TM

TYTAN

Inline Water Heater

Instruction Manual

7010 Lindsay Dr., Mentor, OH 44060 Phone: 440-974-1300 Fax: 440-974-9561 USA/CN: 800-621-1998

www.process-technology.com

TABLE OF CONTENTS:

RELATED DOCUMENTS ...............................................................................................3

INTRODUCTION............................................................................................................. 4

SYSTEM SPECIFICATIONS .......................................................................................... 6

MODEL NUMBER.........................................................................................................10

MODEL NUMBER EXPLANATION.........................................................................................................11

FACILITY REQUIREMENTS ........................................................................................13

WATER PLUMBING REQUIREMENTS..................................................................................................14

ELECTRICAL REQUIREMENTS............................................................................................................14

INSTALLATION............................................................................................................ 15

INSPECTION AND UNCRATING ...........................................................................................................15

POSITIONING AND MOUNTING..................................................................................17

PLUMBING..............................................................................................................................................18

WIRING ...................................................................................................................................................20

RC1, RC2 COMMUNICATIONS (OPTIONAL)........................................................................................22

RC3 COMMUNICATIONS (OPTIONAL).................................................................................................23

RI REMOTE INTERFACE (OPTIONAL) .................................................................................................23

OPERATIONS ..............................................................................................................25

CONTROL PANEL..................................................................................................................................25

TEMPERATURE CONTROLLER E5CN.................................................................................................26

PARAMETER SETTINGS E5CN.........................................................................................................29

CHANGING SET POINT E5CN...........................................................................................................30

HIGH ALARM E5CN............................................................................................................................30

PID TUNING E5CN..............................................................................................................................31

TEMPERATURE CONTROLLER E5CK (RC OPTIONS).......................................................................32

PARAMETER SETTINGS E5CK.........................................................................................................35

CHANGING SET POINT E5CK...........................................................................................................36

HIGH ALARM E5CK............................................................................................................................37

PID TUNING E5CK..............................................................................................................................38

OVER TEMPERATURE CONTROLLER: FDC-L91................................................................................39

SYSTEM START UP...............................................................................................................................42

SYSTEM SHUT DOWN...........................................................................................................................42

MAINTENANCE............................................................................................................ 43

WARRANTY .................................................................................................................44

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

2

RELATED DOCUMENTS:

The following documents are to be used in conjunction with this manual:

ANSI/NFPA70 – National Electric Code→, latest edition. To be used to determine

appropriate electrical service, wire sizing, routing and protection.

SEMI S2 – Semiconductor Equipment Safety Guidelines, latest edition. To be used in

conjunction with safe operation, access and decommissioning procedures.

OMRON E5CN INSTRUCTION MANUAL – To be used to access features of the E5CN

temperature controller. (Secure appropriate manual for any optional temperature

controller used in place of the E5CN).

OMRON E5CK INSTRUCTION MANUAL (for units with RC1, RC2 or RC3 option) –

To be used to access features of the E5CK temperature controller.

ANY – State or local building codes that would cover the electrical, mechanical, or

physical installation of electrical heating equipment.

National Electric Code

NFPA 1999 Copyright

National Fire Protection Association

Quincy, Mass. 02269

→

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

3

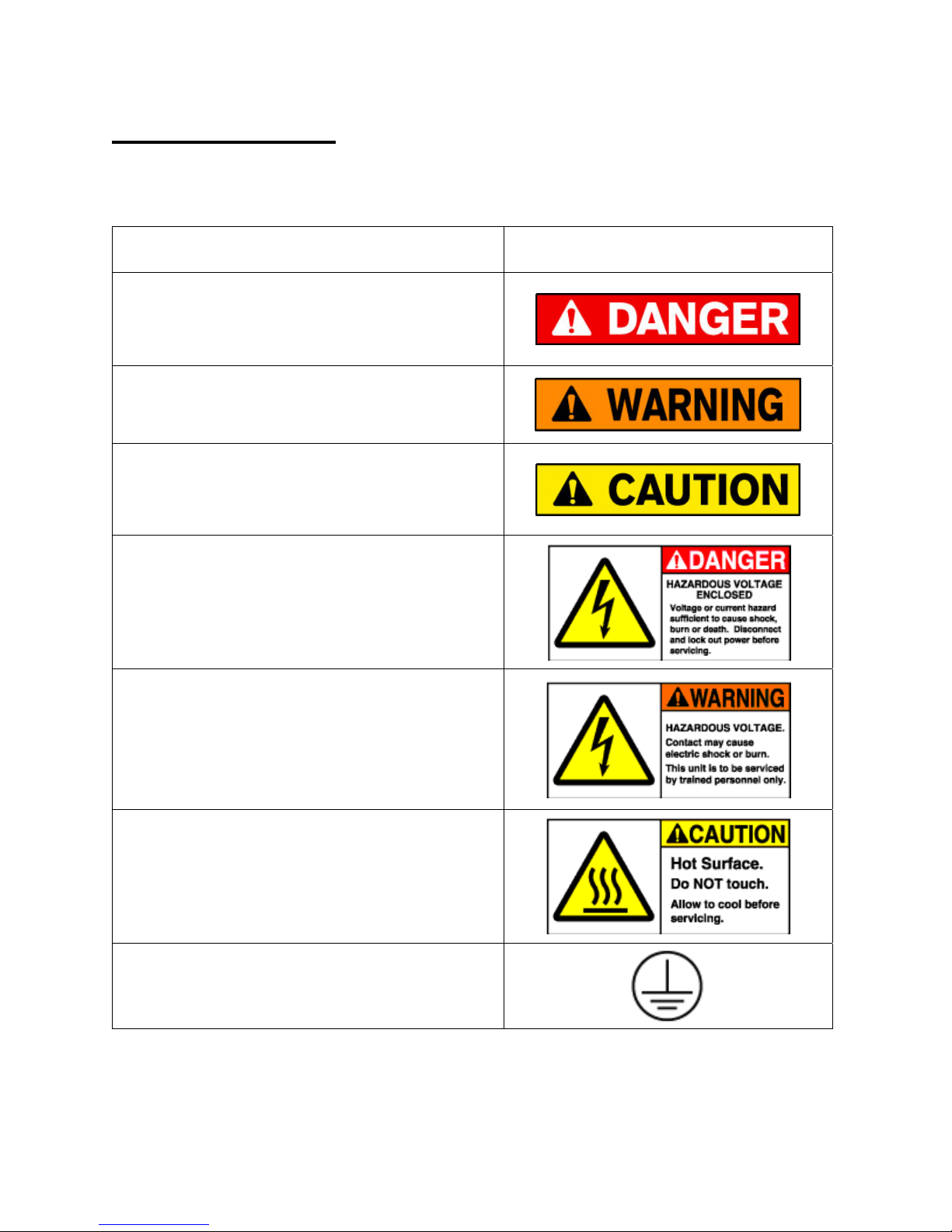

INTRODUCTION:

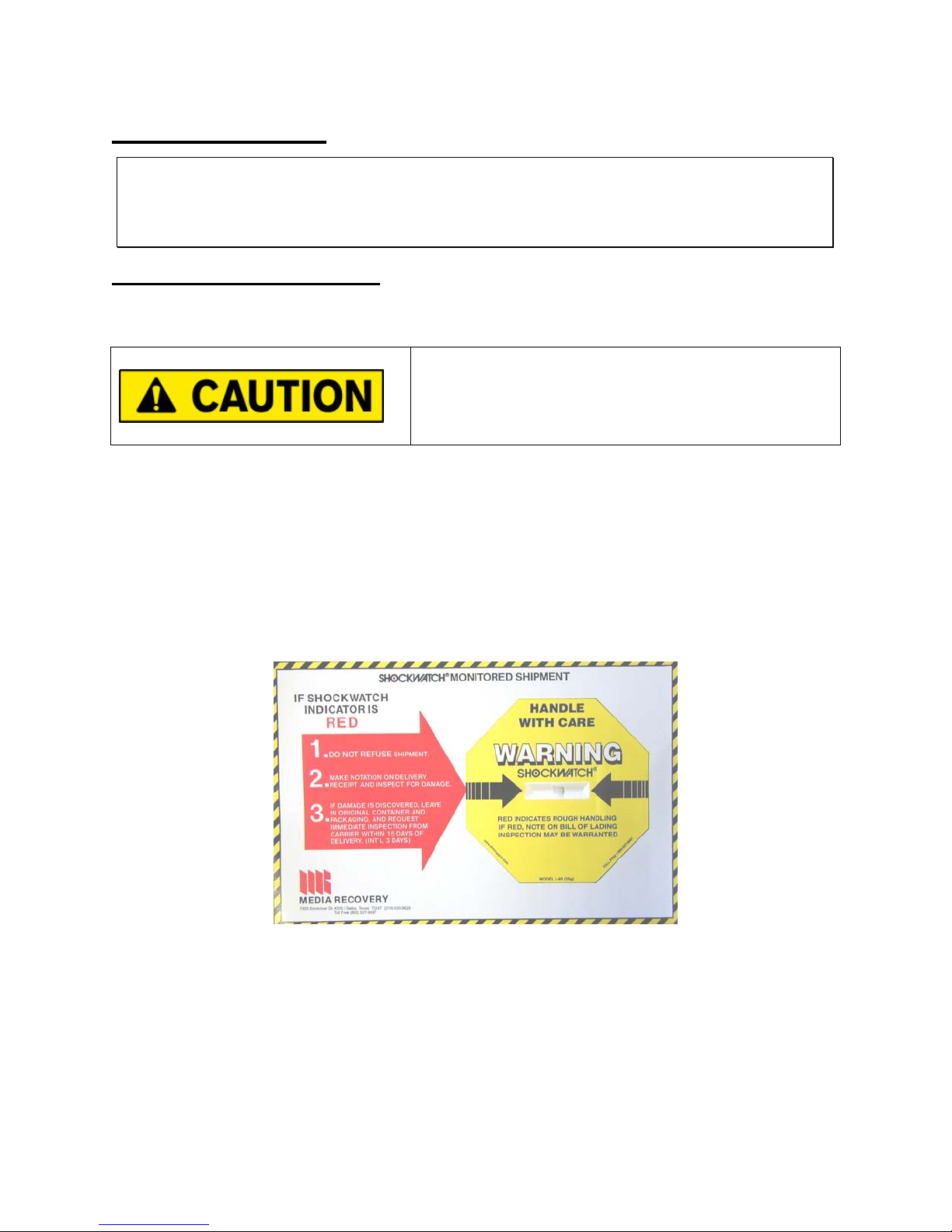

The following symbols and warning labels appear on the unit and in the instruction

manual. The table below provides an explanation of each one.

DESCRIPTION

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury. This signal word is to

be limited to the most extreme situations.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. It may also be used

to alert against unsafe practices.

DANGER: HAZARDOUS VOLTAGE

ENCLOSED

Voltage or current hazard sufficient to cause

shock, burn or death. Disconnect and lock

out power before servicing.

WARNING: HAZARDOUS VOLTAGE

Contact may cause electric shock or burn.

This unit to be serviced by trained personnel

only.

PICTORAL DESCRIPTION

CAUTION: HOT SURFACE. DO NOT

TOUCH

Heater column may be hot. Allow unit to cool

before servicing.

PROTECTIVE EARTH (GROUND)

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

Table 1: TYTAN Warning Labels

4

INTRODUCTION (Continued):

The TYTAN water heater is designed for inline heating of de-ionized (DI) water, city

water, reverse-osmosis (RO) water, and filtered seawater. It can perform both as a

recirculating heater or a single-pass heater.

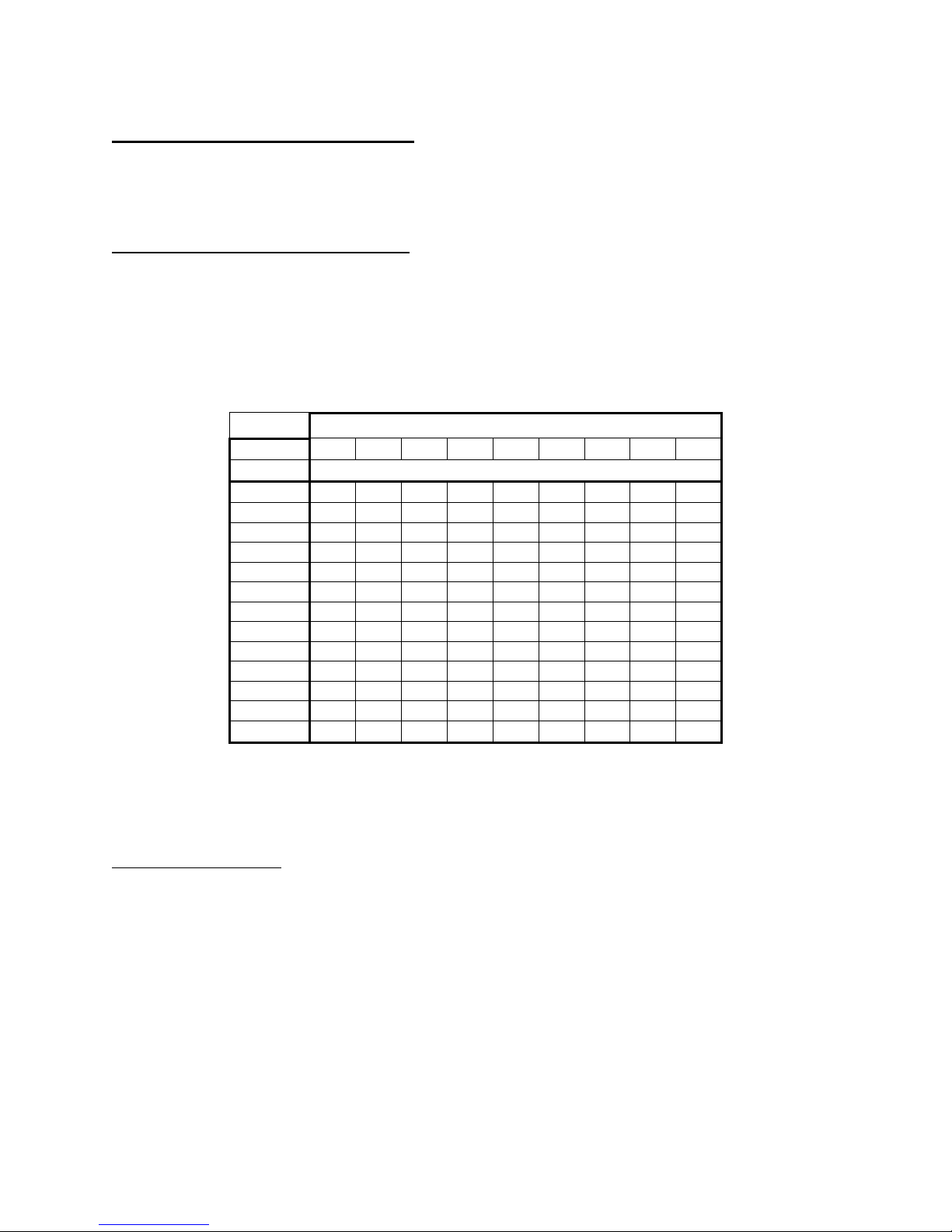

TEMPERATURE PERFORMANCE: The TYTAN water heater is designed to provide a

specified temperature increase at a given flow rate. Table 2 shows the maximum

temperature increase (∆T) that can be achieved for continuous flow conditions at the

specific heater power ratings varying from 24 kW to 144 kW (Higher wattage systems

available upon request). The temperature control system provided with the heater will

modulate the power to the heating columns in order to maintain your specific outlet

temperature setting.

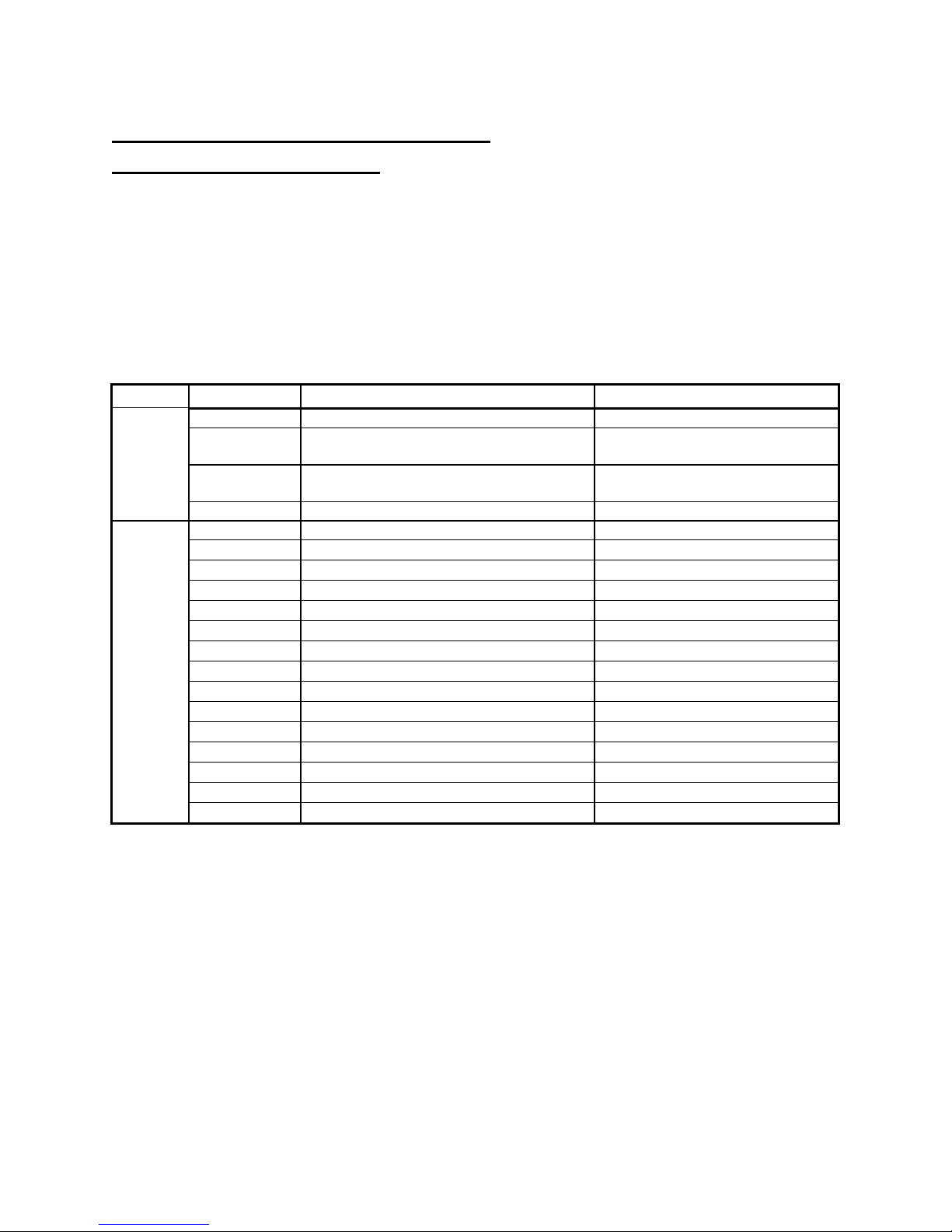

Flow Rate 12 18 24 36 48 72 96 120 144

GPM Maximum Theoretical Temperature Rise (°F)

1 80.8 121.2 - - - - - - 2 40.4 60.6 80.8 121.2 - - - - 4 20.2 30.3 40.4 60.6 80.8 121.1 - - 6 13.5 20.2 26.9 40.4 53.8 80.8 107.7 134.6 -

8 10.1 15.1 20.2 30.3 40.4 60.6 80.8 101.0 121.2

10 8.0 12.1 16.1 24.2 32.3 48.4 64.6 80.8 96.9

12 6.7 10.1 13.4 20.2 26.9 40.4 53.8 67.3 80.8

14 5.7 8.6 11.5 17.3 23.0 34.6 46.1 57.7 69.2

16 5.0 7.5 10.1 15.1 20.2 30.3 40.4 50.5 60.6

18 4.5 6.7 8.9 13.4 17.9 26.9 35.9 44.8 53.8

20 4.0 6.0 8.0 12.1 16.1 24.2 32.3 40.4 48.4

22 3.6 5.5 7.3 11.0 14.6 22.0 29.3 36.7 44.0

24 3.3 5.0 6.7 10.1 13.4 20.2 26.9 33.6 40.4

Heater Power (Kilowatts)

Table 2: Maximum Temperature Rise

SAFETY DEVICES: The TYTAN water heaters include a comprehensive system of

safety controls and devices to insure safe and long-lasting operation. The list of

safeties is included in Table 3: system specifications provided on the following page.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

5

SYSTEM SPECIFICATIONS:

Product TYTAN inline titanium water heater

Standards UL, cUL standard

CE, SEMI S3 optional (-SC)

Available Wattage Range

Available Voltages

Cabinet dimensions: Width Depth Height Weight

12kW – 48kW 28.5-in (75 cm) 13.5-in (34 cm) 36-in (91 cm) 145 lbs. (66 kg)

72kW 37.5-in (95 cm) 13.5-in (34 cm) 36-in (91 cm) 230 lbs. (104 kg)

96kW – 144kW 28-in (71 cm) 17-in (43 cm) 63-in (160 cm) 300 lbs. (136 kg)

Wetted surfaces:

Heating elements CP2 titanium standard, (316SS optional [-S option])

Columns and plumbing CP2 titanium standard, (316SS optional [-S option])

PRV Valve PVDF

Operating temperatures:

Process inlet

Process outlet Up to 194°F (90°C), depending upon operating conditions

Temperature accuracy +/- 1°F, depending upon operating conditions

Ambient air temperature 86°F (30°C) maximum

Water pressure range

Minimum water flow rate:

12kW - 24kW 0.5 gpm (2 lpm)

36kW – 48kW 1.0 gpm (4 lpm)

72 kW 1.5 gpm (6 lpm)

96kW 2.0 gpm (8 lpm)

120kW 2.5 gpm (10 lpm)

144kW 3.0 gpm (12 lpm)

Standard Safety Devices: EMO Pushbutton

12kW – 144kW

Refer to model number label for the wattage of any specific unit

208V – 600V, 50/60Hz, 3 phase standard

(Some voltages available in single phase or with special construction,

consult factory for details)

Minimum 10 psi (69 kPa, 0.69 bar)

Maximum 100 psi (690 kPa, 6.9 bar)

Pressure Relief Valve (PRV), connected to inlet manifold

Electrically grounded heating chamber construction

Ground Fault Protection (GFP)

Safety Limit Control (SLC)

Bimetallic heater over temperature sensor(s)

Heater outlet overtemperature alarm

Solid state relay (SSR) overheat bimetallic sensor

Sensor failure detection

Control circuit fuse protection

Table 3: TYTAN Specifications

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

6

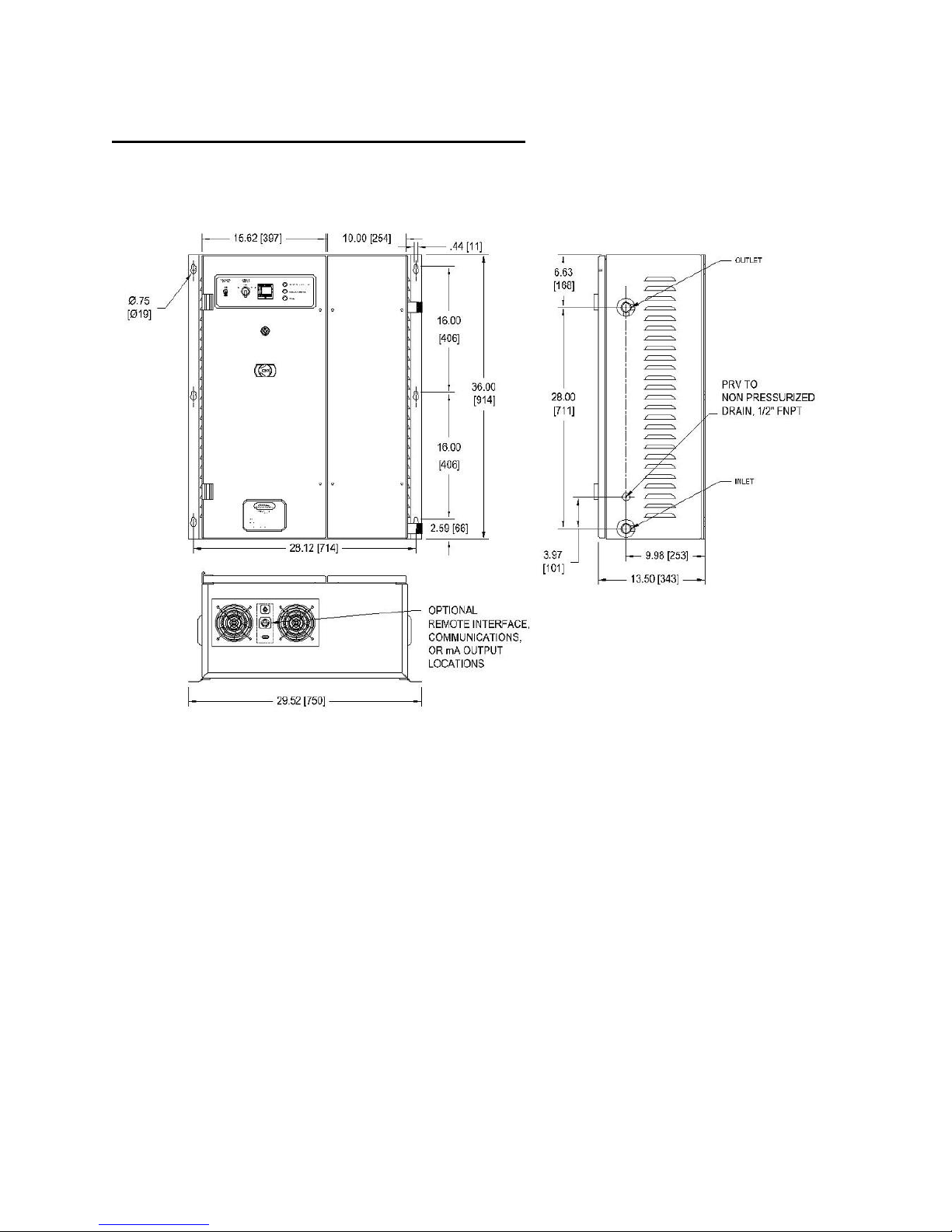

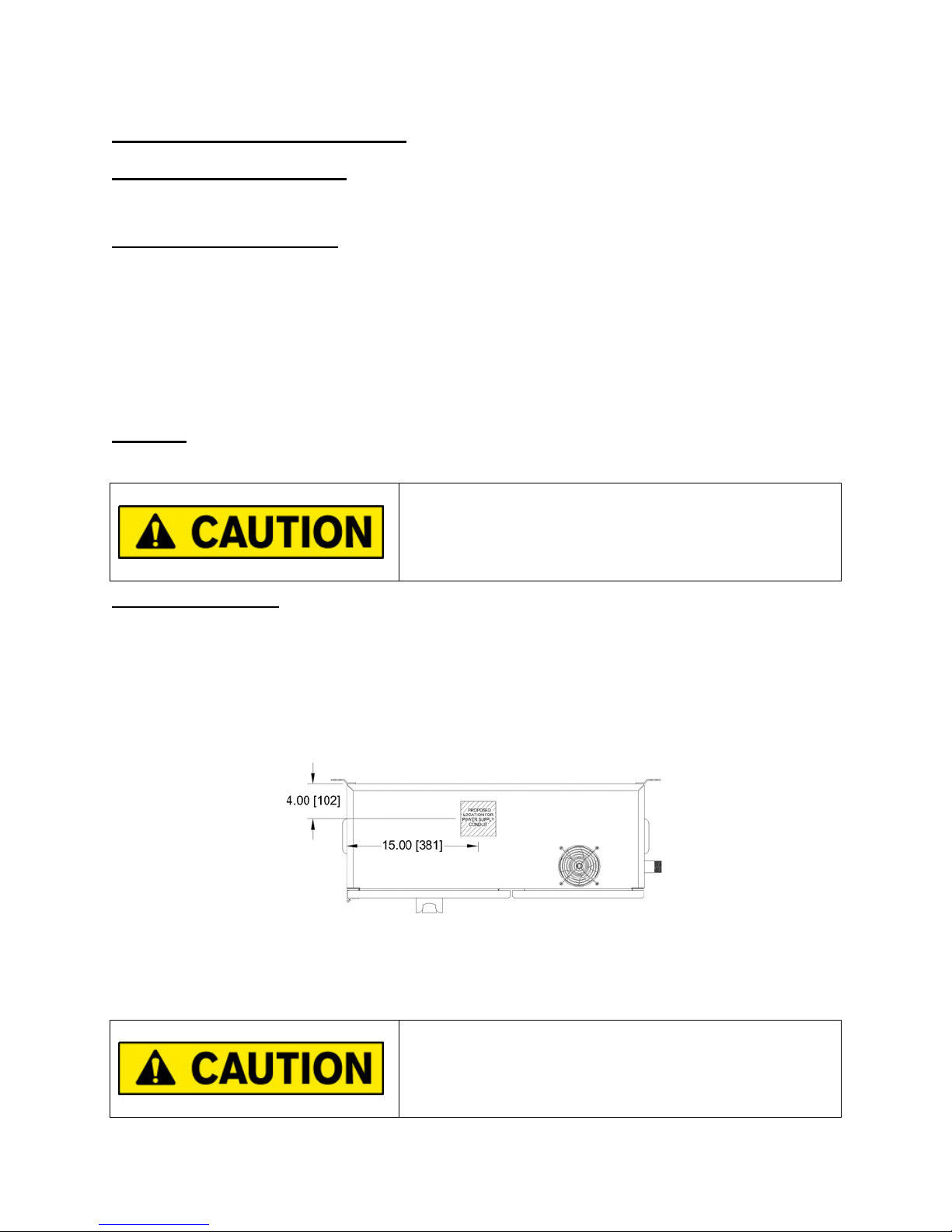

SYSTEM SPECIFICATIONS (Continued):

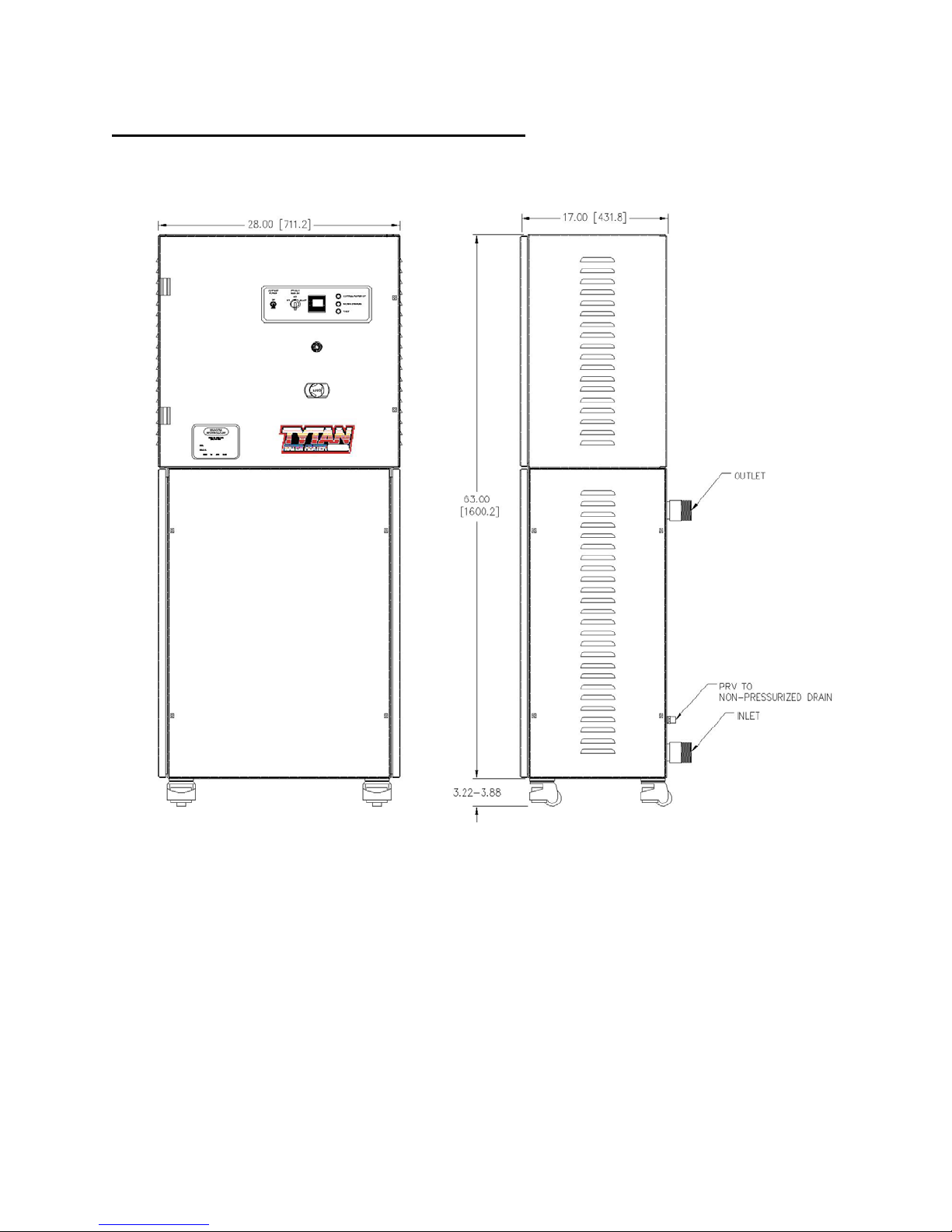

Figure 1: Dimensional Drawing, 12kW – 48kW Units

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

7

SYSTEM SPECIFICATIONS (Continued):

Figure 2: Dimensional Drawing, 72kW Unit

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

8

SYSTEM SPECIFICATIONS (Continued):

Figure 3: Dimensional Drawing, 96kW – 144kW Units

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

9

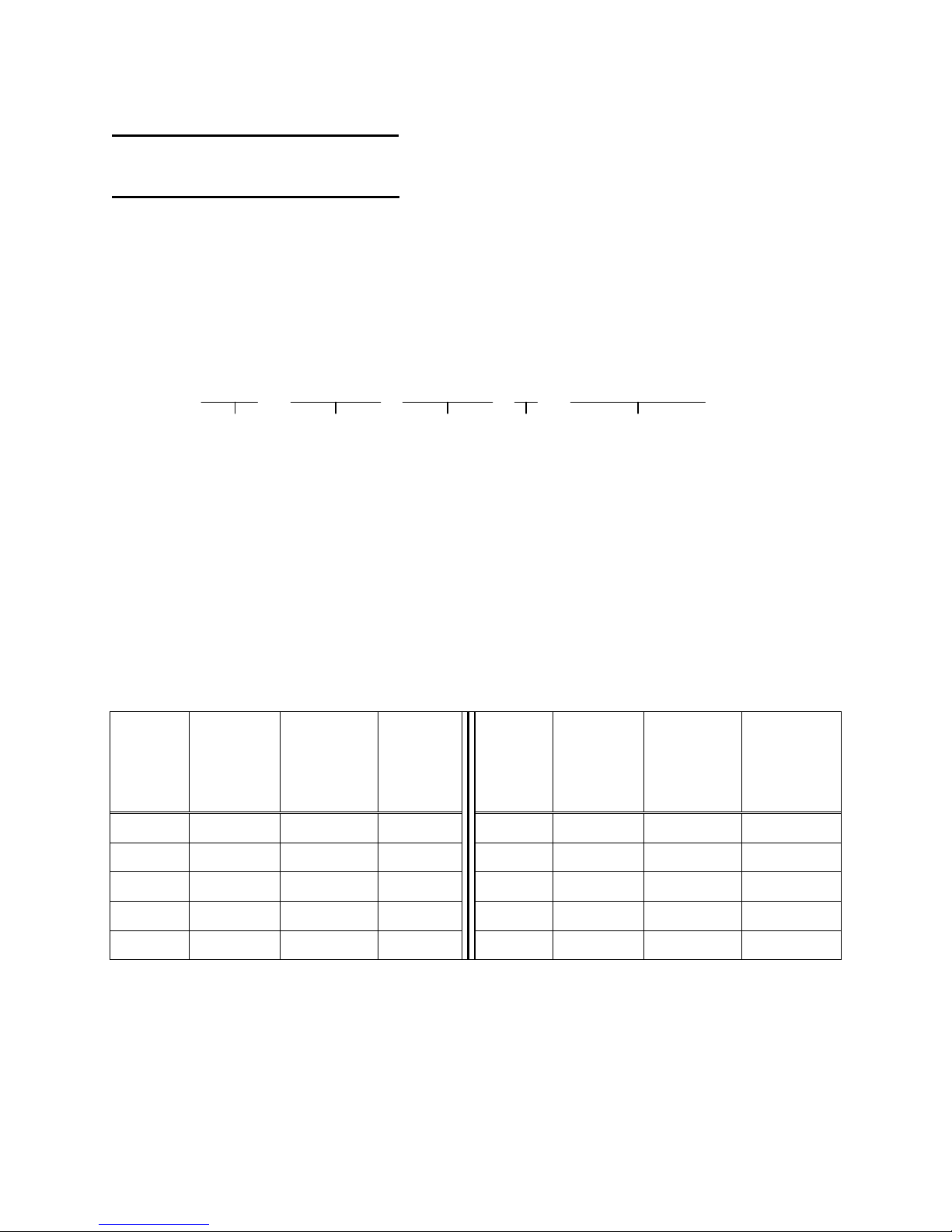

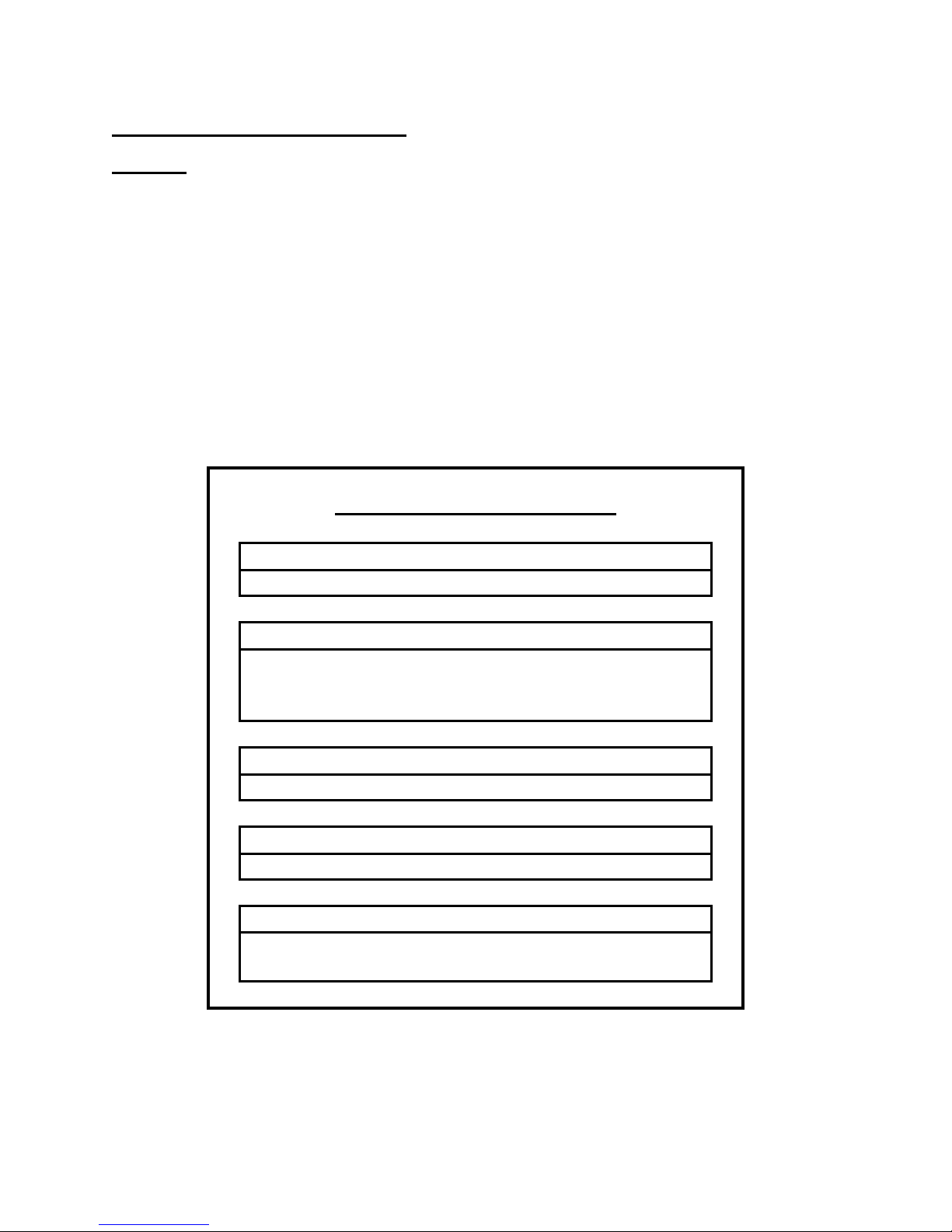

MODEL NUMBER:

Process Technology model numbers are designed to offer some description of the

heater construction, including features and options. The model number can be found on

the model/serial number label located on the front of the unit, near the bottom (see

figures 1-3).

Figure 4: Model/Serial Number Label

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

10

Model Number (Continued):

Model Number Explanation:

Provided below is an example of a typical model number along with an explanation of

each part. This key will help you understand your model number.

Model number example:

TY-072-480-3-SC-RI

c d e f g

c Heater Seri es. The beginning of each model number will designate the product

line. In this case, the TYTAN inline titanium water heater.

d Heater Wattage. The numerical portion of the model number will always begin

with the wattage of your heater. The table provided below identifies the standard

available wattage ratings and the number of heater columns needed to provide

that amount of Wattage.

HEATER

MODEL

NUMBER

012

018

WATTAGE

HEATER

WATTAGE

(W)

12,000 1 12,000

18,000 1 18,000

NUMBER

OF HEATER

COLUMNS

PER

HEATING

COLUMN

(W)

HEATER

MODEL

NUMBER

072

096

HEATER

WATTAGE

(W)

72,000 3 24,000

96,000 4 24,000

NUMBER

OF HEATER

COLUMNS

WATTAGE

PER

HEATING

COLUMN

(W)

024

036

048

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

24,000 1 24,000

36,000 2 18,000

48,000 2 24,000

120

144

Table 4: Wattage and Column Table

11

120,000 5 24,000

144,000 6 24,000

Model Number Explanation (continued):

TY-072-480-3-SC-RI

c d e f g

e Heater Voltage. The first character following the heater Wattage will describe

the rated Voltage of the heater.

f Heater Phase. This character will specify if this unit is designed for single

phase (-1) or three phase (-3) power.

g Options. The remaining characters will specify any options included in this

system. Many of these options can be combined on a single Tytan water heater.

Only a few options are mutually exclusive.

Model Number Option

-CB

-SC Built to SEMI S3 standards, CE compliant version

-PLC PLC temperature controller, in place of the standard PID

-RI Remote interface. This will allow the user to start, stop,

-RC1 RS485 communications interface with the Omron PID

Include circuit breaker with disconnect switch.

(Includes –CB option)

controller

reset the unit and monitor the safety circuit remotely.

temperature controller (requires optional E5CK

controller)

-RC2 RS232 communications interface with the Omron PID

temperature controller (requires optional E5CK

controller)

-RC3 4-20mA process output (requires optional E5CK

controller)

-S

-X

-##

Wetted surfaces to be passivated 316 stainless steel.

Special option, consult factory

Special construction design, consult factory for details

Table 5: TYTAN Options

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

12

FACILITY REQUIREMENTS:

Before installing the TYTAN inline water heater confirm the facility requirements listed

below.

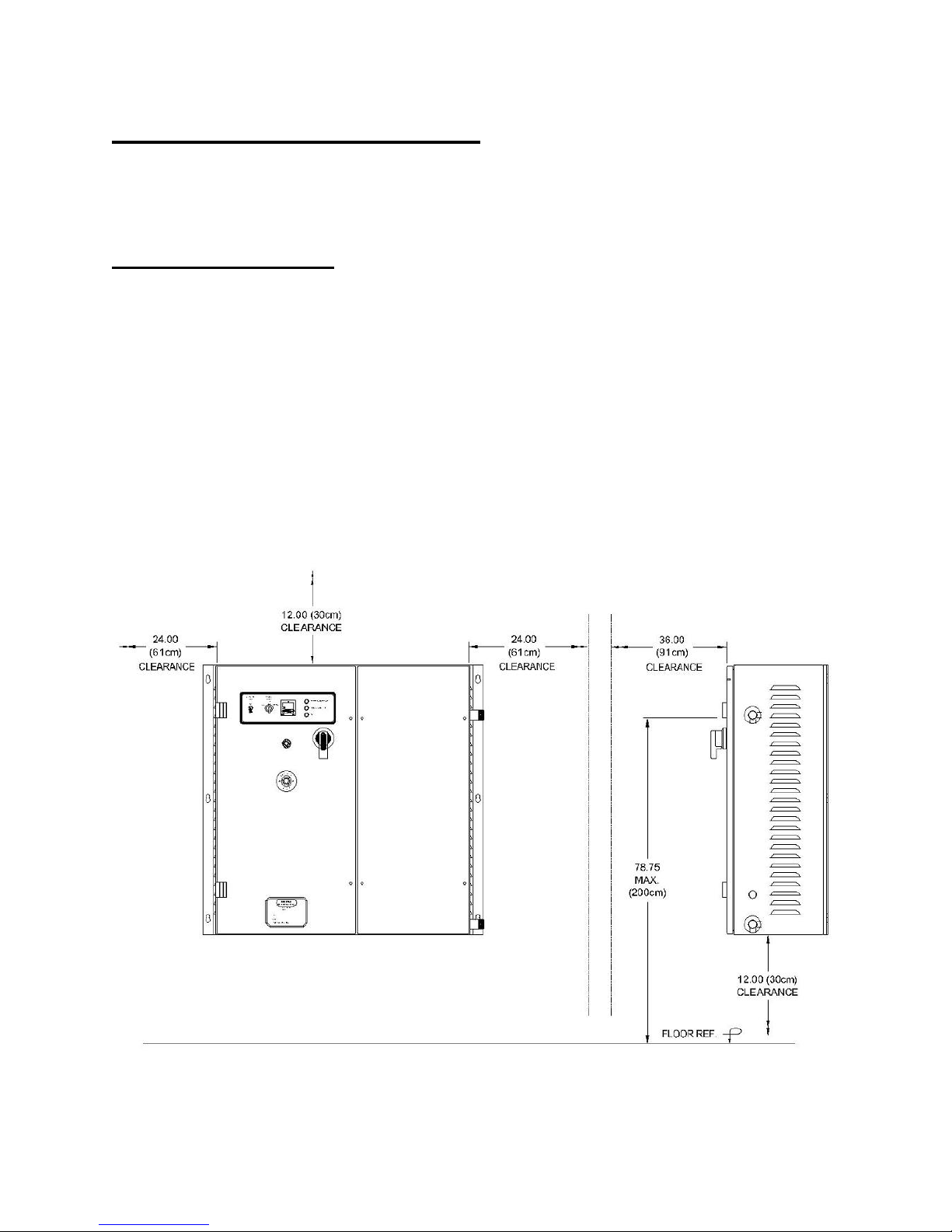

Space Requirements:

The TYTAN inline water heater is constructed in a wall-mounted or freestanding

enclosure. The dimensions of this enclosure are based upon the wattage of the unit.

This enclosure includes the common framework for the heating column(s) as well as the

electrical components.

The enclosure requires adequate ventilation. Locate equipment so that ventilation

provisions on the bottom and sides of the enclosure are not obstructed. The ventilation

fan exhausts air through these openings which prevents overheating of the interior. Be

sure to provide adequate clearance for normal operation and maintenance of this

heater.

The standard dimensions of the various models are shown in Table 3 (see appendix for

custom made units). Allow additional space on all sides of the unit for the control

ventilation and service access. (all dimensions are in inches).

Figure 5: Clearance Dimensions for Wall-Mounted Units (72kW Model Shown)

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

13

Facility Requirements (continued):

Water Plumbing Requirements:

The customer supplied inlet and outlet plumbing must be rated to withstand

temperatures up to 275°F (135°C) at pressures up to 100 psi (6.9 Bar).

The wall-mounted TYTAN units are supplied standard with 1-inch MNPT threaded pipe

connections for the plumbing inlet and outlet. These connections extend from the right

side of the unit, with the inlet near the bottom and the outlet near the top (see figures 1-

2). There is also a ½-inch FNPT threaded pipe connection for the PRV valve on the

right side of the enclosure which must be plumbed to a non-pressurized drain. Special

plumbing connections are available as an option. Refer to your specific unit for any

special connections.

The free-standing TYTAN units are supplied standard with 2-inch MNPT threaded pipe

connections for the plumbing inlet and outlet. These connections extend from the back

of the unit, with the inlet near the bottom and the outlet near the top (see figure 3).

There is also a ½-inch FNPT threaded pipe connection for the PRV valve on the back of

the enclosure, which must be plumbed to a non-pressurized drain. Special plumbing

connections are available as an option. Refer to your specific unit for any special

connections.

Do not reverse the plumbing connections of

this unit. Failure to observe the correct

plumbing orientation will result in hightemperature conditions and heater failure.

Electrical Requirements:

NOTE: Ensure electrical power fusing and disconnects meet local jurisdictional

requirements. Fuse ratings noted in this document are for reference only.

Ensure external electrical components comply with local requirements before

operating this unit.

Reference the model/ serial number label to identify the electrical power requirements of

this unit (see figure 4). Verify that the incoming electrical service is rated and fused for

the required amperage draw.

Do not exceed the rated voltage. Irreparable

damage to the heating column or control

circuitry may result.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

14

INSTALLATION:

NOTE: The mounting and installation of this unit should only be performed by

qualified personnel.

Inspection and Uncrating:

The wall-mounted TYTAN units are shipped in a horizontal position. The free-standing

TYTAN units are shipped in a vertical position.

Due to the weight of the unit, DO NOT

ATTEMPT to move or lift the unit without the

appropriate material handling equipment.

1) Inspect the shipping crate for evidence of damage. If any damage is detected,

contact the carrier immediately.

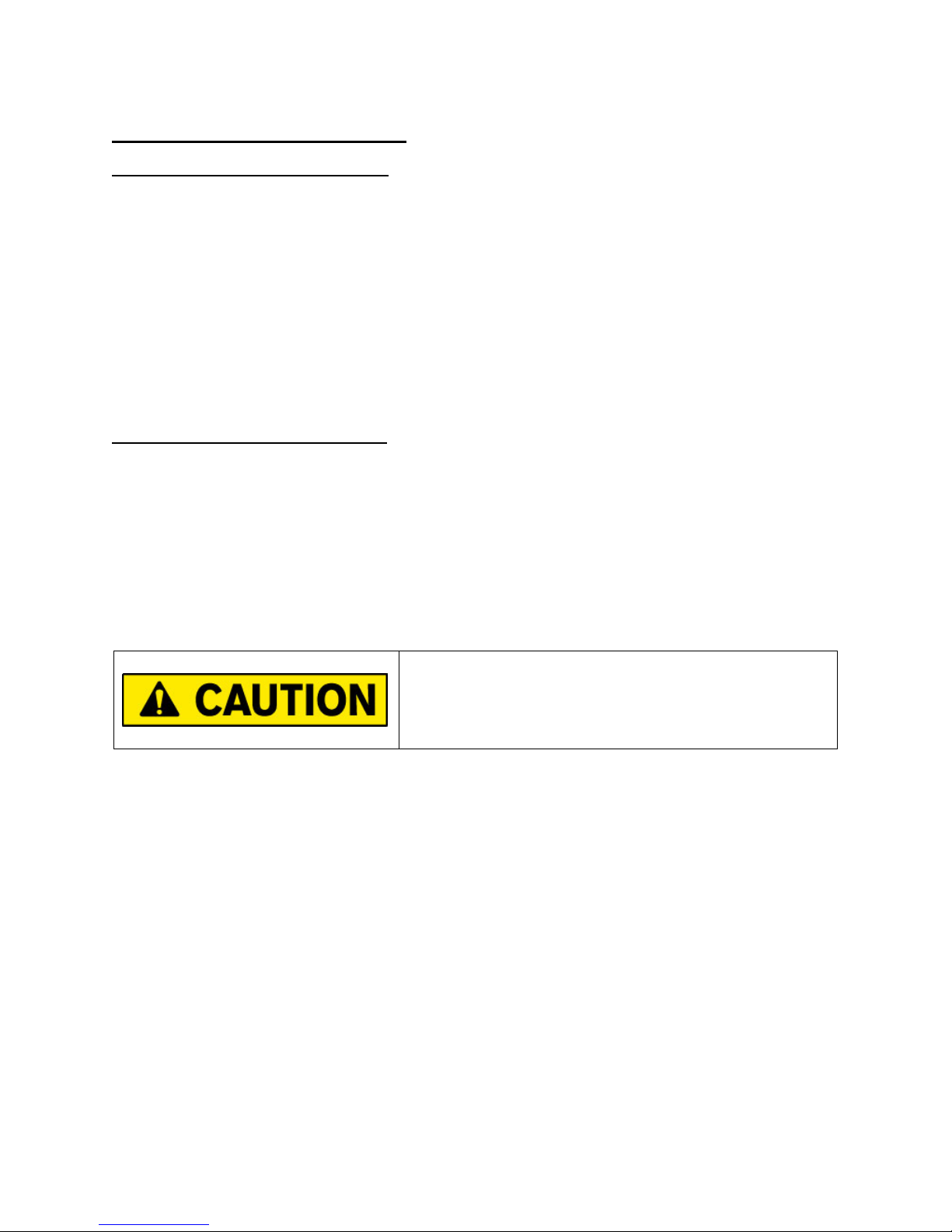

2) Inspect the shock sensors located on the outside of the crate. The shock sensors

will indicate if the unit experienced rough handling. If the sensors indicate that the

unit has experienced rough handling, contact the carrier immediately. If the shock

sensor on the outside of the crate is missing, there is also a shock sensor located on

the inside of the crate.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

Figure 6: Shockwatch Sensor

15

INSTALLATION (Continued):

Uncrating the wall-mounted units:

3) Remove the top of the crate.

4) Remove any protective packaging material and any other materials that may have

been packed in the crate with the enclosure.

5) Remove any braces used to hold the unit in place during shipping.

6) Using a hoist or other suitable lifting device, lift the unit from the mounting holes on

the side flanges and remove from the crate. Do NOT lift the unit by holding the

plumbing connections or (if present) the disconnect handle.

Uncrating the free-standing units:

3) Remove the front of the crate.

4) Remove any protective packaging material and any other materials that may have

been packed in the crate with the enclosure.

5) Remove any braces used to hold the unit in place during shipping.

6) Using a hoist or other suitable lifting device, lift the unit from underneath and remove

from the crate. Do NOT lift the unit by holding the plumbing connections or (if

present) the disconnect handle.

Do not tip the unit beyond 10° from vertical.

Serious personal injury or equipment damage

may result.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

16

INSTALLATION (Continued):

Positioning and Mounting:

Wall-mounted units:

The wall-mounted TYTAN units must be anchored to a support structure that can

support at least 275-pounds (125 kg). We recommend that the mounting bolts are no

smaller than a 3/8-16 thread.

We recommend that the unit is mounted such that the temperature controller is no more

than 78-inches (2 meters) above the floor level (see figure 5).

Free-standing units:

Move the unit into position by lifting the unit from underneath using a fork truck or other

suitable handling equipment. Position the equipment to avoid damaging the cooling

fans located on the bottom of the unit.

The castors should not be used to move the

unit over long distances or on uneven surfaces.

They are intended to facilitate small

adjustments to the position of the unit at its

place of operation. Move the unit slowly, as

there is no means of slowing or stopping the

unit. Ensure that there are sufficient personnel

to move the unit safely. Failure to follow these

instructions can result in serious personal

injury and/or damage to the unit.

Place the unit on a hard, level surface. Ensure the unit is secured so as not to roll as

the casters are unlocked. Once the unit is in position, lock the four castors.

Ensure the unit is on a smooth, level surface

and there are sufficient personnel to hold the

unit in place. As the leveling feet are retracted

and the unit rests on the castors unexpected

movement may result. Failure to properly

secure the unit may result in serious personal

injury and/or damage to equipment.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

17

INSTALLATION (Continued):

Plumbing:

The plumbing installation of this unit should only be performed by qualified technicians.

Verify that the water supply is shut off, and any

necessary lockout/tagout devices are properly

installed.

The customer supplied inlet and outlet plumbing must be rated for temperatures up to

275°F (135°C) at pressures up to 100 psi (6.9 Bar).

On all TYTAN units, the lower plumbing connection will always be the inlet, and the

upper plumbing connections will always by the outlet. The inlet plumbing to the unit

must include the means to drain the unit, which may be necessary in the case of

replacing the heating column or other parts.

Do not reverse the plumbing connections of

this unit. Failure to observe the correct

plumbing orientation will result in hightemperature conditions and heater failure.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

18

INSTALLATION (Continued):

Plumbing (Continued):

When tightening all connections on this unit, be sure to support the TYTAN heater

connection to prevent excessive torque or strain from damaging the internal plumbing of

the unit.

Figure 7: Tytan Heater Connection Support

Failure to properly support the TYTAN

plumbing connections during tightening will

result in equipment damage and internal water

leaks. Such damage is not covered under the

product warranty.

Inlet/Outlet Plumbing Connections:

1) Remove the protective plastic caps from inlet and outlet plumbing.

2) Test fit the piping to insure proper length.

3) Support the TYTAN pipe fittings to avoid any damage during tightening.

4) Tighten the connections as required. Take care not to over-tighten.

5) Establish water flow through the unit. Inspect the plumbing for leaks.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

19

INSTALLATION (Continued):

Plumbing (Continued):

PRV Plumbing Connection:

1) Test fit the drain pipe to insure proper length. The PRV must be connected to a nonpressurized drain.

2) Support the TYTAN PRV fitting to avoid any damage during tightening.

3) Tighten the connection as required. Take care not to over-tighten.

Wiring:

The wiring of this unit should only be performed by qualified technicians.

Verify that the electrical power supply is shut

off, and any necessary lockout/tagout devices

are properly installed.

Power Connections:

TYTAN units are designed to operate on 4 wire electrical power supplies (3 power

wires, 1 ground wire). All electrical connections should conform to local electrical codes

and/or NFPA 70/79.

There is no pilot hole for incoming power supply conduit. This hole will have to be cut in

the top of the enclosure during installation.

Figure 8: Recommended location for power supply conduit (72kW unit shown)

1) Check the model/serial number on the front of the unit for power requirements.

Do not exceed the rated voltage. Irreparable

damage to the heating column or control

circuitry may result.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

20

INSTALLATION (Continued):

Wiring:

2) Remove front cover of the control side of the cabinet by loosening the cover

mounting screws.

3) Cut a hole in the top of the enclosure for the incoming power supply to allow for the

power supply to enter the top of the enclosure.

4) Fuse the incoming line for the rated amperage using an approved electrical

disconnect box.

5) Connect the leads from the incoming power line to the appropriate terminals

(reference the Electrical Schematic) making sure not to disturb existing wiring. Use

care that no loose strands of wire are exposed out of the terminal connection.

Torque all wires to the specified ratings located on the wiring diagrams and

component labels.

SECONDARY:

SECONDARY:

INPUT :

OUTPUT :

TORQUE SPECIFICATIONS

CIRCUIT BREAKER

DISTRIBUTION BLOCK

PRIMARY:

POWER FUSES

SAFETY CONTACTOR

SOLID STATE RELAYS

6) Grounding is done internally from the Incoming Power Strip.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

Figure 9: Torque Specifications Label

21

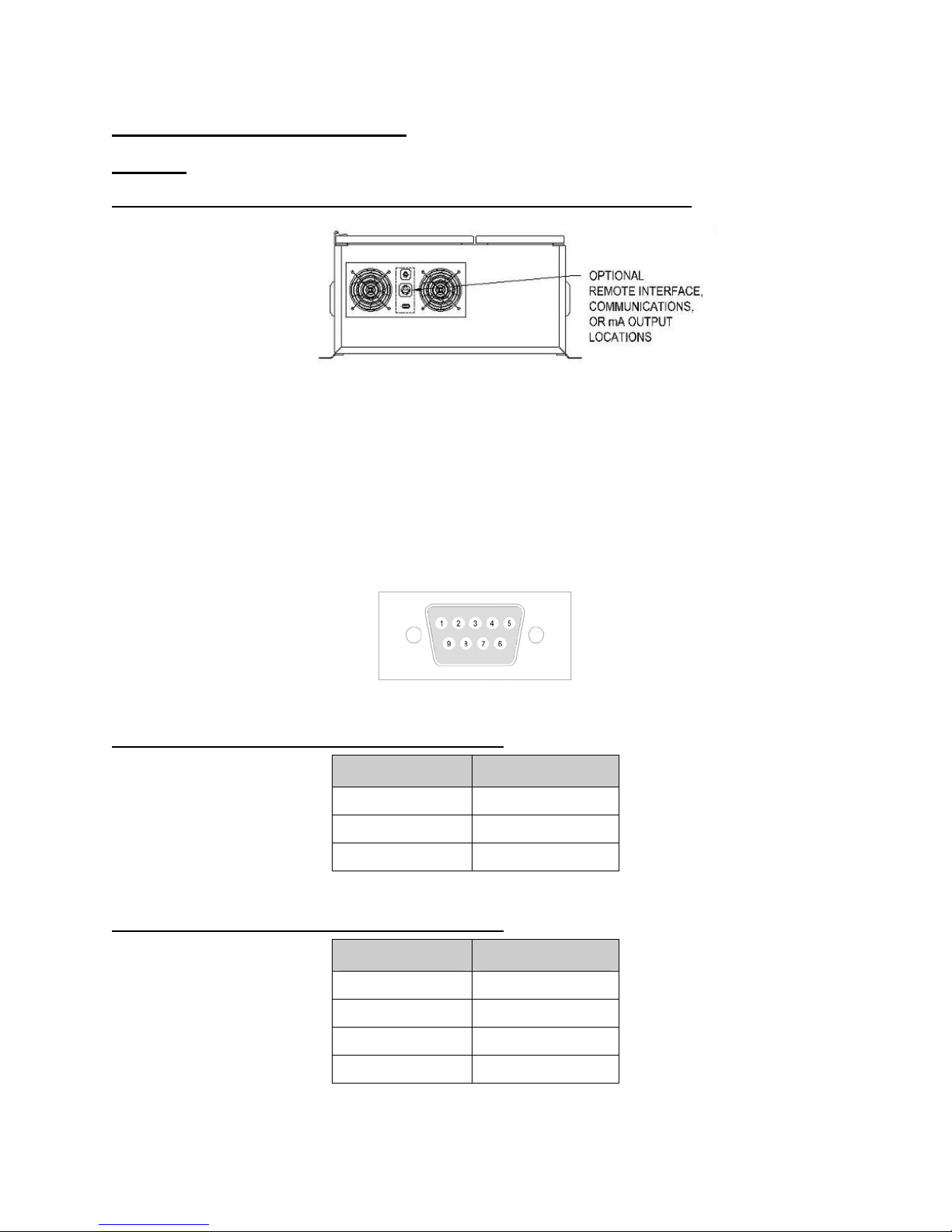

INSTALLATION (Continued):

Wiring:

RC1 (RS232), RC2 (RS485) Options: Serial Communication Interface:

Figure 10: Location of optional interface connections

In units supplied with the RC1 (RS485) or RC2 (RS232) options, the Omron E5CK

temperature controller is equipped with RS-232 / RS-485 Serial Communication

capability for use with a customer-supplied host computer. If this option is used, all

temperature and related parameters can be monitored or altered from the host

computer. On these units, the communications wiring is made through a DB-9

receptacle located on the side or bottom of the cabinet. An independent serial cable

should be installed between the host computer and the DB-9 receptacle (not included

with unit).

Figure 11: DB9 connector, for optional -RC# remote communications

RC1 (RS485) Communications pin assignment:

Pin Number Signal

2 Positive (+)

3 Negative (-)

1, 4, 5, 6, 7, 8, 9 Not used

RC2 (RS232) Communications pin assignment:

Pin Number Signal

2 Send

3 Receive

5 Signal Ground

1, 4, 6, 7, 8, 9 Not used

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

22

INSTALLATION (Continued):

Wiring:

RC3 (4-20 mA) Option: Process Output:

Units provided with the RC3 option will include a 4-pin connector plug, for wiring of the

4-20 mA process output. This process output will allow the user to record the outlet

temperature of the Tytan heater from a remote device. This signal is an output only.

Figure 12: 4-pin connector plug, for optional –RC3 process output

RC3 option process output pin assignment:

Pin Number Signal

1 Positive (+)

2 Negative (-)

3, 4 Not used

RI Option: Remote Interface:

Units provided with the RI option will include a 16-pin connector plug which will allow

remote operation of the Tytan inline water heater. The remote interface will allow remote

operation of heater start/stop, remote EMO trip and remote monitoring of heater

enabled and the status of the alarm system. Some of the remote interface inputs have

been jumped at the factory, to allow for heater operation with the remote interface cable

disconnected. These jumpers are located in the electrical side of the heater cabinet,

and are marked by a red tag. If the customer wants to use the remote interface, these

red tag jumpers must be removed.

If the unit was provided with a custom remote interface (-RI# at the end of the model

number), then refer to the electrical prints (provided with the unit) for your specific

signals and pin-out assignments.

Figure 13: 16-pin connector plug, for optional -RI, -RI# remote interface

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

23

INSTALLATION (Continued):

Wiring:

RC3 option process output pin assignment:

Pin

Signal Signal type Description

Number

1, 2 EMO

3, 4 Start/Stop

9, 10 System Fault

Input,

Dry contacts

Input,

Dry contacts

Output,

Dry Contacts

The customer supplied remote controller can trip

an EMO condition on the unit by opening contacts

across these two pins.

This is one of the signals that has been bypassed

at the factory. In order to use this remote EMO

feature, the red tag jumper must be removed.

The EMO condition must be reset at the unit.

The customer supplied remote controller can start

heater operation by closing the contacts across

these pins, when the controller is in REMOTE

mode only.

This is one of the signals that has been bypassed

at the factory. In order to use this remote EMO

feature, the red tag jumper must be removed.

Open contacts will stop heater operation.

This output will apply open contacts across these

pins when any alarm condition has been tripped.

Once the alarm condition has been corrected, the

unit will require a manual reset at the unit. The

unit can not be reset remotely.

Open contacts indicate all of the safety devices

are in normal operating mode.

This output will apply closed contacts across

these pins when power is applied to the unit, there

11, 12

Heater

Enabled

Output,

Dry contacts

is not EMO condition and the heater selector

switch is set to ON.

Open contacts indicate the EMO has been tripped

or the unit has been stopped or shut down.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

24

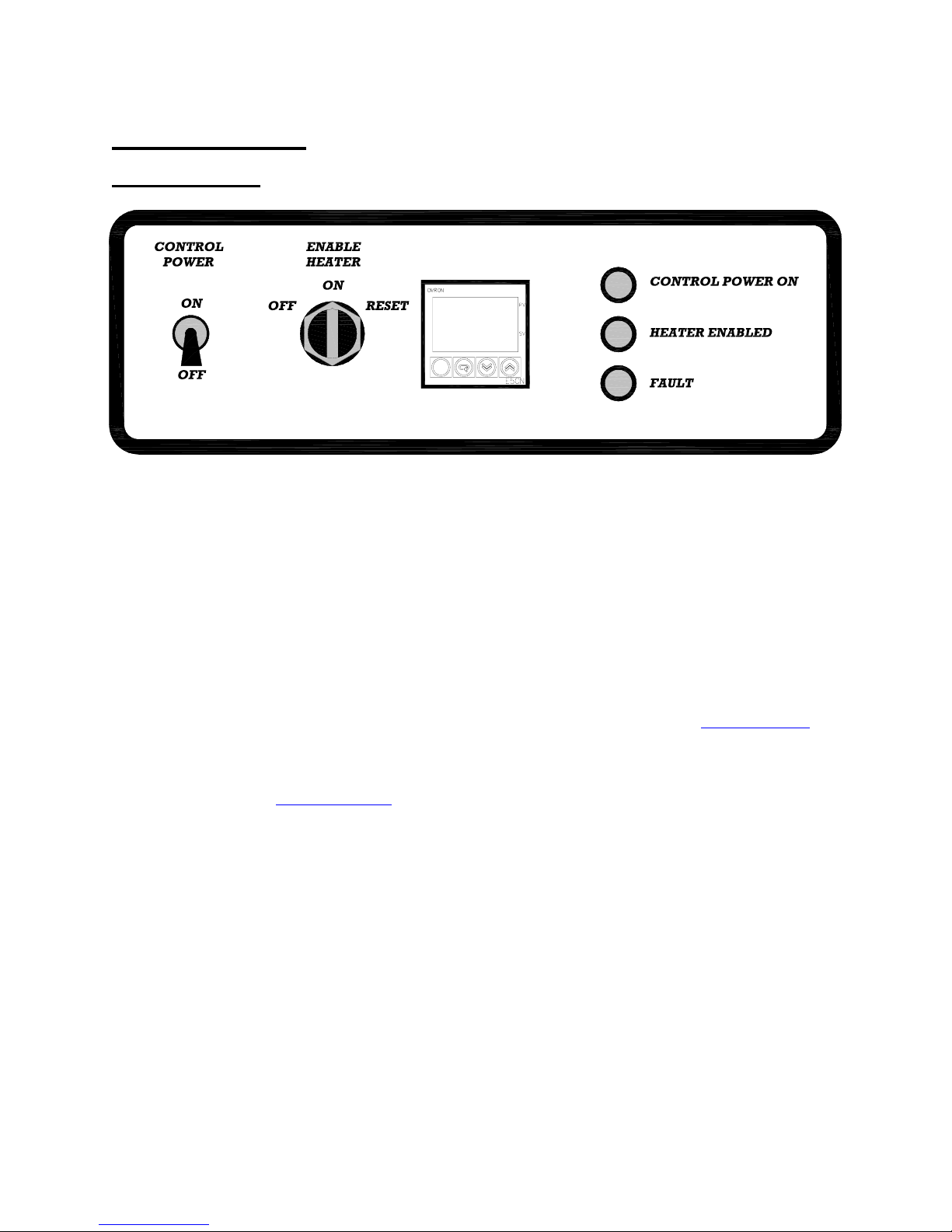

OPERATIONS:

Control Panel:

Figure 14: Temperature Controller and Control Panel.

The TYTAN Heating System incorporates a self-tuning, PID microprocessor based,

digital temperature controller with a set high temperature alarm. The PID feature

enhances the controller's ability to reach and maintain a constant process temperature.

The self-tuning feature enables the controller to measure the process characteristics

and indicate desired values, which can be displayed on LED displays.

The following sections provide a description and instructions for two available

temperature controllers:

1. The Omron E5CN Controller. This is the temperature controller used on standard

Tytan heaters. For a complete user guide, visit the Omron website;

www.omron.com.

2. The Omron E5CK Controller. This is the temperature controller used on Tytan

heaters with the RC1, RC2 or RC3 options. For a complete user guide, visit the

Omron website;

www.omron.com

These two temperature controllers program differently, and have slightly different control

settings. Be sure to refer to the correct temperature controller section when

programming your unit.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

25

OPERATIONS (Continued):

Temperature Controller E5CN:

This section contains information for the E5CN

controller only. Do not use these instructions

for any other temperature controller, or

controller damage may result.

DISPLAY FEATURES:

No. 1 display (PV): Shows the process value (outlet temperature), modes and

parameter symbols.

No. 2 display (SV): Shows set points, parameter operation read value, or the variable

input value.

Level key: Switches the controller between auto and manual operation.

Mode key: Press this key to change parameters within a setting level.

Up and Down arrow keys: Advances, increases or decreases the setting or values in

the No. 2 display. Holding these keys down will speed up the rate of change.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

Figure 15: Omron Temperature Controller

26

OPERATIONS for E5CN (Continued):

Display Symbols:

Operation Indicators:

ALM1: Illuminates when the alarm 1 setting is ON (tripped) (120°C).

ALM2: Illuminates when the alarm 2 setting is ON (tripped) (110°C).

ALM3: Not available on this controller.

HA: Not available on this controller.

OUT1: Illuminates when the control output 1 is ON.

OUT2: Illuminates when control output 2 is ON (Not used).

STOP: Illuminates when the control operation has stopped.

CMW: Illuminates when communications wiring is enabled.

: Illuminates when setting change protection is ON.

MANU: Illuminates when the controller is in Manual operation mode.

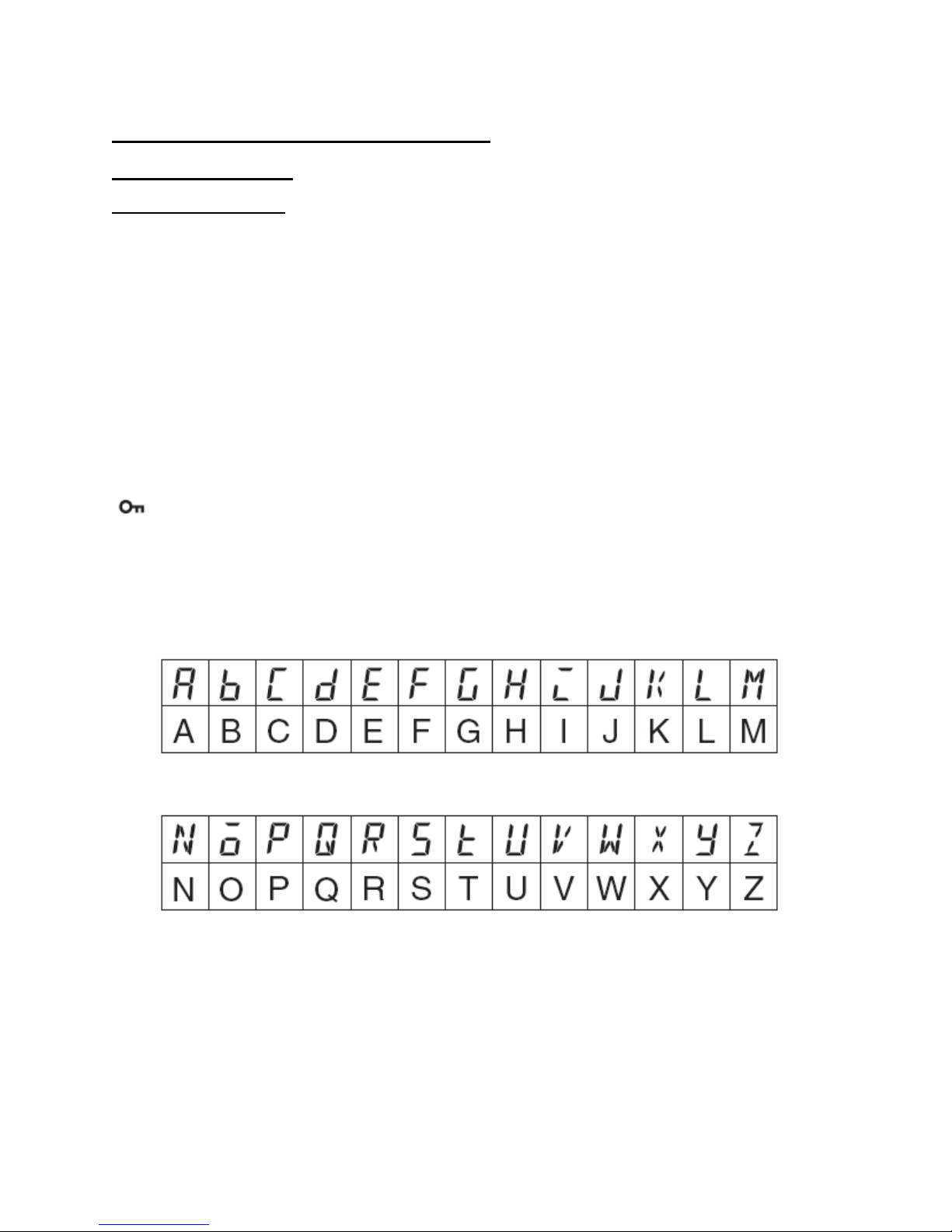

The following tables show the correspondence between symbols shown on the No.1

and No.2 displays and alphabetic characters.

Figure 16: Omron Temperature Controller Display Symbols

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

27

OPERATIONS for E5CN (Continued):

Using the keys:

This section describes the basic functions of the front panel keys.

Level Key: Press this key to move between setting levels. The setting level is

selected in the following order: operation level: adjustment level, initial setting

level, communications setting level.

Mode Key: Press this key to change parameters within a setting level. The

parameters can be reversed by holding down the key (moving one per second in

reverse order).

Up Key: Each press of this key increments the value displayed on the No. 2

display or

advances the setting. Holding the key down speeds up the incrementation.

Down Key: Each press of this key decrements values displayed on the No. 2

display or reverses the setting. Holding the key down speeds up the

incrementation.

Selecting Menu Levels:

The following section describes how to access the various menu levels in the Omron

controller.

Operations Level: Press the mode key.

Adjustment Level:

Initial Setting Level:

Protect Level:

Advanced Function Setting Level:

Press and hold the level key for at least 1 second.

Press and hold the level key for at least 3 seconds.

Press and hold the level key and the mode key

simultaneously for at least 3 seconds.

(Note: in order to access this level, the ICPt setting

in the protect level must be set at 0) Index through the

initial setting level and adjust the AmoV setting to “-169”.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

28

OPERATIONS for E5CN (Continued):

Mode Parameter Settings:

The Omron E5CN temperature controller has been programmed prior to shipment, so

no additional programming is normally necessary. The table below shows the various

controller settings for this unit when properly configured to operate the TYTAN inline

heater. Some internal menus have been factory programmed and subsequently locked.

Those menus are not listed.

The selections in bold indicate settings that have been changed from the original

factory default for operation with the TYTAN inline heater.

Level Parameter

Description Setting

Operations

Level

Adjustment

Level

R-S Run – Stop selection RUN

AL-1 Alarm value 1 120°C

AL-2 Alarm value 2 110°C

LAdJ Adjustment level

At Autotune execute OFF

INS Temperature input shift 0.0

P Proportion band 80**

I Integral time 233**

D Derived time 40**

SPRt SP ramp set value OFF

OL-H MV upper limit 100.0

OL-L MV lower limit 0.0

** The P, I and D values may change following the execution of Auto-tune.

Table 6: Omron E5CN Parameters

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

29

OPERATIONS for E5CN (Continued):

Changing Primary Set Point:

The process Set Point can be changed in the normal display mode. 1.

2. Press the up and down arrow keys to select the desired setting.

After changing the process set point (SP-0) on the Omron controller, you must

manually adjust the SP2 setting on the Future Design over-temperature control.

See OPERATIONS Over-Temperature Controller FDC-L91 section.

High Alarm:

The Omron E5CN temperature controller incorporates an independent high-temperature

alarm. Alarm 1 (AL-1) prevents heater operation above a preset maximum temperature

that may harm the process and potentially the tank material. If the process temperature

exceeds the preset high alarm value, the heater will be disengaged and the audibly

alarm will sound. The temperature controller will activate once the process temperature

exceeds the set point by the preset value. The factory setting of this alarm temperature

is 248°F (120°C).

The high alarm value can be adjusted to a lower setting through the operations level.

Press the mode key to enter the operations level. 1.

Press the mode key to index through the operations level to the AL-1 setting. 2.

Press the up or down key to adjust AL-1 to the desired setting. 3.

4. Press the mode key to index through the operations level to the AL-2 setting.

The AL-2 setting is normally set at 10°C below AL-1. Press the up and down keys to

5.

adjust AL-2 to the desired setting.

6. Press and hold the level key for a minimum of three seconds to return to the normal

display.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

30

OPERATIONS for E5CN (Continued):

PID Tuning:

The Omron E5CN temperature controller incorporates the capability of automatically

tuning the PID parameters (Auto-Tuning) to fit the characteristics of the process. The

optimum PID parameters are automatically set by forcibly changing the Manipulated

Variable (MV) to calculate the characteristics (limit cycle method) of the control target.

Depending on the auto-tune level selected, AT-1 or AT-2, the controller will run this test

at either 40% or 100% of the actual Process Set Point. When the auto tuning is

complete, the appropriate PID tuning parameters will be automatically installed into the

non-volatile memory of the temperature controller.

1. Turn on water supply and set the desired water flow.

2. Set the Process Temperature Set point to the desired value.

(See OPERATIONS; Changing Primary Set point,).

3. Press and hold the level key for a minimum of one second to enter the

adjustment level.

4. Press the mode key to index through the adjustment level to get to the At

settting.

5. Press the up or down arrow key to adjust the At value to oN.

6. Press and hold the level key for at least 3 seconds to return to the normal

display.

7. Turn the ENABLE HEATER switch past the ON position to the RESET position,

then release the switch, which will move to the ON position. If all criteria for the

various safety devices have been met, the heater will begin to heat.

8. When the process is complete, the appropriate PID tuning parameters will be

installed and retained in the non-volatile memory.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

31

OPERATIONS for E5CK:

Temperature Controller E5CK:

This section contains information for the E5CK

controller only. Do not use these instructions

for any other temperature controller, or

controller damage may result.

The Omron E5CK temperature controller is used on Tytan heaters that utilize the RC1,

RC2 or RC3 options. For units with these options, refer to this section (E5CK

controller). Do NOT use the section for the E5CN controller

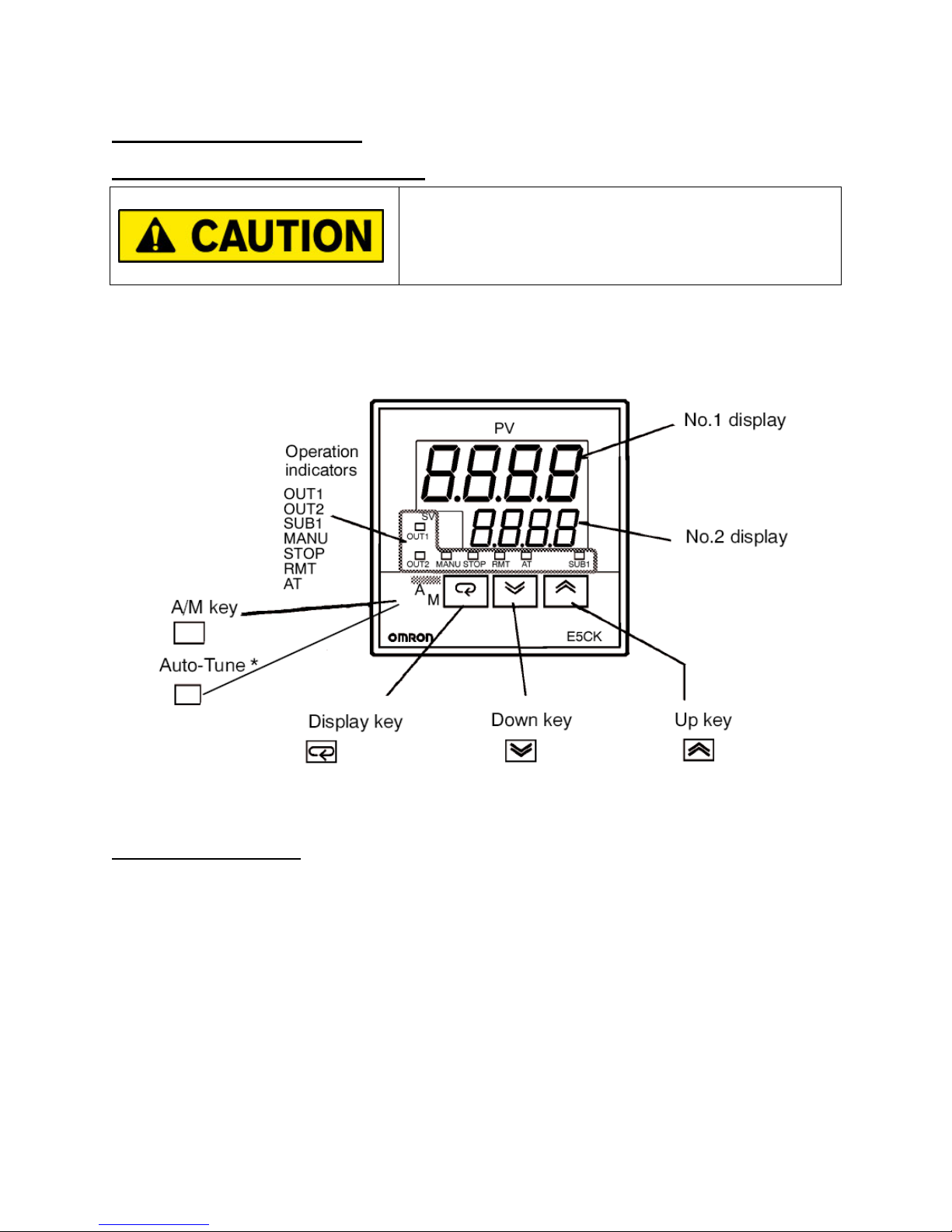

DISPLAY FEATURES:

No. 1 display (PV): Shows the process value (outlet temperature), modes and

parameter symbols.

No. 2 display (SV): Shows set points, parameter setting and the manipulated variable

heat.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

Figure 17: Omron Temperature Controller

32

OPERATIONS for E5CK (Continued):

A/M key: Switches the controller between auto and manual operation.

Display key: Allows selection of the mode when depressed for more than 1 second.

Switches parameters when depressed for less than one second.

Up and Down arrow keys: Advances, increases or decreases the setting or values in

the No. 2 display.

OUT1: Illuminates when the controller’s heat output is ON.

OUT2: Illuminates when the alarm 1 setting is ON (tripped).

SUB1: Illuminates when the alarm 2 setting is ON (tripped).

MANU: Illuminates when the controller is in Manual operation mode.

STOP: Illuminates when the control operation has stopped.

RMT: Illuminates when in Remote operation.

AT: Flashes during auto-tuning.

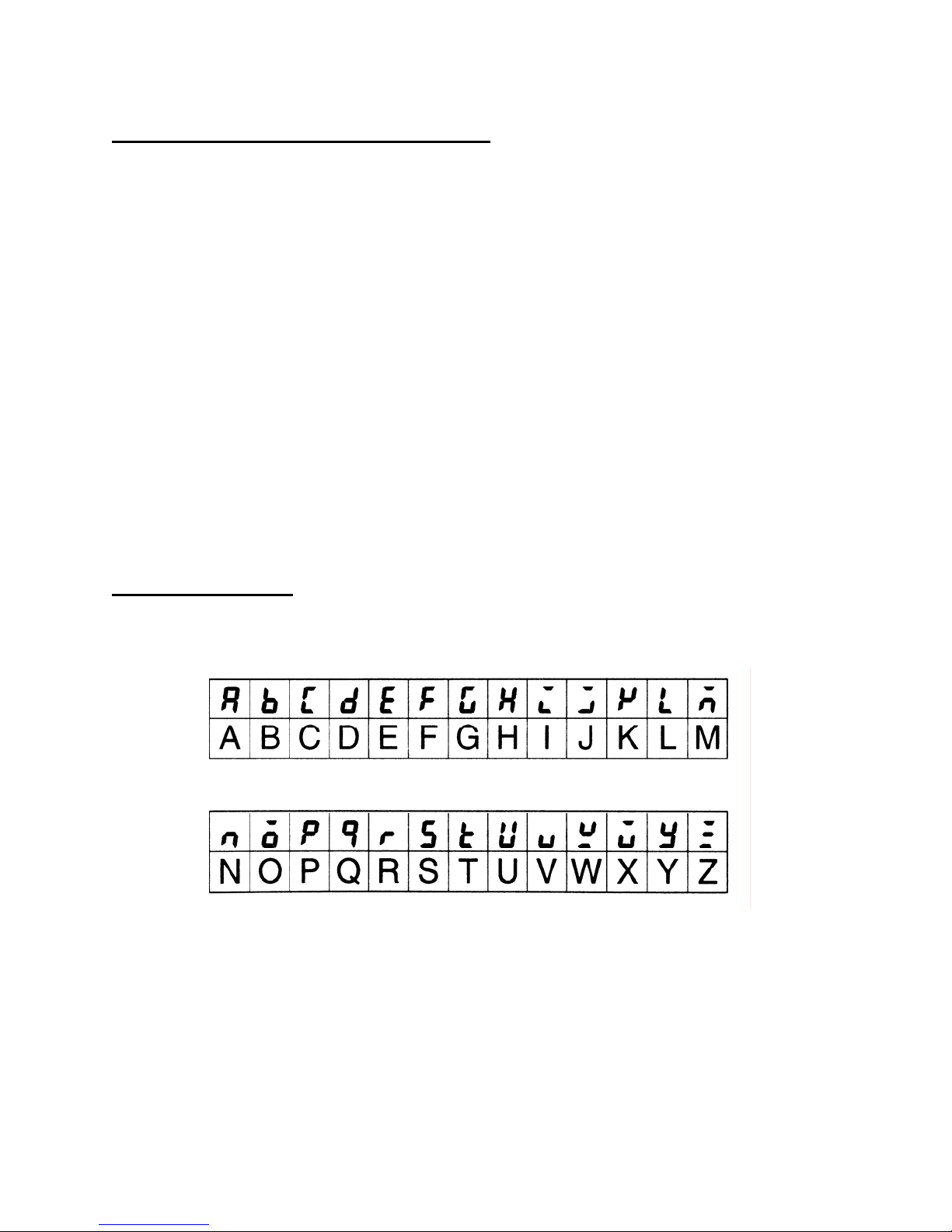

Display Symbols:

The following tables show the correspondence between symbols shown on the No.1

and No.2 displays and alphabetic characters.

Figure 18: Omron Temperature Controller Display Symbols

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

33

OPERATIONS for E5CK (Continued):

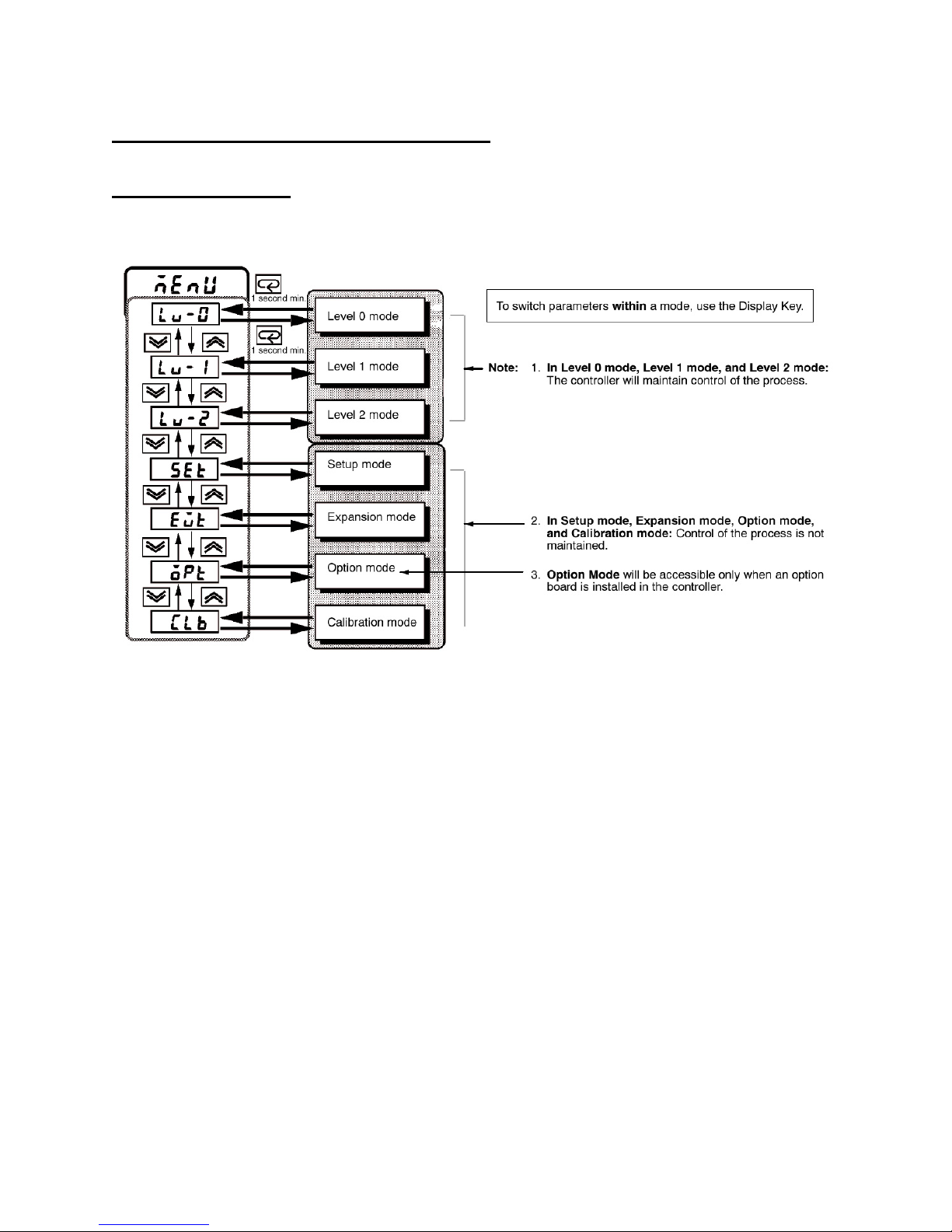

Selecting Modes:

The modes are selected by pressing the Display Key for one second or greater. The up

and down arrow keys allow the movement between modes in the top display.

Figure 19: Omron E5CK Menu Navigation

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

34

OPERATIONS for E5CK (Continued):

Mode Parameter Settings:

The Omron E5CK temperature controller has been programmed prior to shipment, so

no additional programming is normally necessary. The table below shows the various

controller settings for this unit when properly configured to operate the TYTAN inline

heater. Some internal menus have been factory programmed and subsequently locked.

Those menus are not listed.

The selections in bold indicate settings that have been changed from the original

factory default for operation with the TYTAN inline heater.

Mode Parameter Description Setting

Level 0

Level 1

SP-n Set point during ramp NP

O Manipulated variable (MV) monitor for

heat

C-o Manipulated variable (MV) monitor for

cool

r – S Run/Stop Run

A t Auto Tune (AT) execute/cancel o-FF

SP-0 Set point 0 (Process Set point) Determined by Operator

A L – 1 High Alarm 120°C (248°F)

A L – 2 Temperature Deviation 10°C (15°F)

P Proportional Band 10.0 (default)**

i Integral Time 233 (default)**

D Derivative Time 40 (default)**

C-SC Cooling coefficient

C-db Dead band

Of-R Manual reset value

HYS Hysteresis (heat)

CHYS Hysteresis (cool)

C P Heating control period/cycle time 1sec

C-CP Cooling control period/cycle time

S P r U Set Point ramp time unit M, minutes

0

NP

** The P, I and D values may change following the execution of Auto-tune.

Table 7: Omron E5CK Parameters

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

35

OPERATIONS for E5CK (Continued):

Changing Primary Set Point:

The process Set Point can be changed in the level 1 mode menu. 3.

4. Press the Display Key for a minimum of one second to enter the level select

mode.

Press the up or down arrow key to select the desired level. (Level 1 for process

5.

set point adjustment).

6. Press the Display Key for a minimum of one second to enter the selected

level mode menu.

Press the Display Key for less than one second to cycle through the selected

7.

level mode menu until (SP-0) is shown on the upper display.

Press the up or down arrow key to adjust the (SP-0) value to the desired point. 8.

9. Press the Display Key for a minimum of one second to once again enter the

level select mode.

Press the up or down arrow key to select the desired level. (Level 0 for normal

10.

control operation).

After changing the process set point (SP-0) on the Omron controller, you must

manually adjust the SP2 setting on the Future Design over-temperature control.

( See OPERATIONS Over-Temperature Controller FDC-L91 section.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

36

OPERATIONS for E5CK (Continued):

High Alarm:

The Digital Temperature Controller incorporates an independent alarm. The High

Process Temperature Alarm (AL-1) prevents heater operation above a preset maximum

temperature that may harm the process and potentially the tank material. If the process

temperature exceeds the preset high alarm value, the heater will be disengaged. The

temperature controller will activate once the process temperature exceeds the set point

by the preset value. The factory setting of this alarm temperature is 248°F (120°C).

The high alarm value can be adjusted to a lower setting through mode Level 1.

The process Set Point can be changed in the level 1 mode menu. 7.

8. Press the Display Key for a minimum of one second to enter the level select

mode.

Press the up or down arrow key to select the desired level. (Level 1 for high process

9.

temperature alarm adjustment).

10. Press the Display Key for a minimum of one second to enter the selected level

mode menu.

Press the Display Key for less than one second to cycle through the selected

11.

level mode menu until (AL-1) is shown on the upper display.

Press the up or down arrow key to adjust the (AL-1) value to the desired point. 12.

13. Press the Display Key for a minimum of one second to once again enter the

level select mode.

Press the up or down arrow key to select the desired level. (Level 0 for normal

14.

control operation).

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

37

OPERATIONS for E5CK (Continued):

PID Tuning:

The Digital Temperature Controller incorporates the capability of automatically tuning

the PID parameters (Auto-Tuning) to fit the characteristics of the process. The optimum

PID parameters are automatically set by forcibly changing the Manipulated Variable

(MV) to calculate the characteristics (limit cycle method) of the control target.

Depending on the auto-tune level selected, AT-1 or AT-2, the controller will run this test

at either 40% or 100% of the actual Process Set Point. When the auto tuning is

complete, the appropriate PID tuning parameters will be automatically installed into the

non-volatile memory of the temperature controller.

The PID Tuning Process can be started by adjusting the (At) parameter.

9. Turn on water supply and set the desired water flow.

10. Set the Process Temperature Set point to the desired value.

(See OPERATIONS; Changing Primary Set point,).

11. Press the Display Key

for a minimum of one second to enter the level select

mode.

12. Press the up or down arrow key to select the desired level. (Level 1 for Auto

Tune adjustment).

13. Press the Display Key

for a minimum of one second to enter the selected

level mode menu.

14. Press the Display Key

for less than one second to cycle through the selected

level mode menu until (At) is shown on the upper display.

15. Press the up or down arrow key to adjust the (At) value to the desired setting of

(AT-2).

16. Press the Display Key

for a minimum of one second to once again enter the

level select mode.

17. Press the up or down arrow key to select the desired level. (Level 0 for normal

control operation). The “AT” LED will flash during the Auto-Tune cycle.

18. Turn the ENABLE HEATER switch past the ON position to the RESET position,

then release the switch, which will move to the ON position. If all criteria for the

various safety devices have been met, the heater will begin to heat.

19. When the process is complete, the “AT” LED will stop flashing. The appropriate

PID tuning parameters are now installed and retained in the non-volatile memory.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

38

OPERATIONS (Continued):

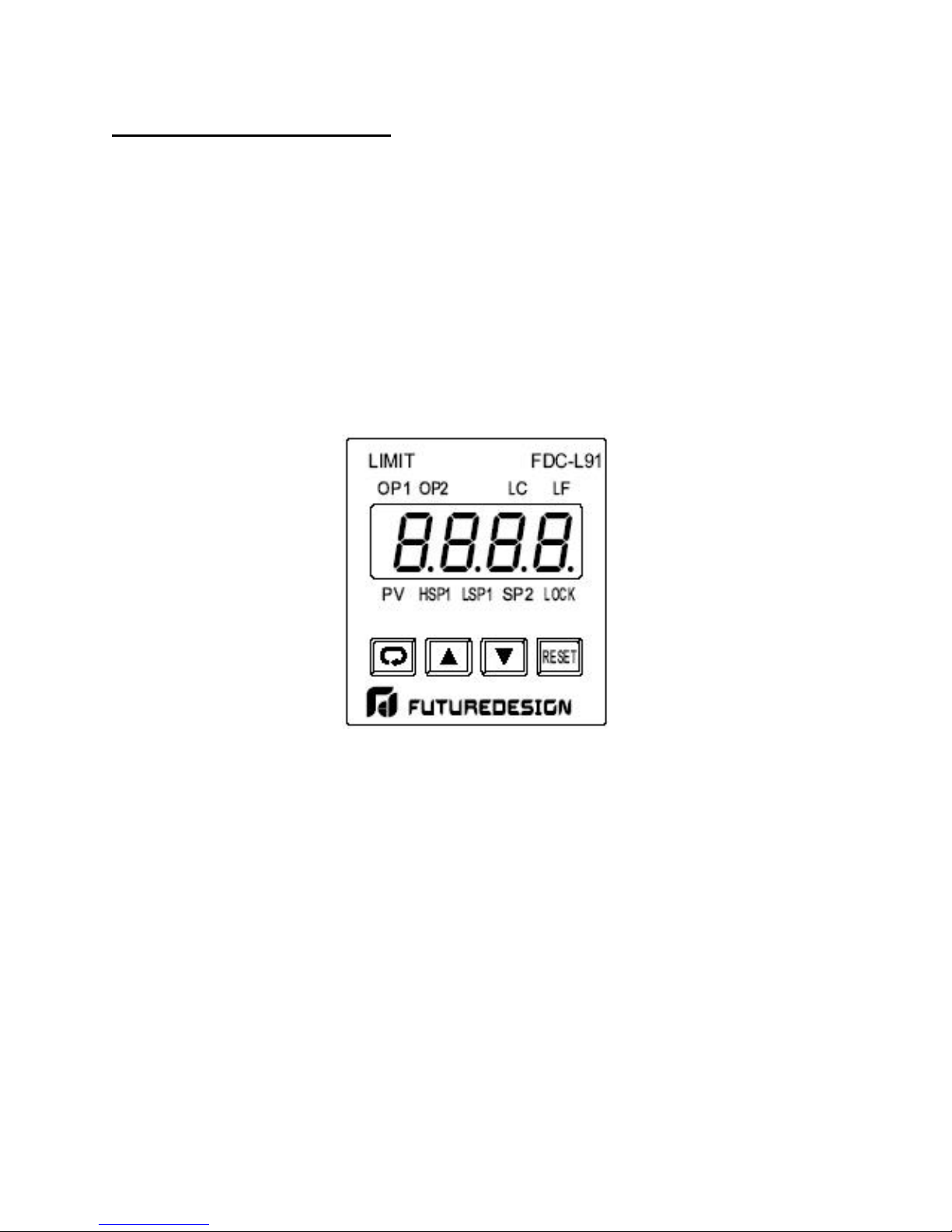

Over-Temperature Controller FDC-L91:

1. This over-temperature controller is located inside the electrical portion of the Tytan

heater. It uses a separate temperature sensor to monitor the temperature on the

surface of the heating elements.

2. This controller has two discreet set points:

SP2: This is the over-temperature cutoff setting, which is set for 18°F

(10°C) ABOVE the primary set point on the Process temperature

controller.

HSP1: This is an element high-temperature alarm setting, which is factory

set at 248°F (120°C).

Do not adjust this setting.

Figure 20: Futuredesign Over Temperature Controller

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

39

OPERATIONS (Continued):

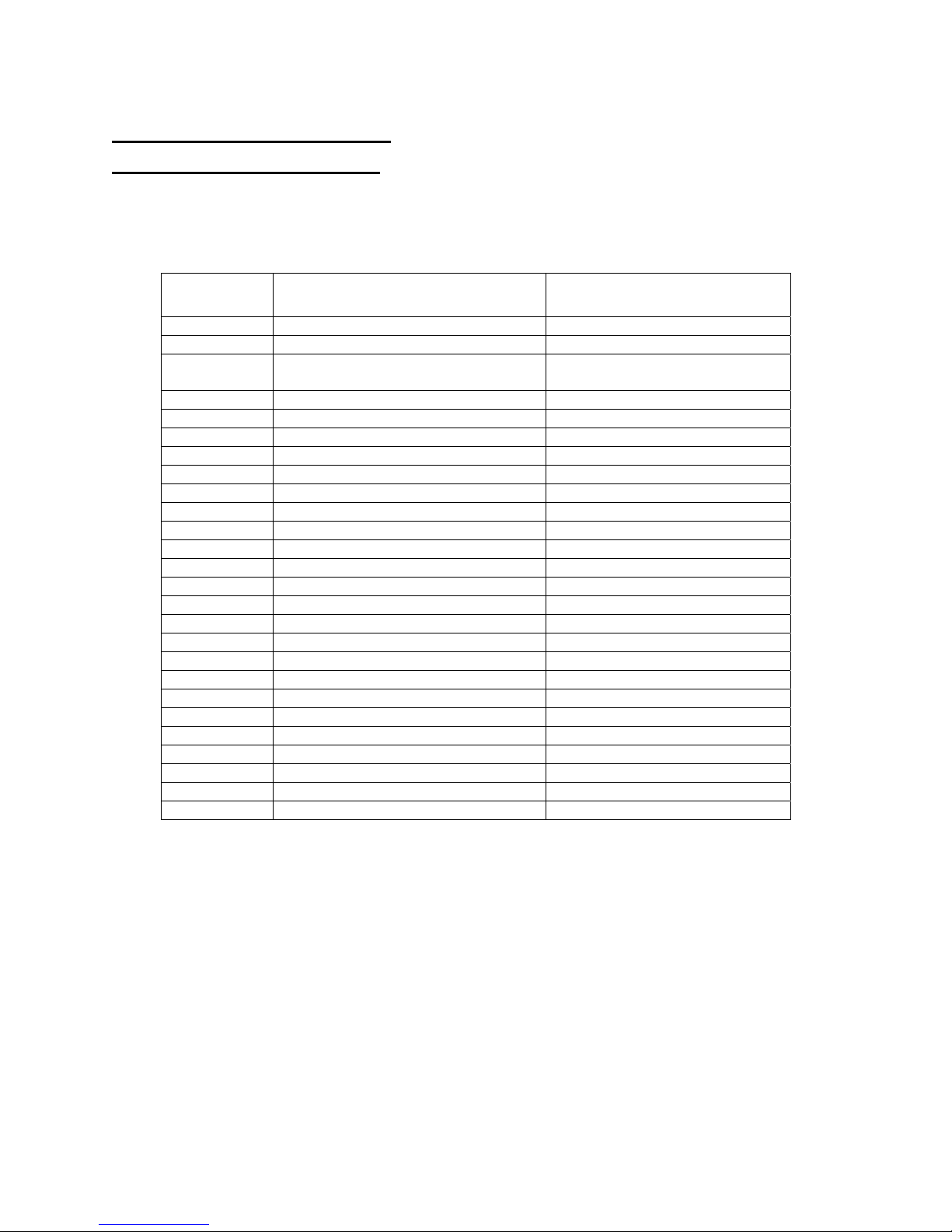

Mode Parameter Settings:

The Futuredesign FDC-L91 temperature controller has been programmed prior to

shipment, so no programming will be necessary. The table below shows the various

controller settings for this unit when properly configured to operate the TYTAN inline

heater.

Parameter

Description Default Setting

HSP1 Hi Limit Set Point 120 C / 248 F

LSP1 Low Limit Set Point 82 C / 180 F

SP2 Set Point 2 value, for Output 2 10 C / 18 F above”SP0” of the

E5CN Temperature Controller

INPT Input Type Selection J_tC

UNIT Process Unit C / F

RESO Display Resolution NodP

IN.LO Low Scale for Linear Input 0

IN.HI High Scale for Linear Input 100 C / 212 F

SHlF PV Shift (offset) Value 0

FILT PV Filter Time Constant 2

OUT1 Output 1 Function HI

O1.HY Output Hysteresis Value 0.1

HSP.L Lower Limit of HSP1 0

HSP.H Upper Limit of HSP1 150 C / 302 F

LSP.L Lower Limit of LSP1 0

LSP.H Upper Limit of LSP1 120 C / 248 F

OUT2 Output 2 Function ALA

ADDR Address Assgnmnt of Digital Com Not used

BAUD Baud Rate of Digital Com Not Used

PARI Parity Bit of Digital Com Not Used

AL.FN Alarm Function PYLA

AL.MD Alarm Mode Norm

AL.HY Alarm Hysteresis 0.1

AL.FT Alarm Failure Transfer ON

EIFN Event Input Function 0

DISP Normal Display Format PV

Table 8: Future Design L91 Parameters

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

40

OPERATIONS (Continued):

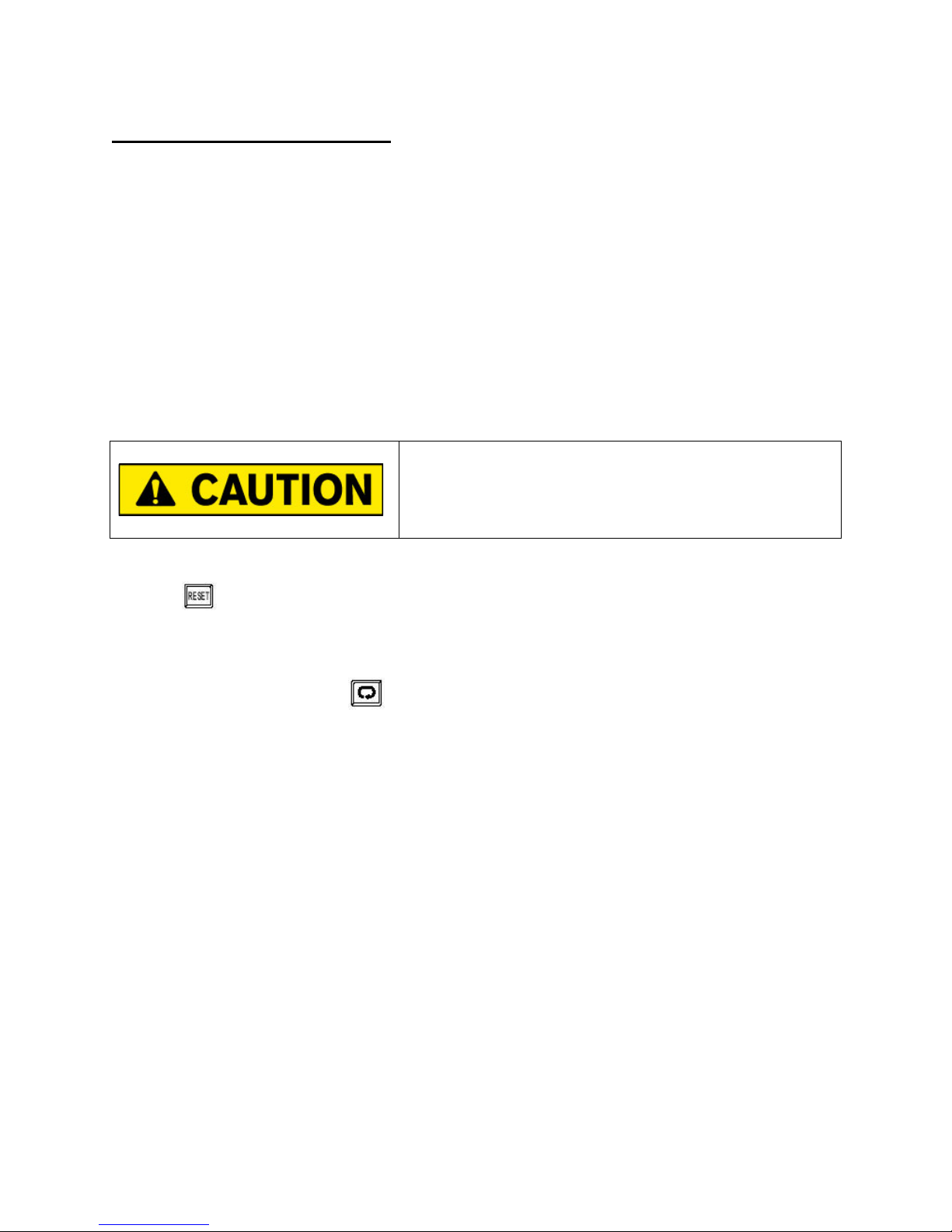

Programming FDC-L91:

Every time the primary set point of the main controller E5CN is modified, the SP2

setting on the over-temperature controller FDC-L91 must be changed manually.

To Change the SP2 set point on the FDC-L91 over-temperature controller, follow the

following procedure:

Do not change any of the other settings in this controller.

1. Turn the “Enable Heater” switch to the Off position. Leave the “Control Power”

switch in the On position.

2. Open the door to the control-portion of the unit.

When the enclosure door is open, be careful

not to touch the electrified components inside.

To avoid shock hazard, qualified personnel

should only perform this procedure.

Note: If the “Lock” LED is lit on the face of the Over-temperature Controller, press

the (

) key for 4 seconds to clear “lock” feature of the FDC-L91, enabling up /

down key function.

3. Identify the over-temperatu re controller, tagged 1SLC.

4. Press the Index key (

) to advance through the menu until “SP2” is

highlighted.

5. Using the up and down arrow keys, adjust the SP2 value until it is 18°F (10°C)

higher than the set point on the temperature controller.

Note: Do not change any other settings on this controller.

6. Close the door to the control portion of the enclosure.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

41

OPERATIONS (Continued):

System Start-Up:

1) Turn on water at its supply source. Allow water to flow for several minutes to insure

that all entrapped air has been purged from the heating column(s).

2) Stop water flow at point of use location and check all plumbing connections and

water heater for leaks. Repair any water leaks if applicable.

3) Enable the power at the MAIN SERVICE DISCONNECT (provided by customer).

4) Ensure that the disconnect handle on the front of the unit (if provided) is ON and the

EMO button on the front panel is not depressed.

5) Turn the CONTROL POWER toggle switch to the ON position. At this time the

temperature controller and all optional displays will come on.

Note: Temperature controller set point should be set to "0" at this time to

prevent accidental heater engagement during calibration procedures. Reference

temperature controller section if required.

6) Adjust the setpoint of the temperature controller to the desired value.

7) Turn the ENABL E HEATER switch past the ON position to the RESET position, then

release the switch, which will move to the ON position. If all criteria for the various

safety devices have been met, the heater will begin to heat.

System Shut-Down:

1) Turn the ENABLE HEATER switch from the ON position to the OFF position.

Continue water flow through the heater until the outlet temperature display indicates

95°F (35°C) or less.

2) Turn the CONTROL POWER toggle switch to OFF.

3) Turn off the MAIN SERVICE DISCONNECT to the unit (provided by customer).

4) Stop water flow through the unit. If the shut down will be for an extended period,

open the customer supplied drain located near the inlet plumbing connection to drain

the water from the unit. Once the unit is drained, dry the unit by blowing inert gas

(N2 or CDA) through the piping system.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

42

MAINTENANCE:

The Tytan water heater requires only a routine inspection every 6 months to check the

operation of the various operation and safety devices. Many of these devices require

the control system to remain operational during inspection, while others may be

checked while the unit is completely powered down.

Note: Several maintenance tasks can be completed simultaneously while the

cabinet access covers are open and lockout/tagout procedures are in place.

The maintenance procedures for this unit must be performed by qualified technicians.

Normal maintenance of TYTAN™ DI Water Heaters consists of the following:

1) Disinfect the water heater along with the rest of the plumbing system on a regular

basis if continuous sanitizing such as ozone injection is not employed.

2) Inspect the temperature sensors every 24 months, replace as needed.

3) Replace the heater control relays and fan after approximately 24-30 months of use.

Actual life expectancy varies with application conditions such as hours of operation;

control tuning parameters, applied voltage and amperage.

4) The Solid State Relay fan should be replaced and the heat sink is to be cleaned

every 24 months.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

43

WARRANTY:

All PROCESS TECHNOLOGY equipment, heaters and controls have been carefully inspected before

shipping and are warranted to be free from defects in workmanship and materials for a period of one year

from date of purchase on a pro-rated basis. At its option, PROCESS TECHNOLOGY will repair or

replace any defects that are exhibited under proper and normal use. PROCESS TECHNOLOGY

disclaims any responsibility for misuse, misapplication, negligence or improper installation of equipment,

tempering or other operating conditions that are beyond its control (such as excessively high or low purge

gas supply pressure). PROCESS TECHNOLOGY makes no warranty or representation regarding the

fitness for use or the application of its products by the customer.

All products and components not manufactured by PROCESS TECHNOLOGY will carry the original

manufacturer's warranty, copies of which are available upon request. PROCESS TECHNOLOGY makes

no warranty or representation, expressed or implied, with respect to the products not manufactured by

PROCESS TECHNOLOGY.

Products must be installed and maintained in accordance with PROCESS TECHNOLOGY instructions.

PROCESS TECHNOLOGY is not liable for labor costs incurred in removal, reinstallation, or unauthorized

repair of the product or for damage of any type including incidental or consequential damage.

PROCESS TECHNOLOGY neither assumes nor authorizes any representative of PROCESS

TECHNOLOGY or any other person to assume for it any other liabilities in connection with the sale of the

products. This warranty may not be verbally changed or modified by any representative of PROCESS

TECHNOLOGY.

Shipping Damages:

Claims against freight carriers for damage in transit must be filed by the customer at the time of delivery

or as soon as possible.

Returns:

No product shall be returned to PROCESS TECHNOLOGY without first obtaining a return material

authorization (RMA) number from a PROCESS TECHNOLOGY representative. All returns must be

freight prepaid. Freight collect or shipments without authorization will be refused.

Information:

PROCESS TECHNOLOGY will endeavor to furnish such advice as it may be able to supply with

reference to the use by buyer of any material purchased, but PROCESS TECHNOLOGY makes no

guarantees and assumes no obligation or liability for advice given verbally or in print or the results

obtained. Buyer assumes all risk and liability that may result from the use of any material, whether used

by itself or in combination with other products. No suggestion for product use shall be construed as a

recommendation for its use in infringement on any existing patent.

Conflict Between Documents:

Acceptance of this offer is expressly conditioned upon agreement to all terms and conditions contained

herein. In the event of a conflict between the terms and conditions of purchaser's purchase order, and

PROCESS TECHNOLOGY‘s terms and conditions, proposal or offer, the latter shall govern.

M-45-02 TYTAN Manual

Revision - Date: 01 – 11/16/07

44

Loading...

Loading...