Installation instructions

To be read carefully and kept for future reference

OCTO / OCTO +

Installation instructions Weva Octo, Octo+ 07/2015

GB - Revision: D - Code : 97149997

PROCOPI

Les Landes d’Apigné

B.P.45328

35650 LE RHEU Cedex

FRANCE

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> RESIN BEADS

When resinous wood species

are autoclaved, the alternating

pressure and vacuum can cause

sticky resin residues to rise to the

surface. To remove them, scrape

them carefully with an appropriate

tool, being careful not to touch the

wood. Turpentine spirits could also

be effective, but could stain the

wood if too much is applied.

>> SALT STAINS

Small green stains are frequently

found on the surface of autoclaved

wood. These can be removed

with light sanding. Otherwise, this

colour will disappear over time.

>> GREYING

Wood exposed to sunlight is

susceptible to greying. Some

people like the silvery sheen of

this natural patina. If, however, you

would prefer the wood to keep its

original colour with brown tones,

apply a protective coating (lazure,

oil) when the product is assembled.

>> SPLITTING AND

CRACKING

Wood expands and contracts when

exposed to variations in humidity

and temperature. As it dries, wood

contracts unevenly resulting in

the appearance of cracks. While

these can seem to be cause for

concern, they have no impact on

the mechanical properties of the

product and therefore do not fall

within the scope of the guarantee.

>> KNOTS

Knots mark the places where

branches were attached. The

quantity and size depends on

the species of wood and the

sorting process. For outdoor

installations, small adherent knots

are acceptable. The more stringent

the sorting process to limit the

number and size of knots, the more

expensive the wood will be.

>> JOINED WOOD

To ensure the highest quality in the selection of our

wood, it is sorted meticulously before planing. Planks

that feature defects on both sides are taken out. Defects

(knots, cracks, fl ashes) are removed and the planks are

joined together (see the image above).

This is why it is not unusual to fi nd joined elements in

a wooden pool, it in no way penalises the mechanical

properties of the wood. For the same reason, imperfections

on the interior surface of the pool (knots, cracks, fl ashes)

are entirely acceptable.

>> SURFACE MOULD

Mould, caused by microscopic fungi, can grow on wood,

particularly on resinous species, on which the growth

can appear as «blueing». It is a surface phenomenon,

exacerbated by heat, humidity and inadequate aeration

and is characterised by stains raging from light to dark blue.

They can be removed by wiping the surface. Remember

that class IV treated wood is protected against attack

by fungi that could destroy the physical and mechanical

properties of the wood. For further information, please

refer to Procopi’s guarantees concerning the types of

wood and their treatment.

>> COLOUR

VARIATIONS

Colour variations are common to

every species of wood. Treatment

brings them our because the depth

of penetration of the product will

depend on the wood density

and grain. Weathering of wood

outdoors will signifi cantly attenuate

these colour variations.

WOOD, A NATURAL

MATERIAL.

Being a natural material, wood will have some imperfections. These are normal

and have no impact on the service life of the product.

A certain number are superfi cial and are not covered within the scope of the

guarantee.

CAUTION

storage. If you do not intend to assemble your pool immediately, you should store it without opening it in a well-

ventilated room, or failing this, in an area protected from humidity and sunlight. If, however, you were obliged to

unpack your pool, redo and restrap the pallet. Once the pallets are undone, the kit must be assembled within 24 to

48 hours.

2

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> CONTENTS

Foreword ...............................................................................p-4

Storage & time required for assembly ................................. p-4

Siting and preparation of the ground

for Octo & Octo + pools ..................................................... p.5-6

Assembly of the Octo pool structure ................................p.7-9

Assembly of the Octo+ pool structure .......................... p.10-14

Gaskets, laying and cutting out the liner ....................p.15-17

Assembling coping on Octo pools ...................................... p.18

Assembling coping on Octo+ pools ................................... p.19

Assembling and installing ladders ................................p.20-21

Installation of in-ground and partially in-ground pools ... p.22-24

Maintenance and use .....................................................p.25-26

Safety ................................................................................... p.27

Guarantee ....................................................................... p.28-29

Exploded view of the wooden structure ......................p.30-31

3

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

We shall now explain how to assemble your pool, but first some instructions before you begin.

Please read these instructions carefully, this will allow you to prepare each stage to achieve optimum efficiency.

Please keep these instructions for future reference.

You should take the time to go through the components using the nomenclature page enclosed with the

accessories kit and make sure that no items are missing.

Keep the following documents;

- the productions sheets for the various kits

- proofs of purchase

STORAGE

If you do not intend to assemble your pool immediately, you should store it without opening it, in a well ventilated

room, or failing this, in an area protected from humidity and sunlight. Once the pallets are undone, the kit must be

assembled within 24 hours. Once work has begun, try to avoid leaving the structure exposed to significant climatic

variations that could cause the wood to “work” too quickly. This could lead to deformations that could render the item

unusable. By preference, the wooden structure should be assembled in one go on a day that is not too hot. The liner

should be stored at a minimum of 20°C for at least 24 hours before it is fitted. This is to render the liner more supple

and thus facilitate fitting. The liner should only be fitted if the ambient temperature is higher than 20 °C.

TOOLS AND TIME REQUIRED TO MOUNT AN OCTO POOL

- To prepare the ground (does not include pouring a concrete slab): shovel, rake, pick axe, cord, aluminium ruler

and a spirit level.

- To assemble the structure: spirit level, screw gun, mallet, measuring tape, stanley knife, metal saw, flat head and

cross head screw drivers, sanding paper and a fine grain file.

- The time taken for assembly is 2 days for 2 people (does not include excavation, pouring the slab or filling of the

pool).

keep on hand: sand and cement for tamping the soil

TOOLS AND TIME REQUIRED TO MOUNT AN OCTO+ POOL

- To prepare the ground (does not include pouring a concrete slab):

shovel, rake, pick axe, cord, aluminium ruler and a spirit level.

- To assemble the structure: spirit level, screw gun, mallet, measuring tape, stanley knife, metal saw, flat and

socket wrenches, flat head and cross head screw drivers, sand paper and a fine grain file.

- The time taken for assembly is 3 days for 2 people (does not include excavation, pouring the slab or filling of the

pool).

keep on hand: sand and cement to support the cradles and tamp the soil

>> STORAGE & TIME REQUIRED FOR ASSEMBLY

Congratulations on acquiring your pool. We have taken great care with the design and manufacture of your pool to

provide you with a top quality product.

The wood used to make the various elements (interlocking walls, coping, ladder, etc.) was carefully selected. Outdoors,

these wooden elements are subject to constant weathering: contact with the ground, temperature variations, exposure

to sunlight, rain and frost, insect attack, etc. The wood’s ability to withstand this aggression depends on the origin of the

wood and the method used to treat it.

For this reason, we choose pine from extensive, sustainably managed forests in northern Europe. Why do we insist

on this? Because the more rigorous climates above the 57th parallel favour very slow tree growth, making the wood

stronger and more resilient.

The wood is autoclaved, this involves subjecting the wood alternately to pressure and vacuum in order to drive

the treatment chemicals into the heart of the wood as opposed to other more superficial treatment techniques such as

soaking.

Class IV treated wood in contact with the ground is immune to insect attack and rotting caused by humidity.

Autoclave treatment is guaranteed 10 years, in accordance with standards currently in effect.

The pool coping is made of treated PINE.

Wood is a living material, variations in temperature and humidity can cause it to expand or contract so take care to

follow the storage and assembly instructions concerning the wooden structure. Similarly, prolonged exposure to UV light

can cause wood to grey. These are natural phenomena that in no way effect the service life of the products.

To preserve the original colour, use a colourless wood finish. You could alternatively opt for a coloured finish or treat

the wood with a colourless oil to slow the decoloration process. Before applying the finish, check that it is microporous

and will allow the wood to breathe. Make sure that the product will not migrate (wet wood) over time to the interior of

the structure and damage the liner. Ideally, the finish should be applied before assembling the pool structure.

>> FOREWORD

4

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

This is the most important step in the procedure as the pool site will determine the service life of your pool. There are

some rules that must be respected.

Given the vast number of possible variations (slope, type and homogeneity of the ground, possible issues with drainage,

etc) we cannot provide recommendations for every possible permutation here. Some optional steps, such as pouring a

concrete slab, laying foundations, footing, laying drains, etc will require assistance from professionals who will be able to

advise you on solutions best suited to your configuration.

We will explain how to prepare the ground without any concrete, the objective being to achieve a flat, level bearing

surface. In as far as possible, avoid siting your pool under trees (to stop you pool from being filled with leaves) or near rises

or dips in the ground that could expose children to danger. Do not assemble your pool under electrical cables. The pool

should be at least 3.50 m from any electrical source (French safety standard C15-100). On a slope, never back fill under

your pool to bring the bearing surface level, always cut into the upward slope.

Lastly, avoid preparing the ground and assembling the pool while a strong wind is blowing.

How should the pool be oriented? Ideally, the pool should be oriented so that the skimmers are facing into the prevailing

wind. This will determine the final orientation of your pool and the manner in which it will lie in your garden, notably in the

case of elongated pools.

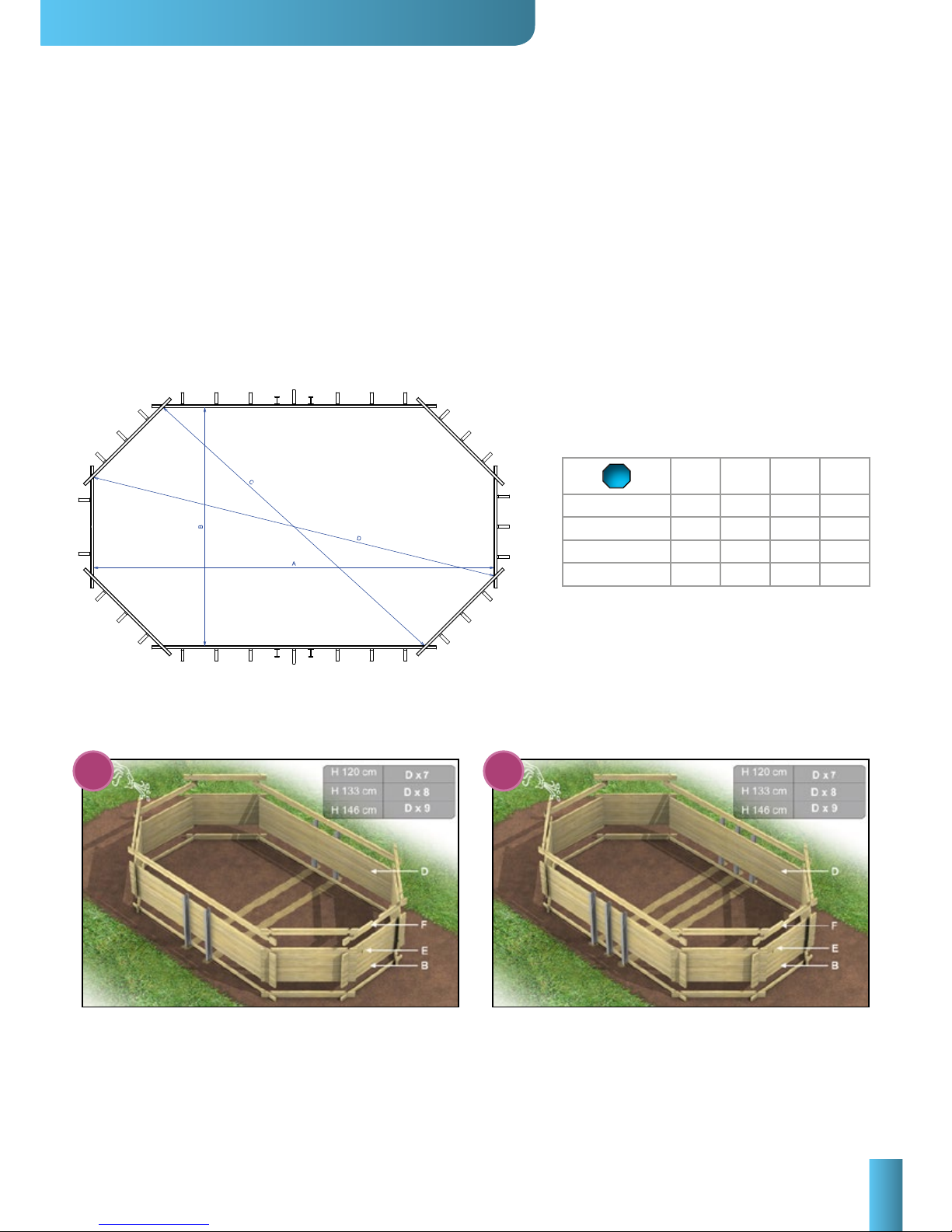

>> OCTO POOLS

(ABOVE GROUND CONFIGURATION ONLY. ADVISE AND INSTRUCTIONS FOR IN-GROUND OR PARTIALLY

SUNKEN CONFIGURATIONS ARE ILLUSTRATED AT THE END OF THIS DOCUMENT).

Soil with a good constitution:

That is properly consolidated soil that has

not been subject to recent backfill. Even after

15 years, the backfill may not be completely

stabilised.

To begin, clear the ground of plants and other

miscellaneous objects. Next, level and smooth

the surface using a spade, rake and a pickaxe (if

necessary). Make sure that you smooth out any

bumps or rough areas that could damage the

underlay, or more seriously, the liner.

After a rough preparation of the surface, plant

a stake in the centre of the circle and mark

the point where it comes into contact with the

ground.

Next, using a flat, straight piece of wood longer

than the radius of your pool, go around the circle

checking that the ground is level. This operation

requires two people (one to make sure that the

bottom of the wood corresponds to the mark on

the stake, and the other to check the level and

move the wood around the entire circumference

to ensure that the surface is perfectly level).

1

>> SITING AND PREPARATION OF THE GROUND FOR

OCTO & OCTO+ POOLS

5

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

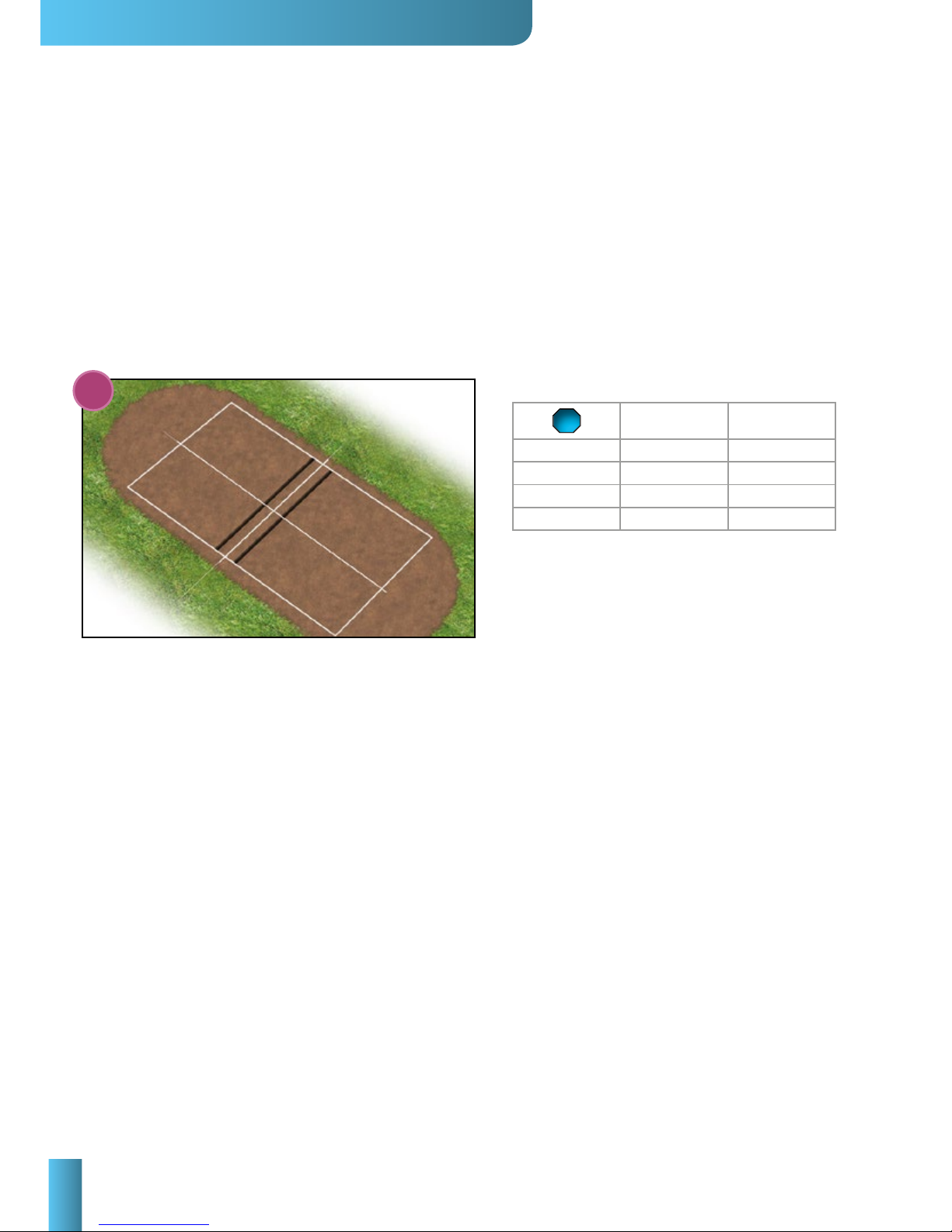

Trace out site of the pool and clear the ground of plants, grass and other miscellaneous objects.

Next, level and smooth the surface using a spade, rake and a pickaxe (if necessary). Make sure that you smooth

out any bumps or rough areas that could damage the underlay, or more seriously, the liner.

Make sure that the bearing surface is completely fl at and perfectly level.

Once the ground has been prepared, use string to mark out the longitudinal axis (A1) of your pool and then

the transversal axis (A2) perpendicular to the axis A1.

OCTO+ footprint

Length

Width

2

>> OCTO+ POOLS

(ABOVE GROUND CONFIGURATION ONLY. ADVISE AND INSTRUCTIONS FOR IN-GROUND OR PARTIALLY

SUNKEN CONFIGURATIONS ARE ILLUSTRATED AT THE END OF THIS DOCUMENT).

The dimensions shown in this table do not take

the footprint of the access steps or plant housing

into consideration.

length width

+460 460 330

+540 540 330

+640 640 400

+840 840 490

Pool sizes

6

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> ASSEMBLY OF THE OCTO POOL STRUCTURE

Fit the 4 half slats (type A - smooth side facing down) together with 4 male/ female slats (type B), grooves facing down,

double tongues facing up (see the detail above).

- Before you begin, familiarise yourself with the

nomenclature enclosed in the “Accessories” kit and the

exploded view (at the end of this notice) that corresponds

to your pool.

- Determine the final orientation of your pool, by preference,

the skimmers should be oriented so that they are facing

into the prevailing winds. Skimmers must be mounted on a

side that starts with a type A slat.

- While assembling the walls, make sure that each slat is fully

engaged before starting on the next.

- You may need to use a hammer and a clamp to remedy any

slight warping of the slats. Do not strike the wood directly,

use the protective brace (provided).

- During assembly, check regularly that the walls are level

and the 4 diagonals are equal in length.

- To avoid the risk of injury or damage to the liner, take care

to eliminate any splinters during and after assembly.

- If you intend to fit your pool with a counter swim unit, you

will need to incorporate the 2 slats specially prepared to

mount this option. .

At this point, fit the skimmer or filtration unit into the

bottom machined slat (type D).

In the case of a filtration unit, fit the 2 slats on either side

of the filtration unit, otherwise, fit the top skimmer slat

(type E) over the bottom skimmer slat (type D). Continue

around the pool with 3 type F slats and 4 type G half-slats

as illustrated.

Attach the finishing profiles (type H) to the exposed edge

of each wall using 4 equally spaced SS rivets (3.1x75 mm)

inserted into holes pre-drilled in the axis.

4

5

6

7

3

Fit together the remaining slats (type B) taking care to

position the slat that will hold the return fitting (type C)

and the machined slat (type D) correctly. The slat that will

hold the return fitting (type C) should be positioned over

4 type B slats + 1 type A slat in the case of a skimmer

and in the case of an autonomous filtration unit. The slat

that will hold the return fitting slat (type C) should be

positioned just underneath the machined slats. The type

D slat is positioned on the same side in the last row of

this step.

7

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> ASSEMBLY OF THE OCTO POOL STRUCTURE (contd.)

The wooden brackets will support the coping that will be

mounted after the pool is filled. Pre-drill the wall from

inside the pool then attach each wooden bracket (type l)

using 2 screws (5x100 mm sachet l) taking care to position

them 3 mm below the top of the structure. Remove any

splinters that may have been raised during this process.

The are 3 wooden brackets per side (except the side

holding the skimmer). Position 1 wooden bracket in the

centre of the slat, the other 2 equidistant on either side of

it (distance D2 in the table).

Mount 2 wooden brackets on the wall holding the skimmer or filtration unit. In the case of a skimmer they should

be positioned 75.5 cm apart and equidistant from the

skimmer axis. In the case of a filtration unit, they should

be 50 cm apart.

Screw a mounting plate to the top of each wooden

bracket (wooden bracket kit) . Make sure that each plate

is flush with the top of the walls.

IMPORTANT !

Check that the structure is correctly assembled

before mounting the liner locking track.

To do this:

- use a spirit level to check that the structure is horizontal

around the entire periphery.

- check that the 4 diagonals are equal in length.

Fix any imperfections before continuing.

The liner locking track should be flush with the top of the

wooden structure.

Before mounting the liner locking track, pre-drill using a

Ø 3 mm drill bit.

Avoid over tightening, this could cause the screws to

break through the track.

8 9

10 11

12

8

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> ASSEMBLY OF THE OCTO POOL STRUCTURE (contd.)

Mount a corner junction piece (junction+corner blister pack) in each corner using 2 SS screws (bag E) inserted through

the notches intended for this purpose. Make sure that these parts are flush with the top of the pool wall. Each wall will

take a 1.18 m length of track and an additional length that will need to be trimmed to size.

Prepare the 8 additional pieces of track according to the table below. Before making the cuts, check that the total length

of the track is equal to the distance between two corner pieces less 2 mm to allow for the corner pieces. Make sure that

the cuts are straight and clean. Deburr the cuts using the fine grain file.

Fit the long section into the corner piece. Bend the track to facilitate fitting onto the junction piece. Hold the track

in position using a screw 2 cm from each end. Then complete attachment of the track by inserting screws at 20 cm

intervals.

FITTING THE UNDERLAY:

Important!

The ground underneath the underlay should be absolutely flat and free of any bumps or rough areas.

Because of the pressure exerted by the water, even the smallest bump will be visible underneath the liner. After clearing the ground, spread a layer of sand mixed with cement (1 part cement to 7 parts sand) over the floor of the pool and

compact it. This layer should be no more than 1 cm deep. (The sand and cement are not supplied). Unfold the underlay

in the pool taking care to line it up correctly with the corners. Smooth out any wrinkles. The underlay will be slightly

smaller than the pool structure.

13 14

15

16

17 18

9

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

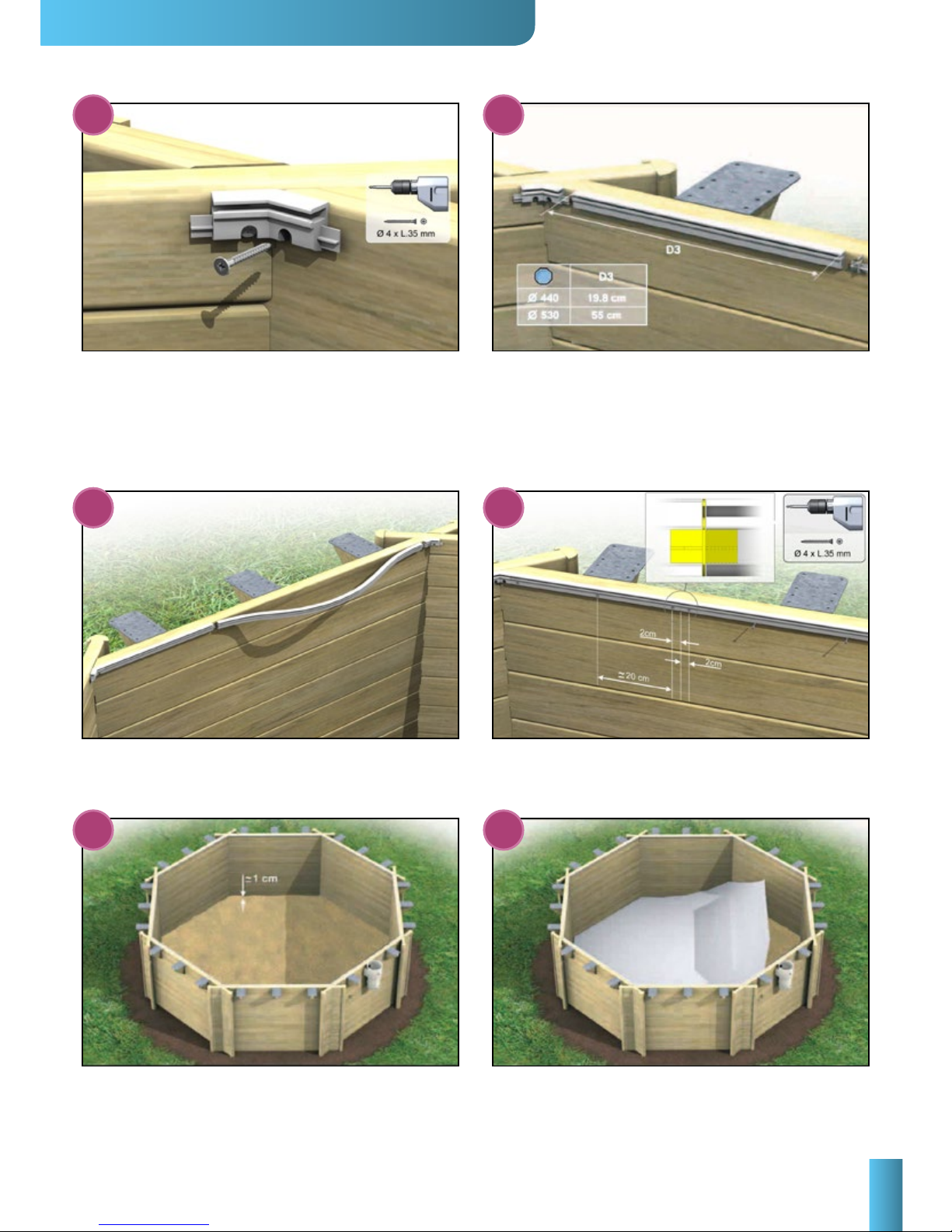

>> ASSEMBLY OF THE OCTO+ POOL STRUCTURE

The pool structure is mounted in two stages:

- Stage 1, excavation of the site and installation of the cradles designed to

reinforce the lateral walls. A cradle comprises a cross beam, vertical posts and

metallic plates to be bolted together.

- Stage 2, assembly of the wooden structure and fi tting of the additional items

(liner, coping, etc.).

We recommend that the pool structure be

assembled by two people.

Before you begin, familiarise yourself with

the nomenclature page (enclosed with the

Accessories kit) and the main exploded

view (at the end of this document) that

corresponds to your pool.

You will need to dig shallow trenches to hold the cradles. Make sure that these are parallel to each other and to the A2 axle. The

number of trenches required will depend on the pool model, refer to the illustrations corresponding to your pool. Trenches should be

regular and sized to hold the cradles in the right position. Only one trench is requried for the Octo 460.

Lay the cradle components out beside the trench and fi t them together (using the cradle kit).

Once the cradles have been assembled, place them in the trenches and block them in position using wet compacted sand

if necessary. During this operation, check that the cradles are level, straight, aligned and parallel. Fill the trenches with wet,

compacted sand. Important ! Make sure that the cradles are buried to the correct depth.

19

20

21 22

23 24

L

P L

540 & 640 cm x 120 cm 34 cm 62 cm

540 & 640 cm x 133 cm 20 cm 62 cm

640 cm x 146 cm 20 cm 62 cm

460 cm x 120 cm 34 cm

Cr

oss section of the cement slab

In the case of a cement slab, it is

better to seal the cradles into the

slab and create a peripheral drain.

10

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> ASSEMBLY OF THE OCTO+ POOL STRUCTURE (CONTD.)

Recommendations and advice:

- Before beginning assembly, identify the various slat types with reference to the exploded view at the end of this

document.

- Establish the fi nal orientation of your pool, the skimmer should be oriented facing into prevailing winds. The skimmer

should be mounted on a side that starts with a type A slat.

- While assembling the walls, make sure that each slat is fully engaged before starting on the next.

- You may need to use a hammer and a clamp to remedy any slight warping of the slats. Do not strike the wood directly,

use the protective brace (provided).

- During assembly, check regularly that the walls are level and the 4 diagonals are equal in length.

- To avoid the risk or injury or damage to the liner, take care to eliminate any splinters during and after assembly.

- Please refer to the various illustrations provided in this document.

- If you intend to fi t your pool with a counter swim treadmill, you will need to incorporate the 2 slats specially prepared

to mount this option.

Fit 2 type A half-slats and 2 type C half slats together with 4 type B wall slats according to the illustration above. The male side

(double tongue) should face upwards (see the detail below).

Fit the remaining slats together using type B slats on the short sides and type D slats on the long walls. Take care to correctly

position the pierced slats (type E) that will hold the return and vacuum fi ttings, the bottom skimmer slat (type F) and, if

necessary, the 2 optional slats from the counter swim unit kit. (Refer to the exploded view at the end of this document for the

position of these slats). In the case of a skimmer, the slat that will hold the return fi tting (E) should be positioned above 4 type

B slats + 1 type A slat. The type F slat should be located on the same side in the last row of this step. Note the position of the

type E slat.

25 26

A B C D

+460 4.28 2.78 3.84 4.43

+540 4.88 2.78 4.28 5.01

+640 5.89 3.50 5.20 6.07

+840 7.89 4.35 6.89 8.09

Pool measurements

Layout

11

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> ASSEMBLY OF THE OCTO+ POOL STRUCTURE (contd.)

At this point, fit the filtration system into the machined slat (F). Slot the top skimmer slat (G) over slat F and continue

around the pool, fitting 2 type H slats, 1 type l slat and 4 type J half-slats into position as shown.

Attach a decorative trim (type K) to the end of each wall

using 4 3.1x75 mm screws (bag L) inserted through holes

pre-drilled at regular intervals along the axis.

Working from the outside, screw the metallic posts

(pre-drilled) onto the wooden walls using 6x40 mm

screws from bag C. Check their verticality. Position two

decorative profiles (Q) on either side of each post and

fasten them together using 3 5x70 screws (bag C) as

shown.

The wooden brackets are designed to support the coping

after the pool is filled. Pre-drill the wall, then, working

from inside the pool, fasten each coping support bracket

(L) in position using 2 5x100 mm screws (bag l), taking

care to ensure that each bracket is 3 mm beneath the

top of the pool structure. Check the verticality of each

support bracket.

The short sides of the 460 and 540 pools should be fitted

with 2 coping support brackets

The short sides of the 640 and 840 pools should be fitted

with 3 coping support brackets, except for the side holding the filtration system which should be fitted with

2 coping support brackets. (illustration 38).

27 28

29 30

31 32

33

540 & 460

640

840

12

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> ASSEMBLY OF THE OCTO+ POOL STRUCTURE (contd.)

On the wall holding the skimmer, position 1 coping

support bracket on either side of the skimmer equidistant

from the skimmer axis as shown.

Mount an anchoring plate (coping support bracket kit) on

each support bracket. Make sure that each plate is fl ush

with the top of the pool structure. Bevel the holes in the

plate before fi xing the plates in position.

Attach the wooden brackets along the lengths as shown.

34

36

37

38

39

35

L 460

Skimmer Filtration

unit

+460

60 cm

50 cm

+540

+640

75 cm

+840

13

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> ASSEMBLY OF THE OCTO+ POOL STRUCTURE (contd.)

IMPORTANT !

Before you begin to install the liner locking track, check that the structure was correctly assembled.

- Using a spirit level, go around the entire structure checking that it is horizontal.

- Check that the four diagonals are equal in length.

- Correct any defects.

Recommendations:

- The liner locking track should be fitted such that it is flush with the top of the wooden structure.

- Use junction pieces between each liner locking track section.

- Check the length of liner locking track required before trimming it.

- Pre-drill the walls using a Ø 3 mm drill bit and fix the liner locking track in position.

- Avoid over tightening, this could cause the screws to break through the track.

Refer to the illustrations on page 9.

IMPORTANT! The ground underneath the underlay should be absolutely smooth flat and free of any foreign bodies.

Because of the pressure exerted by the water, even the smallest bump will be visible underneath the liner. After clearing

the ground, spread a layer of sand mixed with cement (1 part cement to 7 parts sand) over the floor of the pool and

tamp it down. Unfold the underlay in the pool taking care to line it up correctly with the corners. Smooth out any

wrinkles.

44

45

Octo +460 pools - fitting the liner locking rails (with junction strips)

Octo +640 pools - fitting the liner locking rails (with junction strips)

Octo +540 pools - fitting the liner locking rails (with junction strips)

Octo +840 pools - fitting the liner locking rails (with junction strips)

(to be trimmed)

(to be trimmed)

(to be trimmed)

(to be trimmed)

40

43

41

42

14

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> GASKETS FOR POOL FITTINGS

Before fitting the liner, glue one of the 2 rectangular

self-adhesive gaskets (pool fitting skin pack) around the

mouth of the skimmer or filtration unit.

Make sure that the holes in the gasket are correctly

aligned with the holes in the skimmer.

From the pool side, insert return fitting throughwall flange

(pool fitting pack) into the opening in the pierced slats. Fix

it in position using countersunk self-tapping 3x25 screws.

Fit a self-adhesive gasket to each throughwall flange. Screw

carefully by hand to avoid damaging the wood.

IMPORTANT ! The ideal temperature for laying liner is between 18° and 25°C. Outside this range, the liner will be either

two rigid or too pliant and will be difficult to fit. On very hot days, lay the liner early in the morning. During cold weather

(less than 18°C), store the liner somewhere warm for as long as possible to increase it’s suppleness and do not take it out

until the last minute.

Place the liner in the centre of the pool and unfold it. When it is unfolded, the liner will form either an octagon or an

elongated octagon on the ground, depending on the pool model. Line the corners up with the corners of the pool

structure. Working in bare feet from inside the pool, fit the liner lip into the liner locking track, continue around the pool.

CAUTION: The vertical seam than joins the band that covers the walls should not be on the wall that holds the skimmer.

If this is the case, turn the liner.

While fitting the liner, insert wooden half pegs (provided) in the liner locking track to hold it in position in the corners and

at regular intervals around the periphery. This will help position the liner and stop it from slipping in the track. Keep the

pegs in position until the pool has been filled with water.

Make sure that the bottom corners of the liner correspond to the corners of the pool structure. You will note that the

liner is slightly smaller than the structure, this is normal and necessary to ensure correct tension on the liner after the

pool has been filled with water. Make sure that the liner is spread out over the entire surface of the pool.

Leave the liner as is until the warmth of the sun eases out the creases caused by folding (this will take a few hours).

CAUTION:

In the event that you need to move the liner, do not slide it in the track. Take it out of the track by pulling upwards on

the lip and reposition it. Sliding the liner in the track can cause it to tear just below the lip (this type of damage will not

be covered by any guarantee).

46 47 48

49

50

>> FITTING & CUTTING OUT THE LINER

15

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

55

>> FITTING & CUTTING OUT THE LINER (contd.)

Once the liner has been hung and is correctly positioned,

fill the pool with 2 cm of water. Push any creases towards

the walls smoothing out the liner as much as possible.

This operation will not be possible if the pool is empty

or overfilled (contains more than 2 cm of water).

Stick the self-adhesive gaskets to the return fitting and

vacuum fitting flanges.

Locate the holes in the throughwall flange and mark

them.

Screw the flange (fitted with its gasket) into place using

the countersunk SS screws M5x16 from the pool fitting

skin pack. Tighten the screws alternately to ensure a

leaktight fit. Hand tighten, over tightening could damage

the flange.

51

52 53

54

Once the liner is correctly hung and positioned and

creases have been eliminated, continue filling the pool

until the water level is 10 cm below the first pool fitting

(underwater light or return fitting depending on their

position).

Cut out the liner inside the vacuum fitting and return

fitting flanges.

16

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

Screw the multi- directional eyeball assembly into the return fitting

body. The eyeball should be pointed left to facilitate the flow of

water necessary for efficient filtration.

(Prior to assembly, apply a layer of silicon grease to the eyeball and

its housing to facilitate its movement and subsequent removal).

56

Glue the second skimmer gasket to the interior surface of the skimmer or filtration unit flange.

Locate the 4 corner holes of the mouth and mark them with a pen.

Position the flange such that its corner holes are aligned with the points marked in pen.

Use a small screw driver or punch to pierce the liner at the 4 points marked and fix the flange in position with the gasket

against the liner. Once the 4 corner screws are in place, continue, inserting a screw through each hole. Avoid over

tightening, this could deform the flange. Tighten the screws alternately to ensure an even and leaktight fit.

Cut away the liner inside the flange. Keep the offcuts for future repairs.

In the case of skimmers, clip the weir into place,

smooth surface facing the pool. The weir should be

able to swing freely.

Mount the skimmer face plate.

The skimmer basket is passed through the skimmer

mouth, swing the weir towards the pool to make

space.

Place the lid on the skimmer.

(these parts can be found in the Pool Fitting skin

pack)

In the case of a filtration unit, refer to the installation

instructions enclosed with the unit.

57

58

59

17

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

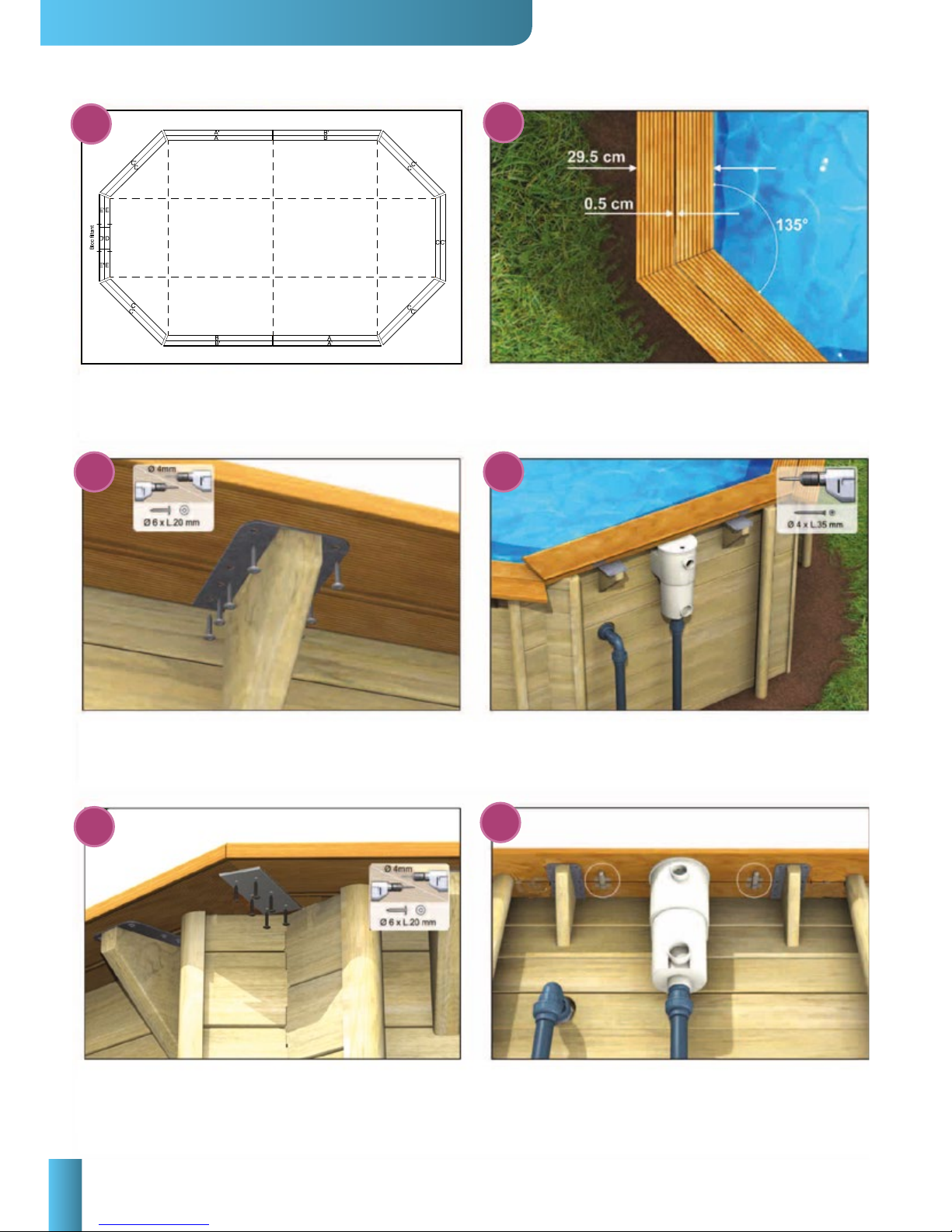

>> FITTING THE COPING ON OCTO POOLS

The coping comprises 8 interior planks and 8 exterior planks. Arrange the planks on the the support brackets as shown.

The interior planks overlap the pool by approximately 25 mm from the edge of the wall. Make sure that the elements are

correctly positionned around the periphery of the pool.

The coping is approximately 295 mm wide with a gap of around 5 mm between the interior and exterior planks

Attach the coping elements to the mounting plates on

the support brackets using roofing screws (bag G and H)

as shown. Pre-drill lightly to ease driving of the screws.

Check continuously that the coping elements are correctly

aligned.

In the case of a skimmer, the outer coping plank anove the

skimmer is attached to the inner plank by means of 2 hinges

(bag A). It is not screwed to the support brackets. The hinge

allows access to the skimmer basket. After use, secure the

latches. (See below).

All that remains is to attach the 8 coping corner connecting

brackets (mounting kit in the coping pack) as shown above,

taking care to position the brackets correctly .

In the case of a skimmer, mount the latches (bag N) as

shown.

61

62 63

64

65

60

18

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

Filtration unit

A or B A’ or B’

between

A & B

C C’ E E’

440 1550 1677 573 637

530 1905 2029 750 812

+460 1377 1429 1254 1378 425 487

+540 1677 1739 1254 1378 425 487

+640 1971 2033 1550 1677 573 637

+840 1971 2033 1500 1905 2029 750 812

>> FITTING THE COPING ON OCTO+ POOLS

66

For instructions on mounting the coping, please refer to pages 18. On the 460+, 540+ & 640+ models it may be necessary

to add additional coping support plates.

Skimmer version

67

68 69

70 71

Skimmer version

19

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> ASSEMBLING AND INSTALLING THE STAINLESS STEEL LADDER

Assemble the various parts of the ladder referring to the

installation instructions provided.

When mounting the hand rails, do not forget the two

rubber seals that will be used to hold the decorative

escutcheon plates in position.

If the pool is fitted with in-pool corner steps, refer to the

installation instructions enclosed with this item.

Position the ladder in the pool on the coping module of

your choice (except the wall holding the filtration system

and counter swim module), remember that it should be

opposite the wooden ladder.

Adjust the position of the ladder paying particular

attention to ensure that it is vertical and that the bumpers

are pressed firmly against the inside wall.

Mark the positions for drilling. Remove the ladder and drill.

Fix the ladder in place according to the instructions

provided, the counter plate should be positioned under

the coping. Tighten moderately. Slide the 2 rubber seals

along the tubes so that they hold the escutcheon plates in

position.

>> ASSEMBLING AND POSITIONING THE WOODEN LADDER

72 73

74

The stringers and the treads for the

wooden steps are in the Wood kit.

Assemble the wooden steps using the SS

screws (bag K). For cleaner, more efficient

assembly, we recommend that you predrill the various elements (4 mm drill bit)

and mill the holes to avoid splitting the

wood and raising splinters.

seal

escutcheon

plate

screwed

flange

20

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> ASSEMBLING AND POSITIONING THE WOODEN LADDER (contd.)

For your children’s safety !

Don’t forget to stick the safety label

to the pool wall stating that the ladder

must be removed while the pool is not

in use.

The wooden ladder is fitted with two lever latches that lock it into position. The lever sections are fitted to the ladder

supports and the hooks are mounted under the coping (these parts are enclosed in bag K). Observe how these 2 parts

interact together to understand how the mechanism works and establish the travel necessary for the ladder to be locked

correctly into position.

Position the assembled ladder under the coping. Insert the blocking parts between the wooden supports and the

coping. These should be positioned in line with the lever latches. Trace the position of the various elements. Remove

the ladder, screw the blocking parts into position and attach the lever elements to the ladder supports. Put the ladder in

place and lock it in position.

The locking mechanism might differ from that illustrated here, but will function according to the same principal.

75 76

77

21

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

CAUTION: This type of configuration must be protected by one of the four safety systems that comply with French

safety standards concerning safety of in-ground pools; safety barrier, alarm, safety cover or a shelter.

The decree no. 2003-1389 dated 31/12/2003 renders it mandatory for clients of pools installed after the 1st of January

to have the pool fitted with a system to prevent drowning before it is filled with water. Said system must comply with

either the French safety standards, or with those standards, technical specifications or manufacturing procedures set

out in the regulations of a member state of the European Community or another state party to the Agreement on the

European Economic Area, providing for an equivalent level of safety.

These provisions apply to open air pools that are partially or fully in-ground.

Below, we suggest implementation configurations that show basic recommendations for non-humid ground. You should

adapt these to your installation, notably, in humid areas (stagnant water, water source, zone subject to flooding, etc.) a

sump drain pump may be required for efficient drainage.

In any case, the drainage system must be adequate to prevent the stagnation of water that could cause the wood to rot.

We recommend that you follow the installation instructions to the letter; failure to abide by these instructions will render

the usual guarantees null and void.

Should you have any questions, and to ensure a quality installation, do not hesitate to contact a specialist.te.

>> INSTALLATION OF PARTIALLY IN-GROUND OR IN-GROUND

POOLS

>> EXCAVATION >> RELIEF WELL

The Delta MS membrane allows ventilation of the wooden

pool structure. This is necessary to prevent rotting of the

wood.

Anti-root or

felt

Undisturbed

ground

Peripheral

drain

Drainage

gravel

Stabilised, levelling course

Waterproofing

membrane

Concrete slab, min.

depth : 150 mn

Wooden structure

Geotextile felt

Ground

Relief well

Crushed

gravel

Peripheral drain

Concrete slab

Delta MS

22

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

For selection of the site, refer to the instructions at the

beginning of this document.

Once the excavation is at the required depth, make sure that

the surface is perfectly flat and level. Next, dig a trench to allow

drainage under the walls of the pool. Trace the shape of the

trench, to assist this process you may temporarily assemble the

first row of slats (illustration 5). It should be wide enough to

extend beyond each side of the wall once it is built.

If you intend to install the filtration system in a box adjoined

to the pool, remember to dig a trench to run the power cable.

Similarly, if the filtration system is to be installed at a distance

from the pool, dig a trench to accommodate passage of the

suction and return lines.

Max. depth of the excavation:

pool height 120 cm = 116 cm

pool height 133 cm = 129 cm

Illustrations shown in this document are valid for a filtration system housed in a box buried at the same level as the pool.

Should you choose another configuration, abide by the instructions above.

After the trench under the pool wall is dug, fill it to a depth

of approximately 10cm using small sized gravel. Make sure

that the gravel is well compacted to avoid future subsidence

that will impact the pool structure. Finish filling the trench

with compacted sand, the filled trench should be level with

the ground.

CAUTION! We strongly recommend that you install the filter

below the water line. If the filter is installed above the water

line, there is a risk of deformation due to depressurisation.

At most, the filter should be installed level with the coping.

In the event that the filter is installed above the water

line, mount a check vent on the return line and an easily

accessible check valve on the suction line.

A

B

>> OCTO POOLS

Assemble you pool as described in the installation

instructions.

Cover the portion of the wooden structure that will be

buried with Delta MS membrane.

Back fill around the pool, taking care not damage the

structure.

D

C

23

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> FOR OCTO+ POOLS

Assemble your pool as described in the installation

instructions.

Cover the portion of the wooden structure that will be

buried with Delta MS membrane.

Back fill around the pool, taking care not damage the

structure.

C

D

For selection of the site, refer to the instructions at the

beginning of this document.

Once the excavation is at the required depth, make sure

that the surface is perfectly flat and level.

Next, dig a

trench to allow drainage under the walls of the pool.

Trace

the shape of the trench, to assist this process you may

temporarily assemble the first row of slats (illustrations

27 and 28, depending on the model). It should be wide

enough to extend beyond each side of the wall once it is

built.

The cradle trenches are dug as described previously

(illustrations 21 to 26). If you intend to install the filtration

system in a box adjoined to the pool, remember to dig a

trench to run the power cable. Similarly, if the filtration

system is to be installed at a distance from the pool, dig a

trench to accommodate passage of the suction and return

lines.

Max. depth of the excavation:

Pool height 120 cm = 116 cm

Pool height 133 cm = 129 cm

Pool height 146 cm = 142 cm

After the trench under the pool wall is dug, fill it to a

depth of approximately 10cm using small sized gravel.

Make sure that the gravel is well compacted to avoid

future subsidence that will impact the pool structure.

Finish filling the trench with compacted sand, the filled

trench should be level with the ground.

CAUTION! We strongly recommend that you install the

filter below the water line. If the filter is installed above

the water line, there is a risk of deformation due to

depressurisation. At most, the filter should be installed

level with the coping. In the event that the filter is

installed above the water line, mount a check vent on the

return line and an easily accessible check valve on the

suction line.

A

B

24

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

Wood is a living material that responds to changes in temperature and humidity; cracks and splits may appear; this is

natural and in no way impacts the service life of our products.

The wooden components of this pool are subjected to a Class IV autoclave treatment that complies with standards in effect,

they present no danger to people or animals that may come into direct contact with the wood.

To preserve the original colour, use a colourless wood finish. You could alternatively opt for a coloured finish or

treat the wood with a colourless oil to slow the decoloration process. Before applying the finish, check that it is

microporous and will allow the wood to breathe. Make sure that the product will not migrate (wet wood) over time

to the interior of the structure and damage the liner. Ideally, the finish should be applied before assembling the pool

structure.

Use high quality products!!! This will guarantee that the finish will last longer. However, we strongly recommend

that you test the product on a small unseen part of the pool before applying it to the entire surface area.

Over time, the wood will inevitably get dirty. Clean it once a year with a high pressure jet to remove dirt trapped in the

pores of the wood. Take care to regulate the water pressure to avoid damaging the finish or raising wood fibres.

This pool is delivered as a kit and is not designed to be dismantled.

This pool is designed to be used by persons 3 years of age and older. It is understood that young children and non-swimmers

using the pool will wear flotation devices.

For your safety and that of your children, we recommend that you read and

apply the safety recommendations on page 27.

Use of a pool kit implies adherence to safety recommendations outlined in the maintenance and operating

instructions.

octo 440 & +460 maximum 4 people allowed in the pool at any one time.

octo 530 maximum 5 people allowed in the pool at any one time.

octo +540 and +640 maximum 6 people allowed in the pool at any one time.

octo+ 840 maximum 8 people allowed in the pool at any one time.

Ladders should only be used to enter and exit the pool. Any other use is prohibited and could be dangerous.

The wooden access ladder should be taken away and stored systematically after the last person leaves the pool. This is to prevent

the risk of drowning. We have designed a fast efficient locking system, use it!! Store the ladder in a dry place during the winter.

There should be no means of access to the pool while it is not in use. The ladder wood should be treated in the same way as the

other wooden elements.

We recommend that you secure access to the finished pool with one of the measures set out in the French pool

safety standard NF P 90-306, 307, 308 & 309 that is: Safety barrier - Alarm - Safety cover - Shelter.

Inspect the accessible nuts and bolts regularly and carry out any maintenance required (re-tighten, treat traces of rust, etc.).

Take care with the liner of your pool, do not treat it roughly. Make sure that correct tension is maintained on the liner, failure to

do so could result in tears and leaks. See the guarantee conditions at the end of these instructions.

During the life of your pool it may be necessary to empty it totally. In this event, take every precaution necessary to avoid

accidents and danger (falls, etc. )

. Avoid leaving the pool empty for more than 48 hours, this could result in deformation

of the structure.

REMINDER: No diving - No walking on the coping - Never leave an empty pool uncovered

WATER TREATMENT & MAINTENANCE OF THE FILTRATION SYSTEM

To ensure the comfort of pool users, you will need to treat the pool water. Follow the recommendations concerning

operation of the filtration group: commissioning, frequency of use for regeneration of the water, maintenance,

inspections (pipes, nuts and bolts), etc. Monitor the build up of dirt in the sand filter (see the section on filter back

washing).

During the pool season, the filter should be run every day for long enough to renew the entire pool water volume at

least three times every 24 hours.

To ensure optimal efficiency of the filtration system, make sure that the water level remains correct and constant. The

water level should be 2/3 of the way up the skimmer mouth.

To fill your pool, use tap water, its pH is close to the ideal pH. If you use water from a well or some other private

source you must have it analysed beforehand. You will need to test the pH of your pool at regular intervals and

adjust it if necessary to keep it between 7.2 and 7.6. Treatment chemicals for this purpose are widely available.

To preserve the quality of the pool water, it will need to be tested and treated regularly. Frequency will depend on a

number of conditions; pool situation, bather load, weather conditions, etc.

As pool water cannot be directed into the sewage system, it must be directed as rain run-off. Familiarise yourself

with the regulations concerning disposal of pool waste water in effect in the area in which the pool is located

Failure to abide by maintenance instructions may entail serious risks to health and safety, notably of children.

>> MAINTENANCE & OPERATION

25

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> MAINTENANCE & OPERATION (contd.)

ACCESSORIES

Electrical equipment such as underwater lights that require an electrical supply must be fitted and wired in according

to the standards in effect. We recommend that you take great care in this matter and that you call on the services of

qualified specialists.

Some models come with a bubble cover that is spread over the pool while it is not in use. The action of sunlight on

the cover heats the water below and the cover helps maintain the water temperature at night. Upon removing the cover

from the pool, turn it over to allow it to dry, then roll it up and store it out of the way. Never fold the bubble cover, this

could cause it to tear. Wipe it down from time to time with a damp cloth. This cover should under no circumstances be

considered a safety device. A safety winter cover (that complies with the French safety standard NF P90-308) is available

as an option to protect the pool. This high quality product is extremely hard-wearing and attractively finished. For

storage and upkeep, follow the same instructions as for the bubble cover.

WINTERIZING THE POOL

Carry out a prolonged back wash of the filter.

The pool should not be emptied during winter (or prolonged periods while the pool is not use). The liquid mass

plays a several roles, providing thermal insulation, holding the liner and pool structure in position.

Lower the water level to about 10 cm below the bottom of the skimmer mouth.

Water can be siphoned from the pool or allowed to drain by gravity by moving the multiport valve to DRAIN. Water

will run through the waste line. Do not run the pump during this operation.

Next, disconnect the pipe underneath the skimmer so that it can act as an overflow in the event the water level rises

due to precipitation. Remove any water treatment chemicals from the skimmer (chlorine tablets, flocculents, etc.).

Unscrew the return fitting face ring from inside the pool.

Use a threaded winterizing plug or rubber plug (not provided) to block the return fitting from inside the pool.

Add an algicide and a winterizing product (not supplied) to the water.

Remove the stainless steel ladder.

Place a winter cover over the surface of the pool.

NOTE: Winterizing is not mandatory, especially if the weather is clement and temperatures remain positive. In this

case, maintain a correct water level in the pool and run filtration 2 to 3 hours per day. Check the water level in the pool

regularly.

WINTERIZING THE HYDRAULIC INSTALLATION

Disconnect the return line.

Allow water to drain from the suction and return lines.

Open the plug at the bottom of the filter and allow water to drain away. Do not replace the plug before putting the

filter back into service.

Open the drain plugs on the pump and pre-filter.

Leave the plugs open.

Cut the power supply to the filtration control panel.

In as far as possible, store the filtration group in a location protected from humidity. In the case of an unprotected

outdoor installation, remove the pump and store it.

We think that we have provided you with main information you required to use and maintain your pool, however you

will find more information in specialised guides and reviews. Don’t hesitate to consult these.

HYGIENE

As regards hygiene, there are no official regulations for family pools. However, for your health and that of your family

and friends, there are some rules that you should respect!

This begins with good personal hygiene.

Next, to maintain water purity, respect the instructions set out in the section “maintenance and operation”. Pay

particular attention to treatment cycles, water testing, filtration and cleaning. The balance of your pool water

depends mainly on you. Do not hesitate to inform yourself and follow the advice of the professionals.

26

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> SAFETY

DO NOT PLAY WITH SAFETY ! ! !

In this fun environment you need to watch your children! You alone are responsible for their safety !

Children should be closely supervised at all times. The risk is at its greatest when children are less than

5 years old.

w Accidents don’t just happen to others. Be ready to act !!

w Never leave a child alone close to the pool.

w Children must be closely supervised at all times.

w Children who don’t know how to swim, or children not supervised by adults, should wear a flotation

device (vest or arm bands). Without these precautions, access to the pool should be strictly denied.

w The access ladder must be removed while the pool is not in use irrespective of the length of time for

which the pool will not be used.

w Designate one person responsible for watching non-swimmers and children.

w Be particularly attentive when there are several people in the pool.

w Keep a pole and/or life ring close to the pool in case of necessity.

w Teach young children how to swim as early as possible!

w Before getting into the pool, wet the back of the neck, legs and arms to prevent irreversible thermal

shock! This warning also applies to older pool users who frequently disregard this safety tip.

w Jumping or diving should be prohibited. The same applies to violent games.

w Do not stand or walk on the coping! No diving.

w Be careful not to leave toys in or around an unwatched pool, these could attract children...

w Keep the water clean and sanitary during the pool season.

w Water treatment chemicals should be kept out of reach of children; store them in a safe, inaccessible

place. Never leave cleaning accessories near the pool.

w Some equipment can contribute to pool safety:

- safety barrier, with a gate that is always kept closed (for example, a hedge could not be considered a

safety barrier).

- a manual or automatic safety cover correctly installed and fixed in position.

- a functional alarm to detect proximity to the pool or falls into the water.

Safety equipment will under no circumstances replace close surveillance.

w Outside the pool season, the pool should be covered with a winter cover correctly positioned and

attached. This serves an additional function in that it renders the pool less attractive.

w Make sure that there is a telephone (land line or mobile) within easy reach of the pool to avoid leaving

children alone in the event of a problem.

w Learn first aid, especially those techniques applicable to children, to provide assistance in the case of an

accident.

w Take steps to prevent access to the pool if the filtration system is damaged and during maintenance

operations.

w In the event of an accident :

w Get the child out of the water as quickly as possible.

w Call for help immediately and follow the advice given.

w Remove the wet clothes and wrap the child in warm blankets.

MEMORISE EMERGENCY SERVICE NUMBERS AND DISPLAY THEM CLOSE TO THE POOL

Fire: Ambulance: Poison centre:

27

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> GUARANTEES

WOODEN COMPONENTS: 10 year guarantee from the manufacturer against insect infestation and rotting (wood is high

pressure autoclaved in accordance with the standards in effect).

This guarantee does not cover natural warping of the wood (appearance of cracks, splits that in no way impact the mechanical

strength of the wood) or changes in colour attributable to weathering. Defects resulting from errors in mounting or storage are

also excluded from the scope of this guarantee: deformed wall slats (exposure to sunlight, assembly deferred after opening the

package), slats altered or broken due to assembly in a manner other than that set out in the installation instructions.

It should also be noted that the any cutting of wood elements, for any reason whatsoever, will cancel the guarantee

against insect infestation and rotting for the altered element.

ACCESSORIES: according to the conditions of coverage against manufacturing defects and assembly defects effecting

the various accessories comprising the pool and that could impinge upon its normal use. The guarantee conditions

stipulate specific periodic inspections and maintenance that must be carried out for the pool to run correctly. The

successful outcome of any claim made under the aforementioned guarantee will be contingent on strict adherence to

its conditions. This guarantee does not cover corrosion that may occur over time, nor does it cover damage caused by

inappropriate handling during assembly or use of accessories (impacts, scratches, etc) or incidents not directly related

to normal usage of the pool or its accessories. All of these guarantees apply to parts recognised as defective by our

services and are limited to replacement of the implicated item(s). The costs of dismantling and reassembly are not

covered.

GUARANTEE CONDITIONS COVERING ITEMS FROM THE ACCESSORIES AND OPTIONAL EQUIPMENT KIT

All of the components of the accessories kit are guaranteed 2 years (except the bubble cover and winter cover).

CAUTION!

The following problems, associated with inappropriate use or maintenance of the membrane, are not covered in the

scope of the guarantee

- folds that appear after the liner has been fitted, these can be caused by sliding of the membrane on loose soil or an uneven

surface, or physico-chemical properties of the pool water that are outside the acceptable ranges: water temperature should

be less than 28°C, pH should be between 7.2 and 7.6 and the concentration of the sterilising agent should be within the range

recommended by the manufacturer of the water treatment products.

- Folds that remain despite following all the instructions regarding fitting of the liner should be reported immediately to

your Procopi agent.

The appearance of yellow stains or discolouration along the water line.

These may be the result of deposition of organic compounds floating on the water surface (sun creams and oils, residue of

hydrocarbon combustion or smoke from wood fires). To prevent this from happening, clean the water line regularly using

products designed for this purpose. (not supplied) and a non-abrasive sponge.

Very hard water can also be the cause of this type discolouration due to the build up of calcium deposits on the membrane. Hard water (TH greater than 250 ppm) should be treated with a product to eliminate calcium and suitable for use

in pools (not supplied).

- Stains caused by the growth of algae and micro-organisms: the pool water should be treated regularly with an appropriate dose of algicide.

- Stains, discolouration and wrinkles caused by direct contact with oxidizing agents (thrown directly into the pool) or

pockets of excessively high concentrations of oxidising agents (frequently associated with failure to run filtration while

the oxidising agents are dissolving).

- Stains caused by stagnation and/or decomposition of a foreign body in direct contact with the liner (dead leaves,

oxidizable metallic objects, miscellaneous detritus, etc.)

- Damage caused by direct contact with incompatible materials such as bitumen, tar, oils, polystyrene panels, polyurethane. Never

apply adhesive tape or glue to the membrane.

- Tears that occur while fitting the liner caused by shifting the liner without releasing it from the liner locking track first.

ARTICLE Subject and scope of the guarantee Term of the guarantee as of the date of

purchase

Conditions governing

acceptance of a claim

LINER

- Leaktightness of welds.

- The guarantee is limited to replacement or

repair of the liner recognised as defective

without any other damages or interest.

10 years against leaks

2 years against stains

Adherence to

conditions governing

fitting, use and

maintenance.

28

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

ARTICLE Subject and scope of the

guarantee

Term of the guarantee as of

the date of purchase

Conditions governing acceptance of a claim

FILTER +

CONNECTIONS

Leaktightness of the filter

tank.

Leaktightness of the

connection elements.

5 years on the filter tank

The hydraulic installation and notably the

pump, should generate an operating pressure

less than 1.2 bar.

Regular back washes to clean the filter to avoid

clumping of the filter medium.

>> GUARANTEES (contd)

CAUTION! The following problems, associated with inappropriate use of the filtration components, are not covered

under the terms of this guarantee:

- Leaks caused by running the filter at an operating pressure greater than 1.2 bar (use of a pump that is too powerful,

clogged filter medium, etc.), or installing the filter above the water level without a vent and check valve. (see the installation

instructions)

- “stress-cracking“ of ABS parts (valve, nuts) caused by surface reactants found in some types of grease: grease should not

be used on these types of components.

- The continuous expulsion of sand if sand with a grain size of less than 0.6 mm is used. (the sand supplied has the correct

grain size).

ARTICLE Subject and scope of the

guarantee

Term of the guarantee as of

the date of purchase

Conditions governing acceptance of a claim

PUMP Motor operation

Operation and leaktightness

of the hydraulic components.

2 years

See below and regular cleaning

ARTICLE Subject and scope of the

guarantee

Term of the guarantee as of

the date of purchase

Conditions governing acceptance of a claim

SUMMER

COVER

Fit for purpose on delivery 2 years

CAUTION! The following problems, associated with inappropriate use of the pump, are not covered under the terms of

this guarantee:

- Running the pump ‘Dry’ (absence of water, clogging of the pre-filter)

- Running the pump without the pre-filter

ARTICLE Subject and scope of the

guarantee

Term of the guarantee as of

the date of purchase

Conditions governing acceptance of a claim

WINTER

COVER

Fit for purpose on delivery 2 years

ARTICLE Subject and scope of the

guarantee

Term of the guarantee as of

the date of purchase

Conditions governing acceptance of a claim

MAINTENANCE

ACCESSORIES

Fit for purpose on delivery 2 years

RECOMMENDATION! While the cover is not rolled out over the surface of the water, it should be dried, rolled up and

stored out of the sunlight.

RECOMMENDATION ! Avoid placing too much traction on the bungee cord, this could pull out the eyelets.

Monitor water quality during the winter. Excessively high concentrations of treatment chemicals, a pH that is

too low or too high, could result in discoloration or damage to the cover material

To prevent the development of mould during periods while the cover is not in use, take care to dry and fold

the cover carefully before storing it.

ARTICLE Subject and scope of the

guarantee

Term of the guarantee as of

the date of purchase

Conditions governing acceptance of a claim

POOL

FITTINGS

Leaktightness and durability

of the pool fittings

10 years

29

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> EXPLODED VIEW OF THE OCTO+ STRUCTURE

(AUTONOMOUS FILTRATION UNIT)

30

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

>> EXPLODED VIEW OF THE OCTO STRUCTURE

(SKIMMER)

Rail PVC

support bracket

31

» INSTALLATION INSTRUCTIONS / OCTO & OCTO+

proswell.fr

INSTALLATION INSTRUCTIONS

/ OCTO & OCTO+

Installation instructions Weva Octo, Octo+ 07/2015

GB - Revision: D - Code : 97149997

QUALITY CERTIFICATE

PEFC CONTROL CHAIN

Company

Control chain no.

The chain of custody of the company designated hereinover

complies with the PEFC* stipulations in effect.

This certifi cate was issued in accordance with the PEFC

reference governing chain of custody of wood, FCBA MQ

CERT 11-360.

Scope Method used

Average percentage method

Manufacture and distribution of

wooden equipment for pools at

the Pleumeleuc site

This certifi cate attests chain of custody

certifi cation based on continuous monitoring.

It cannot prejudge changes or decisions that

could be made during the year.

The list of certifi ed companies is available on

line www.fcba.fr and http:/register.pefc.cz

* appendices 15 and 16 of the french forestry certifi cation scheme,

translation of appendices PEFC ST 2002: 2012 and PEFC ST 2001: 2008 of

the international technical document issued by the PEFC council.

Certifi cate No.

0226/2012

Date: 13th February 2012

Valid up until 01/02/2017

Loading...

Loading...