PRO COMP SUSPENSION

K2079B/K2079BMX/K2079BP

56713B/56713BMX/56713BP

2009 Dodge 1500 Mega Cab/ 2500 4X4 6” Coil

Spring Lift kit

This document contains very important information that includes warranty information and instructions for

resolving problems you may encounter. Please keep it in the vehicle as a permanent record.

56713B/K2079B

Box 1 of 3-PN # 56713B/56713BMX-1

Revised

2.19.15

Part # Description Qty. Illus. Page

DC601-1 PITMAN ARM 1 - 15-10995 BUMPSTOP 2 3 7

90-6029 HARDWARE PACK:

Brake Line

15-10966 3/8” PLASTIC HOSE CLAMPS 4 - 13-20447 #10 X 1/2" HWH ZINC 4 - -

90-2359 LOWER CONTROL ARM 2 4,5 8,9

90-2361 UPPER CONTROL ARM:

90-6273 HARDWARE PACK:

Lower Control Arm

15-10979 BUSHINGS LOWER ARM 8 4 8

90-2101 SLEEVE: 7/8" X .635" X 2.618" 4 4 8

90-6274 HARDWARE PACK:

Upper Control Arm

15-11187 BUSHINGS LOWER ARM 8 4 8

90-2114 SLEEVE: .75” X .095" X 2.360" 4 4 8

90-6024 HARDWARE PACK:

Sway Bar

70-0371501500 3/8” x 1 1/2” USS Gr. 5 Bolt 2 7 11

70-03725001500 3/8” x 2 1/2” USS Gr. 5 Bolt 2 7 11

72-03700100512 3/8” USS LOCKNUT 4 7 11

73-03700030 3/8” SAE FLAT WASHER 4 7 11

73-03700042 3/8” USS HARDENED FLAT WASHER 2 7 11

90-6312 HARDWARE PACK:

SWAY BAR LINK

45359 HOURGLASS BUSHING 4 7 11

P-843 SPACER PACK 2 7 11

61150 3/8" SLEEVE 2 7 11

90-2039 SWAY BAR ADAPTER SLEEVE 2 7 11

90-1010 SWAY BAR END LINK 2 7 11

90-2357 DODGE SWAY BAR END LINK 2 7 11

13-90330 U-BOLTS:

9/16" X 3.65" X 13.5"

20-65302 HARDWARE PACK:

U-BOLT

9/16" WASHERS 8 B 15

9/16" NUTS 8 B 15

95-300D 3" ALUMINUM BLOCK 2 B 15

51255 SHIM KIT 1 - 90-6327 HARDWARE PACK:

SHIM KIT

90-3081 BUMP STOP BRACKETS 4 A 14

90-6223 HARDWARE PACK: 1 - 90-6242 HARDWARE PACK: 1 - -

600026 3/4" BUSHING 2 - P-1036 SLEEVE 2 - -

2

1 - -

15 degree bend

2 4,5 8,9

1 - -

1 - -

1 - -

1 - -

4 B 15

1 - -

1 - -

56713B/K2079B

Revised

2.19.15

Part # Description Qty. Illus. Page

90-6430 HARDWARE PACK: 1 - -

71-140802001000 14mm- 2.0 X 80mm HEX BOLT Gr. 10.9 2 - .140CNUCZ 14mm- 2.0 STOVER NUT 2 - 73-01410930 14mm FLAT WASHER PLATED 4 - -

13-90328 U-BOLTS:

5/8”-18– X 4.125” X 13.875

20-65471 HARDWARE PACK:

U-BOLT

1 - -

5/8" WASHERS 8 B 15

5/8" NUTS 8 B 15

90-1539 FRONT BRAKE LINE EXTENSION BRACKET 2 - 90-6299 HARDWARE PACK:

Front Brake Lines

70-0311001800 5/16” X 1" HEX BOLT GR. 8 2 - -

72-0531100816 5/16” NYLOCK NUT 2 - 73-03100034 5/16” HARDENED FLAT WASHER 4 - -

90-6654 HARDWARE PACK:

Upper Control Arm Bolt

70-0565501800 9/16" X 5 1/2" Gr. 8 HEX BOLT 1 - 72-056100816 9/16" STOVER NUT 1 - 73-05600034 9/16" HARDENED FLAT WASHER Gr. 8 2 - -

96-5779 PITMAN ARM TORQUE TOOL 1 6 10

HERNON427 RED THREAD LOCKER 1 - 90-6748 HARDWARE PACK:

Lower Control Arm: 2010 Model

15-10978 BUSHING LOWER ARM 4 4 8

90-8083 SLEEVE 2 4 8

4 B 15

1 - -

1 - -

1 - -

Box 2 of 3 PN # 56716B-2

91-7658 TRACK BAR DROP BRACKET 1 11 14

90-6874 HARDWARE PACK:

Track Bar Drop Bracket

90-4460 TRACK BAR NUT 1 11 14

90-8233 CROSSMEMBER SLEEVE : 3/4” X 1 1/2” 1 11 14

90-8231 5/8” TRACK BAR DROP BOLT SPACER:

90-8232 5/8” TRACK BAR DROP BOLT SPACER:

61734 7/16” SPLIT- SLEEVE 1 11 14

90-7882 7/16” WASHER 2 11 14

HERNON427 THREAD LOCKER: RED 1 - -

90-6852 HARDWARE PACK:

Track bar Cam Bolt

90-4412 CAM BOLT 1 11 14

90-7663 CAM BOLT WASHER 1 11 14

73-06200838 5/8” GR. 8 AN FLAT WASHER PLATED 1 11 14

72-062200816 5/8"-18 SAE GR. 8 STOVER NUT 1 11 14

90-6875 HARDWARE PACK:

Track Bar Drop Bracket

70-0624501800 5/8” X 4 1/2 HEX BOLTGR 8 1 11 14

72-062100816 5/8” STOVER NUT GR. C 1 11 14

73-06200034 5/8” HARDENED FLAT WASHER 2 11 14

70-0502501800 1/2” X 2 1/2" HEX BOLT GR 8 1 11 14

73-05000034 1/2” HARDENED FLAT WASHER 1 11 14

70-0433001800 7/16” X 3" HEX BOLT GR 8 1 11 14

72-043100816 7/16” STOVER NUT GR. C 1 11 14

73-04300034 7/16” HARDENED FLAT WASHER 1 11 14

3

1 - -

1 11 14

Long

1 11 14

Short

1 - -

1 - -

56713B/K2079B

Box 3 of 3 PN # 56713B-3

Revised

2.19.15

Part # Description Qty. Illus. Page

929592 FRONT SHOCK ABSORBER 2 2,7 7,11

929543 REAR SHOCK ABSORBER 2 - -

OR Box 3 of 3 PN # 56713BMX-3

MX6158 FRONT SHOCK MX-6 SHOCK ABSORBER 2 2,7 7,11

MX6100 REAR SHOCK MX-6 SHOCK ABSORBER 2 - -

OR Box 3 of 3 PN # 56708BP-3

ZX2009 FRONT PRO RUNNER SHOCK 2 - ZX2001 REAR PRO RUNNER SHOCK 2 - -

FOLLOWING PARTS ARE USED IN CONJUNCTION WITH THIS KIT.

THEY ARE PACKAGED AND MUST BE ORDERED SEPARATELY.

COIL SPRINGS: 56160 (Diesel) For 56713 6” Coil Spring kit

COIL SPRINGS: 56170 (Gas) For 56713 6” Coil Spring kit

Transmission Brackets:

90-5143B Transmission Drop Bracket: 2009 (Gas) 1

90-5152B Transmission Drop Bracket: 2009-2011 (6.7L Diesel) 1

OPTIONAL EQUIPMENT:

56711 Long Arm Upgrade Kit

56120 Double Shock Hoop Kit

4

56713B/K2079B

Revised

2.19.15

Introduction:

This installation requires a professional mechanic!

We recommend that you have access to a factory service manual for your vehicle to assist in the disassembly and

reassembly of your vehicle. It contains a wealth of detailed information.

Prior to installation, carefully inspect the vehicle’s steering and driveline systems paying close attention to the tie

rod ends, wheel bearing preload, pitman and idler arm. Additionally, check steering-to-frame and suspension-toframe attaching points for stress cracks. The overall vehicle must be in excellent working condition. Repair or replace all worn or damaged parts!

Read the instructions carefully and study the illustrations before attempting installation! You may save yourself a lot

of extra work.

Check the parts and hardware against the parts list to assure that your kit is complete. Separating parts according

to the areas where they will be used and placing the hardware with the brackets before you begin will save installation time.

Check the special equipment list and ensure the availability of these tools.

Secure and properly block vehicle prior to beginning installation.

ALWAYS

Use caution when cutting is required under the vehicle. The factory undercoating is flammable. Take appropriate

precautions. Have a fire extinguisher close at hand.

Foot pound torque readings are listed on the Torque Specifications chart at the end of the instructions. These are to

be used unless specifically directed otherwise. Apply thread lock compound where specified.

Please note that while every effort is made to ensure that the installation of your Pro Comp lift kit

is a positive experience, variations in construction and assembly in the vehicle manufacturing

process will virtually ensure that some parts may seem difficult to install. Additionally, the current trend in manufacturing of vehicles results in a frame that is highly flexible and may shift

slightly on disassembly prior to installation. The use of pry bars and tapered punches for alignment is considered normal and usually does not indicate a faulty product. However, if you are uncertain about some aspect of the installation process, please feel free to call our tech support department at the number listed on the cover page. We do not recommend that you modify the Pro

Comp parts in any way as this will void any warranty expressed or implied by the Pro Comp Suspension company.

Disconnect the negative battery cable when working on the vehicle.

wear safety glasses when using power tools or working under the vehicle!

Front end and head light realignment is necessary!

Speedometer and ABS recalibration will be necessary if larger tires (10% more than stock diameter) are installed.

Tire and wheel choice is crucial in assuring proper fit, performance, and the safety of

your Pro Comp equipped vehicle. For this application, a wheel not to exceed 10” in width with a

minimum backspacing of 3.25” must be used. Additionally, a quality tire of radial design, not

exceeding 35” tall X 13.5” wide (for the 5” spacer kit) or 37 tall X 13.5” wide (for the 6” coil kit)

is recommended. Violation of these recommendations will not be endorsed as acceptable by Pro

Comp Suspension and will void any and all warranties either written or implied.

SPECIAL TOOLS

PLEASE REFER TO YOUR SERVICE MANUAL FOR MORE INFORMATION.

A SPECIAL REMOVAL TOOL IS REQUIRED FOR SAFE REMOVAL OF THE TIE RODS.

A SPECIAL REMOVAL TOOL IS REQUIRED FOR SAFE REMOVAL O F THE COIL SPRINGS.

THESE TOOL MAY BE PURCHASED AT YOUR LOCAL DEALER.

YOU MAY BE ABLE TO RENT ANY OF THESE TOOLS AT YOUR LOCAL PARTS STORE.

5

Front Installation

56713B/K2079B

Revised

2.19.15

1. Prior to installing this kit. With the vehicle

on the ground, measure the height of your

vehicle. This measurement can b e re corded from the center of the wheel,

straight up to the top of the inner fender

RF: LF:

LR: RR:

lip. Record the measurements below.

2. Ensure that your work space is of adequate size and the work surface is level.

Set the emergency brake. Place your floor

jack under the front axle and raise vehicle.

Place jack stands under the frame rails

behind the front wheel wells and lower the

frame onto the stands. Remove the jack

and place blocks both in front of and behind the rear wheels. Remove the

wheels.

3. Remove any skid plates or debris shields

from the bottom of the vehicle.

4. Unbolt both brake line brackets from the

frame and front axle brackets to allow for

free movement of the suspension components.

5. Unbolt sway bar from end links.

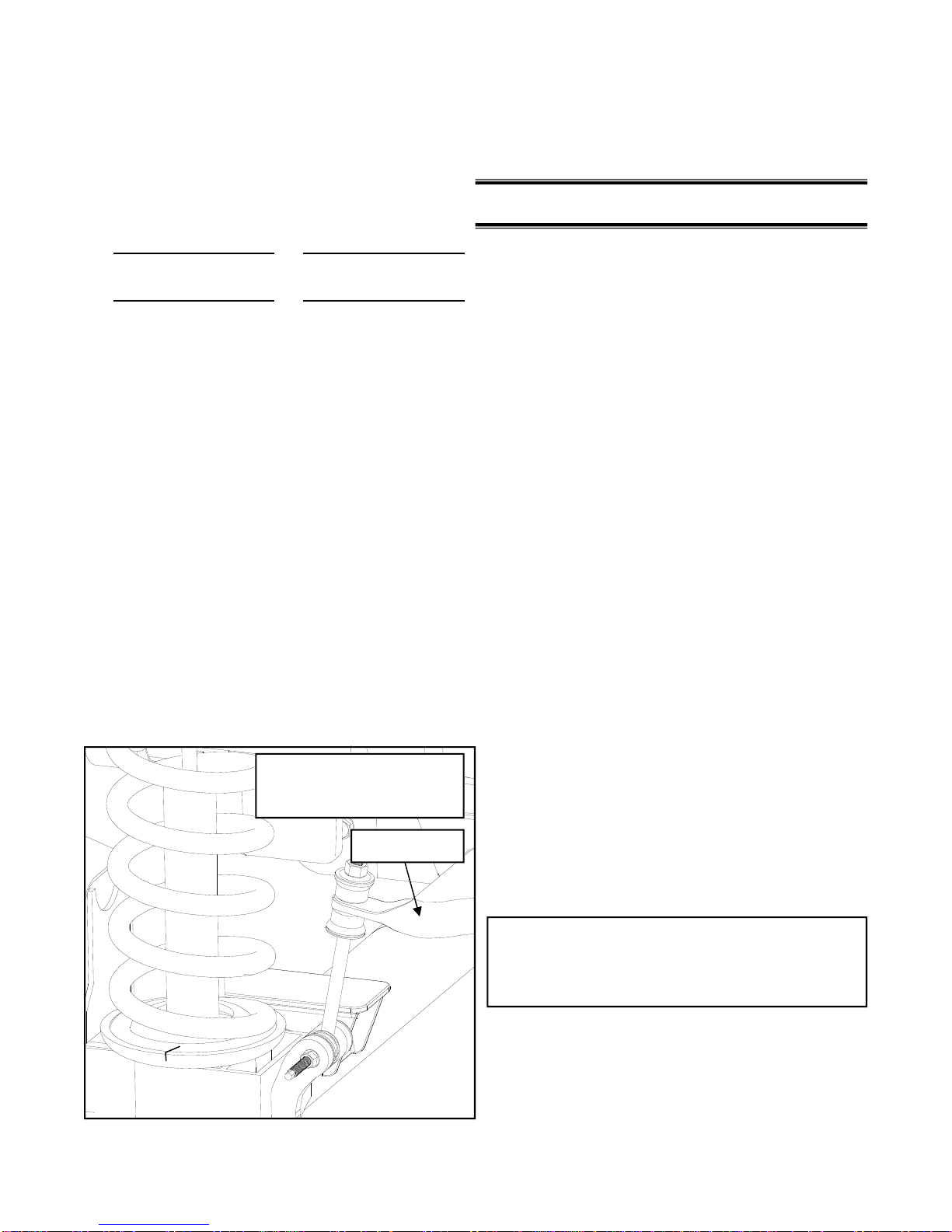

ILLUSTRATION 1

Factory set-up

SWAY BAR

6. Unbolt and remove the front track bar from

the vehicle. Save the OE bolts and hardware for reuse

Work on one side of the vehicle at a time.

7. Raise a jack under the coil springs to support the axle.

8. Compress coil spring with coil spring compressor tool.

9. Locate the top shock mount in the engine

compartment. Remove the nut, retainer

and grommet from the shock. See ILLUS-

TRATION 2.

10. Unbolt the shock absorber from the lower

mount bracket on the axle. Remove the

shock through the engine compartment.

11. Carefully lower the floor jack until coil

spring is free from the upper spring

pocket. Remove the coil spring.

12. Remove and set aside the upper rubber

isolator pad for the coil.

13. Repeat on other side of the vehicle.

14. Locate the front rubber bump stops,

mounted on the frame near the coils. Remove the bump stop from it’s pocket using

a pair of pliers. A back and forth action

will assist in working it out.

15. Place the new bump stops, PN 15-10995,

in existing bump stop pockets, as shown

in ILLUSTRATION 3. By using leverage

against the bottom of the bump stops,

force the bump stop into place (detergent

soap may help if the fit is tight).

Complete control arm replacement on

one side of the vehicle before removing

the control arm from the other side.

16. On the bottom of the lower control arm.

Mark the location of the index mark on the

adjustment cam-bolt and bracket, remove

the cam-bolt, washer and nut.

6

56713B/K2079B

Revised

2.19.15

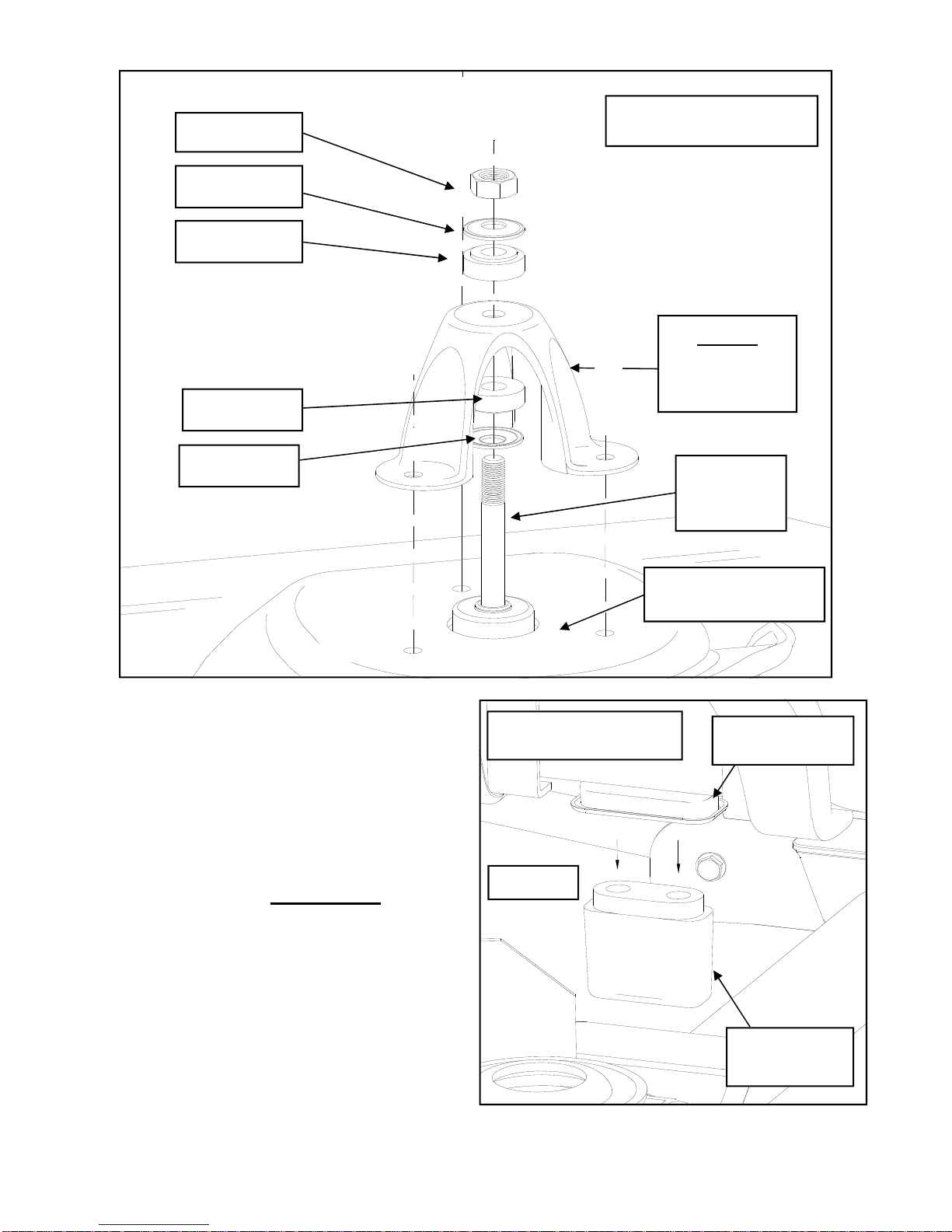

SHOCK NUT

RETAINER

GROMMET

GROMMET

RETAINER

ILLUSTRATION 2

DO NOT

UNBOLT UPPER

SHOCK

BRACKET

SHOCK

MX6104 or

927591

17. Next, remove the hardware from the frame

bracket holding the lower control arm in

place. Remove the control arm at this

time.

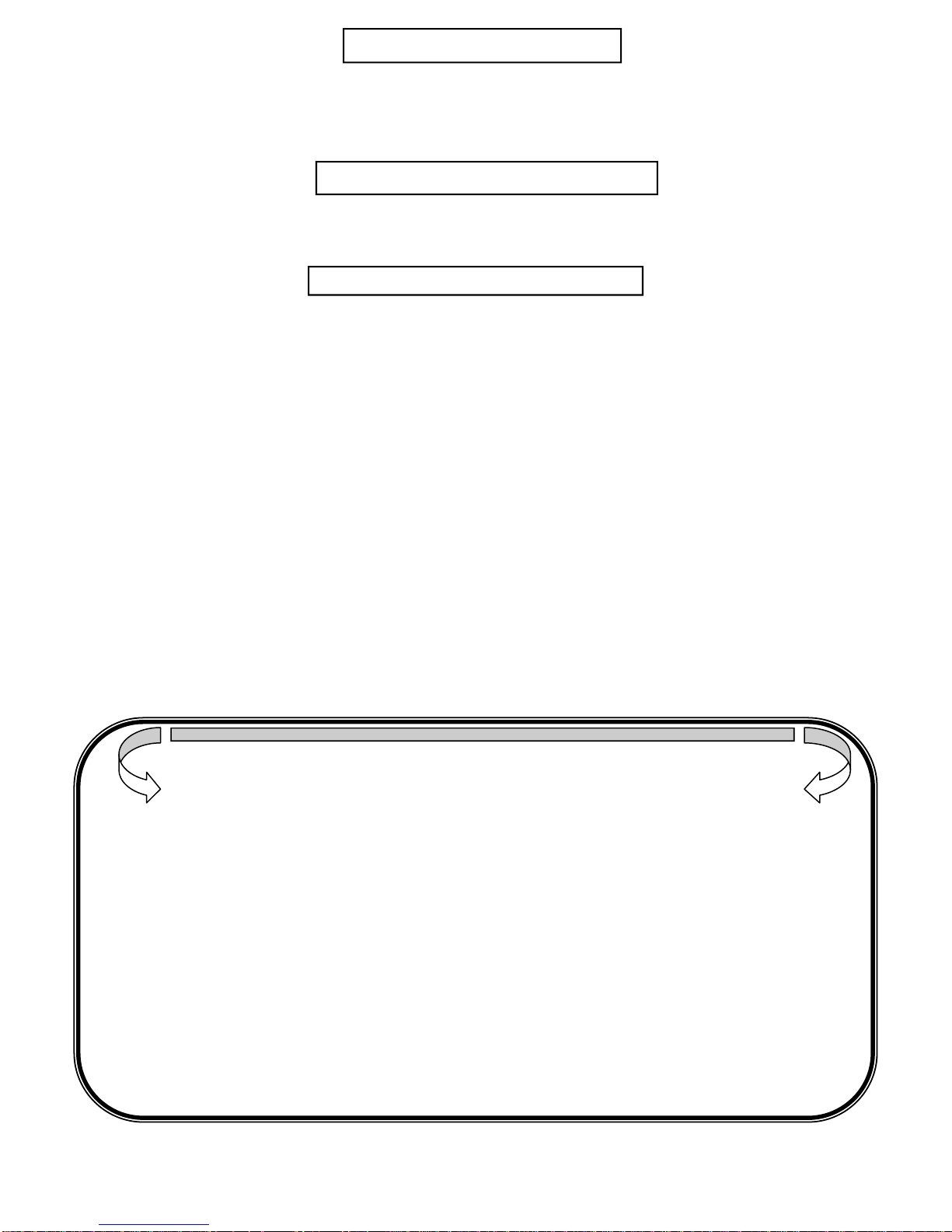

18. Install the bushings and sleeves from

hardware pack 90-6273 into the new lower

control arm PN 90–2359 as shown in IL-

LUSTRATION 4. Use the lubricant as

necessary. Install the supplied sleeves.

IMPORTANT!: 2010 models: Install

the bushings PN 15-10978 and sleeves

90-8083 from hardware pack 90-6748

into the new lower control arm front

arm axle end as shown in ILLUSTRATION 4.

19. Install the new lower control arm with the

OE hardware. Install a new factory cambolt and nut. It is not recommended to

reuse the original cam-bolt. Do not

UPPER COIL POCKET

ILLUSTRATION 3

FRAME

BUMPSTOP

POCKET

BUMPSTOP

15-10995

7

56713B/K2079B

Revised

2.19.15

UPPER CONTROL ARM

90-2361

LOWER CONTROL ARM

90-2359

SLEEVE 2 3/8”

90-2114

Front of Vehicle

ILLUSTRATION 4

BUSHING 15-11187 BUSHING 15-11187

BUSHINGS (TAPERED)

15-10979

SLEEVE

90-2101

BUSHINGS (TAPERED)

15-10979 2009 models or

15-10978 2010 models

torque fasteners at this time.

20. Remove the factory upper control arm existing hardware from the axle bracket and

frame bracket.

21. Remove the factory upper control arm.

22. Install the bushings and sleeves from

hardware pack PN 90-6274 into the new

upper control arms. Refer back to ILLUS-

TRATION 4. Install the supplied sleeve

90-2114.

23. Install the new upper control arm PN 902361 into the original mounting location

with the short bend to the rear of the

truck, the bend will face up. Refer to IL-

LUSTRATION 5

NOTE: Rotating the lower adjusting

cam-bolt may help installation.

24. Use the existing hardware to fasten the

upper control arm as shown in ILLUS-

TRATION 5. Do not torque at this time.

SLEEVE

90-2101 2009 models or

90-8083 2010 models

NOTE

: On V8 and diesel models the

exhaust may need to be removed on

the driver and passenger side. If so,

remove exhaust hanger bushings.

Undo clamp on the turbo or unbolt

from the header. Move exhaust out of

the way to get the control arm bolt in

and out. Remember to reinstall the exhaust to factory specifications.

NOTE: Some installers choose to

cut the head off the passenger side upper control arm bolt rather than remove

the exhaust. If you choose this method

use the replacement bolt from pack

(90-6654).

25. Repeat these procedures on the other

side of the vehicle.

26. Tighten but do not torque the control arms

at this time.

27. Remove the sector shaft Pitman arm retaining nut and save for reinstallation.

8

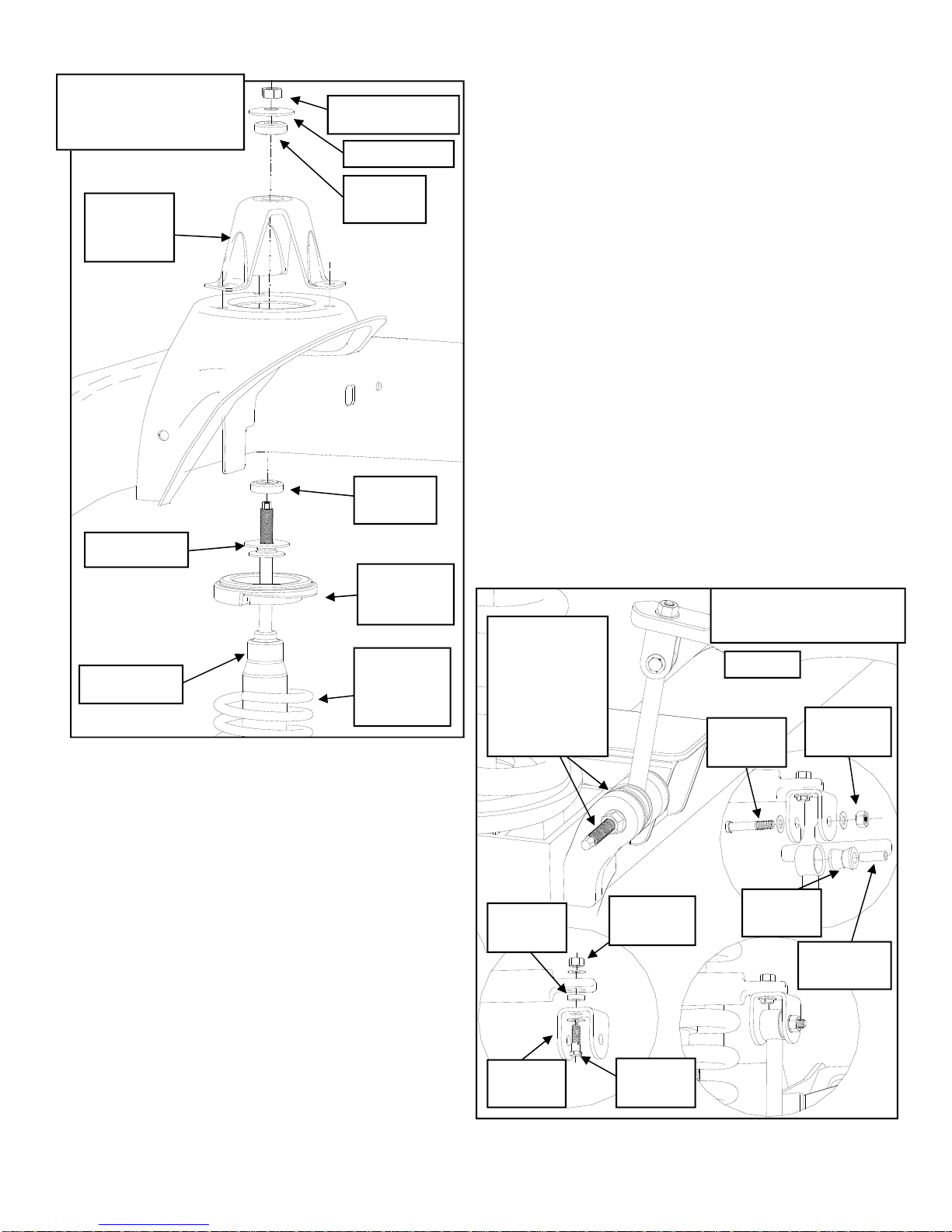

OEM

CONTROL ARM

90-2361.

to the rear of the

Bent end

truck

56713B/K2079B

Revised

2.19.15

ILLUSTRATION 5

PASSENGER SIDE

OEM BOLT

NEW OEM

OEM BOLT

CAM BOLT

CONTROL ARM

90-2359

Use a Pitman arm puller to remove the OE

pitman arm. The threads of the sector

shaft and the Pitman arm retaining nut

must be cleaned of all factory dry adhesive.

IMPORTANT!: THE ENTIRE INSTALLATION PROCESS MUST BE DONE WITH

HAND TOOLS TO ENSURE PROPER IN-

STALLATION. DO NOT USE IMPACT

TOOLS.

28. Install new pitman arm on sector shaft.

Oil the sector shaft threads to ensure a

proper torque reading. Install Pitman arm

retaining nut and tighten until snug.

29. Insert the key and unlock the steering

wheel.

30. Install the Pitman arm torque tool (96-

5779) to the Pitman arm using one of the

previously removed OE track bar bolt and

nut plate. See Illustration 6.

31. Secure the torque tool (96-5779) to the

existing hole in the track bar frame mounting pocket using one of the previously removed OE track bar bolt and nut plate.

See Illustration 6.

9

Pitman

Arm

56713B/K2079B

Revised

2.19.15

ILLUSTRATION 6

96-5779 Torque

Tool

Track Bar

Frame

Pocket

OE Track Bar

Bolt and Nut

Plate

NOTE: The steering wheel may

need to be turned in order for the hole

in the torque tool and the frame crossmember to line up. Once the bolts are

tightened the torque tool will align it’s

self properly.

NOTE: The use of the torque tool is

to keep the Pitman arm from moving

right or left, but allow for movement up

the sector shaft. If you do not have

this tool, a length of chain or a flat bar

with two holes is a suitable replacement.

32. Torque the Pitman arm retaining nut to

225 ft.-lbs.

33. With the torque tool (96-5779) still in place

remove the pitman arm retaining nut. The

threads of the sector shaft and the Pitman

arm retaining nut MUST

be cleaned using

brake cleaner or another suitable method

to remove the previously applied oil.

34. Use the entire supplied thread locking

compound to thoroughly cover the entire

surface of the threads on the Pitman arm

retaining nut.

35. Reinstall the Pitman arm retaining nut to

the sector shaft and torque to 225 ft.-lbs.

NOTE: Whether re-using the exist-

ing pitman arm retaining nut or replacing with a new nut, thread locking compound must be used.

36. Unbolt and remove the Pitman arm torque

tool (96-5779) from the vehicle.

NOTE: Save this Pitman arm torque

tool to add to your toolbox for any future

Pitman arm installations.

37. With the front axle supported with a jack,

disconnect and remove track bar. Lower

the front axle.

38. Install the factory spring isolator onto the

supplied Pro Comp coil springs (56160

diesel or 56170 gas). Carefully compress and install the Pro Comp coil

springs (56160 diesel or 56170 gas) into

the spring buckets. Raise the front axle

into place and make sure the coil spring is

indexed properly on the lower spring

perch. See ILLUSTRATION 7.

39. Install your new Pro Comp shocks (PN

929592, MX6158 or ZX2009) through the

coil spring from the engine compartment.

Install using the previously removed upper

hardware and the lower shock bolt.

Torque the lower bolt to 60 ft-lbs. See

10

56713B/K2079B

Revised

2.19.15

ILLUSTRATION 7

Coil Spring/Shock

Install

UPPER

SHOCK

BRACKET

RETAINER

SHOCK

ILLUSTRATION 7.

SHOCK NUT

RETAINER

SHOCK

BUSHING

SHOCK

BUSHING

COIL

ISOLATOR

56160 or

56170 COIL

SPRING

ers and nuts from 90-6024 to attach the

90-1010 to the sway bar end. Use the

3/8” X 2 1/2” hardware from 90-6024 to

attach the 90-2357 to the 90-1010. See

ILLUSTRATION 8.

43. Repeat on the other side of the vehicle.

44. Install the hose clamps and screws from

hardware pack PN 90-6029 to the brake

lines.

45. Bolt the front brake line extension brack-

ets PN 90-1539 to the original OE brake

line bracket holes, on the front axle brackets, using the previously removed OE

bolts.

46. Secure the OE brake lines to the brake

line extension brackets PN 90-1539 using

the supplied 5/16” X 1” bolt and hardware.

47. Install your wheels and tires and lower the

vehicle to the ground. Tighten the lug nuts

to 90 ft-lbs.

ILLUSTRATION 8

P-843

Spacer Pack

OR

Hardware

From Packs

90-6430 and

90-6242

Sway Bar End Link

Sway Bar

3/8” X 2

1/2” Bolt

3/8”

Hardware

40. Rotate the tie rod at the pitman arm 1/2

turn and attach it to the bottom of the new

pitman arm. Torque nut to 45 ft-lbs.

41. Assemble and install to the axle the

SWAY BAR LINK 90-2357 with the bushings and P-843 hardware from pack 90-

6312.

NOTE: Some models may have a

14mm lower sway bar hole. If so, use the

14mm bolts and hardware from pack 906430, lower bushings and sleeves from

pack 90-6242 on the bottom to attach the

links to the axle.

42. Use the 3/8” X 1 1/2” bolt and 3/8” wash-

End Link

11

90-2039

Spacer

90-1010

3/8”

Hardware

3/8” X 1

1/2” Bolt

45359

Bushing

61150 3/8”

Sleeve

56713B/K2079B

Revised

2.19.15

90-4460

Track Bar

Nut

90-8233

X-member

Sleeve

7/16” Nut

90-7882 7/16” Washer

5/8” X 4

1/2” Bolt

61734 7/16”

Split Sleeve

ILLUSTRATION 9

OE Crossmember

OE Frame

Mounting

Pocket

90-8231

Longer

Sleeve

90-8232

Shorter

Sleeve

5/8”

Hardware

Track Bar Drop Bracket

Side View

Front of Vehicle

90-8232

Shorter

Sleeve

90-8231

Longer

Sleeve

91-7658

Track Bar

Drop Bracket

90-7882

7/16”

Washer

1/2” X 2

1/2” Bolt

Cam

Hardware

7/16” X 3” Bolt

OE Track Bar

43. Torque the control arms to specifications

chart in the rear of the instructions.

44. Drill out the existing track bar mounting

hole in the frame to 5/8”.

45. Secure the track bar drop bracket (91-

7658) to the frame mounting pocket by

inserting the 5/8” X 4 1/2” bolt, from the

backside, 5/8” hardware and (90-8231

long sleeve, in between the OE frame

mounting pocket and the 90-8232

90-4412

Cam Bolt

OE Track Bar

short sleeve, in front of the OE frame

mounting pocket and the backside of

the track bar drop bracket 91-7658).

See ILLUSTRATION 9.

NOTE: Be sure to use thread locker

on this bolt. DO NOT the bolt torque

at this time.

46. Insert the 7/16” X .788” split sleeve

(61734) into the crossmember hole clos-

est to the driver side track bar mount.

5/8” X

4 1/2”

Bolt

91-7658

Track Bar

Drop

Bracket

12

56713B/K2079B

Revised

2.19.15

Insert the 3/4” X 1 1/2” crossmember

sleeve (90-8233) in the center hole in the

crossmember. See ILLUSTRATION 9.

47. Rotate the track bar drop (91-7658) up

into place and secure using 1/2” X 2 1/2”

bolt and track bar nut (90-4460) in the

center hole and the 7/16” X 3” bolt, 90-

7882 washer and hardware in the remaining hole. See ILLUSTRATION 9.

Torque the track bar drop mounting hardware according to the chart on page 15.

Torque the 5/8” X 4 1/2” bolt to 175 ft./

lbs.

NOTE: Be sure to use thread locker

on these bolts.

48. Reinstall the OE track bar using the previously removed OE hardware at the axle

end and the new adjustable cam bolt (90-

4412) and cam hardware from hardware

pack (90-6852) in the new frame mount

end (91-7658). Be sure to install the cam

with the head of the bolt facing the front

of the vehicle. Do not torque the cam

bolt at this time. See ILLUSTRATION 9.

49. With the vehicle on the ground, measure

from the outside edge of the tires to the

edge of the wheel well on the fenders.

Use the cam to center the axle under the

vehicle by rotating the cam until the

measurement is equal on both sides.

Torque the cam bolt to 150 ft./lbs.

50. See the driveshaft note on page 15. See

ILLUSTRATION 10.

51. With the vehicle on the ground, re-attach

sway bar end links. Torque down end

links and sway-bar bolts.

52. On both sides of the vehicle, check the

routing of the brake lines and the ABS

wire harnesses. There must be no pinching, rubbing, or stretching of any component. Use zip ties to secure these items

out of the way of the steering components. At full droop, cycle the steering

from lock to lock while observing the reaction of these components. Reposition

them if needed.

53. Recheck for proper installation and

torque, of all of the newly installed hardware and after any off road use.

54. Have your vehicle aligned.

55. Have your headlights adjusted.

56. After 100 miles recheck for proper torque

on all newly installed hardware.

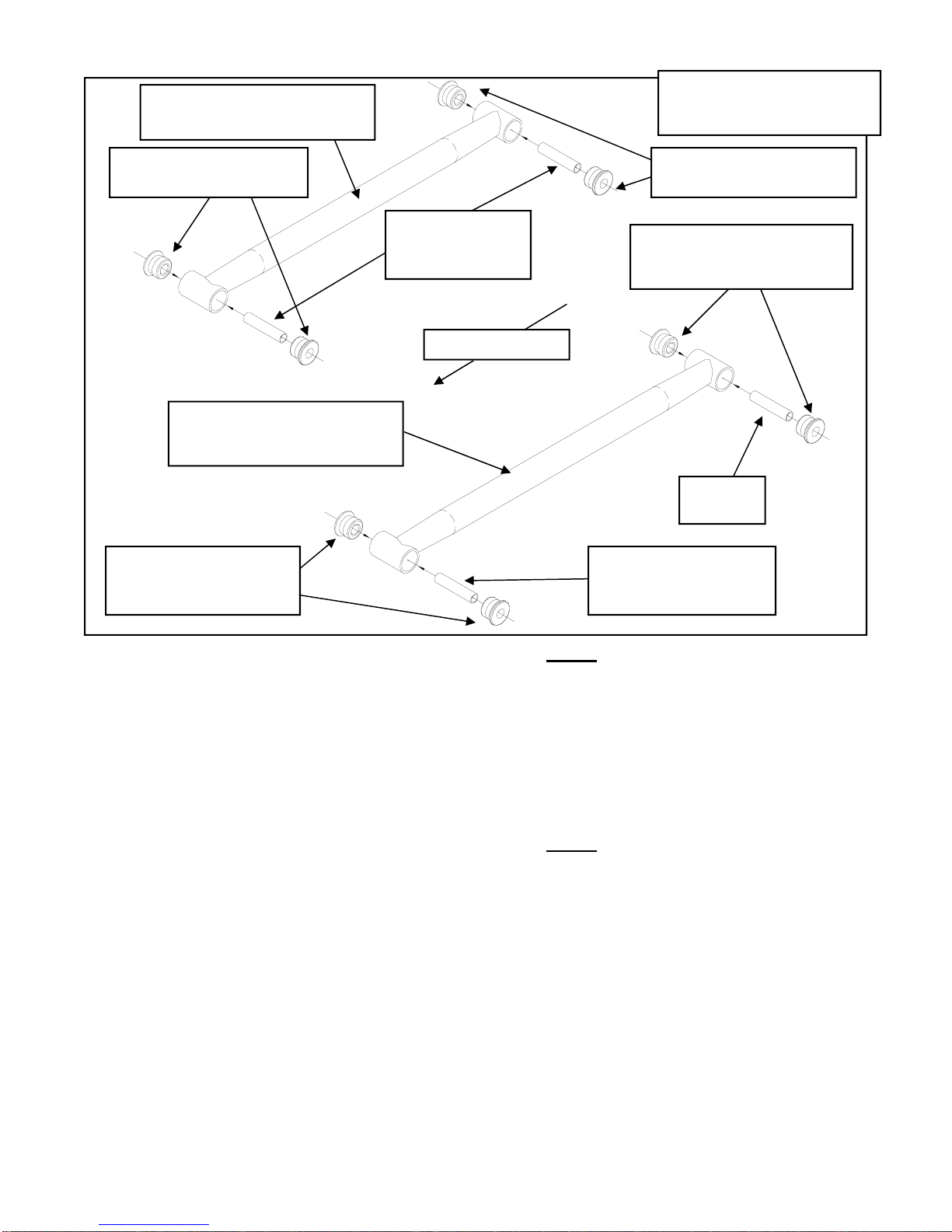

DRIVE SHAFT NOTE: WHILE THE TRUCK IS IN THE AIR SPIN THE FRONT DRIVE SHAFT. IF THE

FRONT DRIVE SHAFT BINDS AT FULL DROOP THE JOINT CAN BE TRIMMED. YOU CAN GRIND

THE OUT SIDES OF THE CLOSE JOINTS ON BOTH SIDES. YOU WILL ALSO NEED TO GRIND THE

INSIDE OF THE FAR JOINTS ON BOTH SIDES. USE THE ILLUSTRATION TO GUIDE YOU. YOU

SHOULD HAVE THE DRIVESHAFT BALANCED BY A QUALIFIED SHOP WHEN YOU ARE FINISHED.

GRIND INSIDE OF JOINT

ILLUSTRATION 10

driveshaft note

13

GRIND OUT SIDE

OF JOINT

GRIND INSIDE

OF JOINT

Rear Installation

56713B/K2079B

Revised

2.19.15

1. Block the front tires and raise the rear of

the vehicle. Support the frame with jack

stands forward of the rear springs.

2. Remove the wheels and tires.

3. Remove the shocks on both sides of the

vehicle. It may be necessary that you

slightly raise the axle to unload the

shocks for removal.

4. Remove the factory bump stop from the

frame.

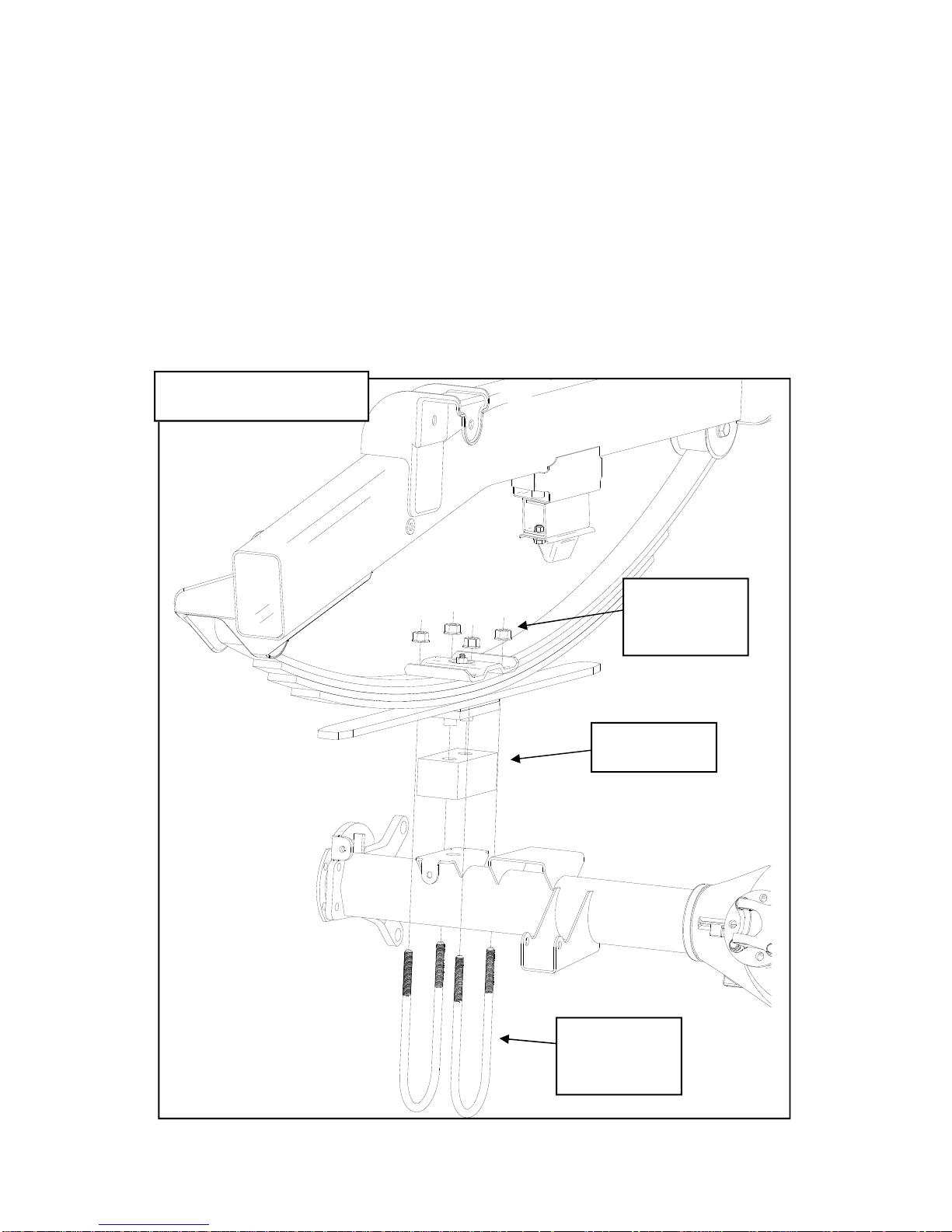

5. Fit 2 of the new BUMP STOP BRACKETS 90-3081 together as shown in Illus-

tration A. Then bolt to the frame using

the factory bolts.

6. Using the hardware

from pack 90-6223

bolt the bump stop to

the brackets. As

OE BOLT

shown in Illustration

A.

tory spring pack will have two metal

pins on the bottom, it may have a third

plastic pin in the center. To install the

lift block this plastic pin can be removed with a pair of pliers.

10. Secure the assembly with the U- bolts

13-90330 and new high-nuts and washers

from hardware pack 20-65302. Do not

tighten the U-bolts at this time. See Il-

lustration B.

NOTE: make sure the block sits flush

on the axle perch.

NOTE: If the vehicle is equipped with

a Dana 80 rear end, use U-bolts 13-90328

and hi-nuts 20-65471. The holes in the

ILLUSTRA TION A

7. Repeat the installation

on the other side of

the vehicle.

8. Loosen the U-bolts

on the passenger

side. Remove the Ubolts on the drive

side.

9. Install the lift block

(95-300D) on the axle

pad and use your floor

jack to raise the axle to

the spring. Apply a

slight amount of pressure with your floor

jack against the spring

pack and engage the

centering pins into the

locating holes at the

top of the lift block.

NOTE: The fac-

3/8” HARDWARE

FROM PACK 90-6223

BUMP STOP BRACKETS

90-3081

14

56713B/K2079B

Revised

2.19.15

spring plate will need to be drilled out to

accommodate the new larger U-bolts.

11. Repeat the installation on the other side

of the vehicle.

12.When the installation of the remaining

side is complete, torque the U-bolts to 85 ft.

lbs.

13.Install your new Pro Comp shocks

(929543, MX6100 or ZX2001) and torque

this hardware to 60 ft./lbs.

ILLUSTRATION B

14.Reinstall the wheels and tires and lower

the vehicle to the ground.

15.Recheck the wheel lug torque on all four

wheels at this time.

16.Recheck all hardware for proper installation and torque at this time.

17.After test driving: If there is a rear drive

line vibration you can install shim kit 51255

with hardware pack 90-6327. Try various

combinations until the vibration is eliminated.

20-65471 or

20-65302

95-300D

13-90330 or

13-90328

15

56713B/K2079B

X

X

Revised

2.19.15

Bolt Torque and ID

Deci mal S ystem Met ric Syst em

All Torque s in Ft. Lbs.

Bolt Size Grade 5 Grade8 Bolt Size Cl ass 9.8 Class 10.9 C lass 12.9

5/16 15 20 M6 5 9 12

3/830 45 M818 23 27

7/16 45 60 M10 32 45 50

1/2 65 90 M12 55 75 90

9/16 95 130 M14 85 120 145

5/8 135 175 M16 130 165 210

3/4 185 280 M18 170 240 290

T T

D D

L L

G

1/2-13x1.75 HHCS

D T L

G = Grade (Bolt Strength) P = Property Class (Bolt Strength)

D = Nominal Diameter (Inches) D = Nominal Diameter (Millimeters)

T = Thread Count (Threads per Inch) T = Thread Pitch (Thread Width, mm)

L = Length (Inches) L = Length (Millimeters)

X = Description (Hex Head Cap Screw) X = Description (Hex Head Cap Screw)

Grade 5 Grade 8

(No. of Marks + 2)

M1 2-1 .25 x50 HHCS

D T L

P

16

56713B/K2079B

Revised

2.19.15

MODIFICATIONS PAGE:

9.23.12: Removed 56713 BOM box-2 and added 56716 box-2 to the BOM. Changed Illustration #9

and the track bar installation text to reflect the part changes.

11.9.12: Removed 90-3561, 96-5068 and 90-6268 from BOM box-1.

12.7.12: Removed BF & BFR shocks from the text and from BOM box-3. Modified options box infor-

mation and front sway bar end link illustration #8.

1.10.13: Added the side view illustration to illustration 9.

7.31.13: Added “K” numbers to the cover box and shock PN’s to the text.

2.2.15: Changed Pitman arm PN from DC600-1 to DC601-1.

2.19.15: Changed Pitman arm retaining nut torque value to 225 ft./lbs.

17

Loading...

Loading...