’s thickness based on the level of panel strength required.

1.6mm [0.06 in.] to 10.0mm [0.39 in.]

• For easier maintenance, operation, and improved ventilation, be sure to install

the PS-A unit at least 50 mm [1.97 in.] away from adjacent structures and other

equipment.

Unit: mm [in.]

50

[1.97]

50

[1.97]

50

[1.97]

50

[1.97]

50

[1.97]

50

[1.97]

50

[1.97]

3-3

PS-3650A/PS-3651A Series Hardware Manual

• Be sure that the ambient operation temperature and the ambient humidity are within

their designated ranges. When installing the PS-A unit on the panel of a cabinet or

enclosure, “Ambient operation temperature” indicates both the panel face and

cabinet or enclosure’s internal temperature.

Unit: mm [in.]

50 [1.97]

30[1.18]

Panel

face

• Be sure that heat from surrounding equipment does not cause the PS-A unit to

exceed its standard operating temperature.

• When installing the PS-A unit in a slanted panel, the panel face should not incline

more than 30°.

30[1.18]

Inside of the

enclosure

30° or less

3-4

• When installing the PS-A unit in a slanted panel, and the panel face inclines more

than 30°, the ambient temperature must not exceed 40°C. You may need to use

forced air cooling (fan, A/C) to ensure the ambient operating temperature is 40°C or

below.

• The PS-A unit does not support longitudinal mounting.

Installing the PS-A unit

(1) Insert the PS-A unit into the panel cut, as

shown.

(2) Insert the installation fasteners into the PS-A

unit insertion slots, at the top and bottom of

the unit. (total: 4 slots)

• Insert each installation

Chapter 3 Installation and Wiring

fastener securely into the

slot’s recess (shaded area).

•

(3) Insert each of the fasteners shown below.

Be sure to pull the fastener back until it is

flush with the rear of the attachment hole.

Slots

Installation Panel

Hook

3-5

PS-3650A/PS-3651A Series Hardware Manual

(4) Use a Phillips screwdriver to tighten each

fastener screw and secure the PS-A unit in

place.

• Tightening th e screws with too much for ce can damage the PS-A unit’s plastic case.

• For the gasket’s moisture resistance to be effective, the torque required to tighten

these screws is 0.5 N•m.

3-6

3.2 Peripheral Devices Installation

A wide variety of optional units, DIM module, CF Cards, manufactured by Pro-face and commercial

Expansion boards (PCI bus compatible board), PCMCIA (PC Cards) can be used with the PS-A unit.

(Expansion boards are used only for PS-3650A Series.)

When installing the optional units, refer to each unit’s “Installation Guide”.

Be sure to confirm that power is not supplied to the PS-A unit before installing or removing

any optional units, DIM module, CF Cards, Expansion boards (PCI boards), or PCMCIA

(PC Cards). Failure to do so can result in an electric shock.

• If the PS-A unit is in the Soft OFF Status, power is supplied to a part of circuits

even when no screen is displayed. Be sure to confirm that a power cable is not

connected before installing or removing peripheral equipment.

Chapter 3 Installation and Wiring

• Use a screwdriver to loosen or tighten the screws. Be sure not to tighten screws

too tightly, since it may damage the unit.

• When removing or replacing screws, be careful that they do not fall inside the

PS-A unit’s chassis.

• When installing the PS-A unit, or when attaching an optional item to the PS-A

unit, do not hold the PS-A unit’s rear-face Fan Unit while performing the work.

Doing so may damage the fan cover or cause the cover to fall off.

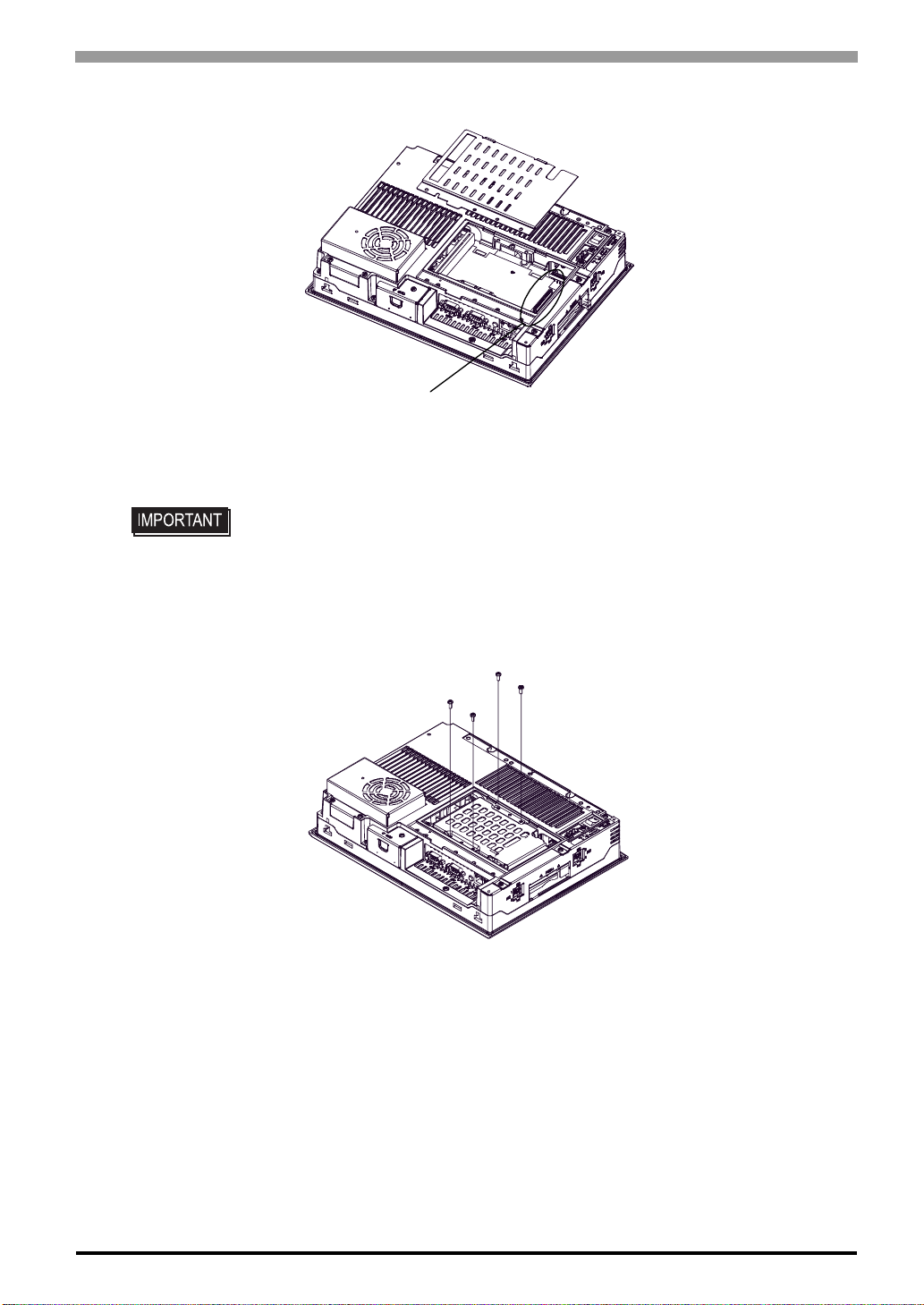

3.2.1 Main Memory Installation PS-3650A Series

(1) Turn OFF the power switch of the PS-A unit and remove the power cable. Place the PS-A unit on a flat,

level surface facing the display face downwards.

(2) Unscrew the screws (2) as you see on the following figure, and remove the Fan Unit.

3-7

PS-3650A/PS-3651A Series Hardware Manual

r

(3) Install the Main Memory where the following figure shows. Insert the optional DIM module into the

connector completely, then gently press it downward until it is locked into the stopper.

Connector

Main Memory

1

2

Main Memory (DIM Module)

(4) Reinstall the Fan Unit and attach with two screws. The torque required to tighten these screws is 0.5 to

0.6N•m.

Stoppe

PS-3651A Series

(1) Turn OFF the power switch of the PS-A unit and remove the power cable. Place the PS-A unit on a flat,

level surface facing the display face downwards.

(2) Unscrew the screws (2) as you see on the following figure, and remove the Memory Slot Cover.

3-8

Chapter 3 Installation and Wiring

r

(3) Install the Main Memory where the following figure shows. Insert the optional DIM module into the

connector completely, then gently press it downward until it is locked into the stopper.

Connector

Main Memory

1

2

Main Memory (DIM Module)

(4) Reinstall the Memory Slot Cover and attach with two screws. The torque required to tighten these

screws is 0.5 to 0.6N•m.

3.2.2 PCI Board Installation

A PCI board, commercially available, can be installed on the PS-3650A Series unit.

• The maximum size allowed for a PCI board is 174.63mm [6.88in.] × 106.68mm [4.2in.].

(1) Turn OFF the power switch of the PS-A unit and remove the power cable. Place the PS-A unit on a flat,

level surface facing the display face downwards

(2) Unscrew a screw of the Expansion Board Support and remove the Expansion Board Support.

Stoppe

3-9

PS-3650A/PS-3651A Series Hardware Manual

(3) Unscrew the Expansion Board Cover’s screws (2) and remove the Expansion Board Cover.

blank panel

(4) Unscrew the blank panel screw and take out the blank panel.

(5) Insert the PCI board into the Expansion Board connector and repl ace the blan k panel screw to attach the

PCI board. The torque required to tighten a screw is 0.5 to 0.6N•m.

PCI Board

(6) Reinstall the Expansion Board Cover and Expansion Board Support. The torque required to tighten each

of the screws is 0.5 to 0.6N•m.

3-10

3.2.3 PCMCIA (PC Card) Installation/Removal

(1) Loosen a screw in the PCMCIA slot on the side of the PS-A unit and slide the cover in the direction of

the arrow as shown below.

PC Card

(2) Press the eject button twice to remove the PC Card from the PCMCIA connector. (Pressing the eject

Chapter 3 Installation and Wiring

Eject Button

button once causes the tip to come out. Pressing the eject button the second ejects the PC Card from the

PCMCIA slot.)

(3) Reinstall the PCMCIA slot cover and tighten a screw. The torque required to tighten these screws is 0.5

to 0.6N•m.

• When using a PC Card with a cable attached, Pro-face recommends you use a clamp or

other type of device to prevent vibration from possibly dislodging the cable.

• When powering ON the PS-A unit, be sure to stop the PS-A unit’s PC Card driver prior to

removing the PC Card. Failure to stop this driver may result in damage to either the PC

®

Card, the PC Card’s data, or may cause W ind ows

procedure for stopping the PC Card’s driver, please refer to your OS’ User Manual.

• With the display face of PS-A unit downward (as illustrated), insert the PC Card face up.

to stop. For information on the

3-11

PS-3650A/PS-3651A Series Hardware Manual

3.2.4 CF Card Insertion/Removal

When using the PS-A unit and a CF Card, observe the following precautions:

Prior to inserting or removing a CF Card, be sure to confirm that the PS-A unit is turned

OFF. If you do not, CF Card internal data may be damaged or lost or the OS may stop.

While a CF Card is being accessed (HDD/IDE Access lamp: Lit in green), NEVER turn OFF

or reset the PS-A unit, or insert or remove the CF Card. If you do not, CF Card internal data

may be damaged or lost.

Prior to inserting a CF Card, familiarize yourself with the CF Card’s front and rear face

orientation, as well as the CF Card connector’s position. If the CF Card is not correctly

positioned and inserted into the PS-A’s CF Card Interface, the CF Card, it’s internal data,

and the PS-A unit may be damaged or broken.

Be sure to use only CF Cards manufactured by Pro-face. The CF Card’s internal data may

be damaged when using another manufacturer’s CF Card.

Once PS-A data is lost, it cannot be recovered. Since accidental data loss can occur at any

time, be sure to back up all PS-A unit screen and CF Card data regularly.

Be sure to follow the instructions given below to prevent the CF Card’s internal data from

being destroyed or a CF Card malfunction from occurring:

• DO NOT bend the CF Card.

• DO NOT drop or strike the CF Card against another object.

• Keep the CF Card dry.

• DO NOT touch the CF Card connectors.

• DO NOT disassemble or modify the CF Card.

3-12

Inserting the CF Card

Use the following steps to insert the CF Card in the PS-A unit.

(1) Confirm that the PS-A unit is turned OFF.

(2) Loosen a screw of the CF Card cover and remove the CF Card cover.

Screw

Chapter 3 Installation and Wiring

Eject Button

(3) Confirm the front and back of the CF Card and insert the CF Card in the CF Card slot. Push the eject

button completely until the eject button is pushed forward.

(4) Install the CF Card cover and attach it with a screw.

• Make sure that the CF Card cover is closed when accessing the CF Card.

• The torque required to tighten a screw is 0.5 to 0.6N•m.

CF Card

Removing the CF Card

Confirm that the PS-A unit is turned OFF. Remove the CF Card cover, press the eject button and carefully

remove the CF Card. After removing the CF Card, be sure to place back the CF Card cover and attach the

cover with a screw .

Backup of CF Card

The CF Card has a data overwrite limit of approximately 100,000 times. Therefore, be sure to back up all CF

Card data regularly to another storage media. (100,000 times assumes the overwriting of 500KB of data in

DOS format.)

< If your PC is equipped with a PC Card Slot >

(1) Install the CF Card into a CF Card Adapter (GP07 7-CFAD10) and insert it into a PC Card slot of a

personal computer.

(2) Save the data of the CF Card with your personal computer.

<If your PC is NOT equipped with a PC Card slot>

(1) Use a commercially available PC Card Reader, or a CF Card Reader.

3-13

PS-3650A/PS-3651A Series Hardware Manual

3.2.5 HDD Unit Installation

Shock Danger! Be sure to unplug the PS-A unit from its power supply prior to installing the

HDD unit.

• Since the HDD unit and the PS-A unit’s circuit board are precision instruments that

have a low resistance to shocks, be sure they are neither hit by nor pressed strongly

against another object when installing the HDD.

• Even when the screen display of the monitor connected to the PS-A unit is blank, the

power might be distributed internally (for example, in the Standby state). Make sure

that the power supply of the PS-A unit is off when installing or removing the HDD unit.

PS-3650A Series

(1) Turn OFF the power switch of the PS-A and remove th e power cable. P lace the PS-A unit on a flat, level

surface facing the display face downwards.

(2) Unscrew the Expansion Board Cover's screws (2) and remove the Expansion Board Cover.

(3) Unscrew the Expansion Board Base's screws (4) and remove the Expansion Board Base.

3-14

Chapter 3 Installation and Wiring

(4) Remove the DISK cover.

Serial ATA Interface

(5) Mount the HDD unit vertically on the circuit board and plug the HDD unit cable connector in the Serial

ATA interface.

• Be sure to mount the HDD unit slowly and vertically and not to hit the circuit board

with the HDD unit. Contact may cause a malfunction or damage the HDD unit and

PS-A unit.

(6) Attach the HDD unit with the screws (4) which are contained in your package. The torque required to

tighten these screws is 0.5 to 0.6 N•m.

(7) Reversing the steps above, return the DISK cover, Expansion Board Base, and Expansion Board Cover

to the PS-A unit, respectively. The torque required to tighten these screws is 0.5 to 0.6 N•m.

3-15

PS-3650A/PS-3651A Series Hardware Manual

PS-3651A Series

(1) Turn OFF the power switch of the PS-A unit and remove the power cable. Place the PS-A unit on a flat,

level surface facing the display face downwards.

(2) Unscrew the DISK cover's screws (3) and remove the disk cover.

(3) Mount the HDD unit vertically on the circuit board and plug the HDD unit cable connector in the Serial

Serial ATA Interface

ATA interface.

• Be sure to mount the HDD unit slowly and vertically and not to hit the circuit board

with the HDD unit. Contact may cause a malfunction or damage the HDD unit and

PS-A unit.

(4) Attach the HDD unit with the screws (4) which are contained in your package. The torque required to

tighten these screws is 0.5 to 0.6 N•m.

(5) Reversing the steps above, return the disk cover to the PS-A unit. The torque required to tighten these

3-16

screws is 0.5 to 0.6 N•m.