Page 1

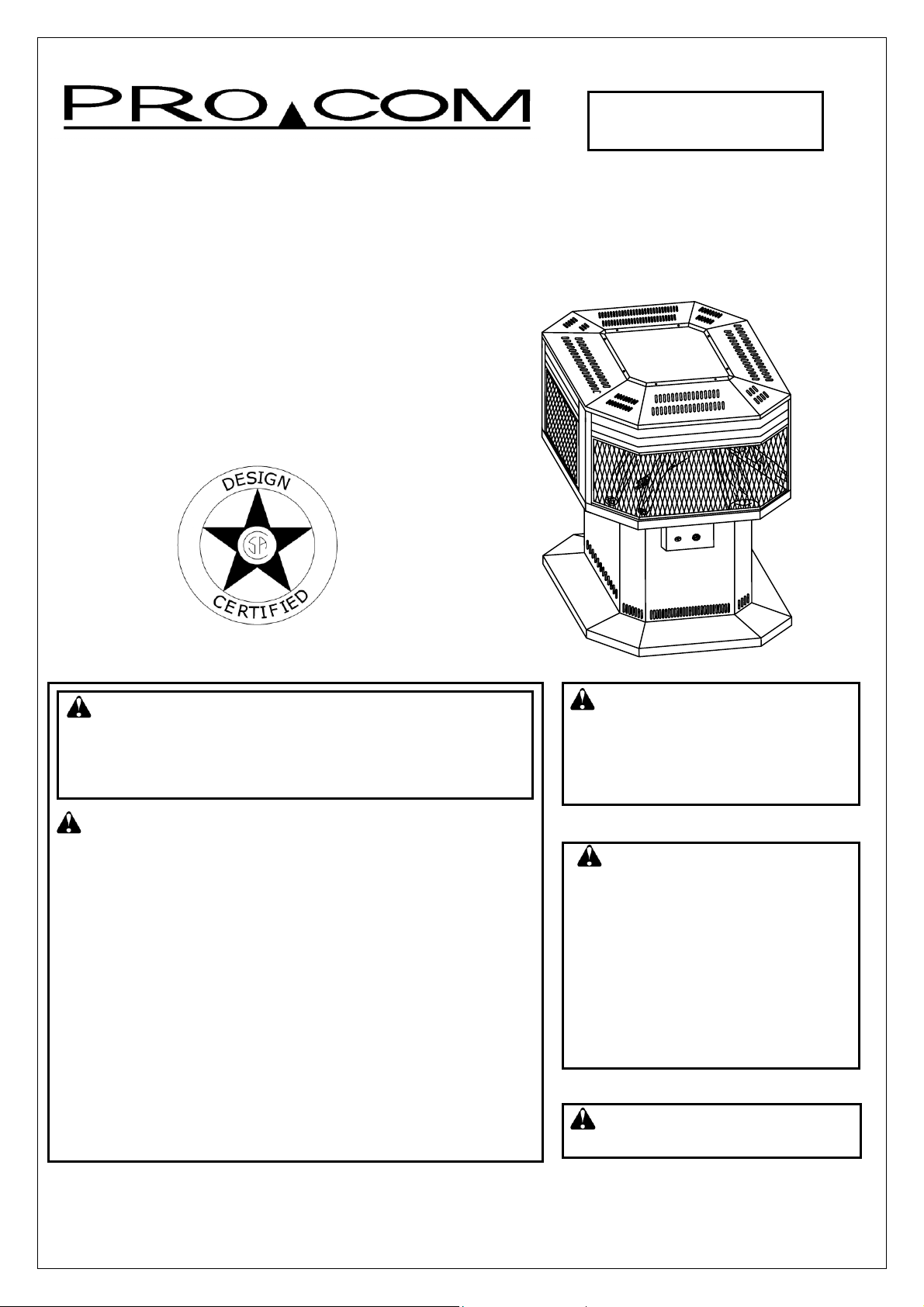

OUTDOOR GAS

FIREPLACE

OWNER’S OPERATION AND INSTALLATION MANUAL

AL500HYLA

50,000 BTU/Hr

Manually Controlled

WARNING: If the information in this manual is

not followed exactly, a fire or explosion may result

causing property damage, personal injury, or loss

of life.

FOR YOUR SAFETY :

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switches; do not use

any phones in your building.

Immediately call your gas supplier from a

neighbor’s phone, follow the gas supplier’s

instructions.

If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

IMPORTANT: Read this

owner's manual carefully and

completely before trying to

assemble, operate, or service

this heater.

WARNING: Improper

installation, adjustment,

alteration, service, or

maintenance can cause injury

or property damage. Read the

installation, operating and

maintenance instructions

thoroughly before installing or

servicing this equipment

WARNING: FOR Outdoor Use

Only.

Save this manual for future reference.

Installer: Leave this manual with customer.

Page 2

SAFETY INFORMATION

2

-

1. Check the heater completely and thoroughly for

damage. DO NOT run a damaged heater.

2. DO NOT alter the heater or operate a heater that

has been modified from its original condition.

3. Use only propane gas.

4. Use only vapor withdrawal propane gas. If any

question, contact your LP dealer.

5. Do not use this heater as a wood-burning heater.

Use only the logs provided with the heater.

6. Inspect hose assembly before each use of the

heater. If there is excessive abrasion or hose is cut,

STOP USING HEATER! Replace with a new hose.

7. This heater is for outdoor use only. Even so make

sure that there is ample fresh air ventilation. Do not

use in buildings, garages or other enclosed spaces.

8. In the event that gas odor is detected,

IMMEDIATELY STOP operation until gas supply

has been located and corrected.

9. Do not place the heater where directly exposed to

water spray, rain, dripping water or wind.

10. Maintain minimum clearance to people or normal

combustible material (like paper) of 2 feet.

11. Place heater on a stable, level surface.

12. You must operate the heater with the heater

screen in place. Make sure heater screen is in

place before running heater.

13. This heater is designed to be smokeless. If logs

ever appear to smoke, turn off heater and call a

qualified service person. Note: during initial

operation, slight smoking could occur due to log

curing and heater burning manufacturing residues.

14. Do not attempt to move, handle or service while

heater is hot or in operation.

15. Use only in accordance with local codes or, in the

absence of local codes, with the National Fuel Gas

Code ANSI223.1-1996.

16. Do not hang or attach clothing or any other

flammable materials on or near the heater.

17. Carefully supervise young children when they are

in the vicinity of heater.

18. Heater becomes very hot while running. Keep

children and adults away from hot surface to avoid

burns or clothing ignition.

19. Installation and repair should be done by a

qualified service person. The appliance should be

inspected before use and at least annually by a

qualified service person. More frequent cleaning

may be required as necessary. It is imperative that

control compartment, burners and circulating air

passageways of the appliance be kept clean.

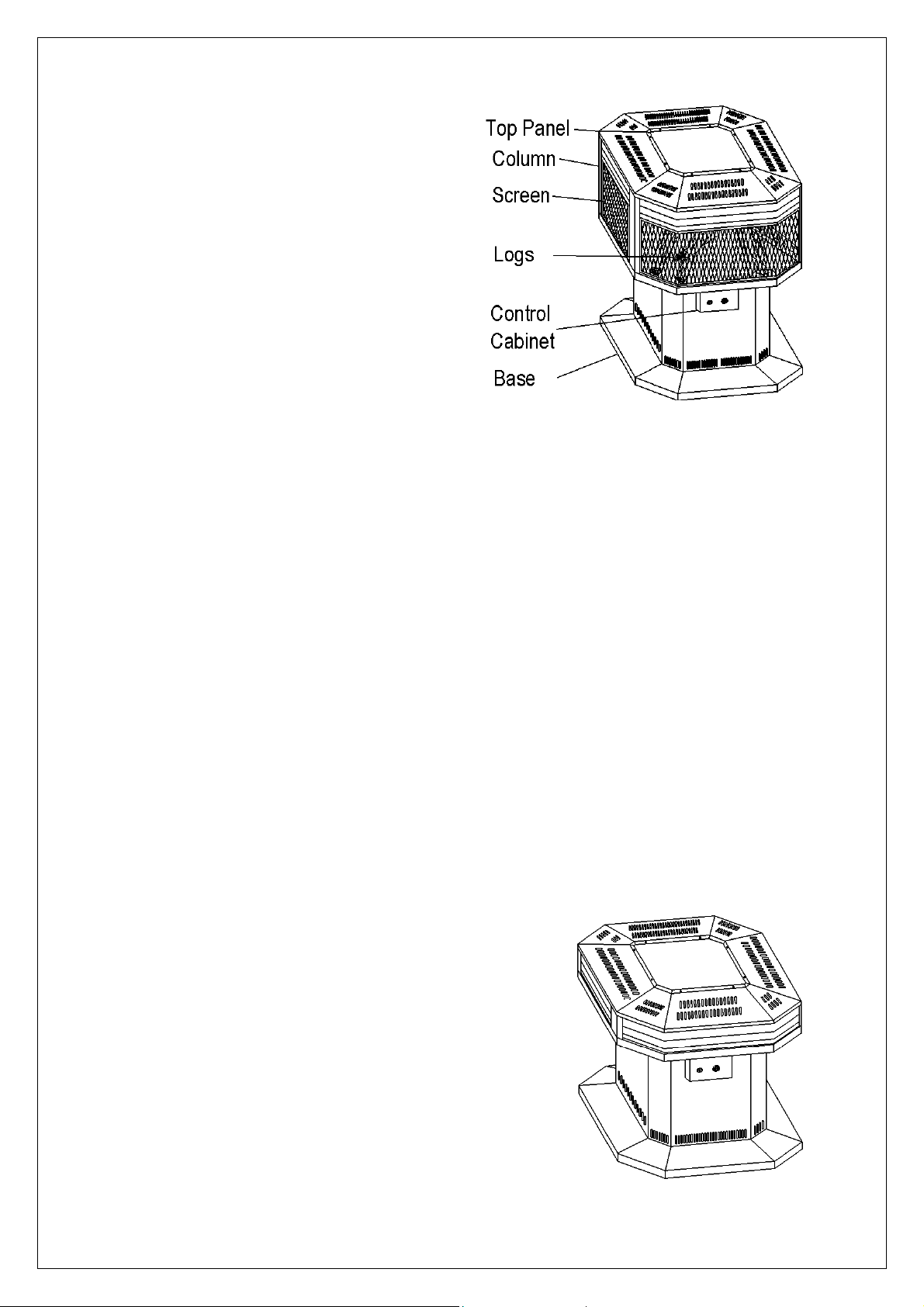

PRODUCT IDENTIFICATION

LOCAL CODES

Install and use heater with care. Follow all local codes.

In the absence of local codes, use the latest edition of

The National Fuel Gas Code, ANSZ223.1, also known

as NFPA54*.

Available from :

American National Standards Institute, INC.

1430 Broadway, New York, NY10018

National Fire Protection Association, INC.

Batterymarch Park Quincy. MA 02269

UNPACKING

1. Remove top inner pack.

2. Slide stove out of carton and set it on the flat floor.

3. Remove protective packaging.(See FIG.2)

4. Remove plastic wrap and carton from MID base.

5. Turn the door knob clockwise, open heater door to

take out log set, Remove all protective plastic wrap.

6. Unwrap log set by cutting plastic ties.

7. Check for any shipping damage. If stove or log is

damaged, promptly inform dealer where you bought

the stove.

Figure

2 AL058-01

shipping fireplace

Page 3

PRODUCT FEATURES

SAFETY PILOT

The heater has a pilot with a safety shutoff system.

The safety pilot is a required feature for outdoor

heaters. It shuts off the heater if flame is extinguished

by rough wind.

PIEZO IGNITION SYSTEM

This heater has a piezo igniter. This system requires

no matches, batteries, or other sources to light heater.

INSTALLATION

TOOLS REQUIRED:

●

Philips screwdriver

●

Wrench

Check if you have the items listed below before

installation.

●

Logs: 10 ● 4×14 self-tapping screw: 5

●

M4×10 screw: 32 ● M5×10 screw: 4

●

Column: 4 ● Log grate: 1

●

Fixing hoop: 1 ● Hex head screw: 2

●

Handle: 1 ● Screen: 4

3 AL058-01

Caution: Some of the steel edges may

be sharp. Please use caution when

assembling the unit.

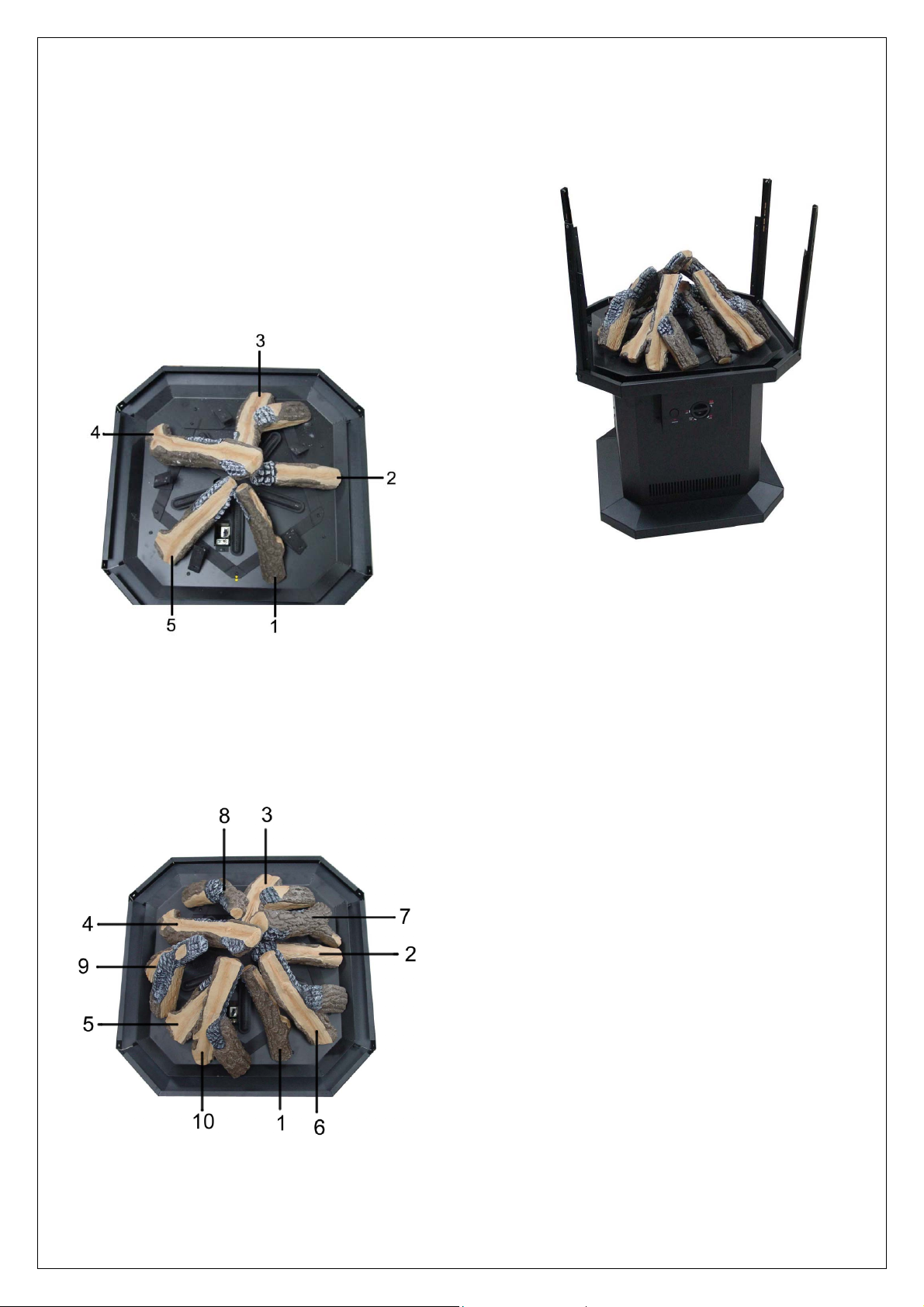

INSTALLATION INSTRUCTIONS:

1. Remove grate out of base and set flat on floor.

2. Take log foam package out of base. Please note

each log fits the number marked on foam package.

3. Unscrew the 16 screws that attach the top panel

and the middle base with short columns. Remove

top panel and short columns. Then set flat on the

floor. (See FIG. 3)

Note: Short Columns and Self-tapping Screws are

used for packing only.

Figure 3-Burner fixing plate

4. Place grate on burn plate. Make sure to line up the

red mark and five holes of grate with that of burn

plate. Then secure grate to burn plate with 5 4×

14 Self-tapping Screws. (See FIG.4)

Figure 4-Place grate on burn plate

Page 4

INSTALLATION INSTRUCTIONS

5. Install logs 1,2,3,4,5 by inserting each log

screw into holes of corresponding grate

branch . Make sure each log is placed in

proper sequence.(See FIG 5.)

Note: If the log is too loose or the screw can’t be

pulled down after inserting the log screw, screw the

nuts to adjust the clearance between nuts and

logs.

Figure 5-Installing log 1.2.3.4.5

6. Install logs 6,7,8,9,10 as step 5.(See FIG.6)

Continued

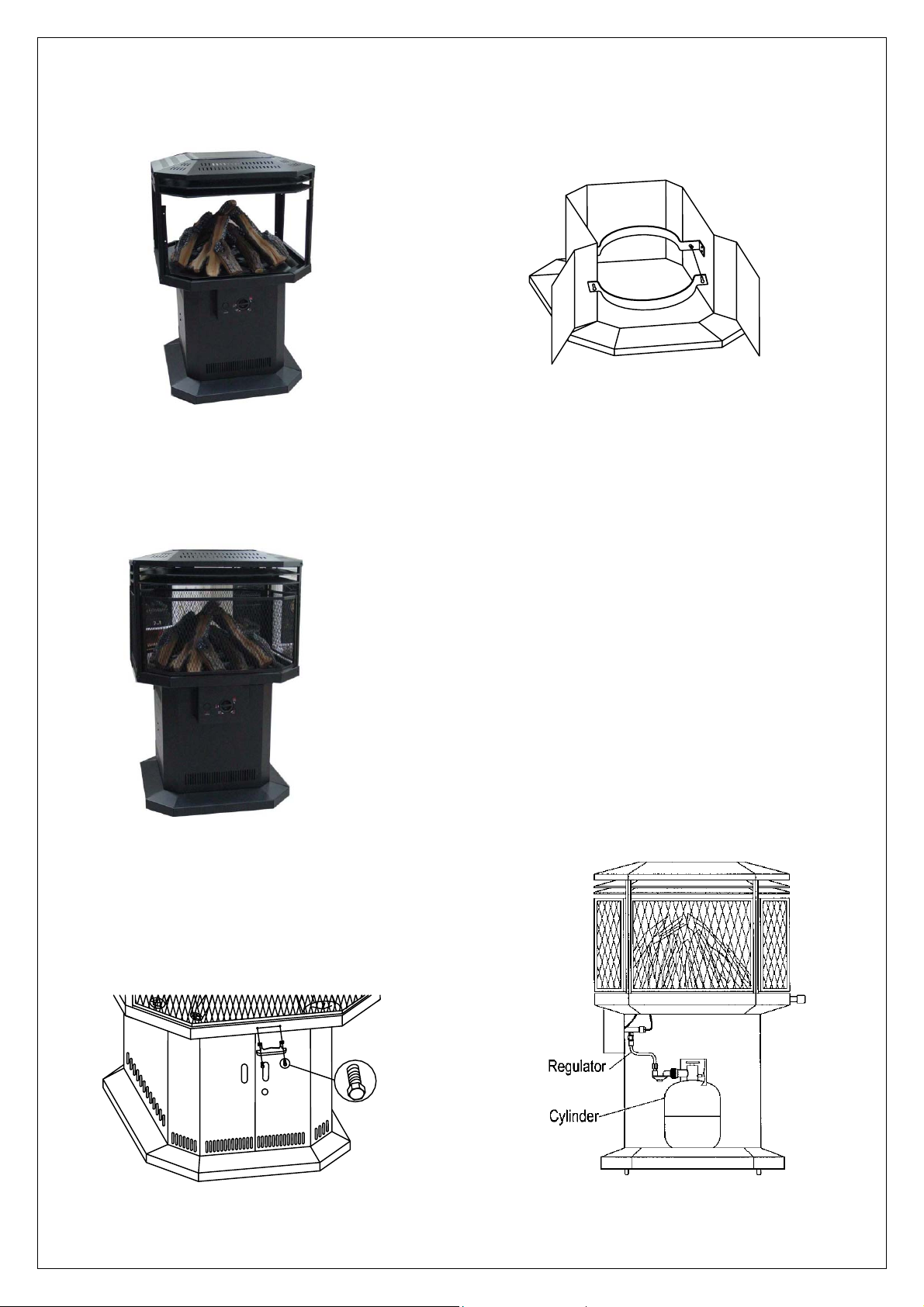

Attach the four columns to the burner plate with

7.

M4×10 screws provided. Do not tighten at this

time. (See FIG.7)

Figure 7-Column installation

Figure 6-Installing log 6.7.8.9.10

4 AL058-01

Page 5

8. Set the top panel in place on the columns and

secure with M4×10 screws provided. Do not

tighten at this time. (See FIG.8)

12. From the outer side, use M5×10 screws to

fasten the fixing hoop on the right and left support.

Fasten the other side of the fixing hoop after the

cylinder is in place. (See FIG.11)

Figure 11-The fixing hoop installation

Figure 8-Top panel installation

9. Attach the screens to columns with M4× 10

screws provided. Do not tighten at this time. (See

FIG.9)

Figure 9-Screens installation

10. Tighten the screws of step 8,9,10 to finish

installation.

11. Attach the handle to the middle base with 2 hex

head screws provided. (See FIG.10)

CONNECTING TO GAS SUPPLY

Note: The installer must supply an external regulator

with a hose (with 5/8” nut at one end, and a regulator

at the other end) and a 20# Vertical Acme with OPD

LP cylinder.

1. Turn the door knob clockwise and open heater

door.

2. Remove dustproof wrap from regulator.

3. Set cylinder flat on base compartment (See FIG.12)

4. Connect regulator with cylinder. Tighten with care.

Do not over-pressurize the valve.

5. Before opening gas supply valve, make sure

control knob is in the OFF position. Open gas

supply valve. Apply a mixture of liquid soap and

water to all joints. Do not use an open flame.

Bubbles forming show a leak. Check all

connections for leaks immediately.

Figure 10-Handle installation

5 AL058-01

Figure 12-Cylinder set and pipe

installation

Page 6

CONNECTING TO GAS SUPPLY

Continued

FUEL REQUIREMENTS:

Connect regulator/hose with standard 20-pound

LP cylinder coupler.

Call the LP gas supplier to inspect the cylinder.

Do not use a damaged LP gas cylinder.

Do not use LP gas without proper

decompression.

Do not connect irregular LP gas supply with

heater.

Use only LP gas on this heater. Do not convert to

other gases.

OPERATING HEATER

Continued

TO TURN OFF HEATER:

1. Turn gas control knob to the “OFF” position.

2. If heater is not to be used, shut off cylinder valve.

3. Do not attempt to relight heater within 5 minutes

after the propane cylinder valve has been closed.

RESTART HEATER:

1. Turn gas control knob clockwise to “OFF” position.

2. Wait 5 minutes before restarting.

3. Repeat step 5,6,7.

MAINTENANCE AND STORAGE

CAUTION: It is dangerous to use a damaged

or rusted cylinder.

OPERATING HEATER

This heater is designed for use with LP gas. You may

light the heater directly.

LP gas is heavier than air. If it leaks from joint, it may

sink down to the floor and mix with ambient air to form

a detonable mixture. If you have questions, contact

your LP dealer for instructions or service.

Warning: Fire, burn, inhalation and explosion

hazard. Keep solid combustibles, such as

building materials, paper or cardboard, at safe

clearances from the heater. Never use heater in

the vicinity of gasoline, solvent, paint thinner or

other combustibles.

Caution: When heater runs in the presence of

other people, the user is responsible to properly

offer those present safety precautions and

hazard information.

LIGHTING INSTRUCTIONS:

Follow adaptable lighting instructions. Apply soap

solution to all joints. Bubbles forming show a leak. Do

not use a match or an open flame to detect leak. Light

heater after ensuring that no gas leak exists.

START HEATER:

1. Turn the control valve knob clockwise to the “OFF”

position.

2. Turn the door knob clockwise and open the heater

door.

3. Check all connections as described in the

“Connecting to Gas” section of this manual on

page 5.

4. Fully open the valve on the propane cylinder.

5. Push in gas control knob and turn it to IGN/ON

position. Then Push and release the ignition button

repeatedly until there is a flame at the pilot.

6. Keep control knob pressed in for 30 seconds after

ignition, then release.

7. Turn the burner on to maximum rate and then set

to desired setting or remain on HI.

8. Replace heater compartment door.

1. The Lp-gas supply cylinder to be used must be

constructed and marked in accordance with the

specifications for LP-gas cylinder of the U.S.

Department of transportation.

2. Storage of an appliance indoors is permissible only

if the cylinder is disconnected and removed from

the appliance. Cylinders must be stored outdoors

in a wellventilated area out of the reach of children.

Disconnected cylinders must have threaded valve

plugs tightly installed and must not be stored in a

building, garage or any other enclosed area.

3. The pressure regulator and hose assembly

supplied with the appliance must be used and a

statement that replacement pressure regulators

and hose assemblies must be those specified by

the appliance manufacturer.

4. If the connection to the LP-gas cylinder is other

than Type I, II or III (as described in the Standard

for Cylinder Connection Devices, ANSI

Z21.81/CGA 6.25), the cylinder with its mating

fitting shall be provided by the appliance

manufacturer. Supplying the cylinder may be

accomplished by a method controlled by the

manufacturer that will result in both the appliance

and the cylinder being available at the time of

purchase.

5. The cylinder supply system must be arranged for

vapor withdrawal.

6. The cylinder used must include a collar to protec t

the cylinder valve.

7. Have the heater inspected by qualified service man

before each use or at least annually.

8. Check the POL fitting for any damage before each

use and replace if any damage is found.

9. Turn off cylinder valve when the heater is not to be

used.

6 AL058-01

Page 7

MAINTENANCE AND STORAGE

r

Continued

11. Spiders and insects can nest and live in outdoor

appliances, especially in the burners and orifices.

This will interrupt the normal flow of LP gas to the

heater and can be a very dangerous situation.

Inspect for insect infiltration of burner/orifice when

one of the following occurs:

A. The smell of gas along with predominating yellow

tipping of the burner flames.

B. Heater can not reach desired temperature.

C. Uneven burner flow.

D. Burner makes popping noises d uring n ormal use or

shutdown.

12. When heater to be stored outdoors, detach

connection between LP cylinder and heater.

Remove cylinder from heater and store in

accordance with chapter 5 of the standard for

Storage and Handling of liquified gas.

13. Adopt rainproof cover (provided with the heater) to

avoid rust of heater when not in use.

WARNING: Local codes for installation of propane

systems may vary considerably. Therefore, ask your

local propane supplier for advice on propane system

installation. In the absence of local codes, install in

accordance with Standard for the Storage and

Handling of Liquified Petroleum Gases ANSI/NFPA

58-1995 and National Fuel Gas Code ANSI

Z223.1-1996. Your supplier, fire marshal or library

should have a copy. The propane used must be

arranged for vapor withdrawal. Propane cylinders

must be secured in the upright position to keep them

from falling or being knocked over.

GENERAL INFORMATION

During use, liquid propane in a cylinder vaporizes. As

it vaporizes, the propane cools itself. If this cooling

process lasts too long and proceeds too fast, the

propane temperature and pressure will fall so low that

the heater operation may be improper or even halt.

Often frost forming on the outside of the propane

container warns excessive refrigeration.

Recommendations on how to reduce refrigeration:

A. Provide considerably more propane than you plan

to consume, it’s better to provide twice as much.

B. Fill containers frequently, especially in cold

weather. Never allow propane to fall below

one-third of container capacity.

CLEANING AND MAINTENANCE

CAUTION:

top panel of heater clean. Inspect these areas of

heater before each use. Have heater inspected

yearly by a qualified service person.

WARNING: Shut off heater and let cool before

servicing.

You must keep control areas and

PILOT AND BURNER:

Clean dust with a vacuum cleaner.

BURNER AIR INLET HOLE:

We recommend that you clean the unit every three

months or after 2500 hours operation. We also

recommend that you keep the burner tube and pilot

assembly clean and free of dust. To clean these parts,

we suggest using compressed air no greater than 30

PSI. You can also use a vacuum cleaner in the blow

position. If using compressed air in a can, please

follow the directions on the can. Otherwise, you might

damage the pilot assembly.

1. Shut off the unit, including the pilot. Allow the unit to

cool for at least thirty minutes.

2. Inspect burner, pilot, and primary air inlet holes on

injector holder for dust and dirt. (See FIG.13)

3. Blow air through the ports/slots and holes in the

burner.

4. Check the injector holder again, remove any large

particles of dust and dirt with a soft cloth or vacuum

cleaner nozzle.

5. Blow air into the primary air holes on the injector

holder.

6. In case large clumps of dust have been pushed into

the burner, repeat steps 3 and 4.

Clean the pilot assembly also. A yellow tip on the pilot

indicates dust and dirt in the pilot assembly.

Figure 13-Injector Holde

On Outlet Burner Tube

EXTERIOR:

Use a soft cloth dampened with a mild soap and water

mixture. Wipe the cabinet to remove dust.

LOGS:

If you remove logs for cleaning, refer to installing logs,

Pages 3 and 4 to properly replace logs. Replace logs

if broken or chipped.

MAIN BURNER:

Periodically check all burner flame holes with the

heater running. All slotted burner flame holes should

be open with a yellow flame present. Some burner

flame holes may become blocked by debris or rust,

with no flame present. If so, turn off heater and let

cool. Either remove blockage or replace burner.

Blocked burner flame holes will create soot.

7 AL058-01

Page 8

t

SERVICE INDICATIONS:

A hazardous condition may result if a heater has

been modified or is not functioning properly. When

the heater is working properly:

1. The flame is contained within the heater.

2. The flame is essentially yellow.

3. There is no strong disagreeable odor, eye

burning or other physical discomfort.

4. No smoke or soot exists internal or external to

the heater.

5. No unplanned or unexplained shut down of the

heater occur.

REPLACEMENT

REPLACEMENT PARTS:

Note: Use only original replacement parts. This will

protect your warranty coverage for parts replaced

under warranty.

PARTS UNDER WARRANTY:

Contact authorized dealers of this product. If they

can't supply original replacement part(s) call

PRO-COM's Technical Service Department a

1-877-886-5989 for referral information.

When calling PRO-COM or your dealer, have

ready

Your name

Your address

Model and serial numbers of your heater

How heater was malfunctioning

Type of gas used (propane/LP or natural gas)

Usually, we will ask you to return the defective

part to the factory.

PARTS NOT UNDER WARRANTY:

Contact authorized dealers of this product or Parts Central if

they can't supply original replacement part(s) Call PRO-COM's

Parts Department at 1-877-886-5989 for referral information.

When calling PRO-COM, have ready

Model number of your heater

The replacement part number

ACCESSORIES

Purchase these heater accessories from your local

dealer or Parts Central. If they cannot supply these

accessories call PRO-COM’s Sales Department at

1-877-886-5989 for referral information. You can also

write to the address listed on the back page of this

manual.

SPECIFICATIONS

Btu 50000

Gas Type LP Gas Only

Ignition Piezo

Inlet Gas Pressure* (In. of water)

Maximum 13”

Minimum 11”

Dimensions, Inches (HxWxD)

Stove 42 9/16”x26”x26”

Carton 30 5/16”x27 3/4”x27 3/4”

Weight, Lbs

Stove 141

Shipping Weight 163

* For purpose of shipment adjustment.

TROUBLESHOOTING

OBSERVED PROBLEM

Burner does not light.

When ignitor buttons pressed in, there

is no spark at safety Pilot.

Burner fire does not last.

8 AL058-01

POSSIBLE CAUSE REMEDY

1. Air in gas lines.

2. Inlet gas pressure is too low.

3. Gas supply turned off.

4. Air passageway on heater blocked.

5. Burner orifice clogged.

6. Control knob not in ING/ON position.

7. Control knob not fully pressed in while

in ING/ON position.

1. Ignitor electrode positioned wrong.

2. Ignitor electrode broken.

3. Broken ignitor cable.

4. Ignitor electrode not connected to

ignitor cable.

1. Damaged thermocouple.

2. Thermocouple electrode

corrosion.

3. Damaged control valve.

4. Control knob not pressed long

enough.

5. Thermocouple connection

loose at control valve.

6. Pilot flame not touching

thermocouple.

1. Continue holding down control knob.

Repeat igniting operation until air is

removed.

2. Check gas pressure.

3. Fully open gas supply.

4. Check air passageway.

5. Clean burner.

6. Turn control knob to ING/ON position.

7. Press down control knob.

1. Reposition ignitor.

2. Replace ignitor.

3. Replace ignitor cable.

4. Connect electrode to ignitor cable.

1. Replace thermocouple.

2. Clean thermocouple electrode.

3. Replace control valve.

4. After ODS/pilot lights, keep control

knob pressed in for 30 seconds.

5. Hand tighten connection or replace

thermocouple.

6. Contact qualified service man.

Page 9

PARTS LIST

HP500MA

This list contains replaceable parts used in your heater. When ordering parts, follow the

instructions listed under Replacement Parts on page 7 of this manual.

KEY

NO.

1

2 AB29001

3

4

5

6

7

8

9

10

11

12

PART

NUMBER

AB01001

AB29002

AL002-01

AL009-01

AL01002

AL033-01

AL013-01

AL011-01

AB01004

AB01005

AL071-01

DESCRIPTION QTY.

Top Panel

Mesh Screen

Mesh Screen

Column

Burner Fixing Plate

MID Base

Support Part

Support

Door

Base

Universal Wheel Fixing Plate

Universal Wheel

1

2

2

6

6

6

1

1

2

1

1

4

9 AL058-01

Page 10

ILLUSTRATED

PARTS BREAKDOWN

AL500HYLA

10 AL058-01

Page 11

PARTS LIST

HP500MA

KEY

NO.

1

2

3

4

5

6

7

PART

NUMBER

NBY50-200A1

NDW-L600×4

AB31002

NV2020-1217

AL031-01

AB31001

AL030-01

This list contains replaceable parts used in your heater. When ordering parts, follow the

instructions listed under Replacement Parts on page 7 of this manual.

DESCRIPTION QTY.

Burner

Safety Pilot

Safety Pilot Inlet Tube ASM

Control Valve

Washer

Gas Outlet Tube ASM

Control Valve Main Inlet Nut

1

1

1

1

1

1

1

8 AL016-01

9 ML031-03

10

11

12

ML083-03

ML029-01

AL037-01

Control Cabinet

Control Knob

Ignitor

Control Valve Fixing Nut

Injector

1

1

1

1

1

11

AL058-01

Page 12

ILLUSTRATED

PARTS BREAKDOWN

AL500HYLA

12

AL058-01

Page 13

LOGS LIST

This list contains replaceable parts used in your heater. When ordering parts, follow the

instructions listed under Replacement Parts on page 7 of this manual.

AL500HYLA

KEY

NO.

1

2

3

4

5

6

7

8

PART

NUMBER

AL057-01

AL057-02

AL057-03

AL057-04

AL057-05

AL057-06

AL057-07

AL057-08

DESCRIPTION QTY.

Log 1

Log 2

Log 3

Log 4

Log 5

Log 6

Log 7

Log 8

1

1

1

1

1

1

1

1

9

10

AL057-09

AL057-10

Log 9

Log 10

1

1

13 AL058-01

Page 14

LOGS LIST

AL500HYLA

NANJING PRO-COM ELECTRIC APPLIANCE CO.,LTD.

#6 CHUANGYE ROAD, HIGH NEW TECH. ZONE,

NANJING, 210061, CHINA

PRO-COM Toll-Free number: 1-877-886-5989

14 AL058-01

Loading...

Loading...