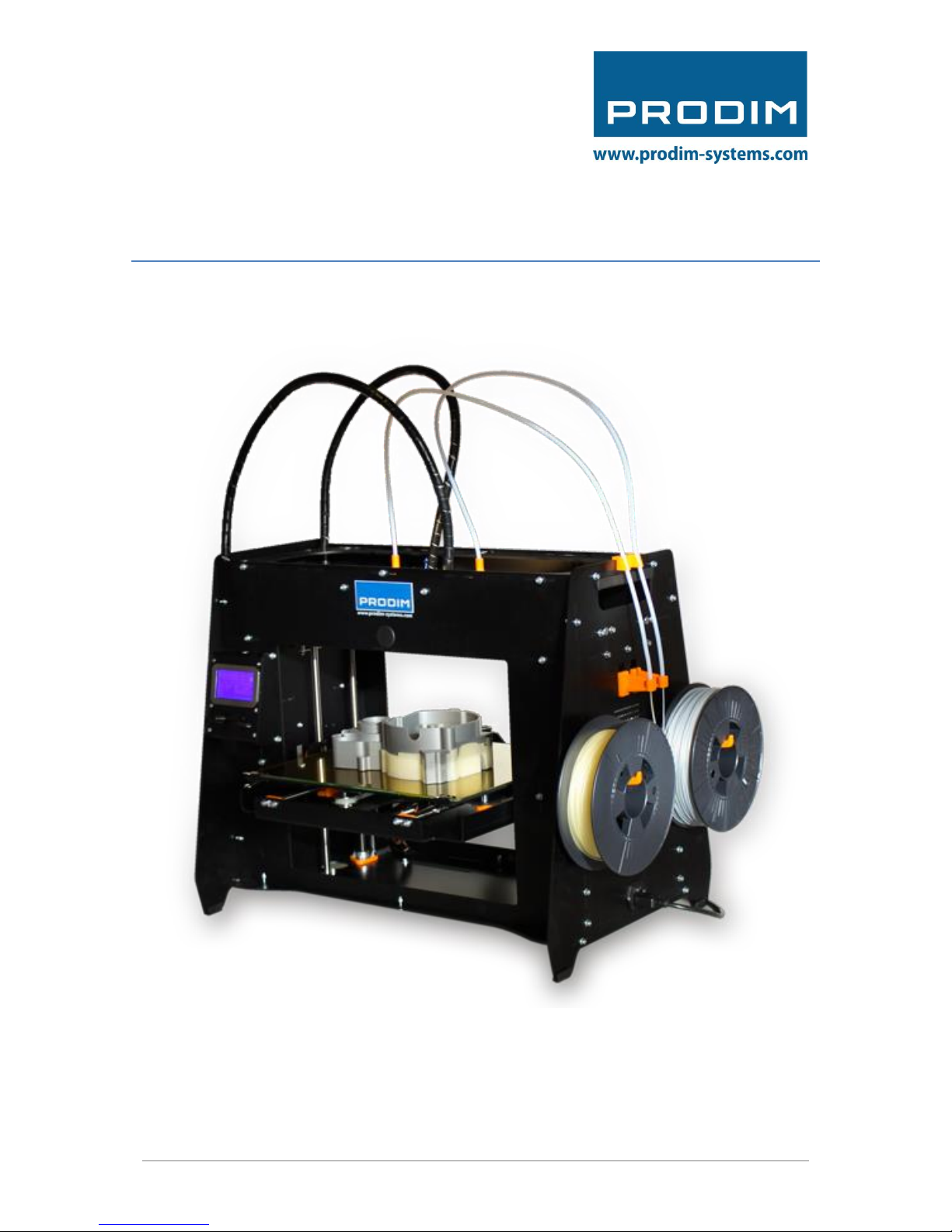

PRODIM ORCABOT XXL PRO2 User Manual

Manual: Prodim XXL

Pro 2

version 1.0.1 Mar 2017 www.prodim-systems.com

Manual: ORCABOT XXL

PRO2

3D printer

Manual: Orcabot XXL

Pro 2

version 1.0.1 Mar 2017 2 www.prodim-systems.com

Welcome in the world of 3D printing

Thank you for choosing Prodim as your supplier!

This manual will show you the basics of the 3D printing world. The world of the future, full of

opportunities and challenges

It is important that you read this manual carefully for the optimal use of your 3D printer.

Furthermore there are important tips to work safely with the 3D printer.

Let us start making wonderful things!

3D printing is a learning process what you must build up with some experience in time. Prodim 3D

Printers are typical for the high level of research and trying. Boundaries are therefore, continuously

challenged. Prodim tries to assist its users by always improving its printer settings. However, it is not

possible to grant a warranty on this. There are several factors that influence the end result of 3d

printing. For example:

- The ambient temperature of the room.

- Printability of the 3D design.

- Properties of the 3D model.

- The speed of printing.

- The selection of filament from a different supplier.

- Different material batches.

- Settings of the extruder clamp.

- Different print Profiles/settings.

- Different Slicer software.

- Etc.

Prodim is only the supplier of the 3D printer. It’s machines are thoroughly tested according to factory

norms and protocols. Beware that the knowledge of 3d printing is the sole responsibility of the

owner/operator.

Manual: Orcabot XXL

Pro 2

version 1.0.1 Mar 2017 3 www.prodim-systems.com

Content

Welcome in the world of 3D printing ...................................................................................................... 2

Content .................................................................................................................................................... 3

1. Safety ............................................................................................................................................ 5

2. FFF 3D-print technology ................................................................................................................ 6

3. Specifications ORCABOT XXL

Pro 2

.................................................................................................. 7

4. Glossary of Terms .......................................................................................................................... 8

5. Installing the ORCABOT XXL

Pro 2

.................................................................................................... 9

5.1. Overview printer ................................................................................................................. 9

5.2. Preparing the printer ......................................................................................................... 10

5.3. Installing “Orcabot Repetier Host software”..................................................................... 11

6. The print process ......................................................................................................................... 12

6.1. Orcabot Repetier Host (object placement) ....................................................................... 13

6.2. G-code generation with different modes (Slicing) ............................................................ 14

6.2.1. Slicing object(s) for Single extruder mode .................................................................... 14

6.2.2. Slicing object(s) for Dual extruder mode ....................................................................... 16

6.2.3. Slicing an object(s) for Copy extruder mode ................................................................. 18

6.3. Change or add a print profile (advanced).......................................................................... 20

7. Printing ........................................................................................................................................ 22

7.1. Overview display ............................................................................................................... 22

7.1.1. Information on the mainscreen .................................................................................... 22

7.2. Menu structure (schematics) ............................................................................................ 23

7.2.1. Menu Structure ............................................................................................................. 24

7.3. Temperature setting on display ........................................................................................ 27

7.4. Load / replacement of filament ......................................................................................... 28

7.5. Start printing & check distance to bed .............................................................................. 29

7.6. Filament cooling (blower).................................................................................................. 31

7.7. Connect Orcabot XXL

PRO 2

with Repetier Host ................................................................... 32

8. Calibration & Service ................................................................................................................... 33

8.1. Printbed alignment ............................................................................................................ 33

8.2. Nozzle alignment (height). ................................................................................................ 35

8.3. Calibration 2nd extruder (X, Y-as calibration 2nd extruder) ................................................ 36

8.4. Cleaning the Hotend .......................................................................................................... 38

9. Problem solving ........................................................................................................................... 39

Manual: Orcabot XXL

Pro 2

version 1.0.1 Mar 2017 4 www.prodim-systems.com

10. Repair and warranty.................................................................................................................... 40

11. Contact Prodim ........................................................................................................................... 41

Manual: Orcabot XXL

Pro 2

version 1.0.1 Mar 2017 5 www.prodim-systems.com

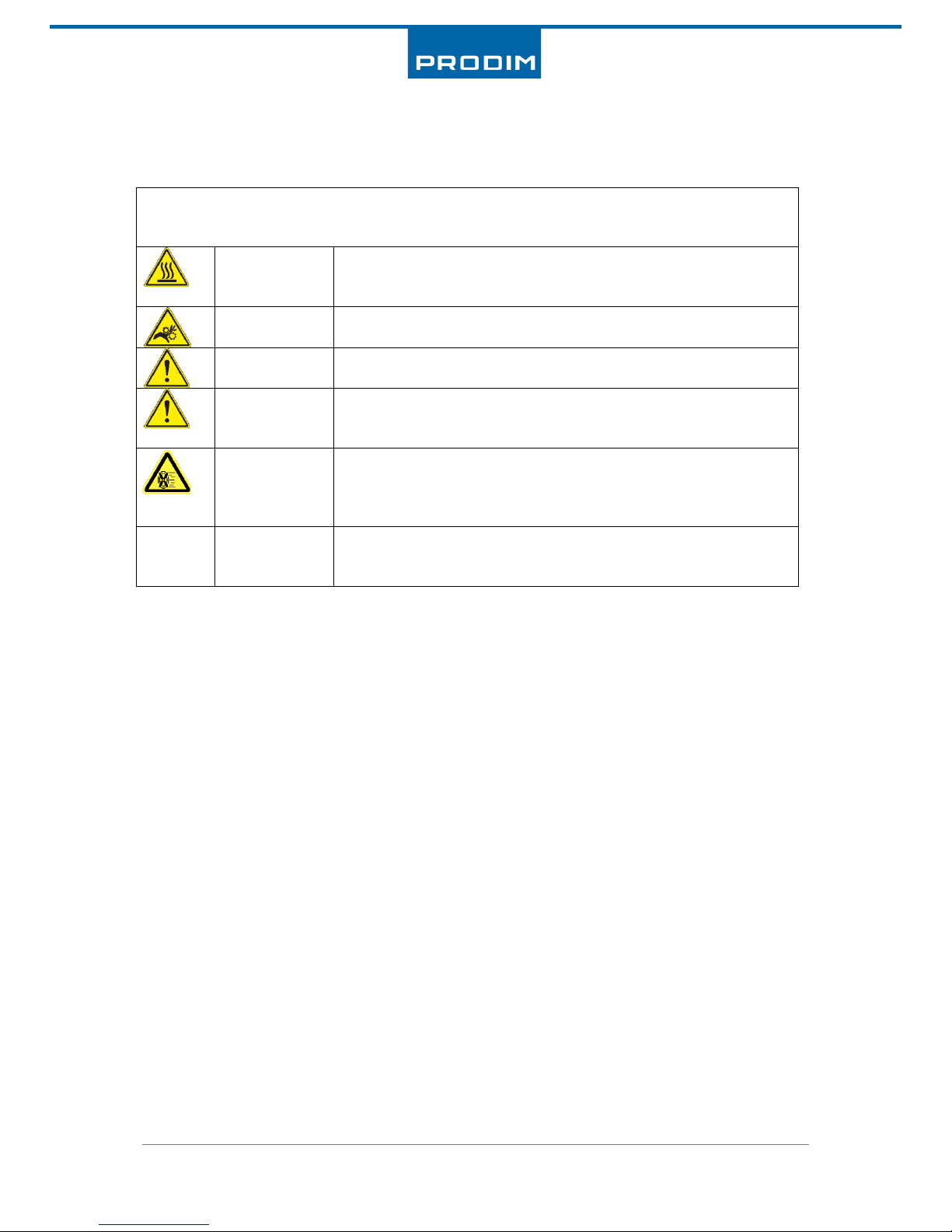

1. Safety

Safety alert symbols precede each safety message in this manual. These symbols indicate potential

safety hazards that could harm you or others or cause product or property damage.

Warning:

The Orcabot XXL

Pro

3D Printer generates high temperatures. Do not

reach inside the machine when operating. Always allow the Orcabot

XXL

Pro 2

to cool down first.

Warning:

The Orcabot XXL

Pro2

3D Printer includes moving parts. Never reach

inside the Orcabot XXL

Pro2

when the machine is in operation.

Warning:

Do not leave the Orcabot XXL

Pro2

3D Printer unattended during

operation. The operator is responsible for the printer.

Caution:

In case of emergency disconnect power supply from wall socket. Or

switch off the printer using the on/off button at the side of the

printer.

Caution:

De Orcabot XXL

Pro 2

3D Printer melts plastic during printing. Plastic

odors are emitted during this operation. Make sure to set up the

printer in a well-ventilated area with little draft and temperature

change.

Remark

Prodim advises the use of filaments delivered by Prodim. Other

materials can have unexpected properties for which Prodim bears

no responsibility.

Manual: Orcabot XXL

Pro 2

version 1.0.1 Mar 2017 6 www.prodim-systems.com

2. FFF 3D-print technology

The Prodim 3D printer uses the FFF 3D-print technology.

Fused filament fabrication (FFF) is an additive manufacturing technology commonly used for

modeling, prototyping, and production applications.

FFF works on an "additive" principle by laying down material in layers; a plastic filament or metal

wire is unwound from a coil and supplies material to produce a part.

The technology was developed by S. Scott Crump in the late 1980s and was commercialized in 1990.

Manual: Orcabot XXL

Pro 2

version 1.0.1 Mar 2017 7 www.prodim-systems.com

3. Specifications ORCABOT XXL

Pro 2

Construction

Printer dimensions: 620x500x520mm

Frame construction: Aluminum

Bed construction: Aluminum / Glass

Extruders: 2 full metal extruders with blowers

Weight: 20,5 kg

Printing

Print technology: Fused Filament Fabrication (FFF)

Print volume (single extruder) 356x274x230mm (LxWxH)

Print volume (dual extruder) 356x274x230mm (LxWxH)

Print volume (copy mode) 176x274x230mm (LxWxH)

Layer resolution: 0.05mm

Position resolution: 0.05mm

Nozzle diameter: 0,40 mm (standard nozzle diameter)

Filament: 1,75mm filament

Temperature

Maximum print temperature: 285 ˚C

Bed temperature ≈ 100 ˚C

Ambient operating temperature*: 10˚C - 40 ˚C

Storage temperature 0˚C - 50 ˚C

Electrical

AC input: 88-264 VAC

Frequency range: 47-63 Hz

DC voltage: 24V

Rated current: 13A

Manual: Orcabot XXL

Pro 2

version 1.0.1 Mar 2017 8 www.prodim-systems.com

4. Glossary of Terms

Extruder:

- The print head assembly where you can insert the filament. The printer has 2 extruders (2

print heads) for combining 2 different materials.

Hobbed shaft

- A Hobbed shaft is a part in the extruder. It has sharp teeth in the shaft for transport the

filament to the hot end.

Hotend

- That is the treated rod where the filament is melted. The Hot end is mounted under the

extruder assembly.

Heater block

- The heater block is the block that’s is mounted above the nozzle. The heater element and the

temperature sensor are mounted in the heater Block.

Nozzle

- It is the end of the hot end were the filament comes out. The nozzles are available in

different sizes. (0.25mm, 0.35mm, 0.4mm & 0.5mm)

Retracting

- Retracting is the technique of taking the molten plastic up in the hotend (e.g. to prevent

oozing).

Oozing

- Oozing is leaking material from the nozzle.

Repetier Host

- That is the software that controls the printer and loads the G-code file.

Sli3er

- Sli3er is a program that converts .stl files to a G-code. It makes from a model a printable file

and also calculates the amount of material to be extruded and many more.

G-Code

- It’s a computer language that describe movement (toolpaths) of the Prodim XXL

pro

3D

printer.

STL

- Is a widely used 3d format for 3d models. STL = Surface Tessellation Language

Feeler gauge

A feeler gauge is a tool used to measure gap widths. Feeler gauges are mostly used in engineering to

measure the clearance between two parts.

Manual: Orcabot XXL

Pro 2

version 1.0.1 Mar 2017 9 www.prodim-systems.com

5. Installing the ORCABOT XXL

Pro 2

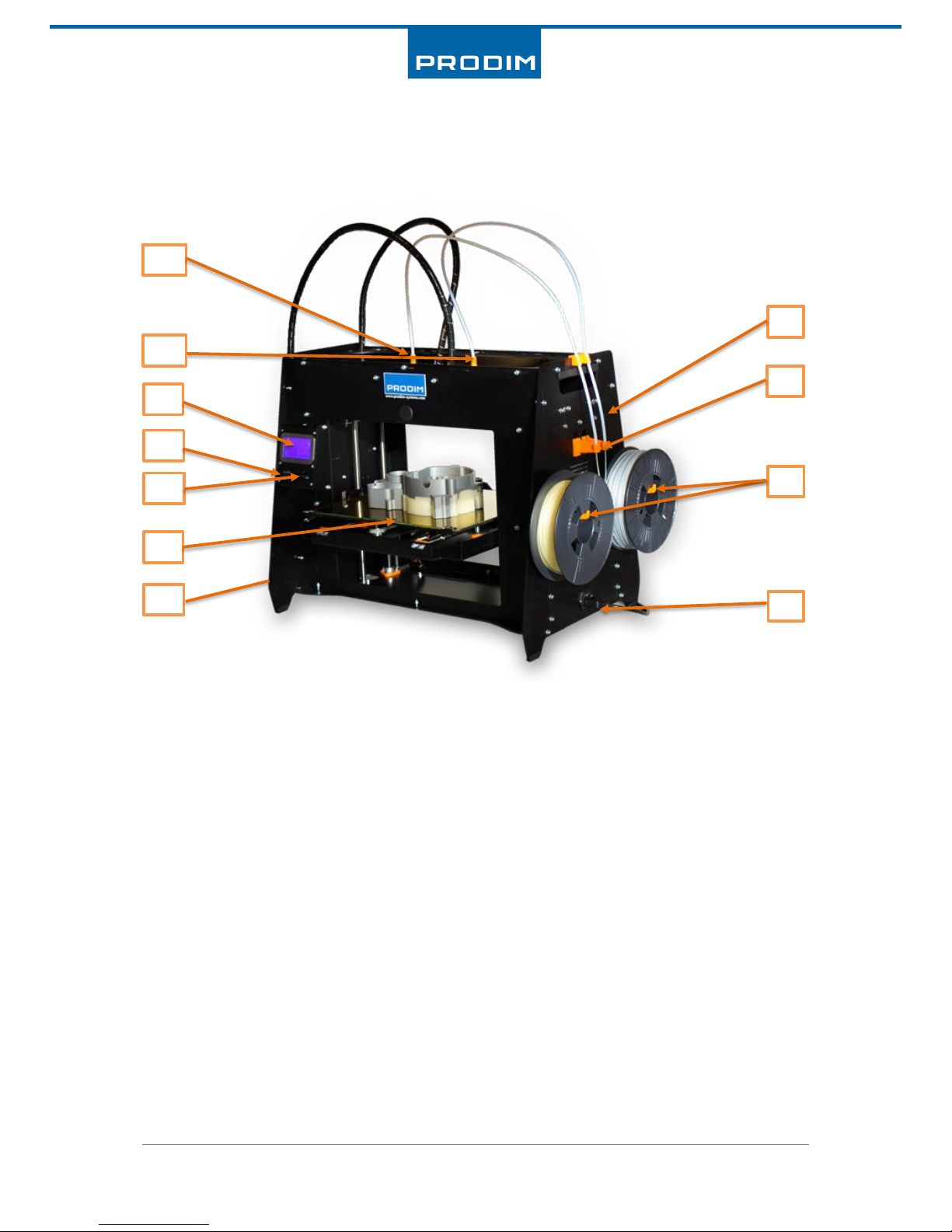

5.1. Overview printer

1. On/off button + socket power plug

2. Display

3. Selection button

4. SD card slot

5. Print bed

6a. Extruder 1

6b. Extruder 2

7. Filament tubes

8. Tube holder

9. Filament roll holders

10. USB port (left)

1

7 9 5 3 4 2 8

6a 106b

Manual: Orcabot XXL

Pro 2

version 1.0.1 Mar 2017 10 www.prodim-systems.com

5.2. Preparing the printer

A few things are important while installing the Orcabot 3D-printer XXL

pro 2

:

- The Orcabot XXL

pro 2

must be placed on a smooth and level surface (solid table).

- There must be an electric socket available.

- The printer melts filament during printing, this can cause damps and odours. Make sure to

choose a room or place which has decent ventilation, little draft and temperature change.

Installing the Printer:

- Take the printer out of the original box and place on a solid table.

(be sure to preserve the original box with original foam inlay)

- Install the float glass plate (use the 4 clamps)

- Install the filament- and tube holders keeping the filament tube to the right side of the

printer.

Glass plate with clamps Tube holder (s) Filament holder(s)

- Connect the supplied power cord to the right side of the printer.

Here you can also find the on/off switch with which you can turn

the printer on or off.

Power cord and on/off switch.

The USB-port is located to the left side of the printer. Running the

printer can be done stand-alone or via a PC-connection. We

advise to use the printer as stand-alone.

Manual: Orcabot XXL

Pro 2

version 1.0.1 Mar 2017 11 www.prodim-systems.com

5.3. Installing “Orcabot Repetier Host software”

The Orcabot Repetier Host software is only available for Windows 7 or higher.

The software and drivers to the Orcabot XXL

Pro 2

3D printer can be found on the Prodim Systems

website or use the following link:

https://www.prodim-systems.com/en-en/Support/software-downloads.html

Software installation:

- Make sure the printer is not connected to the computer during software installation.

- Download the “Orcabot Repetier Host Software” from aforementioned website.

- Install the downloaded file with administrator rights.

(click with the right mouse button on the .exe file and select ‘’run as administrator’’ and click

on yes).

- Follow the steps on the screen.

Manual: Orcabot XXL

Pro 2

version 1.0.1 Mar 2017 12 www.prodim-systems.com

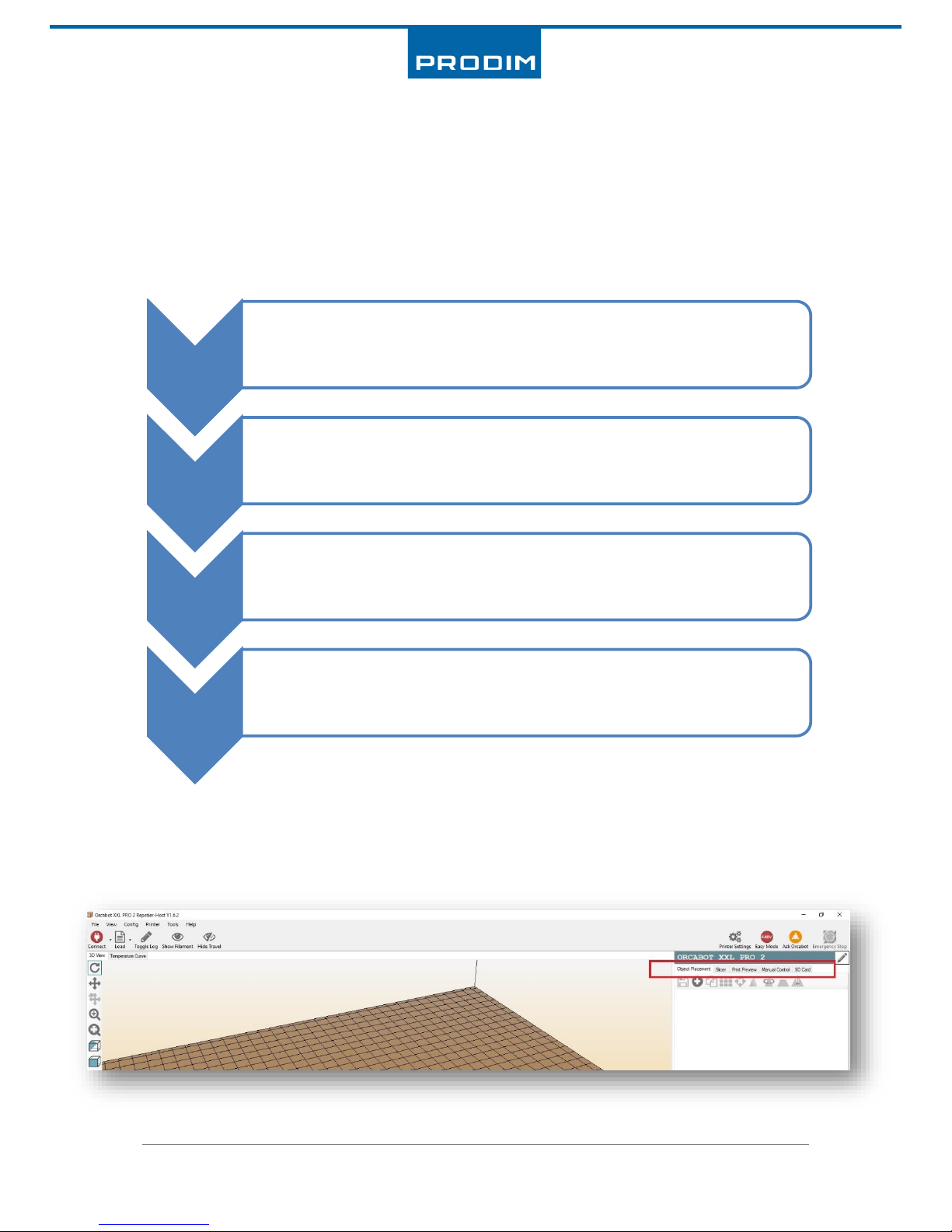

6. The print process

Before you start printing it is important to know how the print process works. Below the steps are

described how an object can be printed. When you are new to printing always use the supplied

Orcabot Repetier Host software. The print process is partly with this software and partly with the

printer itself. Step 1 to 3 are predominantly executed on a computer or laptop. From step 4 onwards

we will work directly on the printer.

Below you can see a part of the software where there are a number of tab pages marked on the

right. These are the process steps from left to right which we use in the printing process which is also

described in the above diagram.

1. Object

placement

•Place Object(s) on the bed and evt. copy, scale, rotate etc.

•This subproces must be done in Orcabot Repetier.

•See chapter 6.1 - Orcabot Repetier Host (object placement)

2. G-code

(slicing)

•Convert placed objects to a G-code.

•Slicing (convert the file in printable layers)

•This is done in the integrated Slic3r program.

•See chapter 6.2 - G-code generation with different modes.

3. Print preview

en save

•Check model with ''Print preview'' in Orcabot Repetier Host

•Save G-code on SD-kaart

•See also chapter 6 - G-code generation with different modes.

4. Printing

•Heating Printer

•Loading of filament

•Start printing from SD-card

•See chapter 7 - Printing with the 3D printer

Manual: Orcabot XXL

Pro 2

version 1.0.1 Mar 2017 13 www.prodim-systems.com

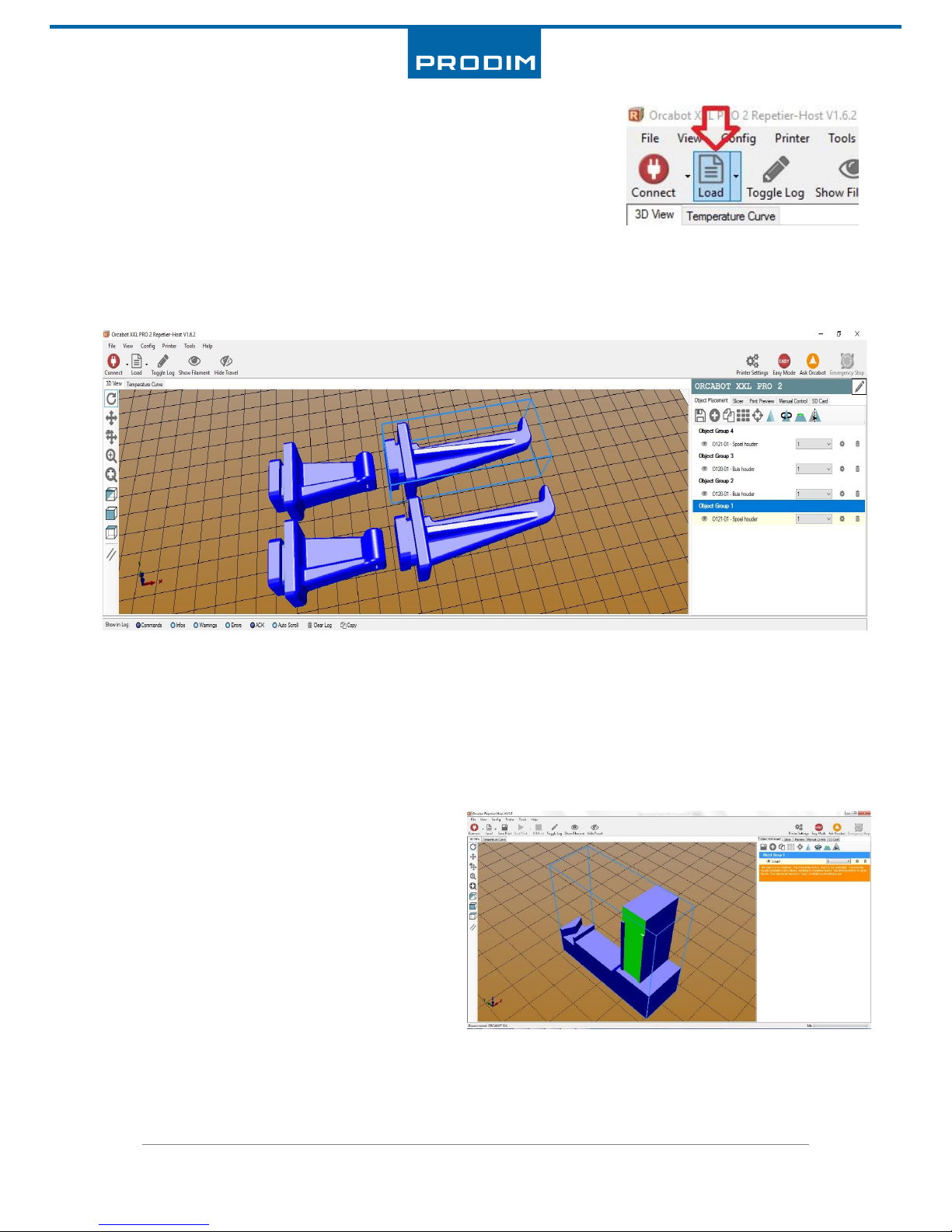

6.1. Orcabot Repetier Host (object placement)

To print an object first a G-code must be created. If you had already

created a G-code you can load this by clicking on the “load” button in

the left corner of the screen and selecting the file from your hard drive.

If you had not done so, it is important you start from a .stl file. Repetier Host works with .stl files that

are subsequently transformed into G-code. The majority of 3d drawingprograms can export a

drawing as .stl.

In “Orcabot Repetier Host” click on the button “Add object” on the tab object placement and choose

the .STL to import. If an object is uploaded, it will be automatiocally displayed on the printbed on the

screen. On the rightside you can see a list of uploaded .STL files. In the Repetier host the model can

be centered, copied, scaled, rotated and mirrored. The object can also be placed at every postion of

the virtual bed. (It is advised to place the object in the middle of the printbed.)

Ensure a correct 3d file. If planes are not

connecting correctly the software will address

this with the notification: “the object is not

manifold”. The surface causing this will be

displayed in green (as depicted in the picture).

If an area is green the .stl will have to be

exported anew from the 3d-cad program.

Another possibility is to fix the file by using the

link given.

Loading...

Loading...