Produal Sensortec PEL 1000-M, Sensortec PEL 1000 User Manual

COMMISSIONING

Mounting

USER GUIDE

PEL 1000 / PEL 1000-M

- The transmitter should be installed above the measuring point to avoid condensation problems.

- The duct overpressure is detected by connecting the measuring point to + connector and by leaving the

- connection open (surrounding space pressure). Accordingly, the duct under-pressure is detected by

connecting the measuring point to - connector and by leaving the + connection open.

- Install the measuring hoses carefully so that the hoses don't bend too tightly. Too tight curves may prevent the

air flow to the sensor.

V1.0 (19.02.2015)

1 (8)

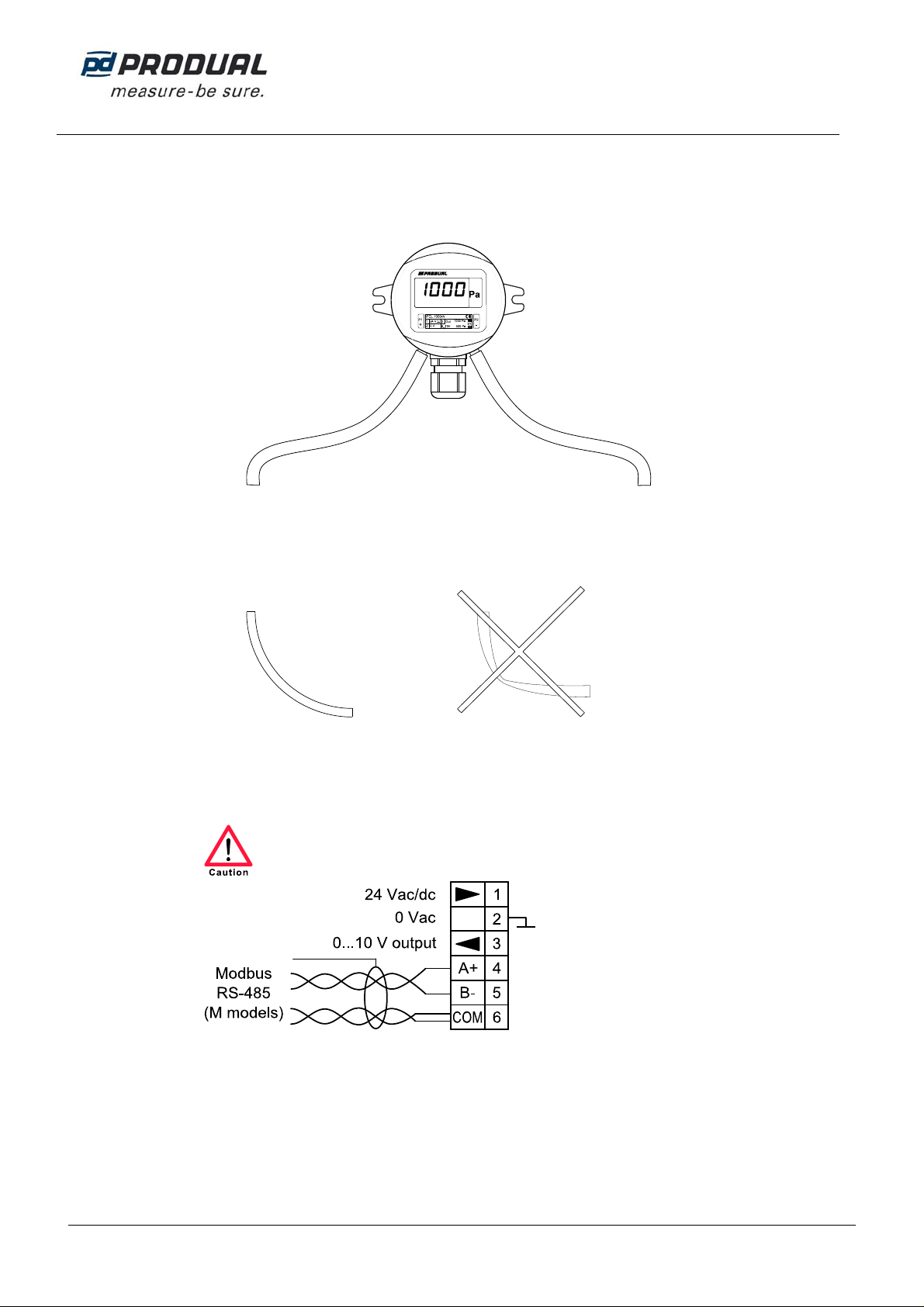

Wiring

- The hose length doesn't effect on the measuring accuracy. However, long hoses generate delay on the

measurement.

- Mount the device cable entry downwards, so that moisture and water gets out of the housing freely.

Device wiring and commissioning can only be carried out by qualified professionals. Always make the

wirings while the power is switched off.

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

USER GUIDE

PEL 1000 / PEL 1000-M

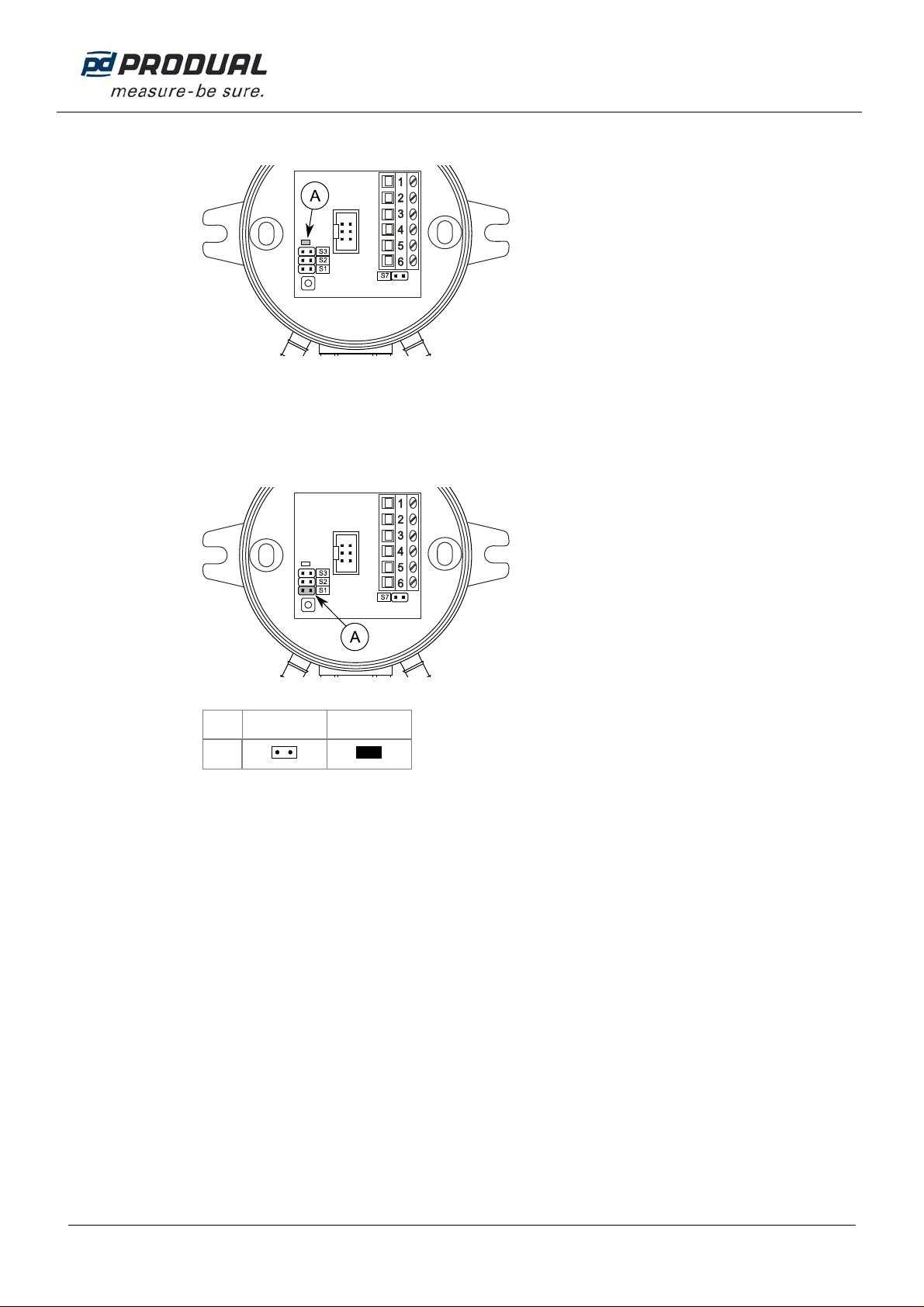

Indicator light functions

A. Indicator light

- The indicator light is illuminated for one second when the power is connected.

- The indicator light illuminates when the transmitter sends data to Modbus (M models only).

Selecting measuring range

Measuring range can be selected with the jumper S1.

2 (8)

A. Measuring range selection jumper

)

Pa 0…500 0…1000 *

S1

*) Factory setting. The 0…1000 Pa range is also used for the custom range setting.

The custom range is 0…1000 Pa as a default. The range can be changed by using ML-SER tool or by defining the

high limit to the Modbus register 40006 (the low limit is 0 Pa).

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

ZERO POINT CALIBRATION

The zero point drift can be eliminated by performing the zero point calibration. It is recommended to calibrate the zero

point every 6 months. At the commissioning the zero point calibration should be done after one hour of powering the

transmitter.

1. Unplug the plastic tubes from the inlets.

2. Press the zeroing button until the indicator light lights up (without flashing).

A. Indicator light

B. Zeroing button

USER GUIDE

PEL 1000 / PEL 1000-M

3 (8)

ML-SER TOOL

Connecting ML-SER tool to the device

With the ML-SER tool you can change the device settings, Modbus and controller settings for example.

1. Remove the cover.

2. Disconnect the display cable (N models).

3. Connect the ML-SER tool cable to the display connector.

A. Display connector

When the ML-SER is successfully connected, the pressure measurement value is displayed on the ML-SER

tool display. The connecting can take few seconds.

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358 10 219 9100 / Fax: +358 5 230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

Loading...

Loading...