Procom EN250TYLA-B, EL250TYLA-B, EN250TYLA-W, EL250TYLA-W, EN250TYLB-O Owner's Operation And Installation Manual

...Page 1

COMP AC T VENT -F REE

FIREPLAC E SYSTEM

OWN ER’S OPERATION AND INSTALLATION MANUAL

EN250TYLA-B

EL250TYLA-B

EN250TYLA-W

EL250TYLA-W

EN250TYLB-O

EL250T YLB-O

EN250TYLB-C

EL250TYLB-C

EN250TYLB-DO

EL250TYLB-DO

T abel of Con t en ts

Safety Information Warnings.......................................2

Air for Combustion and Ventilation............................4

Insta llation......................................................................6

Operating heater.. ................ .................... ................ .....9

Cleaning&Maintenance.............................................10

Trouble Shooti ng.. .... ............... ....................................11

Specifications............ ............... ...................................13

Replacement Parts................... ................................ ..14

Parts Li st....... ........ ............ ......... ......... ........... ......... ......16

Install i ng the Heater....................... ............ ............ .....21

Installing Blower Accessory.......................................22

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

WHAT TO D O IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrica l switch;

do not use any phone in your building.

Immediately call your gas sup plier from

a neighbor’s phone. Follow the gas

supplier ’s

inst r u c tion s .

If you cannot re ac h yo ur gas supplie r,

call the fire department.

Installation and service must be performed

by a qualified installer, ser vice ag enc y, o r

gas supplier.

WARNING: Improper installation,

adjustment, alteration, service or maintena n ce can cause injury or property damage.

Refer to this manual for correct installation

and operational procedures. For assistance

or ad ditional in formation consu lt a qu alified installer, service agency or gas supplier.

This appliance may be installed in a n

aftermarket*, permanently located, manufactured (mobile) home, where not prohibited

by local codes.

WARNING: If the in fo rmatio n in

this manual is not followed exactly,

a fire or explosion may result

causing property dama ge, personal

injury, or loss of l if e.

WARNING: This is an unvented

gas-fired heater. It uses air (oxygen)

from the room in which it is

installed. Provisions for adequa te

combustion and ventilation air must

be provided. Refer to Air For

Combustion and Ve ntilation section

on page 4 of this m anual.

CONTINENTAL A P P LIANCE INC/U.S. OFFICE

5 Musick

Irvine Suite # D/E

CA 92618 Smyrna, GA 30080

TOLL-FREE PHONE NUMBER: (877)886-5989

4600 Highlands Parkway S.E.

This appliance is only for use with the type

of gas indicated on the r ating plate. This

appliance is not convertible for use with

other gase s.

WATE R VAPOR:

A BY-PRODUCT OF UN VE NTED R OO M HEATERS

Water va p or is a b y-pr od uc t of gas co mbusti on .

An unvented room heater produces approximately

one (1) ounce (30ml) of w ater for every 1,000 BTU’s

(3KW’s) of gas input per hour. Refer to page 3.

Installer: Please leave these instructions with the

consumer.

Consumer: Please retain these instructions for futu re use .

*Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer.

1

PR-EL026-01-0803

Page 2

SAFETY INFORMATION WARNINGS

IMPORTANT: Read this

owner’s manual carefully and

completely before trying to

assemble, operate, or service

this heater. Im proper use of

this heat er can caus e seriou s

injury or death from burns,

fire, explosion, electrical

shock, and carbon monoxide

poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning:

Early signs of carbon monoxide

poisoning resemble the flu with

headaches, dizziness, or nausea.

If you have these signs, the heater

may not be working properly. Get

fresh air immed iat ely! Have heat er

serviced. So me peop le are more

affected by carbon monoxide than

others. T hese include pregn ant

women, people with heart or lung

disease or anemia, those under

the influence of alcohol , and those

at high altitudes.

Propane/ LP Gas: Pr opane/LP ga s

is odorless. An odor-making agent

is added to Propane/LP gas. The

odor helps you detect a Propane/

LP gas leak. However, the odor

added to Propane/LP gas can fade.

Propane/LP gas m ay be present

even though no o do r exists.

Make certain you read and understand all warnings. Keep this

manual for reference. It is your

guide to safe and proper operation

of this heater.

WARNI NG: Any change to

this fireplace or its controls can

be d ang er ou s.

W ARNING: Do not a llow fans

to blow directly into the heater. Av oid

any drafts that alter burner flame

pattern s. Ceiling fan s can cr eate

drafts that alter burner flame

patterns. Altered burner patterns

can cause sooting.

WARNING: D o n o t use acces-

sories not approved for use with

this heater.

Due to hig h temp eratu res, th e

appliance should be locat ed out of

traffic and away from furniture

and draperies.

Do no t place clothing or other

flammab le material on or near the

appliance. N ever place any objects

in the fireplace.

Heater becomes very hot when

running fireplace. Keep children and

adults away from hot surfaces to

avoid burns or clothing ignition.

Fireplace will remain hot for a time

after shutdown. Allow surfaces to

cool before touching.

Carefully supervise young children

when they are in the room with

fireplace.

Yo u must operate t his heater with

the heater scree n in p lace. Make

sure heater screen is in place

before running heater.

Keep the appliance area clear and

free from combustible materials,

gasoline, and other flammable

vapors and liquids.

WARNING

Models EN250TYLB is equipped f or

Nature gas. Field c onve rsion is not

permitted.

Models EL250TYLB is equipped for

prop ane gas. Field conversion is not

permitted.

1. This appliance is only for use

with the type of gas indicated

on the rating plate. This

appliance is not convertible for

use with other gases.

2. Do not place Propane/LP

supply tank(s) indoors.

3. If you smell gas

Shut off gas supply.

Do not tr y to light any appliance.

Do not touch any electr ic al switc h;

do not use any phone in your

building.

Immediately call your gas supplier

from a neighbor’s phone. Follow

2

1

the gas supplier’s instructions.

If you cann ot reach your gas

su pp lier, call the fire departm ent.

4. This heater shall not be installed in a

bedroom or bathroom.erating heater.

5. Do not use this heater as a woodburning heater. Use only the logs provided with the heater.

6. D o not add extra logs or ornaments

such as pine con es, vermiculite, or rock

wool. Using these added items can

cause sooting. Do not add lava rock

around base. Rock and debris could

fall into the con trol area of heater. After

servicing, always replace screen before

op

7. You must o perate th isheater with th e

heater screen in place. Make sure heater

screen is in place before running heater.

8. This heater is designed to be

smokeless. If logs ever appear to

smoke, turn off h eater an d c all a qualified ser vice perso n .

Note: During initial operation, slight

smoking could occur due to log curing

and heater burning manufacturing

residues.

9. To prevent the c reation of so o t, follow

the instructio ns in the Cleaning and

Maintenance Section, page 1 0 .

10. Before using furniture polish, wax, carpet cleaner, or similar products, turn

heater off. If heated, the vapors from

these product s may create a white powder residue within burner box or on adjacent walls or furniture.

11. This h eater n eeds f resh air venti lation

to run properly. This heater has an Oxygen Depletion Sensing (ODS) safety

shutoff system. The ODS shuts down

the heater if n ot enou gh f resh air is

availab le. See the Air for Combustion

and Ventilation Section, pages 4 through

5. If heater keeps shutting off, see

Troubleshooting, pages 11 through 12.

12. Do not run heater

Where flammable liquids or vapors

are used or stored.

Under dusty conditions.

13. Do not use this heater to cook food or

burn paper or other objects.

Page 3

SAFETY

INFORMATION

Continued

14. Do not use heater if any part has

been under water. lmmediately call

a qualified service technician to inspect the room heater and to replace any part of the control

system, and an y gas co n trol w hich

has been under water.

15. Turn off and unplug heater and let

cool before servicing. Only a qualified service person should service

and repair heater.

16. Operating heater above elevations

of 4,500 feet could cause pilot

outage.

17. Do not operate heater if any log is

broken. Do not operate heater if a

log is chipped (dime-sized or

larger).

18. To prevent performance problems,

do not use fuel tank of less than

100 lbs. capacity.

PIEZO IGNITION SYSTEM

This heater has a piezo ignitor.

This system re quir es no m atc hes,

batteries , or othe r so urce s to light

heater.

LOCAL CODES

lnstall and use heater with care.

Follow all local codes. In the

absence of loc al codes, us e the

latest edition of The National Fuel

Gas Code. ANSI Z223.1, also known

as NFPA54*.

*Available from:

American National Standards

lnstitute, lnc.

1430 Broa dw ay

New York. NY100 18

National Fire Prote ction

Association, lnc.

Batterymarch Park

Quincy. MA 02269

PRODUCT IDENTIFICATION

This heater i s designed for ventfree operation. State and local codes

in some areas pr ohibit t he use of

vent-free heaters.

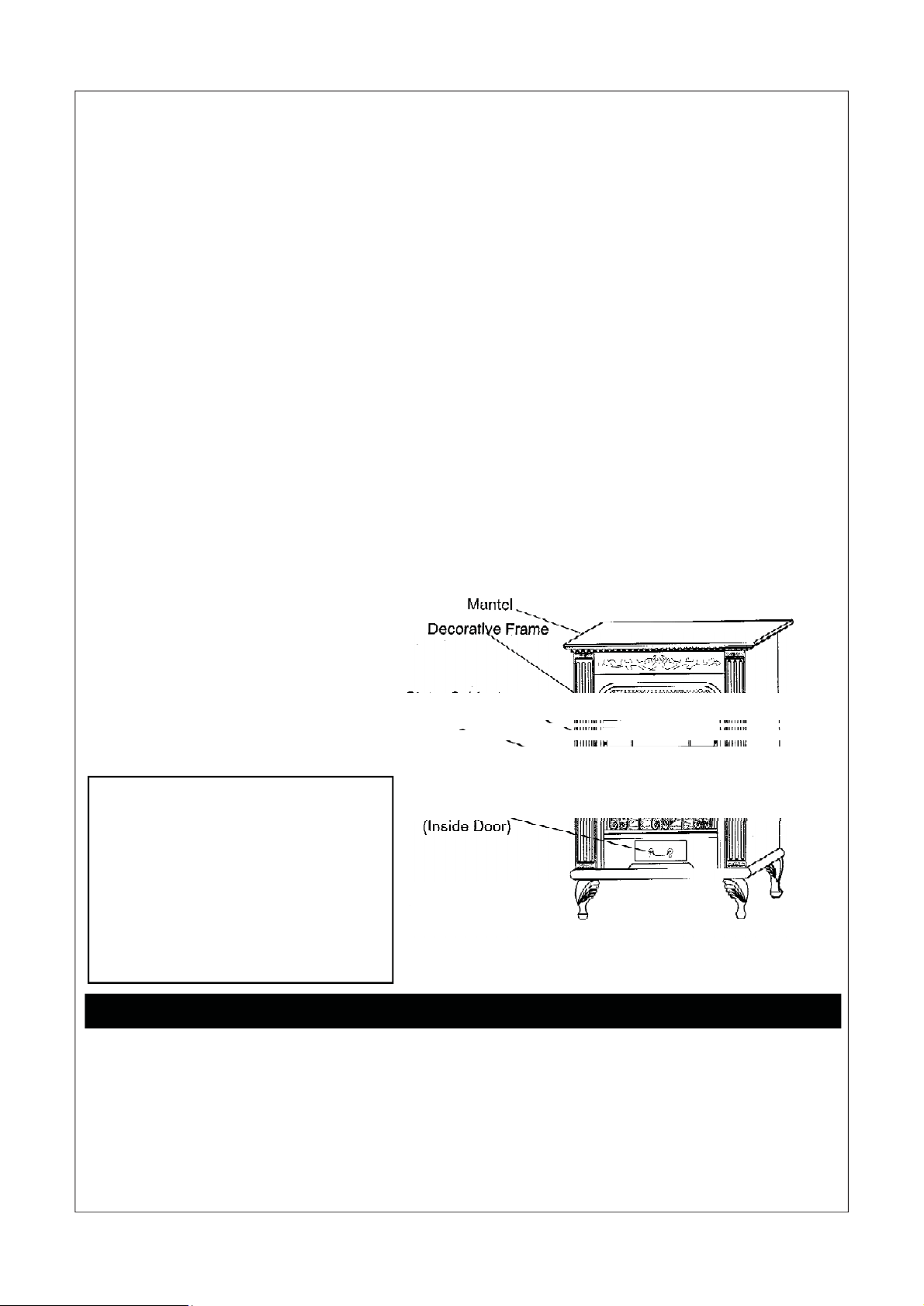

UNPACKING

1. Remove top inner pack.

2. Tilt carton so that fireplace is upright.

3. Remove protective side packaging.

4. Slide fireplace out of carton.

5. Remove protective plastic wrap.

6. Remove screen by lifting and then

pulling forward.

7. Remove log set by cutting plastic

ties.

8. Carefully unwrap logs.

9. Check for any shipping damage. If

f irepl ace or l ogs are dam aged,

promptly inform dealer where you

bo ught the fireplace from.

PRODUCT FEATURES

SAFETY PILOT

This heater has a pilot with an

Oxygen Depletion Sensing (ODS) safety

shutoff system. The ODS/pi lot is a required feature for vent-free room heaters.

The ODS/pilot shuts off the heater if there

is not enough fresh air.

State of Massachusetts: The installation

must be made by a licensed plumber or gas

fitter in the Commonwealth of Massachusetts.

Sellers of unv ented propane or natural gas-fired

supplemental room heaters shall provide to

each pu rch aser a

copy of 527 CMR 30 upon sale of the unit.

In the state of Massachu setts, unvent ed propane or nature gas-fired space heaters shall

be prohibited in bedrooms and bathrooms.

WATER VAPOR: A BY-PRODUCT OF UNVENTED ROOM HEATERS

Water vapor is a by-produ ct of gas combustion.An un vented

room heater productes approximately one (1) ounce (30ml)

of water for every 1,000 BTU’s (.3KW’s) of gas input per hour.

Unvented room heaters are recomm en ded as supplemental

heat (a r oom ) rather th an a pr imary heat sou rce (a n entire

house) .In most supplemental heat application, the water

vapor does not create a problem. In most applications, the

water vapor enhances the low humidity atmosphere

experience during co ld weather.

Figure1-Compact Vent-Free Fireplace

The following steps will help insure that water vapor does

not become a problem.

1. Be sure the heater is sized properly for the application,

including ample combusion air and circulation air.

2. If high humidity is experienced, a dehumidifier may be

used to help lower the water vapor content of the air.

3. Do not use an unvented room heater as the primary

heat source.

3

2

Page 4

AIR FOR COMBUSTION AND VENTILATION

WARNING: This heater shall

not be installed in a confined space

or unusually t ight constr uction

unless provisions are provided for

adequate combustion and ventilation air. Read the following instructions to insure proper fresh

air f or this and other fuel-burning

appliances in your home.

PROVIDING ADEQUATE

VENTILATION

The foll owing are excerpts from

National Fu el Gas Code, NFPA 54/

ANSI Z223 .1.Sect ion 5.3, Air f or

Combustion and Ventilation.

All spaces in homes fall into one

of t h e th ree f ol lowing v entilati on

classifications:

1. Unusually Tight Construction

2. Unconfined Space

3. Confined Space

The information on pages 4 through

5 will help you classify your space

and provide adequate ventilation.

Confined and Unconfined Space

The National Fuel Gas Code, ANSI

Z223.1 defines a confined sp ace as

a space whose v olum e is l ess

than 50 cubic feet per 1,000 Btu per

3

hour (4.8 m

per kw) of the aggregate input rating of all appliances

installed i n that space and an

unconf ini ng space as a space

whose volume is not less than 50

cubic feet per 1,000 Btu p er hour

3

(4.8 m

per kw) of th e aggr egat e

input r ating of all appliances installed in that space. Rooms communicating directly with the space

in which the appliances are

installed*, through openings not

furn ished with doors, are considered a p art of the un confi ned

space.

This heater shall not be installed

in a conf ined space or unusually

tight cons truction un less provisions

are pr ovided for ad equate combustion an d ventilation air.

* Adjoining rooms are communicating only if there are doorless

passageways or ventilat ion grills

betwee n them.

Unusually Tight Construction

The air that leaks around doors

and w indows may provide enou gh

fresh air for com bustion and

ventilation. However, in buildings of

unusually tight constr uction, you

must provide additional fresh air.

Unusua lly tight constr uction is

defined as cons tr uc tion wher e:

a) walls and ceilings exp osed to

the outside atmosphere have a

continuous water vapor retarder with

-11

a rating of one perm ( 6×10

2

pa-sec-m

gasketed or s ealed a

) or le ss with openi ngs

nd

kg per

b) weather stripping has been

added on windows that open and

doors a

nd

c) caul ki ng or seal ant s are applied to areas such as joints around

window and door frames, between

sole plates and floors, between wallceiling join t s, be tween wall panels,

at penetrations for plumbing,

electrical, and gas lines, and at other

openings.

If your home meets all of the

three criteria above, you must provide additional fresh air. See Venti-

latio n Air From Outdoors, pa ge 5.

If your home does not meet all of the

three criteria above, proceed to

Determining Fresh-Air Flow For

Heater Location , below.

AIR FOR COMBUSTION AND VENTILATION

DETERMINING FRESHAIR FLO W FOR HEATER LOCATION

Determining if You Have a Confi ned or Unconfined Space

Use th i s worksh eet to d etermi n e if you have a c onfi n ed or un confin ed sp ace.

Space: Includes the r oo m in which you will install heater plus any adjoining rooms with doorless passageways

or ventilation grills between the rooms.

1. Deter mi ne the volu me of th e sp ac e (len g t h

Length

Example: Space size 20ft. (length)

If additional ventilation to adjoining roo m is supplied with grills or openings, add th e volume of these

rooms to th e tota l volume of th e sp ace.

2. Divide the space volume by 50 cubic feet to determine the maximum Btu/Hr the space can support.

(volume of space)÷50 cu. ft.=(Maximum Btu/Hr the space can support)

Example: 2560 c u. ft. (volume of space)

Width×Height= cu.ft. (volume of space)

×

16ft. ( width)×8ft. (ceiling height)=2560 cu. ft. (volume of space)

×

width×height).

×

÷50 cu.ft.=51.2 or 51,2 00 (maximum Btu/Hr the space can support)

4

3

Page 5

3. Add the Btu/Hr of all fuel burning appliances in the space.

Vent-free heater

Gas water hea te r*

Gas furnace

Vented gas heater

Gas heater logs

Other gas applia nces* +

Total =

*Do not include direct-vent gas appliances. Direct-vent draws combustion air from the outdoors and

vent s to the outdoors.

4. Compare the maximum Btu/Hr the sp ace c an support w i th the act ual am o unt of Btu/ H r use d.

Btu/Hr (maximum the space can support)

Btu/Hr (a ctual amount of Bt u/Hr used)

Example : 51,200 Btu/Hr(maximum the space can support)

56,000 Btu/Hr(actual amount of Btu/Hr use d)

The sp ace in t he ab ove example is a con fined spac e bec ause th e ac tual B tu/H r used is m ore than th e

maximum B tu/H r the sp ace can support.

You must provide additional fresh air. Your options are as follows:

A. R ewo rk w o rksh eet, add ing th e sp ac e of an ad jo ining ro om . If the extra sp ac e pro vides an un co n fined

space, remove door to adjoining room or add ventilation grills between rooms. See Ventilation Air From

Inside Building (below).

B. Vent room directly to the outdoors. See Ventilation Air From Outdoors (bel ow) .

C. Install a lower Btu/Hr heater, if lower Btu/Hr size makes room uncon fined.

If the actual Btu/Hr used is less than the maximum Btu/Hr the space can support, the space is an

uncon fined space. You will need no additional fresh air ventilation.

WARNING: If the area in which the heater may be operated is smaller than that defined as an unconfined space

or if the building is of unusually tight co nstruction, p rovide adequate combu stion and ventilation air by one of the

methods described in the National Fuel Gas Code, ANSI Z223.1/NFPA 54, Air for Combustion and Ventilation, or

app lic ab le lo cal co d es.

Btu/Hr

Btu/Hr

Btu/Hr

Btu/Hr

Btu/Hr

Btu/Hr

Btu/Hr

Example:

Gas wat er heater 30,000 Btu/Hr

Vent-free heater +

Total = 56,000 Btu/Hr

26,000 Btu/Hr

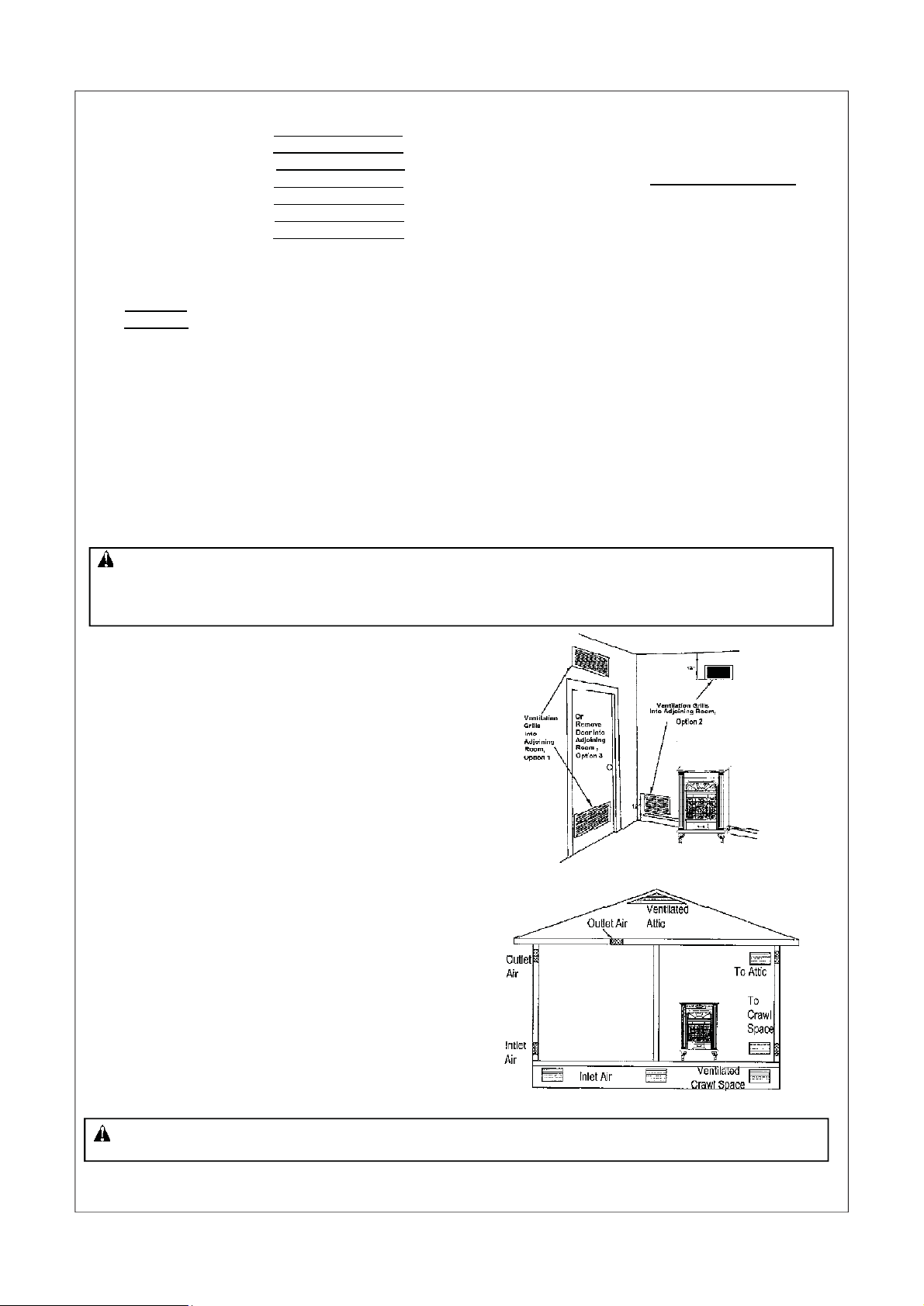

Ventilation Air From lnside Building

This fresh air wo uld c ome from an a djoin ing un confined space. When ventilating to an adjoining

unconfined space, you must prov ide two permanent openings: one within 12" of the ceiling and

one within 12" of the floor on the w all connecting

the two spaces (see options 1 and 2, Fig ure 2).

You can also remove door into adjoinin g r oom

(see option 3, Figure 2). Follow the National Fuel

Gas Code . NFPA 54/ANSI Z223.1. Section 5.3,

Air for Combustion and Ventilation for required

size of ventilation grills or ducts .

Ve n t ila tion Air From Outdo or s

Provide extra fre sh air by using ventilatio n grills or

Figure 2 -Venti lation Air from Inside Building

ducts. You must provide two permanent openings:

one within 12" of the ceiling and one within 12" of the

floor. Connect these items directly to the outdoors or

spaces o pen to the outdoors. These spaces include

attics and crawl spaces. Follow the National Fuel

Gas Code, NFPA 54/ANSI Z223.1, Section 5. 3. Air

for Combustion and Ventilation for required size of

ventilation grills or ducts .

IMPORTANT:Do not provide openings for inlet

or outlet ai r into attic if attic has a t hermostatcontrolled power vent. Heated air entering th e

attic will activate the power vent.

Figure 3 -Ventilation Air f rom Outdoors

W ARNING: Re wor k worksheet, addi ng the s pa c e of the ad joini ng unc onfined space. The

combined spaces must have enough fresh air to supply all appliances in both spaces.

5

4

Page 6

NOTICE: This heater is in-

tended for u se as supplemental

heat. Use this heater along with

your prim ary h eating system . D o

not install this heater as your

primary heat source. If you have a

central heating system, you may

run system's circulating blower

while using heater. This will help circulate the heat throughout the

house . In the event of a po wer

outage, you can use this heater as

your primary heat source.

WARNING: A qualified s ervice

per so n mu st insta ll h ea ter. Fo llo w

all local co des.

WARNING: Never in st all th e

heater:

in a bedroom or bathroom

in a recreational vehicle

where curtains, furnit ure, clothing,

or other flammable objects are

less than 36 inches from the

front, top, or sides o f th e h eater

in high traffic areas

in windy or drafty areas

INSTALLAT ION

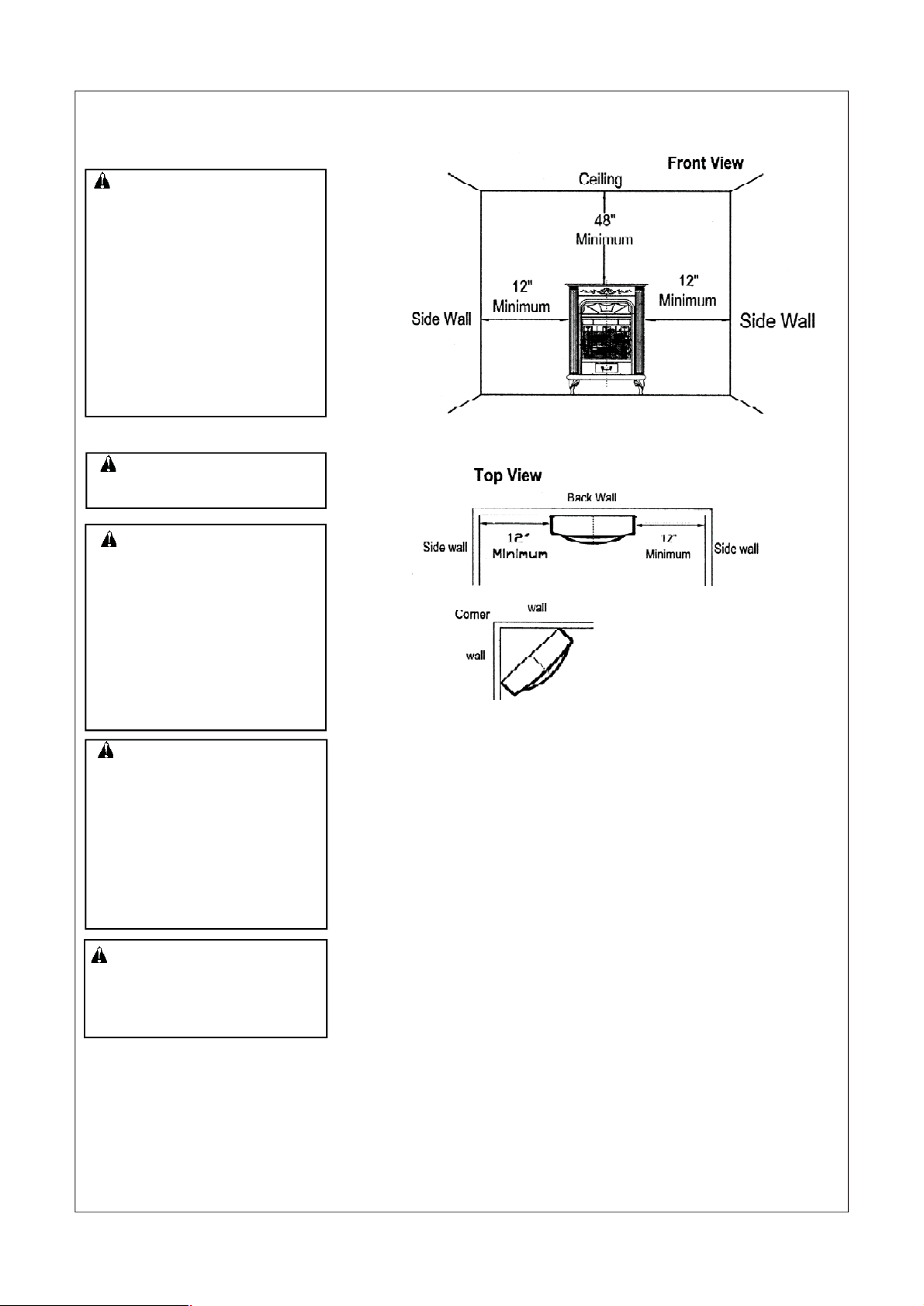

Figure 4 -Minimum Clearance to Wall

CAUTION: This heater creates

warm air currents. Th ese currents

move heat to wall surfaces next to

heater. Installing heater next to vinyl

or cloth wall coverings or operating

heater where impu rities (su ch as

tobacco smoke, aromatic candles,

cleaning fluids, oil or kerosene

lamp s, e tc . ) in th e air exist ,m ay d iscolor walls.

WARNING: Maintain the minimum clearances. If you can, provide greater clearances from floor,

ceiling, and adjoining side and

back walls.

IMPORTANT: Vent-free heaters add

moisture to the air. Alth oug h this is

beneficial, installing heater in rooms

without enough ventilation air may

cau se m ild ew . S ee Air for Combustion

and Ventilatio n, pages 4 through 5.

CHECK GAS TYPE

Use only the type of gas indicated on

the plate. If your gas supply can not

meet that requirement, do not install

heater. Call dealer where you bought

heater from for proper heater type.

CLEARANCES TO COMBUSTIBLES

(V ent -Fr e e Op erat i on On ly )

Carefully follow the instructions below.

This fireplace is a freestanding u nit

designed to set directly on the floor.

6

5

IMPORTANT: You must main tain

minim um wall and ceiling clear an ces

during installation. T he minimum

clearances are sho wn in F igure 4 .

Measure from out ermost point of f ireplace top.

Minimum Wall and Ceiling

Clearances

(see Figure 4)

A. Clearances from outermost point

of fireplace top to any combustible side

wall should not be less than 12 inches.

B. Clearances fro m th e fireplac e to p

to the ceiling should not be less than

48 inches.

Page 7

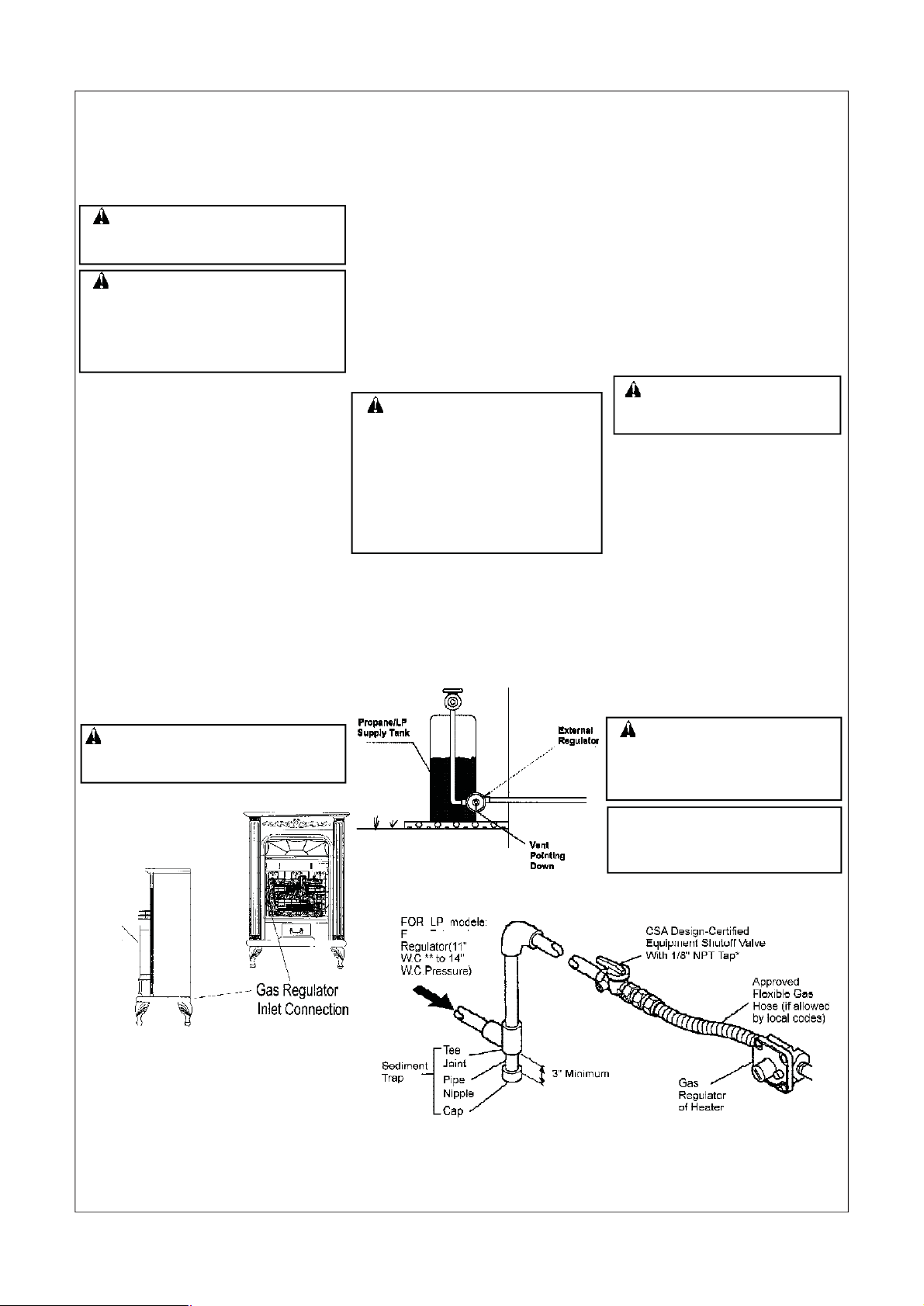

CONNECTING TO GAS SUPPL Y

WARNING: A qualified service person mus t con ne ct he at e r to ga s s upply.

Fo l l ow al l l o c a l c od e s .

CAUTION: Never connect heater

directly to the gas supply. This heater

requires an external regulator (not

supplied). lnstall the external regulator

between the heater and gas supply.

INSTALLATION ITEMS NEEDED

Before installing heater, mak e sure you

have the items listed below.

piping (check local codes)

sealant (resistant to natural or propane/

LP gas)

equipment shutoff valve*

test gauge connection*

sediment trap

see joint

pipe wrench

flexible gas hose ( c heck loc al c odes).

* A CSA design-cert ified e quipment shutoff

valve with 1/8

altern ative to test gaug e conn ect ion.

Purchase the optional CSA designcertifie d equipment shutoff va lve from

your d eal er. See Accessories, page 14.

WARNING: Never connect heater to

private (non-utility) gas wells. This gas

is commonly known as wellhead gas.

Front

of

stove

unit

" NPT tap is an acceptable

Front View

Side View

INSTALLATION

Continued

The installer must supply an external

regulator. The external regu lator will

reduce incoming gas pressure. You

must reduce incoming gas pressure

to between 11 to 1 4

not reduce incoming gas pressure,

heater regulator damage could occur .

lnstall external r egulator with the vent

pointi ng down as shown in Figure 6.

Pointing the vent down protects it

from freezing rain or sleet.

CAUTIO N: Onl y use a ne w black

iron or steel pipe. Internally-tinned

copper tubing may be used in certain areas. Check your local codes.

Use pipe of 1/2

to allow proper gas volume to heater.

If pipe is too small, undue loss of

pressure will occu r.

Installation must include an equipment shutoff valve, union, and plugged

" NPT tap. Loca te N P T tap within

1/8

rea ch f or test gauge hook up. NPT tap

must be u pstr eam from heat er (see

Figure 7).

Figure 6- External Regulator

With Vent Pointing Down

inches. If you do

" diameter or greater

IMPORTANT: Install equipment

shutoff valve in an accessible

location. The equ ipment shutoff

valve is for turning on or shutting

off the gas to the appliance.

Apply pipe joint sealant lightly to

male threads.This will prevent excess sealant from going into pipe.

Excess sealant in pipe co uld result in clogged heater valves.

CAUTION: Use pipe joint sealant that is resistant to liquid

petroleum(LP) gas.

W e recommend that you install a

sediment trap in supply line as

shown in Figure 7. Locate sediment

trap w her e it is within reac h fo r

cleanin g. Install in piping system

between fuel supply and heater.

Locate sediment trap where

trapped matter is not likely to freeze.

A sediment trap traps moisture

and contaminants. This keeps them

from going into heater controls. If

sediment trap is not installed or

is installed incorrectly, heater may

not run properly.

CAUTION: Avoid damage to

reg ulato r. H o ld gas reg u la t o r wit h

wrench when connecting into gas

piping and/or fittings.

NG MODEL S: 5” to 10.5” W.C.

Gas supplier provides external

regulator for natural gas.

Figure 5- Gas Regulat or Locat i on and

Gas Line Access Into Stove Cabinet

Figure 7 -Gas Connection

* Purc h ase the opt ional C SA d esi gn- c erti f ied equipm ent sh u tof f valve from your dealer. See Accessories, p age 14 .

** 11” W.C. p r es sure is th e minim um inlet pr es s ur e for pur pos e of input adjus t m ent.

7

6

Page 8

CHECKING GAS CONNECTIONS

INSTALLATION

Continued

WARNING: Test all gas piping

and connections for leaks after installing or servicing. Correct all leaks at

once.

Pressure Testing Gas Supply

Piping System

T est Pressures In Excess Of 1/2

PSIG(3.5kPa)

1. Disconnect heater with its

appliance main gas valve (control

valve) and equipment shutoff valve

from gas supply piping system.

Pressures in excess of 1/2 psig

will damage heater regulator.

2. Cap off open end of gas pipe

where equipment shutoff valve

was connected.

3. Pressurize supply piping system

by either usin g compressed air or

opening propane/ LP supply valve.

4. Check all joints of gas supply

piping system. Apply mixture of

liquid soap and water to gas

joints. Bubbles forming show a

leak.

5. Co rrect all leaks immediately.

6. Reconnect heater and equipment

shutoff valve to gas supply. Check

reconnected fittings for leaks.

WARNING: Never use an open

flame to check fo r a leak. Apply a

mixture of liquid soap and water to

all join ts. Bub bles form ing show a

leak. C orr ec t all lea k s im med ia tely.

Pressure Testing Heater Gas

Connections

1. Open equipment shutoff valve

(see Figure 8).

2. Open gas supply valve.

3. Make sure control knob of heater

is in the OFF position.

4. Check all joints from equipment

shutoff valve to control valve

(see Figure 9).

Apply mixture of liquid soap and

water to gas joints. Bubbles forming show a leak.

5. Correct all leaks immediately.

6. Light heater (see Operating Heater,

p age 9 ). Ch eck all other internal

joints for leaks.

7. Turn off heater (see To Turn Off

Gas to Appliance, page 9 ).

CAUTION: Make sure external

regulator has been installed betwee n natural gas suppl y and heater.

See guidelines under Connecting to

Gas Supply, page 7.

Test Pr es sur es Equal To or Le ss

Than 1/2 PSIG ( 3.5 kPa )

1. Close equipment shutoff valve

(see Figure 8).

2. Pressurize supply piping system

by either using com pressed air or

opening gas supply tank valve.

3. Check all j oints from gas meter to

equipment shutoff valve (see Fig ure 9). Apply mixture of liquid

soap and water to g as joints.

Bubbles forming show a leak.

4. Co rrect all leaks immediately.

Figure 8 -Equi pment Shutoff Valve

Figure 9 -C hecking Gas Joi nt s

7

8

Page 9

INSTALLATION

Continued

INSTALLING LOGS

WARNING: Failure to position

the pa rts in accor d ance with th e se

diagrams may result in property

damage or personal injury.

CAUTION: After i nsta llation and

periodically thereafter, check to ensure that no flame comes in

contact with any log. With the heater

set to HIGH, check to see if flames

contact any log. If so, reposition logs

according to the log installation

instr u ct io n s in th is m an u al. F lam es

contacting logs will create soot.

IMPORTANT: Make s ure log does not

cover any burner ports (see Figure10).

Figure 10 -Installing Log Set

(Top View)

OPERATING HEATER

FOR YOUR SAFETY

READ BEFORE

LIGHTING

WARNING: If you do not

follow these instru ctions exactly, a

fire or expl osion may result causing

property damage, personal injury or

loss of life.

A. This appliance has a pilot which

must be lit by hand. When

lighting the pilot, follow these

instructions exactly.

B. BEFORE LIGHTING smell all

around the appliance area for

gas. Be su re to smell next to the

floor because some gases are

hea vier t h an air an d will se tt le

on the floo r.

WHAT TO DO IF YOU SMELL GAS

See WARNING on Page 2 for proper

instructions.

C. Use only your hand to push in or

turn the gas control knob. Never use

too ls. If th e kn ob will no t p u sh in or

turn by hand, don't

tr y to rep a ir it . C all a q ua lified s erv ice

technician or gas supplier. Force o r attempted rep air may result in a fire or

explosion.

D. Do not use this appliance if any

part has been under water. Immediately call a qualified service technician

to inspect the appliance and to replace

any part of the control system and any

gas control which has been under water.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety

information on page 2.

2. Make sure equipment shutoff

valve is fully open.

3. Turn control knob clockwise

to th e O FF position .

4. W ait five (5) minutes to clear out

any gas. Then smell for gas,

including near the floor. If you

sme ll gas, STOP ! Fo llow "B " in

the safety information on page 2. If

you don't smell gas, go to the

next step.

5. Tu rn control knob counterclockwise

to the PILOT position. Pre s s in

control knob for five seconds (see

Figure 11).

Note: Yo u may be running this

heater for the first time after

hooking it up to gas supply. If so,

the control knob may need to

be pressed in for 30 seconds

or less . This will allow air to

bleed from th e gas system.

6. With control knob pressed in,

press and release ignitor but ton.

This w ill light pilot. Th e pilot is

attac h ed to th e fro nt bu rn er. If

needed, keep pressing ignitor

button until pilot lights.

Figure 1 1 -Control Knob and

Ignit or But ton locati on

8

9

Note: If pilot does not stay lit,

contact a qualified service

person or gas supplier for

repairs. Until repairs are made,

light pilot with a match. To light

pilot with a match, see Manual

Lighting Procedu res, page 10.

7. Keep control knob pressed in for

30 seconds after lighting pilot.

After 30 seconds, release

control knob.

If control knob does not pop

out when released, contact a

qualified service person or gas

supplier for repairs.

Note: If pilo t goes out, repeat

steps 3 through 7. This heater

has a safety interlock system.

Wait one (1) minute for system

to reset before lighting pilot again .

8. Turn control knob counterclockwise

level. Th e burners should light.

Set control knob to any heat level

between HI and LO.

NOTICE: During initial operation of new hea ter, burning logs will

give off a paper-burning smell. An

orange flame will also be present.

Open a window to vent the smell.

This will only last a few hours.

CAUTION: Do not try to adjust

heating levels by using the

equipment shutoff valve.

to desired heating

TO TURN OFF GAS TO

APPLIANCE

Shutti ng Off Heat er

Turn control knob clockwise

the OFF po sitio n .

Shutting Off Burners Only (Pilot

stays lit )

Turn control knob clockwise

the PILO T/IGN pos ition .

Figure 12 -Pi lot

to

to

Page 10

OPERATING HEATER

Continued

THERMOSTA T CONTROL

OPERA TION

The thermostat control knob can be

set to any comfort level between HI

and LO. Th e thermostat will gradually

modulate the heat output and flame

height from higher to lower settings,

or pilot , in order to ma intain the

co mf o rt leve l you sel ect . Th e idea l

comfort setting will vary by household

depe nding upon the amount of space

to be heated, the output of the

cen tr a l heat in g syst em , etc .

Note: Selecting the HI setting with the

control knob will cause the burners

to remain fully on, without

modulating down in most cases.

MANUAL LIGHTING

PROCEDURE

1. Follow steps 1 through 5 under

Lighting Instructions, page 9.

2. Press control knob and light

pilot with match.

3. Keep control knob pressed in

for 30 seconds after lighting

pilot. After 30 seconds, release

control knob.

INSPECTING BURNERS

Check pilot flame pattern and

burner flame patterns often.

PILOT FLA M E P ATTERN

Figure 13 shows a correct pilot flame

pattern. Fi gure 14 shows an incorrect pilot flam e pat tern . Th e inc orr ect pilot

flame is not touching t he the rmocouple.

Th is will cau se the th ermo co up le to

cool. W hen th e thermocou ple cools,

the heater will shut down.

If pilot flame pattern is inco rrect, as

shown in Figure 14:

turn heater off (see To Turn

Off Gas to Appliance, page 9)

see Troubleshooting (pages 11

through 12).

BURNER FLAME P ATTERN

Figure 15 shows a correct burner flame

pattern. Figure 16 shows an incorrect

burner flame pattern. I f burner flam e pattern is incorrect:

turn h eater off (see To Tur n

Off Gas to Appliance, page 9)

see Troubleshooting, pages 11

through 12

10

9

CLEANING AND MAINTENANCE

WARNING: Turn off heater and

let cool befo re cleaning.

CAUTION: You must keep

control areas, burner, and

circulating air passageways of

heater clean. Inspect these

areas of heater before each

use. Have heater inspected

yearly by a qualified service p erson .

Heater may need more

frequent cleaning due to

excessive lint from carpeting,

bedding material, pet hair, etc.

CLEANING ODS/I GNIT OR AND

BURNER

Clean with a vacuum c leaner.

CLEANING MAIN AIR INLET HOLE

W e recommend th at you clean the unit

every three months or after 2500 hours

of operation. We also recommend that

you keep th e bur ner t ub e and pilot assembly clean and free of d u st and

dirt. To clean th ese parts we recommend using compressed air no greater

than 30 PS I. Yo u can use a vacuum

cleaner in the blow position. If

using compressed air in a can,

please follow the directions on the

can. If you don't follow directions

on the can, you could damage the

pilot assem bly.

1. Shut off the unit, including the

pilot. Allow the unit to cool for

at least thirty minutes.

2. Inspect burner, pilot and

primary air inlet holes on

injector holder for dust and dirt

(see figure 17).

3. Blow air through the

ports/slots and holes in the

burner.

4. Check the injector holder

located at the end of the

burner tube again. Remove

any large particles of dust, dirt,

lint, or p et h air w ith a soft clo th

or vacuum cleaner nozzle.

5. Blow air into the primary air

holes on the injector ho lder.

6. In case any large clumps of

dust have been pushed

into the burn er, repeat step s 3

and 4.

Page 11

CLEANING AND MAINTENANCE

Continued

Clean the pilot assembly also. A

yellow tip on the pilot flame

indicates dust and dirt in the pilot

assemb ly. There is a small pilo t air

inlet hole about two inches from

where the pilot flame com es out of

the p ilot assemb ly (see F igure 1 8).

With the unit off, lightly blow air

through the air inlet hole. You m ay

blow through a drinking straw if

compressed air is not available.

CABINET

Air Pass agew ays

Use a vacuum clea ner or pressur-

ized

air to clean.

EXTERIOR

Use a soft cloth damp ened with a

mild soap and water mixture. Wipe

the cabinet to remove dust.

LOGS

If you remove logs for cleaning,

refer to Installing Logs, page

19, to properly replace logs.

Replace log(s) if broken or chipped

(dime-sized or larger).

MAIN BURNER

Periodically inspect all burner flame

holes with the healer running. All

slotted burner flame holes should

be open with yellow flame present.

All round burne r f l a me hol e s should

be open with a small blue flame

present. Some bur ner flame holes

may become blocked by debris or

rust, with no flame present. If so,

turn off heater and let cool. Either

remove blockage or replace burner.

Blocked burner flame holes will

create soot.

Figure 18-Pilot Air Inlet Hole

Note: All troubleshooting items

are listed in or der of operat ion.

OBSERVED PROBLEM POSSIBLE CAUSE

1. Gas supply turned off or equipment

When ignitor button is

pressed, there is a spark at

ODS/pilot but no ignition.

shutoff valve closed.

2. Control knob not in PILOT position.

3. C on trol k no b n ot p resse d in while in

PILOT position.

4. Air in gas lines when installed.

5. Depleted gas supply.

6. ODS/pilot is clogged.

TROUBLE SHOOTING

WARNING: T urn off heater and

let cool before servicing. Only a

qualified se rvice pe rso n s hou ld

service and repair heater.

CAUTION: Never use a wire,

needle , or similar object to clean

ODS/pilot. This can damage ODS/

pilot uni t.

REMEDY

1. Turn on gas supply or open

equipment shutoff valve.

2. Turn control knob to PILOT position.

3. Press in contr ol knob while in PILOT

position.

4. Continue holding down control

knob. Repeat igniting operation

un t il a ir is re mo ve d .

5. Contact local p ropane/LP gas

company.

6. Clean ODS/pilot (see Cleaning

and Maintenance,page 10 ) or replace

OD S/ pilo t a ss emb ly.

7. G as re gu la tor se t ting is inc or r e ct.

11

10

7. Replace gas control.

Page 12

TROUBLE SHOOTING

Continued

OBSERVED PROBLEM POSSIBLE CAUSE

ODS/pilot lights but flame

goes out when control

kn ob is released .

Burner does not light after

ODS/pilot is lit.

Delayed ignition burner.

1. Control knob not fully pressed in.

2. Control knob not pressed in long

enough.

3. Equi p me nt s hut of f valv e not f ul ly open.

4. Thermocouple connection loose

at control valve.

5. Pilot fla me not touching thermocoupl e .

Th is allow s the rmoc oup le to c ool

causing the pilot flame to go out.

This problem could be caused by

one or both of the following:

A) Low gas pressure.

B) Dirt y or partially clogged ODS/

pi lot.

6. Thermocou ple damaged.

7. Control valve damaged.

1. Burner orifice is clogged.

2. Inlet gas pressure is t oo low.

3. Burner orifice diameter is too small.

4. Thermocoup le leads disconnected

or improperly connected.

1. Manifold pressure is too low.

2. Burner orifice is clogged.

REMEDY

1. Press in control knob all the way.

2. After ODS/pilot lights, keep

control knob pressed in for 30

seconds.

3. Open equipment shutoff valve all the

way.

4. Hand tighten until snug, then

tighten 1/4 t u rn mo r e.

5. A) Contact local propane/LP gas

com pany.

B) Clean ODS/pilot (see Cleaning

and Maintenance, page 10 ) or replace

CD S /p ilo t as se mb ly.

6. Replace thermocouple.

7. Contact Dealer or PRO-COM .

1.Clean burner (see Cleaning

and Maintenance, page 10) or replace

burner orifice.

2. Contact local propane/LP gas

company.

3. Replace burner orifice.

4 . Re conn ect lead s.

1. Contact local gas company .

2. Clean burner (see Cleaning and

Maintenance, page 10).

Burner backfiring during

combustion.

Slight smoke or odor

dur in g in itial operat io n.

Dark residue on logs

or inside of fireplace.

Heater produces a clicking/

ticking noise just after burner

is lit or shut off.

1. Damaged burner.

2. Gas regulator is defective.

1. Residues from manufacturing

processes.

2. Not enough air.

3. Gas regu lator is defective.

1. Improper log placement.

2. Air holes at burner inlet are blocked.

3. Burner flame holes are blocked.

1. Metal expanding while heating

or contracting while cooling.

11

12

1. Clean burner orifice (see Cleaning

and Maintenance, page 10).

2. Replace gas regulator.

1. Problem w ill stop after a few hours

of operation.

2. Check burner for dirt and debris.

If found, clean burner (see C leaning

and Maintenance, page 10).

3. Replace gas regulator.

1. Pro perly lo cate log s (see Installing

Logs, page 9).

2. Clean out air holes at burner inlet.

Periodically repeat as needed.

3. Remove blockage or replace burner.

1. This is common with most

heaters. If noise is excessive,

contact qualified service person.

Page 13

SPECIFICATIONS

EL250TYLA-B

EL250TYLA-W

EL250TYLB-O

EL250TYLA-C

EL250TYLB-DO

Btu 20,000/25,000 20,000/ 25,000

Gas Type LP Gas N atural Gas

Ignition Piezo Piezo

Manifold Pressure 8"W.C. 3"W .C.

Inlet Gas Pressu r e

(In. of water)*

Maxi mum 14" 10.5"

Mi nim u m 11" 5"

Dimensions, Inch es (H×W×D)

Stove 38 3/16”×26 3/8”×14 1/8”

Carton 37”×29 5/16”×15 5/16” (41 3/8” x29 5/16” x17 3/8” ** )

EN250TYLA-B

EN25 0TYLA -W

EN250TYLB-O

EN250TYLA-C

EN250TYLB-DO

Weight, lbs

St ove 73 (78***) 73 (78***)

Shipping 89 (94***) 89 (94***)

*For purpos es of input adjus tment

The carton dimension of model EL250TYLB & EN250TYLB

**

***The weight of model EL250TYLB & EN250TYLB

12

13

Page 14

REPLACEMENT PARTS

REPLACEMENT PARTS

Note: Use only original replacement

parts. This will protect your warranty

coverage for parts replaced und er

warranty.

PARTS UNDER WARRANTY

Contact authorized dealers of this

product. If they can't supply original

replacement part(s) call PRO-COM

at (877)886-5989 for referral

information.

When calling PRO-COM or your

de aler , h ave re ad y:

Your name

Your address

Model and se r i a l number s of

your heater

How heater was malfunction-

ing

Type of gas used (propane/LP

or

natural gas)

Purchase date

warranty card

Usually, we will ask you to

return the defective part to the

factory.

ACC ESSOR IES

Purchase these heater accessories

from your local dealer or call PRO-COM at

(877)886-598 9 for referral information. You

can also write to the address listed on the

front page of this manual.

FLEXIBLE GAS HOSE

Flexible gas hose is used fo r con necting the heater to gas suppy.

The flexible gas hose must be CSA

approved.

EQUIPMENT SHUTOFF V A LVE

Equipment shutoff valve with 1/8" NPT

tap. This part is not currently available

from PRO-COM.

P ARTS NOT UNDER WARRANTY

Contact authorized dealers of this

product. Call PRO-COM at (877)

886-5989 for referral information.

When call i ng PRO- COM, ha v e r e ady:

Model number of your heater

The replacement part nu mber

13

14

Page 15

ILLUSTRATED

PARTS BREAKDOWN

EL250TYLA-B

EL250TYLA-W

EL250TYLB-O

EL250TYLA-C

EL250TYLB-DO

EN250TYLA-B

EN25 0TYLA -W

EN250TYLB-O

EN250TYLA-C

EN250TYLB-DO

15

14

Page 16

PARTS LIST

EL250TYLA-B

EL250TYLA-W

EN250TYLA-B

EN25 0TYLA -W

This list contains replaceable parts used in your

heater. When ordering parts, follow the instructions

listed under Replacement Parts on page 14

of this manual.

EL250TYLB-O

EL250TYLA-C

EL250TYLB-DO

EN250TYLB-O

EN250TYLA-C

EN250TYLB-DO

15

11

16

Page 17

ILLUSTRATED

PARTS BREAKDOWN

EL250TYLA-B

EL250TYLA-W

EN250TYLA-B

EN25 0TYLA -W

16

17

Page 18

PARTS LIST

EL250TYLA-B

EL250TYLA-W

EN250TYLA-B

EN25 0TYLA -W

17

18

12

Page 19

ILLUSTRATED

PARTS BREAKDOWN

EL250TYLB-O

EN250TYLB-O

EN250TYLB - C

EL250TYLB-C

EN250TYLB-DO

EL250TYLB-DO

18

19

Page 20

PARTS LIST

EL250TYLB-O

EN250TYLB-O

EN250TYLB-C

EL250TYLB-C

EN250TYLB-DO

EL250TYLB-DO

20

19

Page 21

1. Install legs and pedestal decorating trim.

Lay the heater down on its back and install the

legs with care on the bottom panel (as shown in

Figure 1). Ma ke sure th e vein side is forw ards.

Except m od el EL(N )2 50TY LB

Install the pedest al decorati ng tri m (front and

side) under the pedestal with screws.

Figure 1

2. I nstall the decora tin g logs.

Figure 2

Fasten decorating logs 123 onto the correspondent angle iron (Figure 4).

Figure 3

Figure 4

Insert the pinhole on the upper part of log 4 into the pin on the left side of log 1. Place the

lowe r par t o n the flat ro of at th e lef t s ide of log 3 (Fig ur e 5).

Insert the pinhole on the upper side of log 5 into the pin on the right side of log 1. Place the

lower part on the flat roof at the right side of log 3 (Figure 6).

Figure 5

Figure 6

5. Ins tall th e h eate r ac cordi n g to th e Installat ion in th e owner’s manual.

20

21

Page 22

INSTALLING BLOWER ACCESSORY

BLOWER ACCESSORY MODEL NFHTX186

ACCESSORY NFHTX186

T ools required: Philips screwdriver

NOTI CE : Shut off gas heater during the following blower

installation.

1.From back of heater remove the knock

out c e n te r p anel with tw o brack e ts at th e

four sides with a Philips head screwdriver

(see Figure 1).

2. Attach the two brackets to blower hous

ing using four white screws provided in

blower kit (2 for each bracket) (see Fig

ure 2). Tighten screws securely. Then

guide the green groun ding means wire

and downlead of motor through the panel

capped hole.

3. Guide the four strand wire of downlead

through the panel hole. Connect the two

yellow leads an d the temperature con trol

switch on the temp er atu r e c ontr o lled

bracket togther. Secure the temperature

controlled bracket on the reflective panel

of firebox using two self-tapping screws

(See Figure 3-A).

4. Using the previously removed screws,

mount blow er assembly to sto ve by reat

ta ching the knock-out center panel to rear

panel. Draw the four strand c able back-

P

ward so as t o expo se t h e t hr ee bl ac k,

green, white lines on the four strand

cable at the bac k of rear panel.Be sur e

not to drop the temperature controlled

wire off the reflective panel. Connect the

green grounding means wire and four

strand cable together.Connect the two

black motor down leads respectively

and the remaining two black and white

wir e s t oge t he r by the s a me mea ns (s e e

Figure 3-A). (Note: the th ree wires

must be connected at the rear panel)

5. Using the thread that previously bond

the electrical wire to c ollect an d p ack

the outside connection wire of the

cable.

6. A . E N(L)250TYLA mo de l Guid e t he

operating control housing through the

bottom ho le of rear panel, and place

it on the mounting bracket in the door.

Mounting operating control housing to

the mounting bracket with two screw.

(see figure 4)

B. EN(L)25 0T YLBmo del Insert opera tion control housing at the back bot tom of stove.Use two black screws

provided in blower kit. Mount blower

operation control housing to the

bracket at the bottom of stove (see Fig

ure 5).

7. Chec k to mak e sure t hat th e po we r

co rd is co mplet ely clear o f blow er

wheel and ther e are no forei gn objects

in blower wheel.

8. Use screws provided in blower

k it to as semble the plate which

ass em b led w ith st rain re lief

bushing and po wer cord on the

knock-out center panel.

9.Peel off the backing paper and

stick the supplied wiring diagram

decal on th e b ack panel as show

in F igure 4-B.

10.Plug power cord into a con ve

nient 3-prong grounded wall

recep tacle near the stove.

WARNING: 1. ELEC TRICAL

GROUNDING INSTRUCTIONS:

This appliance is equipped

with a three-prong (grounding)

plug for your protection

against shock hazard and

shou ld be p lugg ed dir ectl y in to

a properly grounded threeprong receptacle.

2. Do not let the wires touch

the reflective panel of the

firebox.

motor and gr een wir e thr ough

the hole of the knock-out

panel.

11. Using Auto/O/man switch. Turn

12. All remaining parts from

Feed the wires of the

blower on and check for

operat ion. Tur n on Auto/O/Ma n

switch to the desired position.

Man position will remain constantly on. Auto position will be

control led by the thermostat on

fan blower unit. To stop the

operation, turn unit switch to the

O position.

blower kit may be discarded.

Figur e 1 Removing Kno ck- out Panel

22

21

Figure 2 Attaching Brackets To Blower

Page 23

INSTALLING BLOWER ACCESSORY

BLOWER ACCESSORY MODEL NFHTX186

Figure 3-A R outing Power Cord

MODEL EL(N)250TYLA

Figur e 4 Mount in g Contr ol hosi ng

Wiring Diagram

Decal

Figure 3-B R outing Power Cord

Figure 5 Mounting Control Housing

22

23

MODEL EL(N)250TYLB

Loading...

Loading...