Procom Heating MNSD200TBA-BB, MNSD300TBA-BB, MNSD300TBA, MNSD100TBA, MNSD200TBA User Manual

...Page 1

VENT-FREE GAS WALL

US

HEATER

OWNER’S OPERATION AND

INSTALLATION MANUAL

BLUE FLAME MODELS

MNSD100TBA, MNSD200TBA

MNSD300TBA, MNSD100HBA

MNSD200TBA-BB

MNSD300TBA-BB

®

WARNING: If the information in this manual is not

followed exactly, a re or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other ammable va-

pors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

•

Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re

department.

—

Installation and service must be performed by a qualied installer, service agency or the gas supplier.

WARNING: This appliance is equipped for Natural and

Propane gas. Field conversion is not permitted other than

between natural or propane gases.

Questions, problems, missing parts? Before returning to your retailer, call

our customer service department at 1-866-573-0674, 7:30 am - 4:15 pm CST,

Monday through Friday or email customerservice@usaprocom.com

Page 2

TABLE OF CONTENTS

Safety ........................................................ 3

Specications ............................................ 4

Qualied Installing Agency ........................ 5

Product Features ....................................... 5

Local Codes............................................... 6

Product Identication ................................. 6

Unpacking.................................................. 6

Water Vapor: A By-Product Of

Unvented Room Heaters ..................... 7

Air For Combustion and Ventilation ........... 7

Installation ................................................. 9

Operation ................................................. 19

Electrical Connection ............................... 22

Electrical Wiring ....................................... 22

Inspecting Heater .................................... 23

Care And Maintenance ............................ 24

Troubleshooting ....................................... 25

Service Hints ........................................... 28

Technical Service..................................... 28

Replacement Parts .................................. 29

Accessories ............................................. 29

Parts ........................................................ 30

Warranty .................................................. 36

SAVE THIS BOOK

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

This is an unvented gas-red heater. It uses air (oxygen)

from the room in which it is installed. Provisions for ad-

equate combustion and ventilation air must be provided.

Refer to Air For Combustion and Ventilation section on

page 7 of this manual.

WARNING: Improper installation, adjustment, al-

teration, service or maintenance can cause injury or

property damage. Refer to this manual for correct installation and operational procedures. For assistance

or additional information consult a qualied installer,

service agency or the gas supplier.

This appliance may be installed in an aftermarket,* permanently located, manufactured (mobile) home, where

not prohibited by local codes.

This appliance is only for use with propane or natural

gas. Field conversion by any other means including the

use of a kit is not permitted.

* Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer.

PROCOM HEATING, INC. PATENT INFORMATION

This product may be covered by one or more of the following United States patents:

8,915,239 8,851,065 8,764,436 8,757,202 8,757,139 8,752,541 8,568,136

8,545,216 8,517,718 8,516,878 8,506,290 8,465,277 8,317,511 8,297,968

8,281,781 8,241,034 8,235,708 8,152,515 8,011,920 7,967,006 7,967,007

7,654,820 7,730,765 7,677,236 7,607,426 7,434,447

www.usaprocom.com

200213-01B2

Page 3

SAFETY

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble, operate, or service this heater.

Improper use of this heater can

cause serious injury or death

from burns, fire, explosion,

electrical shock and carbon

monoxide poisoning.

Only a qualied installer, service

agent, or local gas supplier may

install and service this product.

WARNING: Keep the appli-

ance area clear and free from

combustible materials, gasoline,

and other ammable vapors and

liquids.

WARNING: This appliance

can be used with propane or

natural gas. It is shipped from

the factory adjusted for use with

propane.

This appliance is only for use

with the type of gas indicated on

the rating plate. This appliance

is not convertible for use with

other gases.

DANGER: Carbon monoxide

poisoning may lead to death!

CARBON MONOXIDE POISONING: Early

signs of carbon monoxide poisoning resemble

the u, with headaches, dizziness or nausea.

If you have these signs, the heater may not be

working properly. Get fresh air at once! Have

heater serviced. Some people are more affected by carbon monoxide than others. These

include pregnant women, people with heart or

lung disease or anemia, those under the inuence of alcohol and those at high altitudes.

NATURAL AND PROPANE/LP GAS: Natural

and Propane/LP gas are odorless. An odormaking agent is added to the gas. The odor

helps you detect a gas leak. However, the

odor added to the gas can fade. Gas may be

present even though no odor exists.

WARNING: Any change to

this heater or its controls can

be dangerous.

WARNING: Do not use any

accessories not approved for

use with this heater.

WARNING: Carefully supervise young children when they

are in the room with the heater.

WARNING: Make sure grill

guard is in place before running

heater.

WARNING: Due to high temperatures, the appliance should

be located out of trafc and away

from furniture and draperies.

WARNING: Heater becomes

very hot when running. Keep

children and adults away from

hot surfaces to avoid burns or

clothing ignition. Heater will remain hot for a time after shutoff.

Allow surfaces to cool before

touching.

WARNING: Do not place

clothing or other flammable

material on or near the appli-

ance. Never place any objects

in the heater.

www.usaprocom.com

3200213-01B

Page 4

SAFETY

1. Do not place Propane/LP supply tank(s)

inside any structure. Propane/LP supply

tank(s) must be placed outdoors.

2. Heaters with a maximum input over

6,000 Btu/Hr shall not be installed in a

bathroom. Heaters with a maximum input

over 10,000 Btu/Hr shall not be installed

in a bedroom.

3. This heater needs fresh air ventilation to

run properly. This heater has an Oxygen

Depletion Sensing (ODS) safety shutoff

system. The ODS shuts down the heater

if not enough fresh air is available. See

Air for Combustion and Ventilation, pages

7 and 8. If heater keeps shutting off, see

Troubleshooting, page 25.

4. Keep all air openings in front and bottom

of heater clear and free of debris. This will

ensure enough air for proper combustion.

5. If heater shuts off, do not relight until you

have provided fresh, outside air. If heater

keeps shutting off, have it serviced.

6. Do not run heater:

• Where ammable liquids or vapors are

used or stored.

• Under dusty conditions.

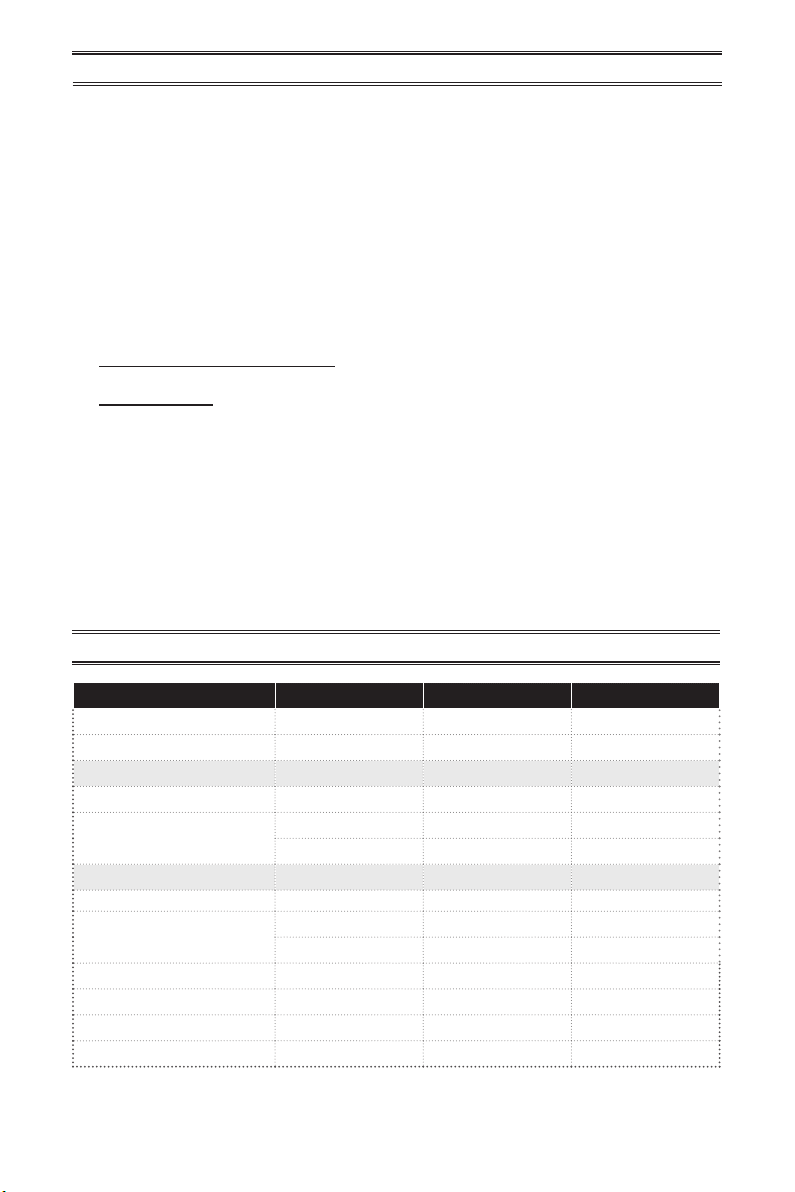

SPECIFICATIONS

7. Before using furniture polish, wax, carpet

cleaner, or similar products, turn heater off.

If heated, the vapors from these products

may create a white powder residue within

burner box or on adjacent walls or furniture.

8. Manual Control Models Only: Always

run heater with control knob at PILOT/

IGN, LOW (1) or HIGH (5) locked positions.

Never set control knob between locked

positions. Poor combustion and higher

levels of carbon monoxide may result.

9. Do not use heater if any part has been

under water. Immediately call a qualied

service technician to inspect the room

heater and to replace any part of the

control system and any gas control which

has been under water.

10. Turn off and unplug heater and let cool

before servicing. Only a qualied service

person should service and repair heater.

11. Operating heater above elevations of

4,500 feet could cause pilot outage.

12. To prevent performance problems, do

not use propane/LP fuel tank of less than

100 lbs. capacity.

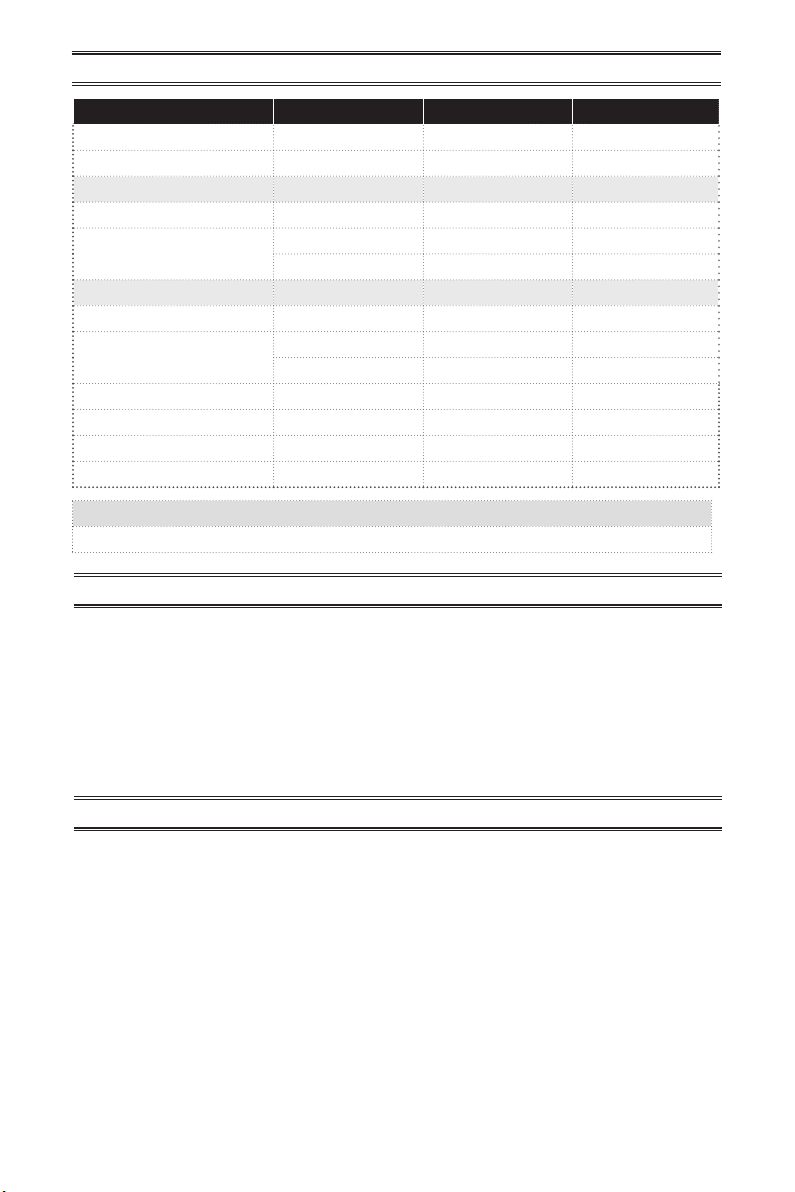

MODEL MNSD100TBA MNSD200TBA MNSD300TBA

BTU (available) 10,000 20,000 30,000

Ignition Electric Piezo Electric Piezo Electric Piezo

Gas Type Using Natural Gas Using Natural Gas Using Natural Gas

Pressure Regulator Setting 4" W.C. 4" W.C. 4" W.C.

Inlet Gas Pressure*

(inches of water)

Gas Type Using Propane Gas Using Propane Gas Using Propane Gas

Pressure Regulator Setting 9.5" W.C. 9.5" W.C. 9.5" W.C.

Inlet Gas Pressure*

(inches of water)

Heater Dimensions (HxWxD)

Carton Dimensions (HxWxD)

Heater Weight 14.6 lbs 22.2 lbs 28.1 lbs

Shipping Weight 17.6 lbs 26.2 lbs 33.1 lbs

Maximum 9" Maximum 9" Maximum 9"

Minimum 5" Minimum 5" Minimum 5"

Maximum 14" Maximum 14" Maximum 14"

Minimum 11" Minimum 11" Minimum 11"

19 1/8" × 14 1/8" × 6 3/8"

22 ×16 3/4" × 8 1/8"

www.usaprocom.com

23 1/2" × 19 1/4" × 8" 23 1/2" x 26 5/8" x 8"

25 3/4" × 21 3/4" × 9 1/4"

25 3/4" x 28 1/2" x 9 1/4"

200213-01B4

Page 5

SPECIFICATIONS

MODEL MNSD100HBA MNSD200TBA-BB MNSD300TBA-BB

BTU (available) 10,000 20,000 30,000

Ignition Electric Piezo Electric Piezo Electric Piezo

Gas Type Using Natural Gas Using Natural Gas Using Natural Gas

Pressure Regulator Setting 4" W.C. 4" W.C. 4" W.C.

Inlet Gas Pressure*

(inches of water)

Gas Type

Pressure Regulator Setting 9.5" W.C. 9.5" W.C. 9.5" W.C.

Inlet Gas Pressure*

(inches of water)

Heater Dimensions (HxWxD)

Carton Dimensions (HxWxD)

Heater Weight 14.1 lbs 25.1 lbs 31 lbs

Shipping Weight 17.1 lbs 29.1 lbs 36 lbs

Electrical Requirement for Blower Kit (if equipped)

Maximum 9" Maximum 9" Maximum 9"

Minimum 5" Minimum 5" Minimum 5"

Using Propane Gas

Maximum 14" Maximum 14" Maximum 14"

Minimum 11" Minimum 11" Minimum 11"

19 1/8" × 14 1/8" × 6 3/8"

22 ×16 3/4" × 8 1/8"

Voltage • 120 VAC, 60 Hz

Using Propane Gas

23 1/2" × 19 1/4" × 8" 23 1/2" x 26 5/8" x 8"

25 3/4" × 21 3/4" × 9 1/4" 25 3/4" x 28 1/2" x 9 1/4"

Using Propane Gas

QUALIFIED INSTALLING AGENCY

Only a qualied agency should install and

replace gas piping, gas utilization equipment

or accessories, and repair and equipment servicing. The term “qualied agency” means any

individual, rm, corporation, or company that

either in person or through a representative

is engaged in and is responsible for:

PRODUCT FEATURES

SAFETY PILOT

This heater has a pilot with an Oxygen Depletion Sensing (ODS) safety shutoff system. The

ODS/pilot shuts off the heater if there is not

enough fresh air.

2 GAS OPTIONS AVAILABLE

Your heater is equipped to operate on either

Propane/LP or Natural gas. The heater is

shipped from the factory ready for connecting to Propane/LP. The heater can easily be

changed to Natural gas by having your qualied installer follow the instructions on page

14 and the markings on the heater.

www.usaprocom.com

a) Installing, testing, or replacing gas piping

or

b) Connecting, installing, testing, repairing,

or servicing equipment; that is experienced

in such work; that is familiar with all precautions required; and that has complied with

all the requirement of the authority having

jurisdiction.

THERMOSTATIC CONTROL

(Thermostat Models Only)

These heaters have a control valve with a

thermostat sensing bulb. This results in the

greatest heater comfort and may result in

lower gas bills.

5200213-01B

Page 6

LOCAL CODES

Install and use heater with care. Follow all

local codes. In the absence of local codes,

use the latest edition of The National Fuel

Gas Code, ANSI Z223.1/NFPA 54*.

*Available from:

American National Standards Institute, Inc.

25 West 43rd Street

New York, NY 10036

National Fire Protection Association, Inc.

1 Batterymarch Park

Quincy, MA 02269-9101

PRODUCT IDENTIFICATION

State of Massachusetts: The installation

must be made by a licensed plumber or

gas tter in the Commonwealth of Massachusetts.

Sellers of unvented propane or natural

gas-red supplemental room heaters shall

provide to each purchaser a copy of 527

CMR 30 upon sale of the unit.

In the State of Massachusetts the gas

cock must be a T-handle type. The State

of Massachusetts requires that a exible

appliance connector cannot exceed three

feet in length.

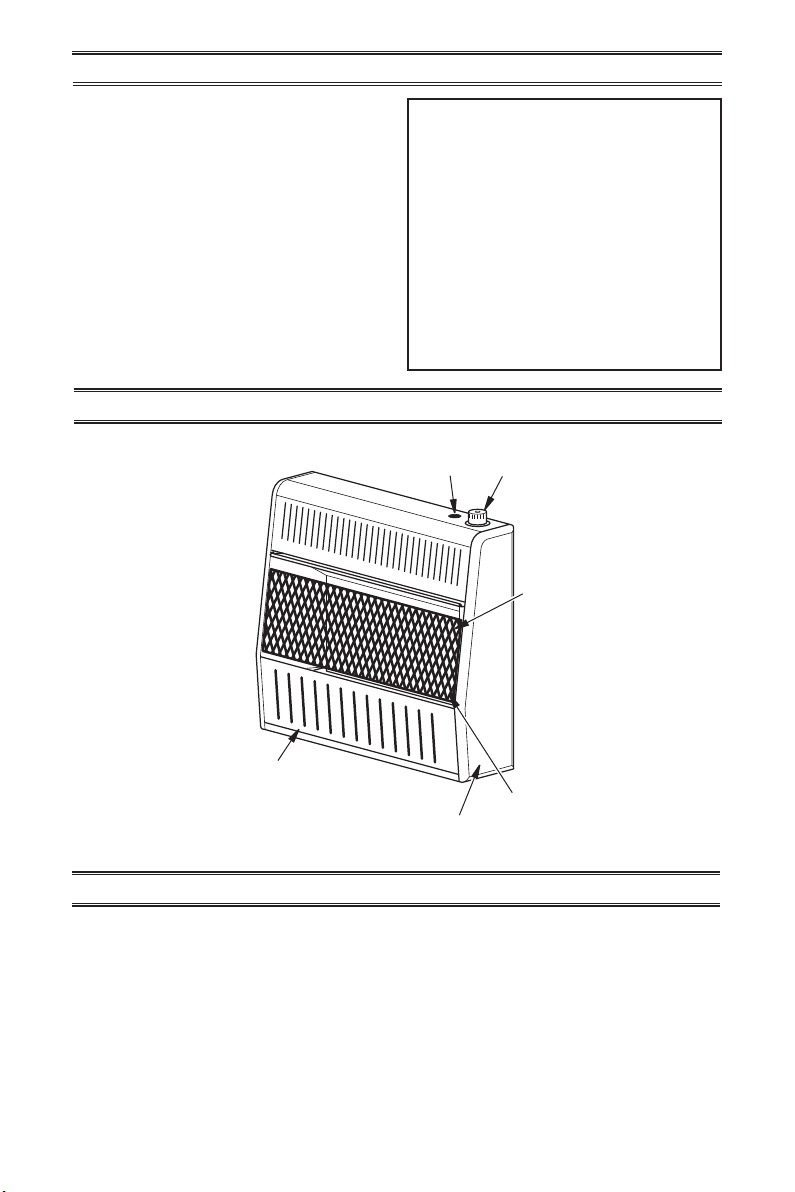

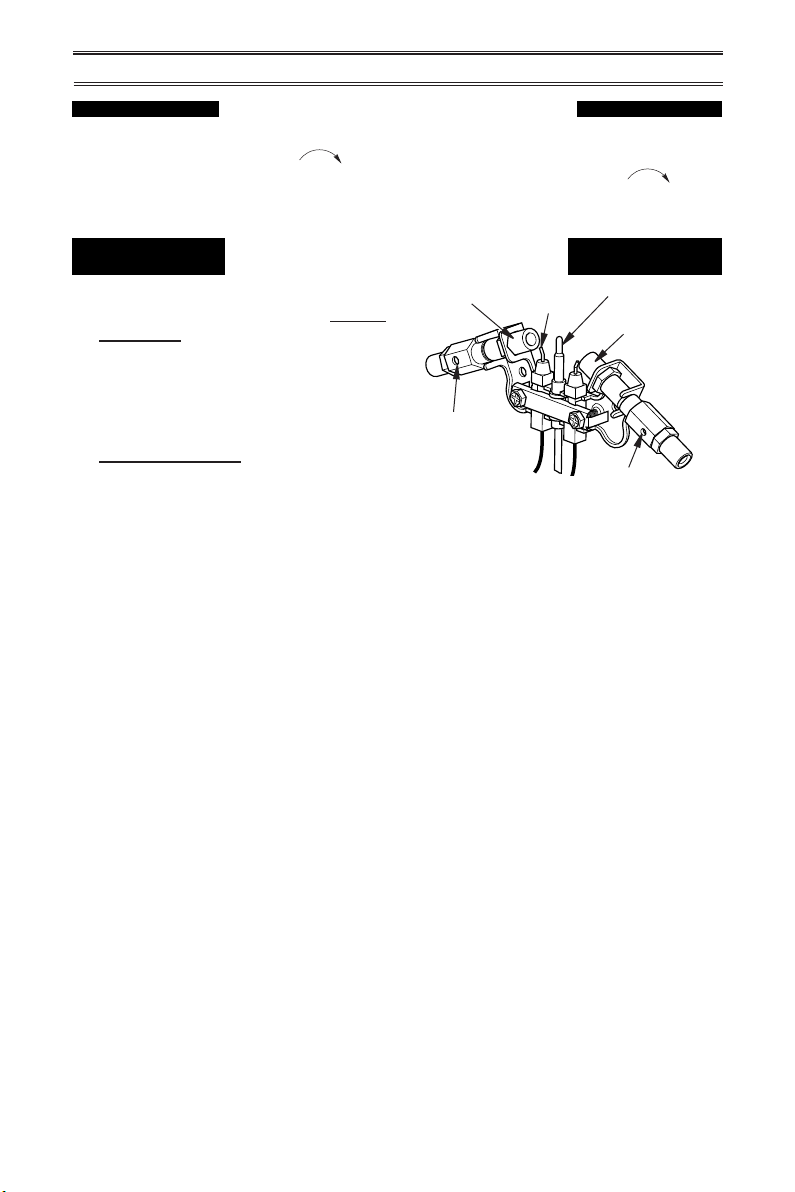

Ignitor

Button

Control

Knob

Grill

Front

Panel

Figure 1 - Vent-Free Gas Heater

UNPACKING

1. Remove heater from carton.

2. Remove all protective packaging applied

to heater for shipping

www.usaprocom.com

Burner

Heater Cabinet

3. Check heater for any shipping damage. If

heater is damaged, promptly inform dealer

where you bought heater.

200213-01B6

Page 7

WATER VAPOR: A BY-PRODUCT OF

UNVENTED ROOM HEATERS

Water vapor is a by-product of gas combustion. An unvented room heater produces approximately one (1) ounce (30 mL) of water for

every 1,000 BTUs (0.3 KWs) of gas input per

hour. Unvented room heaters are recommended

as supplemental heat (a room) rather than a

primary heat source (an entire house). In most

supplemental heat applications, the water vapor

does not create a problem. In most applications,

the water vapor enhances the low humidity

atmosphere experienced during cold weather.

AIR FOR COMBUSTION AND VENTILATION

WARNING: This heater shall

not be installed in a conned

space or unusually tight construction unless provisions are

provided for adequate combustion and ventilation air. Read the

following instructions to insure

proper fresh air for this and other

fuel-burning appliances in your

home.

Today’s homes are built more energy efcient

than ever. New materials, increased insulation

and new construction methods help reduce

heat loss in homes. Home owners weather

strip and caulk around windows and doors

to keep the cold air out and the warm air in.

During heating months, home owners want

their homes as airtight as possible.

While it is good to make your home energy

efcient, your home needs to breathe. Fresh

air must enter your home. All fuel-burning appliances need fresh air for proper combustion

and ventilation.

Exhaust fans, replaces, clothes dryers and

fuel burning appliances draw air from the

house to operate. You must provide adequate

fresh air for these appliances. This will insure

proper venting of vented fuel-burning appliances.

The following steps will help ensure that water

vapor does not become a problem.

1. Be sure the heater is sized properly for the

application, including ample combustion

air and circulation air.

2. If high humidity is experienced, a dehumidier may be used to help lower the

water vapor content of the air.

3. Do not use an unvented room heater as

the primary heat source.

WARNING: This heater shall

not be installed in a room or

space unless the required vol-

ume of indoor combustion air

is provided by the method described in the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, the

International Fuel Gas Code, or

applicable local codes.

WARNING: If the area in which

the heater may be operated does

not meet the required volume for

indoor combustion air, combustion and ventilation air shall be

provided by one of the methods

described in the National Fuel

Gas Code, ANSI Z223.1/NFPA 54,

the International Fuel Gas Code,

or applicable local codes.

www.usaprocom.com

7200213-01B

Page 8

AIR FOR COMBUSTION AND VENTILATION

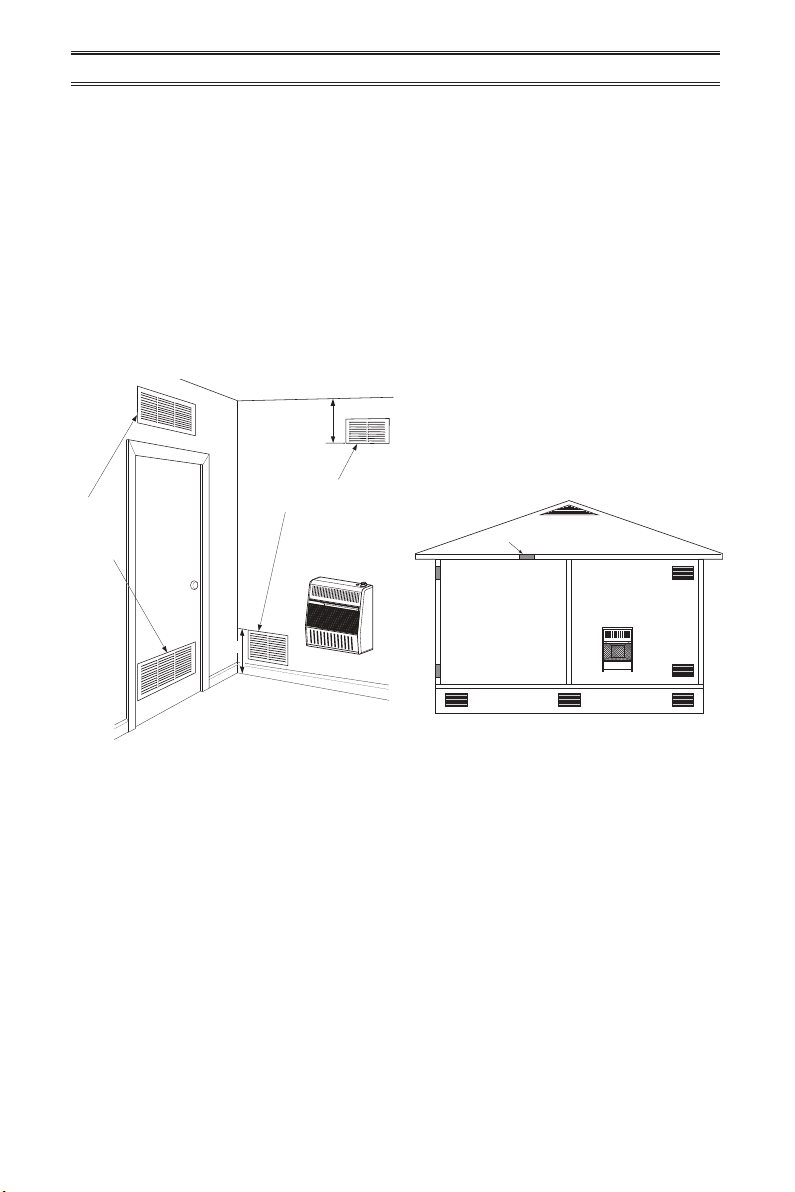

Ventilation

VENTILATION AIR

Ventilation Air From Inside Building

This fresh air would come from an adjoining

unconned space. When ventilating to an

adjoining unconned space, you must provide

two permanent openings: one within 12" of the

ceiling and one within 12" of the oor on the

wall connecting the two spaces (see options

1 and 2, Figure 2). You can also remove door

into adjoining room (see option 3, Figure 2).

Follow the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, Air for Combustion and

Ventilation for required size of ventilation

grills or ducts.

12"

Ventilation Grills

Into Adjoining Room,

Grills into

Adjoining

Room,

Option 1

Or

Remove

Door into

Adjoining

Room,

Option 3

12"

Figure 2 - Ventilation Air from Inside

Building

Note: Base not included. Not for use in bedrooms or bathrooms.

Option 2

Ventilation Air From Outdoors

Provide extra fresh air by using ventilation

grills or ducts. You must provide two permanent openings: one within 12" of the ceiling

and one within 12" of the oor. Connect these

items directly to the outdoors or spaces open

to the outdoors. These spaces include attics

and crawl spaces. Follow the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, Air for

Combustion and Ventilation for required size

of ventilation grills or ducts.

IMPORTANT: Do not provide openings

for inlet or outlet air into attic if attic has a

thermostat-controlled power vent. Heated air

entering the attic will activate the power vent.

Rework worksheet, adding the space of the

adjoining unconned space. The combined

spaces must have enough fresh air to supply

all appliances in both spaces.

Ventilated

Attic

Crawl Space

Ventilated

To Attic

To

Crawl

Space

Outlet

Air

Inlet

Air

Outlet

Air

Inlet Air

Figure 3 - Ventilation Air from Outdoors

www.usaprocom.com

200213-01B8

Page 9

INSTALLATION

NOTICE: This heater is intended

for use as supplemental heat.

Use this heater along with your

primary heating system. Do not

install this heater as your primary heat source. If you have a

central heating system, you may

run system’s circulating blower

while using heater. This will help

circulate the heat throughout the

house. In the event of a power

outage, you can use this heater

as your primary heat source.

CAUTION: When installing

heater in a home garage

• heater pilot and burner must

be at least 18" above oor

• locate heater where moving

vehicle will not hit it

WARNING: A qualied service person must install heater.

Follow all local codes.

WARNING: Never install the

heater

• 10,000 Btu/Hr in a bathroom

• over 10,000 Btu/Hr in a bedroom or bathroom (Check local

codes.)

• in a recreational vehicle

• where curtains, furniture,

clothing, or other ammable

objects are less than 36" from

the front, top, or sides of the

heater

• in high trafc areas

• in windy or drafty areas

CAUTION: This heater creates warm air currents. These

currents move heat to wall surfaces next to heater. Installing

heater next to vinyl or cloth wall

coverings or operating heater

where impurities (such as tobacco smoke, aromatic candles,

cleaning uids, oil or kerosene

lamps, etc.) in the air exist, may

cause walls to discolor.

IMPORTANT: Vent-free heaters add moisture

to the air. Although this is benecial, installing

heater in rooms without enough ventilation air

may cause mildew to form too much moisture.

See Air for Combustion and Ventilation, pages

7 and 8.

www.usaprocom.com

9200213-01B

Page 10

CEILING

2" Minimum to Top Surface of Carpeting,

INSTALLATION

CHECK GAS TYPE

Be sure your gas supply is right for your heater. Otherwise, call dealer where you bought

the heater for proper type heater.

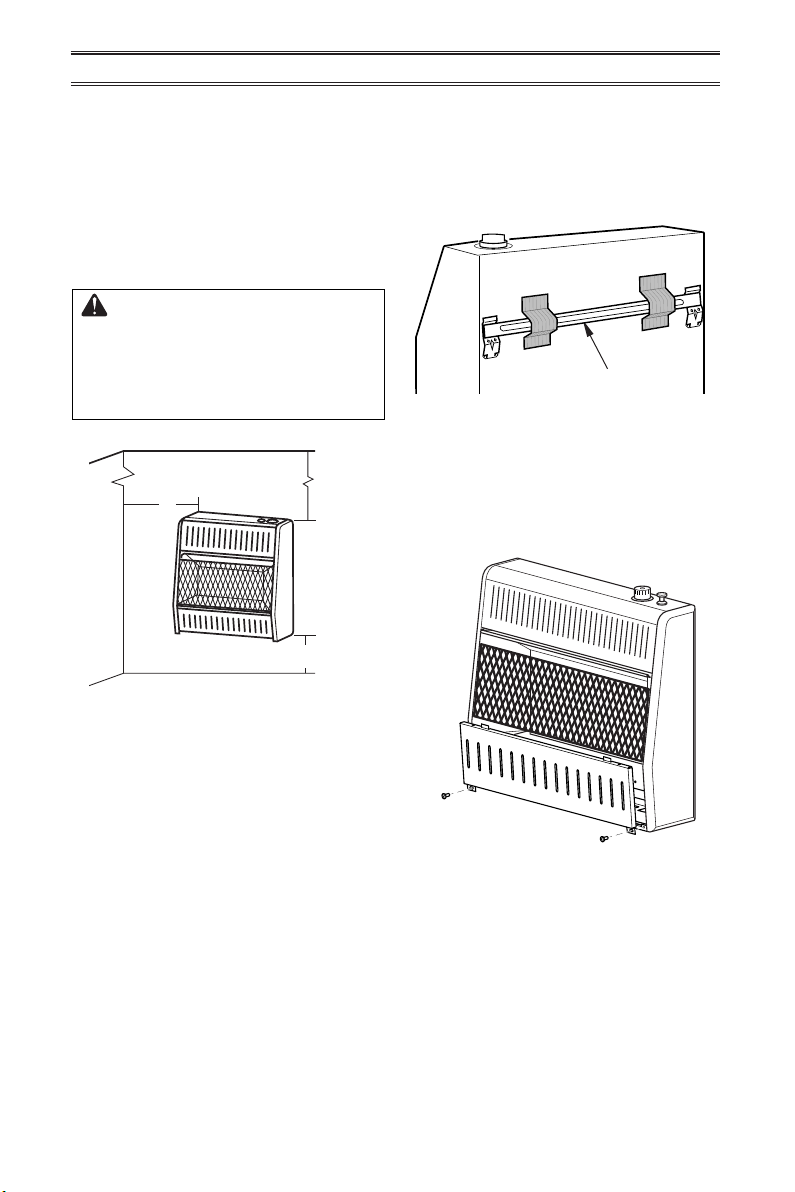

CLEARANCES TO

COMBUSTIBLES

Carefully follow the instructions below. This

heater is a freestanding unit designed to be

mounted on a wall or set on a base.

WARNING: Maintain the

minimum clearances shown in

Figure 4. If you can, provide

greater clearances from oor,

ceiling, and joining wall.

36"

6"

Minimum

From

Sides of

Heater

Left

Side

Tile or Other Combustible Material

FLOOR

Figure 4 - Mounting Clearances as

Viewed From Front of Heater

Minimum

Right

Side

FASTENING HEATER TO WALL

Mounting Bracket

The mounting bracket is located on back panel

of heater (see Figure 5). It has been taped

there for shipping. Remove mounting bracket

from back panel.

Mounting Bracket

Figure 5 - Mounting Bracket Location

Removing Front Panel of Heater

1. Remove two screws near bottom corners

of lower front panel.

2. Pull bottom of lower front panel forward,

then down (see Figure 6).

LOCATING HEATER

This heater is designed to be mounted on a

wall. For convenience and efciency, install

heater:

1. Where there is easy access for operation,

inspection, and service.

2. In the coldest part of room.

www.usaprocom.com

Figure 6 - Removing Front Panel Of

Heater

200213-01B10

Page 11

INSTALLATION

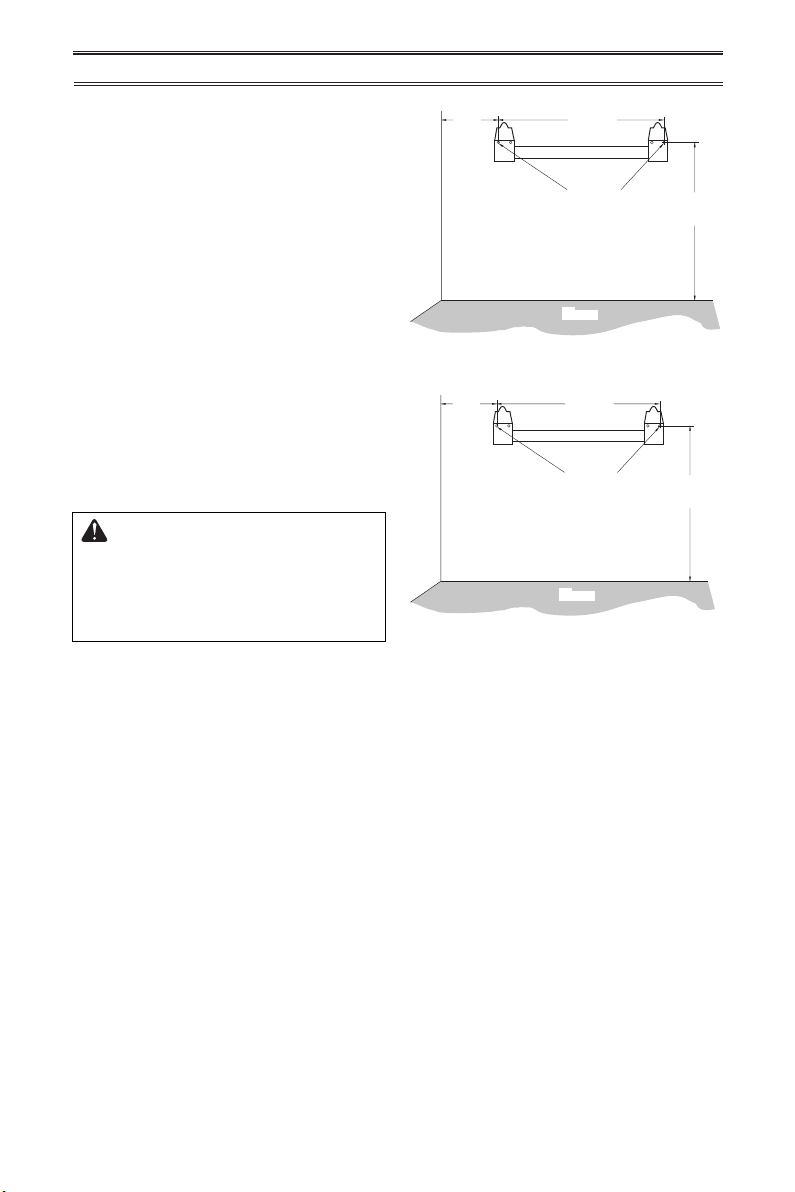

Methods For Attaching Mounting

Bracket To Wall

Use only the last hole on each end of mounting bracket to attach bracket to wall. Attach

mounting bracket to a wall only in one of two

ways:

1. Attaching to wall stud: This method pro-

vides the strongest hold. Insert mounting

screws through mounting bracket and into

wall studs.

2. Attaching to wall anchor: This method

allows you to attach mounting bracket to

hollow walls (wall areas between studs)

or to solid walls (concrete or masonry).

Decide which method better suits your needs.

Either method will provide a secure hold for

the mounting bracket.

Marking Screw Locations

1. Tape mounting bracket to wall where

heater will be located. Make sure mounting bracket is level.

WARNING: Maintain minimum

clearances shown in Figure

4, page 10. If you can, provide

greater clearances from oor and

joining wall.

2. Mark screw locations on wall (see Figure

7).

Note: Mark only last hole on each end of

mounting bracket. Insert mounting screws

through these holes only.

3. Remove tape and mounting bracket from

wall.

3

/4"

6

Min.

Only Insert Mounting

Screws Through Last

Adjoining Wall

121/8"

Hole On Each End

Floor

141/2"

Min.

Models: MNSD100TBA & MNSD100HBA

10 5/8"

Min.

Only Insert Mounting

Screws Through Last

Hole On Each End

17

3

/8"

1

18

/2"

Min.

Adjoining Wall

Floor

MNSD200TBA, MNSD300TBA

MNSD200TBA-BB, MNSD300TBA-BB

Figure 7 - Mounting Bracket Clearances

Attaching Mounting Bracket To Wall

Note: Wall anchors, mounting screws, and

spacers are in hardware package. The hardware package is provided with heater.

Attaching to Wall Stud Method

For attaching mounting bracket to wall studs:

1. Drill holes at marked locations using 9/64"

drill bit.

2. Place mounting bracket onto wall. Line

up last hole on each end of bracket with

holes drilled in wall.

3. Insert mounting screws through bracket

and into wall studs.

4. Tighten screws until mounting bracket is

rmly fastened to wall studs.

Models:

www.usaprocom.com

11200213-01B

Page 12

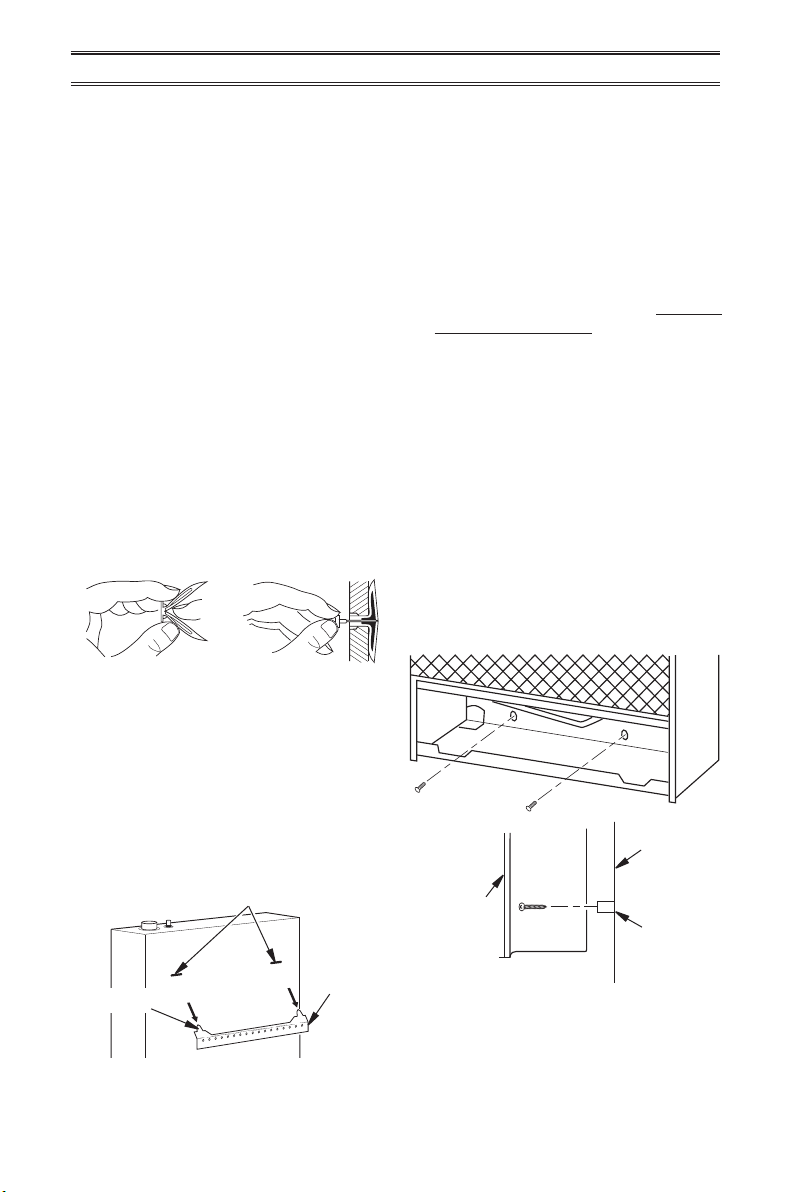

Attaching to Wall Anchor Method

For attaching mounting bracket to hollow

walls (wall areas between studs) or solid walls

(concrete or masonry):

1. Drill holes at marked locations using

5/16" drill bit. For solid walls (concrete or

masonry), drill at least 1" deep.

2. Fold wall anchor as shown in Figure 8.

3. Insert wall anchor (wings rst) into hole.

Tap anchor ush to wall.

4. For thin walls (1/2" or less), insert red key

into wall anchor. Push red key to “pop”

open anchor wings (see Figure 9).

IMPORTANT: Do not hammer anchor key! For

thick walls (over 1/2" thick) or solid walls, do

not pop open wings.

5. Place mounting bracket onto wall. Line up

last hole on each end of bracket with wall

anchors.

6. Insert mounting screws through bracket

and into wall anchors.

7. Tighten screws until mounting bracket is

rmly fastened to wall.

Installing Bottom Mounting Bracket

1. Install bottom bracket to heater bottom

with two screws. It may be more convenient to remove heater from wall bracket

to attach.

2. Place heater on wall mounting bracket.

3. Mark screw locations on wall.

4. Remove heater from mounting bracket.

5. If installing bottom mounting screws into

hollow or solid wall, install wall anchors.

Follow steps 1 through 4 under Attaching

To Wall Anchor Method. If installing bottom

mounting screw into wall stud, drill holes at

marked locations using 9/64" drill bit.

6. Replace heater onto mounting bracket.

7. Place spacers between bottom mounting

holes and wall anchor or drilled hole.

8. Hold spacer in place with one hand. With

other hand, insert mounting screw though

bottom mounting hole and spacer. Place

tip of screw in opening of wall anchor or

drilled hole.

9. Tighten both screws until heater is rmly

secured to wall. Do not over tighten.

Note: Do not replace front panel at this time.

Replace front panel after making gas connections and checking for leaks.

Figure 8 - Folding

Anchor

Figure 9 - Popping

Open Anchor Wings

For Thin Walls

Placing Heater On Mounting

Bracket

1. Locate two horizontal slots on back panel

of heater (see Figure 10).

2. Place heater onto mounting bracket. Slide

horizontal slots onto stand-out tabs on

mounting bracket.

Horizontal Slots

Mounting

Bracket

(attached

Stand-Out Tab

to wall)

Figure 10 - Mounting Heater Onto

Mounting Bracket

www.usaprocom.com

Front View

Wall

Heater

Spacer

Side View

Figure 11 - Installing Bottom Mounting

Screws

200213-01B12

Page 13

INSTALLATION

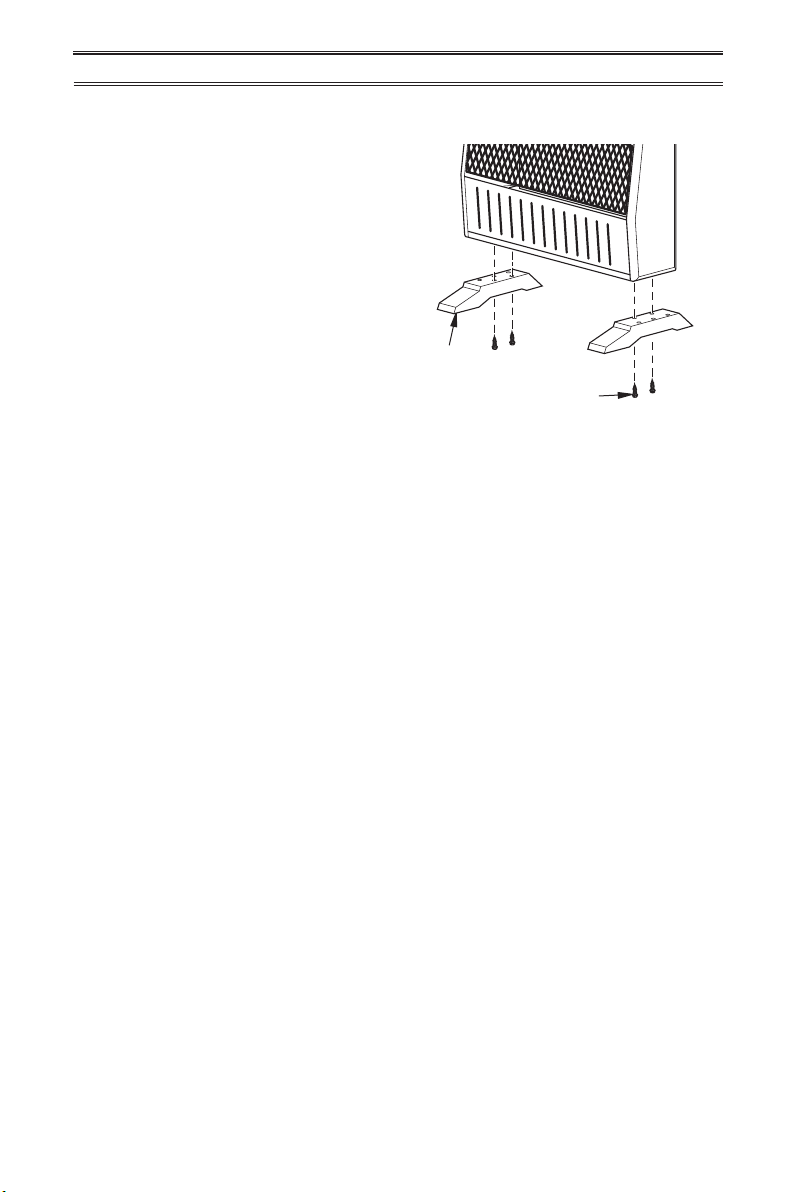

INSTALLATION OF BASE STAND

(If Equipped)

Before installing heater to base, please make

sure you have a hardware packet that contains the following items:

2 - Base Feet

4 - Sheet Metal Screws

1. Carefully lay heater on its back on a table

with the bottom of the heater extending

outside the table edge.

2. Attach base feet to heater using sheet

metal screws.

Base Feet

Sheet Metal Screws

Figure 12 - Installing Base Feet

www.usaprocom.com

13200213-01B

Page 14

INSTALLATION

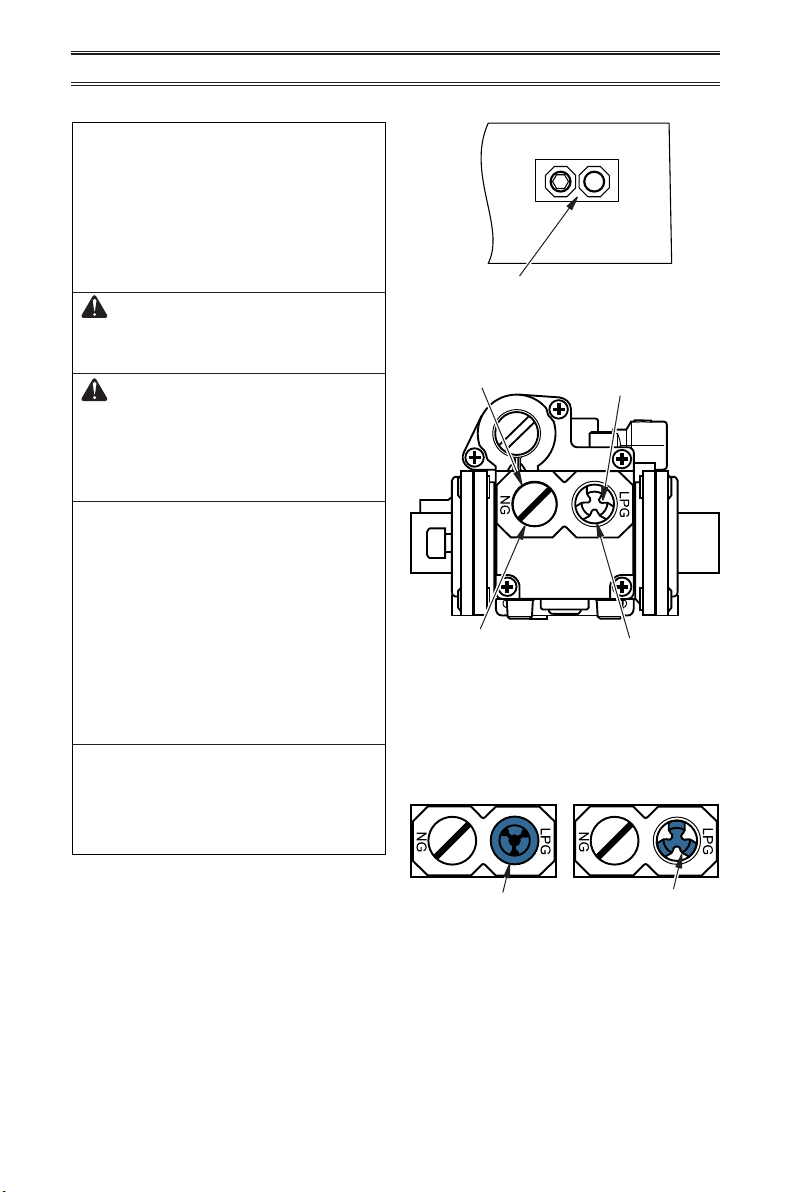

GAS SELECTION

This appliance is factory

preset for propane/LP gas.

No changes are required for

connecting to propane/LP.

Only a qualied installer or service

technician can perform gas selection and connecting to gas supply.

CAUTION: Two gas line in-

stallations at the same time are

prohibited.

CAUTION: To avoid gas leakage for the gas not being used at

the inlet of regulator, a qualied

installer or service technician

must use supplied cap.

You will notice a color coded

plunger on the inside of the regulator. This is normal. When the in-

let connection tting is inserted

and tightened, this plunger will

be pushed back by the tting

making all of the adjustments

for the gas being supplied. DO

NOT REMOVE THE PLUNGER.

The regulator will not work.

The inlet regulator is color coded

for identication of the correct

gas type. Blue is for propane (LP

gas) and yellow is for natural gas.

INLET GAS PRESSURE

MAX 1/2 PSIG (3.5 KPA)

NG

Gas Connection

Figure 13 - Back of Heater

Yellow Natural Gas

Plunger Underneath

Metal Cap

Insert Gas Fitting

for Natural Gas

Figure 14 - Gas Regulator

Blue Propane/LP Gas

Plunger Underneath

Dust Cover

Insert Gas Fitting

for Propane/LP Gas

FOR PROPANE/LP GAS

INSTALLATION: BLUE

1. Remove blue dust cover.

LPG

Blue Dust Cover

www.usaprocom.com

DO NOT REMOVE

Blue Propane/LP

Plunger

Install Gas Fitting Here

200213-01B14

Page 15

INSTALLATION

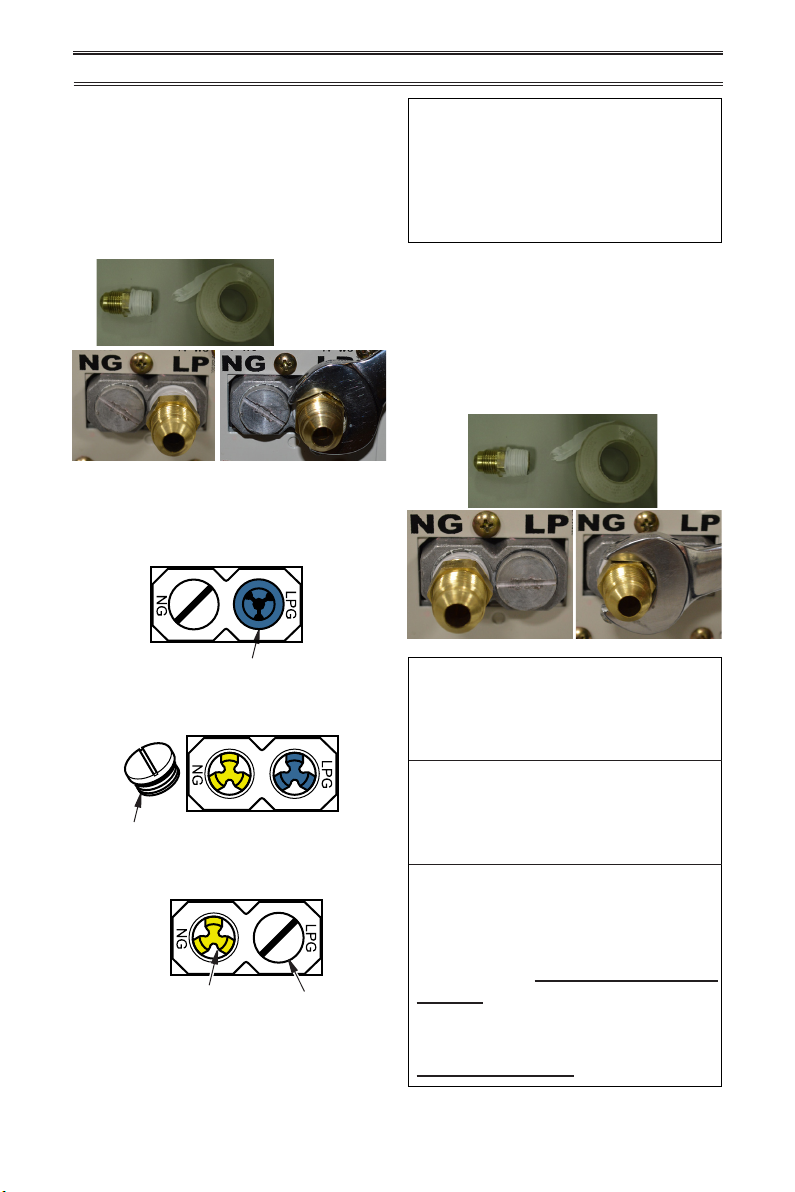

2. Apply thread sealant to the threads on

the connection tting. While pushing in,

rotate the tting clockwise until the threads

engage the regulator. After the tting has

been hand tightened into the regulator

use a wrench to complete tightening of the

tting. Install additional tting to connect

to the house supply.

Fitting

supplied

by installer,

may vary.

FOR NATURAL GAS (NG)

INSTALLATION: YELLOW

1. Remove the blue dust cover from the

regulator.

Blue Dust Cover

2. Remove the metal cap installed over the

NG regulator inlet.

Use only the cap supplied on the

regulator. Do not use an off the

shelf pipe plug. This can damage

the plunger. The supplied regulator cap is designed so it will not

engage the unused gas type.

4. Apply thread sealant to the threads on

the connection tting. While pushing in,

rotate the tting clockwise until the threads

engage the regulator. After the tting has

been hand tightened into the regulator

use a wrench to complete tightening of the

tting. Install additional tting to connect

to the house supply.

DO NOT use an off the shelf 3/8"

NPT pipe plug. This will damage

the plungers located inside the

regulator.

Metal Cap

3. Install metal cap over LP/Propane regulator

inlet. This will keep debris out of regulator.

DO NOT REMOVE

Yellow Natural Gas Plunger

Install Gas Fitting Here

Metal Cap

www.usaprocom.com

DO NOT try to remove the plungers from inside the regulator. The

plunger will be pushed back as

the tting is installed.

Make sure the type of gas being

used is correct. Check to make

sure the connection tting is in

the correct inlet on the regulator. Refer to Connecting to Gas

Supply, page 16.

If you are using natural gas

and the pilot will not light, see

Troubleshooting, page 25.

15200213-01B

Page 16

INSTALLATION

CONNECTING TO GAS SUPPLY

WARNING: A qualied service technician must connect

heater to gas supply. Follow all

local codes.

WARNING: This appliance

requires a 3/8" NPT (National

Pipe Thread) inlet connection to

the pressure regulator.

WARNING: For natural gas,

Never connect heater to private

(non-utility) gas wells. This gas

is commonly known as wellhead

gas.

WARNING: Do not over-

tighten gas connections.

CAUTION: Use only new,

black iron or steel pipe. Internally tinned copper tubing may

be used in certain areas. Check

your local codes. Use pipe of

1/2" diameter or greater to allow

proper gas volume to heater. If

pipe is too small, undue loss of

pressure will occur.

CAUTION: For propane/

LP gas, never connect heater

directly to the gas supply. This

heater requires an external

regulator (not supplied). Install

the external regulator between

the heater and gas supply. Gas

supplier provides external regulator for natural gas. The installer

provides the external regulator

for propane/LP gas.

CAUTION: For natural gas,

check your gas line pressure

before connecting heater to gas

line. Gas line pressure must be

no greater than 9.5" of water. If

gas line pressure is higher, heater

regulator damage could occur.

CAUTION: Avoid damage to

regulator. Hold gas regulator

with wrench when connecting

into gas piping and/or ttings.

CAUTION: Use pipe joint

sealant that is resistant to gas

(Propane/LP or Natural Gas).

Before installing heater, make sure you have

the items listed below:

• external regulator for propane/LP unit only

(supplied by installer)

• piping (check local codes)

• sealant (resistant to natural gas and propane/LP gas)

• equipment shutoff valve*

• test gauge connection*

• sediment trap

• tee joint

• pipe wrench

• exible gas hose (check local codes)

* A CSA design-certied equipment shutoff

valve with 1/8" NPT tap is an acceptable alternative to test gauge connection. Purchase

the optional CSA design certied equipment

shutoff valve from your dealer.

Typical Inlet Pipe Diameters

Use 3/8" black iron pipe or greater. Installation must include an equipment shutoff valve,

union, and plugged 1/8" NPT tap. Locate NPT

tap within reach for test gauge hook up. NPT

tap must be upstream from heater (see Figure

15, page 17).

IMPORTANT: Install an equipment shutoff

valve in an accessible location. The equipment shutoff valve is for turning on or shutting

off the gas to the appliance.

www.usaprocom.com

200213-01B16

Page 17

INSTALLATION

Apply pipe joint sealant lightly to male threads.

This will prevent excess sealant from going

into pipe. Excess sealant in pipe could result

in clogged heater valves.

For propane/LP gas, t

an external regulator. The external regulator

will reduce incoming gas pressure. You must

reduce incoming gas pressure to between 11"

and 14" of water. If you do not reduce incoming gas pressure, heater regulator damage

could occur. Install external regulator with

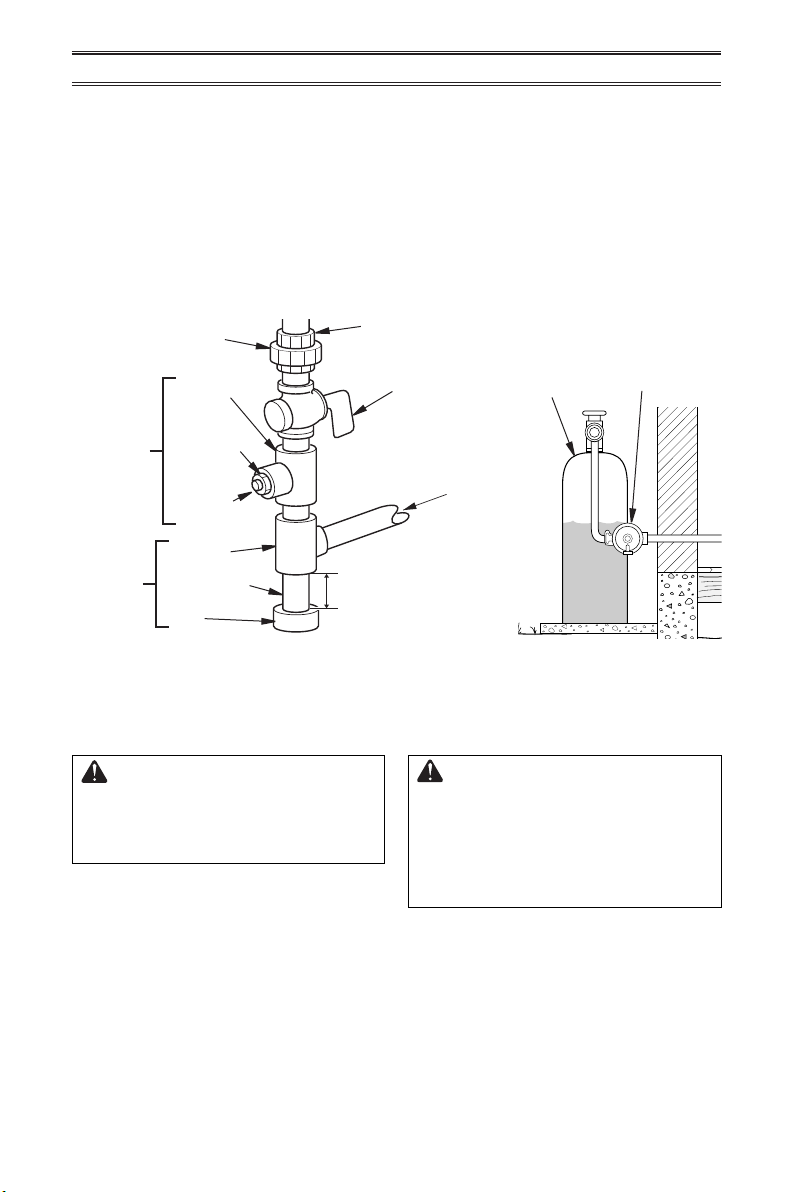

Ground

Joint Union

Test Gauge

Connection*

Sediment

Trap

* Purchase the optional CSA design-certied equipment

shutoff valve from your dealer.

he installer must supply

Tee Joint

Reducer

Bushing to

1/8" NPT

1/8" NPT

Plug Tap

Tee Joint

Pipe Nipple

Gap

Figure 15 - Gas Connection

3" Minimum

the vent pointing down as shown in Figure

16. Pointing the vent down protects it from

freezing rain or sleet.

Install sediment trap in supply line as shown

in Figure 15. Place sediment trap where it is

within reach for cleaning. Place sediment trap

where trapped matter is not likely to freeze.

A sediment trap traps moisture and contaminants. This keeps them from going into heater

controls. If sediment trap is not installed or is

installed wrong, heater may not run properly.

3/8" NPT

Pipe Nipple

Equipment

Shutoff Valve

Meter (4" W.C.

From External

Regulator (11" W.C.

to 14" W.C. Pressure)

Propane/LP

Supply Tank

Natural Gas

From Gas

to 9.5" W.C.

Pressure)

Propane/LP

Figure 16 - External Regulator

with Vent Pointing Down

External

Regulator with

Vent Pointing

Down

CHECKING GAS CONNECTIONS

WARNING: Test all gas piping

and connections for leaks after

installing or servicing. Correct

all leaks at once.

Pressure Testing Gas Supply Piping System

Test Pressures In Excess Of 1/2 PSIG (3.5 kPa)

1. Disconnect heater with its appliance main

gas valve (control valve) and equipment

shutoff valve from gas supply piping system. Pressures in excess of 1/2 PSIG will

damage heater regulator.

2. Cap off open end of gas pipe where equipment shutoff valve was connected.

www.usaprocom.com

WARNING: Never use an

open ame to check for a leak.

Apply a mixture of liquid soap

and water to all joints. If bubbles

form, there is a leak. Correct all

leaks at once.

3. Pressurize supply piping system by either

opening propane/LP supply tank valve

for propane/LP gas or opening main gas

valve located on or near gas meter for

natural gas or using compressed air.

17200213-01B

Page 18

INSTALLATION

4. Check all joints of gas supply piping system. Apply a noncorrosive leak detection

uid to all joints. If bubbles form, there may

be a leak.

Test Pressures Equal To or Less Than 1/2 PSIG (3.5 kPa)

1.

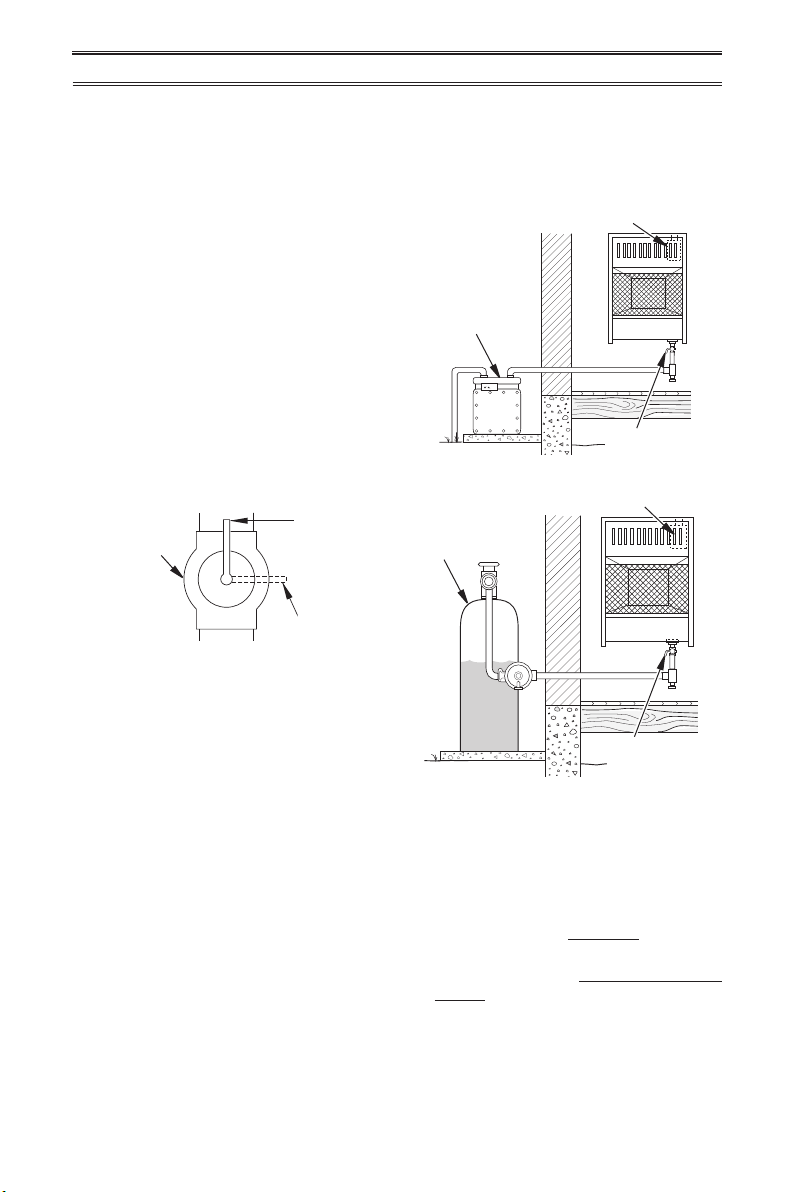

Close equipment shutoff valve (see Figure 17).

2. Pressurize supply piping system by either

opening propane/LP supply tank valve

for propane/LP gas or opening main gas

valve located on or near gas meter for

natural gas or using compressed air.

3. Check all joints from gas meter (natural

gas installations, see Figure 18) or from

propane/LP tank (propane/LP gas installations, see Figure 19) to equipment shutoff

valve. Apply a noncorrosive leak detection

uid to all joints. If bubbles form, there is

a leak.

4. Correct all leaks at once.

Equipment

Open

Shutoff Valve

Closed

Figure 17 - Equipment Shutoff Valve

5. Correct all leaks at once.

6. Reconnect heater and equipment shutoff

valve to gas supply. Check reconnected

ttings for leaks.

Gas Valve

Gas Meter

Equipment

Shutoff Valve

Figure 18 - Natural Gas Supply

Gas Valve

Propane/LP

Supply Tank

PRESSURE TESTING HEATER GAS CONNECTIONS

1.

Open equipment shutoff valve (see Fig-

ure 17).

2. For natural gas open main gas valve located on or near gas meter. For propane/

LP gas open propane/LP supply tank valve.

3. Make sure control knob of heater is in the

OFF position.

4. Check all joints from equipment shutoff

valve to control valve (see Figure 18 or

www.usaprocom.com

Equipment

Shutoff Valve

Figure 19 - Propane/LP Fuel Supply

19).

Apply a noncorrosive leak detection

uid to all joints.

Bubbles forming show a

leak.

5. Correct all leaks at once.

6. Light heater (see Operation, page 19).

Check all other internal joints for leaks.

7. Turn off heater (see To Turn Off Gas Ap-

pliance, page 20 or 21).

8. Replace lower front panel.

200213-01B18

Page 19

OPERATION

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a

re or explosion may result causing property damage, personal

injury or loss of life.

A. This appliance has a pilot which must

be lighted by hand. When lighting the

pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all around the

appliance area for gas. Be sure to smell

next to the oor because some gas is

heavier than air and will settle on the oor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do

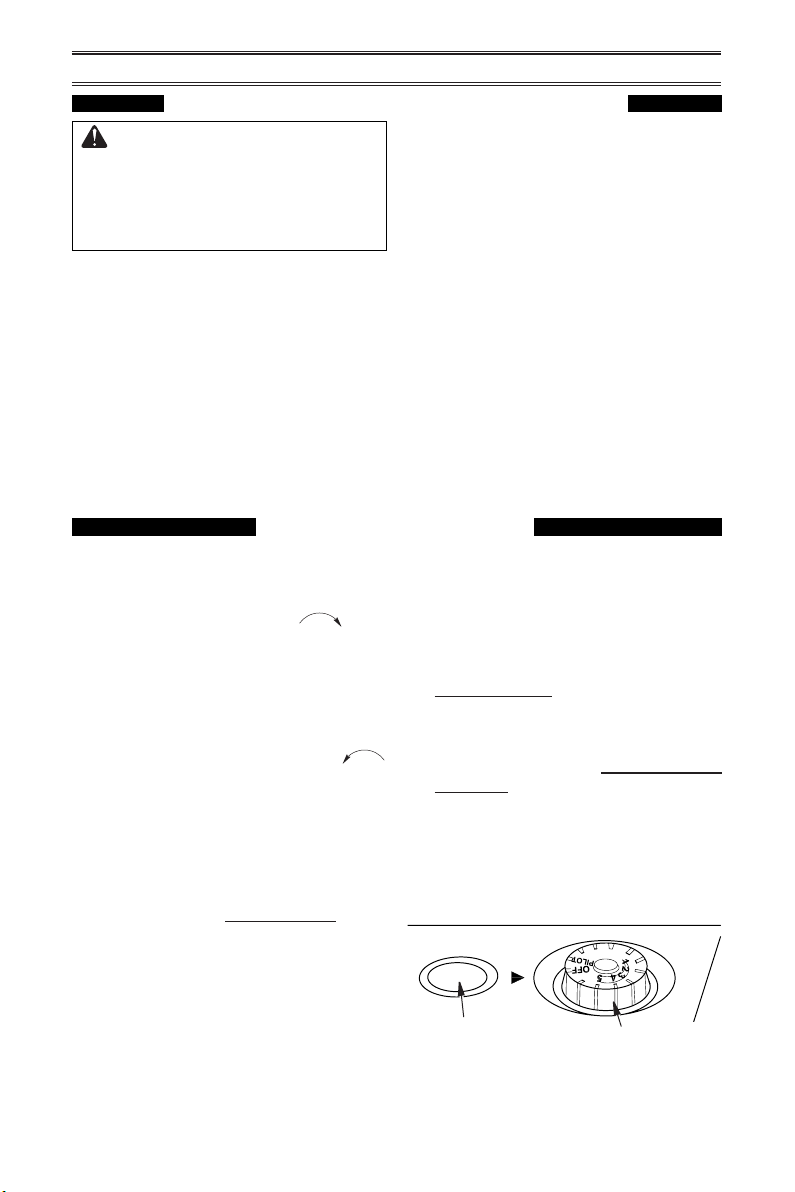

MODELS MNSD100TBA, MNSD200TBA, MNSD300TBA,

MNSD200TBA-BB AND MNSD300TBA-BB

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Make sure equipment shutoff valve is fully

open.

3. Turn control knob clockwise to the

OFF position.

4. Wait ve (5) minutes to clear out any air.

Then smell for gas, including near the

oor. If you smell gas, STOP! Follow "B"

in the safety information above. If you do

not smell gas, go to the next step.

5. Turn control knob counterclockwise

to the PILOT position. Press in control

knob for ve (5) seconds (see Figure 19).

Note: The rst time that the heater is oper-

ated after connecting the gas supply,the

control knob should be pressed for about

thirty (30) seconds. This will allow air to

bleed from the gas system. If pilot does

not stay lit, refer to Troubleshooting, pages

25 though 28. Also contact a qualied

service technician or gas supplier for

repairs. Until repairs are made, light pilot

with match.

• If control knob does not pop up when

released, contact a qualified service

technician or gas supplier for repairs.

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the re department.

C. Use only your hand to push in or turn

the gas control knob. Never use tools.

If the knob will not push in or turn by

hand, don’t try to repair it, call a qualied

service technician. Force or attempted

repair may result in a re or explosion.

D. Do not use this appliance if any part

has been under water. Immediately call

a qualied service technician to inspect

the appliance and to replace any part of

the control system and any gas control

which has been under water.

6. With control knob pressed in, push

down and release ignitor button. This

will light pilot. The pilot is attached to

the front of burner. The pilot can be

seen through the grill. If needed, keep

pressing ignitor button until pilot lights.

Note: If pilot does not stay lit, refer to

Troubleshooting, pages 25 though 28.

Also contact a qualied service technician

or gas supplier for repairs. Until repairs

are made, light pilot with match. To light

pilot with match, see Manual Lighting

Procedure, page 21.

7. Keep control knob pressed in for 30

seconds after lighting pilot. After 30

seconds, release control knob. If control

knob does not pop up when released,

contact a qualied service technician or

gas supplier for repairs.

Ignitor Button

Figure 20 - Control Knob in the OFF

Control Knob

Position

www.usaprocom.com

19200213-01B

Page 20

OPERATION

Note: If pilot goes out, repeat steps 3

through 7. This heater has a safety interlock system. Wait one (1) minute before

lighting pilot again.

8. Turn control knob counterclockwise

to desired heating level. The main burner

should light. Set control knob to any heat

level between 1 and 5.

THERMOSTAT CONTROL OPERATION

The thermostatic control used on this model

differs from standard thermostats. Standard

thermostats simply turn the burner on and off.

The thermostat used on this heater senses

the room temperature. At times the room may

TO TURN OFF GAS TO APPLIANCE

Shutting Off Heater

Turn control knob clockwise to the

OFF position.

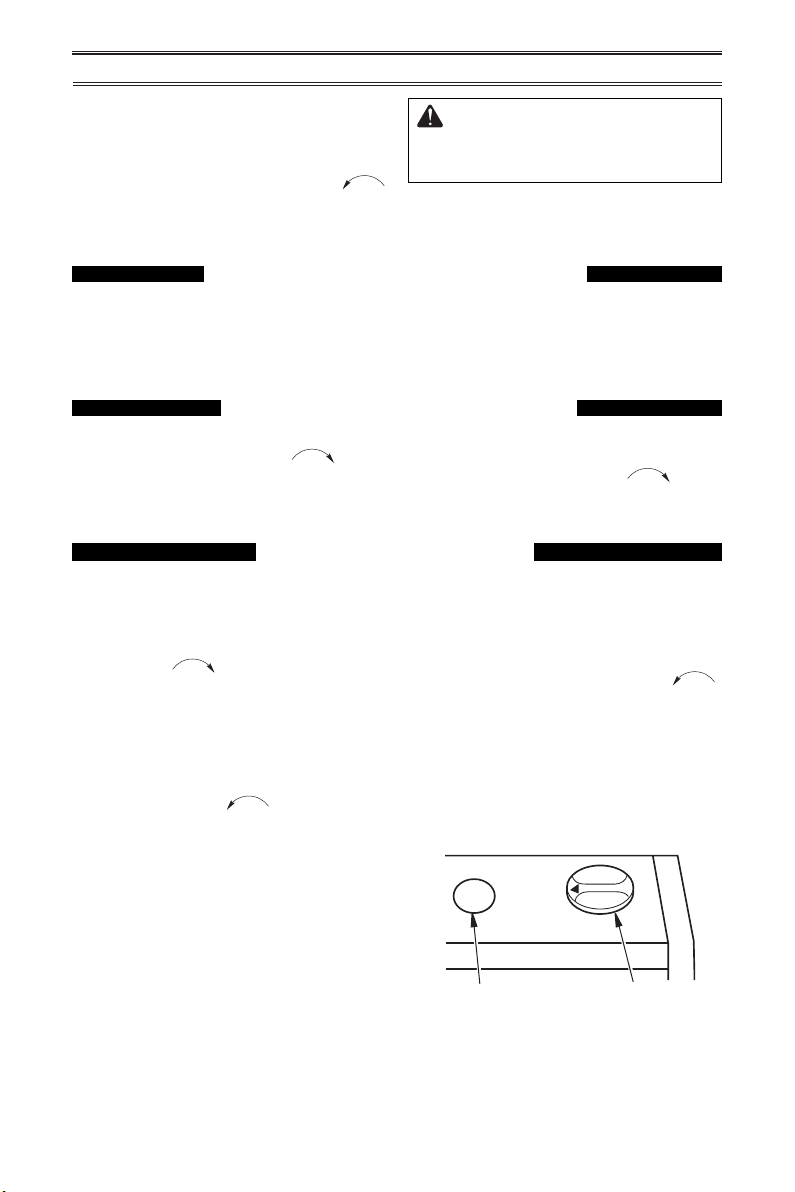

MODEL MNSD100HBA

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information on

page 19.

2. Check that gas supply to heater is on.

3. Push in gas control knob slightly and turn

clockwise to the OFF position.

4. Wait ve (5) minutes to clear out any gas.

Then smell for gas, including near the

oor. If you smell gas, STOP! Follow "B"

in the safety information on on page 18. If

you do not smell gas, go to the next step.

5. Push in gas control knob slightly and turn

counterclockwise to "PILOT/IGN"

and press for ve (5) seconds

Note: The rst time that the heater is oper-

ated after connecting the gas supply, the

control knob should be pressed for about

thirty (30) seconds. This will allow air to

bleed from the gas system.

6. With control knob pressed in, push down

and release the ignitor button. This will

light pilot. If needed, keep pressing ignitor

button until pilot lights.

CAUTION: Do not try to ad-

just heating levels by using the

equipment shutoff valve.

exceed the set temperature. If so, the burner

will shut off. The burner will cycle back on

when room temperature drops below the set

temperature. The control knob can be set to

any comfort level between 1 and 5.

Shutting Off Burner Only (pilot

Turn control knob clockwise to the

PILOT position.

7. Keep control knob pressed for ten (10)

seconds after lighting pilot. If pilot goes

out, repeat steps 5, 6 and 7.

8. To select the desired heating level, partially press down the control knob slightly

and rotate counterclockwise .

Release the downward pressure on the

knob while continuing to turn until the knob

locks at the desired setting position. Do

not operate between locked positions. Set

control knob to desired heating position.

Note: Both HIGH and LOW are locked

positions. You must press in control knob

before turning it from these positions.

Ignitor Button Control Knob

Figure 21 - Control Knob in the OFF

stays lit )

OFF

PILOT/IGN

Position

LOW

HIGH

www.usaprocom.com

200213-01B20

Page 21

OPERATION

TO TURN OFF GAS TO APPLIANCE

Shutting Off Heater

1. Turn control knob clockwise to the

OFF position.

2. Turn off all electric power to the appliance

if service is to be performed.

MANUAL LIGHTING PROCEDURE

(ALL MODELS)

1. Remove lower front panel.

2. Follow steps 1 through 5 under Lighting

Instructions, page 19 or 20.

3. With control knob pressed in, strike match.

Hold match to pilot until pilot lights.

4. Keep control knob pressed in for 30 seconds after lighting pilot. After 30 seconds,

release control knob. Follow step 8 under

Lighting Instructions, page 19 or 20.

5. Replace lower front panel.

Shutting off burner only

Turn control knob clockwise to the

PILOT/IGN position.

Natural Gas

Burner

Pilot Air

Inlet Hole

(pilot stays lit)

Ignitor

Electrode

Figure 22 - Pilot Assembly

Thermocouple

Propane/LP

Gas Burner

Pilot Air Inlet Hole

www.usaprocom.com

21200213-01B

Page 22

ELECTRICAL CONNECTION

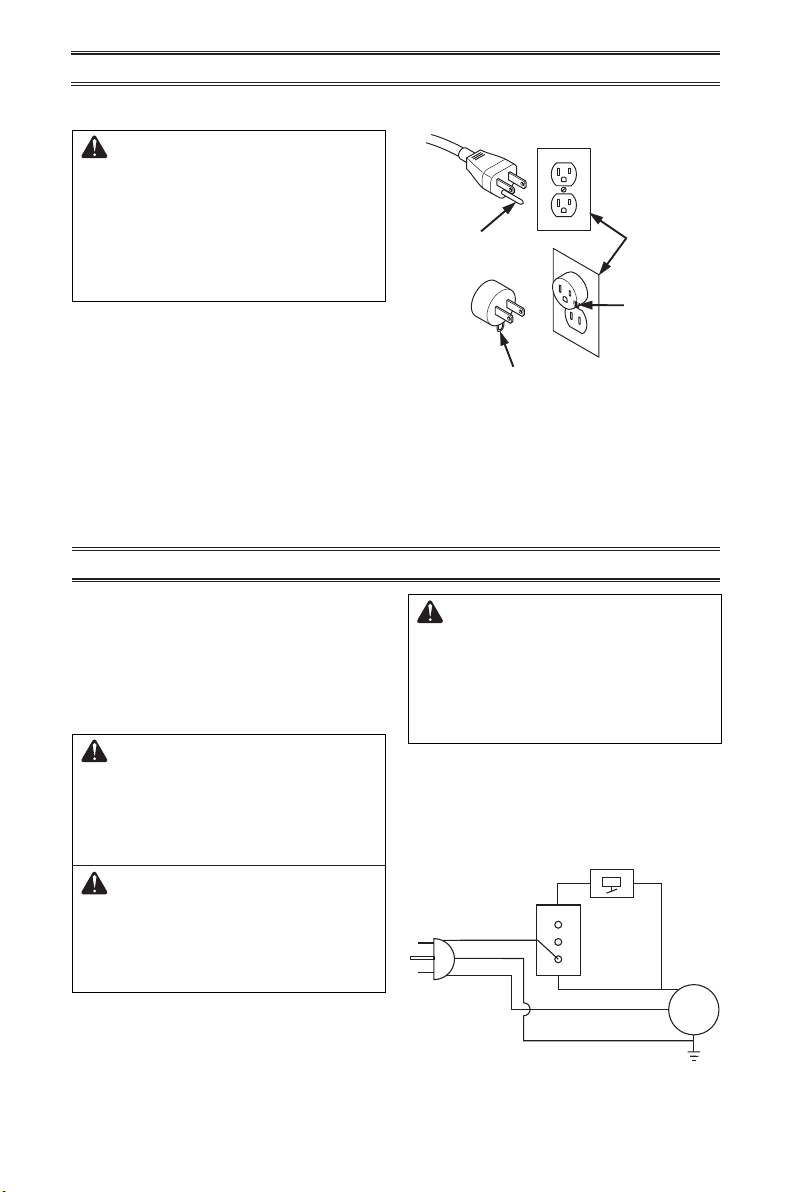

Grounding Means

Metal Screw

A

Thermostat Switch

FOR HEATERS EQUIPPED WITH A BLOWER

Do not use this heater if any

part of it has been under water.

Immediately call a qualied ser-

vice technician to inspect the

replace and replace any part

of the electrical system which

has been under water.

GROUNDING INSTRUCTIONS

This heater is for use on 120 volts. The cord

has a plug as shown at A in Figure 23. An

adapter as shown at C is available for connecting three-blade grounding-type plugs to

two-slot receptacles. The green grounding

lug extending from the adapter must be

connected to a permanent ground such as

a properly grounded outlet box. The adapter

should not be used if a three-slot grounded

receptacle is available.

ELECTRICAL WIRING

Cover of

Grounding Pin

B

Grounded

Outlet Box

C

Adapter

Figure 23 - Grounded Electrical Outlet

Any electrical re-wiring of this appliance must

be done by a qualied electrician. This wiring

must be done in accordance with local codes

and/or in Canada with the current CSA C22.1

Canadian Electrical Code, and for US installations, the National Electrical Code ANSI/

NFPA NO 70.

WARNING: If repairing or

replacing any electrical component or wiring, the original wire

routing, color coding and secur-

ing locations must be followed.

CAUTION: Label all wires

prior to disconnection when

servicing controls. Wiring errors

can cause improper and dangerous operation.

www.usaprocom.com

WARNING: Never attempt to

service heater while it is plugged

in, operating, or hot. Burns and

electrical shock could result.

Only a qualied service person

should service or repair heater.

Verify proper operation after servicing. If any

of the original wire as supplied with the appliance must be replaced, it must be replaced

with a wire of at least a 105º C temperature

rating.

Switch

Black

Green

White

AUTO

O

MAN

Motor

200213-01B22

Page 23

1/2 Glass

Height

Yellow

1/2 Glass

INSPECTING HEATER

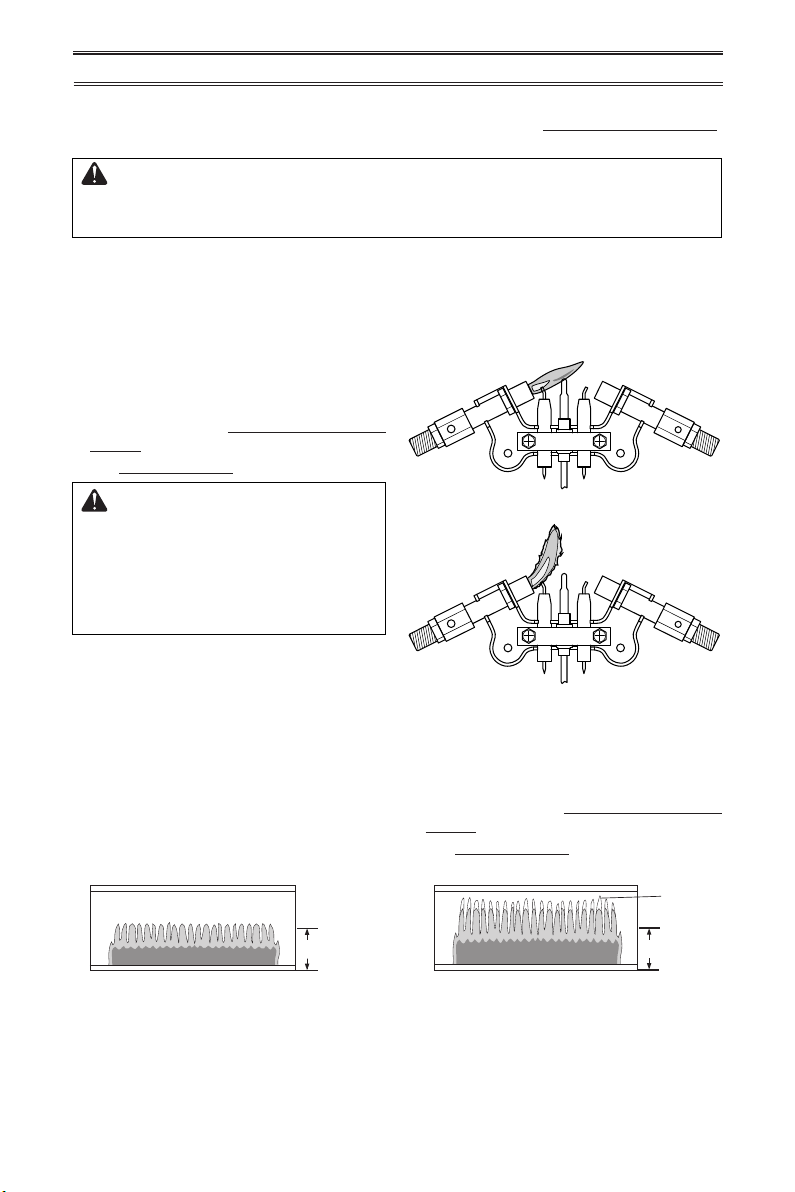

IMPORTANT: Owner’s should check pilot ame pattern and burner ame pattern often.

Incorrect ame patterns indicate the need for cleaning (see Care and Maintenance,

page 24) or service.

WARNING: Only a qualied service person should service and

repair heater. This includes maintenance requiring replacement or

alteration of components.

PILOT FLAME PATTERN

Figure 24 shows a correct pilot ame pattern.

Figure 25 shows an incorrect pilot ame pattern. The incorrect pilot ame is not touching

the thermocouple. This will cause the thermocouple to cool, which shuts the heater off.

If pilot ame pattern is incorrect, as shown

in Figure 25

• turn heater off (see To Turn Off Gas to Ap-

pliance, page 20 or 21)

• see Troubleshooting pages 25 through 28.

Notice: Do not mistake orange ames with

yellow tipping. Dirt or other ne particles enter

the heater and burn causing brief patches of

orange ame.

Natural Gas

Shown

3-3.5" WC

NG

8-11" WC

LP

WARNING: If yellow tipping

Figure 24 - Correct Pilot Flame Pattern

occurs, your heater could pro-

duce increased levels of carbon

monoxide. If the burner ame

pattern shows yellow tipping,

follow instructions below.

BURNER FLAME PATTERN

Figure 26 shows a correct burner ame pattern. Figure 27 shows an incorrect burner

ame pattern. The incorrect burner ame

pattern shows yellow tipping of the ame. It

also shows the ame higher than 1/2 the heat

shield height.

Height

Figure 26 - Correct Burner Flame Pattern Figure 27 - Incorrect Burner Flame Pattern

Natural Gas

Shown

3-3.5" WC

NG

8-11" WC

LP

Figure 25 - Incorrect Pilot Flame Pattern

If burner ame pattern is incorrect, as shown

in Figure 27

• turn heater off (see To Turn Off Gas to Ap-

pliance, page 20 or 21)

• see Troubleshooting pages 25 through 28.

Tipping

1/2 Glass

Height

www.usaprocom.com

23200213-01B

Page 24

CARE AND MAINTENANCE

WARNING: Turn off heater and let cool before servicing.

CAUTION: You must keep control areas, burner, and circulating

air passageways of heater clean. Inspect these areas of heater before

each use. Have heater inspected yearly by a qualied service techni-

cian. Heater may need more frequent cleaning due to excessive lint

from carpeting, bedding material, pet hair, etc.

WARNING: Failure to keep the primary air opening(s) of the

burner(s) clean may result in sooting and property damage.

ODS/PILOT AND BURNER

Use a vacuum cleaner, pressurized air, or a small, soft bristled brush to clean.

BURNER PILOT AIR INLET

The primary air inlet hole allows the proper

amount of air to mix with the gas. This provides a clean burning ame. Keep this hole

clear of dust, dirt and lint. Clean this air inlet

hole prior to each heating season. A blocked

air hole will create soot. We recommend that

you clean the unit every three months during

operation and have heater inspected yearly

by a qualied service person.

We also recommend that you keep the burner

tube and pilot assembly clean and free of dust

and dirt. To clean these parts we recommend

using compressed air no greater than 30 PSl.

Your local computer store, hardware store,

or home center may carry compressed air in

a can. You can use a vacuum cleaner in the

blow position. If using compressed air in a

can, please follow the directions on the can.

If you don’t follow directions on the can, you

could damage the pilot assembly.

1. Shut off the unit, including the pilot. Allow

the unit to cool for at least thirty minutes.

2. Inspect burner and pilot for dust and dirt.

3. Blow air across the ports/slots and holes

in the burner.

4. Never insert objects into the pilot tube.

Clean the pilot assembly also. A yellow tip on

the pilot ame indicates dust and dirt in the

pilot assembly. There is a small pilot air inlet

about 2" from where the pilot ame comes out

of the pilot assembly (see Figure 28). With

the unit off, lightly blow air through the air

inlet. You may blow through a drinking straw

if compressed air is not available.

Natural Gas

Burner

Pilot Air

Inlet Hole

Figure 28 - Pilot Inlet Air Hole

Ignitor

Electrode

Thermocouple

Propane/LP

Gas Burner

Pilot Air Inlet Hole

Use pressurized air to clean.

Air Passageways

CABINET

Use a soft cloth dampened with a mild soap

and water mixture. Wipe the cabinet to remove dust.

www.usaprocom.com

Exterior

200213-01B24

Page 25

TROUBLESHOOTING

WARNING: If you smell gas:

• Shut off gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re department.

WARNING: Only a qualied service technician should service and

repair heater. Make sure that power is turned off before proceeding.

Turn off and let cool before servicing.

CAUTION: Never use a wire, needle, or similar object to clean

ODS/pilot. This can damage ODS/ pilot unit.

IMPORTANT: Operating heater where impurities in air exist may create odors. Cleaning supplies, paint, paint remover, cigarette smoke, cements and glues, new carpet or textiles, etc.,

create fumes. These fumes may mix with combustion air and create odors.

Note: All troubleshooting items are listed in order of operation.

Problem Possible Cause Corrective Action

Using natural gas and

pilot will not light.

Inlet pressure exceeds

9.5" WC.

Bypass pressure switch. See

instructions below.

When using natural gas (NG), there is a

Pressure Switch

pressure switch that acts to turn off the gas

ow to the pilot if the inlet pressure exceeds

9.5" WC. This is to prevent the operation of

the unit on the wrong gas (propane/LP). If

your natural gas supply exceeds 9.5" WC the

unit will not operate. Either contact your gas

supplier to check and adjust the inlet pressure

or a qualied service technician can bypass

the pressure switch.

Before attempting to bypass the pressure

switch, make sure the type of gas being used

is correct. Check to make sure the connection

tting is in the correct inlet on the regulator.

Refer to Connecting to Gas Supply, page 16.

Only a qualied installer should bypass the

pressure switch. To bypass the pressure

switch locate the set screw on the regulator.

Use a small at bladed screw driver to turn the

set screw counterclockwise 2 turns. This will

bypass the pressure switch function.

www.usaprocom.com

The entire gas delivery piping including connections inside the heater should be leak

tested by the qualied installer. After leak

testing the qualied installer should light the

appliance. Refer to the correct ame pattern

as illustrated on page 23. All ame patterns

should be safely inside the product. If for any

reason they are not, stop use of the appliance

and call for repairs.

NG

Pressure Switch Set Screw

Figure 29 - Gas Regulator Pressure

Switch

25200213-01B

Page 26

TROUBLESHOOTING

Problem Possible Cause Corrective Action

When ignitor button is

pressed in, there is no

spark at ODS/pilot.

When ignitor button is

pressed in there is a

spark at ODS/pilot but

no ignition.

ODS/pilot lights but ame

goes out when control

knob is released.

1. Ignitor electrode is positioned wrong. Ignitor electrode is broken.

2. Ignitor electrode is not connected to ignitor cable.

3. Ignitor cable is pinched or

wet.

4 Broken ignitor cable.

5. Bad piezo ignitor.

1. Gas supply is turned off or

equipment shutoff valve is

closed.

2. Control knob not fully

pressed in while pressing

ignitor button.

3. Air in gas lines when installed.

4. ODS / pilot is clogged.

5. Incorrect inlet gas pressure

or inlet regulator is damaged.

6. Control knob not in PILOT

position.

7. Depleted gas supply (propane).

1. Control knob is not fully

pressed in.

2. Control knob is not pressed

in long enough.

3. Equipment shutoff valve is

not fully open.

4. Thermocouple connection is

loose at control valve.

5. Pilot flame not touching

thermocouple, which allows

thermocouple to cool, causing pilot ame to go out. This

problem could be caused by

one or both of the following:

A) Low gas pressure

B) Dirty or partially clogged

ODS/pilot

6. Thermocouple damaged.

7. Control valve damaged.

1. Replace pilot assembly.

2. Replace ignitor cable.

3. Free ignitor cable if pinched

by any metal or tubing. Keep

ignitor cable dry.

4. Replace ignitor cable.

5. Replace piezo ignitor.

1. Turn on gas supply or open

equipment shutoff valve.

2. Fully press in control knob

while pressing ignitor button.

3. Continue holding down control knob. Repeat igniting operation until air is removed.

4.

Clean ODS/pilot (see Care

and Maintenance, page 24) or

replace ODS/pilot assembly.

5. Check inlet gas pressure or

replace inlet gas regulator.

6. Turn control knob to PILOT

position.

7. Contact local propane/LP

gas company.

1. Press in control knob fully.

2. After ODS/pilot lights, keep

control knob pressed in 30

seconds.

3. Fully open equipment shutoff

valve.

4. Hand tighten until snug, and

then tighten 1/4 turn more.

5. A) Contact local natural or

propane/LP gas company

B) Clean ODS/pilot (see

Care and Maintenance,

page 24) or replace ODS/

pilot assembly

6. Replace thermocouple

7. Replace control valve.

www.usaprocom.com

200213-01B26

Page 27

TROUBLESHOOTING

Problem Possible Cause Corrective Action

Burner(s) does not light

after ODS/pilot is lit.

Delayed ignition of

burner(s).

Burner backring during

combustion.

High yellow ame during

burner combustion.

Gas odor during combustion.

Slight smoke or odor

during initial operation.

Heater produces a whistling noise when burner

is lit.

1. Burner orice is clogged.

2. Burner orice diameter is too

small.

3. Inlet gas pressure is too low.

1. Manifold pressure is too low.

2. Burner orice is clogged.

1. Burner orice is clogged or

damaged.

2. Burner is damaged.

3. Gas regulator is damaged.

1. Not enough air.

2. Gas regulator is defective.

3. Inlet gas pressure is too low.

1. Foreign matter between

control valve and burner.

2. Gas leak. (See Warning

Statement at top of page 25).

1. Residues from manufacturing process.

1. Turning control knob to high

(5) position when burner is

cold.

2. Air in gas line.

3. Air passageways on heater

are blocked.

4. Dirty or partially clogged

burner orice.

1. Clean burner orifice (see

Care and Maintenance,

page 24) or replace burner

orice.

2. Replace burner orice.

3. Contact local gas supplier.

1. Contact local gas supplier.

2. Clean burner (see Care and

Maintenance, page 24) or

replace burner orice.

1. Clean burner orifice (see

Care and Maintenance,

page 24) or replace burner

orice.

2. Replace burner.

3. Replace gas regulator.

1. Check burner for dirt and

debris. If found, clean burner

(see Care and Maintenance,

page 24).

2. Replace gas regulator.

3. Contact local gas supplier.

1. Take apart gas tubing and

remove foreign matter.

2. Locate and correct all leaks

(see Checking Gas Connec-

tions, page 17).

1. Problem will stop after a few

hours of operation.

1. Turn control knob to low (1)

position and let warm up for

a minute.

2. Operate burner until air is

removed from line. Have gas

line checked by local gas

supplier.

3 Observe minimum installa-

tion clearances (Figure 4,

page 10).

4 Clean burner (see Care and

Maintenance, page 24) or

replace burner orice.

www.usaprocom.com

27200213-01B

Page 28

TROUBLESHOOTING

Problem Possible Cause Corrective Action

Heater produces a clicking/ticking noise just after

burner is lit or shut off.

White powder residue

forming within burner

box or on adjacent walls

or furniture.

Heater produces unwanted odors.

Heater shuts off in use

(ODS operates).

Gas odor exists even

when control knob is in

OFF position.

Moisture/condensation

noticed on windows.

1. Metal is expanding while

heating or contracting while

cooling.

1. When heated, the vapors

from furniture polish, wax,

carpet cleaners, etc., turn

into white powder residue.

1. Heater is burning vapors from

paint, hair spray, glues, etc.

See IMPORTANT statement,

page 25.

2. Gas leak. See Warning State-

ment at the top of page 25.

3. Low fuel supply (propane/LP

gas only).

1. Not enough fresh air is available.

2. Low line pressure.

3. ODS/pilot is partially

clogged.

1. Gas leak. See Warning

Statement at top of page 25.

2. Control valve is defective.

1. Not enough combustion/

ventilation air.

1. This is common with most

heaters. If noise is excessive, contact qualied service technician.

1. Turn heater off when using

furniture polish, wax, carpet

cleaner or similar products.

1. Ventilate room. Stop using

odor causing products while

heater is running.

2. Locate and correct all leaks

(see Checking Gas Connec-

tions, page 17).

3. Rell supply tank (Propane/

LP models).

1. Open window and/or door for

ventilation.

2. Contact local gas supplier.

3. Clean ODS/pilot (see Care

and Maintenance, page 24).

1. Locate and correct all leaks

(see Checking Gas Connec-

tions, page 17).

2. Replace control valve.

1. Refer to Air for Combus-

tion and Ventilation requirements, page 7.

SERVICE HINTS

• pilot will not stay lit

• burners will have delayed ignition

• replace will not produce specied heat

• propane/LP gas supply might be low (propane/LP units only)

You may feel your gas pressure is too low. If so, contact your local gas supplier.

When Gas Pressure Is Too Low

TECHNICAL SERVICE

You may have further questions about installation, operation, or troubleshooting. If so, contact

ProCom Heating, Inc. at 1-866-573-0674.

When calling, please have your model and serial numbers of your heater ready.

www.usaprocom.com

200213-01B28

Page 29

REPLACEMENT PARTS

Note: Use only original replacement parts. This will protect your warranty coverage for parts

replaced under warranty.

PARTS UNDER WARRANTY

Contact authorized dealers of this product.

If they can’t supply original replacement

parts, call Customer Service toll free at

1-866-573-0674 for referral information.

When calling Customer Service or your dealer,

have ready:

• Your name

• Your address

• Model and serial number of your heater

• How heater was malfunctioning

• Type of gas used (Propane/LP or Natural

gas/NG)

• Purchase date

Usually, we will ask you to return the defective

part to the factory

PARTS NOT UNDER WARRANTY

Contact authorized dealers of this product.

If they can’t supply original replacement

part(s) call Customer Service toll free at

1-866-573-0674 for referral information.

When calling Customer Service have ready:

• Model number of your heater

• The replacement part number

ACCESSORIES

Purchase these heater accessories from your local dealer. If they can not supply these accessories, contact ProCom Heating, Inc. at 1-866-573-0674 for information.

EQUIPMENT SHUTOFF VALVE

For all models. Equipment shutoff valve with

1/8” NPT tap.

OPTIONAL FAN KIT

Optional fan kit, part PF06-YJLF-B (ts

model # MNSD200TBA, MNSD300TBA,

MNSD200HBA, MNSD300HBA,

MNSD200TBA-BB, MNSD300TBA-BB,

MNSD200HBA-BB, MNSD300HBA-BB).

The fan has 3 settings ON/OFF/Auto.

Please refer to PF06-YJLF-B instructions.

FLOOR MOUNTING STAND

For locating heater on the oor, away from a

wall. Complete installation instructions provided with oor mounting stand.

www.usaprocom.com

29200213-01B

Page 30

PARTS

9

1

2

3

4

5

11

14

13

8

6

7

10

15

12

T-Stat

Manual

MODELS MNSD100HBA & MNSD100TBA

www.usaprocom.com

200213-01B30

Page 31

PARTS

MODELS MNSD100HBA & MNSD100TBA

This list contains replaceable parts for your heater. When ordering replacement parts, follow

the instructions listed under Replacement Parts on page 29 of this manual.

ITEM MNSD100HBA MNSD100TBA DESCRIPTION QTY

1 ** ** Cabinet Assembly 1

2 ** ** Reector Unit 1

3 ML087-03 ML087-03 Upper Glass Retainer 1

4 ML086-03 ML086-03 Glass 1

5 ML088-03 ML088-03 Lower Glass Retainer 1

6 ** ** Middle Panel 1

7 MB09003 MB09003 Lower Front Panel Assembly 1

8 MB29003 MB29003 Grill Guard 1

9 161132-01 161132-01 Mounting Bracket 1

10 161133-01 161133-01 Ignitor Assembly 1

11 ** ** Burner Assembly 1

12 ** 161130-01 Thermostat Valve Assembly 1

12 NV2020-1213B ** Manual Control Valve 1

13 ** ** Pressure Regulator Assembly 1

ND0310A-600-P-PI6 ND0310A-600-P-PI6 ODS Pilot 1

14

ML031-03 ** Control Knob 1

15

PARTS AVAILABLE - NOT SHOWN

161607-01 161607-01 Hardware Package 1

** 161605-01 Thermostat Sensing Bulb Clip 1

**Not a eld replaceable part.

www.usaprocom.com

31200213-01B

Page 32

PARTS

MODELS MNSD200TBA & MNSD300TBA

9

2

2

1

11

3

4

5

6

14

7

8

www.usaprocom.com

12

13

10

200213-01B32

Page 33

PARTS

MODELS MNSD200TBA & MNSD300TBA

This list contains replaceable parts for your heater. When ordering replacement parts, follow

the instructions listed under Replacement Parts on page 29 of this manual.

ITEM MNSD200TBA MNSD300TBA

1 ** ** Cabinet Assembly 1

2 ** ** Reector Unit 1

3 ML087-02 ML087-01 Upper Glass Retainer 1

4 ML086-02 ML086-01 Glass 1

5 ML088-02 ML088-01 Lower Glass Retainer 1

6 ** ** Middle Panel 1

7 MB09002 MB09051 Lower Front Panel Assembly 1

8 MB29002 MB29001 Grill Guard 1

9 161562-01 161562-01 Mounting Bracket 1

10 ** ** Pressure Regulator Assembly 1

11 161133-01 161133-01 Ignitor Assembly 1

12 161130-01 161130-01 Thermostat Valve Assembly 1

13 ** ** Burner Assembly 1

14 ND0310A-800-P-PI6 ND0310A-800-P-PI6 ODS Pilot 1

PARTS AVAILABLE - NOT SHOWN

161607-01 161607-01 Hardware Package 1

161605-01 161605-01 Thermostat Sensing Bulb Clip 1

**Not a eld replaceable part.

DESCRIPTION QTY

www.usaprocom.com

33200213-01B

Page 34

PARTS

MODELS MNSD200TBA-BB & MNSD300TBA-BB

9

2

2

1

11

3

4

5

6

14

7

8

www.usaprocom.com

12

13

10

15

16

200213-01B34

Page 35

PARTS

MODELS MNSD200TBA-BB & MNSD300TBA-BB

This list contains replaceable parts for your heater. When ordering replacement parts, follow

the instructions listed under Replacement Parts on page 29 of this manual.

ITEM

**Not a eld replaceable part.

MNSD200TBA-BB MNSD300TBA-BB

1 ** ** Cabinet Assembly 1

2 ** ** Reector Unit 1

3 ML087-02 ML087-01 Upper Glass Retainer 1

4 ML086-02 ML086-01 Glass 1

5 ML088-02 ML088-01 Lower Glass Retainer 1

6 ** ** Middle Panel 1

7 MB09002 MB09051 Lower Front Panel Assembly 1

8 MB29002 MB29001 Grill Guard 1

9 161562-01 161562-01 Mounting Bracket 1

10 ** ** Pressure Regulator Assembly 1

11 161133-01 161133-01 Ignitor Assembly 1

12 161130-01 161130-01 Thermostat Valve Assembly 1

13 ** ** Burner Assembly 1

14 ND0310A-800-P-PI6 ND0310A-800-P-PI6 ODS Pilot 1

15 PF06-YJLF-BMB PF06-YJLF-BMB Fan Accessory 1

16 PF09B PF09B Base Assembly 1

PARTS AVAILABLE - NOT SHOWN

161607-01 161607-01 Hardware Package 1

161605-01 161605-01 Thermostat Sensing Bulb Clip 1

DESCRIPTION QTY

www.usaprocom.com

35200213-01B

Page 36

WARRANTY

KEEP THIS WARRANTY

Model _______________________________

Serial No. ____________________________

Date Purchased _______________________

Keep receipt for warranty verication.

REGISTER YOUR PRODUCT AT WWW.USAPROCOM.COM

IMPORTANT: We urge you to register your product within 10 days of date of installation, complete

with entire serial number which can be found on the rating plate. Please ll out the warranty information above for your personal records. Retain this manual for future reference.

Always specify model and serial numbers when communicating with customer service.

We reserve the right to amend these specications at any time without notice. The only warranty applicable

is our standard written warranty. We make no other warranty, expressed or implied.

LIMITED WARRANTY

ProCom Heating, Inc. warrants this product to be free from defects in materials and components for ONE

(1) year from the date of rst purchase, provided that the product has been properly installed by a qualied

installer in accordance with all local codes and instructions furnished with the unit, operated and maintained in accordance with all applicable instructions. To make a claim under this warranty, the Bill of Sale

or cancelled check must be presented.

RESPONSIBILITY OF OWNER

This warranty is extended only to the original retail purchaser. This warranty covers the cost of part(s)

required to restore this heater to proper operating condition. Warranty part(s) MUST be obtained through

ProCom Heating, Inc. who will provide original factory replacement parts. Failure to use original factory

replacement parts voids this warranty.

IMPORTANT: The heater MUST be installed by a qualied installer in accordance with all local codes

and instructions furnished with the unit or the warranty is voided.

WHAT IS NOT COVERED

This warranty does not apply to parts that are not in original condition because of normal wear and tear or

parts that fail or become damaged as a result of misuse, accidents, lack of proper maintenance or defects

caused by improper installation. Travel, diagnostic cost, labor, transportation and any and all such other

costs related to repairing a defective heater will be the responsibility of the owner.

TO THE FULL EXTENT ALLOWED BY THE LAW OF THE JURISDICTION THAT GOVERNS THE SALE

OF THE PRODUCT, THIS EXPRESS WARRANTY EXCLUDES ANY AND ALL OTHER EXPRESSED

WARRANTIES AND LIMITS THE DURATION OF ANY AND ALL IMPLIED WARRANTIES. INCLUDING

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE TO ONE (1)

YEAR ON ALL COMPONENTS FROM THE DATE OF FIRST PURCHASE. PROCOM HEATING, INC.'S

LIABILITY IS HEREBY LIMITED TO THE PURCHASE PRICE OF THE PRODUCT AND PROCOM HEATING, INC. SHALL NOT BE LIABLE FOR ANY OTHER DAMAGES WHATSOEVER INCLUDING INDIRECT.

INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states do not allow a limitation on how long an implied warranty lasts or an exclusion or limitation of

accidental or consequential damages, the above limitation on implied warranties, or exclusion or limitation

on damages may not apply to you.

This warranty gives you specic legal right, and you may also have other rights that vary from state to state.

ProCom Heating, Inc.

Bowling Green, KY 42101

www.usaprocom.com

1-866-573-0674

200213-01

Rev.B

07/16

Page 37

CALENTADOR DE GAS DE

US

PARED SIN VENTILAS

MANUAL DE

FUNCIONAMIENTO

E INSTALACIÓN DEL

PROPIETARIO

LLAMA AZUL MODELOS

MNSD100TBA, MNSD200TBA

MNSD300TBA, MNSD100HBA

MNSD200TBA-BB

MNSD300TBA-BB

ADVERTENCIA: Este

aparato está equipado para

funcionar con gas (natural

y propano). No se permite

®

convertir más que a gas

natural o gas propano.

ADVERTENCIA: si la información contenida en este

manual no se sigue al pie de la letra, se puede producir un

incendio o una explosión que podría ocasionar daños a

la propiedad, lesiones personales o la pérdida de la vida.

- No guarde ni utilice gasolina u otros vapores y líquidos

inamables cerca de este aparato ni de cualquier otro.

- QUÉ HACER SI PERCIBE OLOR A GAS

• No intente encender ningún aparato.

• No toque ningún interruptor eléctrico; no use ningún

teléfono en el edicio.

• Llame inmediatamente a su proveedor de gas desde

el teléfono de algún vecino. Siga las instrucciones

del proveedor de gas.

• Si no puede localizar al proveedor de gas, llame al

departamento de bomberos.

- La instalación y el servicio deben ser realizados por

un instalador capacitado, una agencia de servicio o el

proveedor de gas.

¿Preguntas, problemas, piezas faltantes? Antes de volver a la tienda, llame a