Page 1

IMPORTANT: Read and understand this manual before

assembling, starting or servicing heater. Improper use

of heater can cause serious injury. Keep this manual for

future reference.

Never use heater in living or sleeping areas.

Heater is suitable for outdoor use and for use on com-

bustible oors.

PORTABLE FORCED AIR HEATER

KEROSENE/DIESEL HEATER WITH BUILT-IN THERMOSTAT

OWNER’S MANUAL

PCK80T - 80,000 BTU/HR

Questions, problems, missing parts? Before returning to your retailer, call

our customer service department at 1-866-573-0674, 7:30 am - 4:15 pm CST,

Monday through Friday or email customerservice@usaprocom.com

Page 2

www.usaprocom.com

160177-01B2

2. Fueling

a) Personnel involved with fueling shall be

qualied and thoroughly familiar with

the manufacturer's instructions and

applicable regulations regarding the

safe fueling of heating units.

b) Only the type of fuel specied on the

heater's data plate shall be used.

c) All ame shall be extinguished and the

heater allowed to cool, prior to fueling.

d) During fueling, all fuel lines and fuel-

line connections shall be inspected for

leaks. Any leaks shall be repaired prior

to returning the heater to service.

e) At no time shall more than one day's

supply of heater fuel be stored inside

a building in the vicinity of the heater.

Bulk fuel storage shall be outside the

structure.

f) All fuel storage shall be located a mini-

mum of 25 feet (762 cm) from heaters,

torches, welding equipment and similar

sources of ignition (exception: fuel reservoir integral with heater unit or any

authorized auxiliary tank connected to

heater unit).

g) Whenever possible, fuel storage shall

be conned to areas where oor penetrations do not permit fuel to drip onto

or be ignited by a re at lower elevation.

h) Fuel storage shall be in accordance

with the authority having jurisdiction.

3. Use only the electrical voltage and frequency specied on model plate.

4. Heater is suitable for outdoor use.

5. Heater must be grounded. Use only a

properly grounded three-wire extension

cord. Plug into grounded outlet only.

6. Use only in areas free of ammable vapors or high dust content.

WARNING: This product

contains and/or generates

chemicals known to the State

of California to cause cancer or

birth defects or other reproductive harm.

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble,

operate or service this heater.

Improper use of this heater can

cause serious injury or death

from burns, fire, explosion,

electrical shock and carbon

monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning: Early signs of

carbon monoxide poisoning resemble the u,

with headaches, dizziness and/or nausea. If

you have these signs, the heater may not be

working properly. Get fresh air at once! Have

heater serviced. Some people are more affected by carbon monoxide than others. These

include pregnant women, persons with heart

or lung disease or anemia, those under the

inuence of alcohol and those at high altitudes.

Make certain you read and understand all

warnings. Keep this manual for reference. It

is your guide to safe and proper operation of

this heater.

1. Use only kerosene, #1/#2 diesel/fuel oil,

JET A or JP-8 fuels to avoid risk of re or

explosion. Never use gasoline, oil from

crank cases, naphtha, paint thinners,

alcohol or other highly ammable fuels.

SAFETY

TABLE OF CONTENTS

Safety ........................................................ 2

Unpacking.................................................. 3

Assembly ................................................... 3

Product Identication and Label Locations ... 4

Specications ............................................ 5

Fuels .......................................................... 5

Ventilation .................................................. 5

Operation ................................................... 6

Operation with Portable Generator ............ 7

Storing, Transporting or Shipping .............. 7

Preventative Maintenance Schedule ......... 7

Troubleshooting ......................................... 8

Service Procedures ................................... 9

Wiring Diagram ........................................ 15

Technical Service..................................... 15

Accessories ............................................. 15

Parts ........................................................ 16

Replacement Parts .................................. 19

Warranty .................................................. 20

Page 3

www.usaprocom.com

3160177-01B

SAFETY

UNPACKING

7. Minimum clearance from any combustible

materials: 8 feet (244 cm) from hot air

outlet, 6 feet (183 cm) from top, and 4

feet (120 cm) from sides and inlet.

8. Locate heater on a stable and level surface while hot or operating or a re may

occur.

9. Heater is acceptable for use on ooring

such as wood (a combustible material).

10. Use only in well vented areas. Before

using heater, provide at least a 3 ft2

(2800 cm2) opening of fresh, outside air

for each 100,000 Btu/Hr (30 kw) of rating.

11. Keep children and animals away from

heater at all times.

12. Never start heater when combustion

chamber is hot or if fuel has accumulated

in combustion chamber.

13. This heater is equipped with a thermostat.

Heater may start at anytime.

14. Never leave a heater plugged in without

adult supervision if children or animals are

likely to be present.

15. Use caution when moving or storing

heater when fuel tank contains fuel. Fuel

spillage can occur.

16. Use heater only in accordance with local ordinances and codes. Canadian

residents should refer to CSA standard

B139, Installation Code for Oil Burning

Equipment for recommended installation

practice.

17. Never use gasoline, crankcase drainings,

naphtha, paint thinners, alcohol or other

highly ammable fuels.

18. Never use heater where gasoline, paint

thinner or other highly ammable vapors

are present.

19. Never use heater in living or sleeping

areas.

20. Never move, handle, refuel or service a

hot, operating or plugged-in heater.

21. Never attach duct work to front or rear of

heater.

22. Heaters used in the vicinity of tarpaulins,

canvas or similar enclosure materials shall

be located a safe distance from such materials. The recommended minimum safe

distance is 10 feet (304.8 cm). It is further

recommended that these enclosure materials be of a re retardant nature. These

enclosure materials shall be securely fastened to prevent them from igniting or from

upsetting the heater due to wind action.

23. Unplug heater when not in use.

24. Never block air inlet (rear) or air outlet

(front) of heater.

25. Warning to New York City Residents

For Use Only At Construction Sites in

accordance with applicable NYC codes.

26. Never use external fuel sources or tanks

that are not specically designed for use

with this heater.

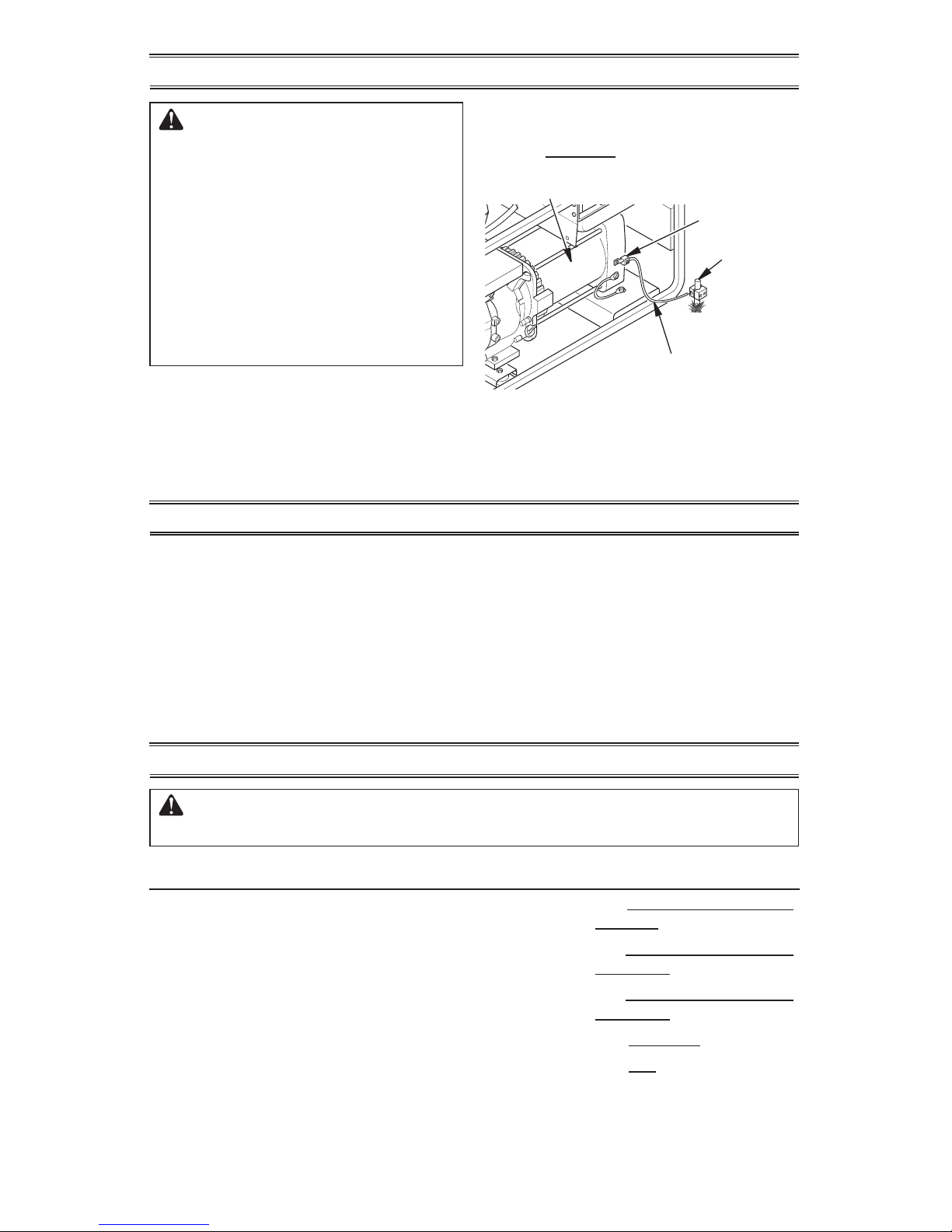

Figure 1 - Wire Guard Moved to Locked

Position

1. Remove all packing items applied to

heater for shipment.

2. Remove all items from carton.

3. Check items for any shipping damage. If

heater is damaged call ProCom Heating,

Inc. at 1-866-573-0674 for replacement

parts before returning to dealer.

ASSEMBLY

WIRE GUARD

All Models

Grasp wire guard from top of shell and pull

towards front of heater until it locks into place

in slots on both sides of upper shell.

Page 4

www.usaprocom.com

160177-01B4

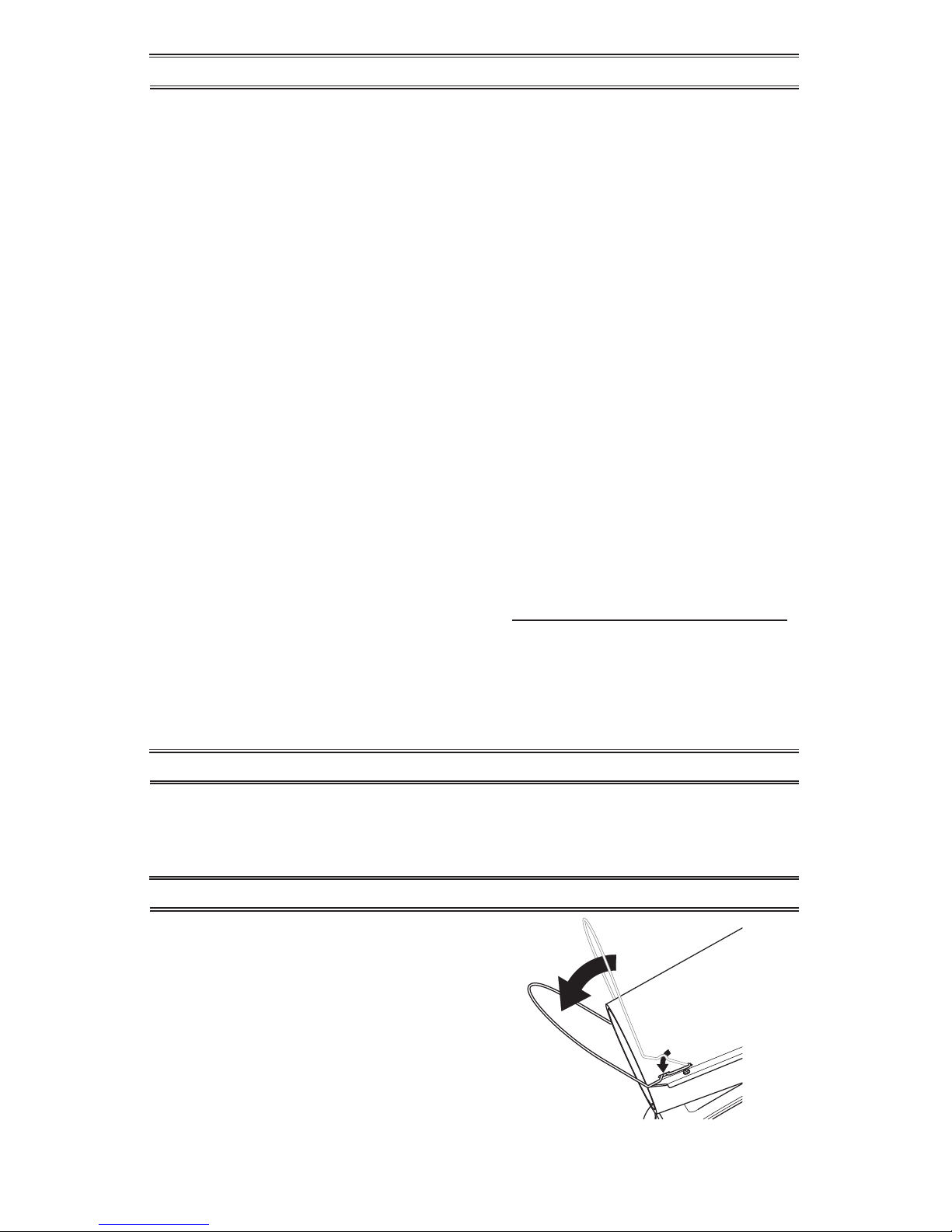

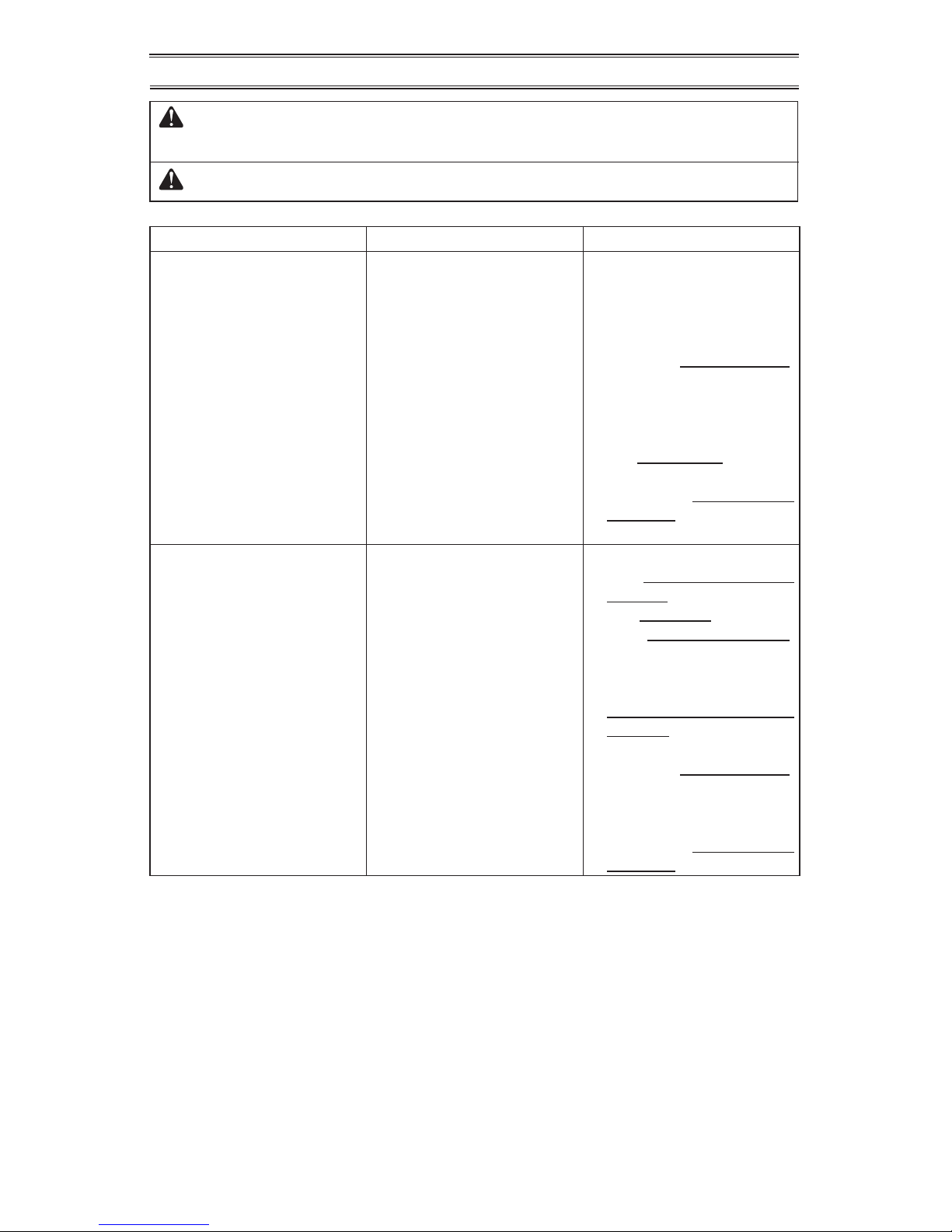

PRODUCT IDENTIFICATION AND LABEL LOCATIONS

Fueling Label

Part No. 160168-01

Warning Label

Part No. 160110-01

Operating Label

Part No. 160173-02

Maintenance Label

Part No. 160175-01

Caution Label

Part No. 160172-01

Figure 2 - Product Identication & Label Locations

CSA/Control Label

Part No. 160111-02

NY, MA and CA

Information Label

Part No. 160169-01

Right Side

Left Side

Hot Air

Outlet

Thermostat

Knob

Wire

Guard

Top Handle

Top Handle

Fuel Tank

Cold Air

Inlet

Power

Cord

Fuel Cap

Fuel

Gauge

Hot Air

Outlet

Serial

Number

Label

Page 5

www.usaprocom.com

5160177-01B

SPECIFICATIONS

VENTILATION

Example: A 80,000 Btu/Hr (23.4 kw) heater

requires one of the following:

• a two-car garage door [16 feet (4.88 meter)

opening] raised 2.2" (5.6 cm)

• a single-car garage door [9 feet (2.74 me-

ter) opening] raised 3.3" (7.4 cm)

• two, 30" (76.2 cm) windows raised 6.2"

(13.9 cm)

FUELS

• noticeable odor

• additional fuel lter maintenance

* Use of #2 diesel/fuel oil in extreme cold

temperatures may require nontoxic anti-icer

additives.

Do not use fuels heavier than No. 2 grade

or heavy oils such as oil drained from crankcases. These heavy oils will not ignite properly

and will contaminate the heater.

IMPORTANT: Use a KEROSENE ONLY (blue)

or DIESEL ONLY (yellow) storage container.

Be sure storage container is clean. Foreign

matter such as rust, dirt or water will cause the

ignition control assembly to shut down heater.

Foreign matter may also require heater's fuel

system to be frequently cleaned.

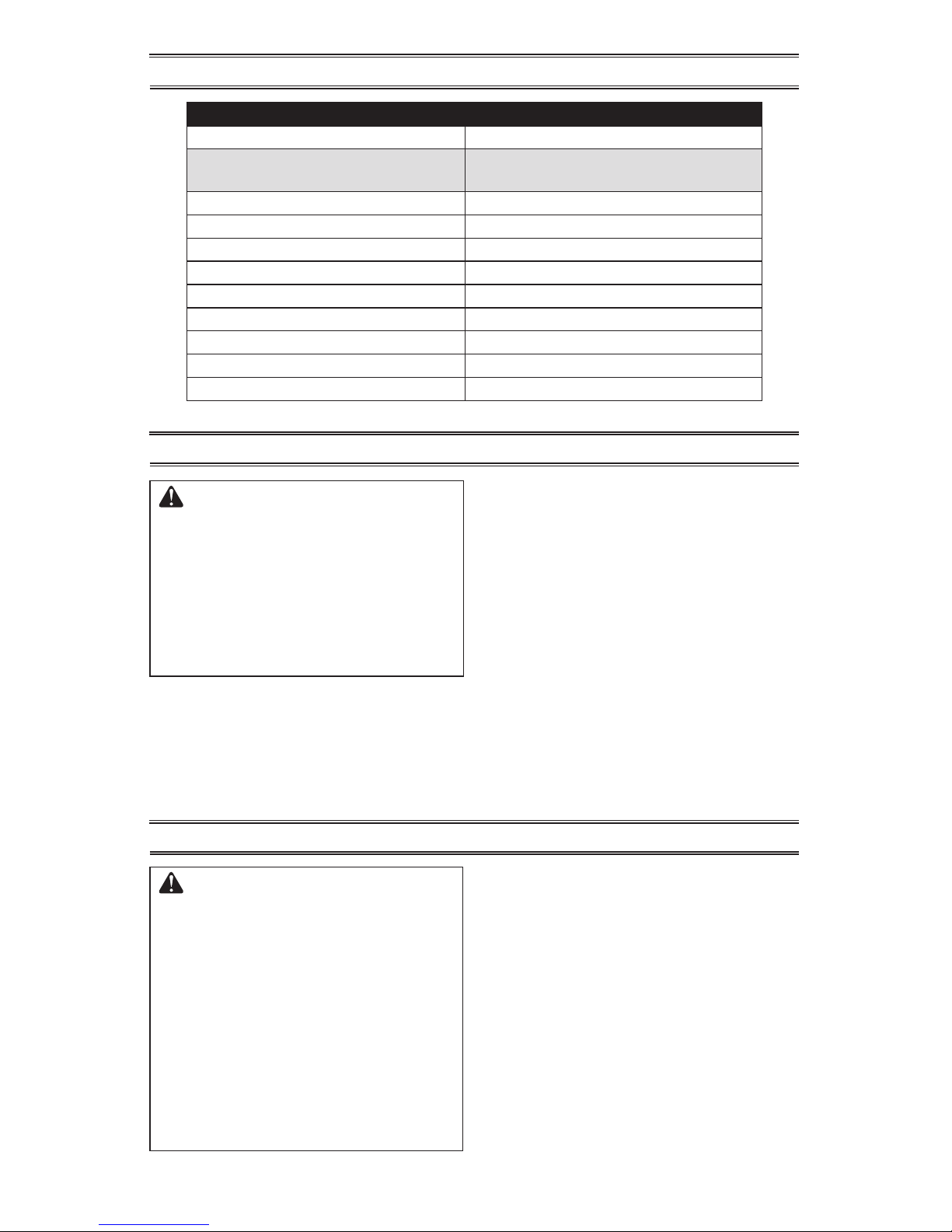

PCK80T

Output Rating 80,000 Btu/Hr

Fuel Use only kerosene, #1/#2 diesel*/fuel oil,

JET A or JP-8 fuels

Fuel Tank Capacity 5.5 gal/20.8 L

Fuel Consumption (per hr) 0.60 gal/2.3 L

Pump Pressure 3.8 PSI (hot)

Electric Requirements 120 V/60 HZ

Amperage (Normal Run) 2.5

Typical Motor Speed 3400 RPM

Motor 1/4 hp

Shipping Weight 42 lbs/19 kg

Heater Weight without Fuel (approx) 36 lbs/16.3 kg

WARNING: Use only kerosene, #1/#2 diesel/fuel oil, JET

A or JP-8 fuels to avoid risk

of re or explosion. Never use

gasoline, oil drained from crankcases, naphtha, paint thinners,

alcohol or other highly ammable fuels.

Use only kerosene, #1/#2 diesel*/fuel oil,

JET A, JP-8 fuels. Heavier fuels such as No.

2 fuel oil, No. 2 diesel fuel may also be used

but will result in:

WARNING: Provide a fresh air

opening of at least three square

feet (2,800 square cm) for each

100,000 BTU/HR rating. Provide

extra fresh air if more heaters

are being used. The minimum

ventilation requirements must

be followed to avoid risks associated with carbon monoxide

poisoning. Make certain these

requirements are met prior to

operating heater.

Page 6

www.usaprocom.com

160177-01B6

ASSEMBLED IN THE USA BY:

ASSEMBLE AUX ETATS-UNIS PAR:

ENSAMBLADA EN LOS EE.UU.POR:

PROCOM HEATING, INC.

2800 GRIFFIN DRIVE

BOWLING GREEN, KY 42101

40

50

60

70

80

90

THERMOSTAT F

THERMOSTATO F

O

O

START/RUN

ENCIENDA/OPERACION

DEMARRE/MARCHE

`

`

STANDBY

IMPORTANT: Review and understand the warnings in the

Safety section, pages 2 and 3.

They are needed to safely operate this heater. Follow all local

ordinances and codes when

using this heater.

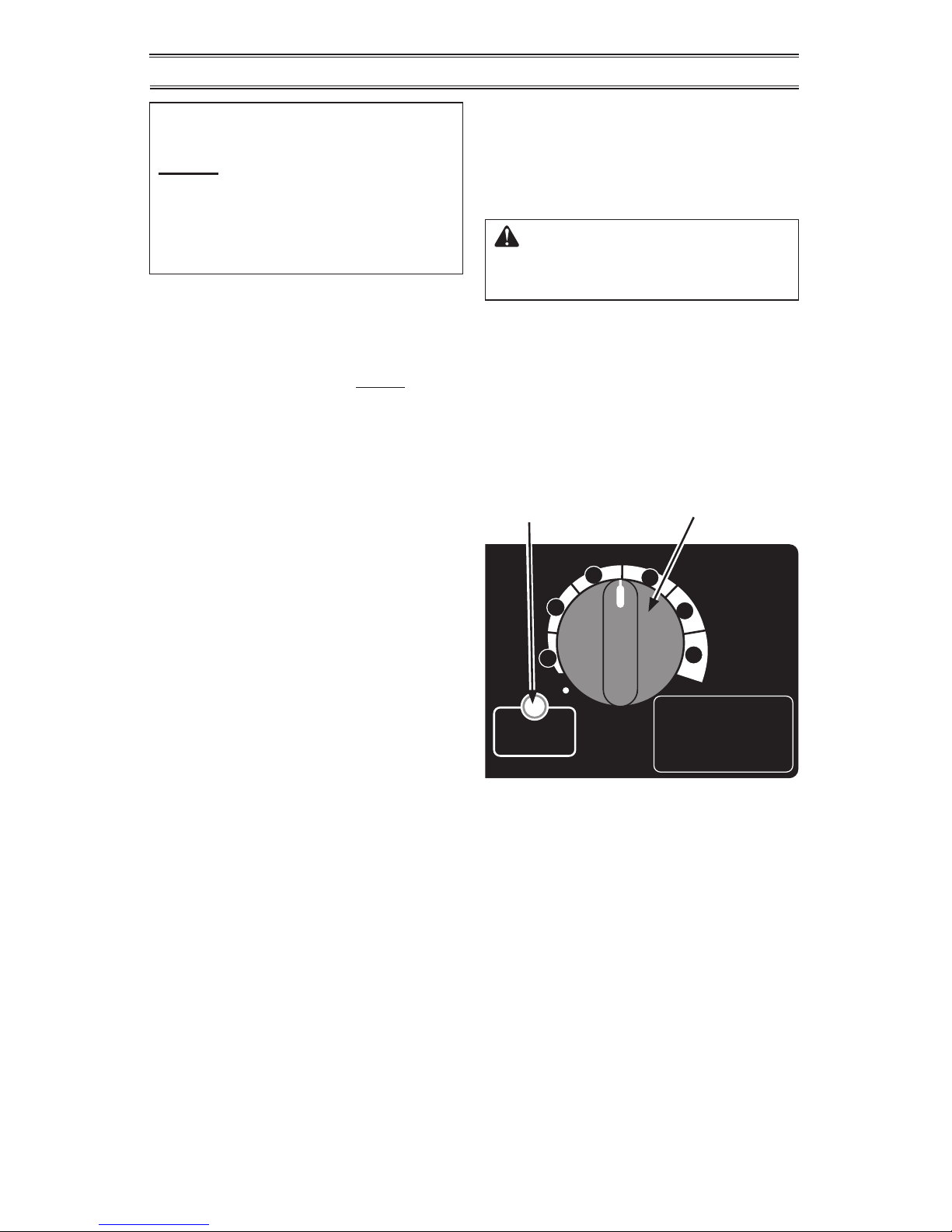

TO START HEATER

1. Follow all ventilation and safety information.

2. Locate heater to provide maximum circulation of the heated air. Follow all location

requirements noted in Safety, pages

2 and 3.

3. Fill fuel tank with fuel and attach fuel cap.

Use only kerosene, #1/#2 diesel/fuel oil,

JET A or JP-8 fuels to avoid risk of re or

explosion. Never use gasoline, oil drained

from crank cases, naphtha, paint thinners,

alcohol or other ammable fuels.

4. Plug heater’s power cord into approved,

grounded, three-wire extension cord.

Extension cord must be at least 6 feet

(1.8 m) long.

Extension Cord Size Requirement

• 6 to 10 feet (1.8 to 3 m) long, use 18

AWG (0.75 mm2) rated cord

• 11 to 100 feet (3.3 to 30.5 m) long, use

16 AWG (1.0 mm2) rated cord

• 101 to 200 feet (30.8 to 61 m) long, use

14 AWG (1.5 mm2) rated cord

5. Plug extension cord into standard 120

volt/60 hertz, 3-prong grounded outlet.

6. Turn thermostat knob to the desired tem-

perature setting.

If thermostat set temperature is higher

than the surrounding air temperature,

heater should ignite immediately. If heater

thermostat set temperature is lower than

surrounding air temperature, heater will

not ignite. Exposure to direct sunlight

or extreme cold may affect temperature

reading and/or thermostat operation.

The LED will ash for 8 seconds before

ignition. The LED will remain on during

heater operation, even if the heater is

cycled off by the thermostat. The LED will

ash rapidly if the heater shuts down for

any reason (Example: If out of fuel).

WARNING: This heater is

equipped with a thermostat.

Heater may start at any time.

TO STOP HEATER

1. Turn thermostat knob counterclockwise

to STANDBY.

2. Unplug heater when not in use.

TO RESET HEATER

1. Wait two minutes before restarting.

2. Turn thermostat knob to STANDBY for 10

seconds, then restart heater.

OPERATION

Figure 3 - Controls Display

Thermostat Knob

LED Light

Page 7

www.usaprocom.com

7160177-01B

Ground Wire (#10 AWG Stranded-Copper)

Copper

or Brass

Grounding

Point

Figure 4 - Typical Generator Grounding

Method (Generator construction may

vary from that shown)

PREVENTATIVE MAINTENANCE SCHEDULE

WARNING: Never service heater while it is plugged in, operating

or hot. Severe burns and electrical shock can occur.

OPERATION WITH PORTABLE GENERATOR

Alternator

Ground Lug

WARNING: Before operating

heater or any appliance from a

portable generator, verify that

generator has been properly connected to earth ground. Improper

grounding or failure to ground

generator can result in electrocution if a ground fault occurs.

Refer to owner’s manual supplied

by generator manufacturer for

proper grounding procedures.

Operating voltage range of heater is 95 to 135

Volts. Prior to plugging heater into generator

output voltage should be veried (if generator

is equipped with automatic idle feature, output

voltage should be measured with generator

running at full speed). If voltage does not

STORING, TRANSPORTING OR SHIPPING

3. Properly dispose of old and dirty fuel.

Check with local automotive service stations that recycle oil.

4. If storing, store heater in dry place. Make

sure storage place is free of dust and

corrosive fumes.

IMPORTANT: Do not store kerosene over

summer months for use during next heating

season. Using old fuel could damage heater.

measure in this range heater should not be

plugged into generator.

Refer to Operation, page 6, for starting, stop-

ping and resetting heater procedures.

Note: If shipping, transport companies require

fuel tanks to be empty.

1. Remove excess fuel from tank using a siphon pump. Drain remaining fuel through

ller neck by tipping heater to the rear.

2. If any debris is noted in old fuel, add 1 or 2

quarts of clean kerosene to tank, stir and

drain again. This will prevent excess debris

from clogging lters during future use.

Item How Often How To

Fuel tank Clean every season or as needed. See Storing, Transporting, or

Shipping, above.

Air output and

lint lters

Replace every 500 hours of operation or

once a year.

See Air Output, Air Intake and

Lint Filters, page 10.

Air intake lter Wash and dry with soap and water every 500

hours of operation or as needed.

See Air Output, Air Intake and

Lint Filters, page 10.

Fuel lter Clean twice a heating season or as needed. See Fuel Filter, page 11.

Fan blades Clean every season or as needed. See Fan, page 10.

Motor Not required/permanently lubricated.

Page 8

www.usaprocom.com

160177-01B8

TROUBLESHOOTING

WARNING: Never service heater while it is plugged in, operating

or hot. Severe burns and electrical shock can occur.

WARNING: High voltage! Unplug heater before servicing.

FAULT CONDITION POSSIBLE CAUSE REMEDY

Motor does not start eight sec-

onds after heater is plugged in.

1. No power to heater.

2. Thermostat setting is too

low.

3. Bad electrical connection

between motor and ignition

control assembly or ignition control assembly and

power cord.

4. Binding pump rotor.

5. Defective ignition control

assembly.

6. Defective motor.

1. Check circuit breaker in

electrical panel.

2. Turn thermostat knob to a

higher setting.

3. Check all electrical connections. See Wiring Diagram,

page 15.

4. If fan does not turn freely,

see Pump Rotor, page 14.

5. Replace ignition control assembly. See Ignition Control

Assembly, page 13.

6. Replace motor.

Motor starts and runs but

heater does not ignite.

1. No fuel in tank.

2. Pump pressure incorrect.

3. Dirty fuel lter.

4. Obstruction in nozzle.

5. Water in fuel tank.

6. Bad electrical connection

between ignitor and ignition

control assembly.

7. Defective ignitor.

8. Defective ignition control

assembly.

1. Fill tank with kerosene.

2. See Pump Pressure Adjustment, page 11.

3. See Fuel Filter, page 11.

4. See Nozzle Assembly,

page 13.

5. Drain and ush fuel tank

with clean kerosene. See

Storing, Transporting, or

Shipping, page 7.

6. Check electrical connections. See Wiring Diagram,

page 15.

7.

Replace ignitor, see page 12.

8. Replace ignition control assembly. See Ignition Control

Assembly, page 13.

Page 9

www.usaprocom.com

9160177-01B

TROUBLESHOOTING

WARNING: High voltage! Unplug heater before servicing.

FAULT CONDITION POSSIBLE CAUSE REMEDY

Heater ignites but ignition

control assembly shuts heater

off after a short period of time.

1. Pump pressure incorrect.

2. Dirty air intake, air output,

and/or lint lter.

3. Dirty fuel lter.

4. Obstruction in nozzle.

5. Photocell assembly not

properly installed (not seeing the ame).

6. Dirty photocell lens.

7. Bad electrical connection

between photocell and

ignition control assembly.

8. Defective photocell.

9. Defective ignition control

assembly.

1. See Pump Pressure Ad-

justment, page 11.

2. See Air Output, Air Intake,

and Lint Filters, page 10.

3. See Fuel Filter, page 11.

4. See Nozzle Assembly,

page 13.

5. Make sure photocell boot is

properly seated in bracket.

6. Clean photocell lens.

7. Check electrical connections. See Wiring Diagram,

page 15.

8. Replace photocell.

9. Replace ignition control assembly. See Ignition Control

Assembly, page 13.

SERVICE PROCEDURES

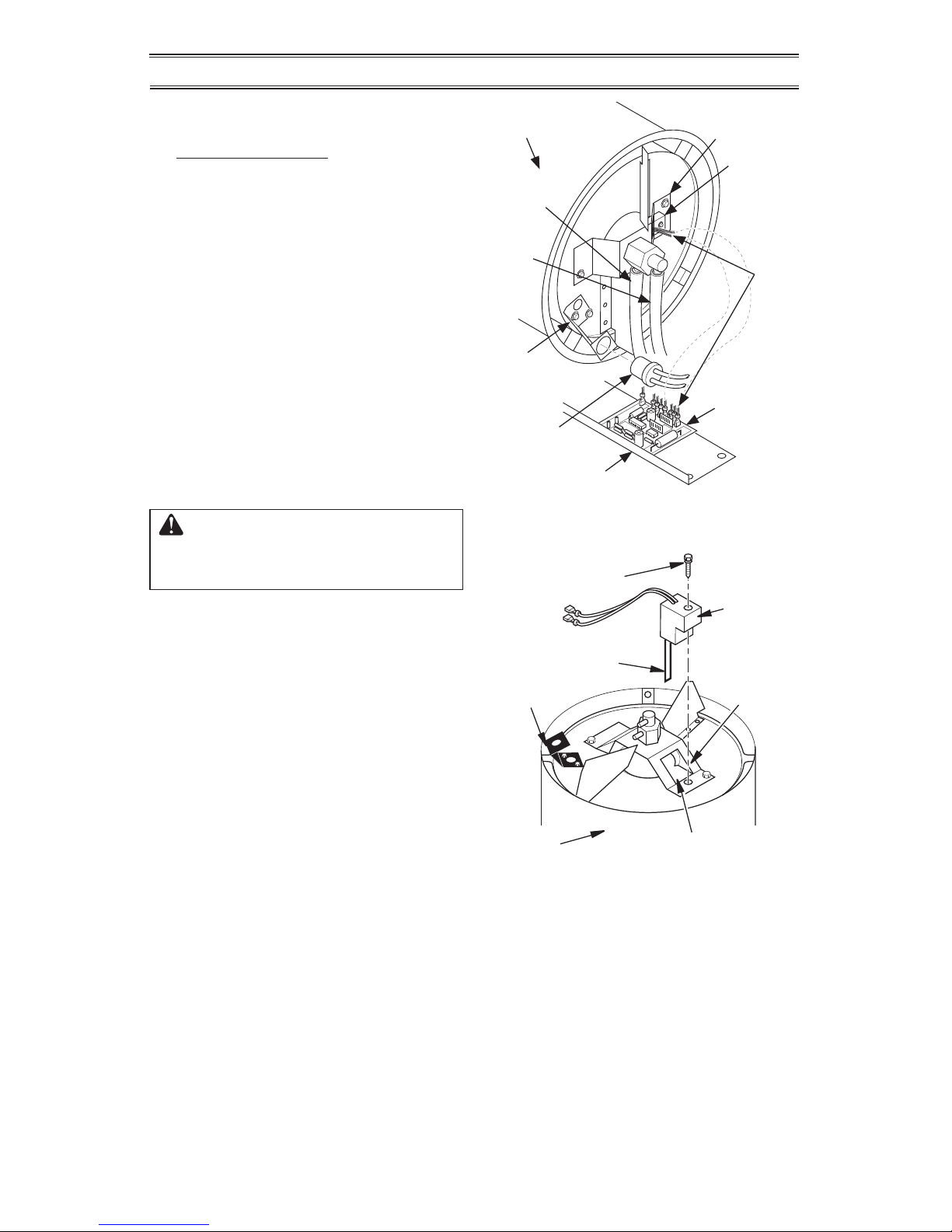

Figure 5 - Upper Shell Removal

WARNING: To avoid risk of

burn and electrical shock, never

attempt to service heater while it

is plugged in, operating, or hot.

UPPER SHELL REMOVAL

1. Remove screws along each side of heater

using 5/16" nut-driver. These screws attach upper and lower shells together. See

Figure 5.

2. Lift upper shell off.

3. Remove fan guard.

Page 10

www.usaprocom.com

160177-01B10

Motor

Shaft

Setscrew

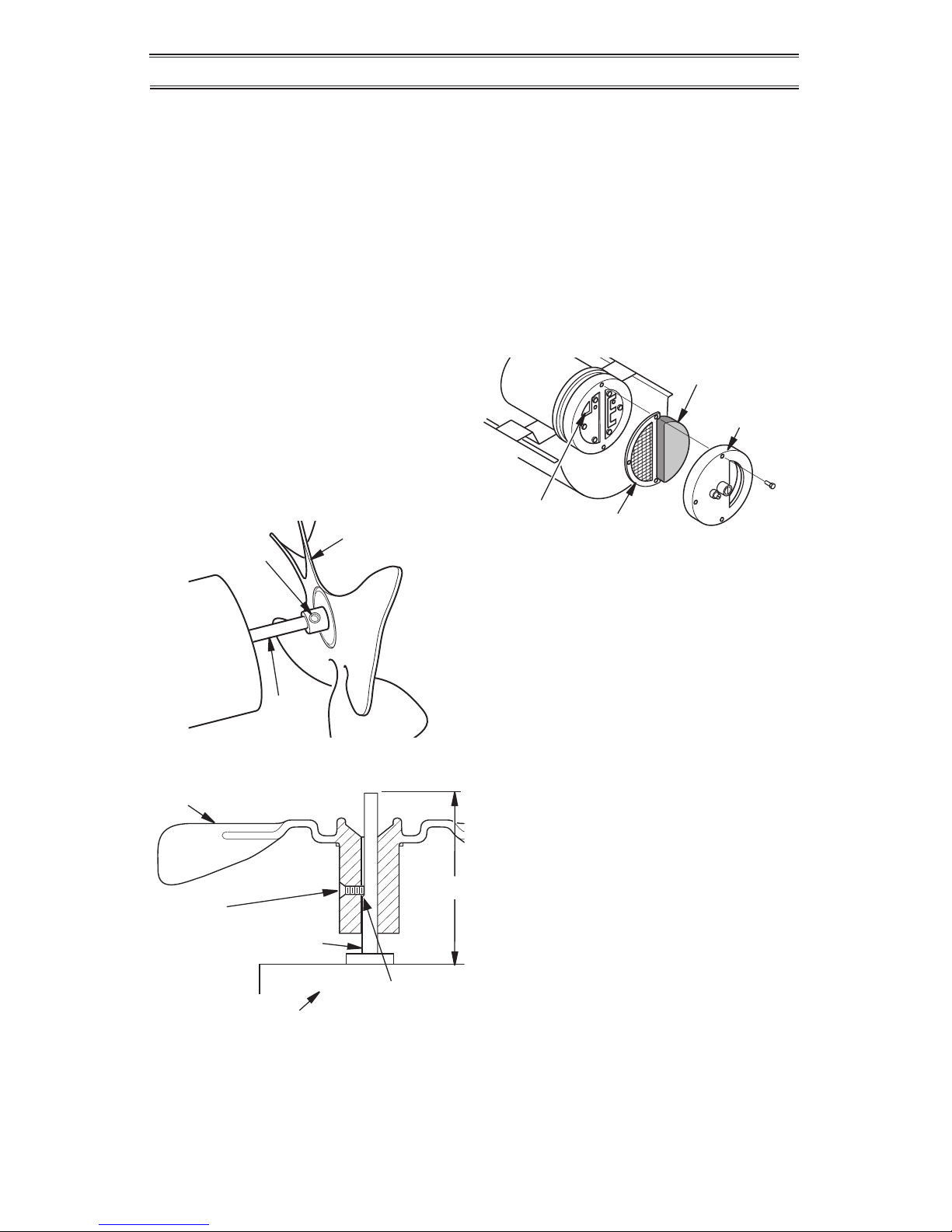

Figure 6 - Fan, Motor Shaft, and

Setscrew Location

Motor

Shaft

Back of Flat on

Motor Shaft

1.82"

Motor

Shaft

Length

Fan

Setscrew

Touching

Back of Flat

on Motor

Shaft

Figure 7 - Fan Cross Section

Fan

Motor

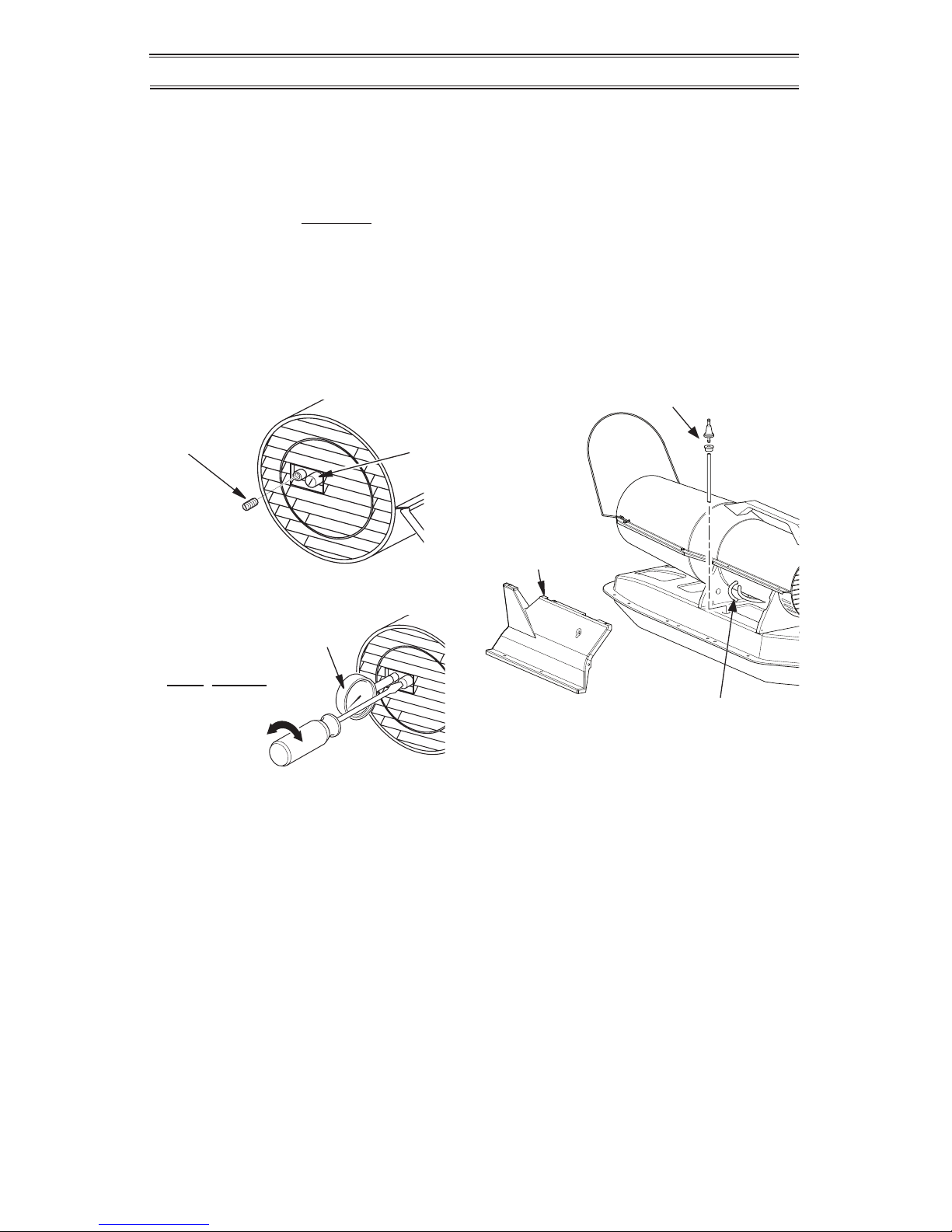

AIR OUTPUT, AIR INTAKE AND

LINT FILTERS

1. Remove upper shell (see Figure 5, page 9).

2. Remove lter end cover screws using

5/16" nut-driver (see Figure 8).

3. Remove lter end cover.

4. Replace air output and lint lters.

5. Wash or replace air intake lter.

6. Replace lter end cover.

7. Replace fan guard and upper shell.

IMPORTANT: Do not oil lters.

Air Intake

Filter

Lint Filter

Filter

End

Cover

Air Output

Filter

Figure 8 - Air Output, Air Intake, and Lint

Filters

SERVICE PROCEDURES

FAN

IMPORTANT: Remove fan from motor shaft

before removing motor from heater. The

weight of the motor resting on the fan could

damage the fan pitch (see Figure 6).

1. Remove upper shell (see Figure 5, page 9).

2. The fan is located with the set screw in

contact with the back of at on motor as

shown in Figure 7.

3. Use 1/8" Allen wrench to loosen setscrew

which holds fan to motor shaft (see Figure 6).

4. Slip fan off motor shaft.

5. Clean fan using a soft cloth moistened

with kerosene or solvent.

6. Dry fan thoroughly.

7. Place setscrew on flat of shaft.

Tighten setscrew firmly (40-50 inchpounds/4.5-5.6 n-m).

8. Replace fan guard and upper shell.

Page 11

www.usaprocom.com

11160177-01B

SERVICE PROCEDURES

PUMP PRESSURE

ADJUSTMENT

1. Remove pressure gauge plug from lter

end cover (see Figure 9).

2. Install 0-15 PSI pressure gauge.

3. Start heater (see Operation, page 6). Allow heater to reach operating temperature

(approx. 10 minutes).

4. Adjust pressure. Turn relief valve to right

to increase pressure. Turn relief valve to

left to decrease pressure. See specications in Figure 10 for correct pressure.

5. Remove pressure gauge. Replace pressure gauge plug in lter end cover.

Figure 9 - Pressure Gauge Plug Removal

Pressure

Gauge

Plug

Pressure

Gauge

Figure 10 - Adjusting Pump Pressure

Relief

Valve

Pump

Model Pressure

80 3.8 PSI

Fuel Filter, Bushing,

and Lower Fuel Line

Upper Fuel Line

Side

Cover

Figure 11 - Fuel Filter Removal

FUEL FILTER

1. Remove side cover screws using 5/16"

nut-driver.

2. Remove side cover.

3. Pull upper fuel line off fuel lter neck (see

Figure 11).

4. Carefully pry bushing, fuel lter, and lower

fuel line out of fuel tank (see Figure 11).

5. Wash fuel lter with clean fuel and replace

in tank.

6. Attach upper fuel line to fuel lter neck.

7. Replace side cover.

Page 12

www.usaprocom.com

160177-01B12

IGNITOR

1. Remove upper shell and fan guard (See

Upper Shell Removal, page 9.

2. Remove fan (see page 10).

3. Remove the control side cover with a

5/16" nut driver. Remove side cover (see

Figure 12).

4. Disconnect ignitor wires from ignition

control assembly (see Figure 12). Pull

the ignitor wires up through the hole in

the lower shell.

5. Disconnect fuel line hose and air line

hose. Remove photocell from photocell

bracket (see Figure 12).

6. Remove combustion chamber. Stand

combustion chamber on end with nozzle

adapter bracket on top (see Figure 13).

7. Remove ignitor screw with a 1/4" nut

driver. Carefully remove ignitor from

nozzle adapter bracket.

CAUTION: Do not bend or

strike ignitor element. Handle

with care.

8. Carefully remove replacement ignitor from

packing.

9. Carefully guide ignitor into opening in

nozzle adapter bracket. Do not strike

ignitor element. Attach ignitor to nozzle

adapter bracket with screw using a 1/4"

nut driver. Torque 0.90 to 1.69 N-m (8 to

15 in-lbs) Do not over torque.

10. Replace combustion chamber.

11. Route the ignitor wires back down through

the hole in the lower shell. Connect wires

to the ignition control assembly (see Fig-

ure 12).

12. Replace control side cover.

13. Connect and route fuel line hose and air

line hose to nozzle adapter assembly.

14. Replace photocell in photocell bracket.

15. Replace fan (see page 10).

16. Replace fan guard and upper shell (see

pages 9 and 10).

SERVICE PROCEDURES

Photocell

Bracket

Ignitor

Ignitor Screw/

Washer Assembly

Nozzle

Adapter

Bracket

Ignitor

Element

Combustion

Chamber

Nozzle Adapter

Bracket Opening

Figure 13 - Ignitor SP002-01

Replacement

Figure 12 - Disconnecting Ignitor Wires

from Ignition Control Assembly

Photocell

Bracket

Air Line

Hose

Fuel

Line

Hose

Combustion

Chamber

Photocell

Assembly

Ignitor

Nozzle Adapter

Bracket

Ignition

Control

Assembly

Side Cover

Ignitor

Wire

Page 13

www.usaprocom.com

13160177-01B

Figure 14 - Removing Air and Fuel Line

Hoses

Fuel Line

Hose

Air Line

Hose

Nozzle/

Adapter

Assembly

Combustion

Chamber

Photocell

Bracket

Nozzle

Adapter

Bracket

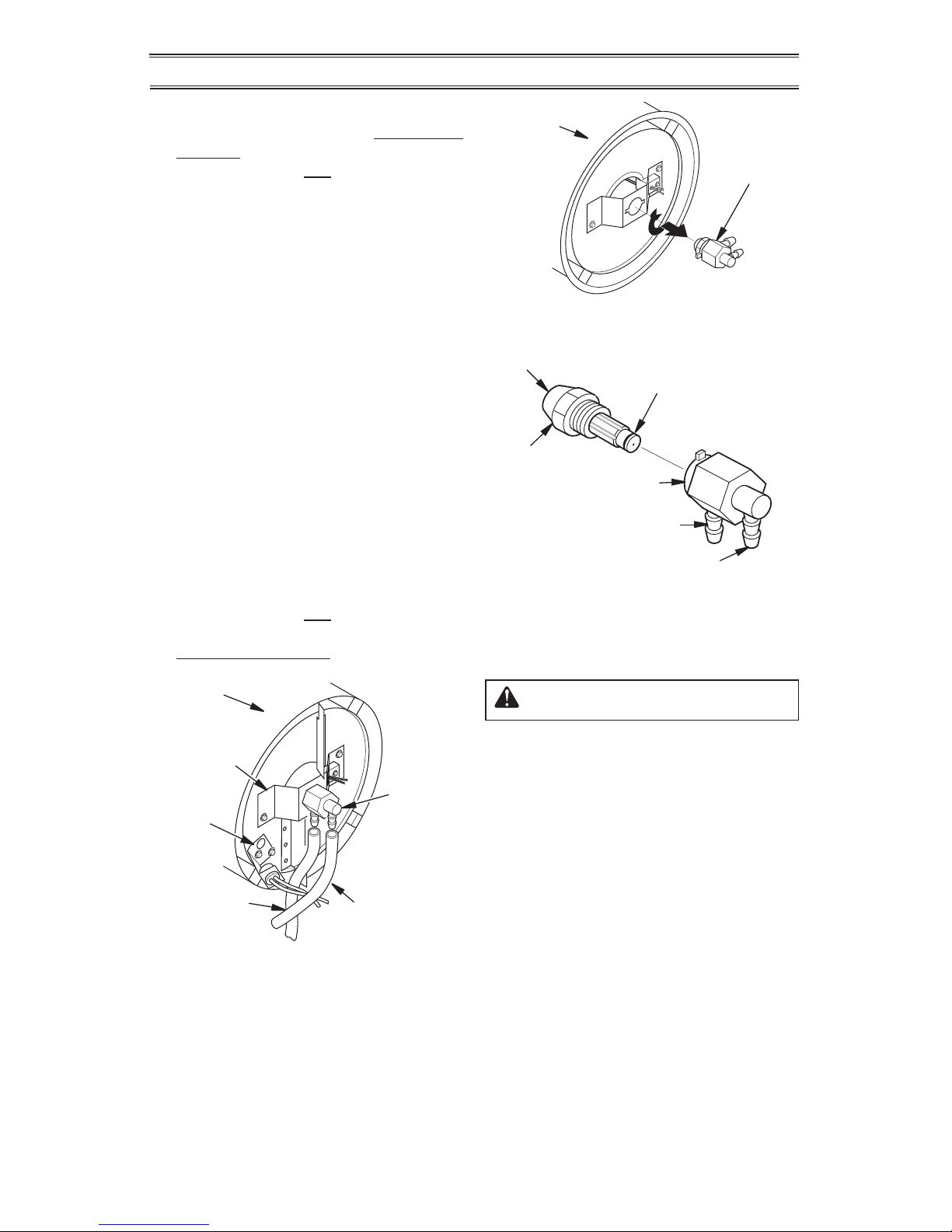

NOZZLE ASSEMBLY

1. Remove upper shell (see Upper Shell

Removal, page 9).

2. Remove fan (see Fan, page 10).

3. Remove fuel and air line hoses from

nozzle assembly (see Figure 14).

4. Turn nozzle assembly 1/4 turn to left and

pull toward motor to remove (see Figure

15).

5. Place plastic hex-body into vise and

lightly tighten.

6. Carefully remove nozzle from the nozzle

adapter using 5/8" socket wrench (see

Figure 16).

7. Blow compressed air through face of

nozzle. This will free any dirt in nozzle

area.

8. Inspect nozzle sleeve for damage.

9. Replace nozzle into nozzle adapter until

nozz l e se ats. Tig h t e n 1/3 tur n mo re u s i n g

5/8" socket wrench 4.5 to 5.1 N-m (40 to

45 in-lbs). See Figure 16.

10. Attach nozzle assembly to burner strap

(see Figure 15).

11. Attach fuel and airline hoses to nozzle

assembly.

12. Replace fan (see Fan, page 10).

13. Replace fan guard and upper shell (see

Upper Shell Removal, page 9).

Figure 15 - Removing Nozzle/Adapter

Assembly

Nozzle/

Adapter

Assembly

Combustion

Chamber

Figure 16 - Nozzle and Nozzle Adapter

Nozzle Face

Nozzle

Nozzle Sleeve

Nozzle

Adapter

Air Line

Fitting

Fuel Line

Fitting

SERVICE PROCEDURES

IGNITION CONTROL ASSEMBLY

WARNING: High voltage!

1. Unplug heater.

2. To expose the ignition control assembly,

remove the control panel side cover

screws using 5/16" nut-driver.

3. Remove old ignition control assembly.

Install new ignition control assembly (see

Figure 12, page 12).

4. Replace control panel side cover.

Page 14

www.usaprocom.com

160177-01B14

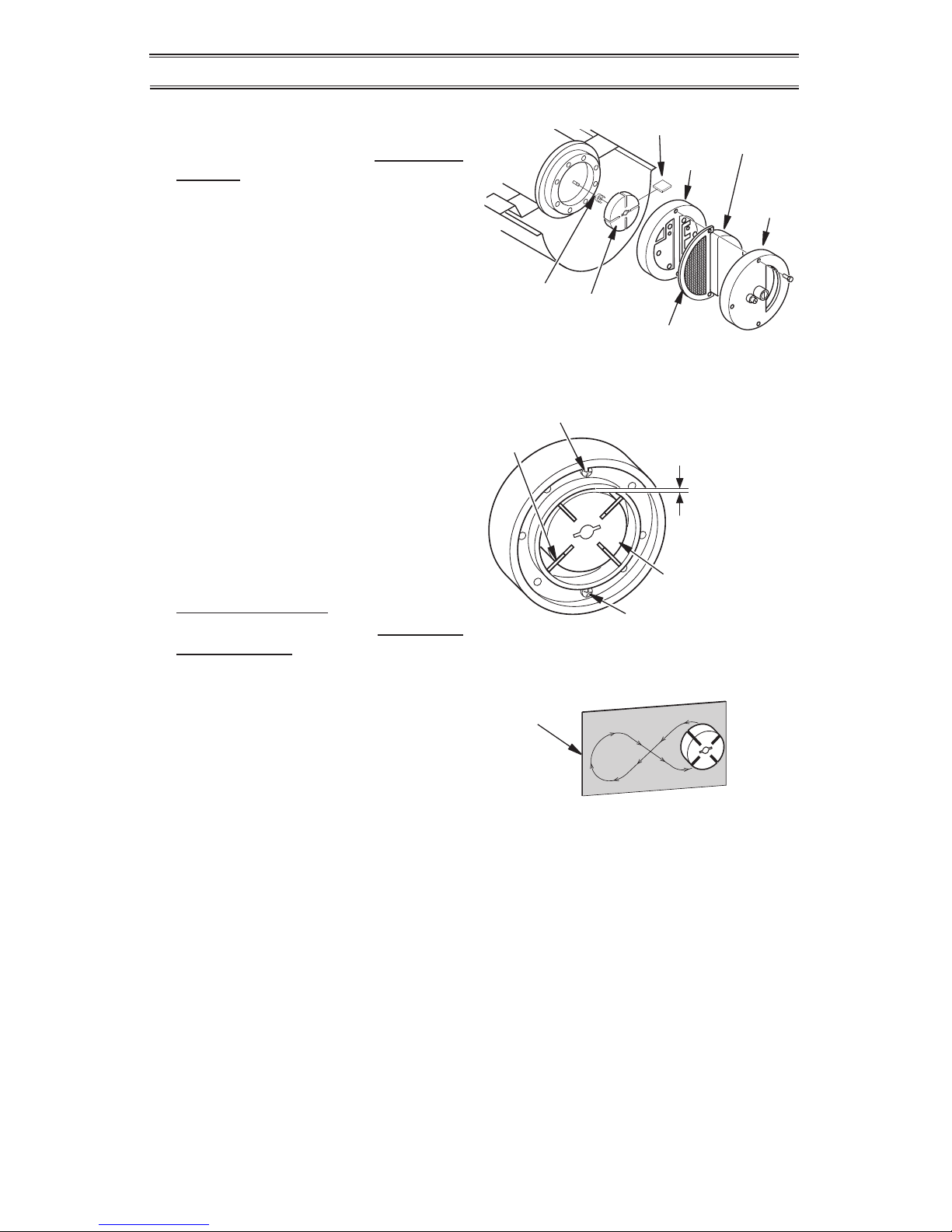

PUMP ROTOR

(Procedure if Rotor is Binding)

1. Remove upper shell (see Upper Shell

Removal, page 9).

2. Remove filter end cover screws using

5/16" nut driver (see Figure 17).

3. Remove filter end cover and air filters.

4. Remove pump plate screws using 5/16"

nut-driver.

5. Remove pump plate.

6. Remove rotor, insert, and blades (see

Figure 18).

7. Check for debris in pump. If debris is

found, blow out with compressed air.

8. Install insert and rotor.

9. Check gap on rotor. Adjust to

0.076/0.101 mm (0.003"/0.004") if needed

(see Figure 18).

Note: Rotate rotor one full turn to ensure

the gap is 0.076/0.101 mm (0.003"/0.004")

at tightest position. Adjust if needed.

10. Install blades, pump plate, air filters, and

filter end cover.

11. Replace fan guard and upper shell (see

Upper Shell Removal, page 9).

12. Adjust pump pressure (see Pump Pres-

sure Adjustment, page 11).

Note: If rotor is still binding, proceed as

follows.

13. Perform steps 1 through 6.

14. Place fine grade sandpaper (600 grit) on

flat surface. Sand rotor lightly in “figure 8”

motion four times (see Figure 19).

15. Reinstall insert and rotor.

16. Perform steps 10 through 12.

Figure 17 - Rotor Location

Pump

Plate

Insert

Rotor

Blade

Filter

End

Cover

Air

Intake

Filter

Air Output Filter

Gap Adjusting

Screw

Rotor

Blade

0.003"/0.004"

(0.076-0.101 mm)

Gap Measured

With Feeler

Gauge

Gap Adjusting Screw

Figure 18 - Gap Adjusting Screw

Locations

Sandpaper

Figure 19 - Sanding Rotor

SERVICE PROCEDURES

Page 15

www.usaprocom.com

15160177-01B

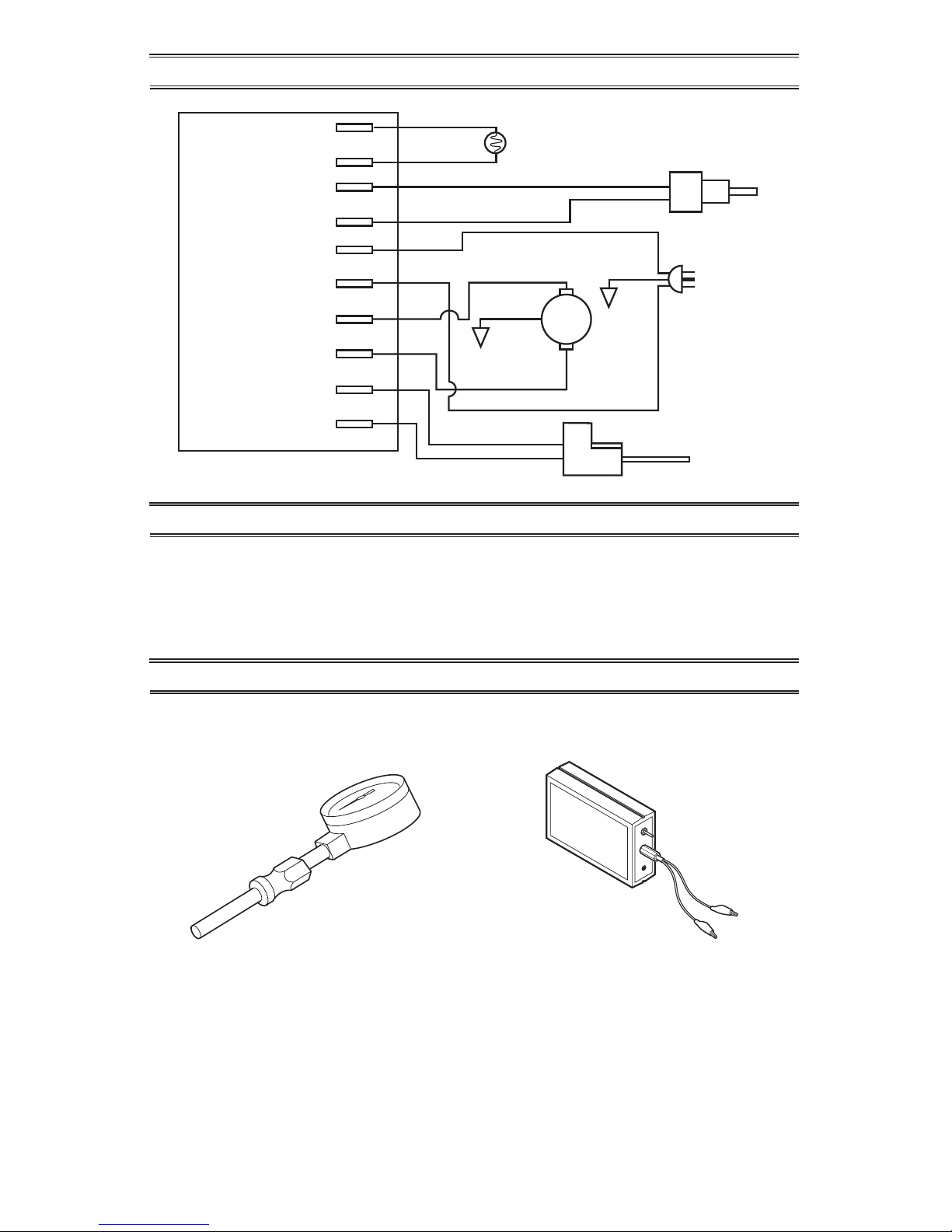

WIRING DIAGRAM

ST002-01

AIR GAUGE KIT

Special tool to check pump pressure.

0-15 PSI gauge. 3/8" NPT pipe thread.

ST001-01

IGNITION CONTROL ASSEMBLY/

PHOTOCELL TESTER

Special tool used to test the ignition control

assembly and photocell.

ACCESSORIES

Purchase these accessories from your local dealer. If they can not supply these accessories,

contact ProCom Heating, Inc. at 1-866-573-0674 for information. You can also write to the

address listed on the back page of this manual.

TECHNICAL SERVICE

You may have further questions about installation, operation, or troubleshooting. If so, contact

ProCom Heating, Inc. at 1-866-573-0674. When calling, please have your model and serial

numbers of your heater ready.

You can also visit ProCom Heating, Inc.’s web site at www.usaprocom.com.

Photocell

Photocell

Blue

Blue

White

White

White

White

Power Plug

120V/60Hz

Thermostat

Control

Green

Green

Red

Black

Black

Yellow/White

Yellow/White

Photocell

Heater Control Assembly

Temp.

Temp.

Ignitor

Ignitor

Ignitor

Motor Return

AC Neutral (N)

120V (L1)

Motor Main

Motor

Page 16

www.usaprocom.com

160177-01B16

PARTS

MODEL PCK80T

12

13

19

20

22

21

22

27

28

23

24

25

26

14

14

16

29

10

15

17

18

3

30

4

5

6

9

7

8

11

1

2

Page 17

www.usaprocom.com

17160177-01B

PARTS

MODEL PCK80T

This list contains replaceable parts used in your heater. When ordering parts, be sure to provide correct model and serial numbers (from model plate), and part number and description

of desired part.

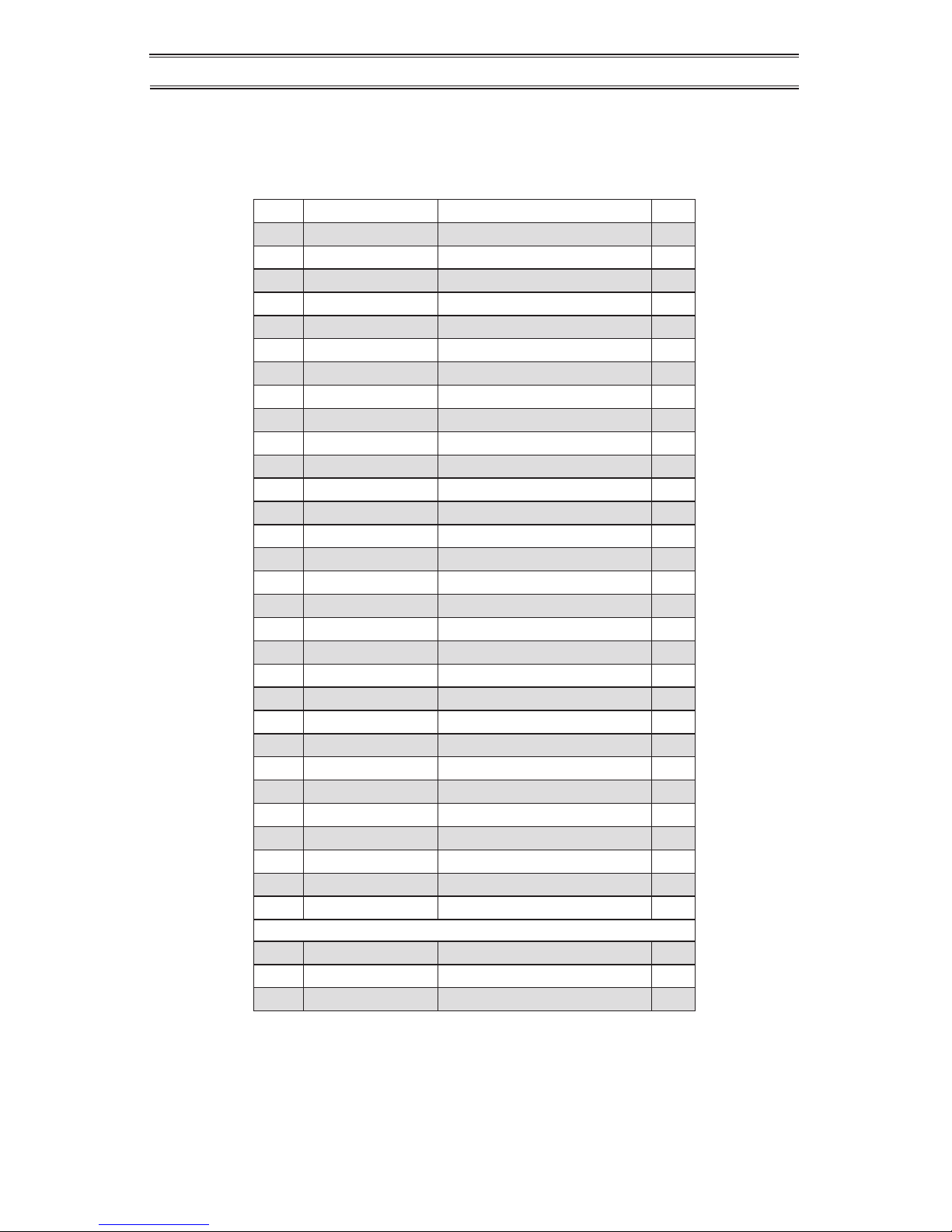

ITEM PART NO. DESCRIPTION QTY

1 160075-01 Guard Wire 1

2 160101-01 Shell Screw 8

3 160050-01GY Upper Shell, Painted 1

4 160134-01 Combustion Chamber Assy. 1

5 160051-01GY Lower Shell, Painted 1

6 see detail, pg 19 Nozzle Bracket Assembly

7 160011-01 Fan 1

8 see detail, pg 18 Motor/Pump Assembly

9 see detail, pg 18 Photocell/Bracket Assembly

10 160043-01 Motor Mounting Bracket 1

11 160066-01 Fan Guard 1

12 160012-02 Fuel Filter 1

13 160034-01 Fuel Tube Bushing 1

14 160060-01 Small Shell Bracket 2

15 160021-01 Power Supply Cord 1

16 160013-01 Strain Relief Bushing 1

17 160056-01 Right Side Cover 1

18 160087-01 Clip, Nut, #10, .08 Wall 6

19 160055-01 Left Side Cover 1

20 160139-01GY Fuel Tank Assy., Small 1

21 160005-01 Fuel Gauge 1

22 160020-02 LED Ignition Control 1

23 160030-01 Vented Fuel Cap Assy. 1

24 160030-03 Vented Fuel Cap Gasket 1

25 160031-01 Plastic Filler Neck 1

26 160036-01 Filler Neck Gasket 1

27 160019-01 Thermostat Control 1

28 160027-01 Control Knob 1

29 160149-01 Handle 1

30 160083-01 Shell Heat Shield 1

PARTS AVAILABLE - NOT SHOWN

160037-01 Airline Tubing 1

160039-01 Upper Fuel Line 1

160038-01 Lower Fuel Line 1

Page 18

www.usaprocom.com

160177-01B18

1

16

15

14

13

12

18

17

11

10

9

8

7

6

5

4

3

2

PHOTOCELL ASSEMBLY

1

2

3

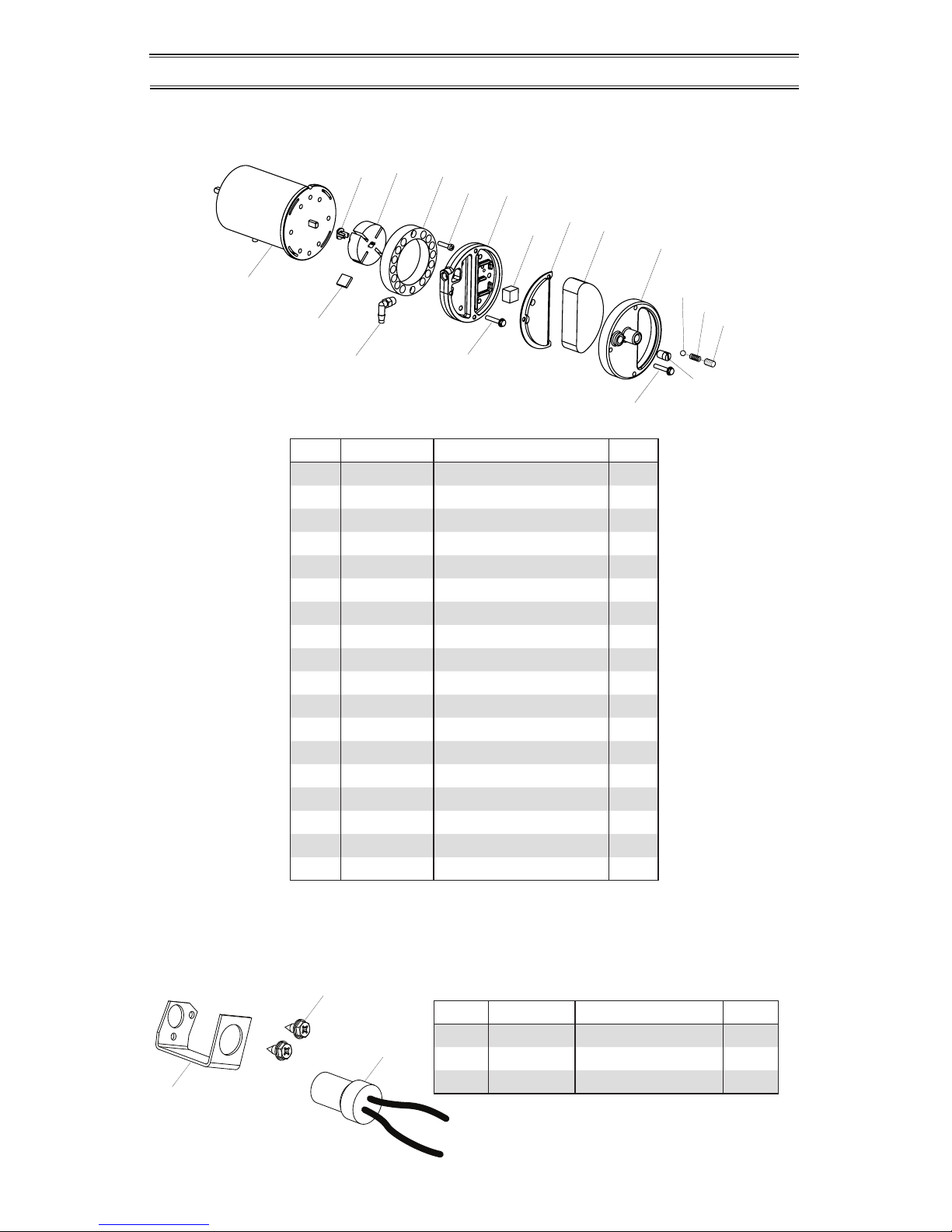

ITEM PART # DESCRIPTION QTY

1 160041-03 Photocell Bracket 1

2 160092-02 Screw, 6-32 x .38 2

3 160016-01 Photocell Assembly 1

ITEM PART # DESCRIPTION QTY

1 160001-01 Motor 1

2 160023-01 Rotor Insert 1

3 160003-01 Pump Rotor 1

4 160006-01 Pump Body 1

5 160088-01 Screw, 10-32 x .62 2

6 160007-01 Pump Cover 1

7 160009-01 Lint Filter 1

8 160008-01 Output Filter Assembly 1

9 160010-01 Intake Filter 1

10 160057-01 Filter End Cover 1

11 160025-01 Adjusting Screw 1

12 160024-01 Pipe Plug 1

13 160090-01 Screw, 10-32 x 1.0 3

14 160089-01 Screw, 10-32 x 1.12 6

15 160029-01 90° Nylon Elbow 1

16 160004-01 Pump Blade 4

17 160052-01 Pressure Relief Spring 1

18 160053-01 Steel Ball 1

PARTS

MOTOR AND PUMP ASSEMBLY

MODEL PCK80T

Page 19

www.usaprocom.com

19160177-01B

PARTS

NOZZLE ASSEMBLY

MODEL PCK80T

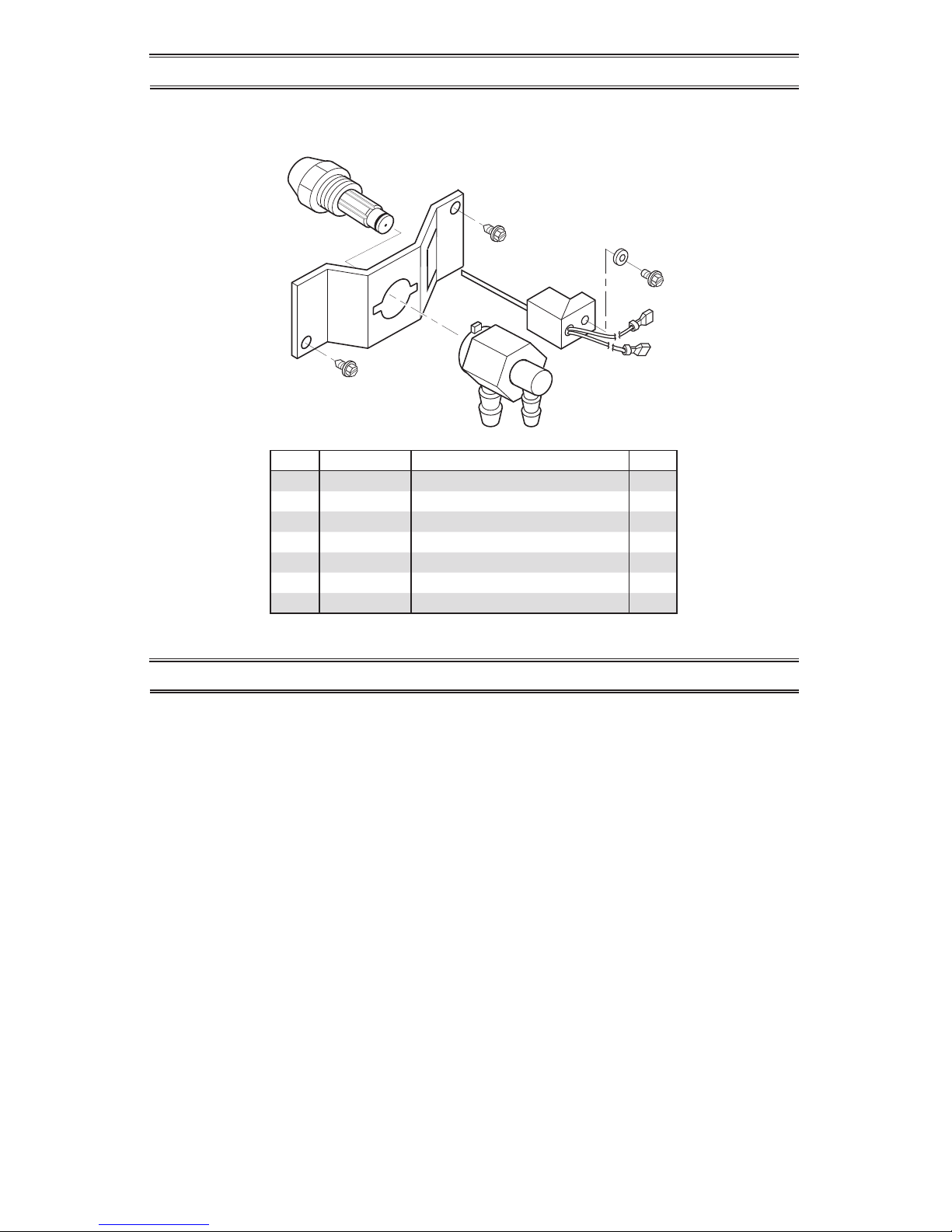

ITEM PART # DESCRIPTION QTY

1 160028-01 Nozzle Adapter 1

2 160042-01 Nozzle Adapter Bracket 1

3 160102-01 Screw, 10-16 x .38 2

4 160002-01 Ignitor 1

5 160093-01 Belleville Washer 1

6 160092-01 Screw, 6-32 x .88 1

7 160040-32 Nozzle Assembly 1

REPLACEMENT PARTS

Contact authorized dealers of this product.

If they can’t supply original replacement

parts, call ProCom Heating, Inc. toll free at

1-866-573-6074 for referral information.

When calling have ready:

• Your name

• Your address

• Model and serial number of your heater

• How heater was malfunctioning

• Type of gas used (Propane/LP or Natural

gas/NG) and Propane/LP tank size

• Purchase date

• Place of purchase

Usually, we will ask you to return the defective

part to the factory. You may be asked to supply

proof of purchase.

Note: Use only original replacement parts. This will protect your warranty coverage for parts

replaced under warranty.

PARTS UNDER WARRANTY

PARTS NOT UNDER WARRANTY

Contact authorized dealers of this product.

If they can’t supply original replacement

part(s) call ProCom Heating, Inc. toll free at

1-866-573-6074 for referral information.

When calling have ready:

• Model and serial number of your heater

• The replacement part number

Page 20

REGISTER YOUR PRODUCT AT WWW.USAPROCOM.COM

PROCOM HEATING, INC. LIMITED WARRANTIES

New Products – Outdoor Heating

Standard Warranty: ProCom Heating, Inc. warrants this new product and any parts thereof to be free from

defects in material and workmanship for a period of one (1) year from the date of rst purchase from an

authorized dealer provided the product has been installed, maintained and operated in accordance with

ProCom Heating, Inc.’s warnings and Instructions.

For products purchased for commercial, industrial or rental usage, this warranty is limited to 90 days from

the date of rst purchase.

Factory Reconditioned Products

Limited Warranty: ProCom Heating, Inc. warrants factory reconditioned products and any parts thereof to

be free from defects in material and workmanship for a period 30 days from the date of rst purchase from an

authorized dealer provided the product has been installed, maintained and operated in accordance with ProCom

Heating, Inc.’s warnings and Instructions. No return will be authorized. Parts will be provided to repair the product.

Terms Common to All Warranties

The following terms apply to all of the above warranties:

Always specify model number and serial number when contacting the manufacturer. To make a claim under

this warranty, the bill of sale or other proof of purchase must be presented.

This warranty is extended only to the original retail purchaser when purchased from an authorized dealer,

and only when installed by a qualied installer in accordance with all local codes and instructions furnished

with this product.

This warranty covers the cost of part(s) required to restore this product to proper operating condition and

an allowance for labor when provided by a ProCom Heating, Inc. Authorized Service Center or a provider

approved by ProCom Heating, Inc. Warranty parts must be obtained through authorized dealers of this

product and/or ProCom Heating, Inc. who will provide original factory replacement parts. Failure to use

original factory replacement parts will void this warranty.

Traveling, handling, transportation, diagnostic, material, labor and incidental costs associated with warranty

repairs, unless expressly covered by this warranty, are not reimbursable under this warranty and are the

responsibility of the owner.

Excluded from this warranty are products or parts that fail or become damaged due to misuse, accidents,

improper installation, lack of proper maintenance, tampering or alteration(s).

This is ProCom Heating, Inc.’s exclusive warranty, and to the full extent allowed by law; this express warranty excludes any and all other warranties, express or implied, written or verbal and limits the duration of

any and all implied warranties, including warranties of merchantability and tness for a particular purpose to

one (1) year on new products and 30 days on factory reconditioned products from the date of rst purchase.

ProCom Heating, Inc. makes no other warranties regarding this product.

ProCom Heating, Inc.’s liability is limited to the purchase price of the product and ProCom Heating, Inc.

shall not be liable for any other damages whatsoever under any circumstances including direct, indirect,

incidental, or consequential damages.

Some States do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

WARRANTY

KEEP THIS WARRANTY

Model (

located on product or identication tag

) _____________________________

Serial No. (

located on product or identication tag

) __________________________

Date Purchased ______________________________________

Keep receipt for warranty verication.

160177-01

Rev. B

08/13

ProCom Heating, Inc.

Bowling Green, KY 42101

www.usaprocom.com

1-866-573-0674

Page 21

IMPORTANTE: Lea y comprenda este manual antes de

ensamblar, encender o dar servicio al calentador. El

uso inadecuado del calentador puede causar lesiones

graves. Conserve este manual para referencias futuras.

Nunca utilice el calentador en dormitorios o salas de

estar y para el uso en combustible pisos.

Calentador apto para uso en exteriores.

CALENTADORE PORTÁTILES DE AIRE FORZADO

CALENTADOR DE KEROSENO/DIESEL CON TERMOSTATO

INCORPORADO

MANUAL DEL PROPIETARIO

¿Preguntas, problemas, piezas faltantes? Antes de volver a la tienda, llame a

nuestro Departamento de Servicio al Cliente al 1-866-573-0674, de lunes a viernes de

7:30 a.m. a 4:15 p.m., Hora del Centro, o envíe un correo electrónico a

customerservice@usaprocom.com.

PCK80T - 80,000 BTU/H

Page 22

www.usaprocom.com

160177-01B22

referencia. Es su guía para la operación segura y correcta de este calentador.

1. Utilice sólo keroseno, diesel/aceite com-

bustible Nº 1 ó Nº 2, bien o combustible

de aviación JET A o JP-8 para evitar el

riesgo de incendio o explosión. Nunca

utilice gasolina, aceite usado de cárter,

nafta, disolventes de pintura, alcohol u

otros combustibles altamente inamables.

2. Carga de combustible

a) El personal que realice la carga de

combustible debe ser idóneo para

esta tarea y conocer a profundidad

las instrucciones del fabricante y las

normas vigentes acerca de la carga

de combustible de calentadores en

condiciones de seguridad.

b) Sólo debe utilizarse el tipo de combus-

tible indicado en la placa de datos del

calentador.

c) Antes de cargar combustible, es nece-

sario apagar cualquier llama y esperar

a que el calentador se enfríe.

d) Durante la carga de combustible, todos

los circuitos de combustible y sus conexiones deben inspeccionarse para

comprobar que no existan fugas. Toda

fuga deberá repararse antes de volver

a utilizar el calentador.

e) Bajo ninguna circunstancia se deberá

guardar el suministro diario de combustible del calentador en una construcción

cercana al equipo. Los grandes volúmenes de combustible deben guardarse en

el exterior de la estructura.

f) Todo lugar de almacenamiento de com-

bustible debe situarse a una distancia

de 7.62 m (25 pies) como mínimo de

calentadores, antorchas, equipos de

soldadura y otras fuentes de ignición

similares (excepción: el depósito de

ADVERTENCIA:Este producto contiene o genera químicos

reconocidos por el estado de California como causantes de cáncer o de defectos de nacimiento,

u otros daños reproductivos.

IMPORTANTE: Lea este manual

del propietario cuidadosa y

completamente antes de intentar

ensamblar, operar o dar servicio

a este calentador. El uso inadecuado de este calentador puede

causar lesiones graves o la muerte

por quemaduras, incendio, explosión, electrocución e intoxicación

con monóxido de carbono.

PELIGRO: ¡La intoxicación

con monóxido de carbono puede

resultar en la muerte!

Intoxicación por monóxido de carbono:

Los primeros síntomas de intoxicación por

monóxido de carbono son similares a los

de la gripe e incluyen jaqueca, mareos o

náuseas. Si usted presenta estos síntomas,

es posible que el calentador no esté funcionando correctamente. ¡Respire aire fresco

inmediatamente! Haga que se le dé servicio

al calentador. El monóxido de carbono afecta

más algunas personas que a otras. Las más

afectadas son mujeres embarazadas, personas con enfermedades del corazón o de los

pulmones o anemia, aquellas bajo la inuencia del alcohol y aquellas a grandes altitudes.

Asegúrese de leer y comprender todas las

advertencias. Conserve este manual como

SEGURIDAD

TABLA DE CONTENIDOS

Seguridad ................................................ 22

Desempaque ........................................... 24

Ensamble................................................. 24

Especicaciones ..................................... 24

Identicación del producto y ubicación

de la etiqueta ..................................... 25

Combustibles ........................................... 26

Ventilación ............................................... 26

Funcionamiento ....................................... 27

Funcionamiento con generador portátil ... 28

Almacenamiento, transporte y envío ....... 28

Programa de mantenimiento preventivo.. 29

Solución de problemas ............................ 29

Procedimientos de servicio...................... 31

Diagrama de cableado ............................ 37

Servicio técnico ....................................... 37

Accesorios ............................................... 37

Piezas de repuesto .................................. 41

Garantía................................................... 42

Page 23

www.usaprocom.com

23160177-01B

SEGURIDAD

combustible integrado al calentador

o todo tanque auxiliar autorizado que

esté conectado al equipo).

g) De ser posible, el combustible debe

almacenarse en áreas en las que la

penetración del suelo no permita que se

ltre o se encienda a causa de un fuego

proveniente de un lugar menos elevado.

h) El almacenamiento de combustible

debe cumplir con las disposiciones de

la autoridad competente.

3. Use solamente la tensión eléctrica y la

frecuencia que se especican en la placa

donde aparece al número de modelo.

4. El calentador es apto para su uso en

exteriores.

5. El calentador debe tener una conexión

a tierra. Utilice únicamente un cable de

extensión trilar correctamente conectado a tierra. Enchúfelo solomente en un

tomacorriente con conexión a tierra.

6. Utilice el equipo sólo en áreas sin vapores

inamables ni alta densidad de polvo.

7. Distancia mínima de materiales combustibles: 2.44 m (8 pies) desde la salida de

aire caliente, 1.83 m (6 pies) desde la

parte superior y 1.20 m (4 pies) desde

los laterales y la entrada de la unidad.

8. Sitúe el calentador sobre una supercie

estable y nivelada mientras está caliente

o en funcionamiento, pues de lo contrario

puede originarse un incendio.

9. El calentador puede utilizarse en pisos

tales como de madera (un material combustible).

10. Úsese solamente en áreas bien ventiladas.

Antes de usar el calentador, asegúrese

de disponer de una abertura de al menos

2800 cm2 (tres pies cuadrados) que permita la entrada de aire fresco por cada 30

kw (100,000 BTU/h) de clasicación.

11. Mantenga alejados a los niños y los animales en todo momento.

12. Nunca encienda el calentador cuando la

cámara de combustión esté caliente o

cuando se haya acumulado combustible

en ella.

13. Este calentador está equipado con termostato. El calentador puede empezar a

funcionar en cualquier momento.

14. Nunca deje el calentador conectado sin la

supervisión de un adulto si es probable la

presencia de niños o animales en el área.

15. Tenga precaución cuando mueva o almacene el calentador si el tanque aún

contienen combustible. Puede ocurrir un

derrame de combustible.

16. El calentador debe utilizarse sólo de acuerdo con las normas y códigos locales. Los

residentes de Canadá deben consultar la

norma CSA B139, Código de instalación

para equipo de combustión de petróleo

para obtener información sobre el procedimiento de instalación recomendado.

17. Nunco utilice gasolina, aceite usado

de cárter, nafta, disolventes de pintura,

alcohol u otros combustibles altamente

inamables.

18. Nunca utilice el calentador en áreas con

gasolina, disolvente de pintura u otros

vapores altamente inamables.

19. Nunca utilice el calentador en dormitorios

o salas de estar.

20. Nunca mueva, maneje, cargue combustible ni repare un calentador en funcionamiento, caliente o conectado.

21. Nunca conecte conductos a la parte anterior o posterior del calentador.

22. Los calentadores que se usen cerca de

lonas impermeables y toldos o materiales

protectores parecidos deben colocarse

a una distancia segura con respecto a

dichos materiales. La distancia mínima

recomendada es de 3.048 m (10 pies).

Se recomienda expresamente que tales

materiales protectores sean retardadores

del fuego. Estos materiales protectores

deben estar bien asegurados para evitar

que se enciendan o que bloqueen el calentador a causa de la acción del viento.

23. Desenchufe el calentador cuando no está

en uso.

24. Nunca bloquee la entrada de aire (parte

posterior) ni la salida de aire (parte anterior) del calentador.

25. Advertencia para los residentes de la

ciudad de Nueva York

El equipo sólo debe utilizarse en obras

de construcción de conformidad con

las disposiciones de los códigos de NYC

vigentes.

26. No use nunca fuentes de combustible

externas ni tanques que no hayan sido

diseñados especícamente para utilizarse

con este calentador.

Page 24

www.usaprocom.com

160177-01B24

DESEMPAQUE

Figura 1 - Guarda de alambre trasladó a

posición de bloqueo

1. Saque todos los materiales en los que se

empacó el calentador para el envío.

2. Saque todas las piezas de la caja.

3. Revise el calentador para ver si hay algún

daño debido al transporte. Si el calentador está dañado, llame a ProCom Heating, Inc. al 1-866-573-0674 para obtener

piezas de repuesto antes de devolverlo al

distribuidor.

ENSAMBLE

ALAMBRE GUARDIA

Todos los Modelos

Tire del protector hacia la parte delantera del

calentador hasta que encaje en su lugar en

las ranuras de ambos lados de la cubierta

superior.

ESPECIFICACIONES

PCK80T

Potencia de salida 80,000 BTU

Combustible Use solamente keroseno, diesel/aceite combustible

#1 ó #2, combustible de aviación JET A o JP-8*

Capacidad de combustible 5.5 gal/20,8 L

Consumo de combustible (por hora) 0.60 gal/2.3 L

La bomba de presión 3.8 PSI (caliente)

Requerimientos eléctricos 120 V/60 HZ

Amperaje (funcionamiento normal) 2.5

Velocidad típica del motor 3400 RPM

Motor 1/4 hp

Peso de envío 42 lbs/19 kg

Peso del calentador sin combustible

(aprox)

36 lbs/16.3 kg

Page 25

www.usaprocom.com

25160177-01B

IDENTIFICACIÓN DEL PRODUCTO Y UBICACIÓN DE LA ETIQUETA

Llenado de Combustible Etiqueta

Parte N º 160168-01

Etiqueta

funcionamiento

Parte N º 160173-02

Mantenimiento

Etiqueta

Parte N º 160175-01

Atención Etiqueta

Parte N º 160172-01

Figura 2 - Identicación del producto y ubicación de las etiquetas

Etiqueta para el Control

Parte N º 160111-02

Nueva York, MA y CA

Información de la Etiqueta

Parte N º 160169-01

Lateral derecho

Lateral Izquierdo

Aire

caliente

salida

Perilla del

termostato

Alambre

guardia

Manija superior

Manija superior

Tanque de

combustible

Aire frío

entrada

Cable

eléctrico

Combustible

tapa

Indicator de

combustible

Aire

caliente

salida

Número

de serie

Advertencias

en la Etiqueta

Parte N º 160110-03

Page 26

www.usaprocom.com

160177-01B26

COMBUSTIBLES

* El uso de diesel o aceite combustible Nº 2 en

temperaturas extremadamente bajas puede

requerir aditivos anticongelantes no tóxicos.

No utilice combustibles con densidad mayor

a 2 ni aceites pesados como el aceite usado

procedente del cárter. Este tipo de aceites

pesados entra en combustión de forma inadecuada y contamina el calentador.

IMPORTANTE: Utilice un contenedor EXCLUSIVO PARA KEROSENO (azul) o

EXCLUSIVO PARA DIESEL (amarillo) para

almacenar estos combustibles. Asegúrese de

que el contenedor esté limpio. Los elementos

extraños como el óxido, la suciedad o el agua

pueden causar que el sistema de control de

encendido apague el calentador. Asimismo,

requerirá la limpieza frecuente del sistema de

combustible del calentador.

ADVERTENCIA: Utilice sólo

keroseno, diesel/aceite combustible Nº 1 ó Nº 2, o bien combustible de aviación JET A o JP-8

para evitar el riesgo de incendio

o explosión. Nunca utilice gasolina, aceite usado de cárter,

nafta, disolventes de pintura,

alcohol u otros combustibles

altamente inamables.

Utilice sólo keroseno, diesel*/aceite combustible Nº 1/Nº 2, o bien combustible de

aviación JET A o JP-8. También pueden

utilizarse combustibles más pesados como

aceite combustible Nº 2 o diesel Nº 2, aunque

el efecto será:

• olor penetrante

• mantenimiento adicional del ltro de com-

bustible

VENTILACIÓN

Ejemplo: Un calentador de 80,000 BTU/h

(23.4 kw) requiere una de las siguientes

opciones:

• una puerta de garaje para dos autos

[abertura de 4.88 metros (16 pies)] con

una elevación de 5.6 cm (2.2")

• una puerta de garaje para un auto [abertura

de 2.74 metros (9 pies)] con una elevación

de 7.4 cm (3.3")

• dos ventanas de 76.2 cm (30") con una

elevación de 13.9 cm (6.2")

ADVERTENCIA: Asegúrese

de que exista una abertura que

permita la entrada de aire fresco

de 2,800 cm2 (3 pies cuadrados) como mínimo por cada

100,000 BTU/h de clasicación.

Proporcione aire fresco adicional si se utilizan más calentadores. Es necesario cumplir con

los requisitos mínimos de ventilación para evitar los riesgos

vinculados con la intoxicación

por monóxido de carbono. Veri-

que el cumplimiento de estos

requisitos antes de utilizar el

calentador.

Page 27

www.usaprocom.com

27160177-01B

IMPORTANTE: Revise y asegúrese de comprender las advertencias indicadas en la sección

Seguridad de la página 22. Son

necesarias para hacer funcionar

este calentador de manera segura.

Al utilizar el calentador, siga todas

las ordenanzas y códigos locales.

PARA ENCENDER EL

CALENTADOR

1. Asegúrese de cumplir con todas las medidas de ventilación y seguridad.

2. Sitúe el calentador de forma tal que brinde

la máxima circulación de aire caliente.

Siga todos los requisitos de ubicación

indicados en la sección Seguridad de la

página 22.

3. Llene el tanque con combustible y adjunte

la tapa del combustible. Utilice sólo keroseno, diesel/aceite combustible Nº 1 o Nº

2, o bien combustible de aviación JET A

o JP-8 para evitar el riesgo de incendio o

explosión. Nunca utilice gasolina, aceite

usado de cárter, nafta, disolventes de

pintura, alcohol u otros combustibles

inamables.

4. Conecte el cable de alimentación del

calentador a un cable de extensión trilar

aprobado y con conexión a tierra. El cable

de extensión debe tener una longitud de

1,8 m (seis pies) como mínimo.

Requisitos de tamaño del cable de

extensión

• 1,8 a 3 m (6 a 10 pies) de longitud: utilice

un cable 18 AWG (0,75 mm2)

• 3,3 a 30.5 m (11 a 100 pies) de longitud:

utilice un cable 16 AWG (1 mm2)

• 30,8 a 61 m (101 a 200 pies) de longitud:

utilice un cable 14 AWG (1,5 mm2)

5. Conecte el cable de extensión un toma-

corriente estándar de tres oricios de 120

voltios/60 hertz con conexión a tierra.

6. Gire la perilla del termostato a la posición

descada, La luz parpadea y el calentador

comenzará dentro de 8 segundos.

Si la temperatura del termostato conjunto

es más alta que la temperatura del aire

circundante, el calentador debe encender

inmediatamente. Si el termostato del

calentador de la temperatura es más

baja que rodea la temperatura del aire, el

calentador no se enciende. La exposición

a la luz solar directa o frío extremo puede

afectar la lectura de temperatura y / o el

funcionamiento del termostato.

El LED parpadea durante 8 segundos an-

tes ignición. La luz permanece encendida

durante calentador operación, incluso si el

calentador se cicla por fuera el termostato. El LED parpadeará rápidamente si el

calentador se apaga por cualquier razón

(por ejemplo: si el combustible).

ADVERTENCIA: El calentador

está equipado con termostato.

El calentador puede comenzar a

funcionar en cualquier momento.

PARA DETENER EL

CALENTADOR

1. Gire el mando del termostato en sentido

antihorario para STANDBY

2 Desconecte el calentador cuando no esté

en uso.

PARA REESTABLECER EL

CALENTADOR

1. Espere dos minutos antes de reiniciar.

2. Gire el mando del termostato en la posición STANDBY durante 10 segundos,

reinicie el calentador.

FUNCIONAMIENTO

ASSEMBLED IN THE USA BY:

ASSEMBLE AUX ETATS-UNIS PAR:

ENSAMBLADA EN LOS EE.UU.POR:

PROCOM HEATING, INC.

2800 GRIFFIN DRIVE

BOWLING GREEN, KY 42101

40

50

60

70

80

90

THERMOSTAT F

THERMOSTATO F

O

O

START/RUN

ENCIENDA/OPERACION

DEMARRE/MARCHE

`

`

STANDBY

Figura 3 - Controles de pantalla

Perilla del termostato

Luz LED

Page 28

www.usaprocom.com

160177-01B28

FUNCIONAMIENTO CON GENERADOR PORTÁTIL

ADVERTENCIA: Antes de

utilizar el calentador o cualquier

dispositivo de un generador por-

tátil, verique que el generador

se encuentre correctamente conectado a tierra. La falta de una

conexión a tierra o la existencia

de una conexión defectuosa pueden ocasionar una electrocución

ante una falla. Consulte el manual

del propietario suministrado por

el fabricante del generador para

obtener información sobre los

procedimientos de conexión a

tierra correctos.

La tensión de funcionamiento del calentador

puede variar de 108 a 132 voltios (120 voltios

+/- 10%). Antes de conectar el calentador al

generador es necesario vericar la tensión de

salida del generador (si el generador cuenta

con una función de suspensión automática,

ALMACENAMIENTO, TRANSPORTE Y ENVÍO

3. Deseche como corresponda el combustible usado. Consulte a las estaciones de

servicio locales que reciclan combustibles.

4. Si desea guardar el calentador, asegúrese

de que sea en un lugar seco. Verique

que en el lugar no haya polvo ni vapores

corrosivos.

IMPORTANTE: No almacene keroseno durante los meses de verano para usarlo en

la próxima estación de calor. El combustible

usado puede dañar el calentador.

la tensión de salida debe medirse mientras

éste funciona a máxima velocidad). Si la

tensión no se encuadra dentro de los valores

indicados, el calentador no debe conectarse

al generador.

Consulte la sección Funcionamiento en la página 27 para conocer los procedimientos para

encender, detener y reajustar el calentador.

Nota: En caso de envío, las empresas de

transporte requieren que el tanque de combustible esté vacío.

1. Extraiga el excedente de combustible por

medio de un sifón. Drene el combustible

restante a través de relleno cuello por el

calentador de inexión en la parte trasera.

2. Si nota que hay residuos en el combustible viejo, agregue 1 ó 2 cuartos de keroseno limpio al tanque, agítelo y vuelva

a vaciar. De esta forma evitará que el

exceso de residuos obstruya los ltros

en el futuro.

Cable a tierra (Nº 10 AWG Cobre trenzado)

Puesta a

tierra de

cobre o

bronce

Figura 4 - Método de conexión a tierra

habitual del generador (la estructura del

generador puede diferir de la imagen

que se muestra)

Alternador

Terminal de

conexión a

tierra

Page 29

www.usaprocom.com

29160177-01B

PROGRAMA DE MANTENIMIENTO PREVENTIVO

ADVERTENCIA: No repare el calentador mientras está enchufado,

en funcionamiento o caliente. Pueden ocurrir quemaduras graves

y electrocución.

Artículo Frecuencia Método

Tanque de combustible

Limpie en cada estación o según sea

necesario.

Consulte la sección Almace-

namiento, transporte y envío,

página 28.

Filtros de salida de

aire y partículas

Reemplace cada 500 horas de uso o una

vez al año.

Consulte Filtros de salida

de aire, entrada de aire y de

pelusa, página 32.

Filtro de entrada

de aire

Lave y seque con agua y jabón cada 500

horas de uso o según sea necesario.

Consulte Filtros de salida

de aire, entrada de aire y de

pelusa, página 32.

Filtro de combustible

Limpie dos veces en cada estación que requiera calefacción o según sea necesario.

Consulte Filtro de combusti-

ble, página 33.

Aspas del ventilador

Limpie en cada estación o según sea

necesario.

Consulte Ventilador, página 31.

Motor No requiere mantenimiento: lubricación

permanente.

SOLUCIÓN DE PROBLEMAS

ADVERTENCIA: No repare el calentador mientras está enchufado,

en funcionamiento o caliente. Pueden ocurrir quemaduras graves

y electrocución.

ADVERTENCIA: Alta tensión! Desenchufar calentador antes de

dar servicio.

CONDICIÓN DE FALLA POSIBLE CAUSA REMEDIO

El motor no enciende ocho segundos después de conectar

el calentador.

1. No llega energía al calentador.

2. Si lo hay, el termostato

señala una intensidad demasiado baja.

3. Mala conexión eléctrica entre el motor y el ensamblaje

del control de encendido, o

del ensamblaje del control

de encendido y el cable de

alimentación.

4. El rotor de la bomba está

atascado.

5. Ensamblaje del control de

encendido defectuoso.

6. Motor defectuoso.

1. Revise el interruptor de circuitos en el panel eléctrico.

2. Gire la perilla del termostato a un ajuste de temperatura más alto.

3. Revise todas las conexiones eléctricas. Consulte

Diagrama de cableado,

página 37.

4. Si el ventilador no gira

libremente, consulte Rotor

de la bomba, página 36.

5. Reemplace el ensamblaje

del control de encendido.

6. Reemplace el motor.

Page 30

www.usaprocom.com

160177-01B30

SOLUCIÓN DE PROBLEMAS

ADVERTENCIA: Alta tensión! Desenchufar calentador antes de

dar servicio.

CONDICIÓN DE FALLA POSIBLE CAUSA REMEDIO

El motor se enciende y funciona pero el calentador no

enciende.

1. No hay combustible en el

tanque.

2. La presión de la bomba no

es la correcta.

3. El ltro de combustible está

sucio.

4. La boquilla está obstruida.

5. Hay agua en el tanque de

combustible.

6. Mala conexión eléctrica

entre el encendedor y el

ensamblaje del control de

encendido.

7. Encendedor defectuoso.

8. Ensamblaje del control de

encendido defectuoso.

1. Llene el tanque con keroseno.

2. Consulte Ajuste de la pre-

sión de la bomba, página 32.

3. Consulte Filtro de combus-

tible, página 33.

4. Consulte Ensamblaje de la

boquilla, página 34.

5. Drene y limpie el tanque de

combustible con keroseno

limpio. Consulte Almace-

namiento, transporte o

envío, página 28.

6. Revise las conexiones eléctricas. Consulte Diagrama

de cableado, página 37.

7. Reemplace el encendedor,

consulte la página 33.

8. Reemplace el ensamblaje

del control de encendido.

El calentador se enciende

pero el ensamblaje del control

de encendido lo apaga después de unos pocos minutos.

1. La presión de la bomba no

es la correcta.

2. Los ltros de entrada de

aire, salida de aire y/o de

pelusa están sucios.

3. El ltro de combustible está

sucio.

4. La boquilla está obstruida.

5. Ensamblaje de la fotocélula

instalado incorrectamente

(no se ve la ama).

6. Las lentes de la fotocélula

están sucias.

7. Mala conexión eléctrica

entre la fotocélula y el

ensamblaje del control de

encendido.

8. Fotocélula defectuosa.

9. Ensamblaje del control de

encendido defectuoso.

1. Consulte Ajuste de la pre-

sión de la bomba, página 32.

2. Consulte Filtros de salida

de aire, entrada de aire y

de pelusa, página 32

3. Consulte Filtro de combustible, página 33.

4. Consulte Ensamblaje de la

boquilla, página 34.

5. Asegúrese de que el recubrimiento de la fotocélula

esté asentado adecuadamente en el soporte.

6. Limpie las lentes de la

fotocélula.

7. Revise las conexiones eléctricas. Consulte Diagrama

de cableado, página 37.

8. Reemplace la fotocélula.

9. Reemplace el ensamblaje

del control de encendido.

Page 31

www.usaprocom.com

31160177-01B

Motor

PROCEDIMIENTOS DE SERVICIO

ADVERTENCIA: Para evitar

el riesgo de sufrir quemaduras

o electrocución, nunca intente

reparar el calentador mientras

está enchufado, en funcionamiento o caliente.

DESMONTAJE DE LA CUBIERTA

SUPERIOR

1. Retire los 8 tornillos ubicados a lo largo

del calentador con un destornillador para

tuercas de 5/16". Estos tornillos mantienen unidas la cubierta superior y la inferior

(consulte la gura 5).

2. Levante y retire la cubierta superior.

3. Retire el protector del ventilador.

VENTILADOR

IMPORTANTE: Extraiga el ventilador del eje

del motor antes de retirar el motor del calentador. El peso del motor colocado sobre el

ventilador puede dañar la inclinación correcta

del ventilador (consulte la gura 6).

1. Extraiga la cubierta superior (consulte la

gura 5).

2. El ventilador está ubicado con el tornillo de

jación tocando el extremo de la parte plana

del eje, como se muestra en la gura 7.

3. Utilice una llave Allen de 1/8" para aojar

el tornillo de jación que une el ventilador

al eje del motor (consulte la gura 6).

4. Saque el ventilador del eje del motor.

5. Limpie el ventilador con un paño suave

mojado con keroseno o con un solvente.

6. Seque completamente el ventilador.

7. Coloque el tornillo de jación en la parte

plana del eje. Apriete rmemente el tornillo de jación (de 40 a 50 pulgadas-libra/

de 4.5 a 5.6 N-m).

8. Vuelva a colocar el resguardo del ventilador y la cubierta superior.

Figura 5 - Desmontaje de la cubierta

superior

Tornillo de

jación

Figura 6 - Ubicación del ventilador, del

eje del motor y del tornillo de jación

Ventilador

Eje del

motor

Eje del

motor

Extremo de la

parte plana del

eje del motor

4,6 cm

(1,82")

Ventilador

Figura 7 - Vista transversal del ventilador

Longitud

del eje

del

motor

Tornillo de

jación

tocando

el extremo

de la parte

plana del eje

del motor

Page 32

www.usaprocom.com

160177-01B32

FILTROS DE SALIDA DE AIRE,

ENTRADA DE AIRE Y DE

PELUSA

1. Desmonte la cubierta superior (consulte

las gura 5, página 31).

2. Extraiga los tornillos de la cubierta del ex-

tremo del ltro con un destornillador para

tuercas de 5/16" (consulte la gura 8).

3. Desmonte la cubierta del extremo del

ltro.

4. Reemplace los ltros de salida de aire y

de pelusa.

5. Lave o reemplace el ltro de entrada de aire.

6. Vuelva a colocar la cubierta del extremo

del ltro.

7. Vuelva a colocar el resguardo del ventilador y la cubierta superior.

IMPORTANTE: No engrase los ltros.

PROCEDIMIENTOS DE SERVICIO

AJUSTE DE LA PRESIÓN DE LA

BOMBA

1. Retire el tapón medidor de presión de la

cubierta del extremo del ltro (consulte la

gura 9).

2. Instale el medidor de presión 0-15 PSI.

3. Encienda el calentador (consulte Fun-

cionamiento, página 27). Permita que el

motor alcance la temperatura de functionemento (aproximadamente 10 minutos).

4. Ajuste la presión. Gire la válvula de escape hacia la derecha para incrementar la

presión. Gire la válvula de escape hacia

la izquierda para disminuir la presión.

Consulte las especicaciones en la Figura

10 para la presión correcta.

5. Desmonte el medidor de presión. Vuelva

a colocar el tapón medidor de presión en

la cubierta del extremo del ltro.

Filtro de

entrada

de aire

Filtro de

pelusa

Cubierta

del

extremo

del ltro

Filtro de salida

de aire

Figura 8 - Filtros de salida de aire,

entrada de aire y de pelusa

Figura 9 - Retiro del tapón medidor de

presión

Tapón

medidor de

presión

Medidor de

presión

Figura 10 - Ajuste de la presión de la bomba

Válvula de

escape

Presión de

Modelo bomba

80 3.8 PSI

Page 33

www.usaprocom.com

33160177-01B

PROCEDIMIENTOS DE SERVICIO

FILTRO DE COMBUSTIBLE

1. Quite los tornillos de la cubierta lateral

utilizando un destornillador para tuercas

de 5/16".

2. Quite la tapa lateral.

3. Quite la línea superior de combustible del

cuello del ltro de combustible (consulte

las gura 11).

4. Saque cuidadosamente el buje, el ltro de

combustible y la línea inferior de combustible del tanque de combustible (consulte

la gura 11).

5. Lave el ltro de combustible con com-

bustible limpio y vuelva a colocarlo en el

tanque.

6. Conecte la línea superior de combustible

al cuello del ltro de combustible.

7. Vuelva a colocar la cubierta lateral.

Filtro de combustible, buje y

línea inferior de combustible

Línea superior de

combustible

Cubierta

lateral

Figura 11 - Desmontaje del ltro de

combustible

ENCENDEDOR

1. Desmonte la cubierta superior y el resguardo del ventilador (consulte Desmon-

taje de la cubierta superior, página 31).

2. Desmonte el ventilador (consulte la página 31).

3. Extraiga la cubierta lateral de control con

un controlador de 5/16" tuerca. Quite la

tapa lateral (ver gura 12).

4. Desconecte los cables del encendedor

del ensamblaje del control de encendido

(consulte la gura 12). Pase los alambres

del encendedor a través del oricio en la

cubierta inferior.

5. Desconecte la manguera de la línea de

combustible y la manguera de la línea de

aire. Desmonte la fotocélula del soporte

correspondiente (consulte la gura 13,

página 34).

6. Desmonte la cámara de combustión.

Coloque la cámara de combustión de

manera que el extremo del soporte adaptador de la boquilla quede hacia arriba

(consulte la gura 13, página 34).

Figura 12 - Desconexión de los cables

del encendedor del ensamblaje del

control de encendido

Soporte

de la

fotocélula

Manguera

de la línea

de aire

Manguera

de la

línea de

combustible

Cámara de

combustión

Ensamblaje

de la fotocélula

Encendedor

Soporte adaptador

de la boquilla

Cubierta lateral

Cable del

encendedor

Ensamblaje

del control de

encendido

Page 34

www.usaprocom.com

160177-01B34

PROCEDIMIENTOS DE SERVICIO

7. Desmonte el tornillo del encendedor con

un destornillador para tuercas de 1/4".

Desmonte cuidadosamente el encendedor del soporte adaptador de la boquilla.

PRECAUCIÓN: No doble ni

golpee el elemento encendedor.

Manéjelo con cuidado.

8. Saque cuidadosamente el encendedor

de repuesto del empaque de espuma de

estireno.

9. Guíe cuidadosamente el encendedor

hacia dentro de la abertura en el soporte

adaptador de la boquilla. No golpee el

elemento encendedor. Fije el encendedor

al soporte adaptador de la boquilla con

un tornillo usando un destornillador para

tuercas de 1/4". Apriete de 0.90 a 1.69

N-m (8" a 15"-lb). No apriete demasiado.

10. Vuelva a colocar la cámara de combustión.

11. Pase los cables del encendedor nueva-

mente hacia abajo a través del oricio en

la cubierta inferior. Conecte los cables

al ensamblaje del control de encendido

(consulte la gura 12, página 33).

12. Vuelva a colocar la cubierta lateral.

13. Conecte y dirija la manguera de la línea

de combustible y la manguera de la línea

de aire al ensamblaje del adaptador de la

boquilla.

15. Vuelva a colocar la fotocélula en el soporte correspondiente.

16. Vuelva a colocar el ventilador (consulte

la página 31).

17. Vuelva a colocar el resguardo del ventilador y la cubierta superior (consulte la

página 31).

Soporte de la

fotocélula

Encendedor

Ensamblaje de

tornillo-arandela

del encendedor

Soporte

adaptador

de la

boquilla

Elemento

encendedor

Cámara de

combustión

Abertura del soporte

adaptador de la boquilla

Figura 13 - Reemplazo del encendedor

ENSAMBLAJE DE LA BOQUILLA

1. Desmonte la cubierta superior (consulte

Desmontaje de la cubierta superior, página 31).

2. Desmonte el ventilador (consulte Ventila-

dor, página 31).

3. Retire las mangueras de las líneas de

aire y combustible del ensamblaje de la

boquilla (consulte las gura 14).

4. Gire el ensamblaje de la boquilla 1/4 de

vuelta a la izquierda y tire de él hacia

el motor para desmontarlo (consulte la

gura 15, página 35).

5. Coloque la parte hexagonal de plástico en

el tornillo de banco y apriete ligeramente.

6. Desmonte cuidadosamente la boquilla del

adaptador de la boquilla utilizando una

llave tubular de 5/8" (consulte la gura

16, página 35).

7. Sople aire comprimido a través de la cara

de la boquilla. Esto eliminará suciedades

del área de la boquilla.

8. Inspeccione el casquillo de la boquilla en

busca de daños.

9. Vuelva a colocar la boquilla en el adaptador hasta que la boquilla se asiente.

Apriete 1/3 de vuelta más usando una

llave tubular de 5/8" de 4.5 a 5.1 N-m (40"

a 45"-lb). Consulte la gura 16, página 35.

Soporte de

la fotocélula

Figura 14 - Desmontaje de las

mangueras de las líneas de aire y

combustible

Manguera de

la línea de

combustible

Manguera

de la línea

de aire

Ensamblaje

de boquillaadaptador

Cámara de combustión

Soporte

adaptador de

la boquilla

Page 35

www.usaprocom.com

35160177-01B

10. Fije el ensamblaje de la boquilla al soporte

del quemador (consulte la gura 15).

11. Conecte las mangueras de las líneas de

aire y combustible al ensamblaje de la

boquilla.

12. Vuelva a colocar el ventilador (consulte

Ventilador, página 31).

13. Vuelva a colocar el resguardo del ventilador y la cubierta superior (consulte

Desmontaje de la cubierta superior,

página 31).

PROCEDIMIENTOS DE SERVICIO

Figura 15 - Desmontaje del ensamblaje

de la boquilla-adaptador

Ensamblaje

de boquillaadaptador

Cámara de

combustión

Figura 16 - Boquilla y adaptador de la

boquilla

Cara de la boquilla

Boquilla

Casquillo de

la boquilla

Adaptador de

la boquilla

Niple de la

línea de aire

Niple de la línea de combustible

ENSAMBLAJE DEL CONTROL

DE ENCENDIDO

ADVERTENCIA: ¡Alta tensión!

1. Desenchufe el calentador.