Page 1

H - I - J

frequency converters

instruction manual

P

Since

1984

Page 2

Page 3

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 3 -

TABLE OF CONTENTS

APPLICATION ............................................................................................................................................................. 4

GENERAL FEATURES ............................................................................................................................................... 4

FUNCTIONING ............................................................................................................................................................ 5

DECLARATION OF CONFORMITY ............................................................................................................................ 5

MECHANICAL INSTALLATION .................................................................................................................................. 5

TEST RUN ................................................................................................................................................................... 6

Cables and fuses .......................................................................................................................................................... 7

Main and Control Circuit Wiring ................................................................................................................................... 8

Connecting the power line ................................................................................................................................. 8

Connecting the motor ......................................................................................................................................... 8

Connecting the protective earth ......................................................................................................................... 8

Connecting the control circuitry.......................................................................................................................... 8

PUTTING IN OPERATON THE FREQUENCY CONVERTER FOR THE FIRST TIME .............................................. 9

ASSIGNMENT AND CONNECTION OF THE V3D TERMINAL BLOCK ................................................................. 10

Jumper settings .......................................................................................................................................................... 11

Connections of the incremental rotation speed encoder (IRE) and thermal protection of the motor ......................... 11

Connecting the brake resistor .................................................................................................................................... 12

Connecting a two-wire (4÷20mA) remote transmitter ................................................................................................ 12

ASSIGNMENT AND CONNECTION OF THE VLD / VHD TERMINAL BLOCK ...................................................... 13

Jumper settings .......................................................................................................................................................... 14

High voltage terminal block ....................................................................................................................................... 14

Connections of the incremental rotation speed encoder (IRE) and thermal protection of the motor ......................... 15

Connecting the brake resistor .................................................................................................................................... 15

Connecting a two-wire (4÷20 mA) remote transmitter ............................................................................................... 16

±10 V analogue input ................................................................................................................................................. 16

OPERATING THE CONVERTER .............................................................................................................................. 17

Programming terminal ................................................................................................................................................ 17

Operating from the computer ..................................................................................................................................... 17

Operating terminal ...................................................................................................................................................... 18

Controlling terminal .................................................................................................................................................... 18

Functions of the push buttons (operating and controlling terminal) ................................................................. 18

PROGRAMMING (operating and controlling terminal) ......................................................................................... 19

Programming procedure ............................................................................................................................................ 19

Quick menu ................................................................................................................................................................ 19

DRIVING TECHNOLOGY SUPPLEMENTS .............................................................................................................. 19

4x16 character display ............................................................................................................................................... 19

Potentiometer ............................................................................................................................................................. 20

Selection of the brake resistors at dynamic braking .................................................................................................. 20

MAINTENANCE ......................................................................................................................................................... 20

GUARANTEE AND REPAIR ..................................................................................................................................... 20

FREQUENCY CONVERTER SELECTION GUIDE ................................................................................................... 21

PERIPHERAL EQUIPMENT SELECTION GUIDE ................................................................................................... 22

Page 4

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 4 -

Dear Customer!

Thank you for having decided in favour of PROCON Ltd’s frequency converter.

This Instruction Manual contains all information necessary for starting up and operating the frequency

converter. Read this manual before installing the frequency converter.

Follow all safety measures, warnings and instructions described in this manual.

The manufacturer bears no responsibility for any personal injury and/or material damage arising from not

taking into consideration the warnings in this manual.

At receiving the frequency converter, please check up followings:

▪ Make sure that the frequency converter is not damaged. If you detect any damage of the frequency

converter contact the manufacturer.

▪ Check the data plate of the device to make sure that you received the ordered model. If not, please contact

the manufacturer

Following graphic symbols will be used in this manual:

6

This symbol is used for those instructions whose negligence could cause electric shock, severe injury or

even death.

7

This symbol is used for those instructions whose negligence could cause fire and injury.

8

This symbol is used for those instructions whose negligence could cause personal injury, damage in the

equipment and property damage.

i

Important information

APPLICATION

The V3D, VLD and VHD series frequency converters are digitally programmable appliances.

They are suitable for the near loss-free regulation of the rotation speed of any type of three-phase asynchronous

motors with squirrel-cage rotor from 0.55 kW to 250 kW power ratings, at 400 V.

The converters comply with the requirements of the standards relating to control devices for use in the electric

industry.

GENERAL FEATURES

Line voltage

3 x 380 ÷ 440 V AC ± 10 %

Line frequency

50 ÷ 60 Hz (sine wave)

Motor voltage

3 x 0 ÷ actual value of the input voltage (PWM modulated sine wave)

Motor frequency

0 ÷ 1000 Hz (free programmable)

Protection grade

IP20 (optionally IP54)

Line filter

Complies with the EN 55011 B1 standard (equipped with built-in RF filter)

Ambient temperature

0°C ÷ +40 °C

Relative humidity

maximum 90 % (non-condensing)

Storage temperature

-20 °C ÷ +60 °C

Requirements for the

place of the installation

Install the drive in an area free from:

▪ oil, oil mist, dust, metal shavings, water or other foreign materials,

▪ combustible materials (e.g., wood),

▪ harmful gases and liquids,

▪ excessive vibration,

▪ chlorides,

▪ direct sunlight

Orientation

The frequency converter must always be mounted in vertical position, with provision

for the ventilation requirements.

Page 5

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 5 -

FUNCTIONING

The alternating voltage from the power line is rectified by a line diode bridge, then electrolytic capacitors smooth

out the pulsating voltage. The intelligent IGBT end stage, driven with sinusoidal modulated pulses, delivers to the

motor a voltage of variable amplitude and frequency. Following the description of the programming, until the motor

reaches its nominal revolution the voltage vs. frequency relation can optionally be changed, according to the

character of the load. (Linear, quadratically modified or knee point characteristics can be programmed.)

At low frequencies the ohmic resistance of the motor winding can be compensated (U boost).

Below the nominal revolution the frequency converter is capable of delivering nominal torque; beyond it the

converter delivers constant power.

The converter can be equipped with an optional braking resistor.

DECLARATION OF CONFORMITY

The frequency converters have been manufactured with considering following directives:

Frequency converters

V3D, VLD, VHD

Machinery directive

2006/42/EK

Low voltage directive

2014/35/EU

Electromagnetic Compatibility (EMC) directive

2014/30/EU

Applied standards

EN 13849-1:2008

EN 61800-5-2:2016

EN 60034-1:2017

EN 61800-5-1:2007

EN 60664-1:2008

EN 61800-3:2017

8

CAUTION

These products serve for being mounted into machineries.

These products are allowed to be put into service only after the machinery comprising the product was found to

comply with the above directives about machineries.

According to the directions on electromagnetic compatibility (EMC) the listed products are not considered as

products which can be operated alone. The electromagnetic compatibility can only be evaluated after the product

was incorporated in the whole system. Certification of this evaluation refers not to the stand-alone product but to

the complete machinery.

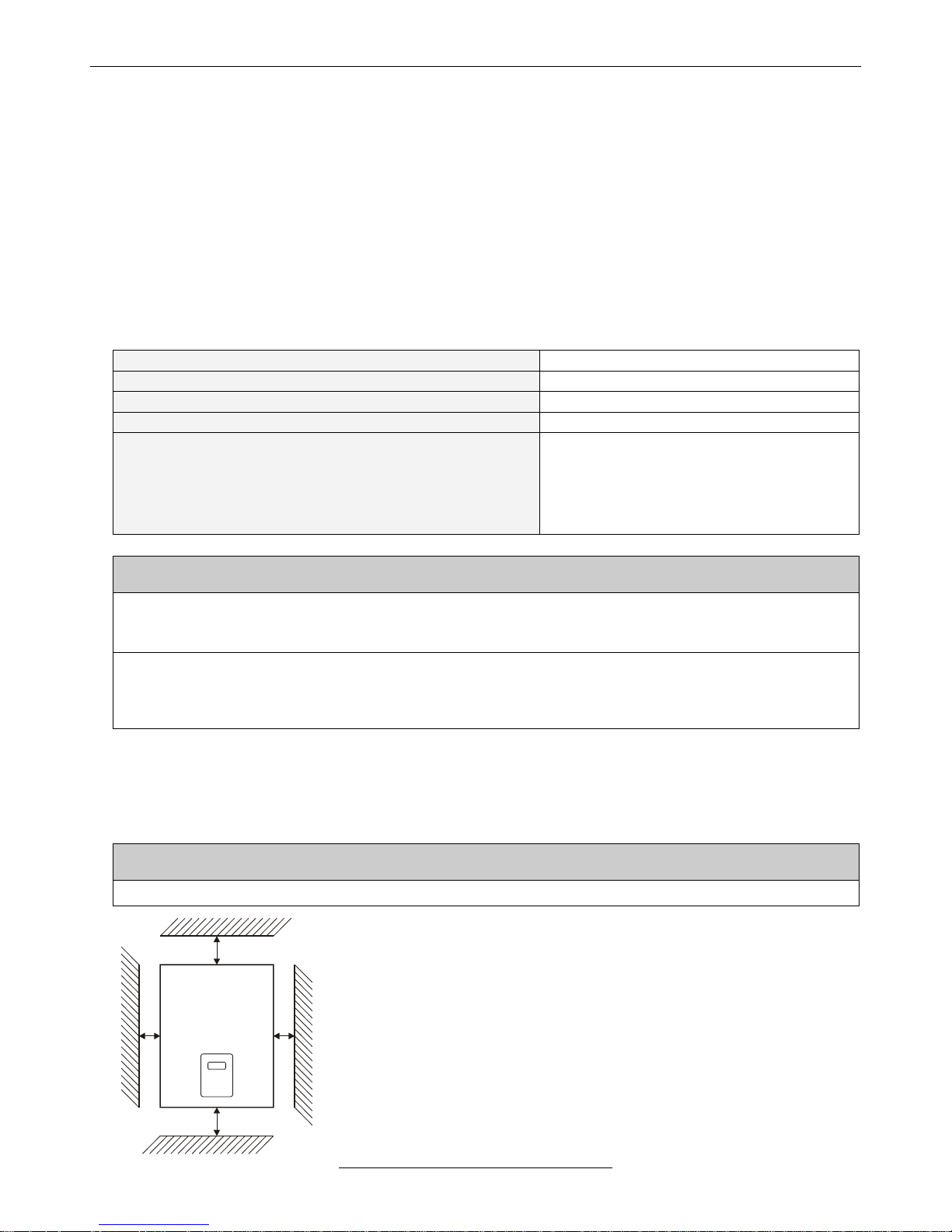

MECHANICAL INSTALLATION

The appliance belongs to protection class IP-20 and is allowed to be operated as a built-in unit only.

Should the appliance need increased protection due to the conditions (water, dust, aggressive materials), use at

least protection IP-54. If the appliance is installed by the user, the issues cooling and arranging the cables need to

be consulted with the manufacturer.

8

CAUTION

The manufacturer takes no responsibility for damages caused by incorrect installation.

200

50

FREQUENCY

CONVERTER

▪ Beside the side walls at least 50mm, below and above the unit at least 200

mm free space must be provided.

▪ If the device is built in closed control cabinet, overheating of the inside room

must be prevented with proper ventilation!

▪ The slots for fresh air and used air must be held free to assure proper

ventilation. The filters of the slots must be cleaned regularly!

▪ At IP54 versions the cooling is facilitated with heatsinks of increased size

that must be placed outside the cabinet, with maintaining the IP54

protection!

▪ On demand the manufacturer builds the equipment in a cabinet of proper

size.

▪ At types with forced ventilation the inlet openings should be on the bottom

side, the ventilated outlets on the upper side (possible diagonally)

Page 6

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 6 -

TEST RUN

In the course of the installation and test run the manufacturer’s attached wiring instructions and the instructions of

the effective standards must be complied with.

8

CAUTION

Test run, maintenance, repair and component replacement in the frequency converter are allowed to be

performed by authorized specialist only!

6

WARNING

ELECTRICAL SHOCK HAZARD

Negligence of these warnings could cause severe injury or even death!

Prior to the total discharge of the capacitors the terminal blocks of the motor must not be touched!

Prior to wiring the connectors of the device switch off the whole power supply of the device! The internal

capacitor remains in charged state even after switching off the power supply. Installation is allowed to be started

if the power LED has ceased lighting.

When taking the equipment from could environment to the place of installation vapour may condense.

Prior to installation wait until the temperature of the equipment equalizes with that of the environment and the

device becomes totally dry.

The appliance must not be put into operation in humid environment.

The circuitries of the frequency converter must not be modified or changed.

In switched-on state the covering of the device must not be removed and any part of it must not be

touched!

The appliance must be earthed according to the standards.

8

CAUTION

DANGER OF UNEXPECTED STARTING

Negligence of this warning could cause injury and property damage!

On switching the line power to the frequency converter, the device depending on its setting may

unexpectedly start the motor.

Prior to powering the frequency converter make sure that nobody stays near to the motor and the machine and

all coverings, mechanical connections, wedges, bolts and machine load are properly fastened!

7

WARNING

FIRE HAZARD

Negligence of this warning could cause fire and injury!

The power line cable must not be connected to the output motor connections of the frequency converter!

Connecting the power line to the output connections could cause severe damage in the device.

Tighten all terminal screws to the specified tightening torque.

Loose electric connections may overheat.

Terminal Size

M3

M4

M5

M6

M8

Tightening Torque [Nm]

0.8 ÷ 1.0

1.2 ÷ 1.5

2.0 ÷ 2.5

4.0 ÷ 5.0

9.1 ÷ 11.0

Page 7

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 7 -

8

CAUTION

EQUIPMENT HAZARD

Negligence of this warning could cause total damage to the device.

The device is not waterproof!

Prevent the interior of the appliance from the penetration of water!

Take care that no external object (e.g. small metal part, metal powder) or liquid can get inside the device.

Avoid short circuit or ground fault at the output terminal blocks.

It is forbidden to connect any capacitor to the output. Regarding other filters, please ask the

manufacturer’s opinion.

Avoid using contactor at the output because the frequency converter may stop working due to switch-on

overcurrent.

If for other reasons using a contactor is necessary (e.g. switch-over between motors), the switchover of the

output of the frequency converter during operation must be prevented by latching.

Use the shortest possible earthing conductor and avoid earth loops.

Earthing conductors common with machines of higher power (e.g. welding machine, machine tool) must

not be used.

For wiring the control unit use shielded cable.

Use shielded twisted wires, and connect the shielding to the reference point of the inputs.

Observe proper electrostatic discharge procedures (ESD) when handling the frequency converter.

Failure to comply may result in ESD damage to the drive circuitry.

Do not operate the device with any visible damage on it or if its any part is missing.

Do not modify the circuitry of the frequency converter to avoid damages and expiring of the warranty.

Check all the wiring to ensure that all connections are correct after installing the frequency converter

and connecting other devices.

• Cables and fuses

At connecting the frequency converters use mains fuses and wires with cross-section as given in the table.

TYPE

Minimum

fuse value

(F1, F2, F3)

[A]

Recomm.

cable

[mm2]

TYPE

Minimum

fuse value

(F1, F2, F3)

[A]

Recomm.

cable

[mm2]

TYPE

Minimum

fuse value

(F1, F2, F3)

[A]

Recomm.

cable

[mm2]

V3D 0.55

6.3

0.75 ÷ 1

VLD 5.5

20

2.5 ÷ 4

VHD 30

80

16 ÷ 25

V3D 0.75

6.3

1 ÷ 1.5

VLD 7.5

25

4 ÷ 6

VHD 37

80

16 ÷ 25

V3D 1.1

6.3

1 ÷ 1.5

VLD 11

30

4 ÷ 6

VHD 45

100

25 ÷ 35

V3D 1.5

10

1.5 ÷ 2.5

VLD 15

50

6 ÷ 10

VHD 55

125

25 ÷ 35

V3D 2.2

10

1.5 ÷ 2.5

VLD 22

63

10 ÷ 16

VHD 75

160

35 ÷ 50

V3D 3

16

2.5 ÷ 4

VHD 90

200

50 ÷ 70

V3D 4

16

2.5 ÷ 4

VHD 110

250

70 ÷ 95

VHD 132

315

95 ÷ 120

VHD 160

355

120 ÷ 150

VHD 200

400

150 ÷ 185

VHD 250

500

240 ÷ 300

Page 8

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 8 -

• Main and Control Circuit Wiring

• Connecting the power line

At connecting the power line comply with following safety measures:

▪ Use only circuit breakers that have been designed specifically for frequency converters.

▪ If an input switch is used, it is allowed to be used not more than once in every 30 minutes.

▪ Use an AC reactor on the input side of the drive:

• to suppress harmonic current,

• to improve the power factor on the power supply side,

• when using an advancing capacitor switch.

• Connecting the motor

At connecting the motor comply with following safety measures:

▪ The output of the frequency converter has to be loaded with a three-phase motor. In case of any other load

consult with the manufacturer!

▪ Never connect a power source to the drives output.

▪ Never short or ground the output terminals.

▪ Do not use phase correction capacitors.

▪ If using a contactor between the drive and motor, it should never be operated when the drive is outputting a

voltage. Operating while there is voltage output can cause large peak currents, thus tripping the over current

detection or damage the drive.

▪ For connecting the output it is recommended to use shielded cable with earthing at both ends.

▪ With an output cable of longer than 30 meters, an output choke coil has to be used. If the cable length

exceeds 200 meters, the output choke coil is not enough, because of the excessive capacitive load. In this

case, a sine filter has to be used. Regarding the output choke coil or the sine filter, please ask the

manufacturer’s opinion.

• Connecting the protective earth

At connecting the earthing of the frequency converter comply with following safety measures:

▪ Never share the ground wire with other devices such as welding machines, etc.

▪ Always use a ground wire that complies with electrical equipment technical standards. Keep ground wires as

short as possible. Leakage current is caused by the drive. Therefore, if the distance between the ground

electrode and the ground terminal is too long, potential on the ground terminal of the drive will become

unstable.

▪ When using more than one frequency converter, do not to loop the ground wire.

▪ Use earth cable of same cross-section as that of the phase conductors.

• Connecting the control circuitry

At connecting the control circuitry comply with following safety measures:

▪ Separate control circuit wiring from main circuit wiring and other high-power lines.

▪ The connections of the SR connectors of the control circuitry (digital output) have to be separated from other

connectors of the control circuitry, unless they are used for control purposes.

▪ In order to avoid operation errors use twisted pair or shielded twisted pair cables for connecting the control

circuitry.

▪ Be sure to earth the shielding with the largest possible contact area between shielding and earth connection.

▪ The shieldings have to be earthed at the frequency converter side of the cables.

Page 9

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 9 -

PUTTING IN OPERATON THE FREQUENCY CONVERTER FOR THE FIRST TIME

8

CAUTION

Prior to put in operation the frequency converter read through thoroughly the description below!

Follow all safety measures, warnings and instructions described in this manual!

Heed the safety messages in this manual.

The operating company is responsible for any injuries or equipment damage resulting from failure to heed the

warnings in this manual.

▪ Check up the operational data of the frequency converter to be put in operation.

page 4. - General features

▪ Install the device according to the instructions.

page 5. - Mechanical installation

▪ Study the safety measures to be complied with.

page 6. - Test run

▪ Connect the cables of the power line, the motor and the control elements to the corresponding terminal

blocks.

page 10. - Assignment and connection of the V3D terminal block

page 13. - Assignment and connection of the VLD / VHD terminal block

▪ If the device is equipped with brake check up the value and the placing of the brake resistor.

page 20. - Selection guide for brake resistors

▪ Switch the line power to the device.

▪ At devices without programming unit the motor can be started with the device’s control elements according

to the default setting (or the required setting).

▪ At devices with programming unit check up and if necessary modify the preset parameters (rising times and

fall times, minimum and maximum frequency etc.)

▪ If possible, perform a trial start with unloaded motor:

• inspect the operation of the motor,

• in case of opposite direction of rotation interchange both phase wires of the motor to achieve the right

basic direction of rotation,

i

Interchanging the phase wires at the mains side does not influence the direction of

rotation!

• with changing the reference signal (e.g. potentiometer) scan the operating frequency band,

• try the functioning of the other controls (e.g. change of direction of rotation)

▪ Let the motor run with load!

▪ If necessary modify the parameters (rising times and fall times, minimum and maximum frequency etc.)

▪ In regulating mode tune the PID parameters

▪ If the settings are appropriate save the parameters!

Programmer’s manual - menu 11-1-2: Save parameters

Page 10

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 10 -

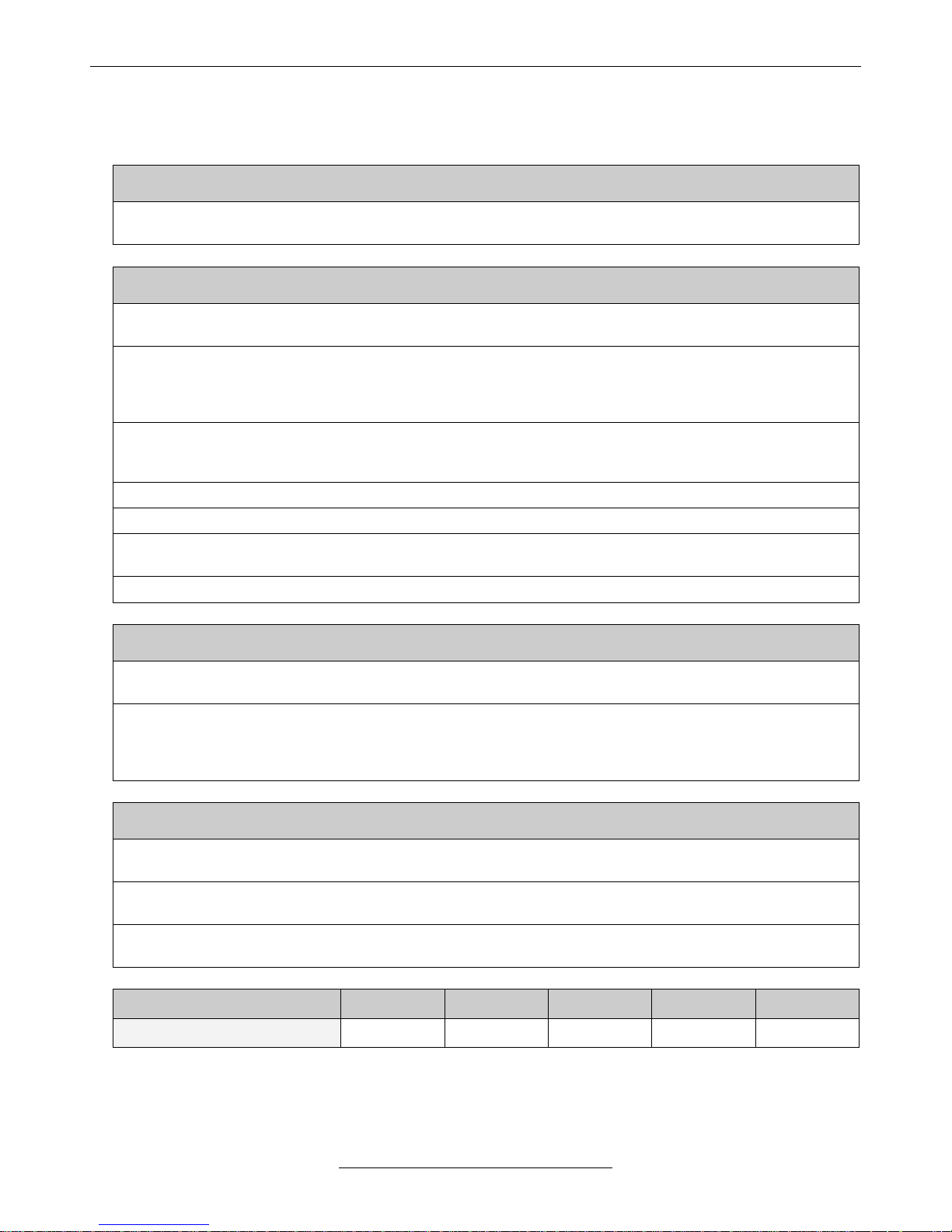

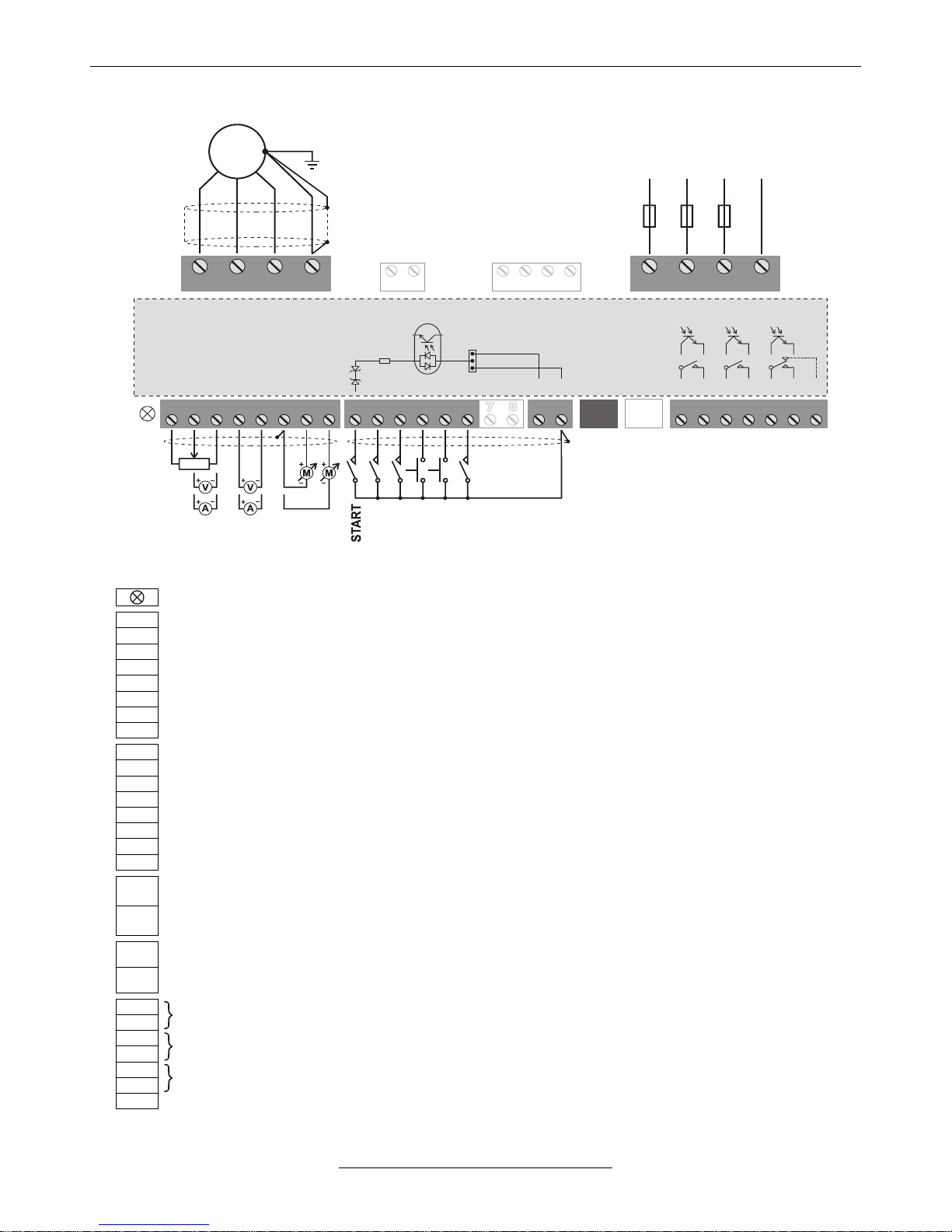

ASSIGNMENT AND CONNECTION OF THE V3D TERMINAL BLOCK

1 1 112 2 223 34 4

SA SD ST CST CSR SR

U V W PE L1 L2 L3 PE

3 x 400VAC

MOTOR

R BRAKE

LINE

2-10K

0÷10V

(0)4÷ 02 mA

REVERSING

JOGGING

ERROR A.

GND/D

M

~

F1 F2 F3

PNP

NPN

12V

12V

1K2

+24V/D

GND/D

Three-colour LED (green: On, yellow: Operate, red: Error)

SA1

+10 V potentiometer driving output (max. 6 mA) (+15 V option)

SA2

Analogue input 1: potentiometer (2÷10 kΩ), 0÷10 V (200 kΩ), 4÷20 mA (0÷20 mA) (200 Ω)

SA3

GND/A (reference point of the analogue inputs)

SA4

Analogue input 2: potentiometer (2÷10 kΩ), 0÷10 V (200 kΩ), 4÷20 mA (0÷20 mA) (200 Ω)

SD1

Digital input 1 * (factory setting: start switch)

SD2

Digital input 2 * (factory setting: reversing switch)

SD3

Digital input 3 * (factory setting: jogging)

SD4

Digital input 4 * (factory setting: error acknowledgement)

SD5

Option (Digital input 5 *, or IRE(A) input)

SD6

Option (Digital input 6 *, or IRE(B) input)

ST1

+24 V/D supply voltage output (max. 100 mA)

In case of PNP logic the common point of the digital inputs (K1, K2 jumpers)

ST2

GND/D (the reference point of the +24 V/D supply voltage output)

In case of NPN logic the common point of the digital inputs (K1, K2 jumpers)

CST

Terminal serial line connector (CAN option, e.g. Master/Slave)

CSR

Option (System serial line and/or CAN)

SR1

Digital output 1 ** (factory setting: ready)

SR2

SR3

Option (Digital output 2 **) (factory setting: operate)

SR4

* Switching level of the digital inputs: 0.6 to 2 mA

** Digital outputs: relay (max. 250 V AC / 1 A or 30 V DC / 0,5 A) or optocoupler (optional) (max. 30 V DC / 10 mA)

i

The analogue inputs 1 and 2 (or analogue inputs 3 and 4) are not equipped with own terminals. If the

configuration includes them, they are connected to the terminals of other functions (mostly to SD5 and 6)

Page 11

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 11 -

• Jumper settings

1 12 23 4 1 12 23 4

V3D frequency converter

AK1

AK2

A1

A2

K1

K2

CAN1

RS1

RS2

factory settings

AK1

Setting the analogue output 1 (option)

0÷10 V

(0) 4÷20 mA

AK2

Setting the analogue output 2 (option)

0÷10 V

(0) 4÷20 mA

A1

Setting the analogue input 1

0÷10 V

(0) 4÷20 mA

A2

Setting the analogue input 2

0÷10 V

(0) 4÷20 mA

K1

Setting the digital input 1÷4

NPN logic

PNP logic

mixed

setting is

allowed

K2

Setting the digital input 5÷6 (option)

NPN logic

PNP logic

CAN1

CAN line termination (200 Ω) (option)

Not terminated

Terminated

RS1

Terminal serial line termination (200 Ω) (option)

Not terminated

Terminated

RS2

System serial line termination (200 Ω) (option)

Not terminated

Terminated

• Connections of the incremental rotation speed encoder (IRE) (optional) and thermal protection of

the motor

1 1 12 2 23 3 54 4 6

SA SD ST CST CSR SR

V3D frequency converter

1 2

A

B

+24V

GND

IRE

PTC or

thermal

contact

The signal device can be NPN open collector type, TTL push-pull type or an output with an output voltage of 5 to 24 V.

Independently of the signal transmitter input, the further digital inputs can be operated with both negative and

positive logic circuitry.

The input selected for the connection of the PTC or the thermal contact has to be provided with “External error”,

“opening”.

Page 12

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 12 -

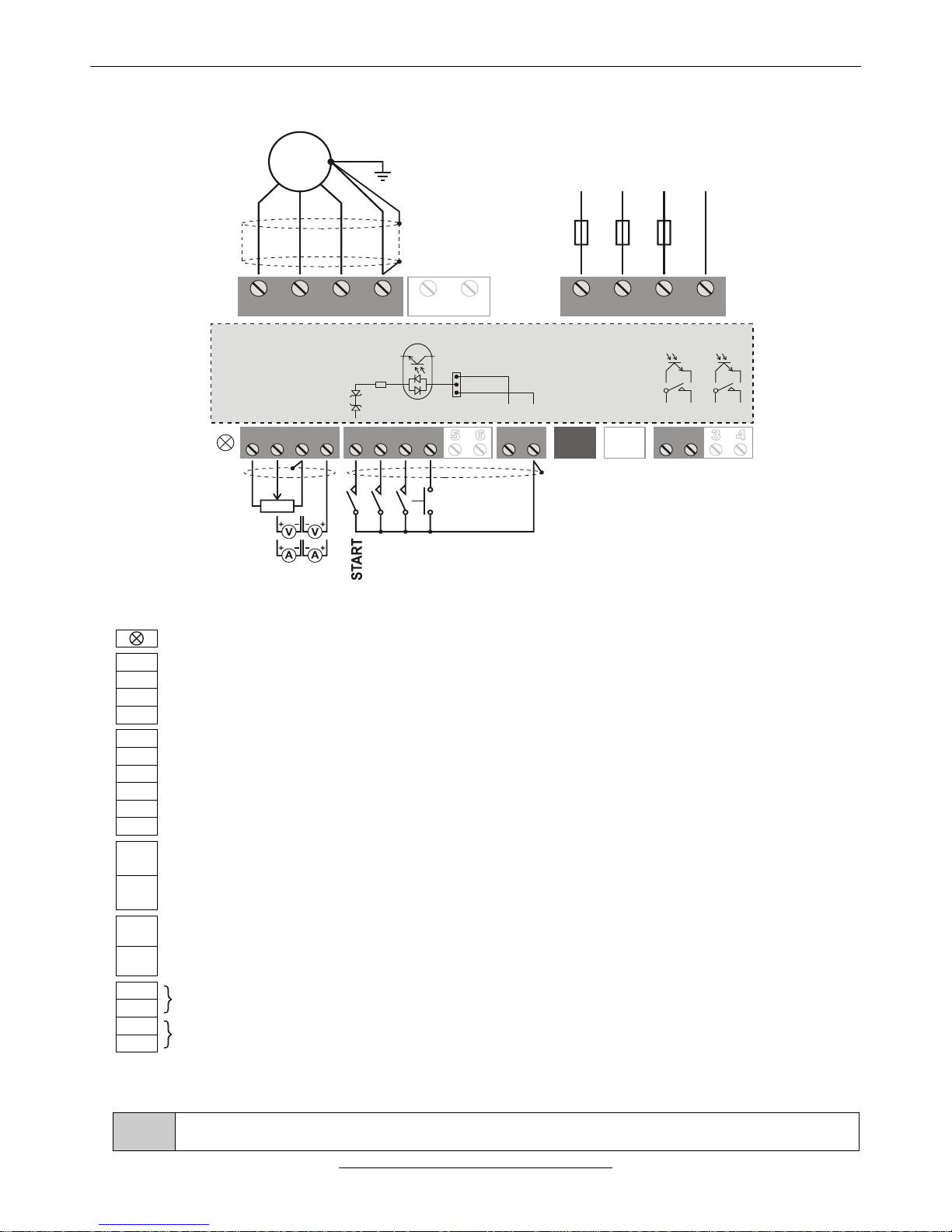

• Connecting the brake resistor (optional, in case of built-in brake chopper)

U V W PE L1 L2 L3 PE

V3D frequency converter

M

~

3 x 400VAC

F1 F2 F3

MOTOR

R BRAKE

LINE

The power on the brake resistor (Pnominal / 50 ÷ Pnominal) depends on the braking time and the duty factor.

Selection guide on page 20.

• Connecting a two-wire (4 ÷ 20 mA) remote transmitter

1 1 12 2 23 34 4

SA SD ST CST CSR SR

V3D frequency converter

A1

A1 jumper on the

lower two pins

remote transmitter

1 12 23 4

+24V/D

Page 13

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 13 -

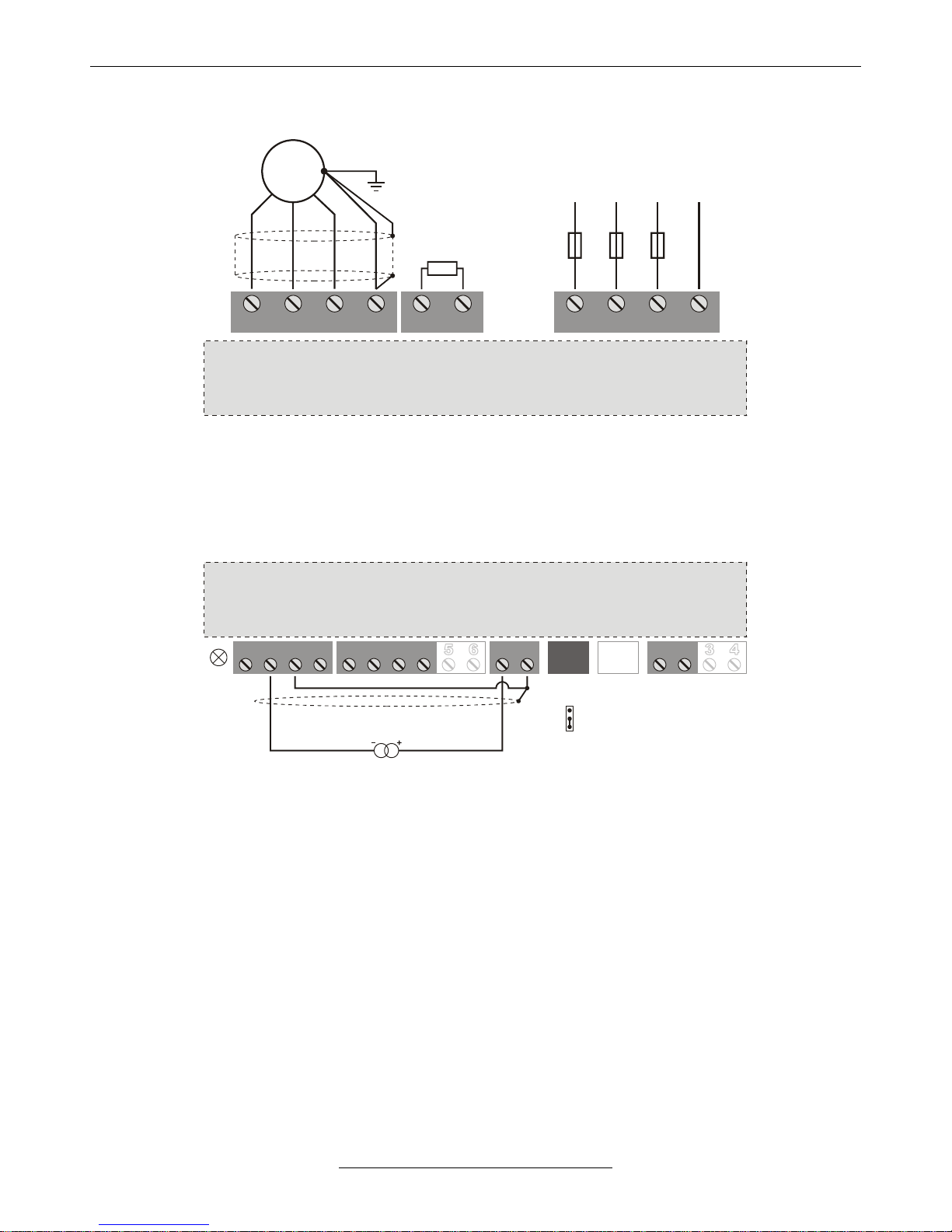

ASSIGNMENT AND CONNECTION OF THE VLD / VHD TERMINAL BLOCK

1 1 112 2 223 3 34 4 45 5 56 6 6 77 8

SA SD ST CST CSR SR

U V W PE L1 L2 L3 PE

MOTOR LINE

2-10K

0÷10V

(0)4÷ 02 mA

REVERSING

JOGGING

ERROR A.

GND/D

STOP

M

~

3 x 400VAC

F1 F2 F3

R BRAKE

FAN

3 x 400VAC

PNP

NPN

12V

12V

1K2

+24V/D

GND/D

Three-colour LED (green: On, yellow: Operate, red: Error)

SA1

+10V potentiometer driving output (max. 6 mA) (+15 V, +5 V option)

SA2

Analogue input 1 (+): potentiometer (2÷10 kΩ), 0÷10 V (130 kΩ), 4÷20 mA (0÷20 mA) (100 Ω)

SA3

Analogue input 1 (–): reference point (pl. GND/A)

SA4

Analogue input 2 (+): potentiometer (2÷10 kΩ), 0÷10 V (130 kΩ), 4÷20mA (0÷20 mA) (100 Ω)

SA5

Analogue input 2 (–): reference point (pl. GND/A)

SA6

GND/A (reference point of the analogue inputs and outputs)

SA7

Analogue 1 output: 0÷10V, (0)4÷20mA, (or Analogue input 3: 0÷10 V option)

SA8

Analogue 2 output: 0÷10V, (0)4÷20mA, (or Analogue input 4: 0÷10 V option)

SD1

Digital input 1 * (factory setting: start switch)

SD2

Digital input 2 * (factory setting: reversing switch)

SD3

Digital input 3 * (factory setting: jogging switch)

SD4

Digital input 4 * (factory setting: error acknowledgement)

SD5

Digital input 5 * (factory setting: external error), (or reference signal IRE(A) input option)

SD6

Digital input 6 * (factory setting: stop switch), (or reference signal IRE(B) input option)

SD7

Option (Digital input 7 *, or feedback signal IRE(A) input)

SD8

Option (Digital input 8 *, or feedback signal IRE(B) input)

ST1

+24 V/D supply voltage output (max. 100 mA)

In case of PNP logic the common point of the digital inputs (K1, K2, K3 jumpers)

ST2

GND/D (the reference point of the +24 V/D supply voltage output)

In case of NPN logic the common point of the digital inputs (K1, K2, K3 jumpers)

CST

Terminal serial line connector (CAN1 option)

CSR

Option (System serial line and/or CAN2)

SR1

Digital output 1 ** (factory setting: ready - closing / error - opening)

SR2

SR3

Digital output 2 ** (factory setting: operate - closing / stop - opening)

SR4

SR5

Digital output 3 ** (factory setting: brake control) (optional for VLD 5,5 ÷ 11)

SR6

SR7

Digital output 3: In case of a relay contact closed in rest position (option)

* Switching level of the digital inputs: 0.6 to 2 mA

** Digital outputs: relay (max. 250 V AC / 1 A or 30 V DC / 0,5 A) or optocoupler (optional) (max. 30 V DC / 10 mA)

Page 14

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 14 -

• Jumper settings

11 22 3 4 5 6 71 2 3 4 5 6 7 8

VLD / VHD frequency converter

K1

K2

K3

A1P

A1N

A2P

A2N

AK1

AK2

DIF1

DIF2

1 2 3 4 5 6

RS1

RS2

CAN2

CAN1

factory settings

A1P, A1N

Setting the analogue input 1

0÷10V

(0)4÷20mA

DIF1

Setting the analogue input 1

Normal

(- point: GND/A)

Differential

A2P, A2N

Setting the analogue input 2

0÷10V

(0)4÷20mA

DIF2

Setting the analogue input 2

Normal

(- point: GND/A)

Differential

AK1

Setting the analogue output 1

0÷10V

(0)4÷20mA

AK2

Setting the analogue output 2

0÷10V

(0)4÷20mA

KOZOS1

(K1)

Setting the digital input 1-4

NPN logic

PNP logic

mixed

setting is

allowed

KOZOS2

(K2)

Setting the digital input 5-6

NPN logic

PNP logic

KOZOS3

(K3)

Setting the digital input 7-8 (option)

NPN logic

PNP logic

CAN1

CAN1 line termination (200Ω) (option)

Not terminated

Terminated

CAN2

CAN2 line termination (200Ω) (option)

Not terminated

Terminated

RS1

Terminal serial line termination (200Ω) (option)

Not terminated

Terminated

RS2

System serial line termination (200Ω) (option)

Not terminated

Terminated

• High voltage terminal block

U V W PE L1 L2 L3 PE

MOTOR

LINE

VLD / VHD frequency converter

R BRAKE FAN

Ventilator terminal block (3 x 400 V AC, switched together with the cooling ventilators of the frequency converter).

Available for connecting external cooling ventilator (e.g. for cooling the control cabinet), for models VHD 45 to 250

(option)

At models VHD 90 to 250, PE will be connected to a grounding screw.

Page 15

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 15 -

• Connections of the incremental rotation speed encoder (IRE) (optional) and thermal protection of

the motor

1 1 12 2 23 34 45 5 76 6 87 8

SA SD ST CST CSR

VLD / VHD frequency converter

1 2 3 4 5 6 7

SR

A

B

+24V

GND

IRE

PTC or

thermal

contact

The signal device can be NPN open collector type, TTL push-pull type or an output with an output voltage of 5 to 24 V.

Independently of the signal transmitter input, the further digital inputs can be operated with both negative and

positive logic circuitry.

The input selected for the connection of the PTC or the thermal contact has to be provided with “External error”,

“opening”.

• Connecting the brake resistor (optional, in case of built-in brake chopper)

U V W PE L1 L2 L3 PE

MOTOR

LINE

VLD / VHD frequency converter

3 x 400VAC

F1 F2 F3

R BRAKE FAN

M

~

The power on the brake resistor (Pnominal / 50 ÷ Pnominal) depends on the braking time and the duty factor.

Selection guide on page 20.

Page 16

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 16 -

• Connecting a two-wire (4 ÷ 20 mA) remote transmitter

1 12 23 4 5 6 7 8

SA SD ST CST CSR

VLD / VHD frequency converter

A1P, A1N jumpers

on the lower two pins

remote transmitter

A1P

A1N

1 2 3 4 5 6 7

SR

1 2 3 4 5 6

+24V/D

• ±10 V analogue input (option)

1 12 23 4 5 6 7 8

SA SD ST CST CSR

1 2 3 4 5 6 7

SR

1 2 3 4 5 6

±10V GND

VLD / VHD frequency converter

Page 17

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 17 -

OPERATING THE CONVERTER

The source of the reference signal can be:

▪ external or front panel potentiometer,

▪ 0÷10 V,

▪ 4÷20 mA (0 ÷ 20 mA),

▪ front panel controlling terminal,

▪ external or front panel operating terminal (varying with the type),

▪ external or front panel programming terminal (varying with the type),

▪ RS 485 serial line,

▪ CAN bus,

▪ motor potentiometer

The source of the logical control signals can be:

▪ terminal blocks,

▪ front panel controlling terminal,

▪ external or front panel operating terminal (varying with the type),

▪ external or front panel programming terminal (varying with the type),

▪ RS 485 serial line,

▪ CAN bus

• Programming terminal

HIBA ÜZEM

ERROR RUN

ELFOGAD

ENTER

KIJELZŐ

DISPLAY

KILÉP

ESCAPE

KÚSZÁS

JOG

IRÁNY

DIR.

START STOP

▪ It comprises a 4x16 character display and 11 push buttons in

two groups.

Upper group: , , , , DISPLAY, ESCAPE, ENTER,

Bottom group: JOG, DIRECTION, START, STOP.

Operation of the push buttons of the upper (programming)

group:

The push buttons of the upper group permit entering and selecting

data in the Parameter setting mode and in the Display mode.

Operation of the push buttons of the bottom (control) group:

The push buttons of the bottom group permit controlling the

operation of the frequency converter if the terminal has been

preset for the control. The bottom four push buttons work

independently from the upper ones. Therefore if the terminal is

the preset operating control, the motor can be stopped or

started etc. even during entering data.

▪ Default setting in Display mode

(The structure of displaying can optionally be varied: in any line

any parameter can be displayed.)

In line 1: the three parts of the status are displayed:

- Motor status: Run / Stop,

- Dynamic status acknowledgement (e.g. I limit),

- Identification of the frequency converter (e.g. 1).

In line 2: Direction Forw. / Backw.

In line 3: Frequency (e.g. f=50.00Hz),

In line 4: Motor current (e.g. Imotor=6.4A)

▪ It can be used as a built-in unit or in casing as a stand alone unit.

• Operating from the computer

The frequency converter can be connected to the computer through RS485-T line using RS 232 / 485 or USB / RS

485 adapter (interface).

Here the TermOnly program permits setting the frequency converter from the computer and provides a user

interface with the same look as that of the programming terminal.

The ProContact program beyond handling the frequency converter permits reading out, modifying and archiving the

actual parameter set as well as reading out and archiving the event- and error log.

Both programs are available on CD as attachment of the adapter (interface) unit or can be downloaded

from www.procon.hu.

Page 18

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 18 -

• Operating terminal

ERROR RUN

ESCAPE ENTER

▪ This terminal allows programming the parameters of the

quick menu, displaying 2 parameters and generating

reference signal.

▪ Includes a 2x16 character display, 4 push buttons and displays

for error state and operation state.

▪ Reading in display mode: first row - the frequency, second row -

another parameter (e.g. voltage, current), which can be stepped

with the and arrows.

▪ Reading in programming mode: first row - the name of the

parameter along with its main menu ordinal number (e.g.

2 Control Tup), second row - the submenu ordinal number

and the value of the actual parameter (e.g. 1-1 5.00s), that

can be modified with the push buttons.

▪ In case of error at the end of the first line the ordinal number of

the error, in the second line the name of the error is displayed.

The error list can be stepped with the and arrows.

▪ The terminal can be used as a built-in unit (VHD), in casing as a

stand-alone unit or as an externally mounted unit (e.g. to the

door off the control cabinet).

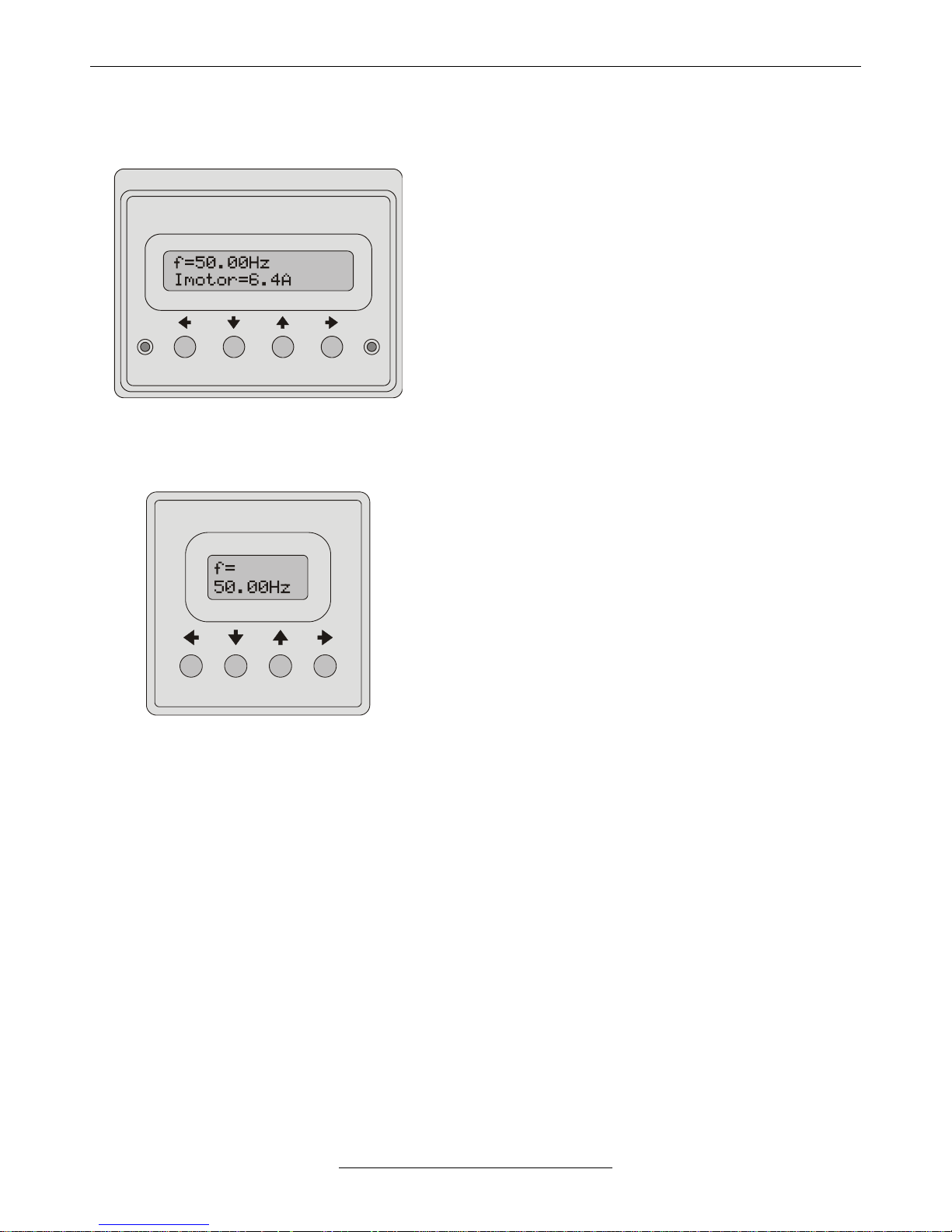

• Controlling terminal

ENTER

ESCAPE

▪ This terminal allows programming, displaying 1 parameter

and reference signal generation.

▪ Equipped with a 2x8 character display and 4 push buttons.

▪ Reading in display mode: first row - the name of a displayable

parameter (e.g. f=), second row - its value (e.g. 50,00Hz).

The display can be stepped with the and arrows.

▪ Reading in programming mode: first row - the parameter’s

ordinal number in the menu (e.g. 3-1-1), second row - (in case

of a variable parameter) the value of the actual parameter

(e.g. 5.00s), that can be modified with the push buttons.

▪ The terminal can be used built in the front panel of the

frequency converter only!

• Functions of the push buttons (operating and controlling terminal)

(Escape)

▪ Change between display mode and programming mode

▪ Parameter setting mode: shift the cursor to the left

▪ Repeated push: exit parameter setting mode without saving (until the cursor blinks)

▪ At error display: displaying the cause of the error

▪ Display mode: scrolling the displayed variables downward

▪ Programming mode: moving in the menu downward

▪ Parameter setting: decreasing the value or scrolling the selector switches downward

▪ With selected terminal motor potentiometer: decreasing the reference signal

▪ With enabled motor potentiometer start / stop: Stop

▪ Display mode: scrolling the displayed variables upward

▪ Programming mode: moving in the menu upward

▪ Parameter setting: increasing the value or scrolling the selector switches upward

▪ With selected terminal motor potentiometer: increasing the reference signal

▪ With enabled motor potentiometer start / stop: Start

(Enter)

▪ Programming mode: starting the parameter setting

▪ Parameter setting mode: shift the cursor to the right

▪ Repeated push: save parameter value (until the cursor blinks)

▪ Acknowledgement at error

Page 19

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 19 -

PROGRAMMING (operating and controlling terminal)

• Programming procedure

(Escape)

▪ Changing from display mode to programming mode

▪ Moving between the menu items

(Enter)

▪ Starting parameter setting

▪ Parameter setting

(Escape)

▪ Repeated push: save parameter value (until the cursor blinks)

or

(Enter)

▪ Repeated push: exit parameter setting mode without saving (until the cursor blinks)

• Quick menu

Submenu

Description, further submenus

Value, range

Default setting

Unit

Parameter - 1 -

2-1-1

control Tup

In default setting the time needed to reach fmax

starting from 0 Hz (in control mode).

0,05 - 3276,7

Depending on

type

s

Parameter - 2 -

3-1-1

control Tdown

In default setting the time needed to reach

f = 0 Hz starting from fmax (in control mode).

0,05 - 3276,7

Depending on

type

s

Parameter - 3 -

6-4

motor In

The durably permitted motor current.

0,5 - dep. on type

Depending on

type

A

Parameter - 4 -

8-1

f maximum

Maximum output frequency.

* default setting is 100 Hz for V3D frequency converters

without operating terminal

0,1 - 1050,0

50,0 *

Hz

Parameter - 5 -

8-2

f minimum

Minimum output frequency.

0,1 - 1000,0

1,0

Hz

Parameter - 6 -

7-2-1

U boost

Starting voltage given to the motor at standing

start.

0,5 - dep. on type

Depending on

type

V

Parameter - 7 -

10-14

active menu

Allows access to the whole menu system for the

controlling terminal.

After switching on/off automatically returns to

handling the quick menu.

quick

all

quick

DRIVING TECHNOLOGY SUPPLEMENTS

• 4x16 character display

▪ Displays the display of the programming terminal.

▪ The display can operate together with the terminal, since it only

receives data and does not answer through the serial line.

▪ The display can be used in built-in form (VHD) or as an

externally mounted unit (e.g. to the door of the control cabinet).

Page 20

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 20 -

• Potentiometer (2 ÷ 10 kΩ, linear)

Wiring:

1 2 3

Frequency conv.

terminal blocks

Potentio-

meter

SA 1

1

SA 2

2

SA 3

3

• Selection of the brake resistors at dynamic braking

The power on the brake resistor depends on the braking time and the duty factor. (Pnominal / 50 ÷ Pnominal)

The necessary power is determined by the braking time and the duty factor.

( see: Programing manual, support for dimensioning the brake resistor)

Frequency

converter type

Resulting

resistance

V3D 0.55 - 1.1

≥ 200 Ω

V3D 1.5 - 4

≥ 100 Ω

VLD 5.5

≥ 50 Ω

VLD 7.5 - 11

≥ 25 Ω

VLD 15

≥ 20 Ω

VLD 22

≥ 13 Ω

VHD 30 - 37

≥ 11 Ω

VHD 45 - 55

≥ 8 Ω

VHD 75 - 90

≥ 4,5 Ω

VHD 110 - 160

≥ 3,3 Ω

VHD 200

≥ 2,2 Ω

▪ 100 W wire-wound

resistors

(50÷200 Ω)

▪ 500 W wire-wound

resistors

(50÷100 Ω)

▪ 2÷4 kW cased brake

resistor modules

(12,5÷100 Ω)

VHD 250

≥ 1,6 Ω

8

CAUTION

The brake resistors are imposed to high voltages of 660 V DC.

The appliance must be installed and wired very carefully because of heat developing and for proper

electric shock protection.

For wiring use cables with heat-resisting coating.

MAINTENANCE

At normal operation the device needs no maintenance. Depending on the surroundings inspect regularly the

ventilators, and at models built in cabinet also the condition of the filter cartridge.

Inspect the screwed fastenings according to the local maintenance regulations, but at least once a year.

GUARANTEE AND REPAIR

The products come with a guarantee period of 24 months.

8

CAUTION

The guarantee covers normal operation only.

In case of improper storage, improper use or unauthorized intervention the guarantee terminates.

Repair will be accomplished both within the guarantee period and after in the manufacturer’s premises, the

appliance has to be transported there by the user.

Page 21

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 21 -

FREQUENCY CONVERTER SELECTION GUIDE

0.55

0.75

1.1

1.5

2.2

3

4

5.5

7.5

11

15

22

30

37

45

55

75

90

110

132

160

200

250

(kW)

F

H

I

J

TYPE

Output

power

[kW]

Nominal

current

[A]

Peak

current

[A]

Mass

[kg]

Physical dimensions [mm]

Fastening

screws

Width

Length

Height

Fastening

Three phase, 3 x 380 ÷ 440 V AC input

V3D 0.55

0.55

1.7 3 2

128

210

91

90 x 200

4 x M4

V3D 0.75

0.75

2.6

4

2.5

128

210

142

90 x 200

4 x M4

V3D 1.1

1.1

3.2

5

2.5

128

210

142

90 x 200

4 x M4

V3D 1.5

1.5

4.2 6 3

128

240

150

90 x 230

4 x M4

V3D 2.2

2.2

6 9 3

128

240

150

90 x 230

4 x M4

V3D 3

3

8

12 4 128

280

150

90 x 265

4 x M4

V3D 4

4

10

14 4 128

280

150

90 x 265

4 x M4

VLD 5.5

5.5

14

19 8 190

290

220

170 x 280

4 x M5

VLD 7.5

7.5

18

30

12

190

390

220

170 x 380

4 x M5

VLD 11

11

26

37

12

190

390

220

170 x 380

4 x M5

VLD 15

15

35

57

14

190

490

220

170 x 470

4 x M5

VLD 22

22

48

75

20

290

490

220

260 x 470

4 x M6

VHD 30

30

62

95

38

300

590

300

260 x 550

4 x M8

VHD 37

37

75

115

38

300

590

300

260 x 550

4 x M8

VHD 45

45

90

135

65

400

740

300

360 x 700

4 x M8

VHD 55

55

110

150

65

400

740

300

360 x 700

4 x M8

VHD 75

75

150

220

80

500

740

300

460 x 700

4 x M8

VHD 90

90

180

255

85

500

790

300

460 x 750

4 x M8

VHD 110

110

220

310

110

500

1100

335

460 x 900

4 x M10

VHD 132

132

260

360

115

500

1100

335

460 x 900

4 x M10

VHD 160

160

320

450

120

500

1100

365

460 x 900

4 x M10

VHD 200

200

400

540

120

500

1100

410

460 x 1040

4 x M10

VHD 250

200

500

670

125

500

1100

410

460 x 1040

4 x M10

Page 22

H - I - J FREQUENCY CONVERTERS INSTRUCTION MANUAL 0,55 ÷ 200 kW

- 22 -

PERIPHERAL EQUIPMENT SELECTION GUIDE

ITEM

E3D

V3D

VLD

VHD

3 x 400 V line voltage

Built-in mains noise suppressor

IP20 cabinet

IP54 cabinet

Analogue input 1 - 2

Analogue input 3 - 4

–

±10V analogue input

–

–

Analogue output 1 - 2

–

Digital input 1 - 4

Digital input 5 - 6

–

Digital input 7 - 8

–

–

Digital output 1

Digital output 2

Digital output 3

–

–

RS-485 serial line 1 (Terminal)

–

RS-485 serial line 2 (System)

–

USB / RS 485 interface

–

RS 485 / 485 interface (optical light cable type)

–

USB / RS 485 interface (optical light cable type)

–

CAN bus 1

–

CAN bus 2

–

–

Reception of incr. rotation speed encoder 1

–

Reception of incr. rotation speed encoder 2

–

–

Built-in dynamic brake

Brake resistor

Mains (input) choke

Output (motor) choke

Stand-alone programming terminal (4 x 16)

–

Built-in programming terminal

– – –

Stand-alone operating terminal (2 x 16)

–

Built-in operating terminal

– – –

External operating terminal

–

Built-in controlling terminal (2 x 8)

Built-in display (4 x 16)

– – –

External display

–

Built-in potentiometer

External potentiometer

Markings

Basic configuration

Option

– Not applicable

Page 23

Page 24

PROCON Hajtástechnika Kft.

H-1047 Budapest, Kisfaludy u. 4.

Tel./fax: +36 1 370 9699

+36 1 379 5387

e-mail: procon@procon.hu

info@procon.hu

Internet: www.procon.hu

Edition: April, 2018

I

II

III

IV

V

VIII

IX

X

XI

XII

XIII

XIV

XV

XVI

XVII

XVIII

XIX

XX

XXI

XXIII

XXII

B

a

r

o

s

s

u

.

V

á

c

i

ú

t

T

í

m

á

r

u

.

N

y

i

t

r

a

u

.

T

i

n

ó

d

i

u

.

P

e

r

é

n

y

i

Z

s

i

g

m

o

n

d

u

.

K

i

s

f

a

l

u

d

y

u

.

S

ö

r

é

t

g

y

á

r

u

.

S

e

m

m

e

l

w

e

i

s

u

.

L

a

b

d

a

r

ú

g

ó

u

.

L

a

b

d

a

v

e

r

ő

u

.

M

i

l

d

e

n

b

e

r

g

e

r

u

.

B

á

n

y

a

g

é

p

g

y

á

r

u

.

D

u

n

a

s

o

r

M

e

g

y

e

r

i

ú

t

Loading...

Loading...