procool

AV Cooling Solutions

SX40 series

PROCOOL LLC – Plano, IL 60545 – P: 630-552-8957 F. 630-552-8963 – www.rackfans.com

PROCOOL SX40 FAN SERIES RACK MOUNT COOLING SYSTEMS

Intake Models: SX2240, SX340, SX440, SX640 and SP640X

Exhaust Models: SX2240-E, SX340-E, SX440-E, SX640-E and SP640X-E

• Specifications are subject to change without notice.

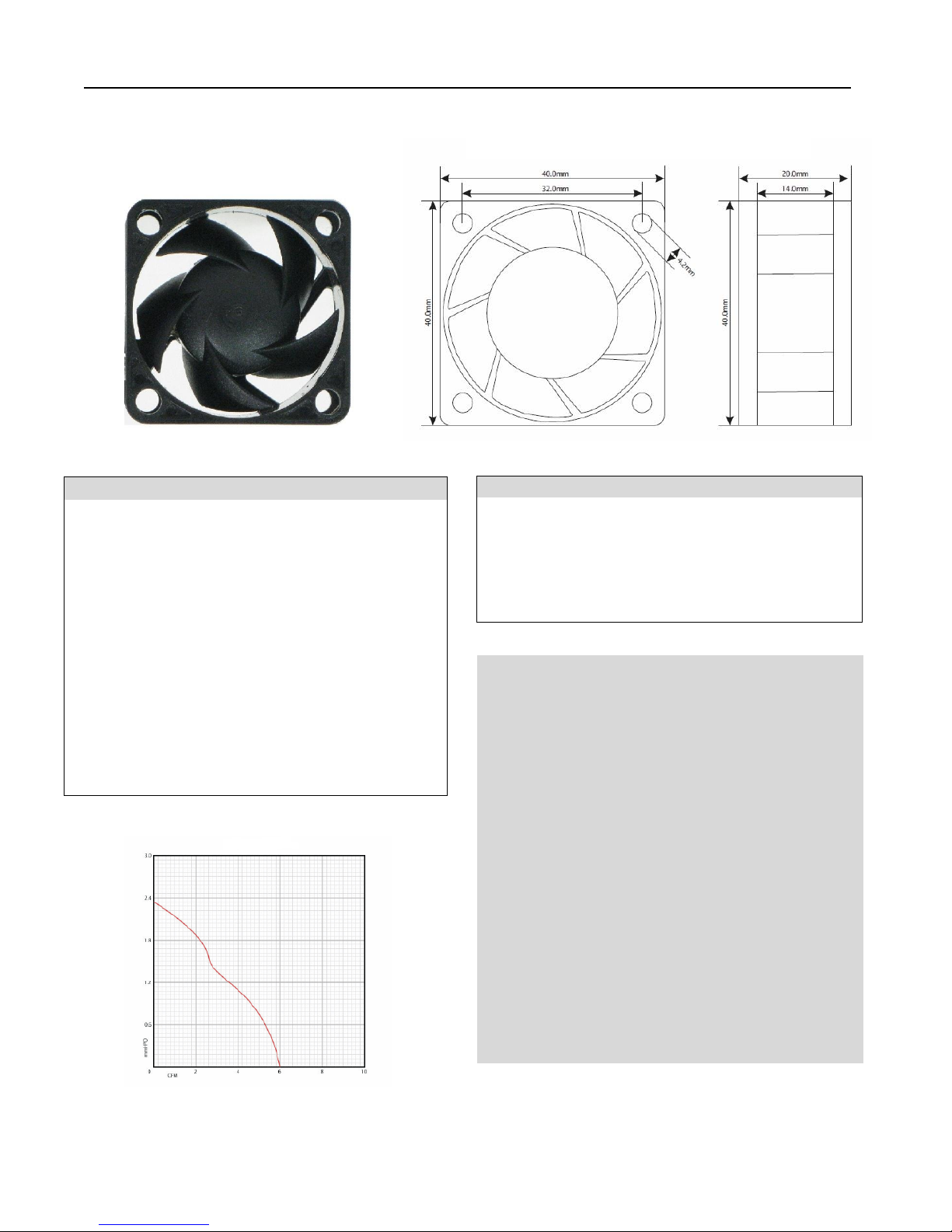

Model SX40 Silent Fan

The SX40 model fans provide the quietest cooling solution for it’s size. Recommended where quiet cooling is required. The

SX40 fans provide 6 CFM of airflow while running at a whisper quiet 14 dBA. When combined on the one rack space panels,

airflow adds up to 36 CFM on the 6 fan model SX640 and SP640X. The special blade design creates more airflow with less

noise than ball bearing type fans while running at very low noise levels.

Model No.

SX2240, SX2240-E

SX340, SX340-E

SX440, SX440-E

SX640, SX640-E

*SP640X, SP640X-E

Panel Size:

1U (19"w x 1.75"h x 2.5”d)

1U (19"w x 1.75"h x 2.5”d)

1U (19"w x 1.75"h x 2.5”d)

1U (19"w x 1.75"h x 2.5”d)

Panel color/material:

Black/metal

Black/metal

Black/metal

Black/metal

Fan Size:

40mm x 40mm x 20mm

40mm x 40mm x 20mm

40mm x 40mm x 20mm

40mm x 40mm x 20mm

Number of Fans:

4 3 4

6

Fan Speed (per fan):

3200 RPM

3200 RPM

3200 RPM

3200 RPM

Air Flow Direction

INTAKE (*E = EXHAUST)

INTAKE (*E = EXHAUST)

INTAKE (*E = EXHAUST)

INTAKE (*E = EXHAUST)

Air Flow (combined):

24 CFM

18 CFM

24 CFM

36 CFM

Static Pressure (per fan):

2.32mm H²O

2.32mm H²O

2.32mm H²O

2.32mm H²O

Noise (combined):

20 dBA

18 dBA

20 dBA

21.77 dBA

Thermistor Probe length

24”

24”

24”

24”

Grills/Guards:

Black Wire

Black Wire

Black Wire

Black Wire

Bearings:

Fluid Dynamic

Fluid Dynamic

Fluid Dynamic

Fluid Dynamic

Power Supply:

100-240 VAC - 12 VDC

100-240 VAC - 12 VDC

100-240 VAC - 12 VDC

100-240 VAC - 12 VDC

Power Supply Plug:

NEMA 1-15 – 2.1mm

NEMA 1-15 – 2.1mm

NEMA 1-15 – 2.1mm

NEMA 1-15 – 2.1mm

Power Supply Cable:

36"

36"

36"

36"

Current draw:

0.12A

0.09A

0.12A

0.18A

Power consumption:

1.44w

1.08w

1.44w

2.16w

Weight

1 lbs.

1 lbs.

1 lbs.

2 lbs.

Operating Temperature

-10°/+70° C

-10°/+70° C

-10°/+70° C

-10°/+70° C

Storage Temperature

-40°/+80° C

-40°/+80° C

-40°/+80° C

-40°/+80° C

procool

AV Cooling Solutions

SX40 series

PROCOOL LLC – Plano, IL 60545 – P: 630-552-8957 F. 630-552-8963 – www.rackfans.com

SX40 Specifications

Rated Voltage

12.0 vDC

Voltage Range

8~14 vDC

Rated Current

0.03 A

Rated Power

0.36 w

Rated Speed

<3200 RPM

Airflow

<6 CFM

Static Pressure

<2.32 mm H²O

Noise Level, 1m, xyz axes avg

<13.5 dBA

Noise Level, 1m, z axis

<14.1 dBA

Operating Temperature

-10°/+70° C

Storage Temperature

-40°/+80° C

Bearing

Fluid Dynamic

Weight

0.8 oz.

Pressure Curve

MTBF Hours

Temperature

L50

L10

30° C

235434

101586

40° C

163186

70412

50° C

115705

49925

60° C

83751

36137

70° C

61775

26655

RoHS Certificate of Compliance:

As of February 2, 2006

This “RoHS Certificate” provides information regarding the absence of

certain substances in the Fan model listed on this document.

The models identified below are in compliance with the European

Union

Directive 2002/95/EC on the restriction of use of certain hazardous

substances (“RoHS Directive”). The models do not contain any of the

restricted

substances referred to in the European Union Commission Decision of

August18, 2006 (2005/618/EC) in connection with Articles 4 and 5 of

the RoHS

Directive in concentrations in excess of the values permitted

thereunder.

For purposes of this RoHS Certificate, the maximum concentration

values of the restricted substances by weight of homogeneous

materials are:

hexavalent chromium 1,000 ppm

poly-brominated biphenyls (PBB's) 1,000 ppm

poly-brominated diphenyl ethers (PBDE's) 1,000 ppm

cadmium 100 ppm

mercury 1,000 ppm

lead 1,000 ppm

Conforms to CE - Reference 73/23/EEC Low Voltage Directive.

Fan housing and fan blade resin flammability conforms to class UL-94V-2.

procool

AV Cooling Solutions

SX40 series

PROCOOL LLC – Plano, IL 60545 – P: 630-552-8957 F. 630-552-8963 – www.rackfans.com

Operation:

Mount in desired location for optimal cooling. Intakes are best positioned lower or adjacent to equipment.

Exhausts are best positioned at the top or above equipment. Connect power.

Maintenance:

Cleaning the fan is the best preventative maintenance. Cleaning frequency would depend on the environment. It

is recommended that the blade be cleaned to prevent any buildup of dust. Canned air works well.

Blade Removal:

For cleaning and maintenance, the blade prop can be removed.

Grasp the blade prop and pull straight out of the fan body. Inspect the shaft and lubricate if needed. Any oil will

work; light grease works best. Clean blade as needed with a dry cloth. Soap and water can be used if needed, but

should be thoroughly rinsed and dried before use. Reinstall the blade; when properly installed the blade will snap

into place. Cleaning and inspection of the blade shaft should be done annually for best performance.

Warranty:

2 Years from the date of purchase.

Loading...

Loading...