2360 Boswell Road

Chula Vista, CA 91914

Phone 619.216.1444

Fax 619.216.1474

E-Mail tech@explorerprocomp.com

PRO COMP SUSPENSION

Suspension Systems that Work!

Part # 57289

Toyota 4WD IFS

Stage II

This document contains very important information that includes warranty information and instructions for

resolving problems you may encounter. Please keep it in the vehicle as a permanent record.

‘86-’95

57289

REVISED

2.1.06

Box 1 of 2-PN 57289-1

Part # Description Qty. Illus. Page

90-1290 Rear Crossmember 1 3-4

90-3375 Front A-Arm Drop Brkt. - Drvr. 1 3

90-3377 Front A-Arm Drop Brkt. - Pass. 1 3

90-3372 Rear A-Arm Drop Brkt. - Drvr. 1 3

90-3371 Rear A-Arm Drop Brkt. - Pass. 1 3

90-2154 Compression Strut - Drvr. 1 11

90-2155 Compression Strut - Pass. 1 11

90-6108 Bracket Pack Containing:

90-55089-5 Front Brake Drop Down Bracket 2 1

90-1280 Rear Brake Drop Down Bracket 1 12

90-1277 Center Differential Bracket 1 5

90-1282 Differential Drop Brkt. - Pass 1 6

90-1283 Differential Drop Brkt. - Drvr. 1 7

90-1278 Sway Bar Drop Down Brkt. - Pass. 1 10

90-1279 Sway Bar Drop Down Brkt. - Drvr. 1 10

90-1276 Rear Brake Cable Exten. Bracket 1 13

90-6125 Hardware Pack Containing:

70-0504001500 1/2” x 4” USS Gd 5 Hex Bolt 2 11

72-05000100512 1/2” USS Nyloc Nut 2 11

73-0505000030 1/2” SAE Flat Washer 4 11

90-6124 Compression Strut Bushing And Sleeve Pack

90-2109 Sleeves, 3/4” x .095 x 2.75 2 11

15-11148 Bushing - Red 4 11

90-6110 Hardware Pack Containing:

70-0622501500 5/8” x 2 1/2” USS Gd. 5 Hex Bolt 2 8

70-0624501500 5/8” x 4 1/2” USS Gd. 5 Hex Bolt 4 3

70-0502501500 1/2” x 2 1/2” USS Gd. 5 Hex Bolt 1 5

70-0502251500 1/2” x 2 1/4” USS Gd. 5 Hex Bolt 1 5

70-0501251500 1/2” x 1 1/4” USS Gd. 5 Hex Bolt 3 6-7

72-06200100512 5/8” USS Nyloc Nut 6

72-05000100512 1/2” USS Nyloc Nut 5

73-05000030 1/2” SAE Flat Washer 10

Loctite Tube Red 1

90-6111 Hardware Pack Containing:

70-0431001500 7/16” x 1” USS Gd. 5 Hex Bolt 8

70-0371001500 3/8” x 1” USS Gd. 5 Hex Bolt 7

70-0311001500 5/16” x 1” USS Gd. 5 Hex Bolt 6

72-04300100512 7/16” USS Nyloc Nut 8

72-03700100512 3/8” USS Nyloc Nut 7

72-03100100512 5/16” USS Nyloc Nut 6

73-04300030 7/16” SAE Flat Washer 16

73-03700030 3/8” SAE Flat Washer 14

73-03100030 5/16” SAE Flat Washer 6

90-6109 Bracket Bag Containing:

90-1301 Locating Washer, Toyota 8 3

90-2014 Spacer, .750” x .120 Wall x .250” 1 5

90-2022 Sleeve, .750 .510 ID x .870” 1 5

90-2136 Spacer Tube, .750” x .120 Wall x 1.220” 1 5

96-4026 Spindle Cone Spacer - Toyota 2 8

2

57289

REVISED

2.1.06

Part # Description Qty. Illus. Page

Box 2 of 2-PN 57289-2

90-4009 Spindle Adapter - Drvr. 1 8

90-4010 Spindle Adapter - Pass. 1 8

THE FOLLOWING PARTS ARE USED IN CONJUNCTION WITH THIS KIT, AND MUST BE ORDERED SEPARATELY.

318514 ES3000 SHOCKS (FRONT) 2

326506 ES3000 SHOCKS (REAR) 2

‘86-’89 4-RUNNER

‘86-’95 PICKUP

-OR326513 ES3000 SHOCKS (REAR)

‘90-’95 4-RUNNER

ONE OF THE FOLLOWING REAR KITS WILL BE USED IN CONJUNCTION WITH THIS BASE KIT:

57589 ‘86-’89 4-Runner with 2.5” Rear U-Bolts

‘86-’95 Pickup w/ 2.5” Rear U-Bolts

95-350 3 1/2” Rear tapered Blocks (9/16”) 2 14

13-90126 9/16” U-bolts (2-1/2” Wide) 4 14

13-10423-Z 9/16” U-bolt Nut 8 14

13-30330-Z 9/16” U-bolts Washers 8 14

-OR57789 ‘86-’89 4-Runner with 3.25” Rear U-Bolts

‘86-’95 Pickup w/ 3.25” Rear U-Bolts

20-830671-2 3 1/2” Rear Tapered Blocks (7/8” Pin)2 14

13-90321 9/16” U-bolts (3.25” Wide) 4 14

13-10423-Z 9/16” U-bolt Nut 8 14

13-30330-Z 9/16” U-bolt Washers 8 14

-OR57489 ‘90-’95 4-Runner

90-1204 Lower Link Relocating Bracket 2

90-1272 Upper Link Relocating Bracket 2

90-2130 Bump Stop Extension 2

90-1268 Trac Bar Relocating Bracket 1

90-2133 Sway Bar Extension 2

90-7210E Brake Hose 1

5242-1 Limiting Strap 2

PLEASE NOTE: ON SOME V6 MODELS, A HIGH MISALIGNMENT

DRIVESHAFT MAY BE REQUIRED IF THE ORIGINAL EQUIPMENT DRIVESHAFT BINDS AT THE CONSTANT VELOCITY JOINT AFTER THE LIFT KIT

IS INSTALLED.

3

57289

REVISED

2.1.06

Introduction:

♦ This installation requires a professional mechanic!

♦ We recommend that you have access to a factory service manual for your vehicle to assist in the

disassembly and reassembly of your vehicle. It contains a wealth of detailed information.

♦ Prior to installation, carefully inspect the vehicle’s steering and driveline systems paying close at-

tention to the tie rod ends, ball joints, wheel bearing preload, pitman and idler arm. Additionally,

check steering-to-frame and suspension-to-frame attaching points for stress cracks. The overall

vehicle must be in excellent working condition. Repair or replace all worn or damaged parts!

♦ Read the instructions carefully and study the illustrations before attempting installation! You may

save yourself a lot of extra work.

♦ Check the parts and hardware against the parts list to assure that your kit is complete. Separating

parts according to the areas where they will be used and placing the hardware with the brackets

before you begin will save installation time.

♦ Check the special equipment list and ensure the availability of these tools.

♦ Secure and properly block vehicle prior to beginning installation.

♦ ALWAYS wear safety glasses when using power tools or working under the vehicle!

♦ Use caution when cutting is required under the vehicle. The factory undercoating is flammable.

Take appropriate precautions. Have a fire extinguisher close at hand.

♦ Foot pound torque readings are listed on the Torque Specifications chart at the end of the instruc-

tions. These are to be used unless specifically directed otherwise. Apply thread lock

pound where specified.

retaining com-

♦ Please note that while every effort is made to ensure that the installation of your Pro

Comp lift kit is a positive experience, variations in construction and assembly in the

vehicle manufacturing process will virtually ensure that some parts may seem difficult to install. Additionally, the current trend in manufacturing of vehicles results in

a frame that is highly flexible and may shift slightly on disassembly prior to installation. The use of pry bars and tapered punches for alignment is considered normal

and usually does not indicate a faulty product. However, if you are uncertain about

some aspect of the installation process, please feel free to call our tech support department at the number listed on the cover page. We do not recommend that you

modify the Pro Comp parts in any way as this will void any warranty expressed or

implied by the Pro Comp Suspension company

.

Please Note:

• Front end and head light realignment is necessary!

• Speedometer and ABS recalibration will be necessary if larger tires (10% more than stock

diameter) are installed.

• Tire and wheel choice is crucial in assuring proper fit performance and the safety of your

Pro Comp equipped vehicle. For this application a wheel not to exceed 8 in width with a

maximum backspacing of 3.5 must be used. Diameter of wheel may be any of the following 3 choices, 15, 16, 17. Any other diameter, either smaller or larger, will not be endorsed

as acceptable by Pro Comp Suspension and will void any and all warranties, written or implied. In addition, a quality tire of radial design, not to exceed 33” tall x 12.5 wide is recommended.

4

INSTRUCTIONS:

57289

REVISED

2.1.06

PLEASE NOTE:

⇒ This is a mechanical change of 4”

in front, 3” in rear.

⇒ Front end alignment is needed after

installation, set to factory specs.

⇒ Do not adjust torsion bars; leave at

factory specs.

BEFORE YOU BEGIN:

⇒ Read the instructions and study

the illustrations before attempting installation. Separating parts according

to the areas where they will be used

and placing the hardware with the

brackets before you begin will save

installation time.

⇒ Check the parts and hardware

against the parts list to assure that

your kit is complete.

⇒ Secure and properly block vehicle

prior to beginning installation.

⇒ Always wear safety glasses when

using power tools.

FRONT:

1) Place floor jack under front axle and

raise vehicle. Place jack stands under frame

to support vehicle. Set emergency brake

and block rear wheels, in front and behind

tires. Remove front wheels.

2) Remove clip from front of brake line

and bracket. Cut bracket to center of hole to

remove brake line of bracket. Install new

brake line drop down bracket to OEM

bracket and put 3/8” flat washer on top. Insert 3/8” x 1” hex bolt through both brackets

and tighten with 3/8” nyloc nut on bottom.

You may need to reform line slightly. Be

sure not kink or cause any interference of

line. Reinstall OEM brake line clip to hose at

bracket. See ILLUSTRATION 1.

3) Remove the shocks, sway bar, and

bump stops on each side (4 bump stops total). Remove eccentric bolt and nut front and

rear. Remove front crossmember from

mounting bracket. On passenger side only,

cut the mounting bracket tabs off of the exist-

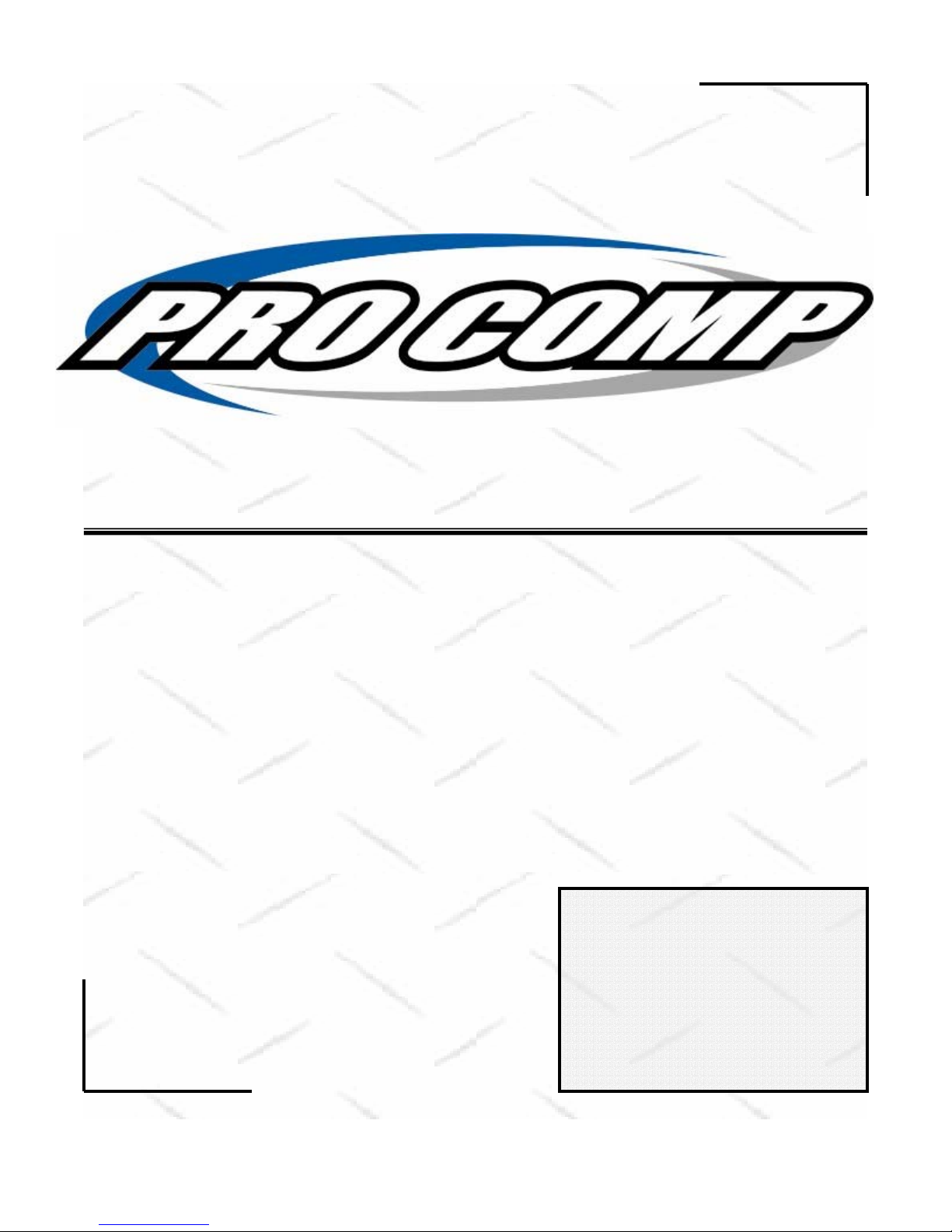

ILLUSTRATION 1

FLAT

WASHER, 3/8”

BRAKE

LINE DROP

DOWN

BRACKET

90-55089-5

HEX BOLT,

3/8” X 1” LG.

ILLUSTRATION 2

NYLOC

NUT,

3/8”

EXISTING

OEM

BRACKET

BRAKE

LINE

CUT HERE FOR

DIFFERENTIAL CLEARANCE

5

57289

REVISED

2.1.06

ILLUSTRATION 3

LOCATING

SPACER

90-1301

LOCK NUT, 5/8”

EXISTING

EXISTING

ECCENTRIC

BOLT

HEX BOLT, 5/8”

X 4-1/2” LG.

NOTE: BOLT

MUST BE INSTALLED AS

SHOWN.

EXISTING

A-ARM

DROP

BRACKET

A-ARM

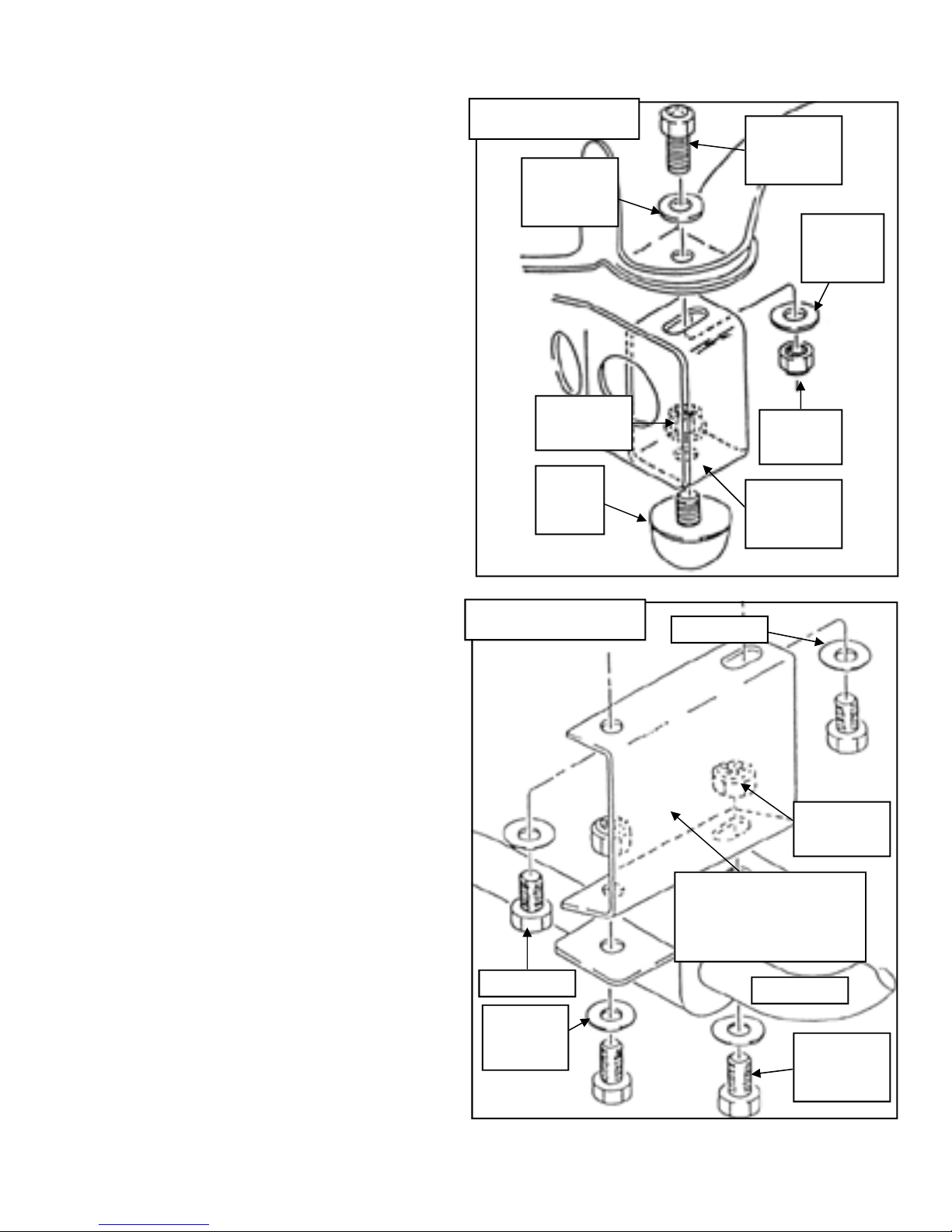

ILLUSTRATION 4

HEX BOLT,

7/16” X 1”

LG.

REAR CROSSMEMBER

90-1290

NYLOC

NUT,

7/16”

FLAT

WASHER

, 7/16”

FLAT

WASHER,

7/16”

FLAT

WASHER

, 7/16”

A-ARM

DROP

BRACKET

NYLOC

NUT, 7/16

FLAT

WASHER

, 7/16”

HEX

BOLT,

7/16” x

1” LG.

6

57289

REVISED

2.1.06

ing bracket between the bolt holes for differential clearance. See ILLUSTRATION 2.

4) Remove eccentric bolts (front and

rear) on front lower a-arm.

5) Install the 4 a-arm drop brackets into

OEM brackets. Use new 5/8” x 4-1/2” hex

bolts and 5/8” lock nuts, placing the a-arm

drop bracket locating spacers on the outside.

NOTE: Locating spacers will go in only

one way and all 8 spacers are the same.

Reinstall front crossmember with OEM bolts.

Hand tighten bolts until brackets are aligned.

See ILLUSTRATION 3.

6) Using a straight edge, line up bottom

bracket tabs with upper OEM tabs. Then

tighten bolts. Torque to 100 ft./lbs. (Not

crossmember bolts yet). Install OEM bolts

and nut into front crossmember to front differential. Tighten bolts and then tighten

crossmember bolts.

7) Install new rear crossmember using

7/16” x 1” bolts, 7/16” flat washers and ny-

loc nuts. Torque to 45 ft./lbs. Using a

straight edge, align upper tabs with lower

tabs and tighten bolts. Torque to 100 ft./lbs.

See ILLUSTRATION 4.

8) Install lower a-arms into lower a-arm

brackets. Reinstall OEM eccentric bolts with

hole in OEM cam washers at bottom. Install

OEM nuts and tighten nuts. NOTE:

Tighten nut, not bolt because cam will not

turn inside of tabs. Torque to 103 ft./lbs.

Refer back to ILLUSTRATION 3, if necessary.

9) Lower differential (keep steady so not

to pull out front driveshaft). Install center differential bracket (90-1277) at rear of front

differential as shown in ILLUSTRATION 5.

a) Install the 1/4” spacer tube at rear

lower mounting between differential and

ILLUSTRATION 5

HEX BOLT,

1/2” X 2-1/2”

LG.

FLAT

WASHER,

1/2”

SPACER

90-2022

CENTER

DIFFERENTIAL

BRACKET 90-1277

NYLOC

NUT, 1/2”

SPACER

90-2014

ILLUSTRATION 6

HEX BOLT,

1/2” X 11/4” LG.

EXISTING OEM

BOLT

(USE LOCTITE)

HEX BOLT,

1/2” X 2-1/4”

LG.

F

O

T

N

O

R

F

PASSENGER SIDE

DIFFERENTIAL

DROP BRACKET

90-1282

NYLOC

NUT, 1/2”

O

T

N

O

R

F

SPACER

90-2136

EXISTING

L

C

I

H

E

V

FLAT

WASHER

, 1/2”

C

I

H

E

V

F

E

E

L

7

57289

REVISED

2.1.06

bracket. Install existing OEM bolts

through bracket, spacer and into the two

bottom holes (with loctite). Torque to 70

ft./lbs.

b) Install 1-1/8” spacer tube at rear

of upper OEM rubber mount with 1/2” x

2-1/2” hex bolt, 1/2” flat washer and 1/2”

nyloc nut. Torque to 70 ft./lbs.

c) Install 3/4” spacer tube at rear of

upper OEM rubber mount with 1/2” x 2-

1/4” bolt, 1/2” flat washer and 1/2” nyloc

nut. Torque to 70 ft./lbs.

10) Install passenger side differential

drop bracket using 1/2” x 1-1/4” hex bolt

with 1/2” flat washer and nyloc nut into

upper hole of OEM rubber mount. Wide

part of bracket should be at bottom with

hole towards front, as shown in ILLUSTRATION 6. Reinstall OEM bolt through

bracket and into side of differential (using

loctite). Torque to 70 ft./lbs.

11) Install driver side differential

drop bracket using OEM bolts in two

bottom holes (using loctite). Use 1/2” x

1-1/4” hex bolts, 1/2” flat washers and

1/2” nyloc nuts in two upper holes.

Torque to 70 ft./lbs. See ILLUSTRATION 7.

12) Remove tie rods from steering

knuckles. Remove two bolts on back

side of spindle which hold the metal

bracket for the brake hose.

13) Support lower a-arm with floor

jack and separate upper ball joint from

spindle. Using file, file corners off of

spindle to contour with bottom of new

spindle adapter so that the bottom of

the new spindle seat surface is in contour with OEM spindle top surface.

Clean out hole on top of steering

knuckle (spindle).

NYLOC NUT, 1/2”

EXISTING

ILLUSTRATION 8

EXISTING

TAPERED

SPINDLE

SLEEVE

96-4026

HEX

BOLT, 5/8”

X 2-1/2”

E

L

C

I

H

E

V

F

O

T

N

O

R

F

EXISTING

(USE LOCTITE)

FLAT WASHER, 1/2”

PASSENGER SIDE SHOWN

ILLUSTRATION 7

DRIVER SIDE

DIFFERENTIAL

DROP BRACKET

90-1283

FLAT

WASHER, 1/2”

HEX BOLT,

1/2” X 1

1/4” LG.

UPPER

BALL

JOINT

LOCK

NUT, 5/8”

ADAPTER

SPINDLE

90-4010

90-4009

EXISTING

(USE

LOCTITE)

8

57289

REVISED

2.1.06

14) Insert tapered spindle sleeve with

small end going downward, install 5/8” x 2-

1/2” hex bolt and 5/8” lock nut as shown in

ILLUSTRATION 8. Torque to 100 ft./lbs.

15) Referring again to ILLUSTRATION 8,

reinstall brake hose bracket to new spindle

with OEM bolts (using loctite). Torque to

120 ft./lbs. Insert spindle into upper ball

joint; tighten. Torque to 105 ft./lbs. Reinstall

the rod. Torque to 67 ft./lbs. Reinstall all

cotter pins.

16) File down front bump stop lip on each

side of front for shock clearance. Install new

long shocks and tighten.

17) Install stock bump stop as shown in

ILLUSTRATION 9 using the 3/8” x 1” hex

bolt, 3/8” flat washer and 3/8” nyloc nut.

Repeat on other three bump stops.

18) Reinstall sway bar with the two sway

bar drop down brackets using OEM bolts

and nuts in top holes, adding a 5/16” flat

washer to the OEM flat washers; tighten.

Install sway bar to bottom of drop down

bracket using 5/16” x 1” hex bolts, 5/16” flat

washers and 5/16” nyloc nuts; tighten. See

ILLUSTRATION 10. (Driver side, use first

forward round hole and rear slotted hole with

slant downward, open side inward. Passenger side, use first slotted hole and rear round

hole with slant downward, open side inward).

Tighten sway bar bracket bolts and sway bar

pins in a-arm.

19) Install lower end of the compression

strut into the tabs located on the a-arm drop

brackets using the bushings and hardware

provided. Install the upper compression strut

mount, as shown in ILLUSTRATION 11. Using existing hardware.

20) Install the front wheel and lower the

vehicle.

ILLUSTRATION 9

FLAT

WASHER,

3/8”

EXISTING

NUT

STOCK

BUMP

STOP

ILLUSTRATION 9

EXISTING

FLAT

WASHER,

5/16”

HEX BOLT,

3/8” X 1”

LG.

FLAT

WASHER

, 3/8”

NYLOC

NUT, 3/8”

A-ARM

DROP

BRACKET

EXISTING

NYLOC

NUT, 5/16”

SWAY BAR DROP

DOWN BRACKET 901279 (DRIVER)

90-1278 (PASSENGER)

SWAY BAR

HEX BOLT,

5/16” X 1”

LG.

9

A-ARM

DROP

BRACKET

FLAT

WASHER,

1/2”

57289

REVISED

2.1.06

ILLUSTRATION 11

NYLOC

NUT, 1/2”

COMPRESSION STRUT

90-2155 (PASS.)

90-2154 (DRVR).

SLEEVE

90-2109

HEX BOLT,

1/2” X 4” LG.

BUSHING

15-11148

NOTE:

⇒ Measure from center of eccentric

adjustment bolt to ground to ensure

proper height.

⇒ On alignment, both sides inner and

outer tie rods may need to be pulled

out of adjusting sleeve and cut 1/2” off

tie rod ends so proper adjustment can

be achieved.

⇒ After installation is complete, dou-

ble check that all nuts and bolts are

tight. (Do not retighten nuts and bolts

where loctite was used). Recheck periodically.

F

PASSENGER SIDE

R

O

N

T

O

F

V

E

H

I

C

L

E

10

REAR INSTALLATION:

REAR: 86-89 4-Runner

86-95 Pickup

1) Place floor jack under rear axle and

raise vehicle. Place jack stands under frame

to support vehicle. Set emergency brake and

block front wheels, in front and behind tires.

Remove wheels and shocks.

2) Pull out brake line clip at rear brake

hose bracket. Bolt rear brake line drop down

bracket to existing bracket using 3/8” x 1”

hex bolt, 3/8” flat washer and 3/8” nyloc nut;

tighten. Install brake line into lower bracket

hole and reinstall OEM brake line clip. Refer

to ILLUSTRATION 12.

3) Unbolt brake equalizer arm bracket

from axle. Install rear brake cable extension

to axle with OEM bolts and tighten. Mount

equalized cable bracket to top of extension

using 5/16” x 1” hex bolts and 5/16” nyloc

nuts and tighten. See ILLUSTRATION 13.

4) Loosen emergency cables by removing

cotter pin, pulling pin out from back side of

brake backing plate at adjuster.

5) Remove u-bolts, lower axle and install

3 1/2” tapered blocks with tapered end towards transmission, as shown in ILLUSTRATION 14. Install new u-bolts, washers and

nuts and tighten. Reinstall emergency brake

cable, keeping cable under spring.

6) Install new longer shock absorbers.

7) Install the rear wheels and lower the

vehicle.

NOTE:

⇒ After installation is complete, dou-

ble check that all nuts and bolts are

tight. (Do not retighten nuts and bolts

where loctite was used).

ILLUSTRATION 12

NYLOC

NUT, 3/8”

REAR BRAKE LINE

DROP DOWN

BRACKET 90-1280

BRAKE LINE

⇒ Recheck periodically.

FLAT

WASHER

, 3/8”

ILLUSTRATION 13

NYLOC

NUT, 5/16”

EXISTING

HEX BOLTS

57289

REVISED

2.1.06

HEX

BOLT,

3/8” X 1”

LG.

HEX BOLT,

5/16” X 1” LG.

REAR

BRAKE

CABLE

EXTENSION

90-1276

11

57289

REVISED

2.1.06

TORQUE SPECIFICATIONS:

A-Arm Drop Bracket Bolts............... 100

ft./lbs.

Crossmember Bolts........................ 45

ft./lbs.

Eccentric Bolts.............................. 103

ft./lbs

Center Differential Bolts................ 70

ft./lbs.

Pass. Differential Brkt. Bolt........... 70

ft./lbs.

ILLUSTRATION 14

Drvr. Differential Brkt. Bolt........... 70

ft./lbs.

Tapered Spindle Sleeve Bolt........... 100

ft./lbs.

Brake Hose Brkt. to Spindle........... 120

ft./lbs.

Spindle to Upper Ball Joint............. 105

ft./lbs.

Tie Rod......................................... 67

ft./lbs.

U-Bolts......................................... 100 ft./lbs.

U-BOLTS

3 1/2” TAPERED

BLOCK 95-350

E

L

C

I

H

E

V

F

O

T

N

O

R

F

FLAT

WASHER,

9/16”

HIGH

NUT,

9/16”

12

57289

REVISED

2.1.06

13

Notice to Owner operator, Dealer and Installer:

Vehicles that have been enhanced for off-road performance often have unique handling characteristics due to the

higher center of gravity and larger tires. This vehicle may handle, react and stop differently than many passenger cars or

unmodified vehicles, both on and off–road. You must drive your vehicle safely! Extreme care should always be taken to

prevent vehicle rollover or loss of control, which can result in serious injury or even death. Always avoid sudden sharp turns

or abrupt maneuvers and allow more time and distance for braking! Pro Comp reminds you to fasten your seat belts at all

times and reduce speed! We will gladly answer any questions concerning the design, function, maintenance and correct use

of our products.

Please make sure your Dealer/Installer explains and delivers all warning notices, warranty forms and

instruction sheets included with Pro Comp product.

Application listings in this catalog have been carefully fit checked for each model and year denoted. However, Pro

Comp reserves the right to update as necessary, without notice, and will not be held responsible for misprints, changes or

variations made by vehicle manufacturers. Please call when in question regarding new model year, vehicles not listed by

specific body or chassis styles or vehicles not originally distributed in the USA.

Please note that certain mechanical aspects of any suspension lift product may accelerate ordinary

wear of original equipment components.

factory warranty as it pertains to certain covered parts; it is the consumer’s responsibility to check with their local dealer for

warranty coverage before installation of the lift.

Further, installation of certain Pro Comp products may void the vehicle’s

Warranty and Return policy:

Pro Comp warranties its full line of products to be free from defects in workmanship and materials. Pro Comp’s obligation under this warranty is limited to repair or replacement, at Pro Comp’s option, of the defective product. Any and all

costs of removal, installation, freight or incidental or consequential damages are expressly excluded from this warranty. Pro

Comp is not responsible for damages and / or warranty of other vehicle parts related or non-related to the installation of Pro

Comp product. A consumer who makes the decision to modify his vehicle with aftermarket components of any kind will

assume all risk and responsibility for potential damages incurred as a result of their chosen modifications. Warranty coverage does not include consumer opinions regarding ride comfort, fitment and design. Warranty claims can be made directly

with Pro Comp or at any factory authorized Pro Comp dealer.

IMPORTANT! To validate the warranty on this purchase please be sure to mail in the warranty card.

Claims not covered under warranty-

• Parts subject to normal wear, this includes bushings, bump stops, ball joints, tie rod ends and heim joints

• Discontinued products at Pro Comp’s discretion

• Bent or dented product

• Finish after 90 days

• Leaf or coil springs used without proper bump stops

• Light bulbs

• Products with evident damage caused by abrasion or contact with other items

• Damage caused as a result of not following recommendations or requirements called out in the

installation manuals

• Products used in applications other than listed in Pro Comp’s catalog

• Components or accessories used in conjunction with other manufacturer’s systems

• Tire & Wheel Warranty as per Pro Competition Tire Company policy

• Warranty claims without “Proof of Purchase”

• Pro Comp Pro Runner coil over shocks are considered a serviceable shock with a one-year

warranty against leakage only. Rebuild service and replacement parts will be available and sold

separately by Pro Comp. Contact Pro Comp for specific service charges.

• Pro Comp accepts no responsibility for any altered product, improper installation, lack of or

improper maintenance, or improper use of our products.

E-Mail: tech@explorerprocomp.com

Website: www.explorerprocomp.com

Fax: (619) 216-1474

Ph: (619) 216-1444

PLACE

WARRANTY REGISTRATION

NUMBER

HERE: __________________

Loading...

Loading...