Page 1

OPERATING INSTRUCTIONS

ECON-A-4C/A/S/M

Page 2

Page 3

INDEX

1.0 Introduction

2.0 Salient features, Protection & Supervision

3.0 Display/ Front Panel

4.0 Switches Description

5.0 LED Annunciations Description

6.0 Lamp Test

7.0 Digital Input

8.0 Analog Input

9.0 Digital Output

10.0 Modes of Operation

10.1 AMF Mode (ECON-A & ECON -A-4C)

10.1.1 Auto Mode

10.1.2 Semi Auto Mode

10.1.3 Manual Mode

10.2 Auto Stop Mode ( ECON-A & ECON - A-4C or ECON-S)

10.3 Manual Controller ( All models)

11.0 Setting Procedure

12.0 Parameter Mode

12.1 System Parameter

12.2 Generator Parameter

12.3 AMF Parameter

12.4 Protection Parameter

12.5 RS 485 parameters

12.6 Reset Service Alarm

12.7 Adjust Clock

12.8 Reset Password

13.0 Model Selection Chart

14.0 Load Management

15.0 Event Recording

16.0 Faults

16.1 Internal Faults

16.2 External Faults

16.3 Fault Reset

17.0 Communication

18.0 MODBUS Specifications.

19.0 Terminal description

20.0 Specifications

21.0 Dimension

Operating Instructions

Page - 1

Page 4

• 1.0 Introduction

Microprocessor based controller for DG Set which can be configured as both

automatic or manual controller.

ECON comes in various models to cater for varieties of requirements:

• ECON-A-4C

• ECON-A

• ECON-S

• ECON-M

• ECON-A-4C: It is a AMF controller with 4 channel of analog measurement

and can be site configured as ECON-A or ECON-S or ECON-M.

• ECON-A: It is a AMF controller with 3 Analog channels and is site

configurable to ECON-S or ECON-M

• ECON-S: It is a manual controller with Shunt trip contact for MCCB. This is to

avoid shutting down the engine on load in manual operation. After the shunt

trip is initiated the generator stops after re-cooling time. ECON-M is sub set of

this model

• ECON-M: This is a pure manual controller for manual operation only.

All these models can be ordered with optional features such as RS485

communication,3 Extra digital inputs of Canopy fan current protection. This

manual has to be read along with the controller selected and all the features

may not be available in all the models.

• Display: 128*64 pixel graphial backlit LCD for ease of readout and symbolic

representation.

• Cyclic Timer based Engine Operation. Maximum engine on time as well as

rest time are programmable

• Fan Current monitoring for canopy fan (Optional)

• Menu driven MM1 for easy in field configuration without PC or any

customized equipment.

• Load Management . Load Dependent start/stop of 2nd DG in case of two DG

application.

• Periodic Automatic Start of engine if not used for a predefined time to charge

the battery as well as maintenance.

• ECON reminds user for timely service by indicating service due alarm.

• True RMS measurement of all measured parameters with 1% accuracy of

measured value.

• Plug in connectors for error free replacement.

• Programmable DG on delay, DG continuous on time, DG Rest Time, warm-up

time along with 33 other times.

• Automatic real time based DG Start and Stop(Manual Control Configuration.).

• Dimensions 167 х 129 х 41.8 mm.

Operating Instructions

Page - 2

Page 5

• 2.0 Salient Features, Protection and Supervision

• Mains Measurements

◦ 1 Phase/ 3 Phase Voltage

◦ 1 Phase/ 3 Phase Current

◦ Frequency

◦ PF, KW, KVA,

• Generator Measurements

◦ 1 Phase / 3 Phase Voltage

◦ 1 Phase / 3 Phase Current

◦ Frequency

◦ PF, KW, KVA, KWH .

◦ Battery Voltage

◦ Water Temperature

◦ Oil Pressure

◦ Fuel Level

◦ RPM

◦ Run Hour

◦ Service Due Hour

• Protection / Supervision Mains

◦ Under/Over Voltage

◦ Under/Over Frequency

◦ Phase Sequence

◦ Voltage Unbalance

◦ Overload

• Protection / Supervision DG

◦ Under/Over Voltage

◦ Under/Over Frequency

◦ Current Unbalance

◦ Over Speed

◦ RWL

◦ LLOP

◦ HWT

◦ LFL

◦ Charging Alternator/V-belt

◦ Emergency off

◦ Service Due

◦ Fail To Start

◦ Fail To Stop

• Digital Input : 10 digital [3 fixed, 4 programmable, 3 programmable (optional)]

• Output: 9 digital

Operating Instructions

Page - 3

Page 6

◦ AMF Operation: 9 outputs (five fixed and three programmable) and one for

charging Alternator

• Fault Data Recording: Last 64 fault with date and time stamping

• Event Recording: Last 64 event with date and time stamping

• Start Stop Recording: Last 100 records with date and time stamping

• Password Protection: Three digit password protection for system settings.

• Real Time Clock (RTC)

• Communication: RS232, USB, Fully Isolated RS485(Optional)

• Provision for switching ON or OFF the measurement for individual sensors.

• Option of warning or tripping when open sensor is detected

• Programmable crank cut off method based on either voltage built up, or oil

pressure build up & voltage built up

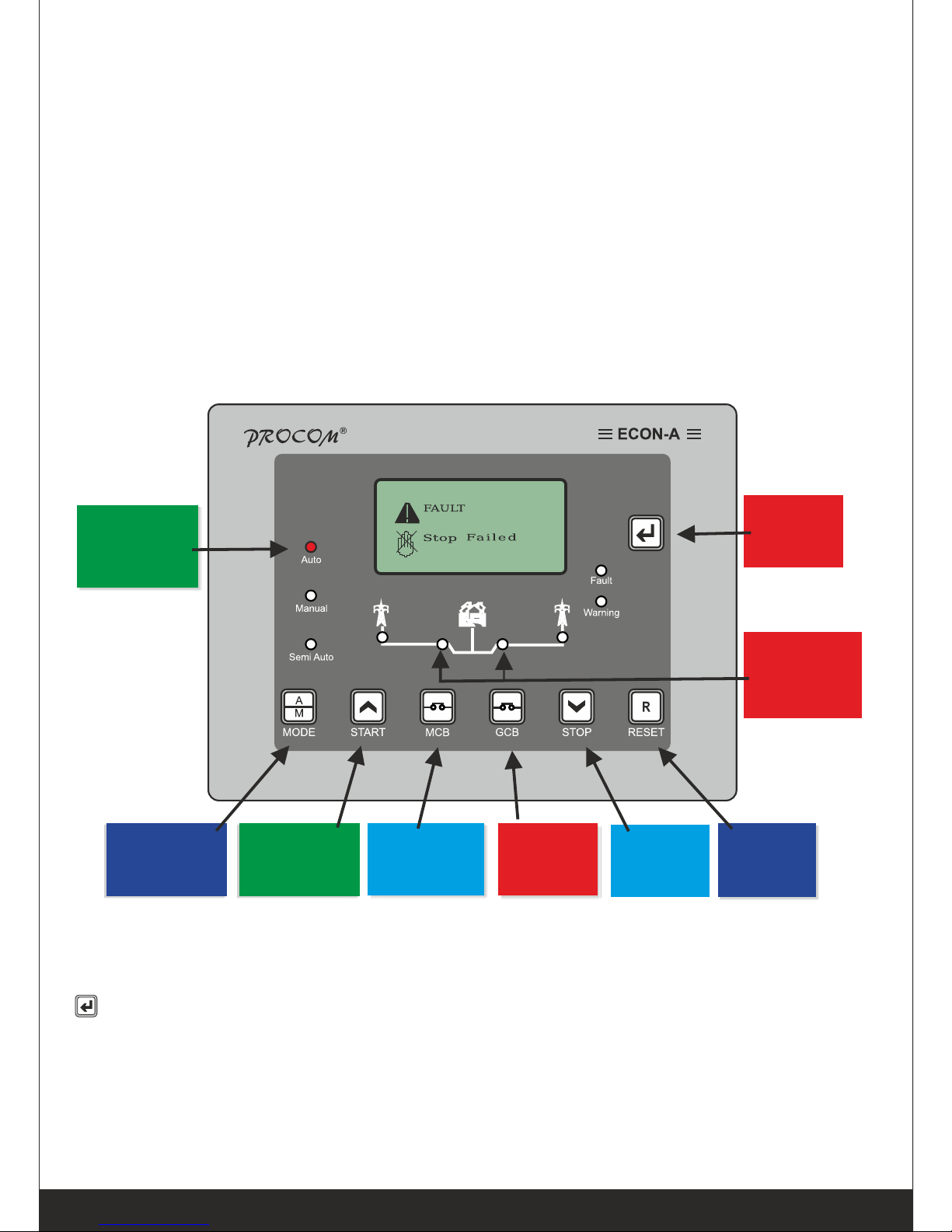

• 3.0 Display / Front Panel

• 128x64 pixels Graphical LCD Display for ease of readout. Parameters are

displayed in English along with symbolic representation. Normally the display

auto scrolls and displays a parameter for 10 seconds, but any time the Next key

( ) can be pressed to select the next parameter window.

• 4.0 Switches Description

ECON has 7 switches provided on its front panel. The table below describes

the operation of these.

Start

Switch

MCB

Switch

Reset

Switch

Mode

Indication

LEDs

Next

Switch

GCB

Switch

Stop

Switch

Mode

selection

switch

Mains & DG

Contactor

Indicator

Operating Instructions

Page - 4

Page 7

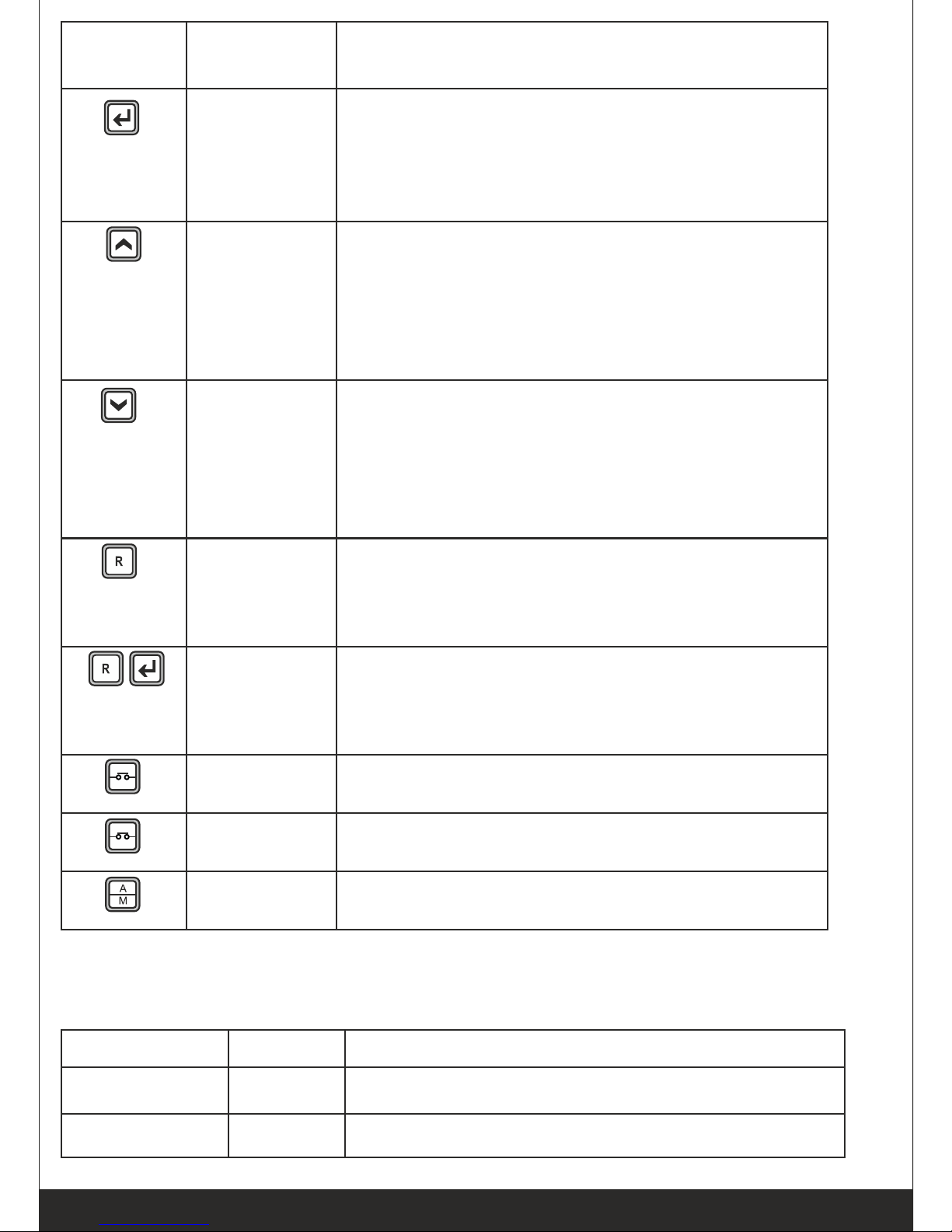

Switch

Symbol

Switch

Function

Description

Next

Normal operation mode: In this mode, it is

used to change the parameters being

displayed on LCD.

Programming Mode: Next key is used to

select the next parameter to be programmed.

Increment

/Start

This key has dual function

Programming Mode: It is used to increment

the value of the parameters under

programming.

Manual mode: it is used to issue the crank/

start command to DG

Decrement

/Stop

This key has dual function

Programming mode: It is used to decrement

the value of the parameter under

programming.

Manual mode: It is used to issue the stop

command to DG

Reset

Reset key resets the Hooter and Fault signals.

The first press shall reset the hooter and next

shall reset the faults. A long press of 1 Sec

shall reset both.

Programming

/History

Fault Mode

Entry

If both the keys are pressed simultaneously

the unit will enter in Programming Mode

History Fault/Service Hours

MCB

In Manual Mode this toggles the mains

contactor, On/Off

GCB

In Manual Mode this toggles the generator

contactor, On/Off

MODE

Toggle between Auto, Manual & Test Mode

• 5.0 LED Annunciations Description: ECON has nine annunciations on its

front panel. These either announce the faults or indicate status of the

system.

Nomenclature

Symbol

Description

Auto

Led lights up when ECON is in Auto mode

Manual Mode

Led lights up when ECON is in manual mode

Operating Instructions

Page - 5

Page 8

Nomenclature

Symbol

Description

Semi Auto

Led lights up when ECON is in Semi Auto

Mains Voltage

This symbol lights up continuously if Main is

healthy else starts blinking.

MCB

LED turns on in case the mains breaker is

switched on or else turned off

GCB

LED turns on in case the DG breaker is switched

on or else turned off

DG Voltage

This indication glows continuously when the

generator is running.

Warning

This LED blinks in case of a warning.

Fault

This LED blinks in case of a fault

• 6.0 Lamp Test:

If the ECON is switched on while the reset switch is pressed, all the LEDs

start blinking till reset switch is kept pressed.. This state shall persist till the

switch is kept pressed and on release of the switch ECON shall start

functioning normally

• 7.0 Digital Input:

ECON has 10 digital input as below

• Fixed Inputs

◦ Remote Start,

◦ Remote Stop / Semi Auto

◦ Emergency

• Programmable 4 inputs each can be programmed as one of the

following inputs.

◦ RWL Switch ◦ LLOP Switch

◦ Fuel Switch ◦ HWT Switch

◦ Oil Level Switch ◦ Canopy Temperature Switch

◦ Oil Temperature Switch

• Optional programmable 3 inputs each can be programmed as one of the

following inputs.

◦ Earth Fault ◦ Oil Level Switch

◦ Canopy Temperature Switch ◦ Oil Temperature Switch

Operating Instructions

Page - 6

Page 9

Operating Instructions

Page - 7

• 8.0 Analog Input: ECON has 4 Analog Input

◦ Low Lube Oil Pressure Sensor

◦ High Water Temperature Sensor

◦ Low Fuel Level Sensor

◦ OIL Temperature (ECON-A-4C only )

• 9.0 Digital Output: ECON has 9 digital outputs :

• Programmable output

Three digital outputs can independently be configured for the any functions

from the list below.

◦ Unit Healthy ◦ Load Warning

◦ Fuel Pump ◦ Heater/Choke

◦ Pull Solenoid ◦ None

• Fixed output: The remaining 6 digital outputs are fixed:

◦ Charging Alt( Battery Voltage) ◦ Crank

◦ Solenoid ◦ Hooter

◦ Mains Contactor ◦ Generator Contactor

• 10.0 Modes of Operation

10.1 AMF Mode (ECON-A & ECON -A-4C)

• 10.1.1 Auto Mode

ECON monitors the Mains supply, if Mains supply varies beyond set limit of

under/over voltage or under/over frequency or voltage unbalance for more

than their individual programmed supervision time, ECON releases the MCB

contactor (to protect the contactor from failure because of low input voltage)

and attempts to starts the generator after the following conditions are meet:

1. If engine start delay is enabled than the engine will wait for the programmed

delay before cranking the engine

2. In case the mains voltage returns to normal before cranking the engine the

engine shall not be cranked.

Heater/Fuel Pump contact are switched on depending upon their settings.

Heater/choke/glow plug is first switched followed by fuel pump. Next ECON

cranks the engine. Crank command is withdrawn once the engine start which

is detected, either by LLOP pressure or by build-up of generator voltage, as

per the setting by the user. Max duration of crank command is user settable.

In case of non-start of the engine ECON re-cranks it till it starts or user

programmed crank attempts are exhausted. If generator fails to start after the

maximum programmed crank attempts, Fail to Start LED starts blinking,

indicating start failure and the hooter is switched on.

After successful start of the generator, it is allowed to warm up for a user

programmed time before the load is transferred to generator.

While the generator is running ECON monitors it for external fault (Digital

Page 10

Inputs: Emergency, V-Belt, RWL,, LLOP Switch etc) and internal faults

(Measured Values faults: LLOP, HWT, Fuel, Over Load, voltage and

frequency).

On persistence of any fault for more than the programmed supervision

delay,for that fault, generator is stopped, corresponding fault is announced &

hooter is switched on. On restoration of healthy mains supply, continuously,

for the programme duration the load is transferred to the mains and generator

is stopped after expiry of re-cooling time. In case mains again become

unhealthy during the re-cooling period the load is switched to generator.

After successful stopping of the generator either normally or on fault the Fuel

Pump Contact is removed. In case of fail to stop, the Fuel Pump Contact is

not removed to avoid air locking.

Cyclic Operation: ECON can be programmed to automatically shut down

the engine, for a predefined duration, after a predefined duration of

operation, even if the mains is unhealthy. In case the mains continue to be

unhealthy this cyclic operation will continue till the mains is restored.

• 10.1.2 Semi Auto Mode

Semi Auto Mode is sub set of Auto mode. This mode can be selected by

pulling the pin 28(Semi/Auto) low and selecting auto mode from the front

panel. The Auto LED will blink indicating that the unit is in Semi-Auto Mode.

In this mode the unit does not automatically starts the engine after the mains

has failed and mains supervision timer has expired but waits for an external

start signal pin 29(Remote Start/Stop). Once the start signal is given the unit

now functions like auto mode with 3 crank attempts. The unit can be stopped

by pulling low Pin 29(Remote Stop). Both Remote start and remote stop are

one touch and hence should not be continuously activated. These pins shall

only function during semi auto mode.

• 10.1.3 Manual Mode

ECON-A, in this mode is under the manual control of the operator for starting

and stopping of the generator. Engine has to be started manually by manually

pressing “Start” switch. The “Start” switch shall not operate if GCB contact is

closed, to provide protection to generator. Once the generator is started the

load can be switched to generator by pressing “GCB” switch or to mains by

pressing MCB switch. At any given time, either of GCB or MCB can be

operational. Attempt to switch on GCB while MCB is on will be ignored and

vice versa. Both MCB and GCB key have dual function of either switching

ON or OFF the respective contactor. A press shall toggle the state.

Continuously pressing these keys shall keep toggling the status. To stop the

generator, switch off the GCB contactor and press “STOP” key. Any attempt

to stop the generator, while the GCB contact is engaged, shall be ignored.

While the generator is running ECON-A protects the generator by monitoring

all internal and external faults.

Operating Instructions

Page - 8

Page 11

• 10.2 MCCB Shunt trip or Auto Stop Mode (ECON-A , ECON -A-4C or

ECON-S)

This mode is a mix of Manual and Auto mode. In this mode the engine is

manually started but its shut down on the restoration of the mains. To make

sure that the engine is not shut down on load and also to recool the engine

before shutting it down it has provision to activate the shunt trip coil of MMCB

before shutting it down it has provision to activate the shunt trip coil of MMCB

and isolate the generator from load and engine is stopped after running it for

the predefined recooling time.

Engine can be started or stopped either the front keys or remotely by use of

Remote start/stop keys. ECON will monitor the engine and alternator for any

fault and take corrective action

• 10.3 Manual Controller ( All models)

This mode is a pure manual operation mode. The engine has to be manually

started and stopped. The responsibility of disengaging the load from

generator and allowing the engine to cool before stopping has to be

performed by the operator. The engine and Alternators are protected while

the engine is running.

*RTC Based operation :

In ECON-M/ECON-S and other models when used as manual controller the

RTC based start stop can be activated. If activated the engine can be made

to automatically start at a given time of the day and stop at a predefined time.

• 11.0 Setting Procedure: How to Enter in Parameter Mode

Press Next & Reset switches simultaneously. The LCD shall display, “System

Parameter”

To enter System Parameter setting mode, press Next Switch, the LCD

shall display, “Enter Password” and default password is 123 then press

Next Switch. For any change in value, press Start switch and Stop

switch. For next parameter, press Next Switch.

To go to next menu press Start Switch the LCD shall display “Generator

Parameter” To enter Generator Parameter setting mode press Next Switch.

For any change in value, press Start switch and Stop switch. For next

parameter, press Next Switch.

To go to next menu press Start Switch the LCD shall display “AMF

Parameter” To enter AMF Parameter setting mode press Next Switch. For

any change in value, press Start switch and Stop switch. For next

parameter, press Next Switch.

Operating Instructions

Page - 9

Page 12

Operating Instructions

Page - 10

To go to next menu press Start Switch the LCD shall display “Protection

Parameter” To enter Protection Parameter setting mode press Next Switch.

For any change in value, press Start switch and Stop switch. For next

parameter, press Next Switch.

To go to next menu press Start Switch the LCD shall display “Comm Rs485

Parameter”To enter Comm RS-485 Parameter setting mode press Next

Switch. For any change in value, press Start switch and Stop switch.

For next parameter, press Next Switch.

To go to next menu press Start Switch the LCD shall display

“Display History” To View Display History mode press Next Switch.

To go to next menu press Start Switch the LCD shall display “Display Event”

To View Display Event mode press Next Switch.

To go to next menu press Start Switch the LCD shall display “Display

Start/Stop” To View Display Start/Stop mode press Next Switch.

To go to next menu press Start Switch the LCD shall display

“Reset Service Alarm”

To enter Reset Service Alarm mode press Next Switch. The LCD shall display

“Press START to Reset

Press STOP to ESC”

The unit shall ask for confirmation to reset the service hours pressing desired

Switch.

To go to next menu press Start Key the LCD shall display “Adjust Clock” To

enter Adjust Clock setting mode press Next Key. For setting up of the time,

press Start switch and Stop switch.

Press Next Key the LCD shall display DD/MM/YYYY. For setting up of the

date, press Start switch and Stop switch

To go to next menu press Start Key the LCD shall display “Reset Password”

To enter Reset Password setting mode

Press “Enter Password” then Press “Change Password” the LCD

shall display “

Press START to Change

Press STOP to ESC”

Page 13

• 12.0 Parameter Mode:

The following tables give the detailed descriptions. Please note that 20sec of

inactivity will take the unit back in normal mode and all the changes done

shall be cancelled.

• 12.1 System Parameter

Parameter

Name on

LCD & Icon

Explanation of Parameter

Factory

Setting

Setting Range

Enter

Password

Systems setting are password

protected. Password is a three digit

number

123

0-999

System

Config

ECON provides complete flexibility in

system designing; it is possible to

select auto and manual operation for

any combination of mains and DG

phases. E.g. mains 3 phase and DG

single phase or vice versa, or three

phase mains and DG, or single

phase mains and DG.

M:3P/G:1P

AMF M:3P/G:1P

AMF M:3P/G:3P

AMF M:1P/G:1P

MANUAL1P

MANUAL 3P

AUTO STOP 1P

AUTO STOP 3P

Solenoid

Type

Pull To Start

In this mode fuel solenoid contact

changes from Open to Close at the

time of cranking and remains close

till the genset is running. For stopping

the generator this contact opens.

Pull To Stop

In this mode fuel solenoid contact

remains open at the time of cranking

and till the genset is running. For

stopping the generator this contact

closes for a user programmed time.

Pull to

Stop

Pull to Stop

Pull to Start

LLOP

Sensor

Type

Select the installed sensor for LLOP

Type A

Type A

Type B,

M&M,

MNEPL,

VE, TMTL,

HUAFANG,

TATA,

GC(VDO), GC

(MURPHY),

Disabled *

A/M

Operating Instructions

Page - 11

Page 14

Fuel Sensor

Select the installed sensor for Fuel

Type A

Type A,

Sam-0,

Sam-1,

Electronics,

Linear,

0-5V(0-100%),

Disabled*

HWT

Sensor

Select the installed sensor for HWT

Type A

Type A,

Type B,M&M,

MNEPL,VE,

TMTL AIR 1C,

TMTL AIR 3C,

TMTL WATER

HUAFANG,

TATA,

GC(VDO),

GC(MURPHY),

Disabled *

Oil Temp.

Sensor

Select the installed sensor for Oil

Temp.

Type A

Type A,

Type B,M&M,

MNEPL,VE,

TMTL AIR 1C,

TMTL AIR 3C,

TMTL WATER

HUAFANG,

TATA,

GC(VDO),

GC(MURPHY),

Disabled *

Sensor

Open

User can select the action to be

taken in case of sensor open, it can

be configured as a fault, or as

warning or no action to be taken i.e.

disable.

Disabled

Disabled *

Fault

Warning

CT Ratio

Current Transformer ratio

1

1-9999

Gen. RPM

Engine RPM Type

1500RPM

1500RPM

3000RPM

OPEN

CT R

Operating Instructions

Page - 12

Page 15

KW

Contact ON

Pin 32,31,30

These are three programmable

output which can be configured for

any one function from the list

None

None Unit

Healthy Load

Warning Fuel

Pump Heater /

Choke Pull

Solenoid

Over

Load KW

The Power(KW) above which the

over load fault monitoring will start.

The timer for it is as described in 13.

This fault is only enabled while the

generator is running. On expiry of the

timer the generator is stopped

40

1-9999

Over

Current

The current above which the over

current fault monitoring will start. The

timer for it is as described in 13. This

fault is only enabled while the

generator is running. On expiry of the

timer the generator is stopped

50

1-9999

Over Load

Delay

This is the timer for the over load

condition either due to over KW or

over current. On expiry of this timer

the engine shall be stopped

5 Sec

1-999 Sec

Digital Input

1

This can be configured for one out

the listed below Parameters.

RWL

Oil Level

Oil Temperature

Canopy Temperature

RWL

RWL

Oil Level

Oil

Temperature

Canopy

Temperature

Digital Input

2

This can be configured for one out

the listed below Parameters.

LLOP

Oil Level

Oil Temperature

Canopy Temperature

LLOP

LLOP

Oil Level

Oil

Temperature

Canopy

Temperature

Digital Input

3

This can be configured for one out

the listed below Parameters.

FUEL

Oil Level,

Oil Temperature

Canopy Temperature

FUEL

FUEL

Oil Level

Oil

Temperature,

Canopy

Temperature

CT R

Operating Instructions

Page - 13

Page 16

Digital Input

4

This can be configured for one out

the listed below Parameters.

HET

Oil Level

Oil Temperature

Canopy Temperature

HWT

HWT

Oil Level

Oil

Temperature,

Canopy

Temperature

Digital Input

5#

This can be configured for one out

the listed below Parameters.

Canopy door open

Oil Level

Oil Temperature

Canopy Temperature

Oil Temp.

Oil Level

Oil Temp.,

Canopy Temp.

Digital Input

6#

This can be configured for one out

the listed below Parameters.

Fire

Oil Level

Oil Temperature

Canopy Temperature

Oil Level

Oil Level

Oil

Temperature

Canopy

Temperature

Digital Input

7#

This can be configured for one out

the listed below Parameters.

Fuel Warning

Oil Level

Oil Temperature

Canopy Temperature

Earth

Fault

Earth Fault

Oil

Temperature

Oil Level

Digital input

1 polarity

Normally open: Open contact is

healthy.

Normally close: Close contact is

healthy.

Normally

open

Normally

closed

Normally open

Digital input

2 polarity

Normally open: Open contact is

healthy.

Normally close: Close contact is

healthy.

Normally

open

Normally

closed

Normally open

Digital input

3 polarity

Normally open: Open contact is

healthy.

Normally close: Close contact is

healthy.

Normally

open

Normally

closed

Normally open

Operating Instructions

Page - 14

Page 17

Operating Instructions

Page - 15

Fan High

Current

Maximum limit for fan current

2.0

0-3.5

Fan Low

Current

Minimum limit for fan current

0.2

0-3.5

Fan Current

Delay

This is the timer for fan current trip.

5

1-100

>

>

Digital input

4 polarity

Normally open: Open contact is

healthy.

Normally close: Close contact is

healthy.

Normally

open

Normally

closed

Normally open

Digital input

5 polarity #

Normally open: Open contact is

healthy.

Normally close: Close contact is

healthy.

Normally

open

Normally

closed

Normally open

Digital input

6 polarity #

Normally open: Open contact is

healthy.

Normally close: Close contact is

healthy.

Normally

open

Normally

closed

Normally open

Digital input

7 polarity #

Normally open: Open contact is

healthy.

Normally close: Close contact is

healthy.

Normally

open

Normally

closed

Normally open

Page 18

Operating Instructions

Page - 16

• 12.2 Generator Parameter

Generator

O/V

Max. Permissible Generator voltage,

above this the Generator voltage is

treated unhealthy & the Generator is

stopped on voltage fault.

270V

50-300V

Generator

U/V

Min. permissible Generator voltage,

below this the Generator voltage is

treated unhealthy & the Generator is

stopped on voltage fault.

180V

50-300V

Gen Voltage

Delay

Duration for which generator

Over/Under voltage condition can be

tolerated before stopping the

Generator.

10 Sec

1-999 Sec

VOLT

Generator

O/F

Max. Permissible Generator frequency, above this the Generator frequency is treated unhealthy & the Generator is stopped on frequency fault.

65Hz

25-70Hz

Disable*

Generator

U/F

Min. permissible Generator

frequency, below this the Generator

frequency is treated unhealthy & the

Generator is stopped frequency fault.

45Hz

Disable*

25-70Hz

Gen Freq

Delay

Duration for which Generator Over

/Under frequency condition can be

tolerated before stopping the

Generator. This setting is not

available if (4)&(5) are disabled

5 Sec

1-999 Sec.

Current

Unbalance

IN

The maximum permissible current

unbalance in %. The unbalance

starts only after the system is loaded

to 25% of its capacity

Disable

5-100%

Disable

Current

Unbalance

Delay

Duration for which the current

unbalance can be tolerated before

triggering the fault

10 Sec

1-999Sec

Pickup

Voltage

This parameter specifies the

generator voltage at which it is

presumed to have started and crank

has to be terminated

100V

80-150V

Hz

Hz

Hz

A

A

U

U

U

Page 19

Operating Instructions

Page - 17

Service Due

Hr

Time, in hours, for next service due

warning.

250Hrs

10-999 Hrs

Crank Cut

Method

Auto disconnects the crank

command on detection of either

voltage buildup/ voltage or oil

pressure build up

Voltage

Only

Voltage only

Voltage or

LLOP

Pick Up

KVA

warning

If the current level crosses this limit

the contact is energized after the

programmed supervision time

8

1-9999

KVA

Reset KVA

warning

If the current level falls below this

limit the contact is de-energized after

the programmed supervision time.

8

1-9999

KVA

Warning

Delay

The supervision time for the above 2

parameters.

5

1-999Sec

Choke Pre

time

Keep the choke for this time before

the engine has started.

Disable

Disable*

1-999 Sec

Choke Post

time

Keep the choke for this time after the

engine has started.

Disable

Disable*

1-999 Sec

Pump Pre

Time

Activate the Pump by this time before

cranking

2

1-999Sec

Engine Off

Time

In manual mode, some time its

required to switch off/on the engine

at a predetermined time. This setting

set the time for automatic switch off

of the engine

Disable

00:01 to23.59

Disable *

KVA

KVA

E û

Page 20

Operating Instructions

Page - 18

Engine On

Time

In manual mode, some time its

required to switch off/on the engine

at a predetermined time. This setting

set the time for automatic switch ON

of the engine

Disable

00:01 to23.59

Disable*

Eü

Mains O/V

Max. Permissible Mains voltage,

above this the Mains voltage is

treated unhealthy & Generator is

started

270V

50-300V

Mains U/V

Min. permissible voltage, below this

the voltage is treated unhealthy &

Generator is started

180V

80-300V

12.3 AMF Parameter

Mains

Voltage

Delay

Duration for which Mains Over/Under

voltage condition can be tolerated

before starting the Generator.

10

1-999 Sec

Mains O/F

Max. Permissible Mains frequency,

above this frequency the Mains is

treated unhealthy & Generator is

started.

65Hz

40-70Hz

Disable*

Mains U/F

Min. permissible Mains frequency,

below this frequency the Mains is

treated unhealthy & Generator is

started.

45Hz

Disable*

40-70Hz

Mains Freq

Delay

Time for which the Mains frequency

has to be unhealthy (under or over

frequency as defined above in 4 & 5)

before starting the Generator.

5 Sec

1-999 Sec.

Voltage

Unbalance

Max. allowed voltage unbalance in

volt

Disable

10-100 Volt

Disable*

Voltage

Unbalance

Time

Duration for which unbalance can be

allowed before starting the

Generator. This parameter is not

available if above is set to disabled.

10

1-999Sec

VOLT

Hz

Hz

Hz

V

V

Page 21

Operating Instructions

Page - 19

Phase

Sequence

Delay

This setting determines if the engine

shall be started and load switch to

generator in case of reverse phase

sequence of mains.

Disable

Disable

1-999 Sec

Mains

Restoration

Time

The time for which Mains should be

continuously healthy before stopping

the Generator and load transferred to

Mains.

10 Sec

1-999 Sec

Warm Up

Time

The load is transferred to generator

after expiry of this time

0Sec

0-999 Sec

Gen Start

Delay

The starting of generator is delayed

by this time after the mains unhealthy

timers have expired and the mains

contact has been released. This is

required in certain applications where

immediate generator starting is not

required but the mains contactors are

to be protected. This timer is

automatically reset, if during this

duration the mains become healthy

for “Mains Restoration Delay”

Disable

Disable*

1-999 Mins

Gen. 0n

Time

Max. duration for which the generator

is allowed to work continuously

Disable

Disable*

1-999 Mins

Gen Rest

Time

If the generator has run continuously

as per above parameter, the generator is given rest irrespective of the

mains condition. In case of mains

unhealthy during this time the mains

contact is deactivated but the

generator is not started.

This is unavailable if above is

Disabled This timer is automatically

reset, if during this duration the

mains become healthy for “Mains

Restoration Delay”

Disable

Disable *

1-999 mins

Page 22

Operating Instructions

Page - 20

Mains Over

Load

Econ-A can protect contactors from

mains over load. If this setting is

enabled than the mains contactor

shall drop after the mains current

crosses the set limit for a

programmed duration

Disable

Disable*

2-9999Amps

Mains O/L

Delay

The monitoring duration for the

above parameter before the fault is

triggered.

5 Sec

1-999 Sec

Contactor

Protection

In case of the unit placed under

manual mode of tripped due to a fault

condition and the mains voltage falls

below the safe limit of the contactor,

the contactor burns after chattering.

This can be avoided by enabling this

protection. If enabled the mains

contactor shall drop if the mains

voltage becomes unhealthy and the

contactor will again engage after the

mains voltage turns healthy

Disable

Disable /

Enable

Mains Fail

Some application require the

generator to start on failure of one or

more phases

Other wants all the 3 phases to

become unhealthy before starting the

generator

ECON-A can handle both situations

Any

Phase

Fail

Any Phase

Fail/

All Phase

Fail

GCB to

MCB Delay

User programmable delay when the

load is transferred from Generator to

Mains.

2 Sec

1-10 Sec

Recool

Time

The time for which generator is

allowed to run on no load before

switching off

30 Sec

0-999Sec

1/3

Page 23

Operating Instructions

Page - 21

Service

Delay hour

In AMF mode,if this parameter is

enabled, the engine will automatically

start after this periodic time lapse

from the last start. This is meant for

periodic function

Disabled

2-999 Hrs

Service Run

min.

The genset will work for this duration

in service run mode. It will stop

automatically after expiry of this time.

During this time if the mains become

unhealthy the generator contactor

shall be engaged and the engine

shall be stopped after the mains is

healthy

Disabled

1-999 Min

Disabled

s

s

Contact

Type

This setting is for units which have

external change over. The sections

are change over(external) or

contactors (built in and controlled by

ECON)

Contactor

Change over

Contactor

• 12.4 Protection Parameter

Fuel Warn

Level

Monitoring value of fuel level below

which fuel level warning is

generated.

25 %

Disable*

11-80 %

Fuel Warn

Delay

Monitoring time of fuel level after

which fuel level warning is

generated.

10 Sec

1-999Sec

Fuel Trip

Level

Monitoring value of fuel level below

which fuel level trip is generated.

15 %

10-80 %

Fuel Trip

Delay

Monitoring time of fuel level after

which fuel level trip is generated.

10 Sec

1-999 Sec

Page 24

Operating Instructions

Page - 22

LLOP Trip

Level

Monitoring value of lube oil pressure

below which LLOP trip is generated.

1.0

2

Kg/cm

0.4-8.5

2

Kg/cm

LLOP Trip

Delay

Monitoring time of lube oil pressure

after which LLOP trip is generated.

10 Sec

0-999 Sec

HWT Trip

Level

Monitoring value of water

temperature below which HWT trip is

generated.

90

40-250

Disabled*

HWT Trip

Delay

Monitoring time of water temperature

after which HWT trip is generated.

5 Sec

1-999 Sec

Oil Temp.

Trip Level

Monitoring value of Oil temperature

below which Oil Temp. trip is

generated.

90

40-250

Disabled*

Oil Temp.

Trip Delay

Monitoring time of Oil temperature

after which Oil Temp. trip is

generated.

5 Sec

1-999 Sec

D1-D7

Input Delay

Delay for 7 programmable digital

inputs . Digital input are explained

above.

5 sec

1-999 Sec

Chg Alt-

V Belt Delay

Duration for which the V-Belt signal

should be continuously deactive to

be recognized as a fault and action

initiated. This fault is only enabled

while the generator is running.

Disable

Disable*

2-999 Sec

Hooter ON

Time

Duration for which the hooter shall be

ON, if not externally reset, while

announcing a fault.

30Sec

1-999 Sec

Page 25

Operating Instructions

Page - 23

Crank ON

Time

Maximum crank time

5 Sec

1-999 Sec

Crank Gap

Time

The delay between two successive

cranks

5 Sec

1-999 Sec

Crank

Attempts

The maximum number of cranks that

shall be issued to start the Engine

3

1-10

Solenoid

ON time

The time for which stop solenoid will

be kept active while stopping the

engine

22 Sec

1-999Sec

Disp Auto

Scroll

Setting ON will enable Auto Scroll of

display. OFF: No scroll and next

parameter can be viewed by

pressing next switch

ON

ON/OFF

Battery UV

Warning

Min. permissible battery voltage,

below this the voltage is treated

unhealthy & warning is generated.

Disabled

Disabled*

9-35V

Battery OV

Warning

Max. permissible battery voltage,

above this the voltage is treated

unhealthy & warning is generated.

Disabled

9-35V

Disabled*

N

• 12.5 Comm RS485 Parameter #

Device Id

Modbus device ID

1

1-247

Baud Rate

RS 485 Communication Baudrate

9600

1200

2400

4800

9600

19200

Parity

RS 485 Communication Parity Bits

None

Even

Odd

None

Page 26

Page - 24

Operating Instructions

Stop Bit

RS 485 Communication Stop Bits

1

1

2

• 12.6 Reset Service Alarm

Press INC to Reset

Press DEC to esc

• 12.7 Adjust Clock

Automatic real time based DG Start

& Stop (Manual Controller

Configuration) RTC Time and Date

can be easily entered

00.00

00.00

DD/MM/YYYY

• 12.8 Reset Password

Three digit password protection for

system settings

Password can be change easily.

* This parameter can be disabled while programming

# These Parameters are model dependent

Note: To save the parameter, switch of and switch on the controller.

• 13.0 Model Selection Chart

Model

AMF

Mode

Manual

Mode

Auto Stop

Mode

D5-D7

Input

Oil Temp.

Sensor

ECON-A-4C

√√√√√

ECON-A

√√√XX

ECON-S

X√√XX

ECON-M

X√XXX

Page 27

Operating Instructions

Page - 25

• 14.0 Load Management

ECON-A has programmable contact Load management function. The load

management contact will switch on when the current on the generator

has crossed a programmed limit and will reset when the current has fallen

below the reset programmed limit. This function can be used to cut-off

unnecessary loads or start a second generator when the load goes above a

limit.

• 15.0 Event Recording:

ECON keeps a log of last 64 events. Setting change and warning are

considered as event. Events are stamped along with date and time

• 16.0 Faults

ECON keeps a log of last 64 Faults. These Faults are stamped along with date

and time There are two categories of faults

• Internal Faults

• External faults

• 16.1 Internal Faults

Internal faults are the faults, which do not need any external signals and are

detected by the system itself. They are:

• Generator Fails to Start. • Generator Voltage Unhealthy

• Generator Frequency Unhealthy. • Generator over Speed.

• Generator Fails to Stop. • Over Load

• 16.2 External Faults

Those faults which cannot be sensed by the unit itself (these faults are not

reflected by the generator voltage) and are to be provided externally. They are:

• LLOP • HWT • Oil Level

• RWL • Fuel • Oil Temp.

• Emergency • V-Belt • Earth Fault

• 16.3 Fault Reset

Internal Faults & LLOP fault:

All internal faults and LLOP fault can be reset by pressing (R) switch after the

generator is stopped. External Fault except LLOP & V-Belt faults:

These faults cannot be reset till the engine is running and/or fault conditions

persist. Once the faults are rectified, the fault can be reset by pressing Reset

switch (R). In case the engine fails to stop “STOP KEY” can be pressed for

manual attempt to stop engine

• 17.0 Communication

• Rs232 • USB

• Modbus on Isolated Rs485 (optional)

Page 28

Operating Instructions

Page - 26

Terminal No.

Description

1

Fan Current S1

2

Fan Current S2

3

NC

4

CT Common

5

CT B

6

CT Y

7

CT R

8

Sensor Oil Temp.

9

Sensor LLOP

10

Sensor HWT

11

Sensor Fuel

12

V-DG-N

13

V-DG-B

14

V-DG-Y

15

V-DG-R

16

V-Mains-N

17

V-Mains-B

18

V-Mains-Y

19

V-Mains-R

20

NC

21

NC

22

NC

23

D Input 4

24

D Input 3

25

D Input 2

26

D Input 1

27

Emergency

28

SemiAuto

29

R Start/Stop

30

Programmable Output 3

• 18.0 Terminal Numbers

Page 29

Operating Instructions

Page - 27

31

Programmable Output 2

32

Programmable Output 1

33

Hooter

34

Solenoid

35

Crank

36

GCB

37

MCB

38

Chg. Alt. Contact

39

Battery(+ve)(8-35 V DC)

40

Battery(-ve)

41

Sensor(-ve)

42

D Input 5

43

D Input 6

44

D Input 7

45

D(+): RS485

46

D(-):RS485

Page 30

Operating Instructions

Page - 28

Connect the wires as per the labelling done in back sticker:

Page 31

• 19.0 Technical Specifications

AC voltage withstand 330 VAC (Phase to neutral)

Measurement Accuracy

Voltages & Current 1% of Reading

Power & Energies 2% of Reading

Surge 1.2/50Usec 2.5KV

Battery Voltage 9-35 V DC

DC Interruption time 0.4 Sec

Cut out Dimensions 155mm X 117mm

Depth 41.8 mm

Digital Input Level Battery Voltage (Negative)

Digital Output Battery Voltage (Negative)

Page 32

• 20.0 Dimensions

Loading...

Loading...