Process Technology T-DE20 Instruction Manual

Specifications .................................................................. 1

DE20 / T-DE20 Instruction Manual

TABLE OF CONTEN

TS

DE20 / T-DE20 Digital Temperature

General Description ............................................................................ 2

Installation Procedure ......................................................................... 2

Overtemperature Protection .............................................................. 3

Set Point & Features ........................................................................... 4

Alarm Feature ...................................................................................... 4

Error Conditions ................................................................................... 4

Error Messages ................................................................................... 4

Power and Relay Wiring .................................................................... 5

Calibration ............................................................................................. 6

2 Wire RTD Sensor Calibration ........................................................ 6

Resistance Signal Calibration ........................................................... 7

3 Wire RTD Calibration ...................................................................... 7

Thermocouple Calibration ................................................................. 8

Voltage Signal Calibration .................................................................. 8

Current Input Calibration ................................................................. 10

Frequency Signal Calibration ......................................................... 10

Configuration (Setup) ....................................................................... 11

Main Menu Summary...................................................................... 11

Sensor Type (U1) ............................................................................. 12

Signal Offset (U2) ............................................................................. 12

Signal Filter Setting (U4) .................................................................. 12

Set Point Dead Band (U5) .............................................................. 13

Display Stabilizer (U8) ...................................................................... 13

Set Point Limit (L) .............................................................................. 13

Heating or Cooling Switch (F2) ...................................................... 13

Alarm On/Off Switch (F3) ................................................................ 14

Unit Display Enable (F4) ................................................................. 14

Temperature Units Conversion (F5) ............................................. 14

Sensor DIP Switch Settings ........................................................... 14

Electrical Noise and Interference ................................................... 15

Illustration of a Typical Heater

Installation in a Process Tank ......................................................... 15

7010 Lindsay Drive • Mentor, Ohio 44060 • Phone: 440-974-1300

USA/CN: 800-621-1998 • Fax: 440-974-9561 • www

.processtechnolog

COPYRIGHT 2016 Process Technology

y.com

DE20 Specifications

Standard Input

2 wire1000 ohm RTD TCR (alpha),

0.00385 ohm/ohm/°C

RTD Self Heating Coefficient:

5° C/w in 0.2 m/s water; 200° C/w in

1 m/s air measurement current, 0.1 to 0.2 mA

Input Range

-40°F (-40°C) to 1000°F (538°C)

°F or °C field selectable

Set Point Range

Selectable throughout the input range

Sensor Break or

Short Protection

De-energize control output (No sensor short

protection with Thermocouple sensor)

Accuracy

± 0.25% span, ± 1 digit

Enclosure

Type 12, IP54

Face suitable for panel mounting

(#20 ga. through 1/4 thick panels)

Display

4 digit, (1/2" nominal), LED display screen

Control Function

ON/OFF Electromechanical Relays

Control Outputs

SP1 Set Point

(reverse acting) SPDT 20A resistive@240 VAC max

1HP@240 VAC max, 1/2 HP@120VAC

ON/OFF Differential

Field adjustable

1° (F or C) to 99°

Memory

Nonvolatile

Supply Voltage

Operating Conditions

• Indoor Use Only

• 20°F (-7°C) to 130°F (54°C)

• Max Altitude: 3000m

• Max Relative Humidity: 80%

• Pollution Degree 2

• Installation Category II

Input Options

RTD 2 & 3-wire 100 ohm 0.00385 ohm/ohm/ºC or

0.00392 ohm/ohm/ºC

Thermocouples - (types J, K, T, R)

NIST Monograph 175, revision ITS-90 (Obsolete)

Current 4-20mA DC

Voltage (1-10 VDC)

Frequency (0-200 Hz, counts/second),

+/- 6 VDC p to p (up to 30VDC peak with Sw2 ON)

100V to 240V +/- 10% VAC, 50-60 Hz, 13VA

M-33-01-05-3/19/18 1 DE20/T-DE20 Manual

Equipment protected throughout by Double Insulation or Reinforced Insulation.

General Descriptio

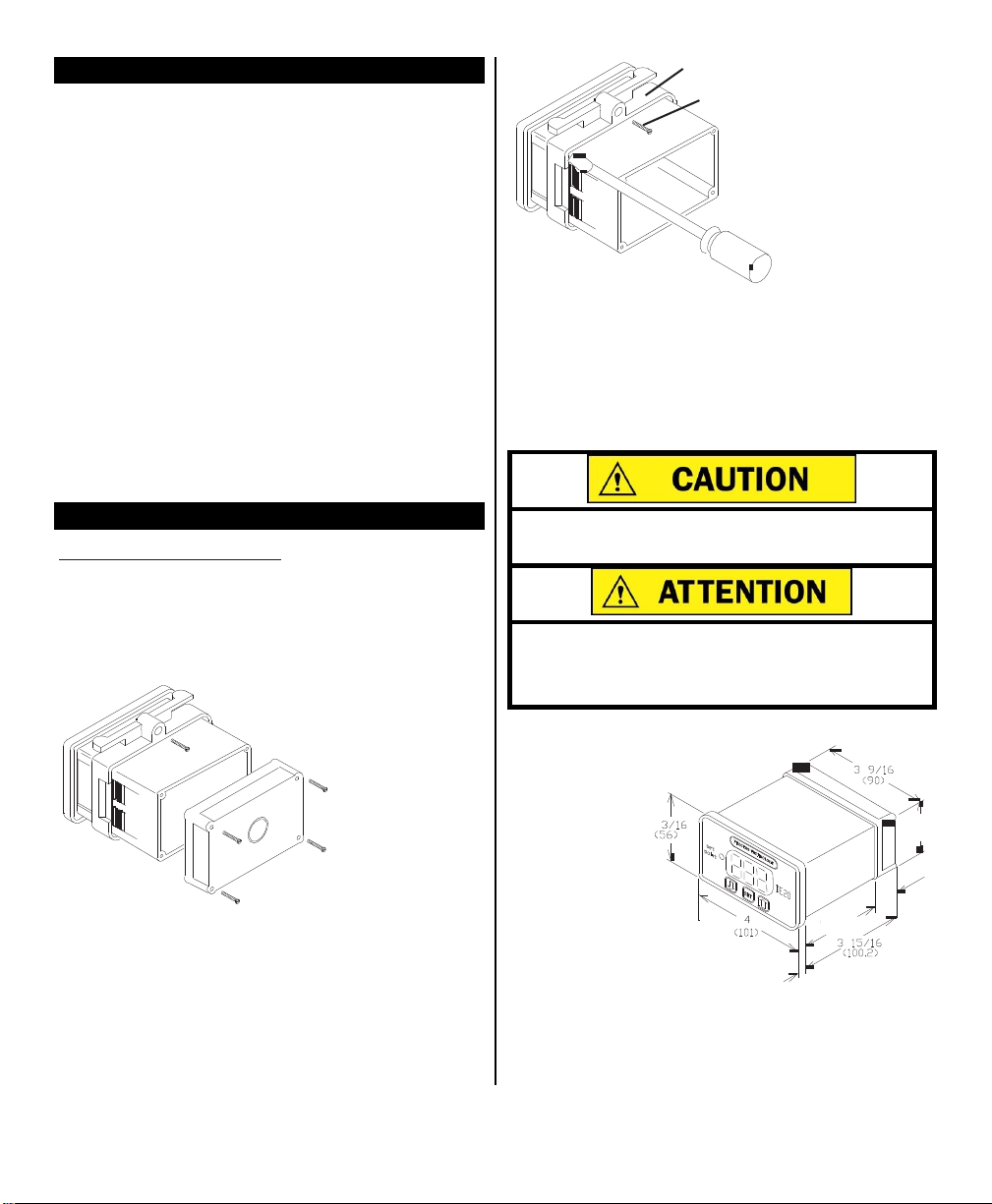

Avoid damaging circuitry. Remove rear cover before removing knockouts with a hammer/punch.

Évitez d'endommager les composants du DE20. Enlevez

le panneau arrière avant d'enlever le plastique pour

faire des trous avec un marteau ou un poinçon.

Retaining collar

Retaining

collar screws

The DE20 digital temperature control is a microprocessor based device that operates one relay. The

relay’s contact state is indicated as SET POINT on the

front panel.

The temperature sensor (i.e. RTD or thermocouple)

sends a signal to the DE20 controller. The DE20 compares this signal to a value, determined by the operator

and set in the control’s memory for the SET POINT. In

the heating mode if the sensor signal is lower than the

set point value, the DE20 energizes the relay and its

isolated contacts close.

The DE20 is also equipped with an “ALARM

CONDITION” feature. This feature is activated by

using the “F3” parameter (described on page 13). The

DE20 enters an “ALARM CONDITION” any time the

sensor signal has exceeded the ALARM SET POINT.

Under this condition, the DE20 de-energizes the relay

and the letters “AAA” flash on the

LED display.

n

Installation Procedure

Suitable for indoor use only.

Unpack and inspect the controller for damage upon

receipt. Any shipping damage claims must be made

through the freight carrier that delivered the controller.

Remove the rear cover and inspect the controller for

internal damage.

Remove the

panel retaining

collar by inserting a flat head

screwdriver

under the collar

on alternating

sides while sliding the collar back.

Cut a 1/8 DIN finished opening: 1.750" x 3.625" (44

mm x 92 mm) in the panel where the DE20 is to be

mounted.

.

Remove the rear

cover. Select

from the four (4)

knockouts on

the rear cover

that which offers

the most convenient routing

for external wiring. Remove the knockouts before reattaching the

rear cover or inserting the control in the panel.

M-33-01-05- 3/19/18

Insert the DE20

through the prepared opening

and slide the

retaining collar

over the case

from the rear of

the panel. After

hand tightening

the collar, tighten

the two (2) collar

screws to ensure a secure

fit.

Install a suitable liquid tight conduit fitting through the

knockout opening following manufacturer’s instructions and install field wiring. Using the wiring diagram

2 DE20/T-DE20 Manual

supplied with the controller, install the required input

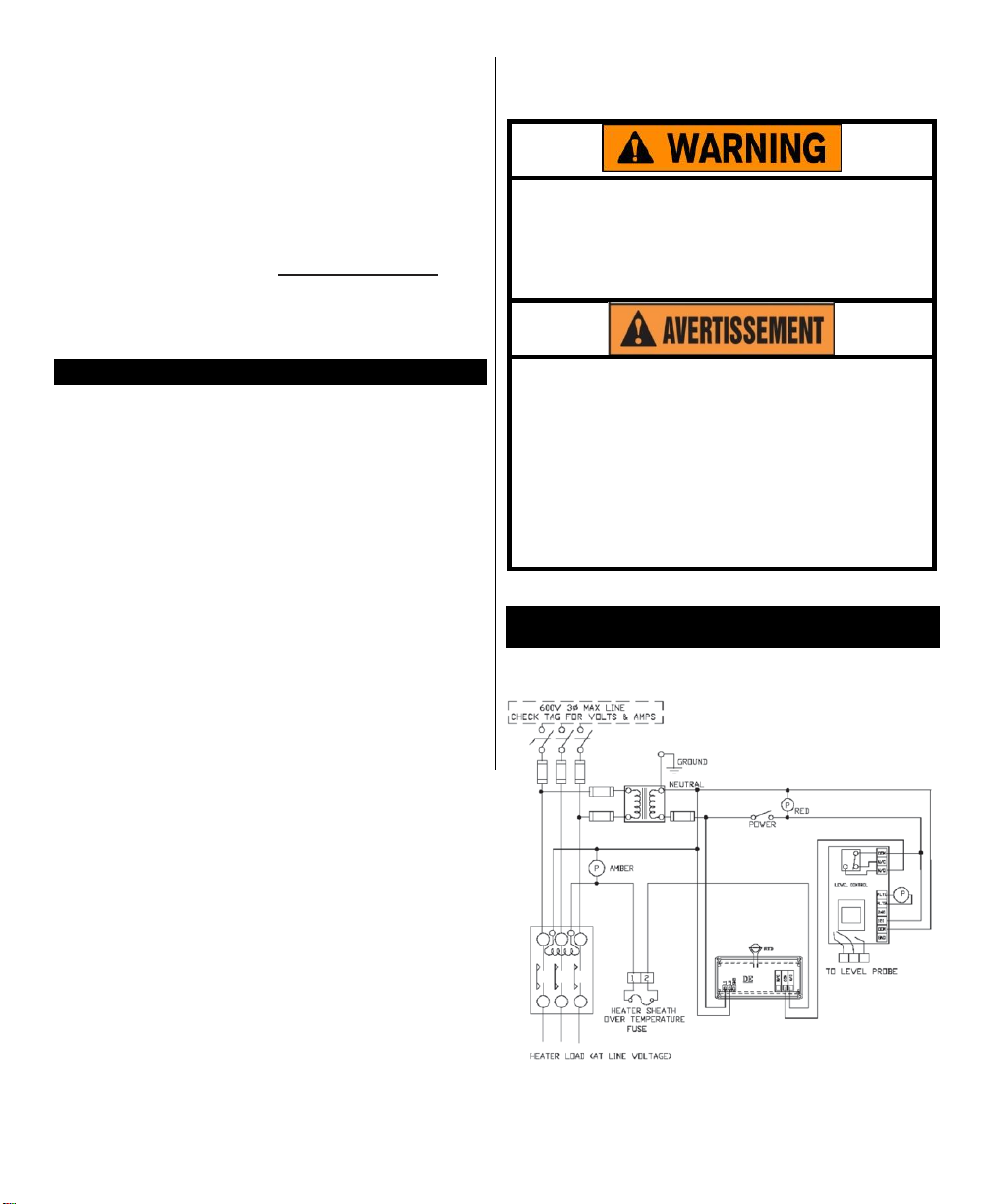

Overtemperature protection is necessary in

any system where a fault condition could produce a fire or any other hazardous condition.

Operation without thorough safety precautions

can result in equipment failure, property damage and personal injury.

La protection de surchauffe est nécessaire

dans n'importe quel système où une condition

fausse avec résultat d'une temperature haute

pourrait produire une incendie ou autre condition dangereuse. L'opération sans les précautions complètes de sécurité pourrait mener à la

défaillance de l'equipement, l'endommagement

de la propriété, ou des blessures.

and output wires. Use National Electric Code and

local codes for determining wire sizing, insulation,

terminations, etc.

The factory supplied 1000 ohm RTD sensor can be

extended using standard electrical hookup wire (22

awg or larger). The effect of additional 22 awg sensor

wire length on control calibration is approximately 1ºF

for every 65 feet.

Note:

This does not apply to

MUST use specific

ing the sensor wire length. Use of incorrect extension wire can cause hazardous operating

thermocouple wire when

THERMOCOUPLES.

extend-

conditions.

You

Overtemperature Protection

Component failure (sensors, relays, temperature controller, etc.) in a temperature controlled process can

result in damage to the product, heater over temperature, and the possibility of a fire.

To safeguard against these events, install over temperature protection. This will interrupt the heater power

supply in the event of low solution level.

Process Technology heaters include a thermal device

(Protector 1, 2, or 3) on the heater to monitor the heater’s surface temperature. When wired properly, these

devices cut the power to the heater in low solution level

conditions. In addition to thermal protection, Process

Technology requires the use of liquid level controls to

monitor the solution level and shut off the heaters prior

to an overtemperature condition occurring.

Ensure you read and adhere to all Over-temperature

protector installation instructions and warnings.

Overtemperature Protection Device with Low Level

Cutoff Sample Wiring Diagram

(your wiring may differ)

M-33-01-05 - 3/19/18

3 DE20/T-DE20 Manual

Set Point and Features

Control Set Point

The set point value will be displayed whenever the

“SET” key is pressed. This value can be changed by

the following procedure:

Note: The units displayed, ºC, ºF, Hz, volts, mA or

ohms are established during the setup of the controller. See F2

set point relay from reverse to direct acting.

Press both the “SET” key and the decrease “” keys

simultaneously and hold for 3 seconds. When released the set point value and a decimal point will

appear, release both keys. Wait approximately one

second, then using the decrease “” key or increase

“” key, adjust the display to your new value. Depress the “SET” key to enter your new value.

Note: If the “SET” key is not pressed within 5 sec-

onds, the new

will revert to its previous setting.

The controller will automatically return to the operating mode and display the current temperature.

instructions

value

will be lo

on page 12 for changing

st and the set

poin

t value

Alarm Feature

Note: This is not a safety device.

The Alarm feature, which is enabled using the “F3”

set-ting during setup (see page 13), allows the

user to establish a set point above which the control

will enter into an alarm condition. This set point

should be higher than the set point setting on the

control. During the alarm condition the control relay

will de-energize the set point relay and flash “AAA”

on the display.

After enabling this feature, you may view and adjust

the “ALARM SET POINT” on the display. The alarm

set point value will be displayed and can be adjusted

by pressing the “SET” key and the increase “” key

simultaneously and holding them for approximately

three seconds. The alarm set point value will appear

as a flashing display.

Note: If the “SET” key is not pressed within 5

sec-

onds, the new

value will revert to its previous setting.

To change the “ALARM

increase “” or decrease “” keys while the display

is flashing. Press the “SET” key to enter your new

value. If you wish to accept the current value, press

the “SET” key.

value

will be lo

SET POINT”,

st and the set

press the

poin

t

Error C

Sensor values that are out of range will generate an

error display. For Celsius: <-40ºC or >+538ºC. For

Fahrenheit: <-40ºF or >+1000ºF.

In the event of an improperly connected RTD sensor

or thermocouple, or if the control reads an “open”

circuit, the message “HHH” is displayed and the control de-energizes the control relay. In the event the

RTD sensor “shorts”, the message “UUU” is displayed

and the control de-energizes the control relay.

Note:

Thermocouple “shorts”

measurement point to be created. This will lead to

false

readings

and

ondition

dangerous operating

s

cause a

new

junction/

conditions.

Error Messages

If the calibration and setup information stored within

the memory becomes corrupt or erased, the control

will switch to its default calibration/configuration settings. The display will flash the letter “c” on the left

side when default values are activated. The physical

size and position of the letter “c” will define the exact

nature of the problem.

Note: Shorted thermocouples will not result in an

error condition. Instead, incorrect readings will be

displayed.

A small “c” in the upper left-hand corner indicates the

control is relying on default (factory set) calibration

values. This happens when the control is new and

has not yet been calibrated (setup).

A small “c” in the lower left-hand corner indicates the

control is relying on default configuration values. This

is a rare condition, but may occur if the control has been

calibrated for use with a two-wire RTD sensor but the

configuration parameters have not been changed from

their default values. Changing any of the configuration

or set point variables will turn off this indication.

A large “C” on the left side of the display indicates the

control is using the default values for the configuration

and the calibration. This can occur in a new control

that has never been calibrated or configured, or in a

control wherein the memory has been erased.

The controller will automatically return to the operating mode and display the current temperature.

M-33-01-05 - 3/19/18

4 DE20/T-DE20 Manual

Loading...

Loading...