Page 1

User Manual

VOR/ILS Analyzer EVS200

0796.1800.02

0798.1988.12-08

Page 2

VOR/ILS Analyzer EVS200

Issue: 01.2002

Version: E8

Copying of this document as well as any other utilization and communication of its content are only admissible

with the permission of the orginator or other authorized persons.

Any disregard will be prosecuted and is subject to restitution (UrhG, UWG, BGB). For the case a patent is

issued or the design is officially registered all rights are reserved.

ROHDE & SCHWARZ GmbH & Co. KG

WerkKöln

D-51147 Köln · Graf-Zeppelin-Straße 18

Telefon: (02203) 49-0 · Int. +49220349-0

Telefax: (02203) 49-51364

Telex: 8874525

Printed in Federal Republic of Germany · Subject to change· Data without tolerances: order of magnitude only

0102

0798.1988.12-08

Page 3

Certificate No.: 0201

This is to certify that

Equipment type: EVS200

Designation: VOR/ILS Analyzer

Order No.: 796.1800.02

EC Certificate of Conf ormity

complies with the provisions of the Directive of the Council of the European Union on the

approximation of the laws of the Member States

− relating to electrical equipment for use within defined voltage limits

(73/23/EEC revised by 93/68/EEC)

− relating to electromagnetic compatibility

(89/336/EEC revised by 91/263/EEC, 92/31/EEC, 93/68/EEC)

Conformity is proven by compliance with the following standards:

− EN61010-1 : 1994 + A2 : 1996 + A2Ber : 1998 + Ber1 : 1998

− EN50081-1 : 1992

− EN50082-1 : 1992

Affixing the EC conformity mark as from 2002-01

ROHDE & SCHWARZ GmbH & Co. KG

Werk Köln

Graf-Zeppelin-Str. 18, D-51147 Cologne

Cologne, 2002-01-17

Quality management 5C-Q / Norres

Page 4

Page 5

Safety Instructions

This unit has been designed and tested in accordance with the EC Certificate of Conformity and has left the

manufacturer’s plant in a condition fully complying with safety standards.

To maintain this condition and to ensure safe operation, the user must observe all instructions and warnings

given in this operating manual.

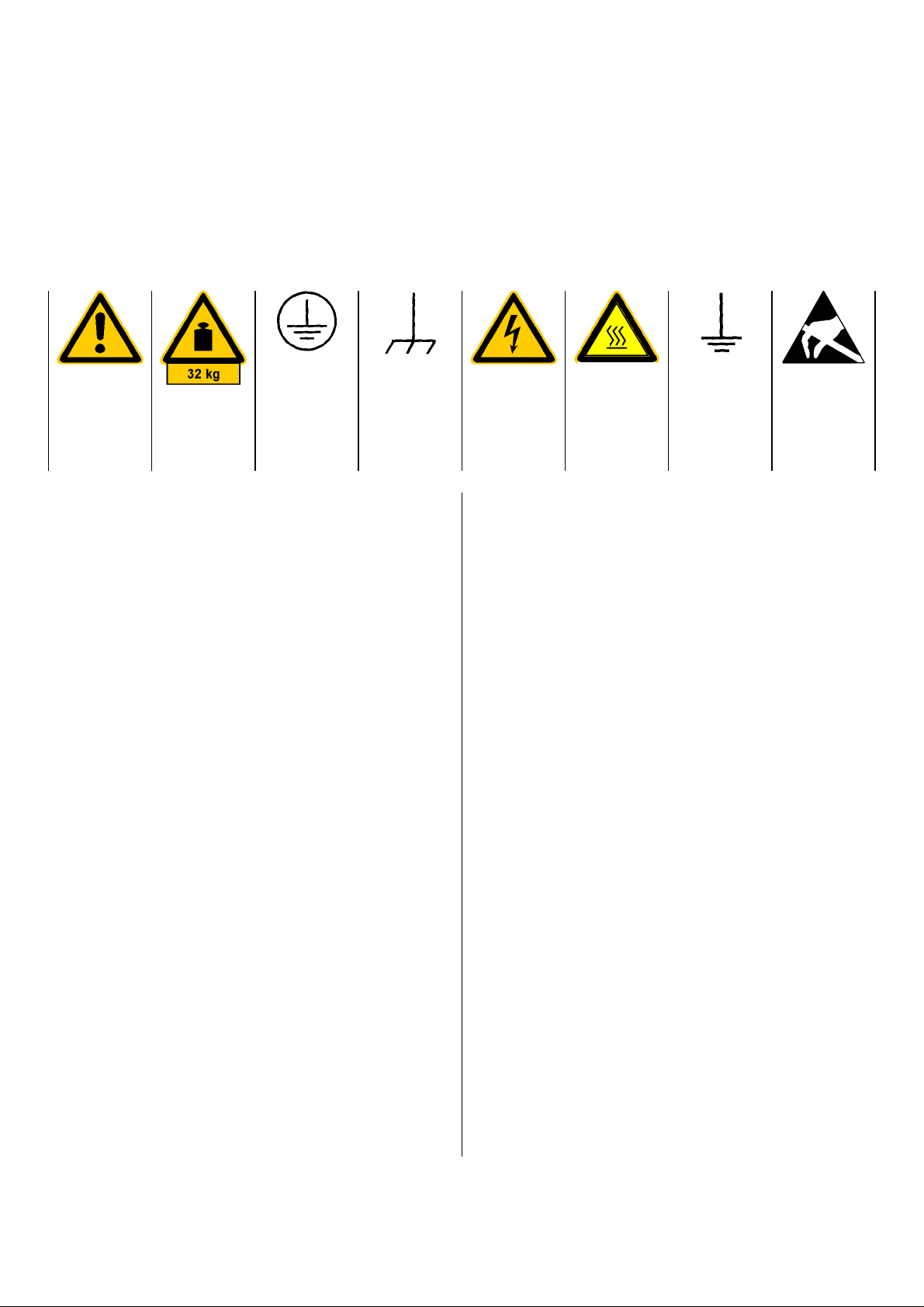

Safety-related symbols used on equipment and documentation from R&S:

Observe

operating

instructions

Weight

indication for

units >18 kg

PE terminal Ground

1. The unit may be used only i n the operating conditions and positions specified by the manufacturer. Unless otherwise agreed, the following

applies to R&S products:

Pollution severity 2, overvoltage category 2, IP

degree of protection 2X, altitude max. 2000 m.

The unit may be operated only from supply networks fused with max. 16 A.

2. For measurements in circuits with voltages V

> 30 V, suitable measures should be taken to

avoid any hazards.

(using, for example, appropriate measuring

equipment, fusing, current limiting, electrical

separation, insulation).

3. If the unit is to be permanently wired, the PE

terminal of the unit must first be connected to

the PE conductor on site before any other connections are made (installation and cabling of

the unit to be performed only by qualified technical personnel).

4. For permanently installed units without built-in

fuses, circuit breakers or similar protective devices, the supply circuit must be fused such as

to provide suitable protection for the users and

equipment.

5. Prior to switching on the unit, it must be ensured

that the nominal voltage set on the unit matches

the nominal voltage of the AC supply network.

If a diff erent voltage is to be set, the power fuse

of the unit may have to be changed accordingly.

6. Units of protection class I with disconnectible

AC supply cable and appliance connector may

be operated only from a power socket with

earthing contact and with the PE conductor connected.

terminal

Danger!

Shock hazard

Warning!

Hot surfaces

Ground

7. It is not permissible to interrupt the PE conductor intentionally, neither in the incoming c able

nor on the unit itself as this may cause the unit

to become electrically hazardous.

Any extension lines or multiple socket outlets

used must be checked for compliance with relevant safety standards at regular intervals.

8. If the unit has no power switch for disconnection

rms

from the AC s upply, the plug of the connecting

cable is regarded as the disconnecting device.

In such cases it must be ensured that the power

plug is easily reachable and accessible at all

times (length of connecting cable approx. 2 m).

Functional or electronic switches are not suitable for providing disconnection from the AC

supply.

If units without power switches are integrated in

racks or systems, a disconnecting device must

be provided at system level.

9. Applicable local or national safety regulations

and rules for the prevention of accidents must

be observed in all work performed.

Prior to performing any work on the unit or

opening the unit, the latter must be disconnected from the supply network.

Any adjustments, replacements of parts, maintenance or repair may be carried out only by

authorized R&S technical personnel.

Only original parts may be used for replacing

parts relevant to safety (eg power switches,

power transformers, fuses). A safety test must

be performed after each replacement of parts

relevant to safety.

(visual inspection, PE conductor test, insulationresistance, leakage-current measurement, functional test).

continued overleaf

Attention!

Electrostatic

sensitive devi-

ces require

special care

095.1000 Sheet 17

Page 6

Safety Instructions

Ensure that the connections with information technology equipment comply with IEC950/EN60950.

11. Lithium batteries must not be exposed to high

temperatures or fire.

Keep batteries away from children.

If the battery is replaced improperly, there is

danger of explosion. Only replace the battery by

R&S type (see spare part list)

Lithium batteries are suitable for environmentally-friendly disposal or specialized recycling. Dispose them into appropriate containers, only.

Do not short-circuit the battery.

12. Equipment returned or sent in f or repair must be

packed in the original packing or in packing with

electrostatic and mechanical protection.

Electrostatics via the connectors may da-

13.

mage the equipment. For the safe handling

and operation of the equipment, appropriate

measures against electrostatics should be implemented.

14. Any additional safety instructions given in this

manual are also to be observed.

095.1000 Sheet 18

Page 7

VOR/ILS Analyzer EVS200

Contents

Contents

Chapter Page

1. Operator Information

- Important operator information 1

- Unpacking 2

- Application of the unit 3

- Characteristics of the unit 4

- Unit l ayout frontview 5

- Unit layout rearview 6

2. Preparation for Operation

- Placing the unit 7

- Mains operation 7

- Mains connection 7

- DC connection 8

- Assembling the FO Cable Jack 8

- Finishing and connection to the Vehicle Board Supply 8

- Connection of Signal/Control Inputs/Outputs 9

- Antenna connection 9

-AFOUT 9

- RS-232-Interface 9

- External AF input 10

- DSP output 10

3. Operation

- Switch On/switch Off the unit at mains supply 11

- Switch On/switch Off the unit at VDC supply 11

- Switchonprocedure 11

- Selftest (BITE) 12

- Battery operation 12

- Operation of the unit 13

- General operating instructions of the VOR/ILS Analyzer EVS200 13

- SETUP-Mode 14

- Operating instructions of SETUP-Mode 15

0796.1800.02 E-8 0.1

Page 8

VOR/ILS Analyzer EVS200

Contents

Chapter Page

- ILS-Mode 16

- Operating instructions of ILS-Mode 16

- Operating instructions of Y / t setup menu 17

- Operating instructions of STORE DDM menu 18

- Signal parameters on ILS Display 20

- VOR-Mode 21

- Operating instructions of VOR-Mode 21

- Signal parameters on VOR Display 22

- BEACON-Mode 23

- Operating instructions of BEACON-Mode 23

- Signal parameters on BEACON Display 24

- ∆∆∆∆ LEVEL-Mode 25

- Operating instructions of ∆ Level-Mode 25

- Storing and recalling reference levels 26

- Signal parameters on ∆ Level Display 28

- SPECTRUM-Mode 29

- Operating instructions of Spectrum-Mode 29

- RS-232-Interface operation 30

- COM-Parameter 30

- Handshake 30

- Control commands 30

- Unit related control commands 31

- Mode related control commands 35

- ILS-Mode 35

- VOR-Mode 44

- ∆ Level-Mode 49

- Beacon-Mode 50

4. Interfaces

- Antenna input 53

- AF output 53

- Headphone connection 53

- XY-Tracer connection 53

- External AF input 54

- RS-232-Interface 54

- External VDC connection 54

- Mains connection 54

0796.1800.02 E-8 0.2

Page 9

VOR/ILS Analyzer EVS200

Contents

Chapter Page

5. Service

- Service 55

- Warranty 55

6. Technical Specification

- Technical data 56

- General data 58

- Accessories 59

0796.1800.02 E-8 0.3

Page 10

VOR/ILS Analyzer EVS200

Important operator information

The symbols used in this description have the following meaning.

Attention: increased vigilance!

Indexfinger: indicates important details

/ Workstep, alphanumeric sequence definition of a workstep!

Chapter 1: Operator Information

Before connecting the unit to a vehicle’s 12-VDC board supply, pay

attention that the battery’s negative pole is connected to ground

(GROUND

Finishing and connection of the auxiliary FO cable jack is

described in chapter „VDC connection" in section 2 "Preparation for

Whilst time of warranty a defective internal battery (option) may

only be changed by Rohde & Schwarz service personnel!

Also after the warranty time it is recommended that

only specialists change the internal battery.

) of the vehicle!

Operating".

0796.1800.02 E-8 1

Page 11

VOR/ILS Analyzer EVS200

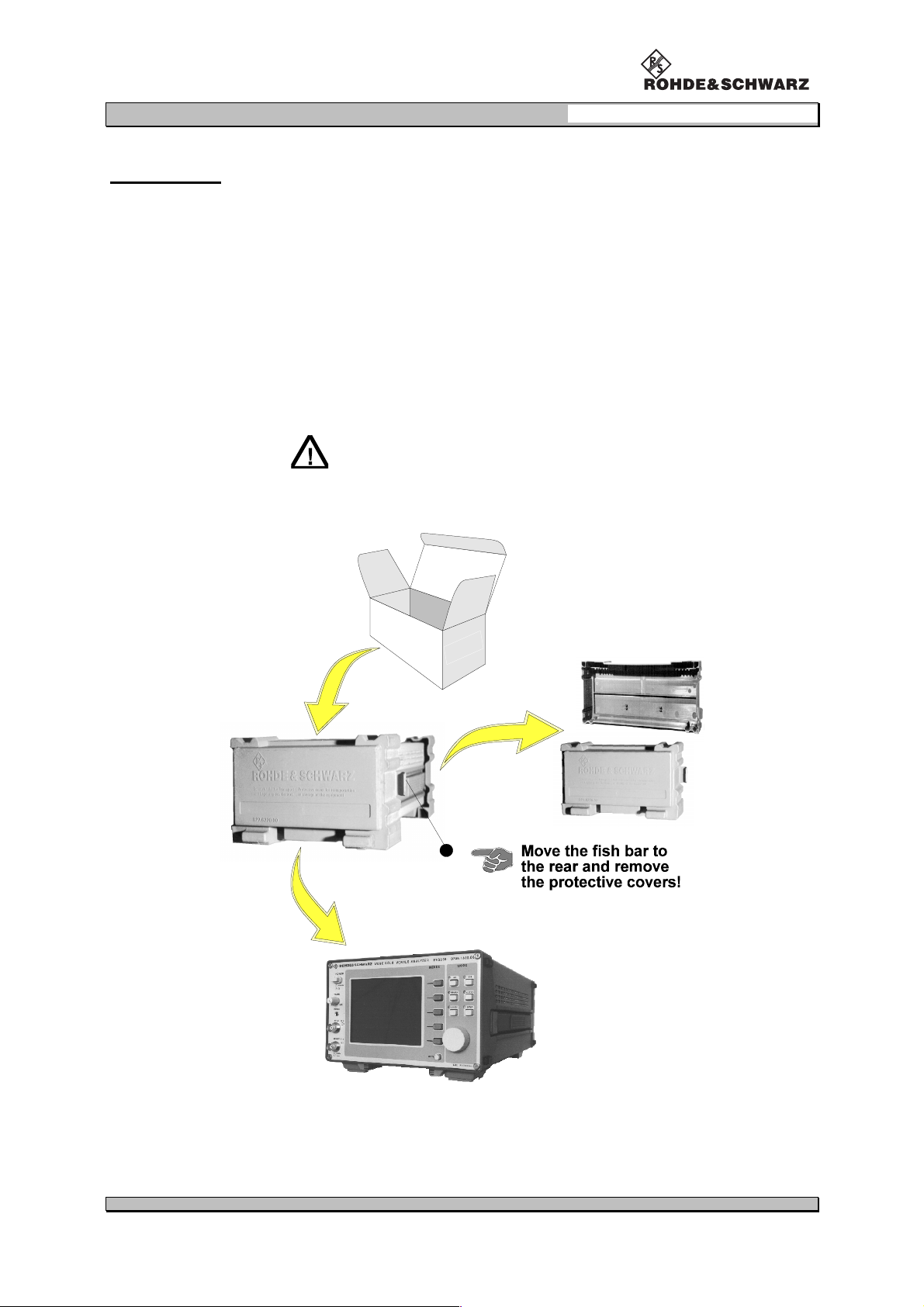

Unpacking

1. Unpack the VOR/ILS Analyzer EVS200.

2. Remove the protective covers.

3. Inspect the unit for evident damage (visual check).

4. Check the auxiliary accessory!

- FO-cabel jack (0018.6700.00)

- power cable

- operating instructions (0798.1988.12-07)

Keep the packing material for reusing!

Chapter 1: Operator Information

0796.1800.02 E-8 2

Page 12

VOR/ILS Analyzer EVS200

Chapter 1: Operator Information

Application of the unit

The VOR/ILS Analyzer EVS200 is used for checking terrestrial radio navigation facilities at airports.

Following components of ILS- and VOR-systems can be checked:

approach to land ILS (Instrument Landing System)

direction localizer LLZ (Localizer) 108 to 118 MHz

glideslope system GS (Glideslope) 320 to 340 MHz

OM (Outer Marker) 75 MHz

MM (Middle Marker) 75 MHz

IM (Inner Marker) 75 MHz

short and medium range navigation

VOR (VHF Omni Range) omnidirectional beacon 108 to 118 MHz

The following measurements can be carried out:

DDM (indication also in 1 / µA / %), SDM, modulation factor

absolute level

delta level (∆ level)

VOR parameter

ILS parameter

75-MHz beacon parameter

Ranges for measurements are e.g:

dynamic runway surveying (limited through high measurement speed

(90 measurements/s))

static distant field surveying

function monitoring of transmitting field stations with data tele-transmitting

surveying of transmitting antenna characteristics through "∆∆∆∆level-mode"

Clearance & Glidepath (common parameter analysis without disconnecting the

transmitting station)

measuring and evaluating of corresponding parameters at high interference intensity

Due to versatile power supply facilities the VOR/ILS Analyzer EVS200 is suitable for operation in field

(battery supply), in vehicles (12-V board supply), and in the lab (AC supply). Among others it is possible to remote control the unit via the RS-232-Interface and recalling all obtained data. Further more

the corresponding parameters of the DSP can be taken at the multifunction output (DSP OUT) for

further analysis (e.g. XY-tracer).

0796.1800.02 E-8 3

Page 13

VOR/ILS Analyzer EVS200

Characteristics of the unit

Remarkable characteristics of the VOR/ILS Analyzer EVS200 are:

high accuracy

easy handling

low power consumption

very compact and light design for mobile operation

battery operation (option) for mobile operation

external DC operation for mobile operation

remote control through RS-232-Interface

selftest facillty (BITE)

Chapter 1: Operator Information

digital signal processing (DSP) on ILS and VOR analysys

high rapidity of measurement (ILS = 90 measurements/s)

immediately display of all measurement data

DDM-/SDM-measurements

calibration of Y / t recorder (DDM = 0)

∆ level measurements (4 reference levels can be stored)

installed loudspeaker and headphone output

suitable for 19" rack assembly

0796.1800.02 E-8 4

Page 14

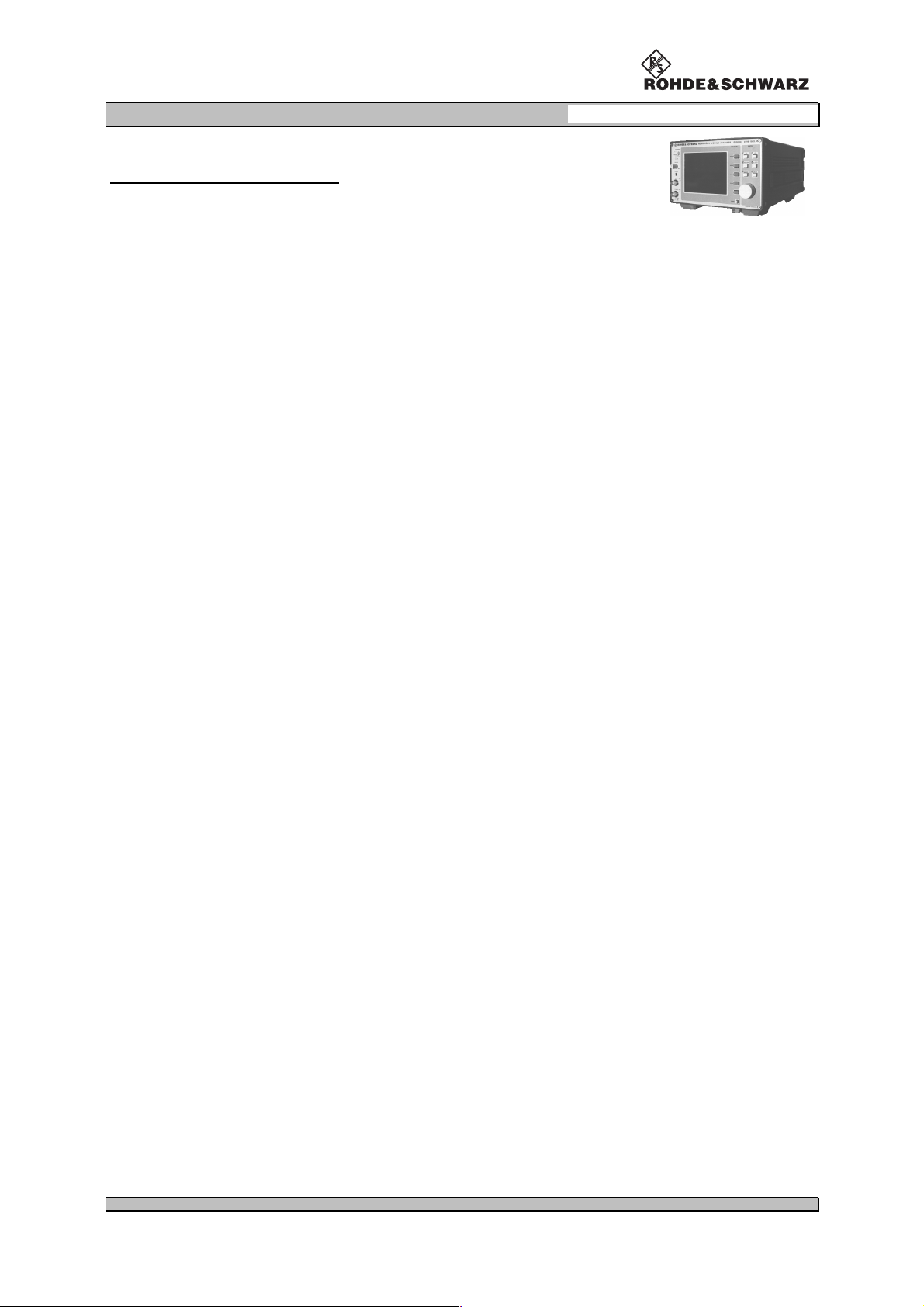

VOR/ILS Analyzer EVS200

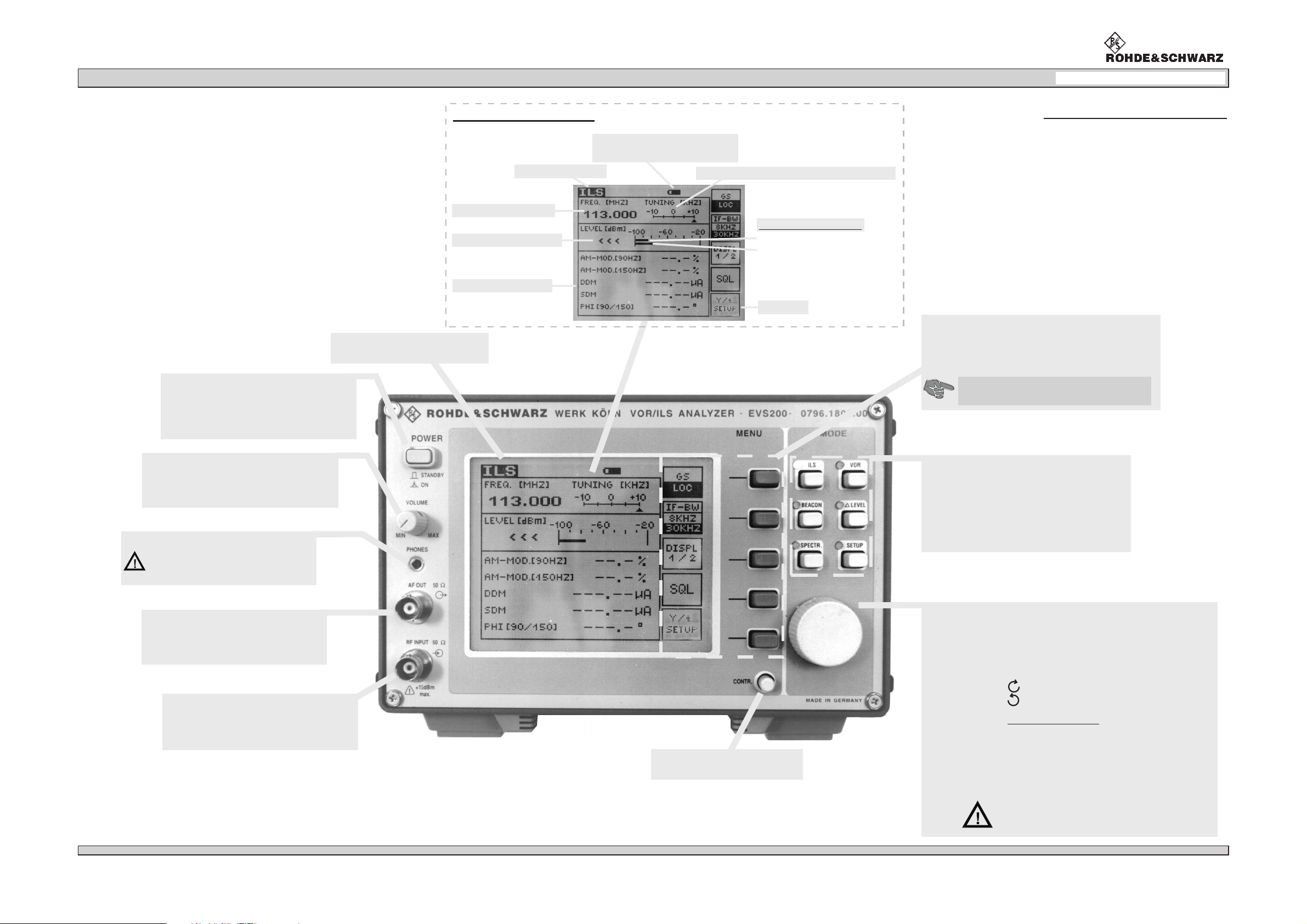

Chapter 1: Operator Information

POWER

Set the unit into operation, on mains

supply and in postion "Standby" the

installed battery (Option) will be

charged.

LC display description

receiver frequency

receiver signal level

signal parameters

LC display

(illuminated dot matrix display)

mode indication

Unit layout frontview

battery indication

(only for built-in battery (option))

bargraph center frequency indication

bargraph indication

receiver signal level

squelch threshold

softkeys

Softkeys

Softkeys (program dependent functional keys)

are allocated to the conforming operation mode.

The softkey function is indicated on the display.

On the display all active modes are

sensitive (grey background)!

volume control

With the potentiometer "Volume" the

loudspeaker´s and headphone´s

volume can be set.

headphone connector

only for connecting headphones

with soundproofing!

e.g. R&S order no.0708.9010.00

AF output

BNC socket

output level:

200 mV / 50

by 50 % AM part

rms

antenna input

BNC socket

input level:

VSWR:

max. +15 dBm / 50 Ω

<1.5

mode keys

The mode keys select the corresponding

measurment and setting mode which will

be indicated by the yellow LED.

A selected mode will be indicated on the

display. Mode settings will be performed

with the softkeys.

rollkey

On principle all possible menu settings will be performed

Ω

contrast control

adjustment of display contrast

with the rollkey.

An exception is the "Setup-Menu" where settings must

be performed with the designated softkeys..

turning direction for increasing values

turning direction for decreasing values

frequency setting

The frequency changes depending on the rollkey´s

turning speed in following steps:

- turn rollkey slow 5-kHz-steps

- turn rollkey fast 100-kHz-steps

⇒

(depending upon the setup-settings)

⇒

0796.1800.02

E-8

Rollkey operation is only possible when

function is switched off!"VAR-LOCK"

5

Page 15

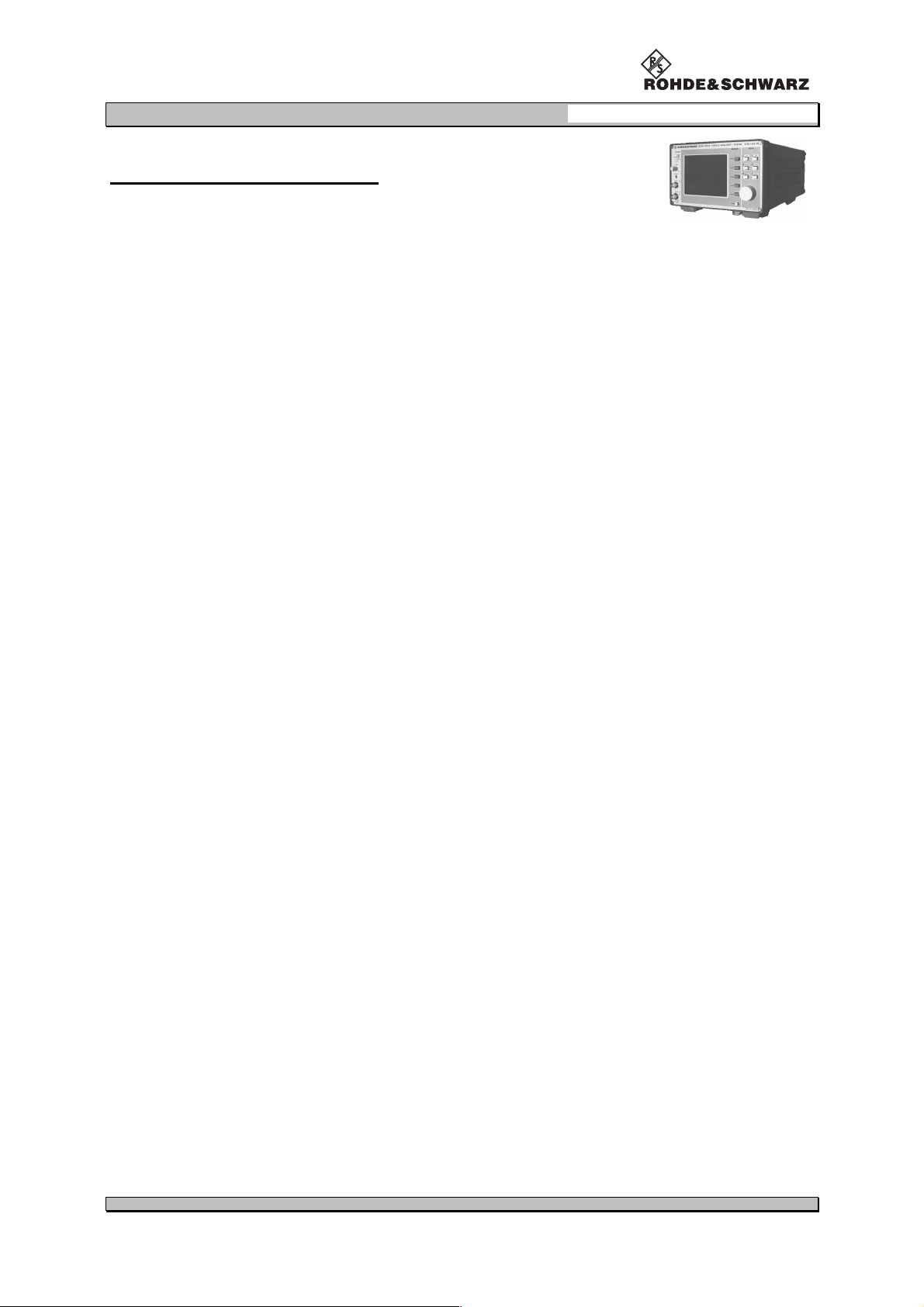

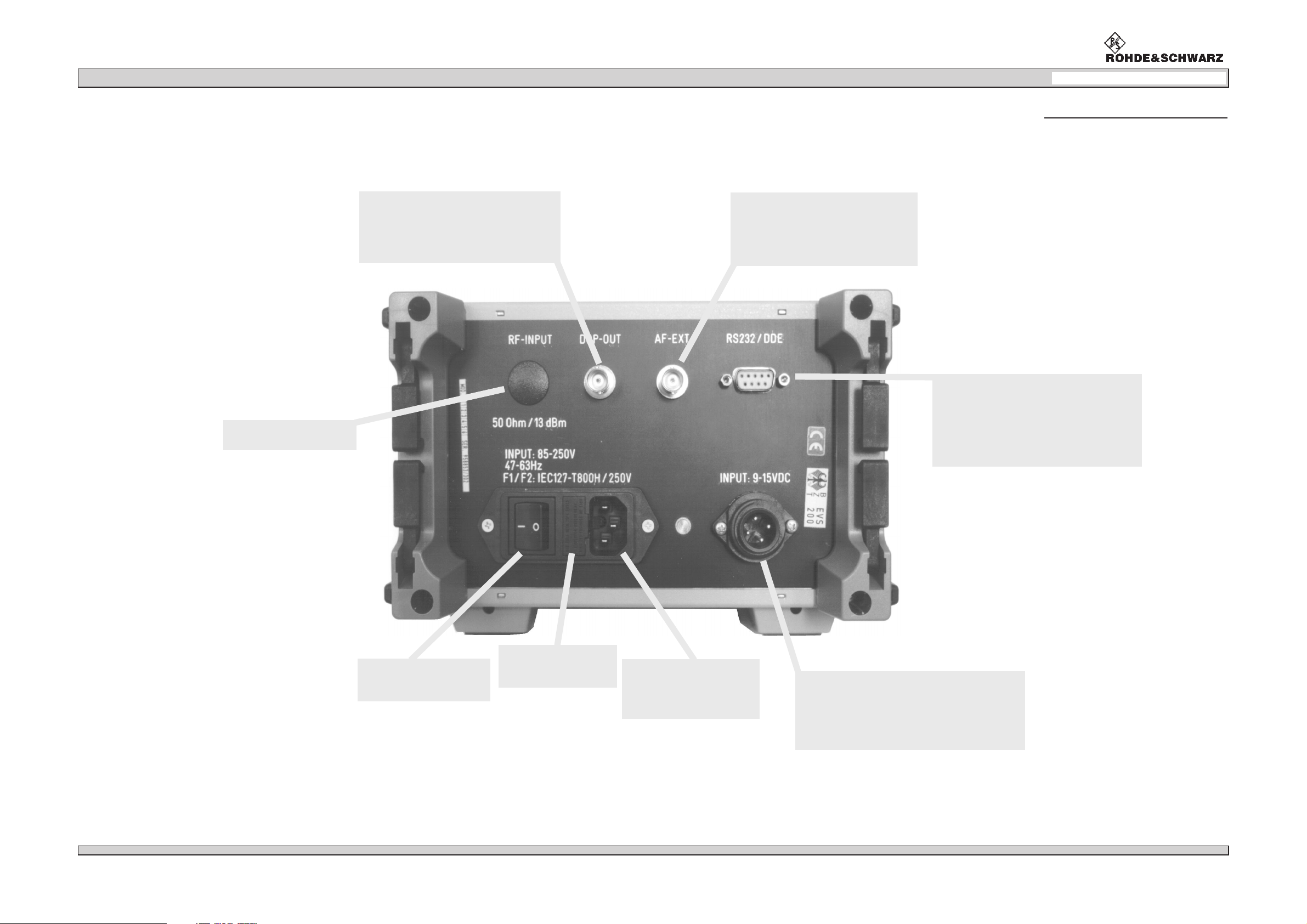

VOR/ILS Analyzer EVS200

Chapter 1: Operator Information

Unit layout rearview

antenna input

not applicable (optional)

DSP output

The scaling of the XY values can be set

in the setup / Y / t setup (ILS mode) for

the and mode.

localizer glideslope

BNC socket

external AF input

The external AF input is to select

in the setup.

BNC socket

input level:

1to2V /50

rms

Ω

RS-232-Interface

SUB-D socket:

COM parameter:

BAUD rate:

9pole

N81

1200, 2400,

4800, 9600,

19200 adjustable in

the setup

0796.1800.02

mains switch

Master switch only

for mains operation

on/off

mains fuses

F1/F2

IEC127-T800H / 250 V

mains connector

socket

87 to 265 VAC

47 to 63 Hz

E-8

external VDC input

When an external VDC supply is connected

the installed battery (option) is switched off.

U 9 to 15 VDC

input

I2A

max

6

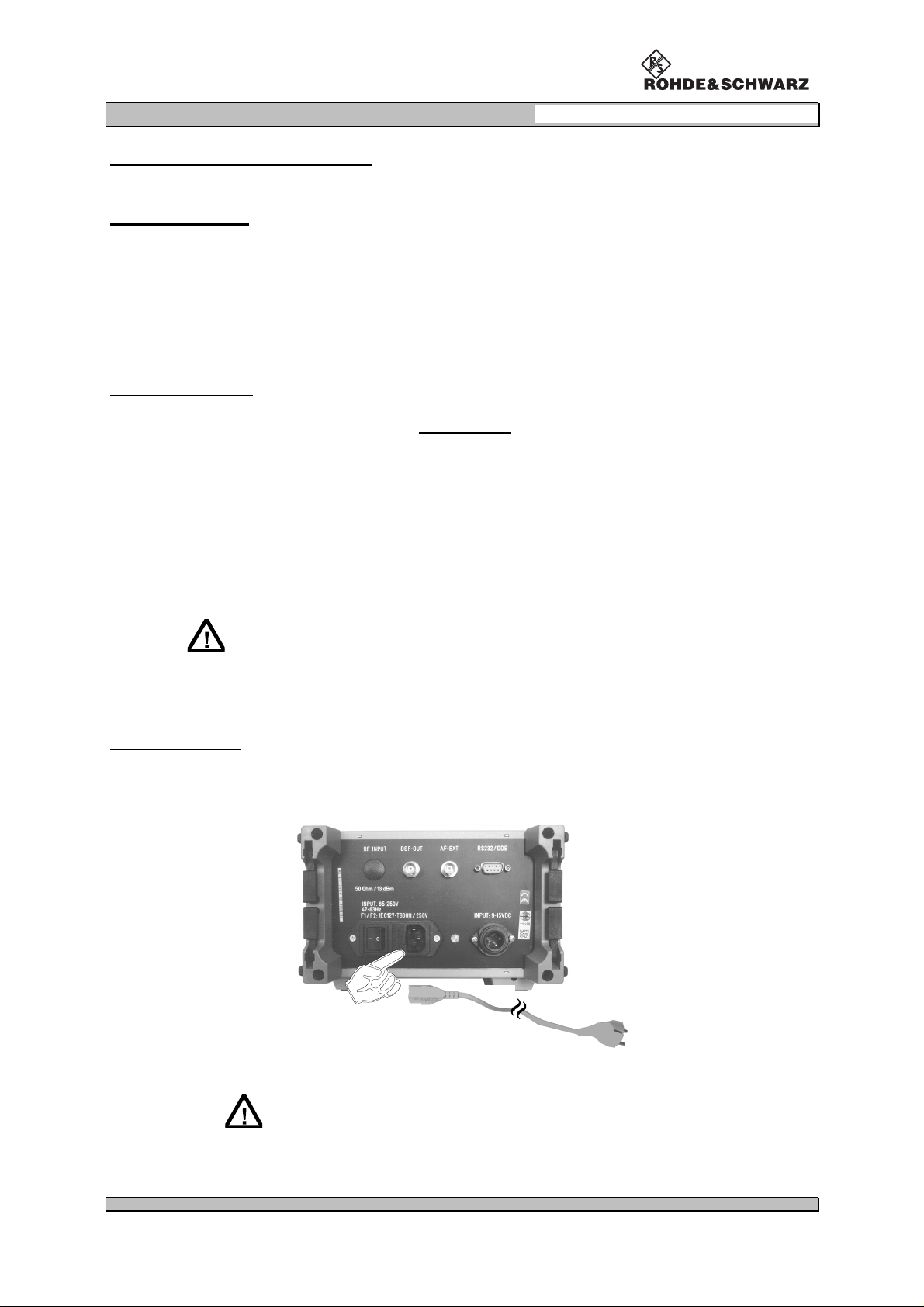

Page 16

VOR/ILS Analyzer EVS200

Chapter 2: Preparation for Operation

Preparation for operation

Placing the unit

The VOR/ILS Analyzer EVS200 can be operated in any position without reduction in its function. Even

shocks during normal transportation or on mobile operation don’t reduce its function.

The unit works at ambient temperatures of -5 to +40°C.

Mains operation

Safety Rules

The VOR/ILS Analyzer EVS200 meets the safety rules in ag-

reement with VDE 0411 and VDE 0804 of safety class I. In

agreement with safety class I all mains circuitry must be insulated and the requirement is a good conductive and durable

together and ground wire connection of all touchable, conductive parts of the unit which can directly be alive in case of a

failure.

Mains connector (earthed plug) put only into a protective

contact socket. If there is a connector it must durable be

connected with a ground wire. The ground wire must not

be insulated.

Mains connection

Connect the VOR/ILS Analyzer EVS200 with the supplied power cord to the AC supply

(87 to 265 VAC / 47 to 63 Hz or corresponding to the technical data).

If the unit shall be connected to another AC supply the

corresponding safety rules must be observed!

0796.1800.02 E-8 7

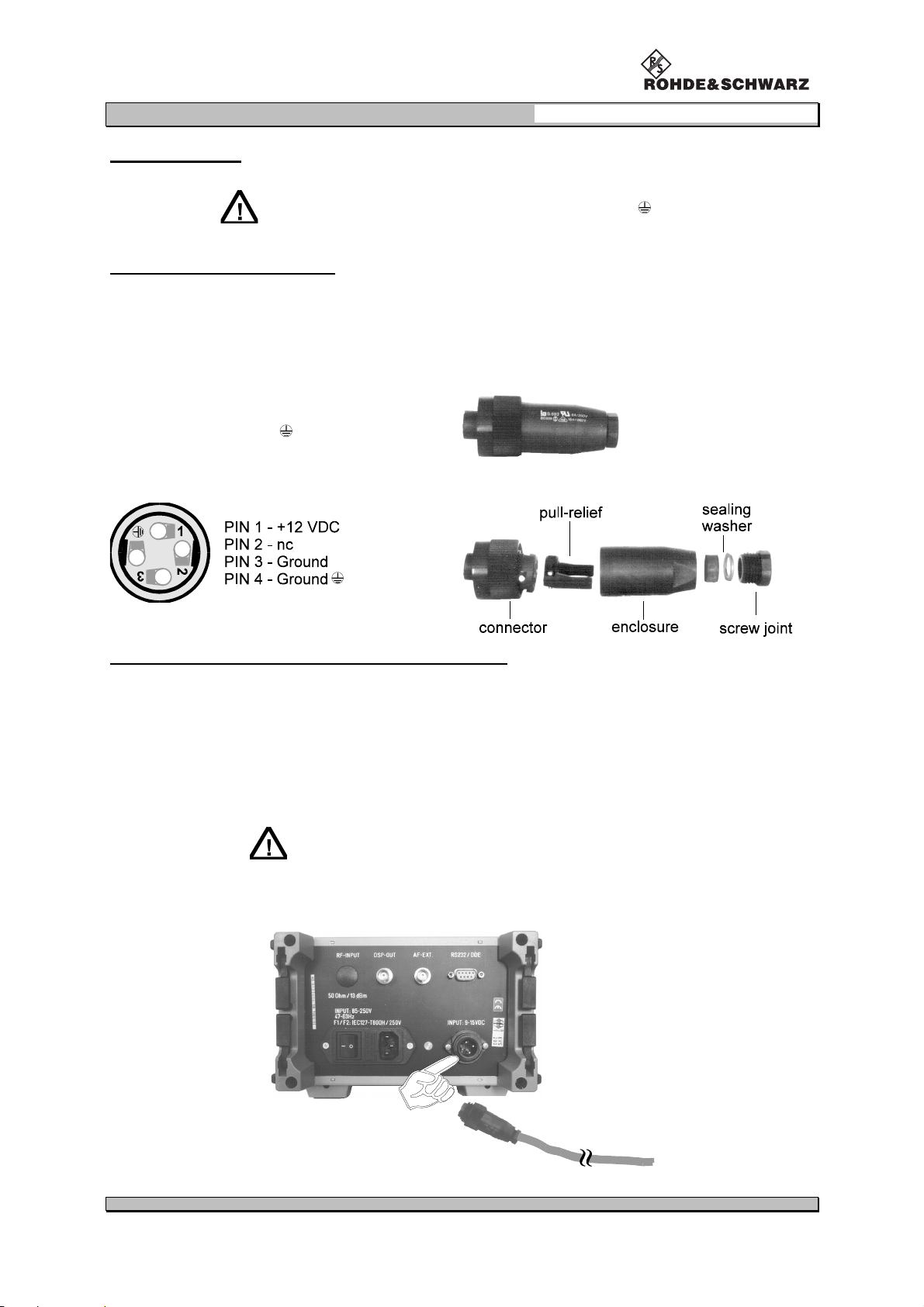

Page 17

VOR/ILS Analyzer EVS200

Chapter 2: Preparation for Operation

DC connection

Only connect the unit when the minus pole of the battery

is connected to vehicles ground (GROUND

input voltage: 9 to 15 VDC

Assembling the FO Cable Jack

Finish the supplied FO cable jack (0018.6700) as following with commercial PVC cables.

)!

cable specification

PVC wiring performance according VDE 0281

wire cross section 1.0 mm

colour RED for +VDC

colour BLUE for ground(

Pin connection of the FO cable jack Assembling the FO cable jack

Finishing and connection to the Vehicle Board Supply

2

or more

)

FO cable jack

order no.: 0018.6700

Strip the cable end ca. 8mmand mount multicore.

Draw the cable through the enclosure and connect it according to the above pin connection of

the FO cable jack.

Fit the pull-relief and assemble the FO cable jack.

Connect the cable to the vehicle board supply.

When connecting the finished cable to the 12-VDC vehicle

board supply there is to perform a protection by a cable fuse

(T2.0 A) or a fuse on board!

Connect and lock the FO cable jack in the VDC input at the rear of the unit.

0796.1800.02 E-8 8

Page 18

VOR/ILS Analyzer EVS200

Chapter 2: Preparation for Operation

Connection of Signal/Control Inputs/Outputs

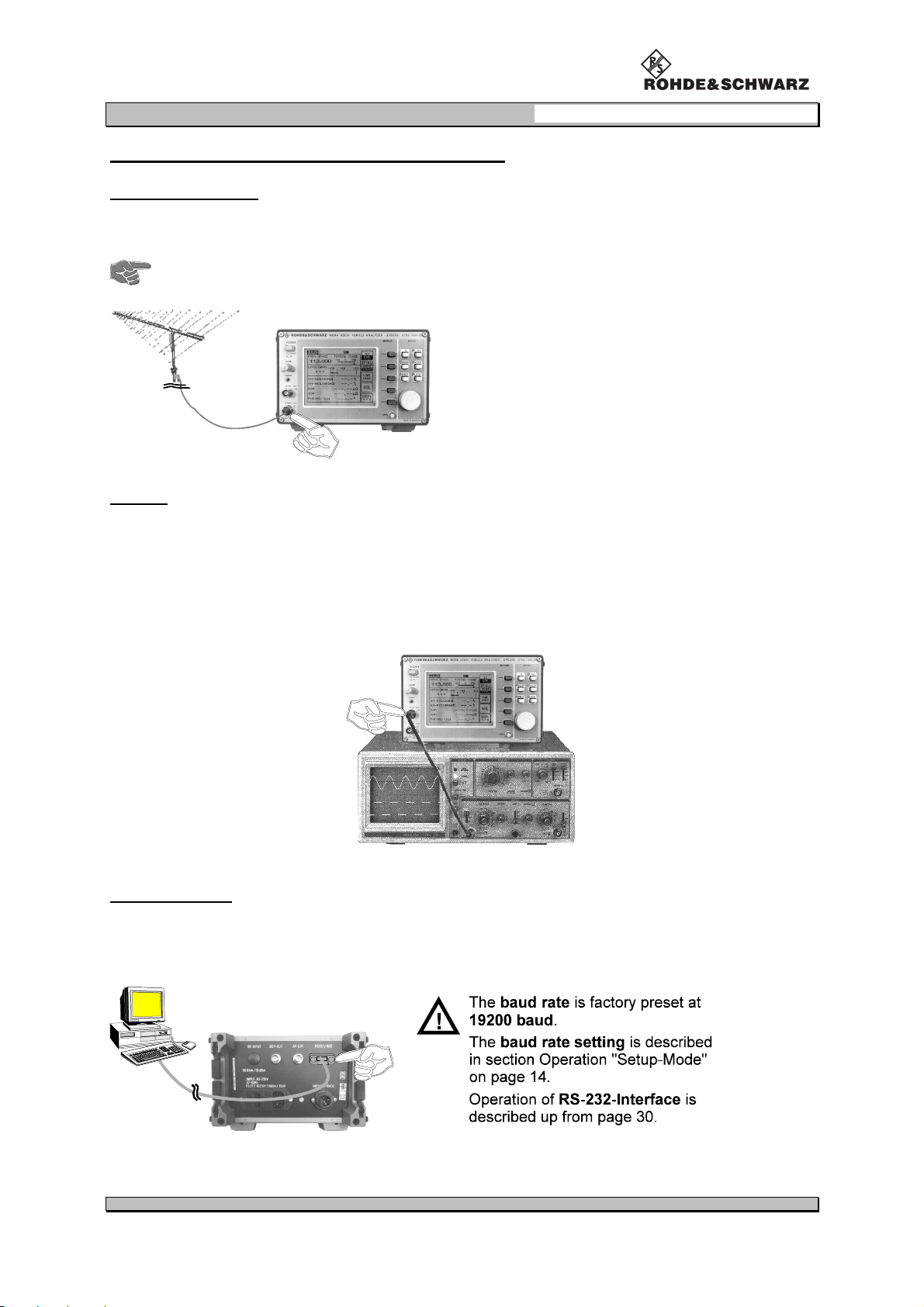

Antenna connection

Via the RF INPUT at the frontside the VOR/ILS Analyzer EVS200 can be connected with a receiver

antenna which agrees to frequency range.

As an option a RF input at the unit’s rear side is possible.

AF OUT

Via the AF OUT at the frontside the demodulated AF signal will be output.

AF signal bandwidth:...............................300 Hz to 4 kHz

output level:.............................approx.: 200 mV

e.g. VOR/ILS Analyzer

RS-232-Interface

Via the RS-232-Interface at the rearside all essential unit functions of the VOR/ILS Analyzer EVS200

can be remote controlled with a PC terminal. For that purpose the unit can be operated with

commercial terminal programs (e.g. Telix, Procomm, etc.)

=oscilloscope

/50Ω / by 50% AM part

rms

0796.1800.02 E-8 9

Page 19

VOR/ILS Analyzer EVS200

Chapter 2: Preparation for Operation

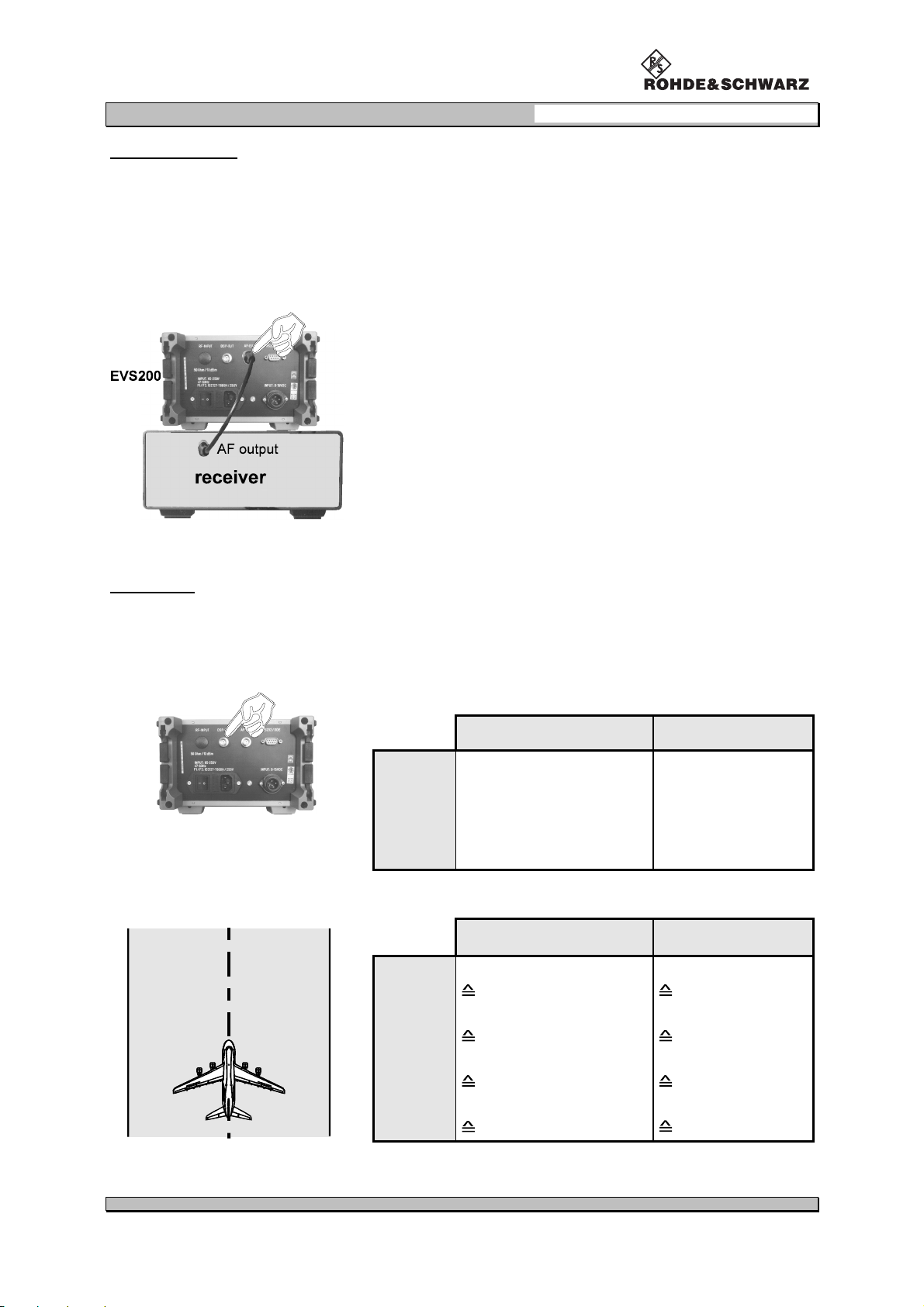

External AF input

Via the AF input (AF-EXT) at the rear side the unit can be fed with an AF signal for further analysis of

typical AF parameters (e.g. level, frequency). This is very applicable for receivers which cannot perform AF analysis.

input level: approx.: 1 to 2 V

e.g. VOR/ILS Analyzer

=external receiver

rms

/50Ω

Connection AF-EXT of the VOR/ILS Analyzer EVS200 with

the AF output of an external receiver

DSP output

On the DSP-OUT at the rearside e.g. a XY-tracer can be connected. The scaling of the XY values

can be set for any mode (localizer/glideslope) in the setup (DDM Y / t-RANGE) or in ILS-Mode

(Y / t-SETUP).

output signals in VOR- and ILS-Mode:

(corresponding

DC voltage)

(0 V ±±±±5mV) 0DDM (1V±±±±5mV)

ILS-Mode VOR-Mode

Display 1

normalized DDM-values

(DC-voltage)

Range1to4

Display 2

voice-frequency

(300 to 3000 Hz)

scaling in the setup:

Localizer Glideslope

Range 1

0.0 ±25%

0 ±0.25 DDM

Range 2

0.0 ±2.5%

0 ±0.025 DDM

Range 3

0.0 ±2.58%

0.0 ±0.0258 DDM

Range 4

0.0 ±50%

0.0 ±0.5 DDM

no output

voice-frequency

(300 to 3000 Hz)

0.0 ±50%

0.0 ±0.5 DDM

0.0 ±5%

0.0 ±0.05 DDM

8.75 ±5%

0.0875 ±0.05 DDM

17.5 +5%

0.175 +0.05 DDM

0796.1800.02 E-8 10

Page 20

VOR/ILS Analyzer EVS200

Operation

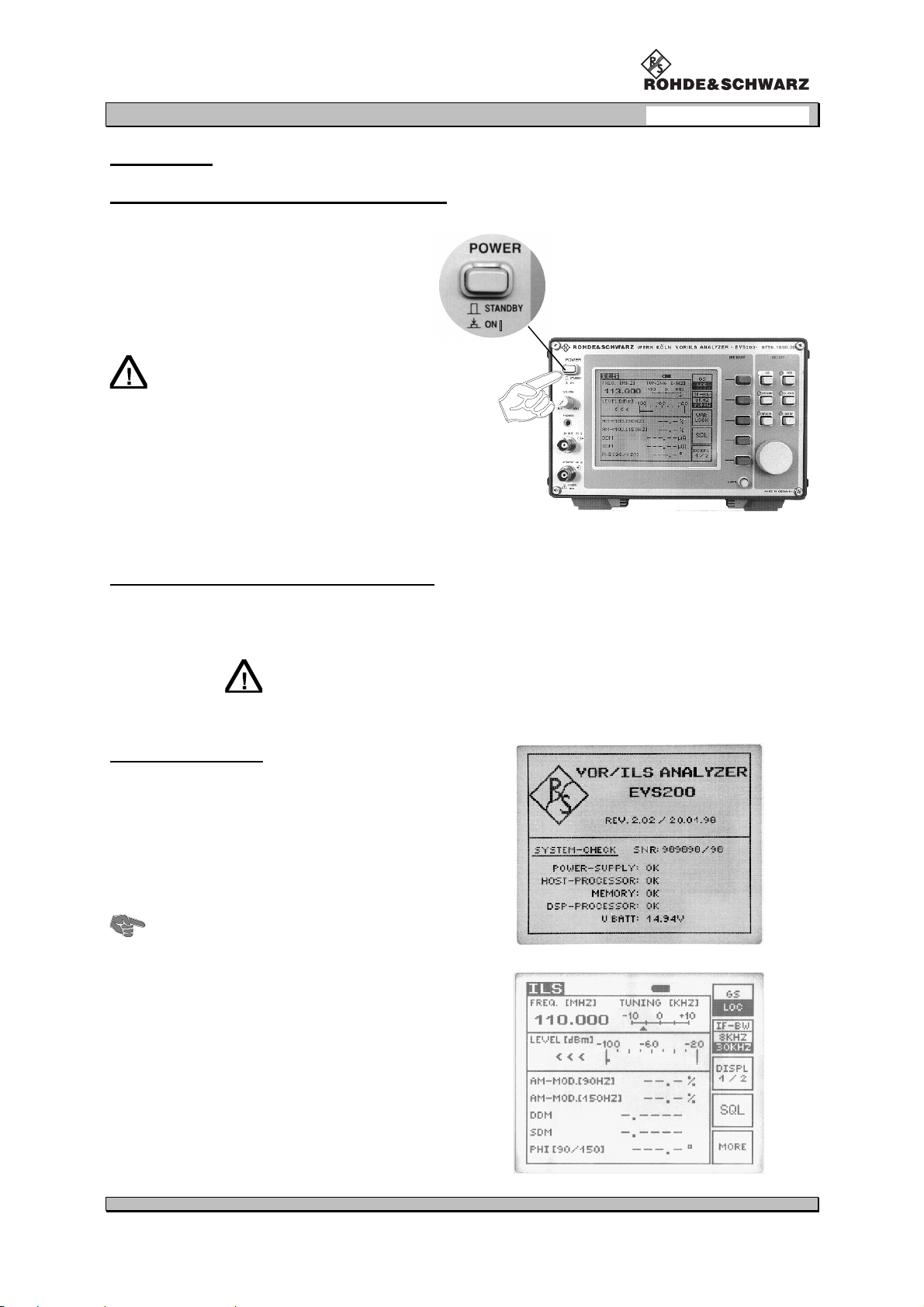

Switch On/switch Off the unit at mains supply

With the mains switch at the rearside

switch the unit on or off.

With the switch "POWER" at the front

side switch the unit on or "STANDBY".

On switch position "STANDBY" the installed battery (option) will be charged.

Details see item "Battery Operation"

(page 12).

Chapter 3: Operation

Switch On/switch Off the unit at VDC supply

When the unit is supplied from the installed battery (option) or through the external DC input it must

be switched on or to "STANDBY" only with the Switch "POWER" at the frontside.

On external DC supply of the unit the installed battery

(option) will not be charged!

Switch on procedure

During the switch on procedure the VOR/ILS

Analyzer EVS200 performs a selftest (BITE). The

tested functions are indicated with "OK". This test

takes approx. 5 s. After that automatically it is

switched over to the startup mode which was set

in the setup.

Because of the displayed battery voltage

(U BATT) it is possible to value the charging

state of the installed battery (option).

ßßßß

Malfunctions of the BITE will be indicated by

"FAIL". In that case the unit does not switch over

to the startup mode (see also item "Selftest").

0796.1800.02 E-8 11

Page 21

VOR/ILS Analyzer EVS200

Selftest (BITE)

Chapter 3: Operation

The selftest checks:

all operating voltages,

host processor,

memory,

DSP processor.

In case of an error the determined functional unit will be indicated with a "FAIL". If the internal

operating voltages totally fail or if they deviate extraordinary from the tolerances a selftest cannot

be carried out.

Error:

In case of an error the unit generally should be

switched off and after a few seconds it schould be

switched on again. If the error message is displayed

again it is recommended to send the unit to the

service, corresponding to Chapter 5 (Service).

Battery operation

The battery operation of the VOR/ILS Analyzer EVS200 is an optional component. It is always possible to retrofit the unit with this mode.

The unit automatically goes into battery operation when the external power supply (DC/AC) is switched

or cut off. The battery operation is indicated on the display by the battery symbol (

) in each mode.

The operation time is >100 minutes (max. brightness) or >150 minutes (at average brightness)

with a completely charged battery.

The charging state can be seen from the battery symbol on the display:

100% battery power

approx. 75 to 25% battery power

flashing symbol, approx. only 5 minutes operation is

ensured. Battery must be charged.

The battery will be charged on AC operation (as well during operation as on "STANDBY") and should

take at least 12 hours (charging time).

After 4 to 5 years or when defect the battery must be

changed according to Chapter 5 "Service".

0796.1800.02 E-8 12

Page 22

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Operation of the unit

Because of the many universal measuring functions of the VOR/ILS Analyzer EVS200 the operation

has to be carried out according to the following instructions. Basically all measurement parameter settings are realized through softkeys and the mode keys. An activated mode is shown by a luminous

LED (beside the belonging mode key). All important signal parameters are analyzed by the DSP (digital

signal processor) and indicated on the display. Due to the variety of the analyzed parameters the indication in the ILS and VOR mode is subdivided into two display parts ("DISPL 1/2" and

DISPL 2/2").

The RS-232-Interface operation of the VOR/ILS Analyzer EVS200 is

described in section "Operating the VOR/ILS ANALYZER EVS200

via RS-232-Interface"

General operating instructions of the VOR/ILS Analyzer EVS200

0796.1800.02 E-8 13

Page 23

VOR/ILS Analyzer EVS200

Chapter 3: Operation

SETUP-Mode

In the following table all possible parameters are listed and its functions are described. Furthermore all

possible setting values per parameter are shown. Next a sequence chart of the operating instructions

in the SETUP mode is following.

Changes in the SETUP can be saved

with the softkey "SAVE".

parameter description setting value

RS232 BAUDRATE baud rate setting 1200, 2400, 4800,

9600, 19200

VOR ANGLE-RESOLUTION BEARING-angle resolution 0,01° / 0,05°

DDM/SDM AVG-FACTOR factor for determining the number of

measurements which form the arithmetical average

DDM Y / t-RANGE [LOC]

DDM Y / t-RANGE [GS]

AF-INPUT-SOURCE AF selection for valuation INT = internal AF

STARTUP mode startup mode setting at switching on the

SQUELCH

XY value scaling in localizer mode at

DSP-OUT (refer to page 10 DSP output)

XY value scaling in glideslope mode at

DSP-OUT (refer to page 10)

unit

on/off switching squelch

1, 2, 4, 8, 16, 32, 64

RNG.1 to RNG.4

RNG.1 to RNG.4

EXT = external AF

via AF-EXT-input

VOR (VOR mode)

ILS (ILS mode)

BCN (Beacon mode)

SPEC (Spectrum mode)

LEVEL (∆

ON / OFF

∆ level mode)

∆∆

setting valid for:

-

∆

level mode

- ILS mode

- VOR mode

When the setting is "ON" an automatical quiet tuning is performed as soon

as the threshold level < the receiver level is.

When setting is "OFF" no quiet tuning will be performed.

DISPLAY ILLUM

DDM/SDM DIMENSIONS value of DDM/SDM indication

DISPLAY-INTERVALL indication interval time

display brightness setting

setting is only valid for display indication

.

OFF ⇐ 1to6Þ MAX

µA/%/1

(1= value without dimension)

1to8

1to 8

approx. 0.4 s to approx. 1.8 s

TUNING-STEP tuning step rate setting 5 / 25 / 50 / 100 (kHz)

0796.1800.02 E-8 14

Page 24

VOR/ILS Analyzer EVS200

Operating instructions of SETUP-Mode

Chapter 3: Operation

0796.1800.02 E-8 15

Page 25

VOR/ILS Analyzer EVS200

ILS-Mode

Operating instructions of ILS-Mode

Chapter 3: Operation

0796.1800.02 E-8 16

Page 26

VOR/ILS Analyzer EVS200

Operating instructions of Y /t setup menu

Chapter 3: Operation

0796.1800.02 E-8 17

Page 27

VOR/ILS Analyzer EVS200

Operating instructions of STORE DDM menu

Chapter 3: Operation

0796.1800.02 E-8 18

Page 28

VOR/ILS Analyzer EVS200

Chapter 3: Operation

0796.1800.02 E-8 19

Page 29

VOR/ILS Analyzer EVS200

Signal parameters on ILS display

Following signal parameters are indicated on the display:

display indication description measuring value

Chapter 3: Operation

DISPL 1/2

FREQ. (MHZ) receiver frequency in MHz (numerical) and

MHz

bargraph center frequency indication in kHz

LEVEL (dBm) receiver signal in dBm (numerical) and

dBm

bargraph indication (the lower bargraph

shows the set squelch threshold)

AM-MOD.(90HZ) AM modulation depth (90 Hz) %

AM-MOD.(150HZ) AM modulation depth (150 Hz) %

DDM differences in depth of modulation DDM-value

(non-dimension value)

µA

%

SDM total modulation factor SDM-value

(non-dimension value)

µA

%

PHI (90/150) phase shift (90 Hz/150 Hz) degree

DISPL 2/2

Y/tSetup

STORE

DDM menu

ID AF-FREQ. AF frequency (1020 Hz) Hz

ID AM-MOD. AMmodulation depth of AF frequency %

VOICE AM-MOD. AM modulation depth in the range of

%

300 to 3000 Hz

Range1to4

XY value scaling in localizer /

%

glideslope mode at DSP-Out.

Locations 1 to 120 DDM/SDM results

0796.1800.02 E-8 20

Page 30

VOR/ILS Analyzer EVS200

VOR-Mode

Operating instructions of VOR-Mode

Chapter 3: Operation

0796.1800.02 E-8 21

Page 31

VOR/ILS Analyzer EVS200

Signal parameters on VOR display

Following signal parameters are indicated on the display:

display indication description measuring value

Chapter 3: Operation

DISPL 1/2

DISPL 2/2

FREQ. (MHZ)

LEVEL (dBm)

BEARING

AM-MOD.(30HZ)

AM-MOD.(9960HZ)

FM-DEVIATION

FM-INDEX

ID AF-FREQ.

ID AM-MOD.

VOICE AM-MOD.

receiver frequency in MHz (numerical) and

bargraph center frequency indication in kHz

receiver signal in dBm (numerical) and

bargraph indication (the lower bargraph

shows the set squelch threshold)

BEARING angle

AM modulation depth (30 Hz)

AM modulation depth (9960 Hz)

frequency deviation

FM index value index value

AF frequency (1020 Hz)

AM modulation depth of AF frequency

AM modulation depth in the range of

300 to 3000 Hz

MHz

dBm

DEG

%

%

Hz

(non-dimension value)

Hz

%

%

0796.1800.02 E-8 22

Page 32

VOR/ILS Analyzer EVS200

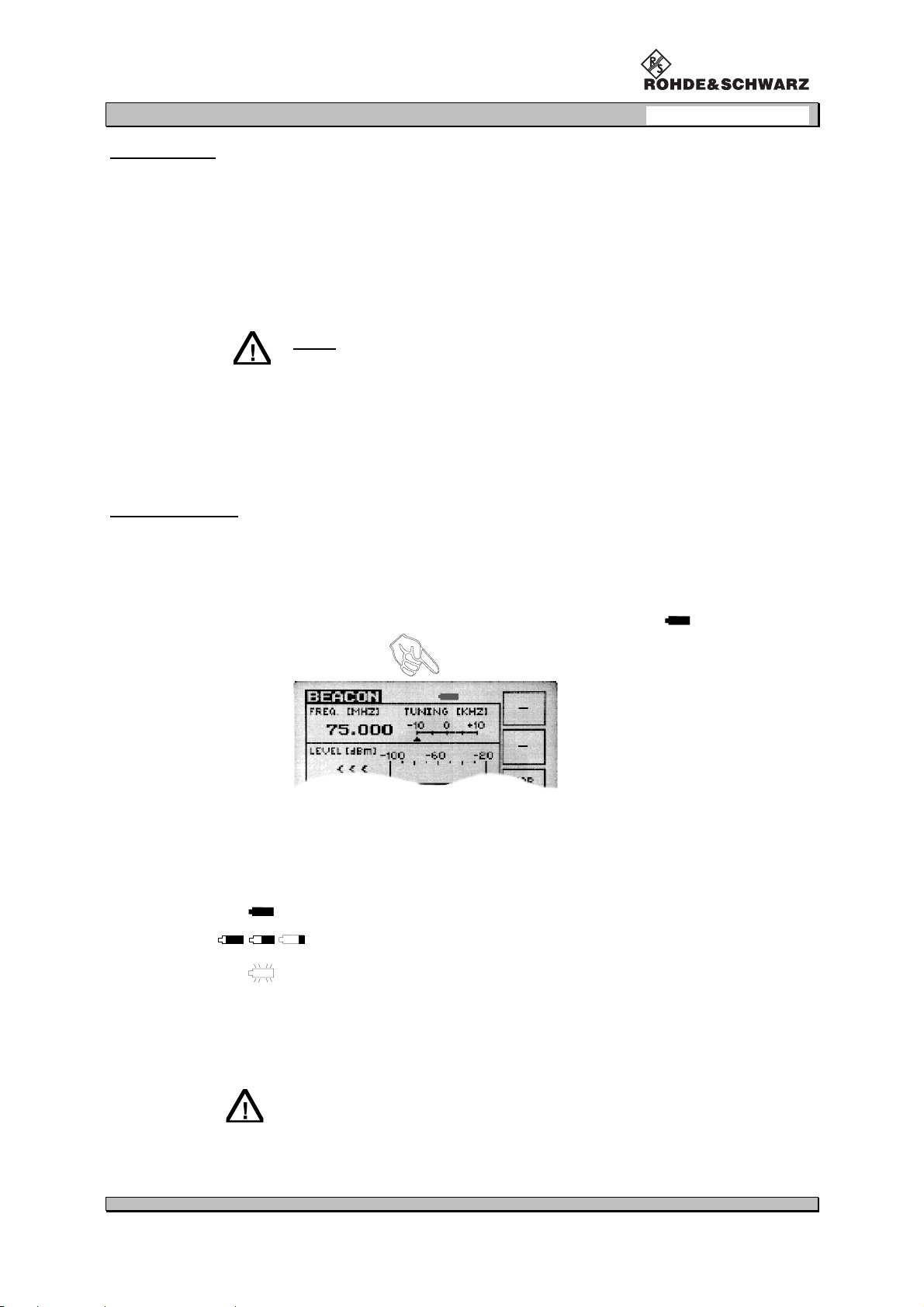

BEACON-Mode

Operating instructions of BEACON-Mode

Chapter 3: Operation

0796.1800.02 E-8 23

Page 33

VOR/ILS Analyzer EVS200

Signal parameters on BEACON display

Following signal parameters are indicated on the display:

display indication description measuring value

Chapter 3: Operation

FREQ. (MHZ)

LEVEL (dBm)

F1

F2

F3

ID

receiver frequency in MHz (numerical) and

bargraph center frequency indication in kHz

receiver signal in dBm (numerical) and

bargraph indication (the lower bargraph

shows the set squelch threshold)

AF frequency and AM modulation depth at

3000 Hz (inner marker)

AF frequency and AM modulation depth at

1300 Hz (middle marker)

AF frequency and AM modulation depth at

400 Hz (outer marker)

AF frequency and AM modulation depth of

the identifier

MHz

dBm

Hz and %

Hz and %

Hz and %

Hz and %

0796.1800.02 E-8 24

Page 34

VOR/ILS Analyzer EVS200

∆∆∆∆ Level-Mode

Operating instructions of ∆∆∆∆ Level-Mode

Chapter 3: Operation

0796.1800.02 E-8 25

Page 35

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Storing and recalling reference levels

To occupy storage capacaty or to call up memory the ∆∆∆∆ level mode has a storage menu which will be

called up by pushing the softkey "MEM".

Until four memory blocks M1 to M4 can be stored or called up. Following data will be allocated to a

storage space:

- actual reference level,

- actual receiver frequency.

After storing or recalling of a memory the ∆∆∆∆ level main window is updated with the relevant memory

data. When the receiving level changes the update ∆ level is permanently indicated in ∆∆∆∆ level window.

Storage menu explanation:

See next page for t he operation diagram for "Storing Reference Levels" and

"Recalling Single Memory".

0796.1800.02 E-8 26

Page 36

VOR/ILS Analyzer EVS200

Chapter 3: Operation

0796.1800.02 E-8 27

Page 37

VOR/ILS Analyzer EVS200

Signal parameters on ∆∆∆∆ Level Display

Following signal parameters are indicated on the display::

display indication description measuring value

Chapter 3: Operation

FREQ. (MHZ)

LEVEL (dBm)

∆ LEVEL (dB) actual ∆ level (difference between actual

LEVEL REF.

receiver frequency in MHz (numerical) and

bargraph center frequency indication in kHz

receiver signal in dBm (numerical) and

bargraph indication (the lower bargraph

shows the set squelch threshold)

receiving level and set reference level)

the bargraph indication shows the ∆ level

as a tendency indication

set reference level

MHz

dBm

dB

dBm

0796.1800.02 E-8 28

Page 38

VOR/ILS Analyzer EVS200

Spectrum-Mode

Operating instructions of Spectrum-Mode

The spectrum analysis of the VOR/ILS Analyzer EVS200 is

only for trend indication in the scanned range.

Chapter 3: Operation

0796.1800.02 E-8 29

Page 39

VOR/ILS Analyzer EVS200

Chapter 3: Operation

RS-232-Interface operation

All important unit functions can be remote controlled via the RS-232-Interface (V24 standard) by a PC

terminal which can be operated with commercial terminal programs (e.g. Telix, Procomm...). AS a data

terminal (DDE) the VOR/ILS Analyzer EVS200 must be connected with a RS-232-1:1-Interface.Also

it is possible to control the unit with an user defined program. The necessary commands for that purpose are described below.

COM-Parameter

The com parameters parity,number of data bits, and stop bits cannot be changed and are defined as

"firmware“.

non parity bit (N),

8 data bits (8),

1stopbit (1).

Handshake

Hardware handshake is renounced.

Handshake is performed by software as a transmitted sequence e.g. "READY“ or as a measuring

value or a tuning value e.g. "RF107000“.

Control commands

There are two categories of control commands.

super commands (mode independant, unit related)

mode dependant commands (specified mode must first be selected)

The following table makes clear the control commands structure.

unit related

control commands

BI

EC0

EC1

LA

LO

MB

MI

ML

MV

RES

RF(Freq. kHz)

RF

TEST

VER

ILS-Mode VOR-Mode

AF8

AM2

AM3

AM8

AM9

BW0

BW1

D1

D2

DD0

DD1

FA0

FA1

FA2

FA3

PH

SD0

SD1

mode dependant control commands

∆∆∆∆ Level-Mode

AF8

AM0

AM1

AM8

AM9

BE

D1

D2

FA0

FA2

FA3

FM0

FM1

BW0

BW1

LR

LD

SR

BEACON-

Mode

AF4

AF5

AF6

AF7

AM4

AM5

AM6

AM7

0796.1800.02 E-8 30

Page 40

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Unit related control commands

Command RF (frequency in kHz)

command function

RF (frequency in kHz) <frequency information> setting or scanning receiving frequency

With the command RF (frequency in kHz) a frequency input is possible in the ranges of 107000 to

119000 kHz and 319000 to 341000 kHz. With this command it is also possible to scan the tuned

frequency when the command RF is transmitted to the EVS200 without additionally parameters. The

unit responses with the frequency information.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

input:

query:

RF107000 <CR>

rf107000 <CR>

RF<CR>

rf<CR>

READY <CR/LF>

READY <CR/LF>

107000kHz <CR/LF>

107000kHz <CR/LF>

Command LO

command function

LO <Local> set unit local mode

Because local operation is automatically locked when the unit is controlled by a controller, the command LO (local) performs further local operation at the unit.

Example:

input:

command from the controller

LO<CR>

lo<CR>

response of the VOR/ILS Analyzer EVS200

READY <CR/LF>

READY <CR/LF>

Command EC0

command function

EC0 <echo off > selection of communication

EVS200 does not retransmit the received control string.

Example:

command from the controller

query:

0796.1800.02 E-8 31

EC0 <CR>

ec0 <CR>

response of the VOR/ILS Analyzer EVS200

READY <CR/LF>

READY <CR/LF>

Page 41

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Command EC1

command function

EC1 <echoon> selection of communication

EVS200 retransmits the received control string.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

query:

EC1 <CR>

ec1 <CR>

READY <CR/LF>

READY <CR/LF>

Command test

command function

TEST < > RS232 test section output

The command TEST initiates a RS232 test section. All ASCII characters 20h to FF will be supplied.

Example:

response of the VOR/ILS Analyzer EVS200

READY <CR/LF>

READY <CR/LF>

query:

command from the controller

EC1 <CR>

ec1 <CR>

Command LA

command function

LA <Level Absolute> query of receiving level

The command LA reads the actual receiving signal level in "∆∆∆∆ Level"-mode.

Example:

command from the controller

query:

0796.1800.02 E-8 32

LA <CR>

la <CR>

response of the VOR/ILS Analyzer EVS200

e.g. -48.1dBm <CR/LF>

e.g. -48.1dBm <CR/LF>

Page 42

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Command RES

command function

RES <RESET> Master-RESET

With the command RES a unit master reset is possible. It works like a restart of the unit.

Example:

command from the controller response of the VOR/ILS Analyzer EVS200

input:

RES<CR>

res<CR>

EVS200 REMOTE-SYSTEM READY <CR/LF>

READY <CR/LF>

READY <CR/LF>

Command BI

command function

BI <BITE-test information> BITE (Build In Test) -asking for result

The EVS200 performs approx. every 500 ms a self test (BITE) and makes the result available as a

9bit binary form. During this test the following voltages and funtionally subunits of the units are

checked.

all operating voltages,

hostprocessor

memory,

DSP-processor,

battery capacity (%)

explanation of BITE information

B8 B7 B6 B5 B4 B3 B2 B1 B0

SYNTH 1 SYNTH 2 EXT-DC PS-DC +12 VDC -12 VDC Batt2 Batt1 Batt0

XXXXXXXXX

X = 1 is function in tolerance (ok)

X = 0 is function out of tolerance (failure)

Example:

command from the controller

query:

0796.1800.02 E-8 33

BI <CR> BI110111101 <CR/LF>

response of the VOR/ILS Analyzer EVS200

Page 43

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Command VER

command function

VER <Version> query of version number and date of the

EVS200 firmware

The command VER initializes the display of the software version number and its issue date.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

query:

VER <CR>

ver <CR>

EVS200 - VERSION < No. > from < Date >

Copyright (C) Rohde & Schwarz Werk Köln

<CR/LF>

Command ML

command function

ML <Mode-Delta Level>

The command ML enables a switching over to the "∆∆∆∆ level" mode.

Exampel:

command from the controller

input:

ML <CR>

ml <CR>

∆∆∆∆ level mode setting

response of the VOR/ILS Analyzer EVS200

READY <CR/LF>

READY <CR/LF>

Command MV

command function

MV <Mode-VOR> VOR mode setting

The command MV enables a switching over to the "VOR“ mode.

Example:

command from the controller response of the VOR/ILS Analyzer EVS200

input:

0796.1800.02 E-8 34

MV <CR>

mv <CR>

READY <CR/LF>

READY <CR/LF>

Page 44

VOR/ILS Analyzer EVS200

Command MI

command function

MI <Mode-ILS> ILS mode setting

The command MI enables the switching over to the "ILS“ mode.

Example:

command from the controller response of the VOR/ILS Analyzer EVS200

Chapter 3: Operation

input:

MI <CR>

mi <CR>

READY <CR/LF>

READY <CR/LF>

Command MB

command function

MB <Mode-BEACON> BEACON mode setting

The command MB enables the switching over to the "BEACON mode“.

Example:

command from the controller response of the VOR/ILS Analyzer EVS200

input:

MB <CR>

mb <CR>

READY <CR/LF>

READY <CR/LF>

Mode related control commands

ILS-Mode

Command DD0

command function

DD0 <DDM information> DDM value query

The command DD0 reads the actual DDM value (value without dimension) in the ILS mode.

Example:

command from the controller

query:

0796.1800.02 E-8 35

DD0 <CR>

dd0 <CR>

response of the VOR/ILS Analyzer EVS200

e.g. 0.2008 <CR/LF>

e.g. 0.2008 <CR/LF>

Page 45

VOR/ILS Analyzer EVS200

Command DD1

command function

Chapter 3: Operation

DD1 <DDM information>

The command DD1 reads the actual DDM value in µA in the ILS mode.

Example:

command from the controller

query:

DD1 <CR>

dd1 <CR>

query of the DDM value in µµµµA

response of the VOR/ILS Analyzer EVS200

e.g. 194.32uA <CR/LF>

e.g. 194.32uA <CR/LF>

Command SD0

command function

SD0 <SDM information> SDM value query

The command SD0 reads the actual SDM value (value without dimension) in the ILS mode.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

query:

SD0 <CR>

sd0 <CR>

e.g. 0.8006 <CR/LF>

e.g. 0.8006 <CR/LF>

Command SD1

Command function

SD1 <SDM information>

The command SD1 reads the actual DDM value in µA in the ILS mode.

Example:

command from the controller

query:

SD1 <CR>

sd1 <CR>

query of SDM value in µµµµA

response of the VOR/ILS Analyzer EVS200

e.g. 774.87uA <CR/LF>

e.g. 774.87uA <CR/LF>

0796.1800.02 E-8 36

Page 46

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Command AM2

command function

AM2 <AM modulation depth (90 Hz)> query of AM modulation depth (90 Hz)

The command AM2 reads the actual AM modulation depth (90 Hz) in the ILS mode.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

query:

AM2 <CR>

am2 <CR>

e.g. 50% <CR/LF>

e.g. 50% <CR/LF>

Command AM3

command function

AM3 <AM modulation depth (150 Hz)> query of AM modulation depth (150 Hz)

The command AM3 reads the actual AM modulation depth (150 Hz) in the ILS mode.

Example:

response of the VOR/ILS Analyzer EVS200

e.g. 29.9% <CR/LF>

e.g. 29.9% <CR/LF>

Query:

command from the controller

AM3 <CR>

am3 <CR>

Command PH

command function

PH <Phase 90/150 Hz> query of Phase angle 90/150 Hz

The command PH reads the actual PHI value between 90 Hz and 150 Hz in the ILS mode.

Example:

command from the controller

query:

0796.1800.02 E-8 37

PH <CR>

ph <CR>

response of the VOR/ILS Analyzer EVS200

e.g. 119.9DEG <CR/LF>

e.g. 119.9DEG <CR/LF>

Page 47

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Command BW0

command function

BW0 <bandwidth information > 8-kHz bandwidth setting

The command BW0 enables the switching over to the 8-kHz bandwidth in the ILS mode and in the

"∆∆∆∆ level" mode.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

input:

BW0 <CR>

bw0 <CR>

READY <CR/LF>

READY <CR/LF>

Command BW1

command function

BW1 <bandwidth information> 30-kHz bandwidth setting

The command BW1 enables the switching over to the 30-kHz-IF bandwidth in the ILS mode and in

the "∆∆∆∆ level" mode.

Example:

input:

command from the controller

BW1 <CR>

bw1 <CR>

response of the VOR/ILS Analyzer EVS200

READY <CR/LF>

READY <CR/LF>

0796.1800.02 E-8 38

Page 48

VOR/ILS Analyzer EVS200

o

d

Chapter 3: Operation

Command FA1

command function

FA1 <Fast DDM measuring on> Activating the Fast DDM measurement

The command FA1 switches on the fast DDM measurement. The measuring, used only for landing

path measurement can only be activated through a controller. The output is performed as DDM value

with RF level (see example) and can be processed accordingly with calculation programs e.g. like

Excel etc. A capacaty of 34 measurements /s at a baud rate set to 19200 baud will be reached. This

conforms to a time interval of 30 ms. The measurement values (DDM, RF level) can be read in and

output as a text file corresponding to the terminal program.

To reach 34 meas/s the baud rate must be set to 19200 baud in the Setup of the

VOR/ILS Analyzer EVS200. It must be attended the acceptance of the data transfering

rate by the terminal program.

Example:

The measurement can be stopped through the command FA0 (refer to Command

FA0).

command from the controller

response of the VOR/ILS Analyzer EVS200

input: FA1 <CR>

fa1 <CR>

With the command FA1 the ech

mode is automatically switche

OFF.

1/90Hz = 11.1msec.

N N+1 N+2 N+3 N+4 N+5 N+6 N+7 N+8 N+9 N+10

DATA-

Transfer

DDM, RF-Level

Calculation

RS232-

Transfer

N

DATA-

0.2008 -48.2 <CR/LF>

0.2008 -48.2 <CR/LF>

Both values are separated through a tabulator

ASCII 9.

RS232-

DDM, RF-Level

Calculation

30 msec.

DATA-

TransferTransfer

N+2 N+5

DDM, RF-Level

Calculation

RS232-

TransferTransfer

DATA-

Transfer

DSP-Analysis

TXD-Signal

from EVS 200

0796.1800.02 E-8 39

Page 49

VOR/ILS Analyzer EVS200

o

d

:

µ

:

:

:

Chapter 3: Operation

Command FA2

command function

FA2 <Fast DDM measuring on> Activating the Fast DDM measurement

The command FA2 switches on the fast DDM measurement. The measuring, used only for landing

path measurement can only be activated through a controller.

The command FA2 performs the continuous measurement and output of the DDM, RF level, Modfactor 90 Hz and Modfactor 150 Hz with a transmission speed of about 20 measurement value sets

(DDM, RF level, AM90, AM150) per second. This conforms to a time interval of 50 ms. The stated

RS-232-transmission times are related to 19.200 Baud.

The measurement values can be read in and output as a text file corresponding to the terminal program.

To reach 20 meas/s the baud rate must be set to 19200 baud in the Setup of the

VOR/ILS Analyzer EVS200. It must be attended the acceptance of the data transfering

rate by the terminal program.

Example:

The measurement can be stopped through the command FA0 (refer to Command

FA0).

command from the controller

response of the VOR/ILS Analyzer EVS200

input: FA2 <CR>

fa2 <CR>

With the command FA2 the ech

mode is automatically switche

OFF.

1/90Hz = 11.1msec.

N N+1 N+2 N+3 N+4 N+5 N+6 N+7 N+8 N+9 N+10

DATA-Transfer

DDM, AM 90, AM150,

RF-Level - Calculation

output form: (DDM <CR >, RF level <CR >,

AM90 <CR >, AM 150 <CR >)

DDM: four-digit with indication (dimensionless)

example

five-digit with indication (

example

-1000 <CR > (-0.1000 DDM)

A)

-09890 <CR > (-98.90µA)

RF level: three-digit with indication (dBm)

example

-400 <CR > (-40.0dBm)

122 <CR > (12.2dBm)

Modulation depth: three-digit (%)

example

202 <CR > (20.2 %)

004 <CR > (0.4 %)

RS232Transfer

DA T A-Transfe r

DDM, AM 90, AM150,

RF-Level - Calculation

RS232-

Transfer

DA T A-Transfe r

DSP-Analysis

NN+4

40 msec. 10 msec.

TXD-Signal

from EVS 200

0796.1800.02 E-8 40

Page 50

VOR/ILS Analyzer EVS200

o

d

D

Chapter 3: Operation

Command FA3

command function

FA3 <Fast DDM measuring on> Activating the Fast DDM measurement

The command FA3 switches on the fast DDM measurement. The measuring, used only for landing

path measurement can only be activated through a controller. The command FA3 performs the continuous measurement and output of the DDM, RF level, Modfactor 90 Hz and Modfactor 150 Hz.

The 50-ms measurement interval consists of DSP analysis, DSP data transmission to the host

processor and conversion of the DSP raw measurement value into DDM, dBm and AM %. The

measurement values output is performed in this mode as interrupt operation via RS232 interface.

In this Fast-Mode (FA3) a measurement value set will only be transmitted to the PC if it is demanded

by a short command (1 ASCII-Character). The response from the EVS200 is performed without a

longer delay within about 15 to 20 ms between measurement value demand and measurement

value transmission. The stated RS-232-transmission times are related to 19.200 Baud.

The measurement values can be read in and output as a text file corresponding to the terminal program.

The baud rate must be set to 19200 baud in the Setup of the VOR/ILS Analyzer

EVS200. It must be attended the acceptance of the data transfering rate by the

terminal program.

The measurement can be stopped through the command FA0 (refer to Command

FA0) or

<CR>.

Example:

command from the controller

input: e.g. A

all ASCII characters without:

CR (0Dh), LF (0Ah), # (23h), @ (40h)

With the command FA3 the ech

mode is automatically switche

OFF.

1/90Hz = 11.1msec.

N N+1 N+2 N+3 N+4 N+5 N+6 N+7 N+8 N+9 N+10

Demand for measurement

values output:

DATA-Transfer

DDM, AM 90, AM150,

RF-Level - Calculation

response of the VOR/ILS Analyzer EVS200

output form: (DDM <CR >, RF level <CR >,

AM90 <CR >, AM 150 <CR >)

output form as FA2

example: -0001 <CR > (DDM),

-412 <CR > (RF level),

201 <CR > (AM90),

202 <CR > (AM150),

Programm-Interrupt

DATA-Transfer

DDM, AM90, AM150,

RF-Level - Calculation

DDM, AM90, AM150,

RF-Level - Calculation

RS232Transfer

15...20 m s ec.

DATA-Transfer

DSP-Analysis

Request from PCl

to EVS200 (RXD)

N

10 msec.

0796.1800.02 E-8 41

Answer to PCl

fromEVS200 (TX

Page 51

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Command FA0

command function

FA0 <fast DDM measuring off> deactivating the fast DDM measurement

The command FA0 switches off the fast DDM measurement.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

input:

FA0 <CR>

fa0 <CR>

READY <CR/LF>

READY <CR/LF>

Command D1

command function

D1 <display information> switch over to display1

The command D1 enables the switching over to the content of display1 in the VOR / ILS mode.

This is prediction for reading out the data of the corresponding mode (VOR/ILS).

Example:

input:

command from the controller

D1 <CR>

d1 <CR>

response of the VOR/ILS Analyzer EVS200

READY <CR/LF>

READY <CR/LF>

Command D2

command function

D2 <display information> switch over to display2

The command D2 enables the switching over to the content of display2 in the VOR / ILS mode.

This is prediction for reading out the data of the corresponding mode (VOR/ILS).

Example:

command from the controller

input:

0796.1800.02 E-8 42

D2 <CR>

d2 <CR>

response of the VOR/ILS Analyzer EVS200

READY <CR/LF>

READY <CR/LF>

Page 52

VOR/ILS Analyzer EVS200

Command AF8

command function

AF8 <AF-frequency ID> AF-frequency ID query

The command AF8 reads the actual AF frequency (ID) in the ILS /VOR mode.

Prediction for reading out the data of the corresponding mode (VOR/ILS) is the

switching over to display2.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

Chapter 3: Operation

query:

AF8 <CR>

af8 <CR>

e.g. 1020.0Hz <CR/LF>

e.g.. 1020.0Hz <CR/LF>

Command AM8

command function

AM8 <AM-modulation depth (ID)> query of AM-modulation depth (ID)

The command AM8 reads the actual AM-modulation depth (ID) in the ILS / VOR mode.

Prediction for reading out the data of the corresponding mode (VOR/ILS) is the

switching over to display2.

Example:

query:

command from the controller

AM8 <CR>

am8 <CR>

response of the VOR/ILS Analyzer EVS200

e.g. 10.0% <CR/LF>

e.g. 10.0% <CR/LF>

Command AM9

command function

AM9 <AM-modulation depth (voice)> query of AM-modulation depth (voice)

The command AM9 reads the actual AM-modulation depth (voice 300 Hz to 3kHz) in the ILS / VOR

mode.

Prediction for reading out the data of the corresponding mode (VOR/ILS) is the

switching over to display2.

Example:

command from the controller

query:

0796.1800.02 E-8 43

AM9 <CR>

am9 <CR>

response of the VOR/ILS Analyzer EVS200

e.g. 09.6% <CR/LF>

e.g. 09.6% <CR/LF>

Page 53

VOR/ILS Analyzer EVS200

Chapter 3: Operation

VOR-Mode

Command BE

command funcion

BE <Bearing Angle> bearing angle query

The command BE reads the actual bearing angle (indicated in degree) in the VOR mode.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

query:

BE <CR>

be <CR>

e.g. 299.97DEG <CR/LF>

e.g. 299.97DEG <CR/LF>

Command AM0

command function

AM0 <AM-modulation depth (30 Hz)> query of AM-modulation depth (30 Hz)

The command AM0 reads the actual AM-modulation depth (30 Hz) in the VOR mode.

Example:

query:

command from the controller

AM0 <CR>

am0 <CR>

response of the VOR/ILS Analyzer EVS200

e.g. 30.1% <CR/LF>

e.g. 30.1% <CR/LF>

Command AM1

command function

AM1 <AM-modulation depth (9960 Hz)>

The command AM1 reads the actual AM-modulation depth (9960 Hz) in the VOR mode.

Example:

command from the controller

query:

0796.1800.02 E-8 44

AM1 <CR>

am1 <CR>

query of AM-modulation depth (9960 Hz)

response of the VOR/ILS Analyzer EVS200

e.g. 30.1% <CR/LF>

e.g. 30.1% <CR/LF>

Page 54

VOR/ILS Analyzer EVS200

Command FM0

command function

FM0 <FM-deviation)> FM-deviation query

The command FM0 reads the actual FM-deviation value in the VOR mode.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

Chapter 3: Operation

query:

FM0 <CR>

fm0 <CR>

e.g. 479.1Hz <CR/LF>

e.g. 479.1Hz <CR/LF>

Command FM1

command function

FM1 <FM-Index)> query of FM-index value

The command FM1 reads the actual FM-index value in the VOR mode.

Example:

response of the VOR/ILS Analyzer EVS200

e.g. 15.9 <CR/LF>

e.g. 15.9 <CR/LF>

query:

command from the controller

FM1 <CR>

fm1 <CR>

Command D1

command function

D1 <Display-information> switching over to Display1

The command D1 enables the switching over to the content of display1 in the VOR / ILS mode.

This is the prediction for reading out the data of the corresponding mode (VOR/ILS).

Example:

command from the controller

input:

0796.1800.02 E-8 45

D1 <CR>

d1 <CR>

response of the VOR/ILS Analyzer EVS200

READY <CR/LF>

READY <CR/LF>

Page 55

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Command D2

command function

D2 <Display-information> switching over to Display2

The command D2 enables the switching over to the content of display2 in the VOR / ILS mode.

This is the prediction for reading out the data of the corresponding mode (VOR/ILS).

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

input:

D2 <CR>

d2 <CR>

READY <CR/LF>

READY <CR/LF>

Command AF8

command function

AF8 <AF-frequency ID> AF-frequency ID query

The command AM8 reads the actual AF frequency (ID) in the ILS / VOR mode.

Prediction for reading out the data of the corresponding mode (VOR/ILS) is the

switching over to display2.

Example:

query:

command from the controller

AF8 <CR>

af8 <CR>

response of the VOR/ILS Analyzer EVS200

e.g. 1020.0Hz <CR/LF>

e.g. 1020.0Hz <CR/LF>

Command AM8

command function

AM8 <AM-modulation depth (ID)> query of AM-modulation depth (ID)

The command AM8 reads the actual AM-modulation depth (ID) in the ILS / VOR mode.

Prediction for reading out the data of the corresponding mode (VOR/ILS) is the

switching over to display2.

Example:

command from the controller

query:

0796.1800.02 E-8 46

AM8 <CR>

am8 <CR>

response of the VOR/ILS Analyzer EVS200

e.g. 10.0% <CR/LF>

e.g. 10.0% <CR/LF>

Page 56

VOR/ILS Analyzer EVS200

o

d

:

:

:

:

Chapter 3: Operation

Command AM9

command function

AM9 <AM-modulation depth (voice)> query AM-modulation depth (voice)

The command AM9 reads the actual AM-modulation depth (voice 300 Hz to 3 kHz) in the ILS / VOR

mode.

Prediction for reading out the data of the corresponding mode (VOR/ILS) is the

switching over to display2.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

query:

AM9 <CR>

am9 <CR>

e.g. 09.6% <CR/LF>

e.g. 09.6% <CR/LF>

Command FA2

command function

FA2 <Fast measuring on> Activating the Fast measurement mode

The command FA2 switches on the fast measurement mode. The command FA2 performs the continuous measurement and output of the RF level, Bearing, AM30, AM9960, FM-deviation, FM-

Index with transmission speed of 15 measurement value sets (RF level, Bearing, AM30, AM9960,

FM-deviation, FM-Index) per second. This conforms to a time interval of 66 ms. The stated RS-232transmission times are related to 19.200 Baud.

The measurement values can be read in and output as a text file corresponding to the terminal program.

The baud rate must be set to 19200 baud in the Setup of the VOR/ILS Analyzer EVS200.

It must be attended the acceptance of the data transfering rate by the terminal program.

Example:

The measurement can be stopped through the command FA0 (refer to Command FA0).

command from the controller

response of the VOR/ILS Analyzer EVS200

input: FA2 <CR>

fa2 <CR>

With the command FA2 the ech

mode is automatically switche

OFF.

0796.1800.02 E-8 47

output form: (RF level <CR >, Bearing <CR >,

AM30 <CR >, AM 9960 <CR >),

FM-deviation<CR >,

FM-Index <CR >),

RF level: three-digit with indication (dBm)

example

Modulation depth: three-digit (%)

example

FM-deviation: four-digit (Hz)

example

FM-Index: three-digit

example

-400 <CR > (-40.0dBm)

122 <CR > (12.2dBm)

304 <CR > (30.4 %)

004 <CR > (0.4 %)

4800<CR > (480,0Hz)

0004 <CR > (0.4 Hz)

160<CR > (16,0)

Page 57

VOR/ILS Analyzer EVS200

o

d

Chapter 3: Operation

Command FA3

command function

FA3 <Fast measuring on> Activating the Fast measurement mode

The command FA3 switches on the fast measurement mode. The command FA3 performs the continuous measurement and output of the RF level, Bearing, AM30, AM9960, FM-deviation, FM-

Index. The 33 to 66-ms measurement interval consists of DSP analysis, DSP data transmission to

the host processor and conversion of the DSP raw measurement value into dBm, Bearing °, AM %

and FM Hz . The measurement values output is performed in this mode as interrupt operation via

RS232 interface.

In this Fast-Mode (FA3) a measurement value set will only be transmitted to the PC if it is demanded

by a short command (1 ASCII-Character). The response from the EVS200 is performed without a

longer delay within about 15 to 20 ms between measurement value demand and measurement

value transmission. The stated RS-232-transmission times are related to 19.200 Baud.

The measurement values can be read in and output as a text file corresponding to the terminal program.

The baud rate must be set to 19200 baud in the Setup of the VOR/ILS Analyzer EVS200.

It must be attended the acceptance of the data transfering rate by the terminal program.

The measurement can be stopped through the command FA0 (refer to Command FA0)

or

<CR >

.

Example:

command from the controller

input: e.g. A

all ASCII characters without:

CR (0Dh), LF (0Ah), # (23h), @ (40h)

With the command FA3 the ech

mode is automatically switche

OFF.

Demand for measurement

values output:

response of the VOR/ILS Analyzer EVS200

output form: (RF level <CR >, Bearing <CR >,

AM30 <CR >, AM 9960 <CR >),

FM-deviation<CR >,

FM-Index <CR >),

output form as FA2

example: -412 <CR > (RF level),

35506 <CR > (Bearing),

304 <CR > (AM30),

302 <CR > (AM9960),

4800 <CR > (FM-deviation),

160 <CR > (FM-Index),

Command FA0

command function

FA0 <fast DDM measuring off> deactivating the fast DDM measurement

The command FA0 switches off the fast DDM measurement.

Example:

command from the controller

input:

0796.1800.02 E-8 48

FA0 <CR>

fa0 <CR>

response of the VOR/ILS Analyzer EVS200

READY <CR/LF>

READY <CR/LF>

Page 58

VOR/ILS Analyzer EVS200

Chapter 3: Operation

∆∆∆∆ Level-Mode

Command SR

command function

SR <Set REF> reference level setting

The command SR is for setting the actual receiver level as a reference level in the reference level

window "∆∆∆∆ level"-mode.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

input:

SR <CR>

sr <CR>

READY <CR/LF>

READY <CR/LF>

Command LR

command function

LR <level reference> reference level query

The command LR reads the actual set reference level in the "∆∆∆∆ Level" mode.

Example:

query:

command from the controller

LR <CR>

lr <CR>

response of the VOR/ILS Analyzer EVS200

e.g. -48.1dBm <CR/LF>

e.g. -48.1dBm <CR/LF>

Command LD

command function

LR <level delta>

The command LD reads the actual ∆∆∆∆-Level in the "∆∆∆∆ Level" mode.

Example:

command from the controller

query:

0796.1800.02 E-8 49

LD <CR>

ld <CR>

∆∆∆∆-Level query

response of the VOR/ILS Analyzer EVS200

e.g. -000.0dBm <CR/LF>

e.g. -000.0dBm <CR/LF>

Page 59

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Beacon-Mode

Command AM4

command function

AM4 <AM-modulation depth (F1-range)> query of AM-modulation depth (F1)

The command AM4 reads the actual AM-modulation depth (F1 3000 Hz) in the BEACON mode.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

query:

AM4 <CR>

am4 <CR>

e.g. 29.3% <CR/LF>

e.g. 29.3% <CR/LF>

Command AM5

command function

AM5 <AM-modulation depth (F2-range)> query of AM-modulation depth (F2)

The command AM5 reads the actual AM-modulation depth (F2 1300 Hz) in the BEACON mode.

Example:

response of the VOR/ILS Analyzer EVS200

e.g. 30.5% <CR/LF>

e.g. 30.5% <CR/LF>

query:

command from the controller

AM5 <CR>

am5 <CR>

Command AM6

command function

AM6 <AM-modulation depth (F3-range)> query of AM-modulation depth (F3)

The command AM6 reads the actual AM-modulation depth (F3 400 Hz) in the BEACON mode.

Example:

command from the controller

query:

0796.1800.02 E-8 50

AM6 <CR>

am6 <CR>

response of the VOR/ILS Analyzer EVS200

e.g. 29.8% <CR/LF>

e.g. 29.8% <CR/LF>

Page 60

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Command AM7

Kommando Funktion

AM6 <AM-modulation depth ID> query of AM-modulation depth ID

The command AM7 reads the actual AM-modulation depth (ID) in the BEACON mode.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

query:

AM7 <CR>

am7 <CR>

e.g. 10.2% <CR/LF>

e.g. 10.2% <CR/LF>

Command AF4

command function

AF4 <AF-frequency range F1> query of AF-frequency 3000 Hz

The command AF4 reads the actual AF frequency (F1) in the BEACON mode.

Example:

response of the VOR/ILS Analyzer EVS200

e.g. 3000.0Hz <CR/LF>

e.g. 3000.0Hz <CR/LF>

query:

command from the controller

AF4 <CR>

af4 <CR>

Command AF5

command function

AF5 <AF-frequency range F2> query of AF-frequency 1300 Hz

The command AF5 reads the actual AF frequency (F2) in the BEACON mode.

Example:

command from the controller

query:

0796.1800.02 E-8 51

AF5 <CR>

af5 <CR>

response of the VOR/ILS Analyzer EVS200

e.g. 1300.0Hz <CR/LF>

e.g. 1300.0Hz <CR/LF>

Page 61

VOR/ILS Analyzer EVS200

Chapter 3: Operation

Command AF6

command function

AF6 <AF-frequency range F3> query of AF-frequency 400 Hz

The command AF6 reads the actual AM frequency (F3) in the BEACON mode.

Example:

command from the controller

response of the VOR/ILS Analyzer EVS200

query:

AF6 <CR>

af6 <CR>

e.g. 400.0Hz <CR/LF>

e.g. 400.0Hz <CR/LF>

Command AF7

command Funktion

AF7 <AF-Frequenz ID> query of AF-frequency ID

The command AF7 reads the actual AF frequency (ID) in the BEACON mode.

Example:

response of the VOR/ILS Analyzer EVS200

e.g. 1020.0Hz <CR/LF>

e.g. 1020.0Hz <CR/LF>

query:

command from the controller

AF7 <CR>

af7 <CR>

0796.1800.02 E-8 52

Page 62

VOR/ILS Analyzer EVS200

Chapter 4: Interfaces

Interfaces

Antenna input

labeling figure description

RF INPUT 50 Ω input level: 0 dBm / 50 Ω

(Data safety up to 10 dBm is ensured)

frequency range: 74 to 341 MHz

VSWR: <1.5

AF output

max. +15 dBm

labeling figure description

AF OUT 50 Ω output level: 200 mV

frequency range: 0.3 to 3.4 kHz

Headphone connection

labeling figure description

PHONES

Only for connecting headphones

with soundproofing.

e.g. R&S order no. 0708.9010.00

XY-Tracer connection

labeling figure description

rms

/50Ω

DSP-OUT ThescalingoftheXYvaluescanbesetin

the setup / Ils mode (Y / t setup) for the

localizer and glideslope mode.

0796.1800.02 E-8 53

Page 63

VOR/ILS Analyzer EVS200

External AF input

labeling figure description

Chapter 4: Interfaces

AF EXT.

RS-232-Interface

labeling figure description

RS232/DDE

External VDC connection

input level: 1 to 2 V

rms

/50Ω

frequency range: 30 Hz to 10 kHz

standard RS-232-Interface

COM parameter: N81

baud rate: 1200, 2400,

4800, 9600,

19200 adjustable in

the setup

labeling figure description

INPUT: 9-15 VDC

Mains connection

labeling figure description

INPUT: 85-250 V/

47-63Hz

F1/F2: IEC127-

T800H/250V

DC connection: 12 VDC / 30 W

tolerance max. 9 to 15 VDC

mains connection: 87 to 265 VAC

47 to 63 Hz

0796.1800.02 E-8 54

Page 64

VOR/ILS Analyzer EVS200

Chapter 5: Service

Service

To ensure a unit’s repair as quick as possible a defect VOR/ILS Analyzer EVS200

must be send to the service place named in the following.

In case of service questions

please contact us over phone

or FAX.

(49) / 2203 / 49-266

(49) / 2203 / 49-336

Warranty

Warranty conditions are stated in the general terms of business.

Whilst time of warranty a defective internal battery

(option) may only be changed by Rohde & Schwarz

service personnel!

0796.1800.02 E-8 55

Page 65

VOR/ILS Analyzer EVS200

Chapter 6: Technical Specification

Technical data

Receiver section

Frequency range ................................74.7 to 75.3 MHz

107 to 119 MHz

319 to 341 MHz

Accuracy ................................≤2 ppm

Resolution ................................5 kHz

Input voltage ................................ 15 dBm max./ 50 Ω

(data safety up to 10 dBm is ensured)

VSWR ................................<1.5

Sensitivity ................................-96 dBm ≥18 dB (IF bandwidth 8 kHz)

IF bandwidth ................................ min. ±15 kHz (-3 dB), max. ±40 kHz (-60dB)

min.±4 kHz (-3 dB), max. ±12 kHz (-60dB)

or optional:

min.±19 kHz (-6 dB), max. ±38 kHz (-60dB)

min.±8 kHz (-6 dB), max. ±20 kHz (-60dB)

Demodulation ................................AM

RF-Input ................................ BNC

Absolute-level receiver

Display range ................................-96 to +10 dBm

Accuracy ................................< ±2dB

Difference-level receiver

Bargraph (quasi analog)...................... ±12 dB to reference level

Resolution ................................0.1 dB

Accuracy indication ............................. ≤±1dB

ILS signal analysis

Thegivenvaluesarevalidonlyforthe30kHz-or38kHz-IF-filter

RF level ................................-70 to -30 dBm

Frequency range ................................108 to 118 MHz

................................328 to 336 MHz

Modulation depth (10 to 80 %)

90 / 150 Hz ±2% ................................ accuracy 0.5%

300 Hz to 4 kHz (identifier)..................≤1.2% of reading

Phase angle 90/150 Hz

Measurement range............................±60°

Measurement error..............................≤0.2°

Resolution ................................0.1°

DDM measurement

Localizer mode

Measurement error at

15 to 25% modulation..........................≤±0.0004 DDM

±0.1% of reading

10 to 30% modulation..........................≤±0.0004 DDM

±0.2% of reading

0796.1800.02 E-8 56

Page 66

VOR/ILS Analyzer EVS200

Glideslope mode

Measurement error at

30 to 50% modulation..........................≤±0.0008 DDM

Resolution (LOC / GS) ........................ 0.0001 DDM

DSP out

Localizer: Range 1 ..........................0.0 ±25%

Range 2 0.0 ±2.5%

Range 3.......................... 0.0 ±2.58%

Range 4.......................... 0.0 ±50%

Glideslope: Range 1 .......................... 0.0 ±50%

Range 2.......................... 0.0 ±5%

Range 3.......................... 8.75 ±5%

Range 4.......................... 17.5 +5%

Chapter 6: Technical Specification

±0.1% of reading

0 ±0.25 DDM

0 ±0.025 DDM

0.0 ±0.0258 DDM

0.0 ±0.5 DDM

0.0 ±0.5 DDM

0.0 ±0.05 DDM

0.0875 ±0.05 DDM

0.175 +0.05 DDM

SDM measurement

SDM 10 to 80% ................................accuracy 1% absolute

Resolution ................................0.0001 SDM

VOR signal analysis

Bearing

Accuracy ........................................±0.1°

Resolution ........................................0.05° / 0.01° (Setup)

AM modulation depth

30 Hz and 9,96 kHz

Accuracy ........................................≤1%

Resolution ........................................0.1%

FM deviation

Accuracy ........................................0.5%, ±0.1 Hz

Resolution ........................................0.1 Hz

RS-232-Interface ........................................8N1, adjustable baud rate

1200, 2400, 4800, 9600, 19200

0796.1800.02 E-8 57

Page 67

VOR/ILS Analyzer EVS200

General data

Power supply ................................ 100 to 240 VAC

(with build-in charger)............................... 50 to 60 Hz (440 Hz option)

9to15VDC(typ.12VDC1.4A)

120 VA max.

built-in battery (option)..............................12V / 3.2 Ah

charging while mains is connected

Operating time ................................>100 min (max. brightness)

>150 min (at average brightness)

Mechanical resistance.............................. shock-tested to MIL-810D

vibration-tested to

DIN-IEC 68-2-36 & 68-2-6

EMC

RF Emissions ................................ complies with EN 50081-1

RF Immissions ................................ complies with EN 50082-1

Temperature range

Operating temp. range ........................ -5°C to +45°C

Storage temp. range ........................... -20°C to +60°C

Chapter 6: Technical Specification

Dimensions and Weight

Dimensions (WxHxD).......................... 219 x 147 x 350 mm

Weight ................................4.9 kg (without battery)

6.5 kg (with battery)

Order notification

Order-No. EVS200.............................. 0796.1800.00

Battery (option) ................................0796.2012.00

0796.1800.02 E-8 58

Page 68

VOR/ILS Analyzer EVS200

Chapter 6: Technical Specification

Accessories

Description Ident No.

Bag for EVS200 TEVS 0798-4264

Alu-tripod for antenna and measuring unit, Notebook,

inclusivly alignment level

Rigging set for tripod AM 0798-4293

Bag for tripod, plate and rigging set TST 0798-4306