Produal KRM-1, KRM-2 User Manual

USER GUIDE

KRM-1 & KRM-2

V2.0 (05.11.2015)

1 (8)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358-10-219 9100 / Fax: +358-5-230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

5 d

h

3 d

h

5 d

h

SENSOR CONSTRUCTION

A. Electronics.

B. Upper casing with seal.

C. Lower housing with seal

D. Adapter plate with gasket.

E. Optical smoke sensor.

F. Rubber bushing (only for insulated or circular ducts).

G. Air flow in a duct

H. Measuring tube (max. length 3 m).

I. End cap

ASSEMBLY

Device assembly, wiring and commissioning can only be carried out by qualified professionals. Always

make the connections while the power is switched off.

Positioning of the sensor

The KRM is to be positioned in accordance with the current local state regulations on ventilation systems. Reliable

smoke detection must be guaranteed. Depending on the cross section of the ventilation duct the air collecting tube

may be cut to a length of 160 mm. This minimum length of 160 mm must not be undercut. This way, up to <100 mm ø

can be monitored in conjunction with the FP-KRM fitting plate. In the ideal case, install the KRM when structurally

possible, where flow meters, etc. are normally attached, so there is a laminar airflow along the measuring tube.

The KRM is to be installed so that the air collecting tube is constantly in the air stream. In horizontal ventilation ducts

the KRM including air collecting tube should be installed in the upper third of the ventilation ducts or at the top of the

ventilation ducts, if this is structurally possible.

Example of positioning after the

change of air duct direction

Air outlet

Example of positioning after air

outlets.

Where there are large temperature differences, outdoors for example, or in places that are dependent on outside

temperature (roof, attic), the air duct smoke sensor has to be insulated.

DC

A

E

G

F

H

I

B

USER GUIDE

KRM-1 & KRM-2

2 (8)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358-10-219 9100 / Fax: +358-5-230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

Hydraulic diameters, dh

dh=

2xHxW

H+W

H

W

dh=D

øD

Round duct Rectangular duct

Example of positioning (recommendations):

MIN 3xdhMIN 5xd

h

MIN 3xd

h

MIN 5xd

h

MIN 3xdhMIN 5xd

h

MIN 3xdhMIN 5xd

h

KR

M

KRMKRMKRMKRMKRMKRMKRM

Fan Damper Silencer Heater

KRM

KRM

KRM

KRM

KRM

KRM

KRM

KRM

MIN 5xd

h

MIN 3xd

h

MIN 5xd

h

MIN 5xd

h

MIN 3xd

h

MIN 3xd

h

MIN 5xd

h

MIN 5xd

h

MIN 3xd

h

Exhaust air

Supply air

Change in air duct

direction

Air duct forking Air duct narrowing / air

duct enlargement

Air duct device

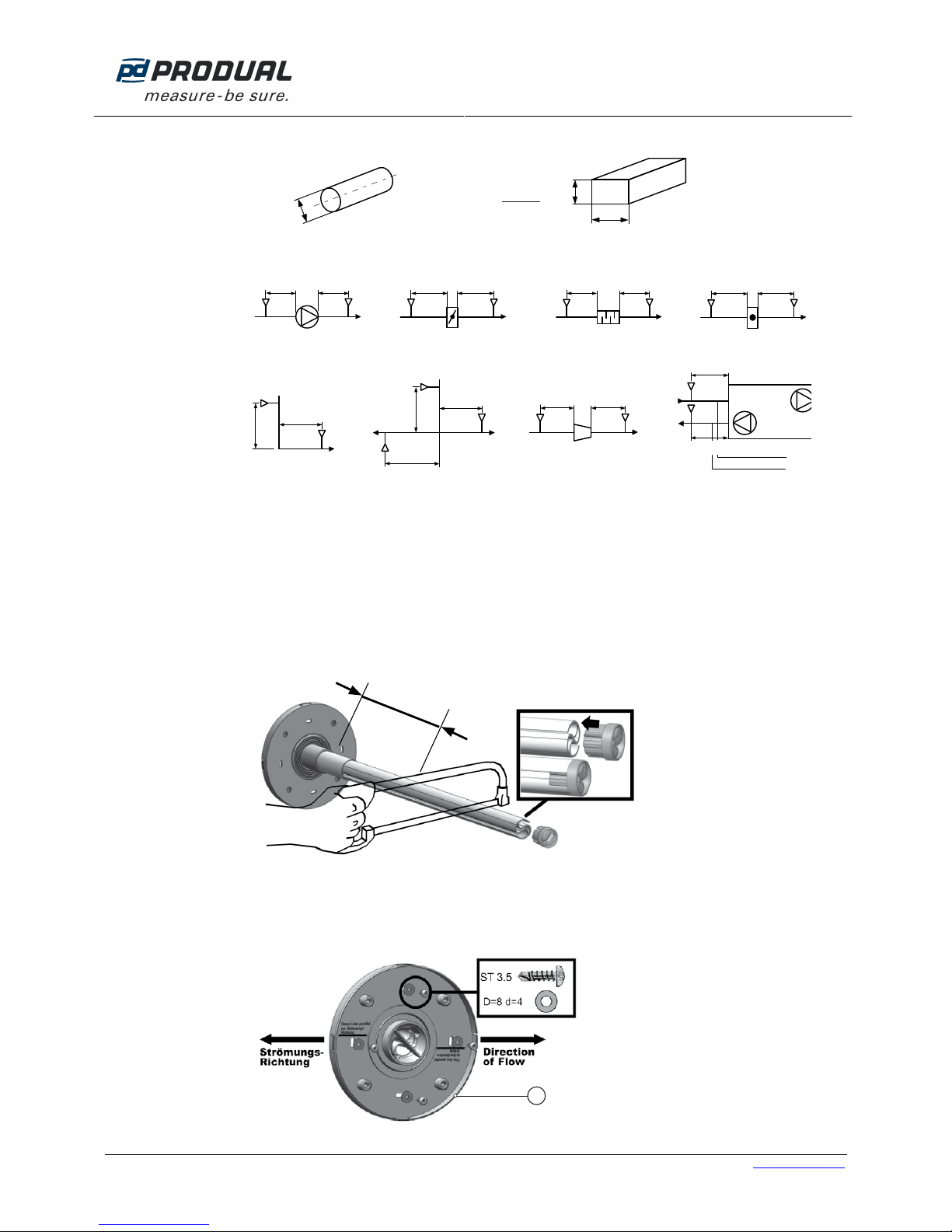

Mounting procedure

1. Drill a hole Ø 43…44 mm in diameter at the intended mounting location.

NOTE: Installation of the measuring tube is possible either from the top, bottom or side of the channel for all duct

cross-sections (for round ducts as well).

2. Determine how long the measuring tube must be. If necessary, shorten the tube. Put the end plug back on up to

the stop collar.

min. 160 mm

IMPORTANT: Operation without end plug not permitted.

3. Determine the direction of flow and fit the adapter plate (A) so that the line on the adapter plate under the text

”Strömungsrichtung” is parallel to the flow direction. Four self-tapping screws serve for attaching it to the sheet

metal duct (not included in delivery).

A

USER GUIDE

KRM-1 & KRM-2

3 (8)

Produal Oy Keltakalliontie 18, 48770 Kotka FINLAND Tel: +358-10-219 9100 / Fax: +358-5-230 9210 info@produal.fi www.produal.com

Information is subject to change without prior notice.

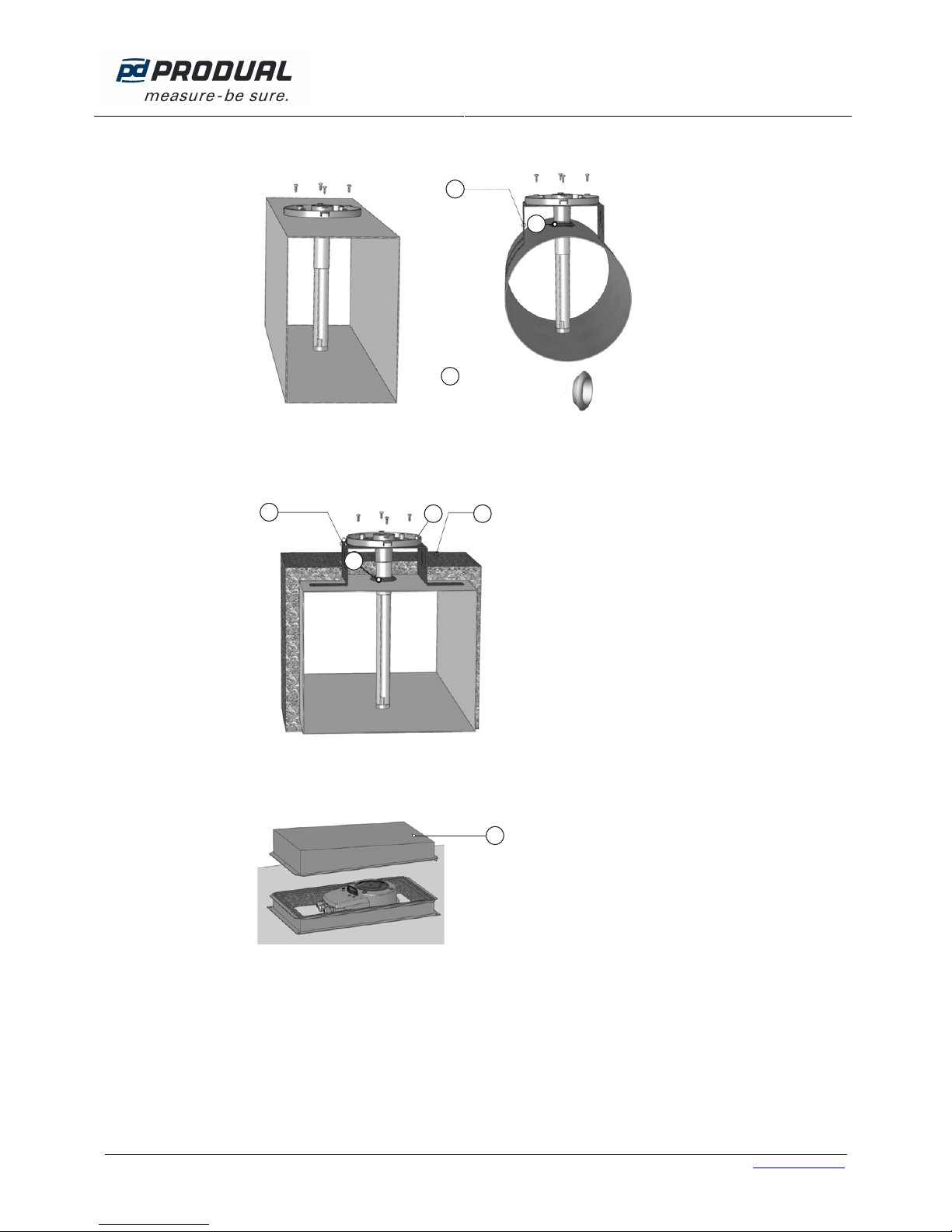

4. Installation on a rectangular air duct, see picture below. When installing on a circular air duct, use KS fitting plate

(B) and rubber bushing (C).

C

B

C

5. When installing on the air ducts with insulation, use the rubber bushing and insert it into opening in the air duct.

Install the fitting plate (B). Insert the assembled adapter plate (A) into the measuring tube by sliding the measuring tube through the grommet, and screw the adapter plate onto the fitting plate (B) using the 4 self-tapping

screws. Install the sensor with fitting plate into air duct. Then the insulation (D) can be installed.

B

D

C

A

6. When installing sensor outdoors or in cold environment, special WDG type housing (E) should be used. Housing

prevents the warm air in the smoke detector duct from condensing. The interior of the housing is insulated with

foam rubber.

E

Rubber

bushing, inner

oute

r

Loading...

Loading...