ProDesign F18E, Fiberglass F18 User Manual

1

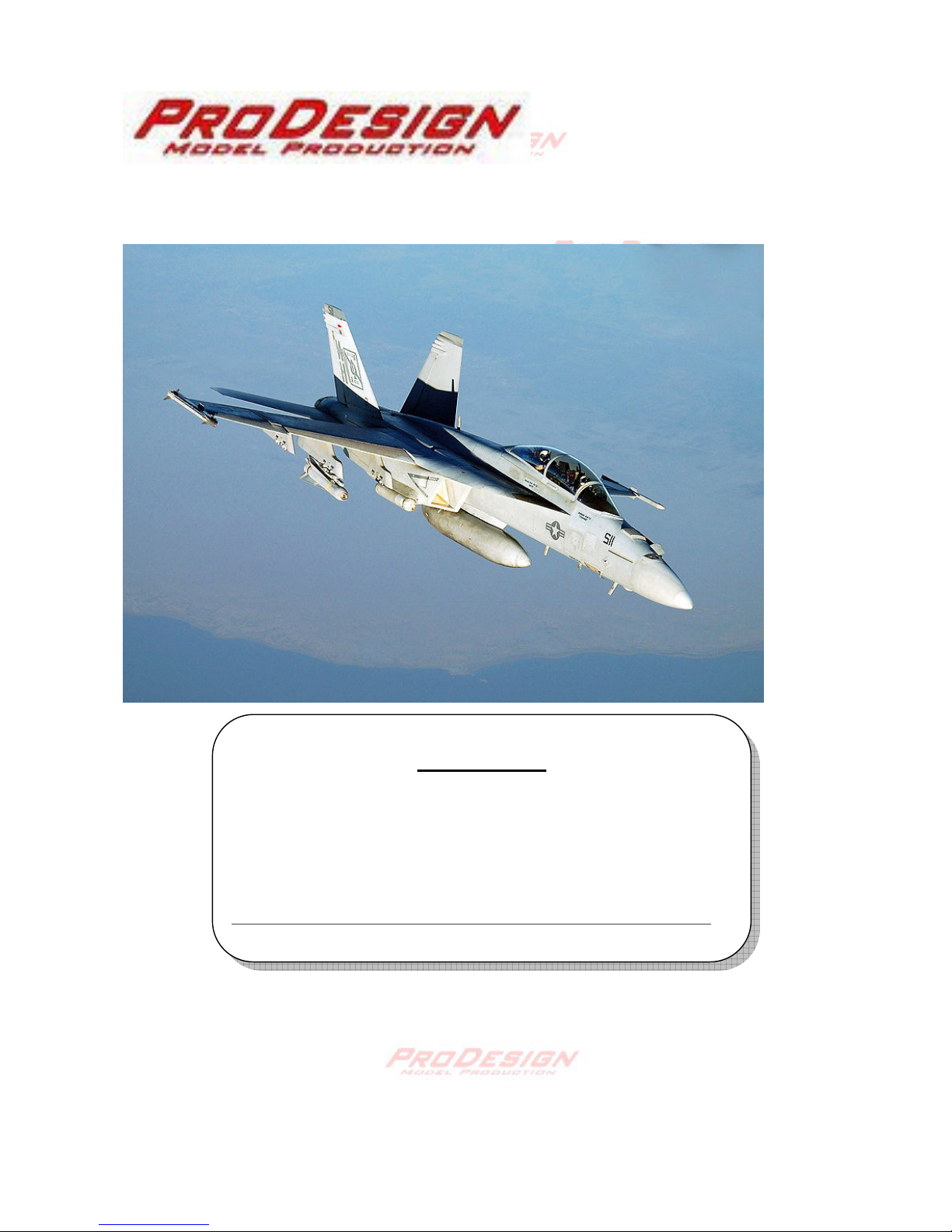

F18E 90mm EDF

High performance Fiberglass F18 for single 90mm electric ducted fan

Specifications are subject to change without notice

Warning !

This model is not a toy and please read the manual carefully before construction and

operating this model aircraft.

Specification

• Flying Weight

~2200g (~4.8 lb)

• Wing span

920mm / 36.2 in.

• Length

1250mm / 49.2 in.

• Rotor diameter

90mm / 3.54 in.

2

Radio system for 4 channels or above

1x Electronic speed controllers for brushless motor

1x 90mm fan-units, EDF shaft adapter diameter 5mm

1x 700-1000W size brushless motors

6-8s Lipo battery for 1600kv brushless motor

4x Servo extension wires

2x Metal gear standard size servo, for elevator

2x 9g servos for ailerons.

5 or 30 minute epoxy, CA Glue

Velcro.

Locktite/ threadlock

Drill , drill bit 2mm, 3mm

Dremel tool

Plier/cutter/ Philip screw driver

2mm , 3mm hex driver

Scissor

Tools needed

Equipment and parts needed

3

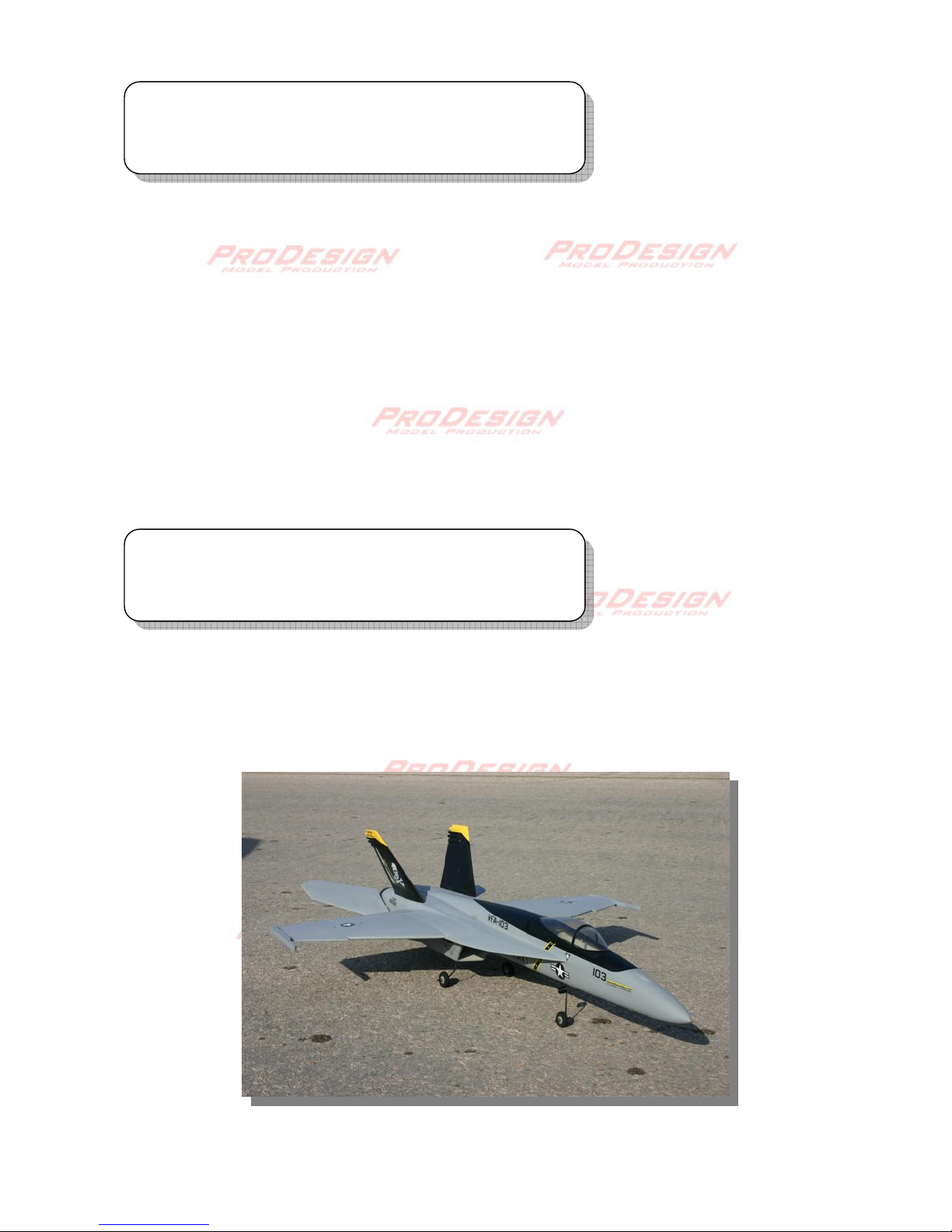

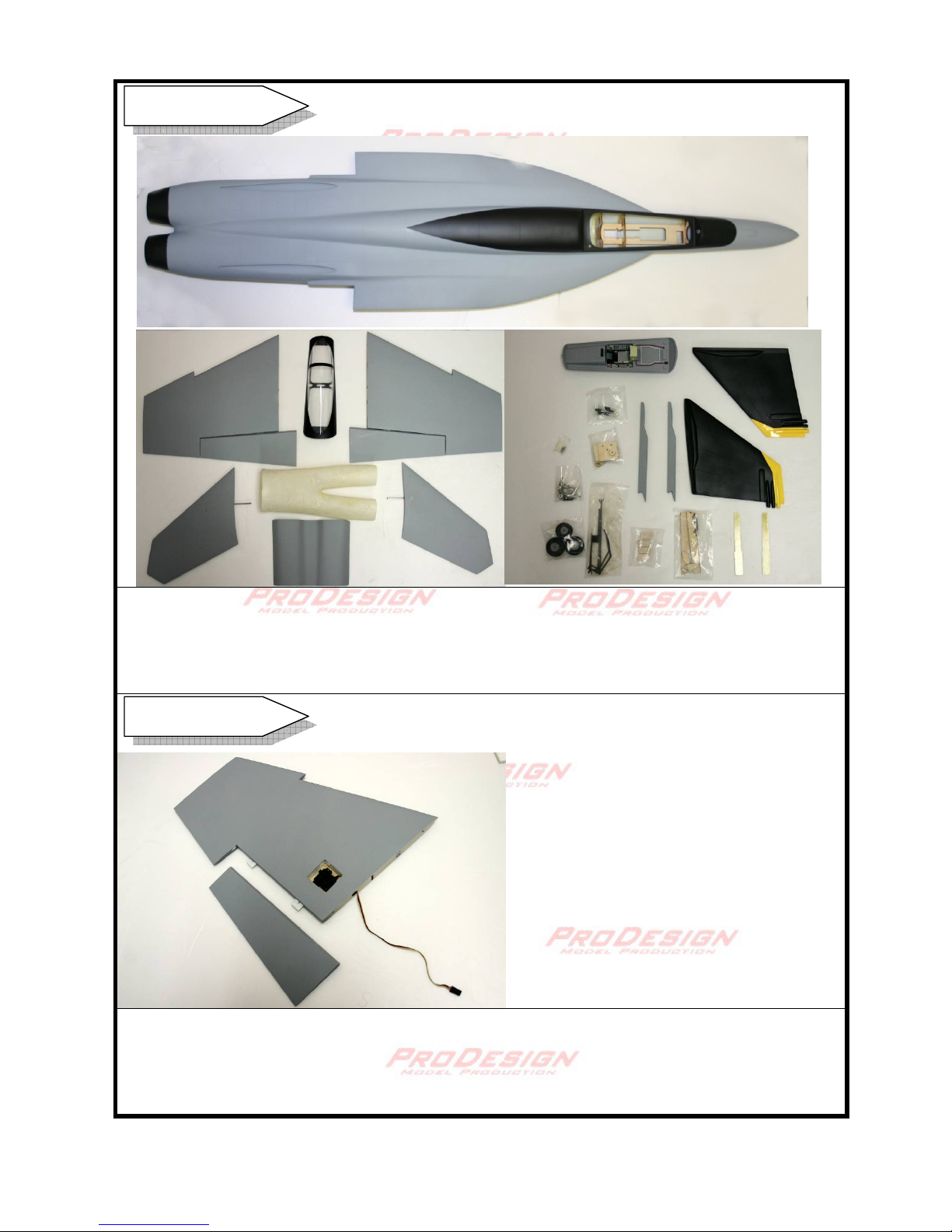

Inside the box : Fuselage, Main wing, Exit ducting, stabilizer, EDF cover, vertical fin, wing

joiner, landing gear and wheel, canopy, cockpit (optional) , hardware bags ( screw, horn,

linkage connector, M3 nut, steering arm, 3mm collar, mounting plate, magnet), Elevator

control hub kit. Waterslide décor. Sidewinder. Pre-painted canopy. Fan unit

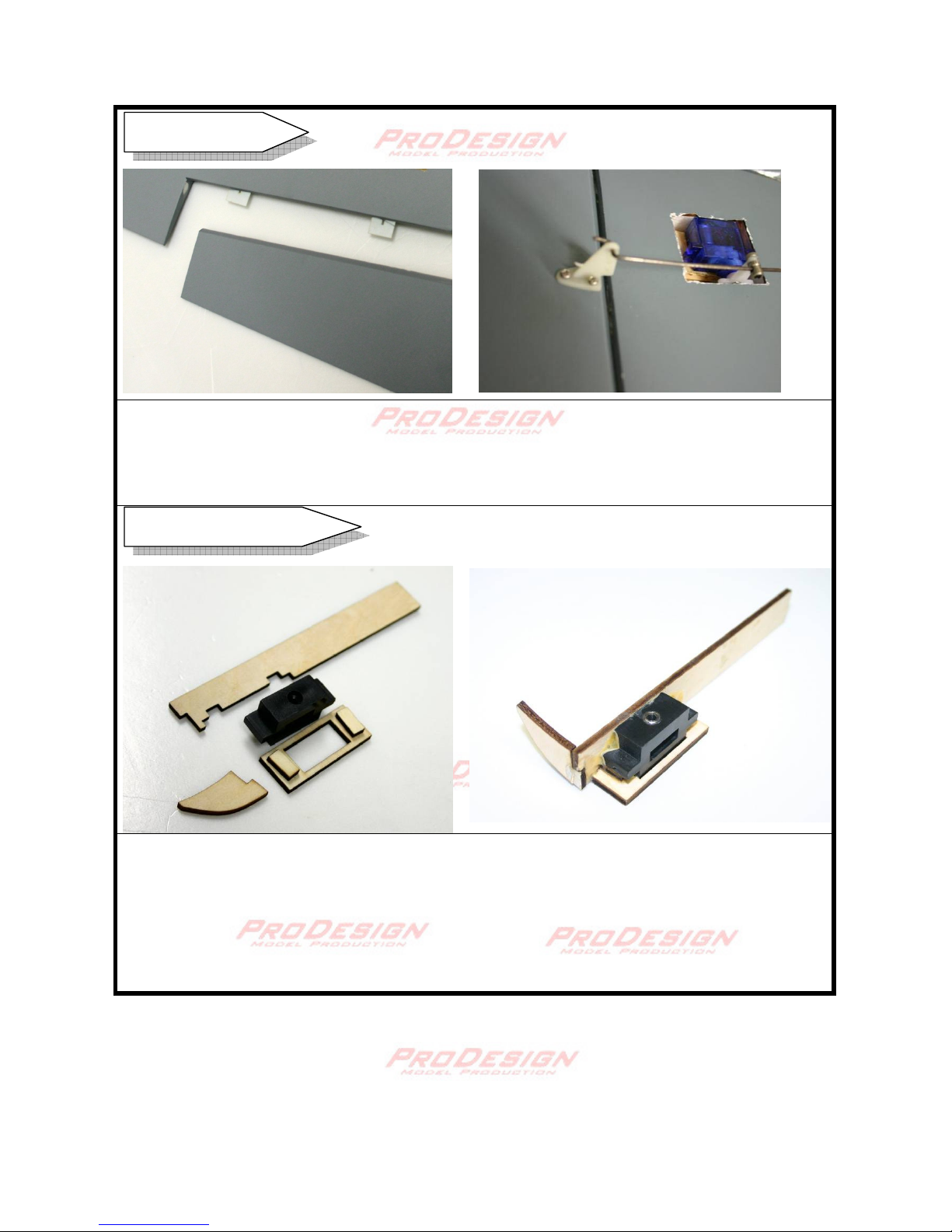

Pay attention the R/L main wings are different. The bottom of each wing is slightly flat in the

airfoil. Remove the aileron control surface. Find a pre-cut slot at the underside of the wing

and cut open the film. Insert the aileron servo and pass the wire through the hole. You may

use servo extension wire.

Inside the Box

Main Wing

4

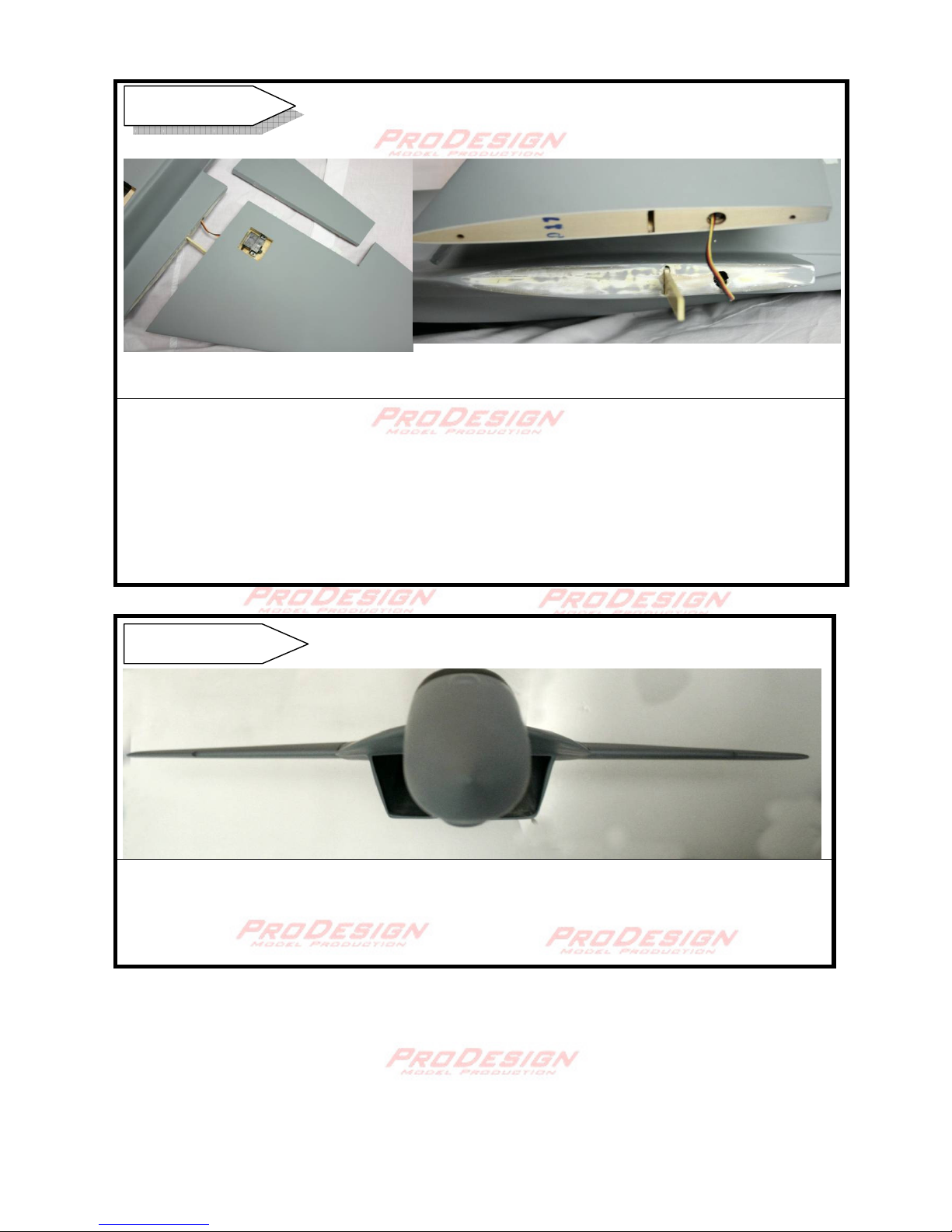

Do not glue the wing at this point. Try fitting the wings to the fuselage with the wing joiner.

The thinner part of the wing joiner goes into the wing. Adjust and orient the joiner such that

both wings are in perfect position. A 5mm hole can be drilled on the side to pass the wire of

the aileron servos.

The wing joiner is made of fiberglass and this guarantee no risk of wing breakage at high

velocity. Sand the surface of the contact area to maximize bonding strength.

Glue the main wings with epoxy, tape or clamp the wings firmly to the fuselage. Support

the wing with blocks if necessary. Check for horizontal and longitudinal symmetry.

Alignment can be confirmed by putting a pitch meter on top of the wing.

Main Wing

Main Wing

5

Before gluing the aileron servo, center the servo horn by means of a servo tester or with a

receiver/ transmitter. Install the servo with the balsa wood block provided. Mark the horn

insertion and cut a 5mm slot in the aileron and epoxy the control horn. Use CA to connect

the aileron to the wing. Connect the 9.5cm linkage wire to the servo horn.

The full motion elevator needs attention when assemble. The pro-design kit includes a

special designed bearing hub that renders the elevator movement precise and

maintenance free. Four pieces of 3x6x2.5mm ball bearing is provided. Insert each bearing

into the side of the hub. Very little amount of CA is needed to hold the bearing in place. Be

very careful to spread out a drop of CA inside the hub with a toothpick. Spilling of CA inside

the bearing must be avoided. This shows the right elevator control hub.

Elevator Control Hub

Aileron Servo

Loading...

Loading...